Patents

Literature

102results about How to "Avoid unstable performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

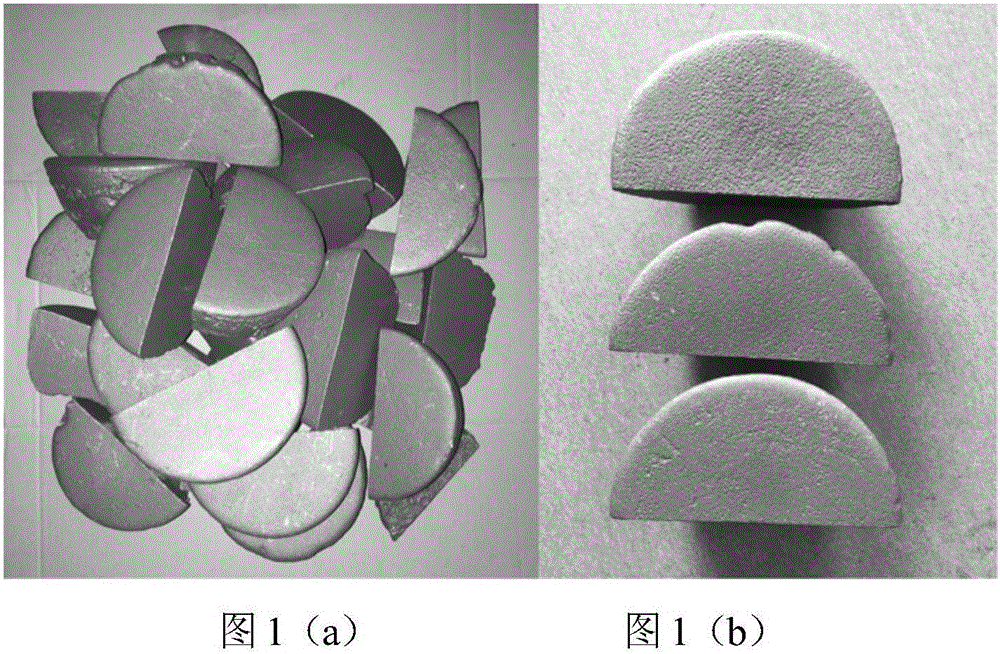

Method for adding rare earth metal into steel to improve performance

The invention relates to the field of manufacturing of high-quality metal materials, in particular to a method for adding rare earth metal into steel to improve the performance. In the smelting process of molten steel, the degree of purity of the molten steel and the degree of purity of the high-purity rare earth metal are strictly controlled; the high-purity rare earth metal is added into a steel ladle; the content of sulfur in the molten steel is below 200 ppm and the total oxygen content is below 40 ppm before the high-purity rare earth metal is added; and the total oxygen content of the added high-purity rare earth metal is below 200 ppm. The method is applicable to the processes such as a converter BOF-ladle refining LF-vacuum degassing RH or VD-continuous casting CC / mold casting MC flow, an electric arc furnace EAF-ladle refining LF-vacuum degassing RH or VD-continuous casting CC / mold casting MC flow and a converter BOF / intermediate frequency furnace GOR / AOD(-ladle refining LF)-continuous casting CC / mold casting MC flow, prepares high-quality carbon structural steel, low alloy steel, medium-high alloy steel, tool and mould steel, bearing steel, spring steel, stainless steel and electrical steel, and solves the bottleneck problems that due to a conventional rare earth adding process, the performance of rolled steel is not stable and a water gap is blocked in the production process.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

