Emulsion continuous demulsification separation method based on magnetic particle dynamic bed

A technology of magnetic particles and separation methods, applied in separation methods, immiscible liquid separation, liquid separation, etc., can solve the problems of inability to achieve continuous demulsification, difficult direct engineering application, cumbersome modification work, etc., and improve demulsification efficiency. , Improve the water quality, strengthen the effect of shear and friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

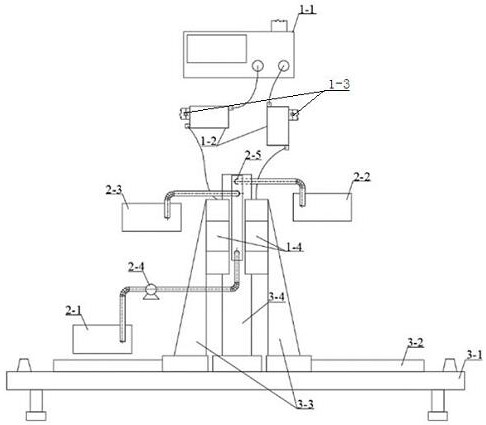

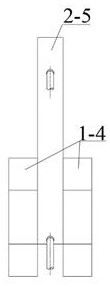

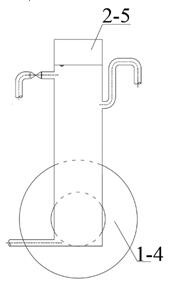

Image

Examples

Embodiment 1

[0070] Using the installation and use method of the above-mentioned continuous emulsion breaking and separation device based on the dynamic bed of magnetic particles, the model emulsion sample whose oil phase is liquid paraffin and whose oil concentration is 10 g / L is processed. The rotational speed of the emulsifier is 13000 r / min, and the emulsification time is 5 minutes; add 2 g of magnetic particles with a particle size of 1 μm into the oil-water separation chamber, which is denoted as MP1.

[0071] Adjust the parameters of the magnetic particle control system as follows: channel 1: CMOS, phase 0°, amplitude 2.4V, frequency 2Hz; channel 2: CMOS, amplitude 2.4V, frequency 2Hz, dual channel phase difference 180°. Power amplifier magnification: 10.

[0072] Adjust the flow path parameters of the emulsion as follows: the dosage of particles is 2 g, the speed of the peristaltic pump is 2.1 rpm, and the flow rate is about 10 ml / min; the hydraulic retention time of the emulsion i...

Embodiment 2

[0079] Using the installation and use method of the above-mentioned continuous emulsion breaking and separation device based on the dynamic bed of magnetic particles, the model emulsion sample whose oil phase is liquid paraffin and whose oil concentration is 10 g / L is processed. The rotation speed of the emulsifier is 13000 r / min, and the emulsification time is 5 minutes; add 2 g of magnetic particles (marked as MP2) with a product particle size of 1000 mesh (≤14 μm) into the oil-water separation chamber.

[0080] The parameters of the magnetic particle control system, the parameters of the emulsion flow path, and the layout of the emulsion breaking and separation operation platform are the same as those in Test Example 1.

[0081] The present invention is following table 2 with the continuous operation effect of above-mentioned parameter, Figure 5 shown.

[0082] Table 2 is the continuous operation effect of embodiment 2:

[0083]

[0084] From the above-mentioned opera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface magnetic field strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com