Polymeric ferric sulfate-poly-dimethyl-diallyl-ammonium chloride composite flocculent, preparation and use method thereof

A technology of polydimethyldiallylammonium chloride and polyferric sulfate, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of inconvenient industrial production, use or complex preparation process, and achieve The method of use is convenient and concise, the effect of ensuring safety and reliability, and the content range is clear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

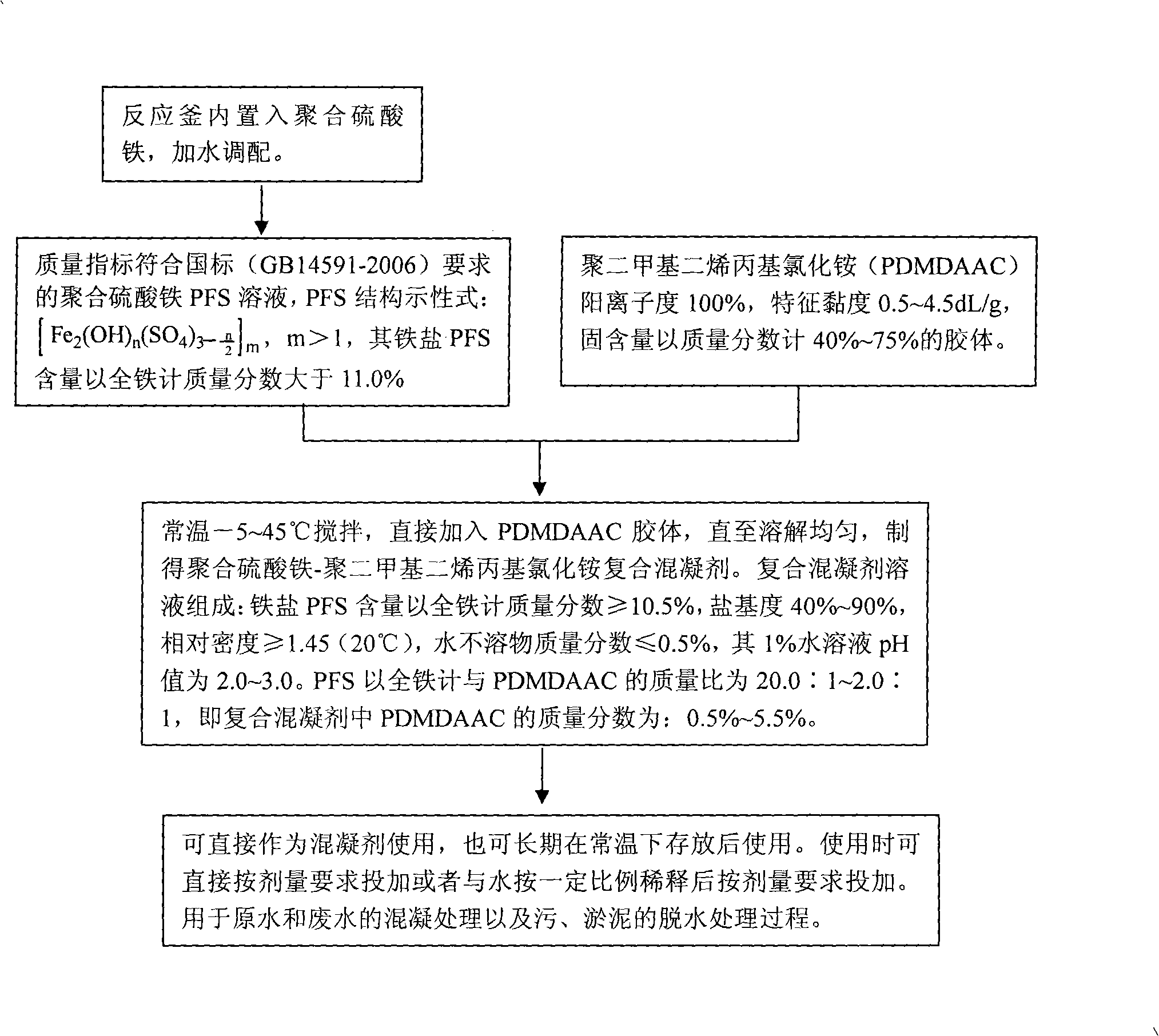

[0035]In conjunction with the accompanying drawings, the polyferric sulfate-polydimethyldiallylammonium chloride composite coagulant of the present invention is prepared by the following method, comprising the following steps:

[0036] (1) The dry powder or solution of polyferric sulfate (PFS) is placed in the mixing tank, and water is added to prepare the PFS solution whose iron salt content is greater than or equal to 11.0% in terms of the mass fraction of total iron;

[0037] (2) Stir the solution at room temperature, add a certain amount of polydimethyldiallylammonium chloride (PDMDAAC) with a mass fraction of 40% to 75% and a characteristic viscosity range of 0.5 to 4.5dL / g colloid, so that the mass ratio of the PFS amount in the mixed solution to the PDMDAAC in terms of total iron is 20.0:1~2.0:1.