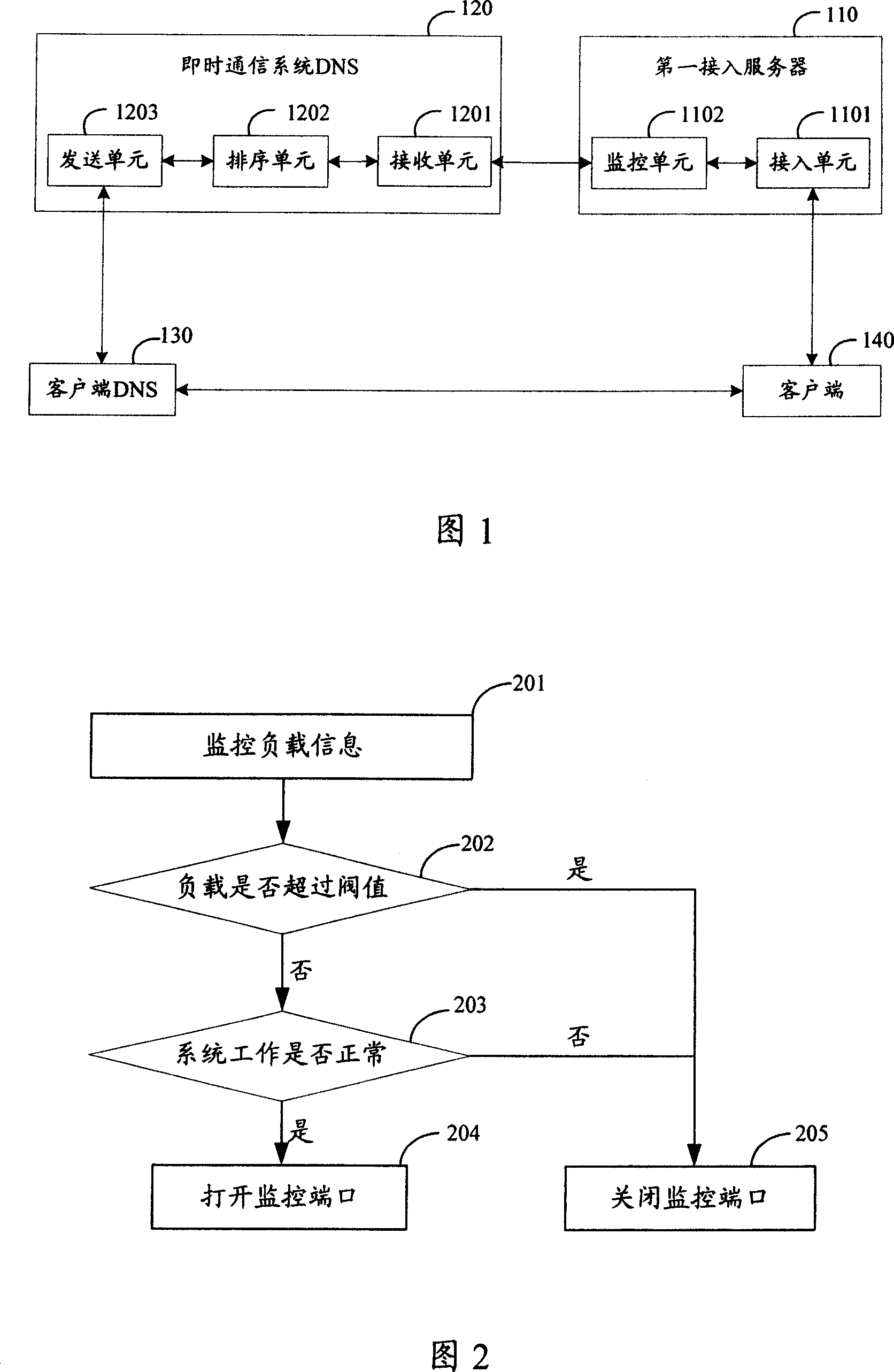

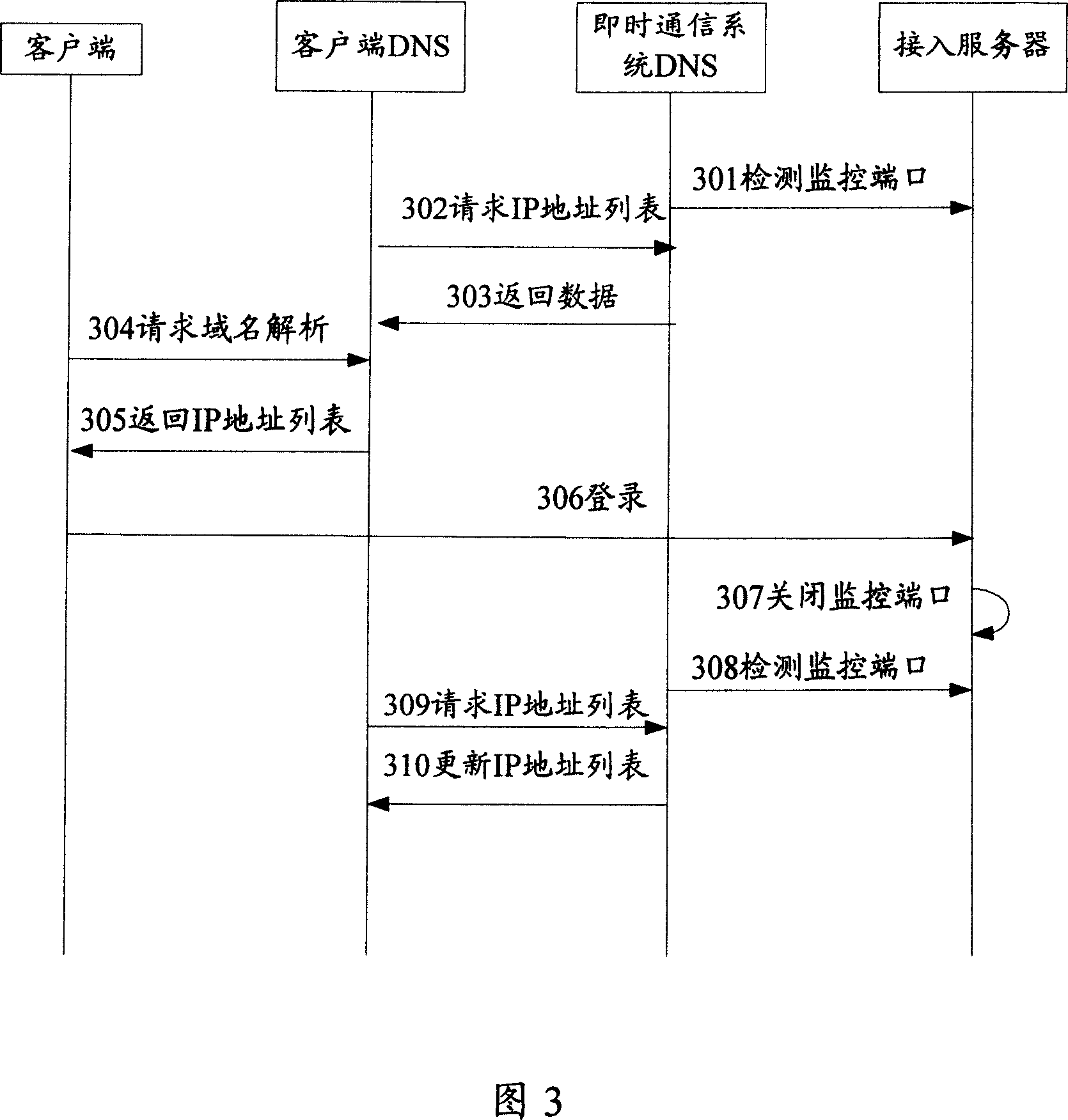

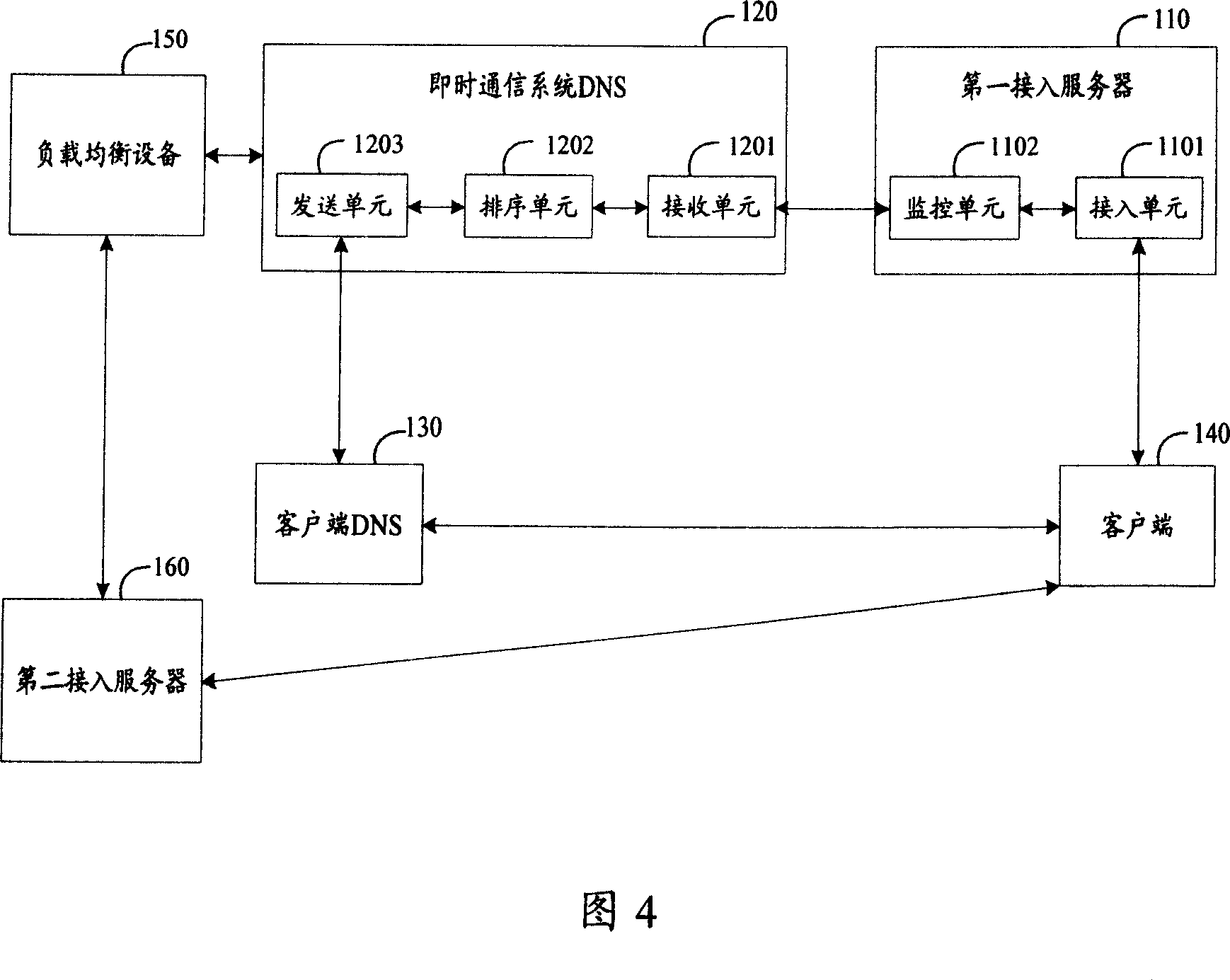

A method and system for realizing large-scale instant message

InactiveCN101102288AImprove reliabilityUniform quantityTrickle coolersData switching networksDomain nameCommunications system

The method is used for solving the issues that are the large instant communication system is unstable and the access of client side is unreliable. It comprises: getting the access information of each access server in the instant communication system; according to the access information, the domain name server (DNS) in the instant communication system provides the information about available access server to the client side; according to the information about available access server, the client side selects an access server to access the instant communication system.

Owner:ALIBABA GRP HLDG LTD

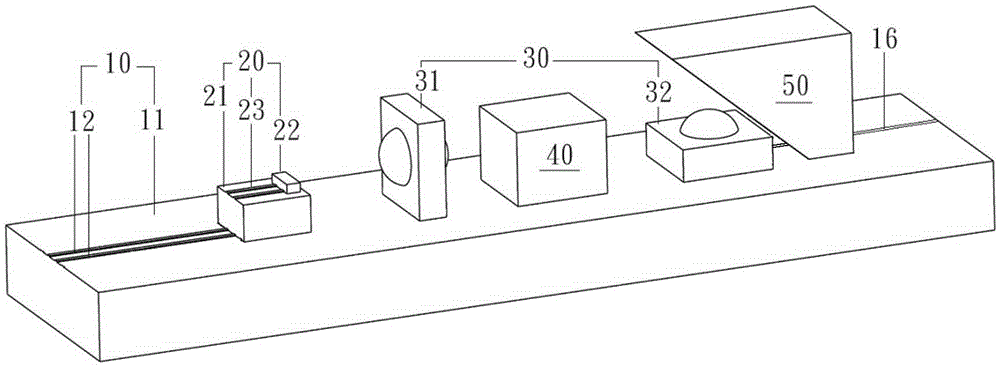

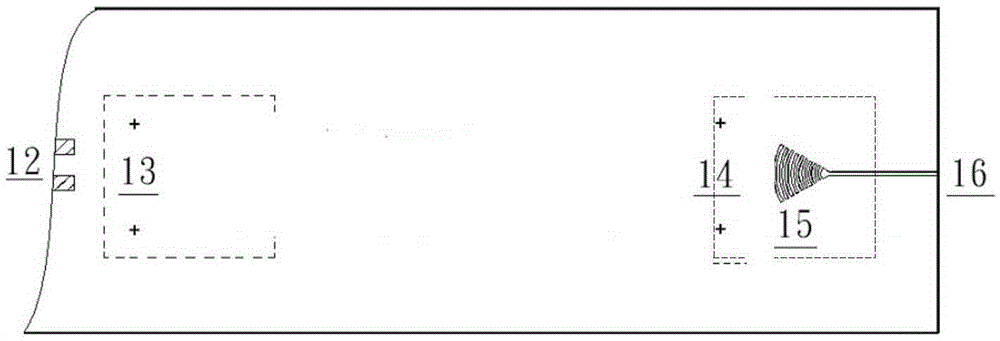

Laser and grating coupler packaging structure and method

ActiveCN105259623AGuaranteed placement accuracyEfficient couplingLaser detailsSemiconductor laser optical deviceGratingEngineering

