Silica matrix chromatogram packing

A chromatographic packing and silica gel matrix technology, which is applied in the field of preparation of silica gel packing for high performance liquid chromatography, can solve the problems of insignificant improvement of tail-capping effect, high device cost, unsatisfactory and the like, and achieves simple post-processing work and time-consuming reaction. Short, high-volume effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Weigh 20.0g spherical silica gel (BaseLine Sil, particle size 5μm, specific surface area 250m 2 / g, aperture 100 Ȧ), put it into a three-necked flask, install a condenser, add 200ml of 10% hydrochloric acid aqueous solution, mechanically stir and reflux at 105°C for 12h, repeatedly wash with deionized water until the filtrate is neutral, and vacuum dry at 90°C for 12h .

[0020] Weigh 10.0 g of pretreated dry spherical silica gel, put it into a three-necked flask, install a condenser tube and a drying tube, add 100 ml of dehydrated toluene (treated with activated molecular sieves for more than 12 hours), 1 ml of triethylamine, and octadecyltrimethoxysilane 5ml, under the condition of mechanical stirring, pass through dry nitrogen and heat to toluene reflux, 110 ℃ constant temperature reaction for 6h, stop the reaction, wash with toluene, methanol, methanol-water (1:1, v / v), methanol, acetone successively, Vacuum-dried at 60°C for 12 hours to obtain octadecyl bonded ...

Embodiment 2

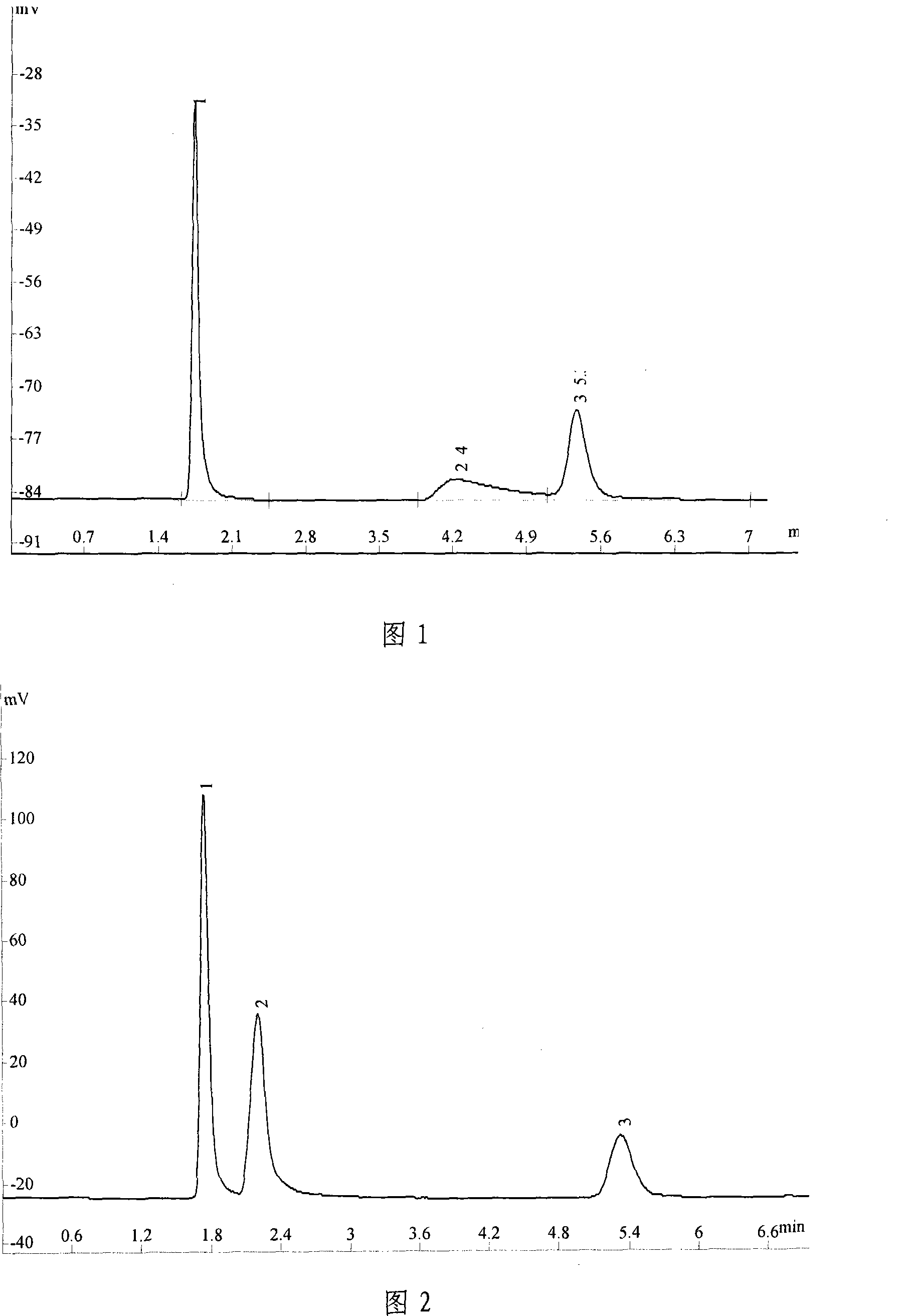

[0023] Use the non-inertized octadecyl reversed-phase chromatography silica gel filler prepared in Example 1, and fill it in a 150×4.6mm I.D. stainless steel column tube by homogenization method. The resulting column is used to separate mixture samples. Fig. 1 is the chromatogram of its separation analysis evaluation octadecyl reversed-phase chromatographic stationary phase commonly used mixture, i.e. 1 uracil, 2 pyridine, 3 phenol, and chromatographic condition is as follows: mobile phase, methyl alcohol: water=45: 55 (v / v); flow rate, 1ml / min; column temperature, 25°C; detection wavelength, UV254nm.

