Method for preparing graphene oxide-loaded nano manganese dioxide

A graphene and nanotechnology, which is applied in the field of preparation of nanocomposite materials, can solve problems such as no discovery, and achieve the effects of convenient equipment, broad application prospects and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

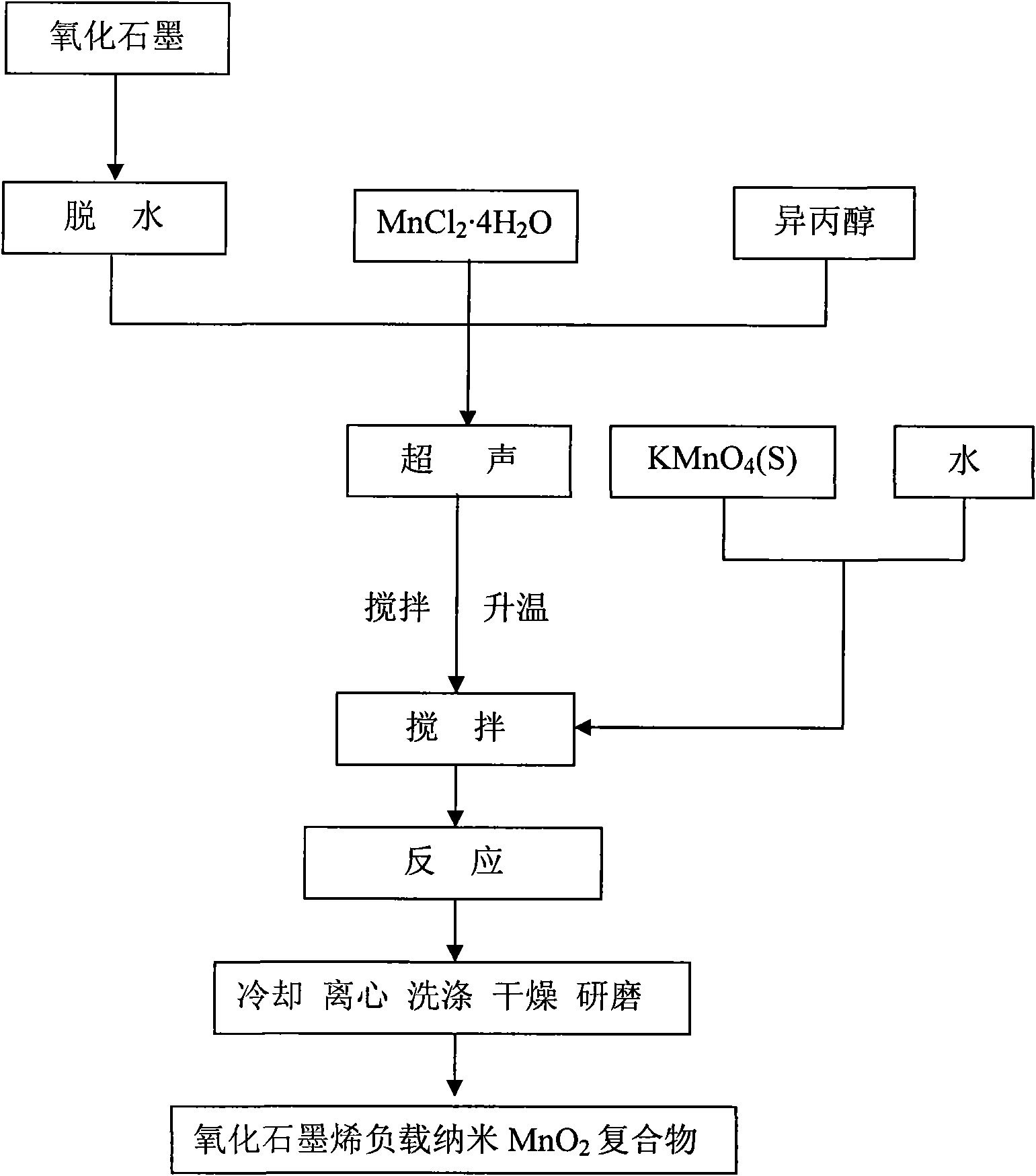

[0016] combine figure 1 , the present invention supports graphene oxide nanometer MnO 2 The preparation method comprises the following steps:

[0017] Step 1: high-speed centrifugation to dehydrate graphite oxide;

[0018] Step 2: MnCl 2 4H 2 O, dehydrated graphite oxide and isopropanol in step one are mixed to form a mixed solution, and ultrasonic is carried out so that graphite oxide is peeled off to a certain extent, MMn 2+ Intercalation into the graphite oxide layer, interacting with the polar groups of graphite oxide, as the active point of the reaction, so that MnO 2 Nanocrystals are grown in situ on graphene oxide sheets. Ultrasonic time is 10min~2h; graphite oxide and MnCl 2 4H 2 The ratio of O is 1:0.009~0.27, in which MnCl 2 4H 2 The unit of O is g, the unit of graphite oxide is mL, and the concentration of graphite oxide is 6.65mg / mL; MnCl 2 4H 2 The ratio of O to isopropanol is 0.0018~0.054:1, where the unit of isopropanol is g, MnCl 2 4H 2 The unit of...