The invention provides a laser and grating coupler packaging structure and method. The packaging structure comprises a laser unit, a collimating lens, an isolator and a reflection prism, wherein the laser unit, the collimating lens, the isolator and the reflection prism are mounted on a silicon-based photoelectric chip. The silicon-based photoelectric chip comprises a first electrode, first and second marks, a grating coupler and a waveguide layer which are all arranged at the surface; the laser unit comprises a transitional substrate and a laser; the collimating lens comprises a first lens and a second lens, the first lens is vertical to the surface, the second lens is arranged at the surface at the position of the second mark, and thus, the grating coupler is placed in the central area of the main axis of the optical path of the second lens; and the isolator is mounted at the surface between the first lens and the second lens, so that diverging light output by the laser is collimated by the first lens, then reflected to the reflection prism through the isolator, deflected by the reflection prism for certain angle, and gathered by the second lens, and the gathering point is placed at the surface of the grating coupler. Thus, technical problems in accurate in-place packaging are solved, convenience is provided for preparation, and the yield rate is improved.

Owner:WUHAN TELECOMM DEVICES

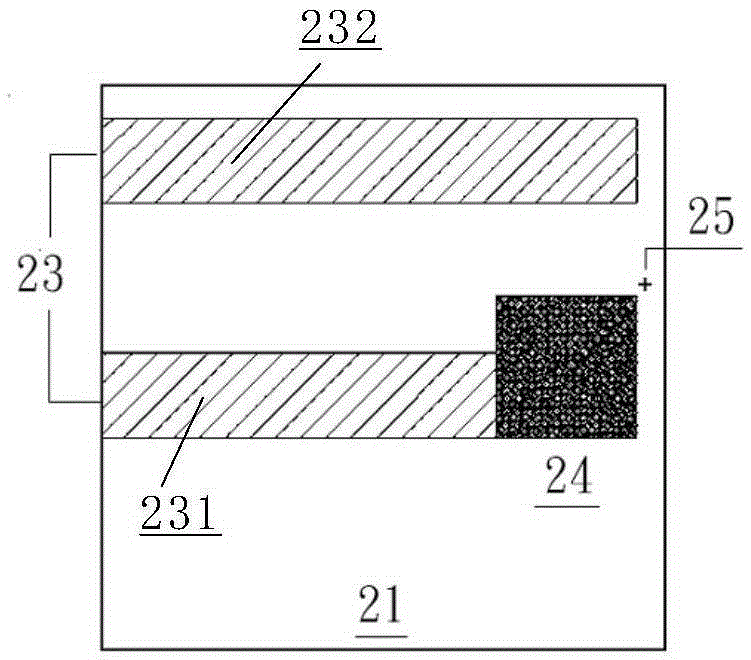

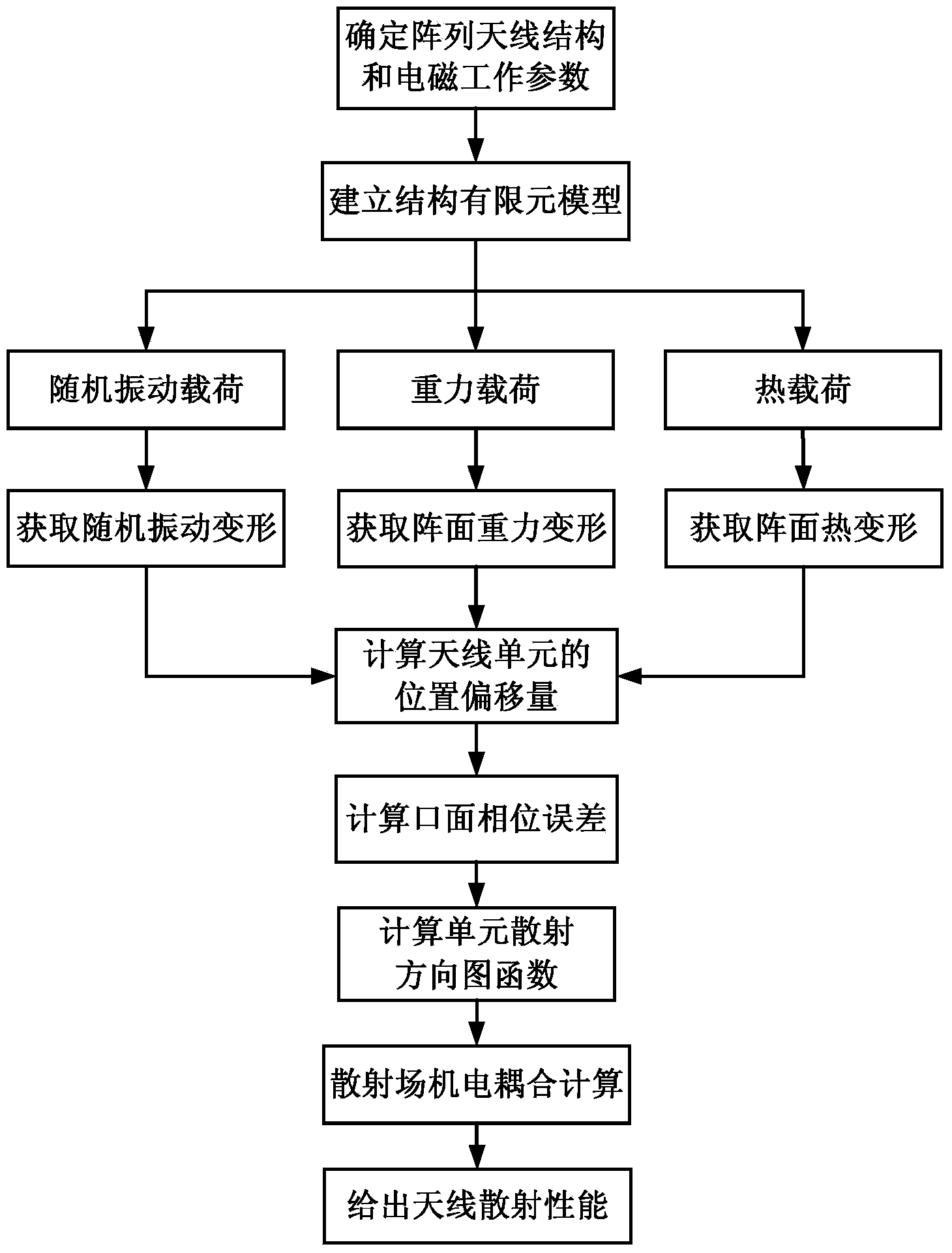

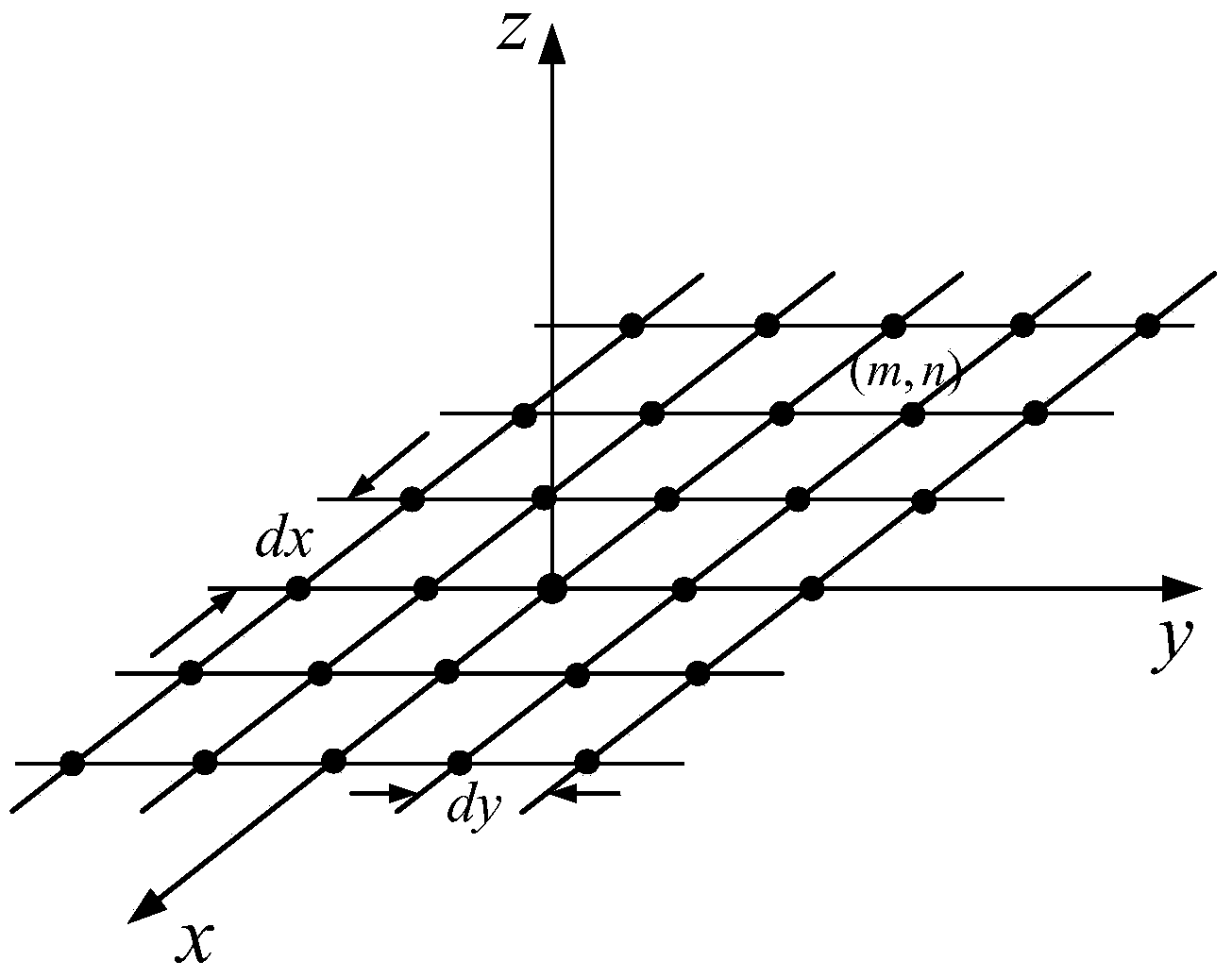

Deformed array antenna scattering performance analyzing method based on electromechanical coupling

ActiveCN104038295ASolve computing problemsShorten the development cycleTransmission monitoringElement modelPhase difference

The invention discloses a deformed array antenna scattering performance analyzing method based on electromechanical coupling. The deformed array antenna scattering performance analyzing method based on the electromechanical coupling includes that determining geometrical model parameters, material attributes and electromagnetic working parameters of an array antenna; building a finite element model of the antenna; determining constraint conditions and random vibration load, gravity load and thermal load environments of the finite element model, calculating the array surface deformation of the array antenna under the constraint conditions and load environments, and extracting the position offsets of antenna center nodes of the finite element model of the antenna under the conditions; accumulating to obtain the total position offset of the antenna; calculating the spatial phase difference of two adjacent antenna unit scatting fields in the array surface to obtain an aperture phase difference; calculating an antenna unit scattering pattern; calculating an array antenna scattering field pattern; analyzing the influence of the array structure deformation on the antenna scattering performance under the load environments. The deformed array antenna scattering performance analyzing method based on the electromechanical coupling is used for quantitatively evaluating the influence of the array surface structure deformation on the antenna scattering performance under the load environments and guiding the array antenna structure design, cooling design and scattering performance simulation analysis and evaluation.