[0038] (3) Stir the mixed solution at room temperature until the PDMDAAC colloid is completely dissolved to obtain a stable polyferric sulfate (PFS)-polydimethyldiallylammoni...

Embodiment 1

[0043] Embodiment 1: in conjunction with accompanying drawing, polyferric sulfate (PFS)-polydimethyldiallylammonium chloride (PDMDAAC) composite coagulant of the present invention and its preparation and application method are:

[0044] In the first step, the polyferric sulfate (PFS) whose quality index meets the requirements of the national standard (GB14591-2006) is placed in the mixing reactor, and its structural formula is Wherein: m>1. Add water to make it into a solution with a PFS content of 11.0% to 12.5% in terms of iron mass fraction;

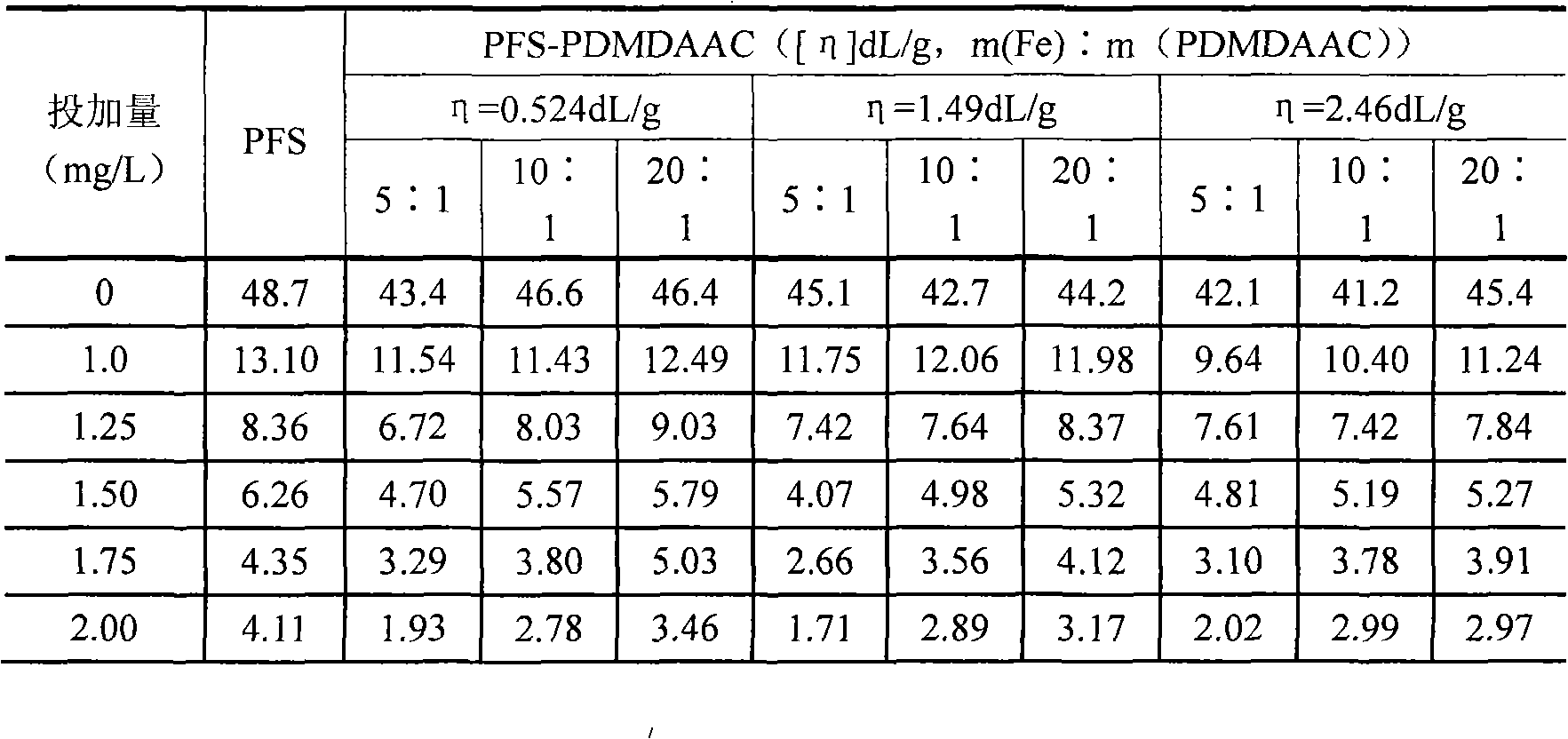

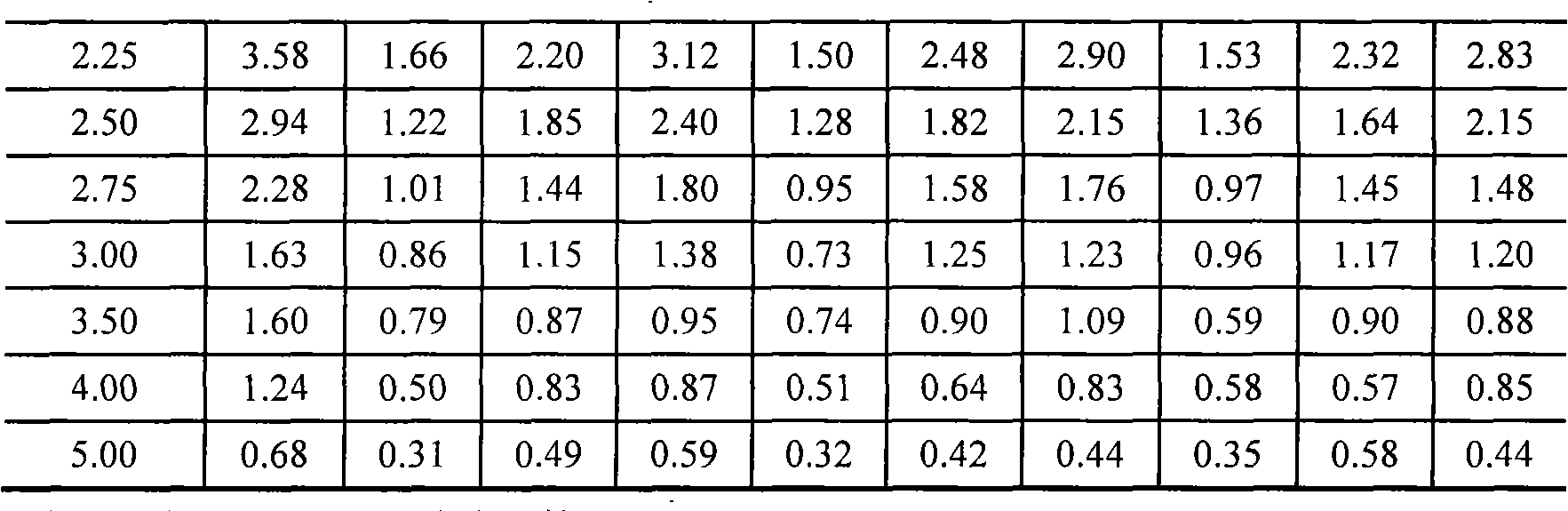

[0045] In the second step, stir the PFS solution at room temperature at 5-25°C, and add (65±5)% mass fraction to the solution, with a characteristic viscosity range of 0.5-4.5dL / g (30.0±0.1°C, 1mol / The polydimethyldiallyl ammonium chloride (PDMDAAC) colloid solution that measures in 1L NaCl solution, make PFS content in the solution be 20.0: 1~2.0: 1 with the mass ratio of total iron meter and PDMDAAC;

[0046] The third step is...

Embodiment 2

[0058] Embodiment 2: in conjunction with accompanying drawing, polyferric sulfate (PFS)-polydimethyldiallylammonium chloride (PDMDAAC) composite coagulant of the present invention and its preparation and application method are:

[0059] In the first step, the polyferric sulfate (PFS) whose quality index meets the requirements of the national standard (GB14591-2006) is placed in the mixing reactor, and its structural formula is Wherein: m>1. Water is added to make it into a solution with a PFS content of (12.5-15.0)% based on the mass fraction of total iron.

[0060] In the second step, stir the PFS solution at room temperature at -5 to 15°C, and add (45±5)% mass fraction to the solution, with a characteristic viscosity range of 0.5 to 4.5dL / g (30.0±0.1°C, 1mol / LNaCl solution) polydimethyldiallyl ammonium chloride (PDMDAAC) colloidal solution, the PFS content in the solution is 20.0: 1~2.0: 1 with the mass ratio of total iron meter and PDMDAAC;

[0061] The third step is to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com