Primary treatment tank for machining waste water

A mechanical processing and primary treatment technology, applied in the field of primary treatment tanks for mechanical processing wastewater, can solve problems such as high concentration of organic matter, difficult treatment efficiency, environmental pollution, etc., and achieve the effect of improving treatment efficiency and reducing treatment difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with embodiment the present invention will be further described, but the present invention is not limited to these examples, under the premise of departing from the gist of the present invention, any improvement made falls within the protection scope of the present invention.

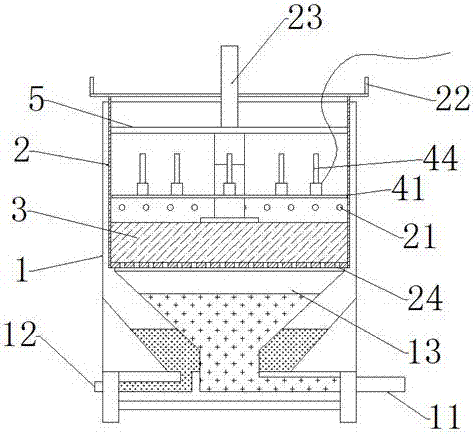

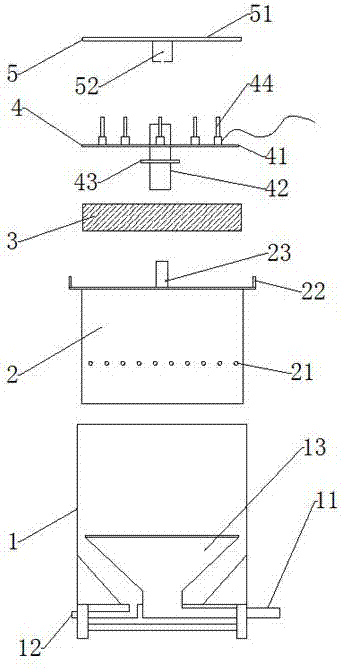

[0015] As shown in the figure, a mechanical processing wastewater preliminary treatment tank according to the present invention includes a tank body 1, the bottom of the tank body 1 is provided with a water outlet pipe 11 and an oil outlet pipe 12, and the inside of the tank body 1 is passed through a collection The water bucket 13 is divided into an intermediate water collection area and an external oil collection area. The water outlet pipe 11 extends into the tank body 1 and connects with the bottom of the water collection bucket 13. The oil outlet pipe 12 directly communicates with the bottom of the tank body 1. The interior of the tank body 1 is located above the water co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com