Method and device for removing nitrates from drinking water

A technology for nitrate and drinking water, which is applied in chemical instruments and methods, water pollutants, water/sludge/sewage treatment, etc., can solve the problems of low hydrogen solubility and low hydrogen utilization rate, and reduce the difficulty of treatment and solve the problem of Effects of excess nitrate, avoiding excess electron donors and microbial overgrowth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

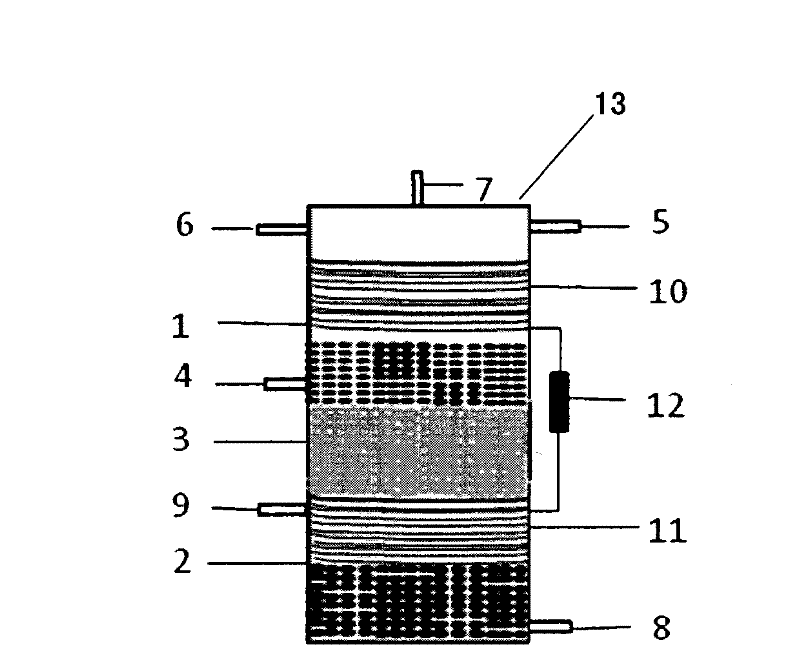

[0019] Such as figure 1 Shown includes a reactor body 13 with an inner diameter of 12.5 cm and a height of 14 cm, a separation diffusion layer 3, a positive electrode 10 and a negative electrode 11, wherein the separation diffusion layer 3 is installed in the reactor body 13 to separate the reactor body 13 into a denitrification unit 1 and the upper and lower parts of the oxygen pressure unit 2, the denitrification unit 1 and the oxygen pressure unit 2 are respectively filled with filling particles, and the positive electrode 10 and the negative electrode 11 are respectively located in the denitrification unit 1 and the oxygen pressure unit 2. on the grain; the denitrification unit 1 is respectively provided with a first water inlet 4, a first water outlet 5, a sampling port 6 and an exhaust port 7; the anaerobic unit 2 is respectively provided with a second water inlet 8 and Second water outlet 9. The water inlet and outlet are respectively located on both sides of the axial...

Embodiment 2

[0025] The difference from Example 1 is: the volume ratio of the denitrification unit to the anaerobic fermentation unit is 2:1; the denitrification unit is filled with activated carbon particles with a particle size of 2-5mm, accounting for 40% of the denitrification unit volume; The fermentation unit is filled with activated carbon particles with a particle size of 2-5mm, accounting for 60% of the volume of the anaerobic fermentation unit; the separation and diffusion layer is 2cm thick, composed of quartz sand with a particle size of 1.0-3.0mm and artificial cotton with a particle size of less than 0.1mm. The porosity is 60%; the ratio of the surface area of the positive and negative electrodes is 2:1, and the positive and negative electrodes are activated carbon fibers, weighing 20 and 10 g respectively. The positive and negative electrodes are connected to an external resistor through a titanium wire. The added concentration of rice husk powder in the anaerobic fermenta...

Embodiment 3

[0027] The difference from Example 1 is: the volume ratio of the denitrification unit to the anaerobic fermentation unit is 3:1; the denitrification unit is filled with activated carbon particles with a particle size of 2-5mm, accounting for 50% of the denitrification unit volume; The fermentation unit is filled with activated carbon particles with a particle size of 2-5mm, accounting for 60% of the volume of the anaerobic fermentation unit; the separation and diffusion layer is 3cm thick, composed of quartz sand with a particle size of 1.0-3.0mm and artificial cotton with a particle size of less than 0.1mm. The porosity is 70%; the ratio of the surface area of the positive and negative electrodes is 2:1. The positive and negative electrodes are activated carbon fibers, weighing 20 and 10 g respectively. The positive and negative electrodes are connected to an external resistor through a titanium wire. The added concentration of rice husk powder in the anaerobic fermentation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com