Grease sewage treatment agent

A technology of sewage treatment agent and grease, applied in the field of sewage treatment agent preparation, can solve the problems of poor effect and high cost, and achieve the effects of rapid precipitation, low moisture content and good hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

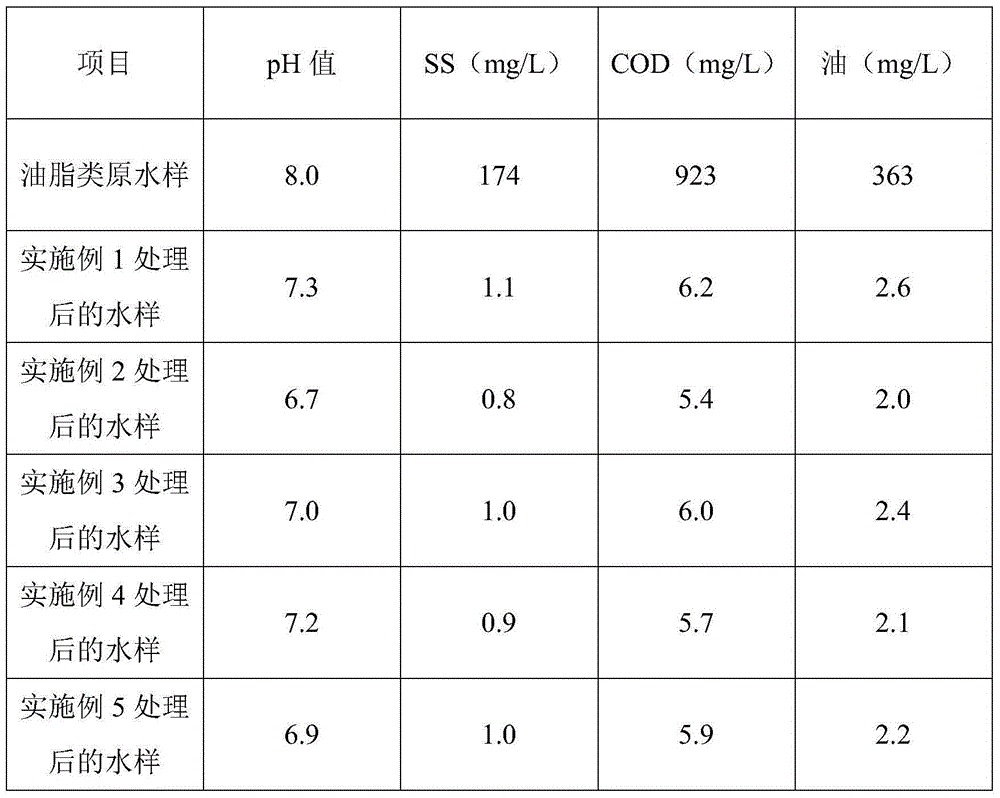

Examples

Embodiment 1

[0027] A grease sewage treatment agent, in parts by weight, comprising the following raw materials: 40 parts of enzyme agent, 40 parts of demulsifier, 30 parts of flocculant, 30 parts of coagulant aid, 30 parts of foaming agent, 20 parts of flotation agent , 20 parts of fungicide, 10 parts of anti-corrosion and scale inhibitor, 10 parts of oxygen scavenger,

[0028] The enzyme preparation includes the following raw materials: 20 parts of whole cell lipase, 10 parts of triacylglycerol acyl hydrolase, and 10 parts of cellulase;

[0029] The demulsifier includes the following raw materials: 10 parts of fatty alcohol polyoxyethylene ether, 10 parts of polyethylene polyamine polyoxypropylene polyoxyethylene ether, 8 parts of secondary octylphenol polyoxyethylene ether, 6 parts of propylene oxide, 3 parts of ethylene oxide, 3 parts of potassium hydroxide;

[0030] The flocculant comprises the following raw materials: 12 parts of zirconium sulfate, 10 parts of aluminum sulfate, and ...

Embodiment 2

[0038] A grease sewage treatment agent, in parts by weight, comprising the following raw materials: 80 parts of enzyme agent, 80 parts of demulsifier, 60 parts of flocculant, 60 parts of coagulant aid, 60 parts of foaming agent, 50 parts of flotation agent , 50 parts of fungicide, 20 parts of anti-corrosion and scale inhibitor, 20 parts of oxygen scavenger,

[0039] The enzyme preparation includes the following raw materials: 40 parts of whole cell lipase, 20 parts of triacylglycerol acyl hydrolase, 20 parts of cellulase;

[0040] The demulsifier includes the following raw materials: 20 parts of fatty alcohol polyoxyethylene ether, 20 parts of polyethylene polyamine polyoxypropylene polyoxyethylene ether, 16 parts of secondary octylphenol polyoxyethylene ether, 12 parts of propylene oxide, 6 parts of ethylene oxide, 6 parts of potassium hydroxide;

[0041] The flocculant comprises the following raw materials: 30 parts of zirconium sulfate, 16 parts of aluminum sulfate, 14 par...

Embodiment 3

[0049] A grease sewage treatment agent, in parts by weight, comprising the following raw materials: 60 parts of enzyme agent, 60 parts of demulsifier, 45 parts of flocculant, 45 parts of coagulant aid, 45 parts of foaming agent, 35 parts of flotation agent , 35 parts of fungicide, 15 parts of anti-corrosion and scale inhibitor, 15 parts of oxygen scavenger,

[0050] The enzyme preparation includes the following raw materials: 30 parts of whole cell lipase, 15 parts of triacylglycerol acyl hydrolase, and 15 parts of cellulase;

[0051] The demulsifier includes the following raw materials: 15 parts of fatty alcohol polyoxyethylene ether, 15 parts of polyethylene polyamine polyoxypropylene polyoxyethylene ether, 12 parts of secondary octylphenol polyoxyethylene ether, 8 parts of propylene oxide, 5 parts of ethylene oxide, 5 parts of potassium hydroxide;

[0052] The flocculant comprises the following raw materials: 20 parts of zirconium sulfate, 13 parts of aluminum sulfate, 12 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| oil removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com