Optical method for detecting defect on inner wall of holes

A technology for hole inner wall and defect, which is applied in the field of optical measurement of hole inner wall defect, can solve the problems of low environmental requirements, inability to detect wear, scratches, etc., achieve effective calculation, facilitate post-processing, and improve detection speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the present invention will be further described:

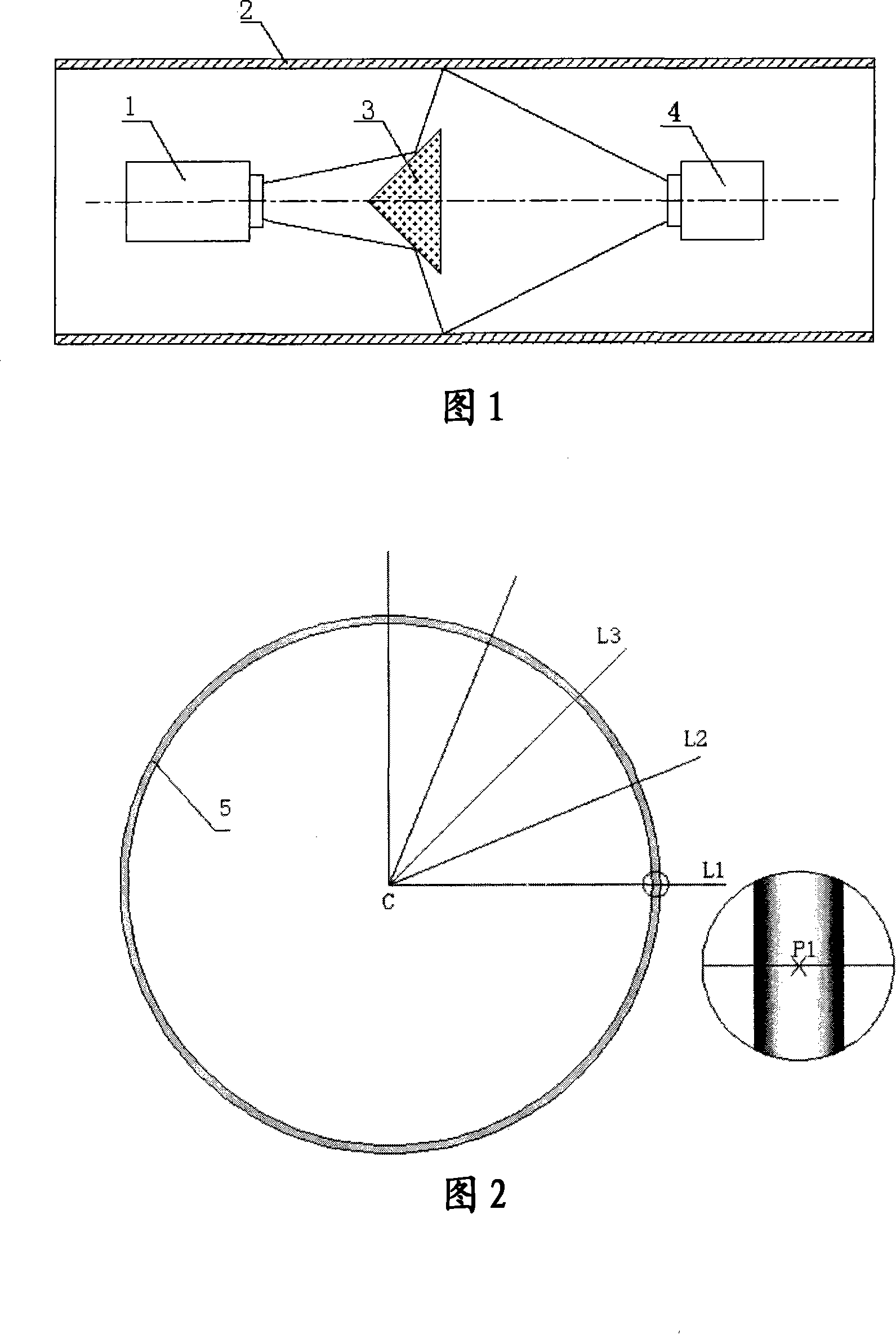

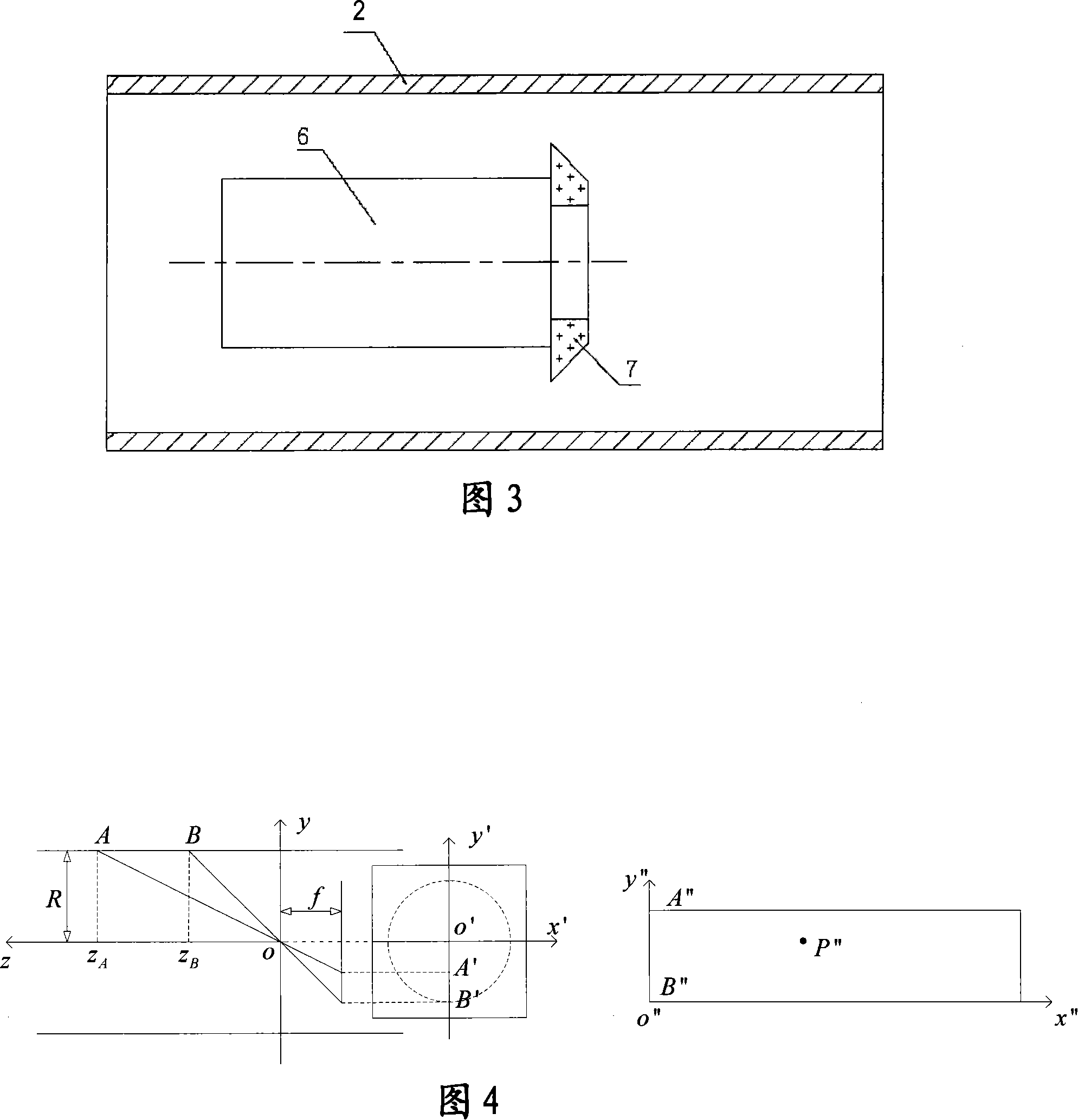

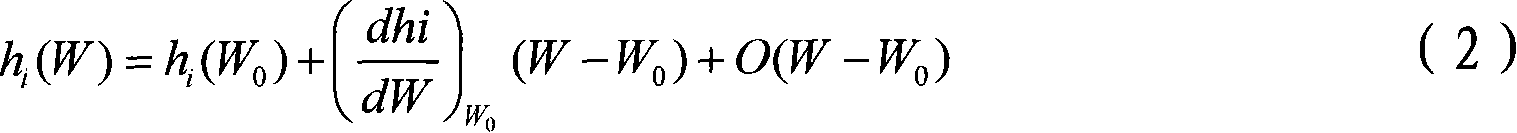

[0031] Fig. 1 is a schematic diagram of the measurement method of the ring laser vision sensor. The light cone projected by the ring laser 1 intersects with the inner wall of the deep hole after passing through the reflector mirror 3 to form a three-dimensional curve in space. The CCD camera acquires the image of the three-dimensional curve to calculate the cross-sectional size and Processing, specific calculation as shown in Figure 2: C in Figure 2 is the initial center of the set, 5 is the contour curve on the cross-sectional view, with C as the vertex as the ray L1 intersects the contour curve, because the contour curve has a certain width, and The brightness distribution on the curve is uneven, the brightness in the middle is high, and the brightness values on both sides are low. After intersecting with L1, a line segment is formed. The brightness distribution on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com