Embodiment 1

[0022] Example 1: Graphene oxide-supported nano-MnO of the present invention 2 The preparation method comprises the following steps:

[0023] Step 1: dehydrate 10 mL of graphite oxide by high-speed centrifugation;

[0024] Step 2: 0.09g MnCl 2 4H 2 O, dehydrated graphite oxide in step 1 is mixed with 50mL isopropanol to form a mixed solution, and ultrasonic 10min;

[0025] Step 3: Heat up the mixed solution prepared in Step 2 to 83°C under stirring;

[0026] Step 4: Add 0.063gKMnO 4 Dissolve in 5mL of water and add to the mixed solution prepared in step 3 at one time, and react for 30min;

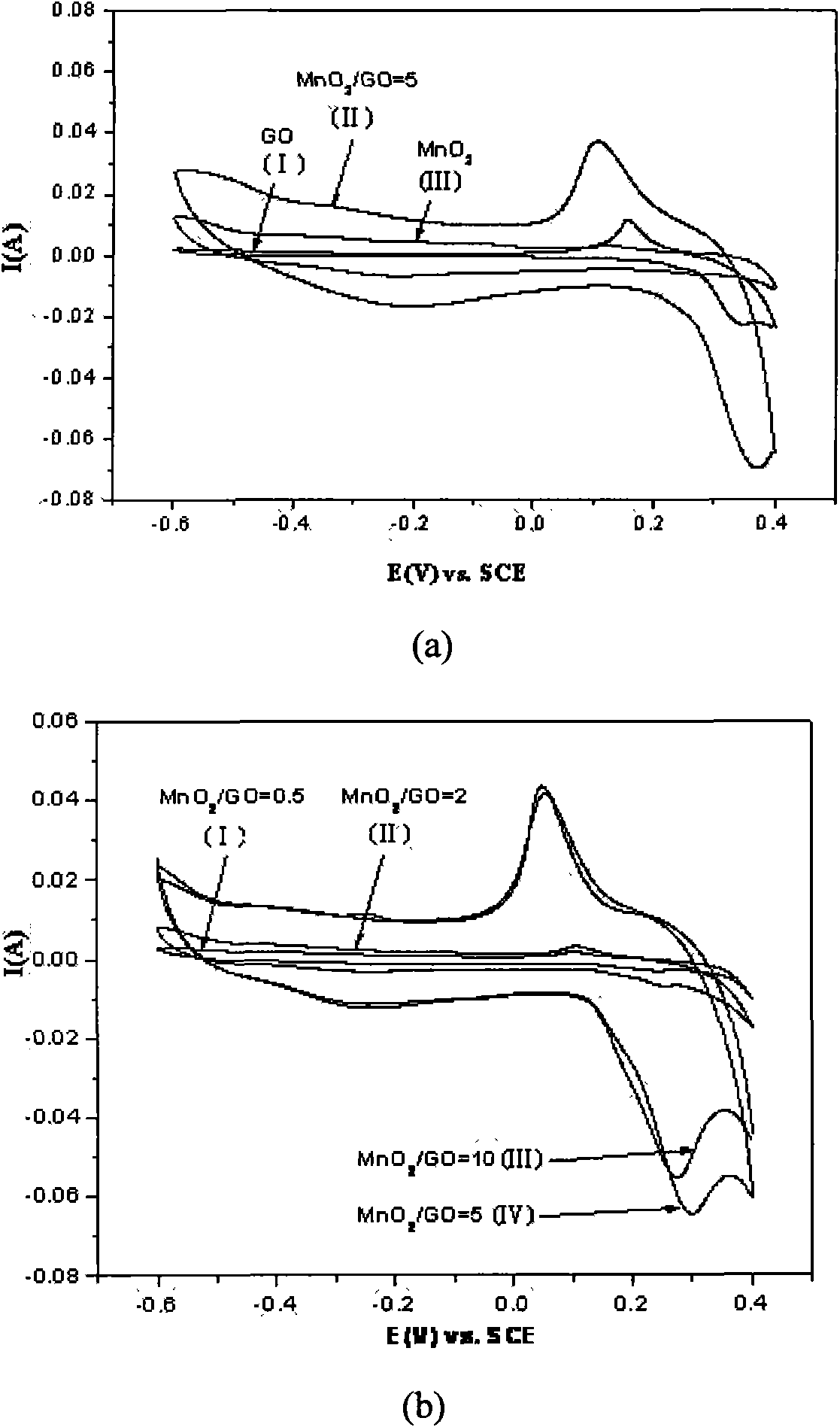

[0027] Step 5: centrifuge, wash, dry, and grind the black precipitate obtained from the reaction in step 4 to obtain graphene oxide-loaded nano-MnO 2 Composite material; loading mass ratio is MnO 2 / GO=0.5 / 1, the cyclic voltammetry curve is as follows image 3 The first curve (I) in (b), the capacitance value calculated according to the curve is 60.3F·g -1 .

