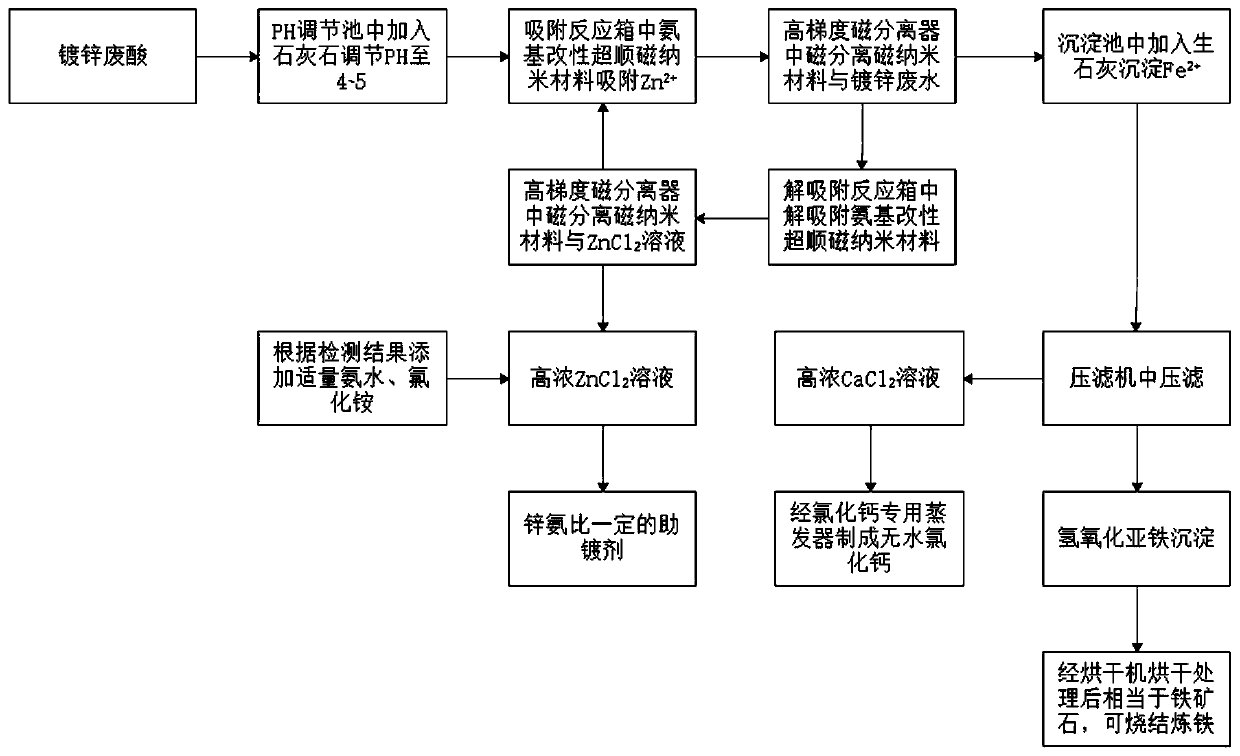

Resource recycling process of galvanizing waste acid

A recycling and waste acid technology, applied in zinc halides, chemical instruments and methods, calcium/strontium/barium halides, etc., can solve the problems of high operating costs, high energy consumption, and high investment costs, and simplify the subsequent processing process , Simple processing and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] Required equipment: pH adjustment pool, adsorption reaction box, high gradient magnetic separator, desorption reaction box, sedimentation tank, filter press, pH value detector, Zn 2+ Content analysis detector.

[0028] 1. Adjust pH

[0029] Taking the pH adjustment pool built by Kunming Yuegao Industry and Trade Technology Co., Ltd. as an example, its volume is 10m 3 . The specific gravity of galvanizing waste acid solution from Yunnan Jinling Material Technology Co., Ltd. is 1.41, 1m 3 About 1.41 tons. The pH value of the solution is detected in real time by a pH analyzer, and an appropriate amount of limestone (mainly composed of CaCO2) is automatically added in real time according to the detection result 3 ), the pH value of the control galvanizing wastewater is about 5, and the reaction is carried out at normal temperature.

[0030] According to statistics, 500.0kg of limestone is needed to control the pH value of galvanizing wastewater to about 5.

[0031] 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com