Owner:XIDIAN UNIV

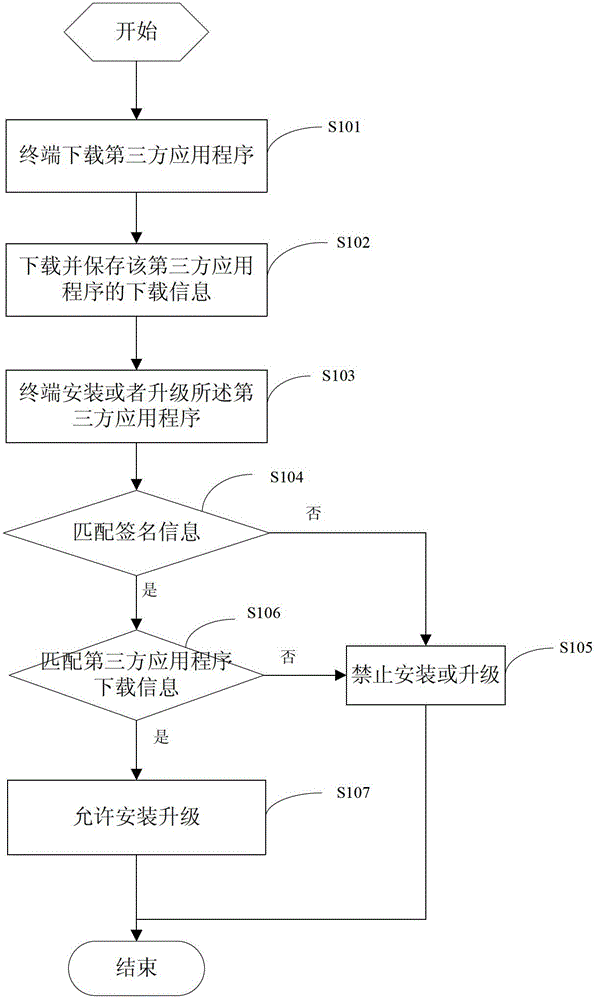

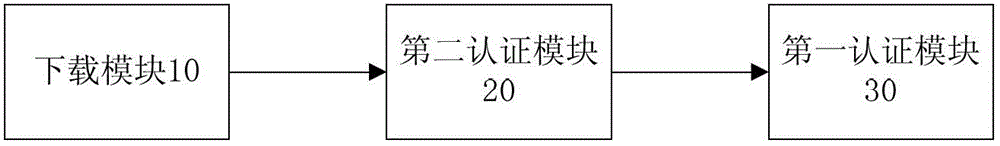

Method and system for restricting terminals from mounting or upgrading third-party application programs

ActiveCN102750491AAffect normal useAvoid unstable performanceComputer security arrangementsThird partySoftware engineering

The invention discloses a method and a system for restricting terminals from mounting or upgrading third-party application programs, wherein the method includes the following steps: downloading and saving downloading information of the third-party application programs while downloading the third-party application programs at the terminals; and matching the downloaded information with prestored and authorized information while mounting or upgrading the third-party application programs at the terminals, and allowing the third-party application programs to be mounted or updated if the information are matched. According to the method and the system for restricting the terminals from mounting or upgrading the third-party application programs, the problem of unstable terminal performances caused by the fact that users download the third-party application programs from informal channels can be solved, and the influence of some malicious third-party application programs on the normal use of users can also be avoided, so that risks of customer complaints about terminal suppliers caused by third-party application programs are reduced greatly.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

Light mixing cured coating composition and preparation method thereof

InactiveCN101709196AImprove physical and chemical propertiesExcellent system performanceEpoxy resin coatingsUltraviolet lightsSpray coating

The invention discloses a light mixing cured coating composition which comprises epoxy acrylic acid monoester, ultraviolet light-heat mixing curing agent or ultraviolet light free radical-cation mixing curing agent, pigmented filler, reactive diluent, dispersing agent, defoaming agent and flatting agent. The invention also discloses a preparation method of the light mixing cured coating composition. The coating composition of the invention has small cure shrinkage and high bonding strength, can be applied to dark systems, can be used for coating some components with complicated structures, and can be used for coating surfaces of wood products, plastics, metals and the like by the construction methods of brush coating, spray coating, curtain coating, roller coating and the like.