Embodiment 3

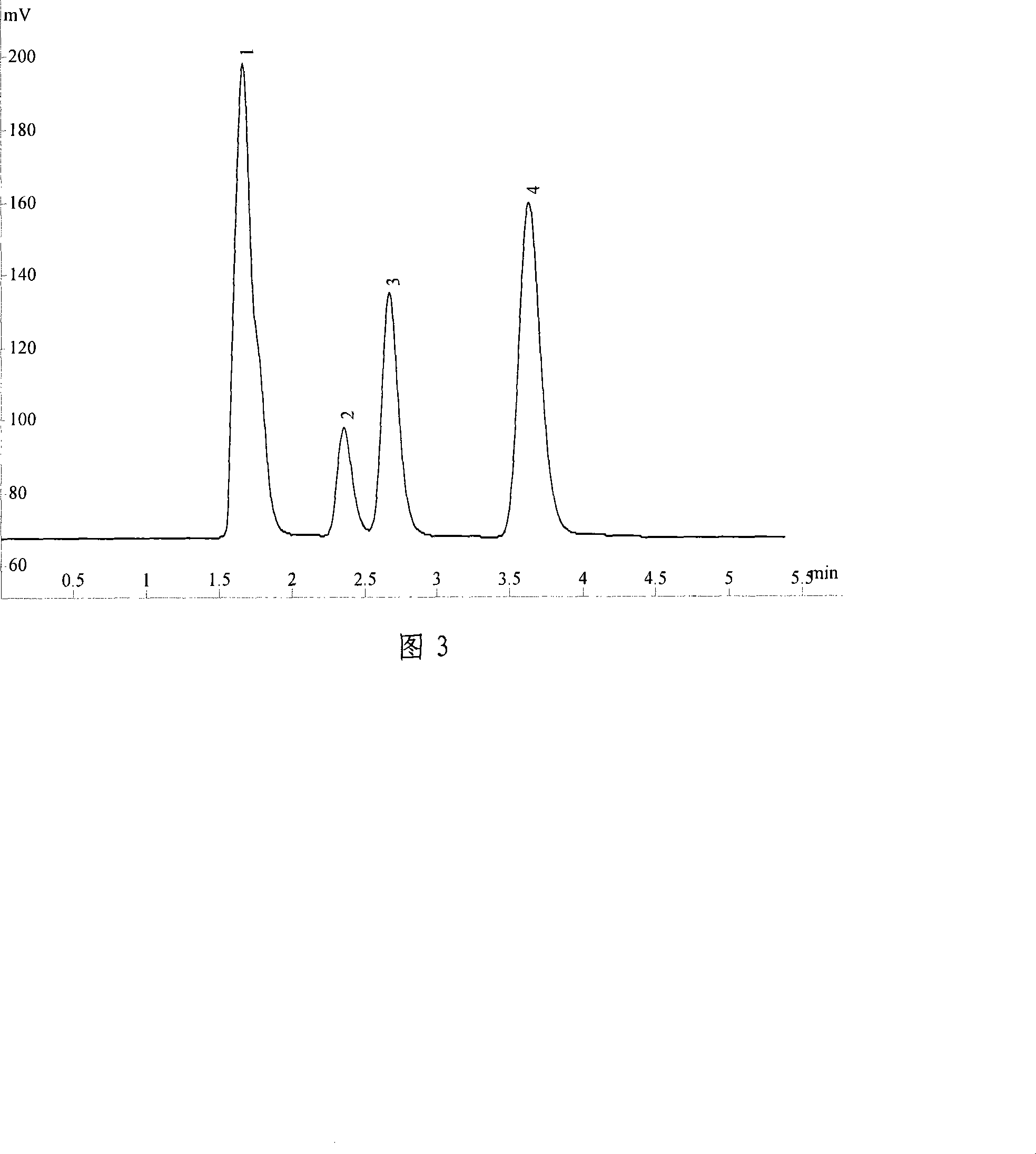

[0025] Use the highly inert octadecyl reversed-phase silica gel chromatography filler prepared in Example 1, and fill it in a 150×4.6mm I.D. stainless steel column by homogenization method. The resulting column is used to separate mixture samples. Its separation and analysis of Fig. 2 is the chromatogram of evaluation octadecyl reversed-phase chromatographic stationary phase commonly used mixture, i.e. 1 uracil, 2 pyridine, 3 phenol, and chromatographic condition is as follows: mobile phase, methyl alcohol: water=45: 55 (v / v); flow rate, 1ml / min; column temperature, 25°C; detection wavelength, UV254nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com