Biomass integrated thermocracking equipment for preparing liquid fuel

A liquid fuel, integrated technology, used in the preparation of liquid hydrocarbon mixtures, petroleum industry and other directions, can solve the problems of ungraded liquid products and low energy utilization, and achieve the effect of reducing costs and ensuring smooth feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

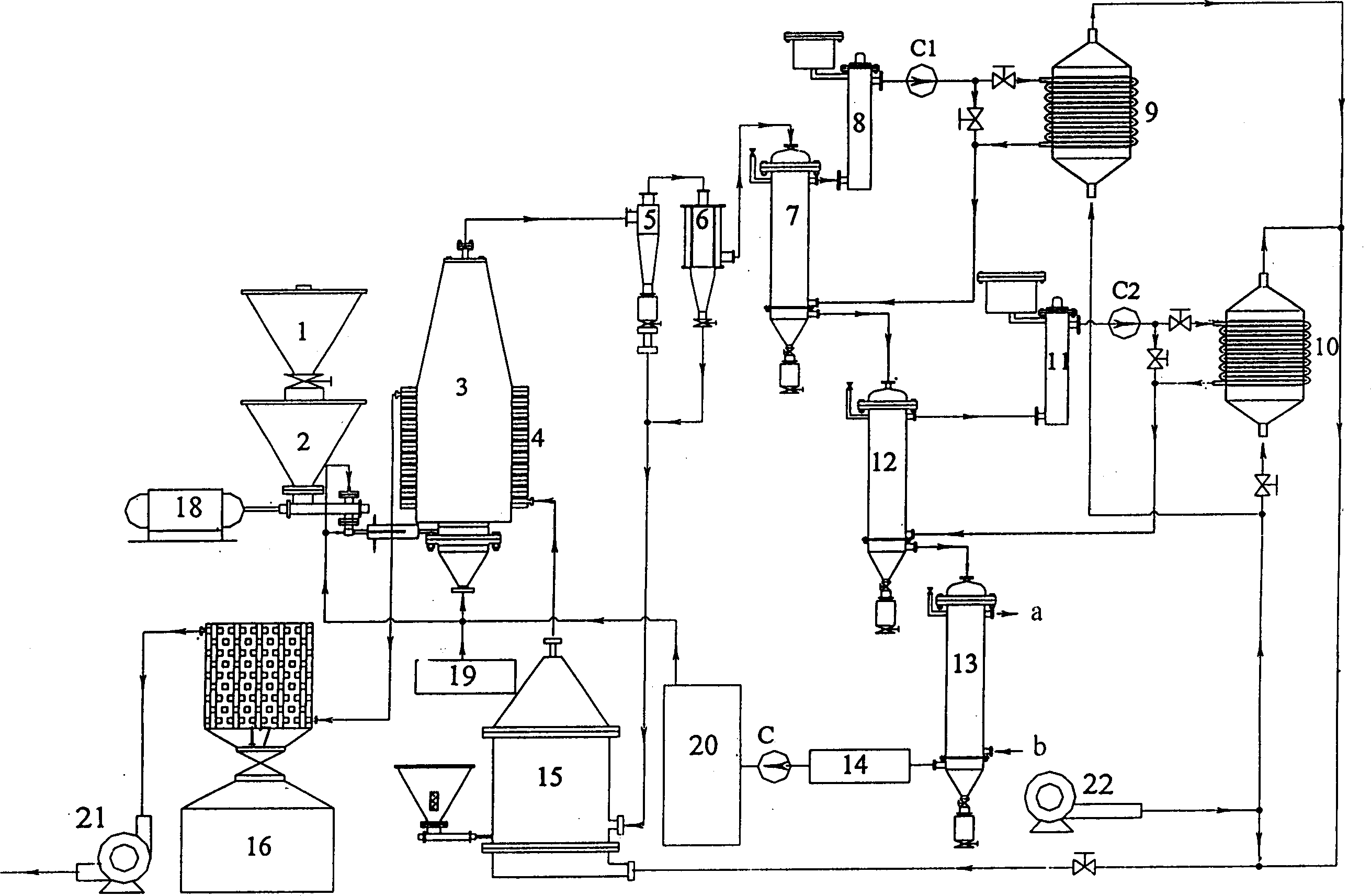

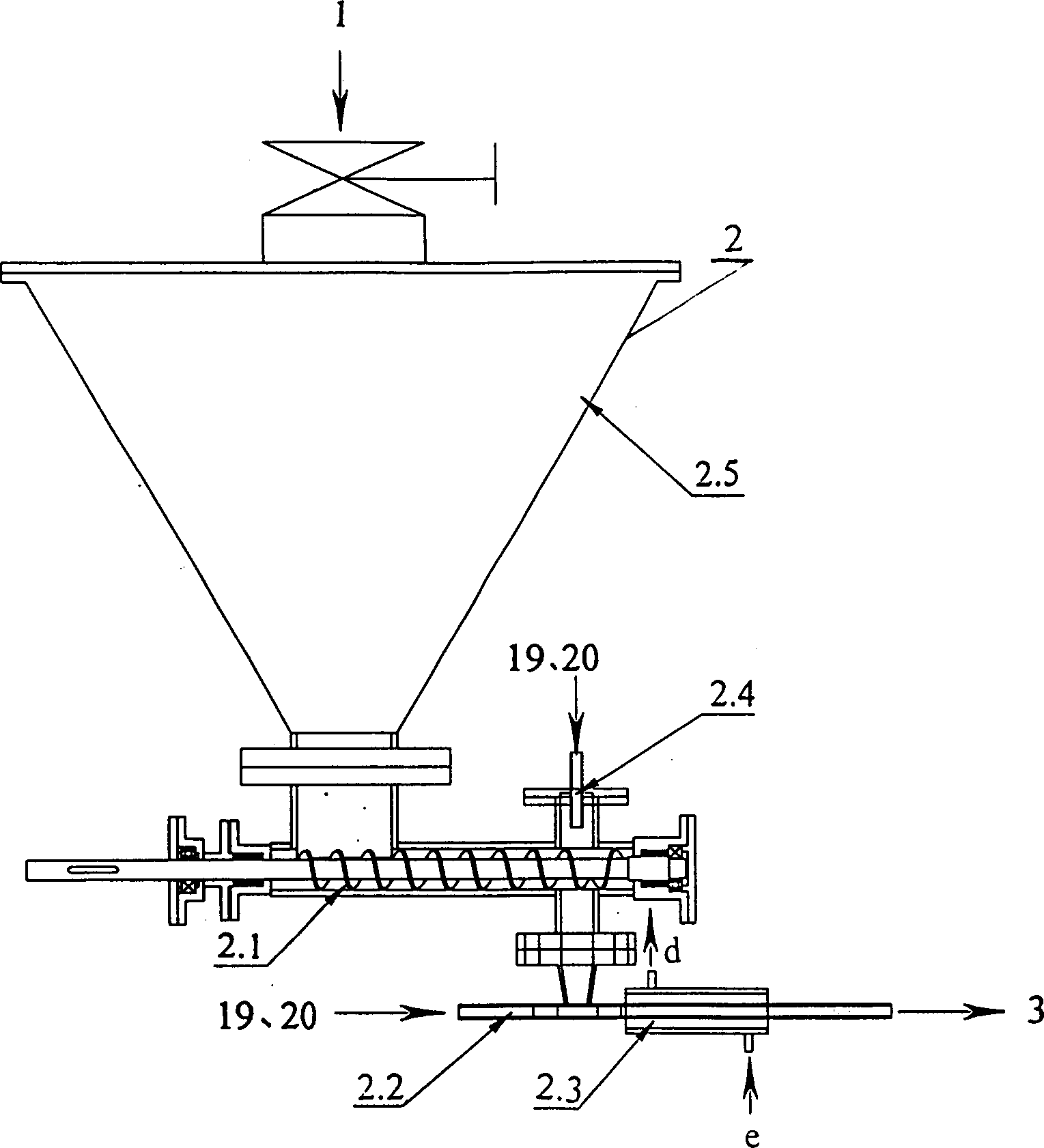

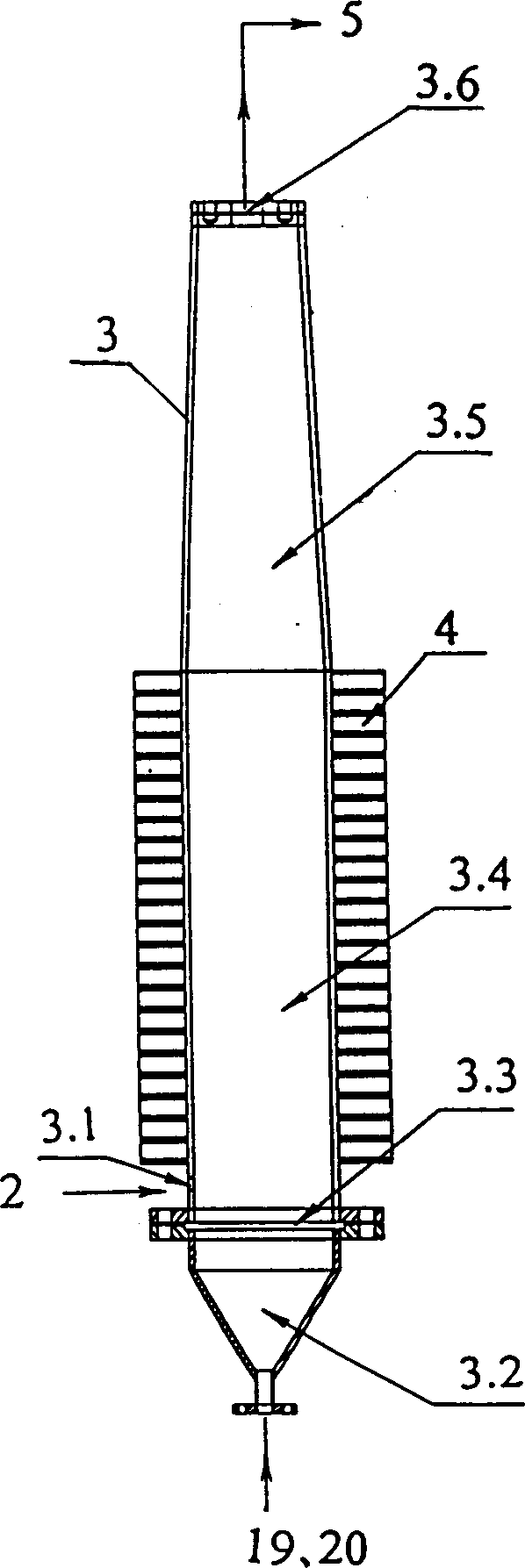

[0019] Such as figure 1 As shown, the present invention includes a preparatory hopper 1 connected to a combined feeding device 2, and the combined feeding device 2 is respectively connected to a variable cross-section fluidized bed reactor 3, a spare gas source 19, an air storage tank 20, and a variable cross-section fluidized bed The reactor 3 is respectively connected to the cyclone separator 5, the backup gas source 19, the gas storage tank 20, and the heat exchanger 4 outside the reactor is respectively connected to the charcoal combustion furnace 15, the raw material drying chamber 17, and the raw material drying chamber 17 is respectively connected to the feed bin 16. The induced draft fan 21 is connected to one end of the cyclone separator 5 and the charcoal filter 6, and the other end of the cyclone separator 5 and the charcoal filter 6 is connected to the charcoal burner 15, and the charcoal filter 6 passes through the high-temperature condenser 7 and the high-temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com