Owner:SHENZHEN POLYTECHNIC

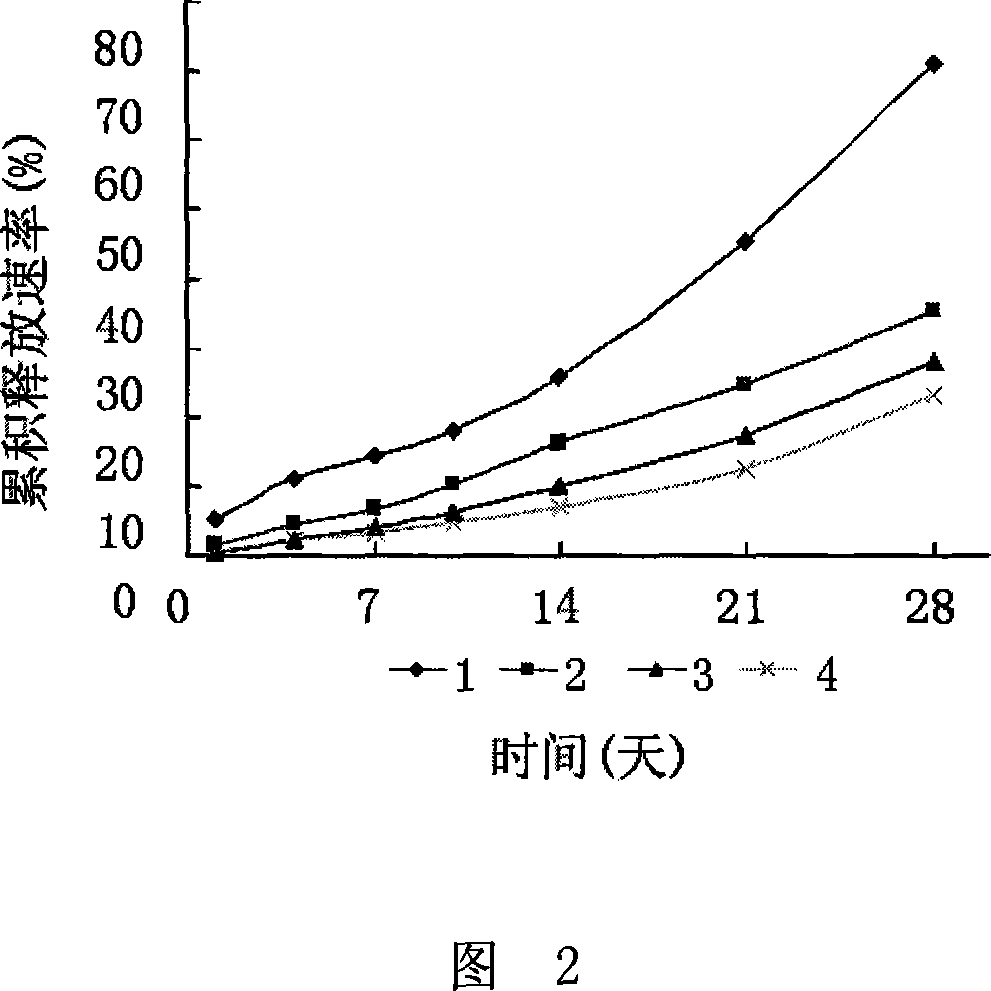

Controlled fertilizer of polymer capsule, production method, and dedicated capsule material

InactiveCN101050148ANo toxicityPromote safe productionFertiliser formsGranulation by powder suspensionLow-density polyethyleneLinear low-density polyethylene

This invention discloses a polymer-coated controlled-release fertilizer, its production method and its specific coating material. The coating material comprises: branched low-density polyethylene with an average molecular weight of 20000-30000, and linear low-density polyethylene with an average molecular weight of 20000-30000 at a weight ratio of 1 :( 0.33-1). The polymer-coated controlled-release fertilizer is composed of water-soluble fertilizer and the coating material defined in claims 1-4. The water-soluble fertilizer is coated with the coating material. The polymer-coated controlled-release fertilizer has good controlled-release performance and safe processing, and can be used on lawns, flowers, vegetables, and economic crops.