Embodiment 2

[0028] Example 2: Graphene oxide-supported nano-MnO of the present invention 2 The preparation method comprises the following steps:

[0029] Step 1: dehydrate 10 mL of graphite oxide by high-speed centrifugation;

[0030] Step 2: 0.36g MnCl 2 4H 2 O, dehydrated graphite oxide in step 1 is mixed with 50mL isopropanol to form a mixed solution, and ultrasonic 2h;

[0031] Step 3: Heat up the mixed solution prepared in Step 2 to 70°C under stirring;

[0032] Step 4: Add 0.20g KMnO 4 Dissolve in 10 mL of water and add to the mixed solution prepared in step 3 at one time, and react for 2 hours;

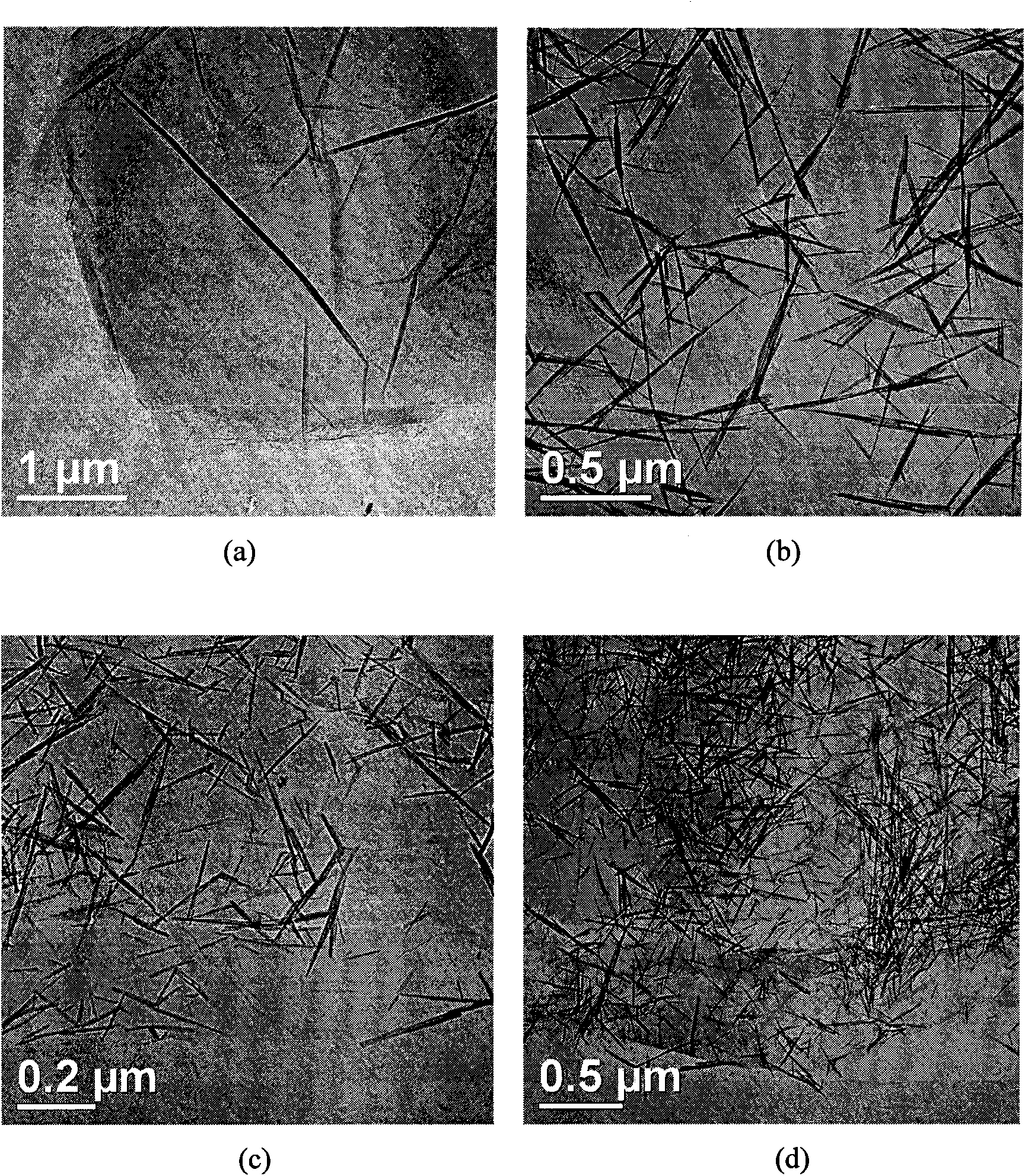

[0033] Step 5: centrifuge, wash, dry, and grind the black precipitate obtained from the reaction in step 4 to obtain graphene oxide-loaded nano-MnO 2 composite materials such as figure 2 (c); The load mass ratio is MnO 2 / GO=2 / 1, its cyclic voltammetry curve is as follows image 3 The second curve (II) in (b), according to the curve, the calculated capacitance value is 111.9F·g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com