Method for control of mercury

a technology for mercury and flue gas, applied in the field of mercury control, can solve the problems of difficult capture of elemental mercury, inability to collect and dispose of fly ash, etc., and achieve the effect of inherent safety advantag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

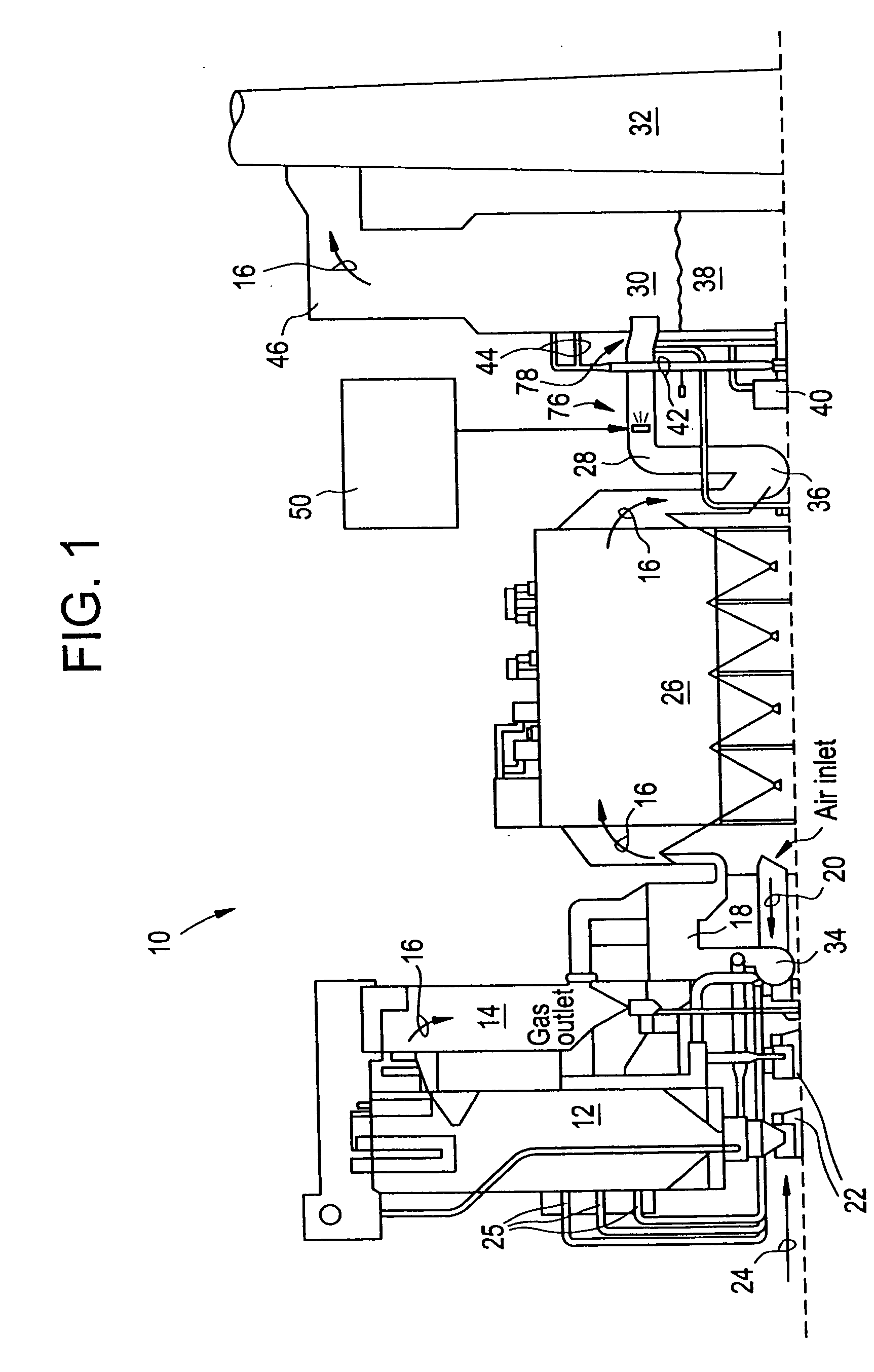

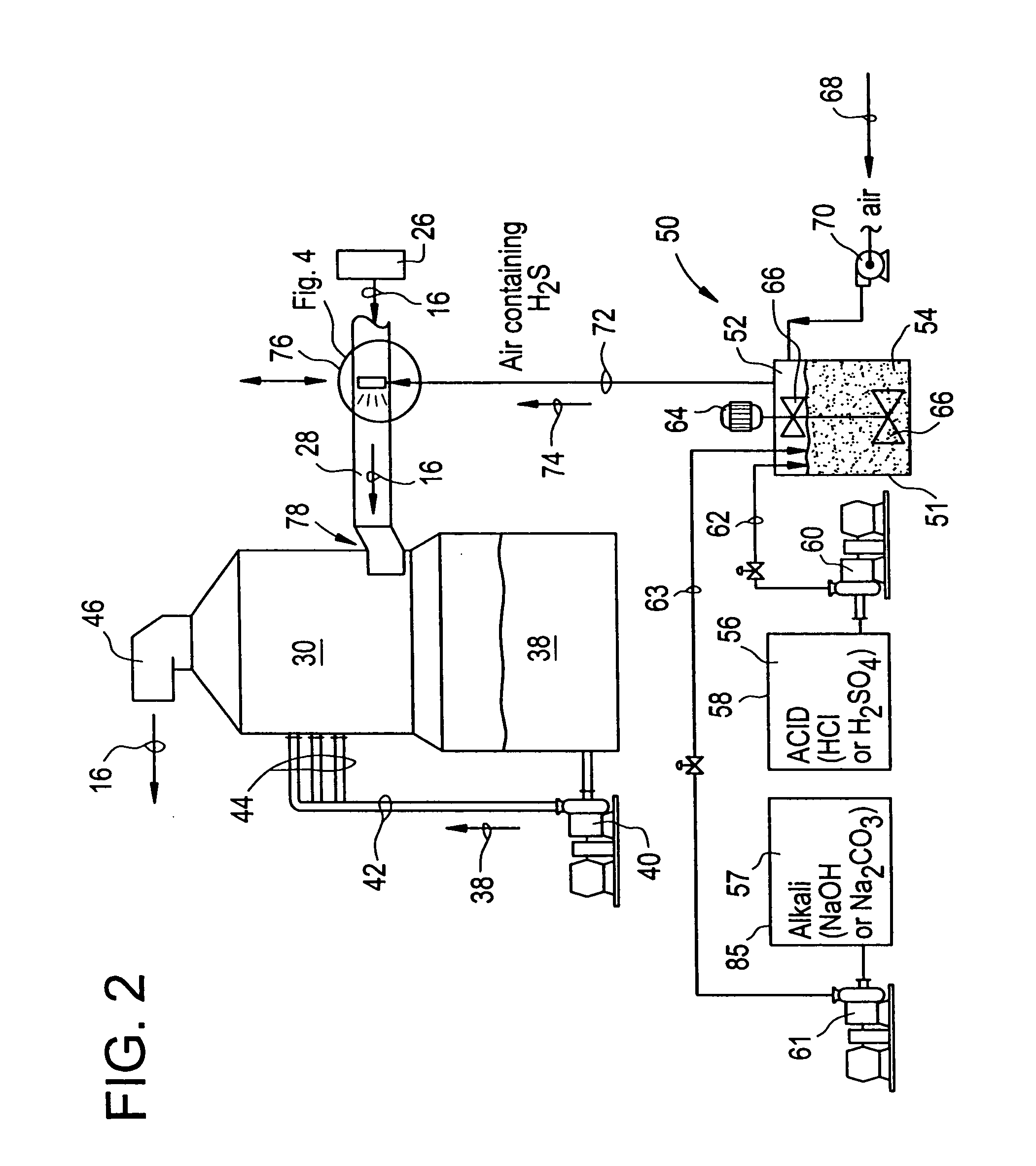

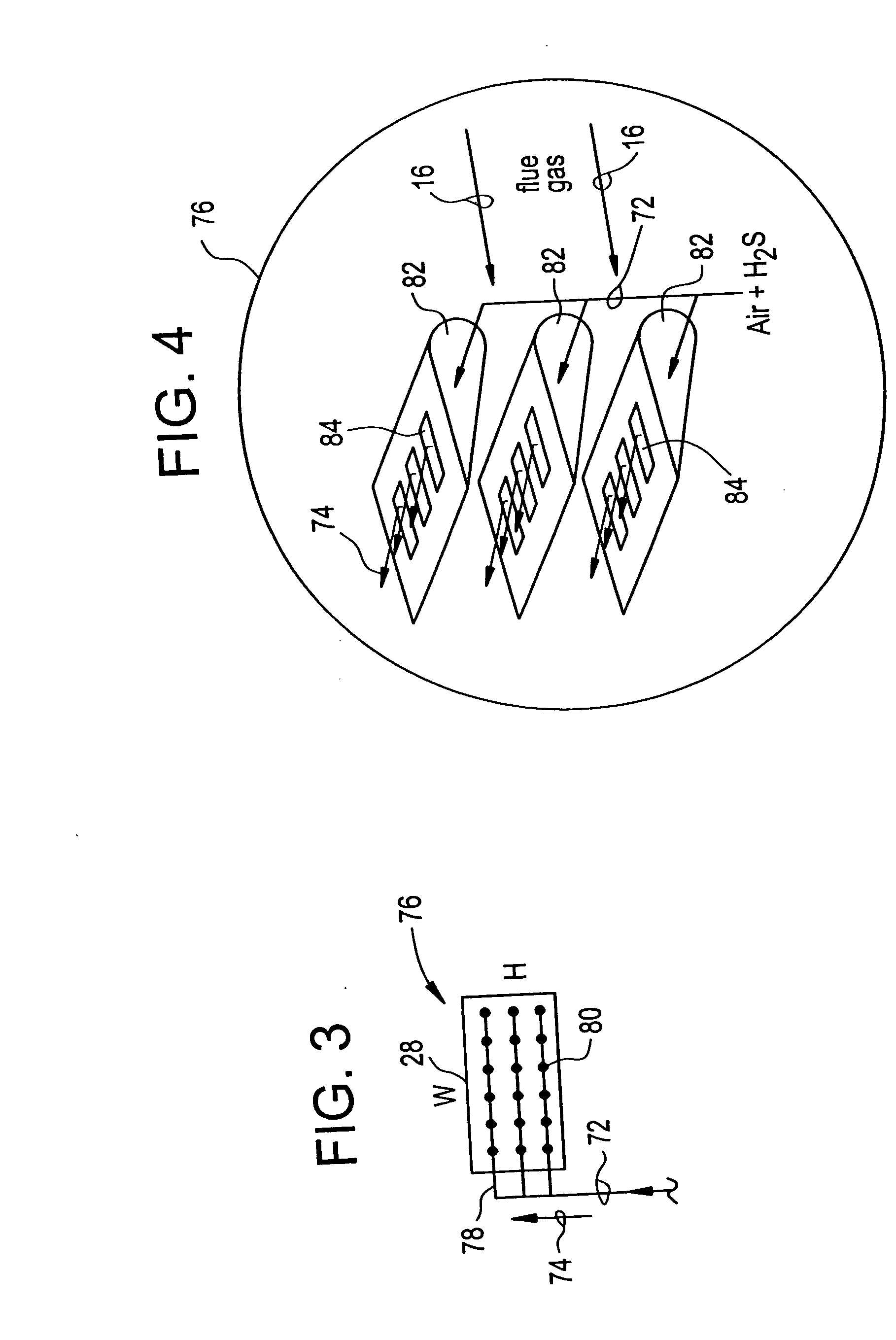

[0025] Referring to the drawings generally, wherein like reference numerals designate the same or functionally similar elements throughout the several drawings, and to FIG. 1 in particular, FIG. 1 illustrates a coal-fired utility boiler installation of the type used by utilities in the generation of electric power, generally designated 10, and which represents one type of industrial process to which the present invention is applicable. In its broadest form, the present invention comprises a method for removing mercury from the flue gas generated during the combustion of fossil fuels or solid wastes through the use of trace amounts of hydrogen sulfide. Of course, while the aforementioned coal-fired utility boiler installations are but one example, and the method of the present invention will likely first find commercial application to the removal of mercury from the flue gases produced by such utility boiler installations which combust such fossil fuels, any industrial process using ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Vapor pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com