Owner:CHINA AGRI UNIV

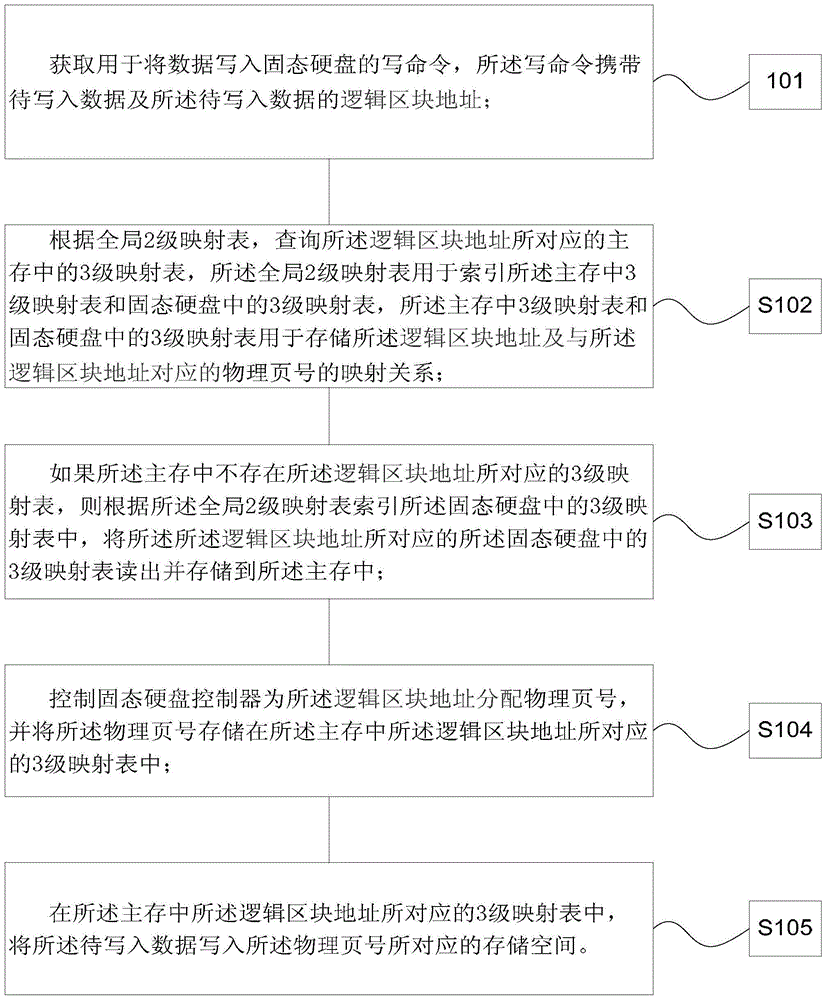

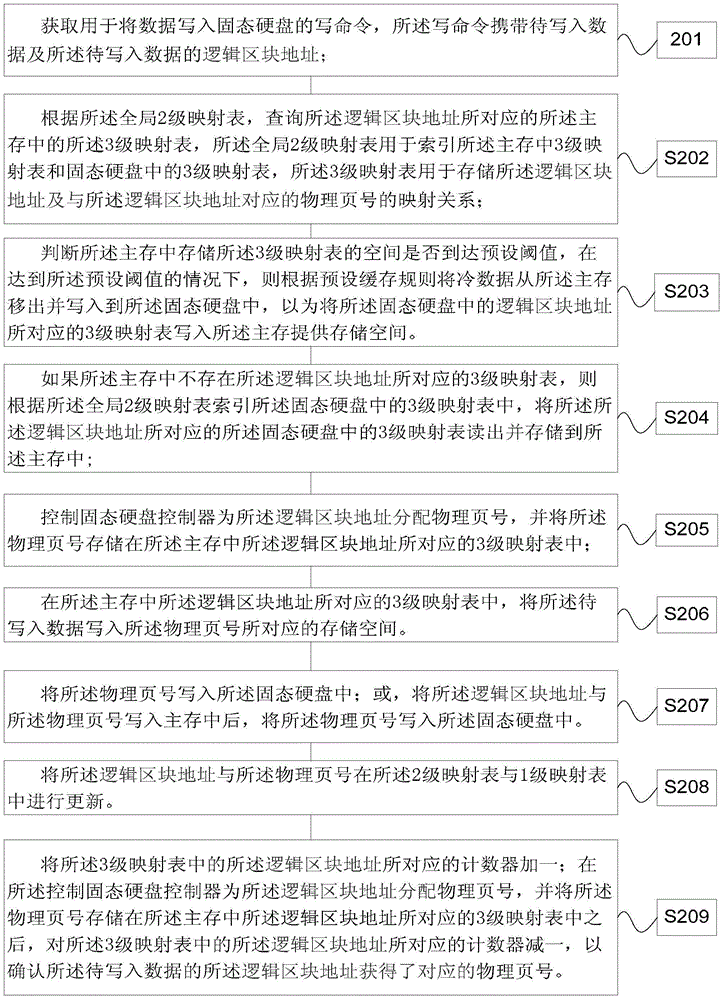

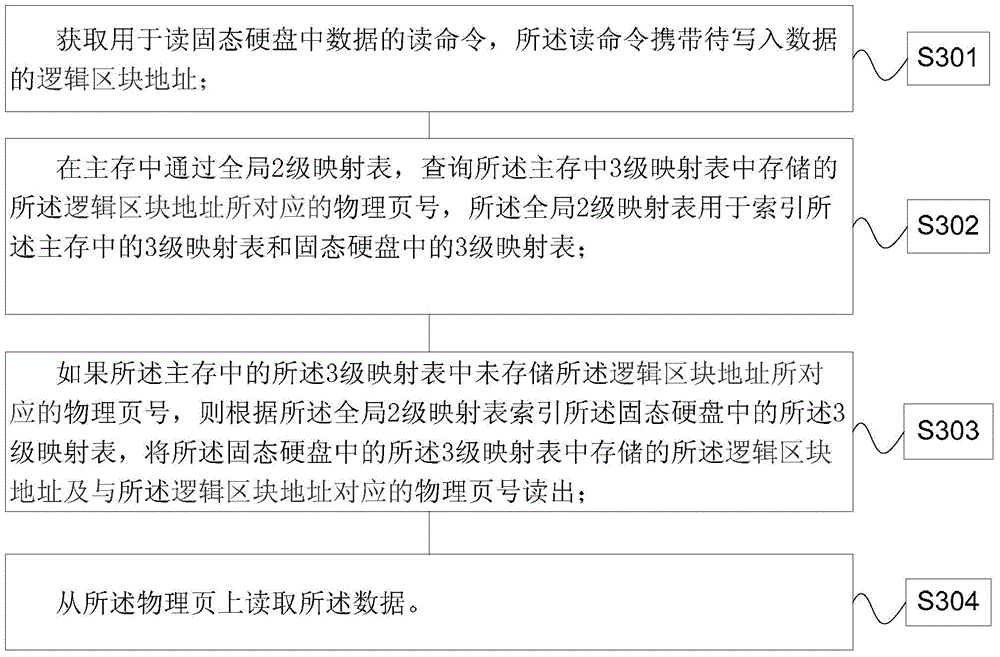

Address mapping method and device based on large-capacity solid storage

ActiveCN105205009AReduce consumptionAvoid unstable performanceMemory adressing/allocation/relocationMemory architecture accessing/allocationLogical block addressingDisk controller

The invention provides an address mapping method based on large-capacity solid storage. The method is characterized by including the steps of obtaining a writing command for writing data in a solid hard disk, wherein the writing command carries data to be written and logic block addresses of the data to be written; inquiring about a third-stage mapping table, corresponding to the logic block addresses, in a main memorizer according to a global second-stage mapping table; if the third-stage logic list corresponding to the logic block addresses does not exist in the main memorizer, indexing the third-stage mapping table in the solid hard disk according to the global second-stage mapping table, reading out the third-stage mapping table, corresponding to the logic block addresses, in the solid hard disk and storing the third-stage mapping table into the main memorizer; controlling a solid hard disk controller to allocate physical page numbers for the logic block addresses, storing the physical page numbers in the third-stage mapping table, corresponding to the logic block addresses, in the main memorizer, and writing the data to be written in the physical page numbers.

Owner:HUAWEI TECH CO LTD

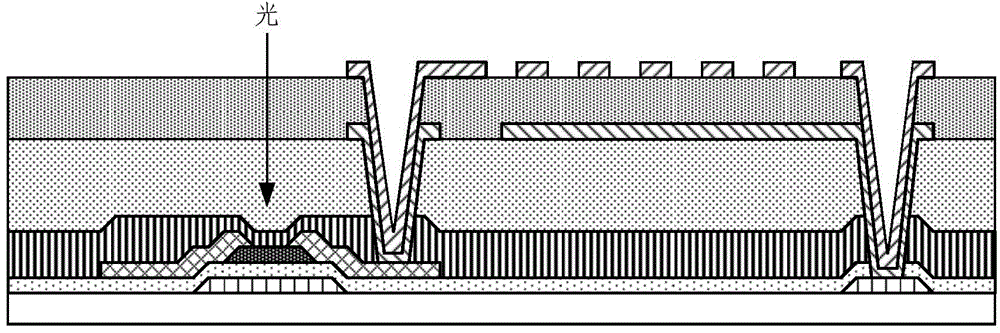

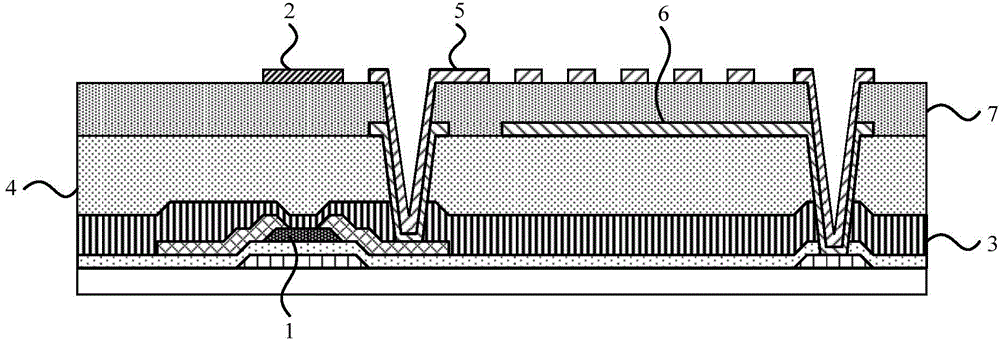

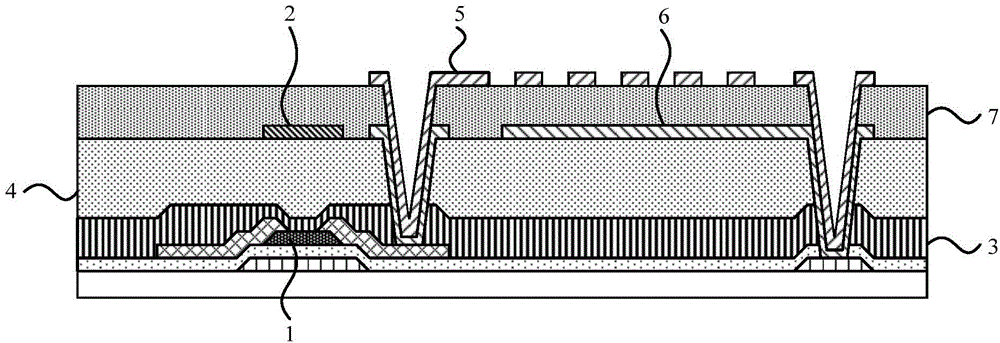

Display substrate and manufacturing method thereof, and display apparatus

ActiveCN104934449AAvoid exposureAvoid unstable performanceSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringTransistor

The present invention relates to a display substrate and a manufacturing method thereof, and a display apparatus. The display substrate comprises: a thin film transistor which is provided with an active layer therein; and a light shield layer which is arranged over the active layer and is used for shielding lights irradiating towards the active layer. According to the technical scheme of the present invention, the light shield layer is arranged over the active layer, so that external lights can be effectively prevented from irradiating to the active layer in the thin film transistor, thereby avoiding unstable performance of the thin film transistor caused by influence on the active layer from the outside illumination.

Owner:BOE TECH GRP CO LTD

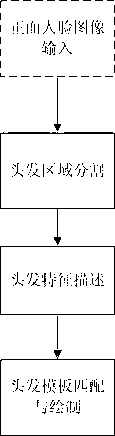

Automatic hair drawing method for human face cartoonlization

InactiveCN103218838AIncrease productivityAvoid instability2D-image generationTemplate matchingComputer science

The invention relates to a method for automatically extracting a hair area in a photo by using a full face photo of the human face and a computer and converting the hair area into a cartoon style drawing effect. The automatic hair drawing method can be used as a constituent part of a cartoonlization technology based on a human face image. The automatic hair drawing method comprises the following steps of: (1) segmenting the hair area; (2) describing hair characteristics; and (3) matching and drawing a hair template.

Owner:苏州华漫信息服务有限公司

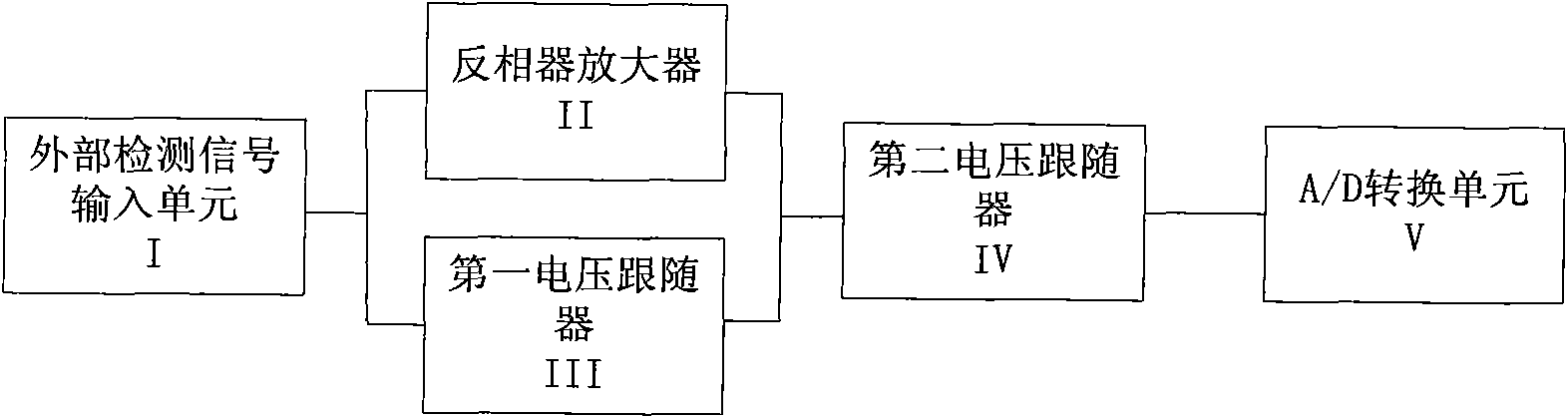

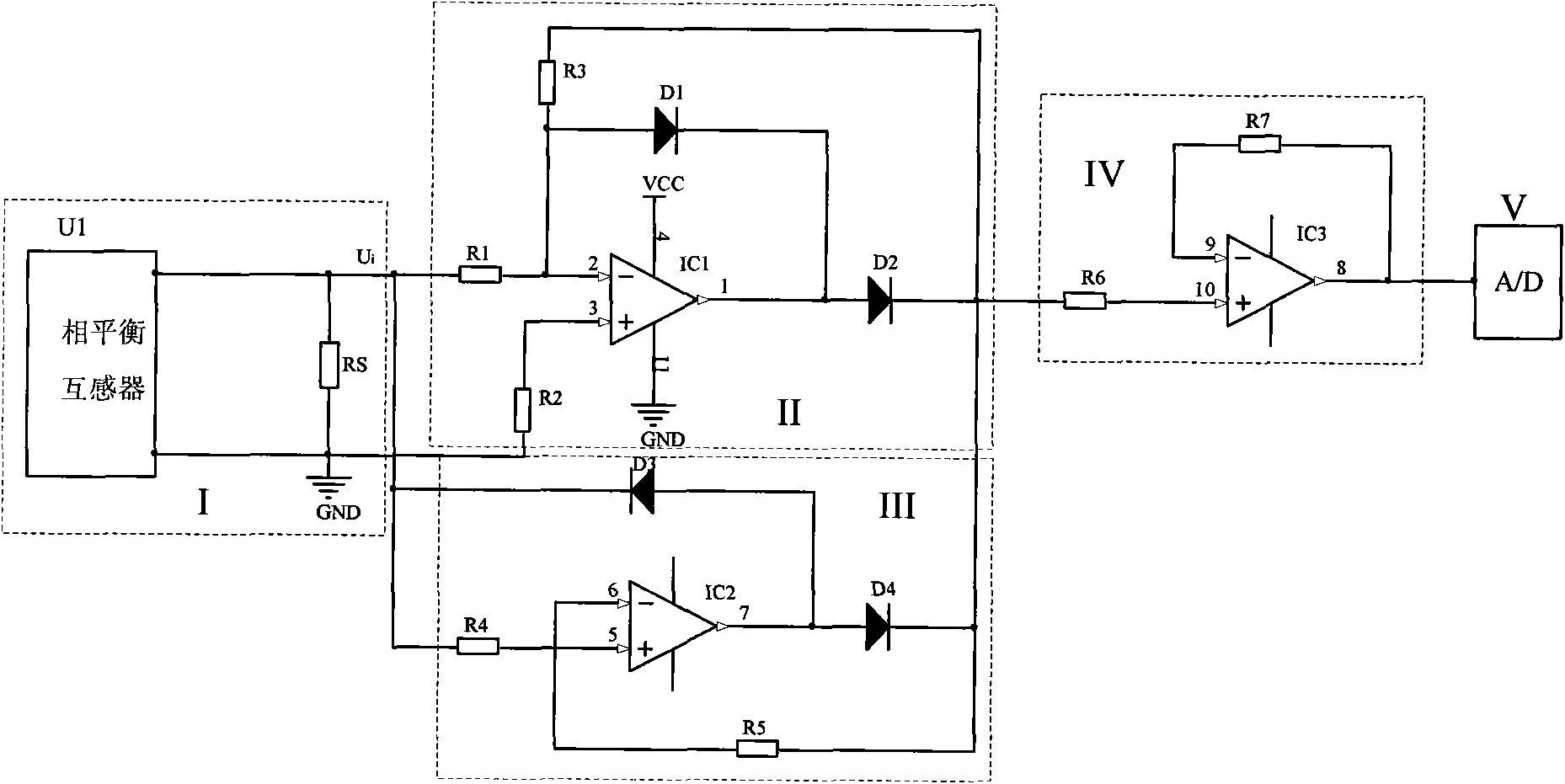

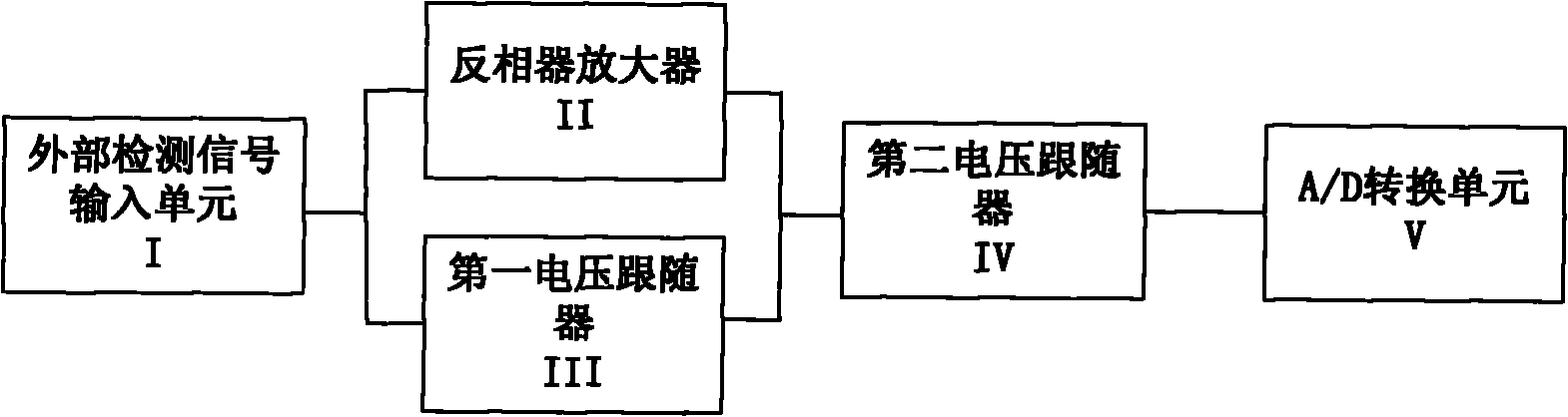

Circuit for conditioning micro-current/voltage conversion signal

ActiveCN101938271AEasy to getLow priceAmplifier combinationsAnalogue-digital convertersSignal conditioning circuitsAudio power amplifier

The invention relates to a circuit for conditioning a micro-current / voltage conversion signal. The circuit comprises an external detection signal input unit, a phase inverter amplifier, a first voltage follower, a second voltage follower and an analog to digital (A / D) converting unit, wherein the phase inverter amplifier and the first voltage follower are connected with the external detection signal input unit and connected with the A / D converting unit through the second voltage follower; the external detection signal input unit provides an external detection signal; and the external detection signal is processed by the phase inverter amplifier and the first voltage follower, synthesized, processed by the second voltage follower and output to the A / D converting unit. A small number of components is used in the circuit and is readily available in the market and the circuit has the advantages of simple structure, stable performance, low cost and high use value; and a small number and a few types of the components are adopted, so that instable performance of a system caused by the properties of elements is avoided.

Owner:SHANGHAI RENMIN ELECTRICAL APP WORKS

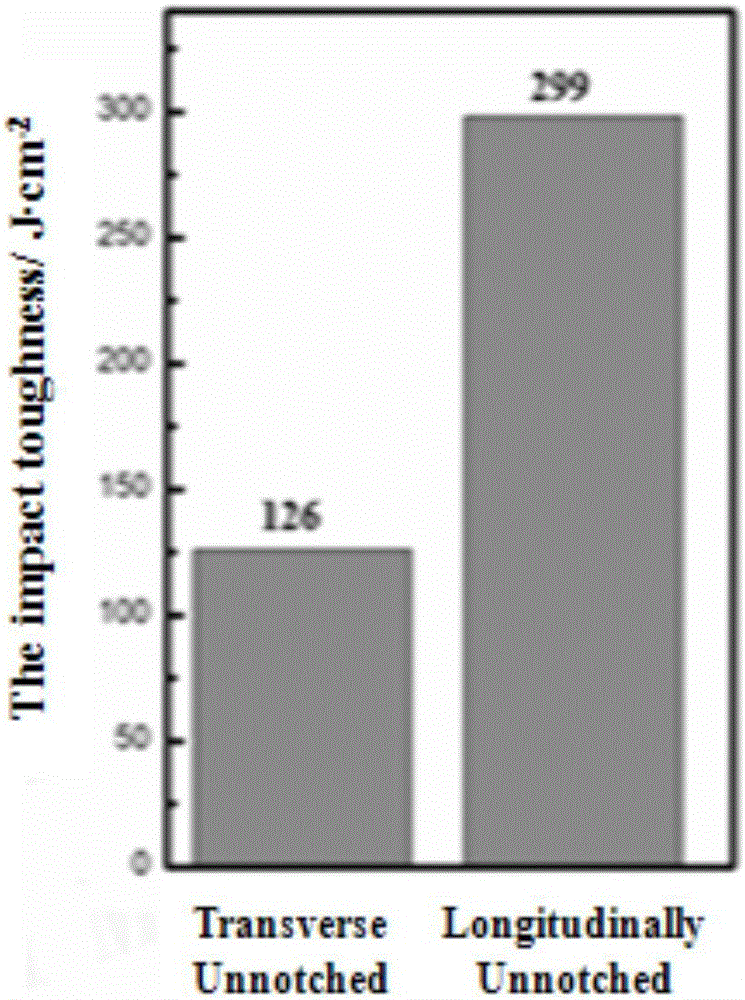

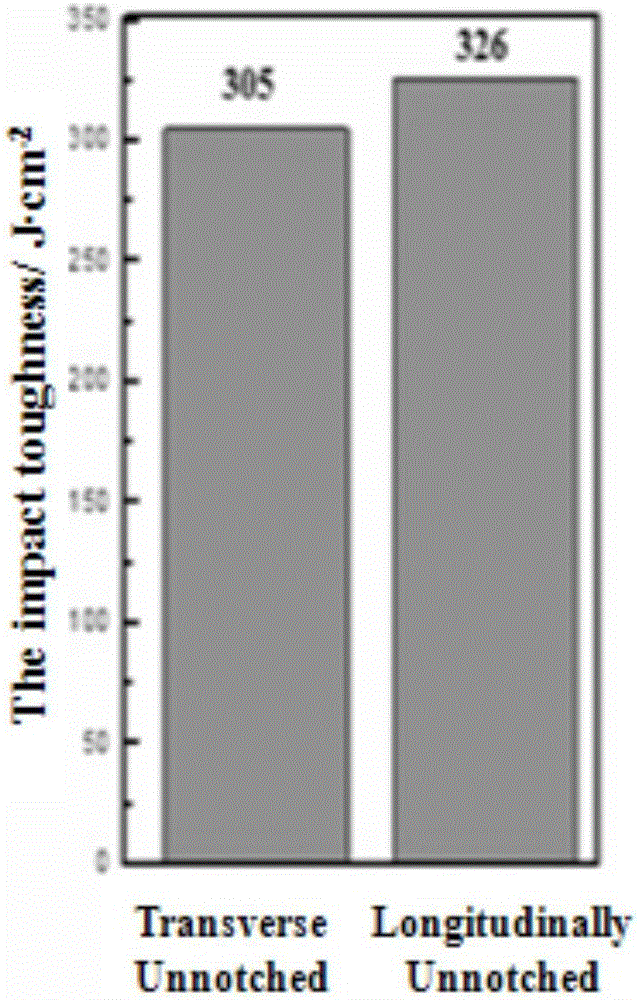

Method for producing high-strength finishing rolling threaded steel bar by online hardening and tempering technology

ActiveCN101514390ASavings on off-line temperingReduce manufacturing costTemperature control deviceIncreasing energy efficiencyInduction heaterHigh intensity

The invention relates to a method for producing high-strength finishing rolling threaded steel bar by an online hardening and tempering technology. The used technical proposal comprises the steps that: a steel blank is heated to 1150-1200 DEG C, the blank is rolled to the shape of the required finishing rolling threaded steel bar, the temperature of final rolling is controlled in a range from 880 to 1050 DEG C, rolling exit velocity is controlled in 20-30 meter / minute, the steel bar enters into a cooling device in 5 seconds from the exit of a rolling machine so as to be quenched and then be cooled at 200-400 DEG C / second, the steel bar has the surface temperature of 50-80 DEG C after getting out of the cooling device, the quenched steel bar is conveyed to an annealing line via a transferring roller channel and a shifting platform for the annealing, the steel bar passes through an induction heater at the speed of 10-15 meter / minute, the annealing temperature is controlled in a range from 520-680 DEG C, and then blanking and cutting are implemented. In the invention, direct quenching is carried out after hot rolling, so that the steel bar can be completely quenched into a martensitic structure and is then directly annealed online to remarkably lower the production cost and dramatically improve toughness index of the steel bar.

Owner:YINGKOU JIULONG FINE SCREW

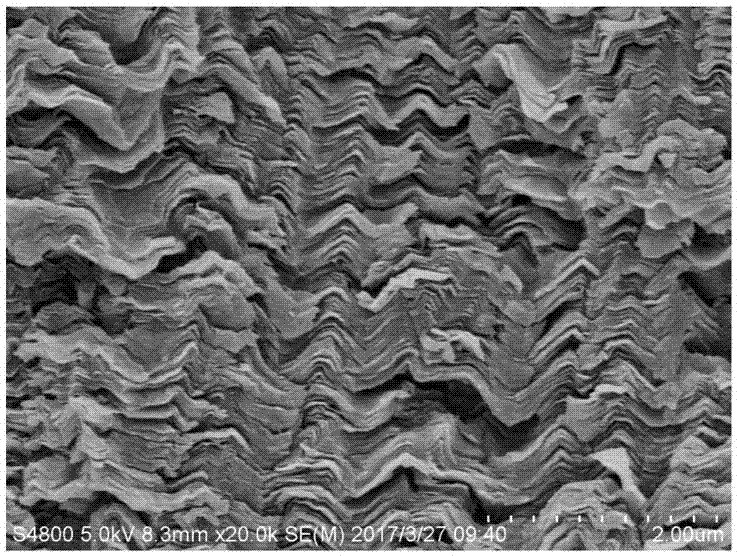

Preparation method of graphene for super capacitor electrode material

InactiveCN104332325AMeet quality requirementsEasy accessHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceUltrasonic dispersion

The invention discloses a preparation method of graphene for a super capacitor electrode material. The preparation method comprises the steps of adding concentrated sulfuric acid to crystalline graphite powder serving as a raw material, adding a strong oxidant and sodium nitrate at a temperature within the range of 0-10 DEG C, respectively, and stirring for 2-3 hours, next, slowly adding water, adding 1-2 hours and controlling the temperature within the range of 80-95 DEG C, centrifuging, washing with water and drying to obtain graphene oxide powder, adding the graphene oxide powder to a reducing agent solution controlling the temperature within the range of 75-85 DEG C, performing ultrasonic dispersion processing for 3-4 hours, and then cooling, settling, filtering by suction, washing and drying in vacuum to obtain the graphene. The graphene obtained by use of the preparation method has superior properties in application to a super capacitor; at the current density of 2A / G, the specific capacitance of the material reaches 141F / g, after 300 cycles at different current densities, the specific capacitance is still kept at 130F / g(2A / g); as a result, the material shows excellent rate and cyclic temperature properties.

Owner:JIANGSU YINJI CARBON TECH CO LTD

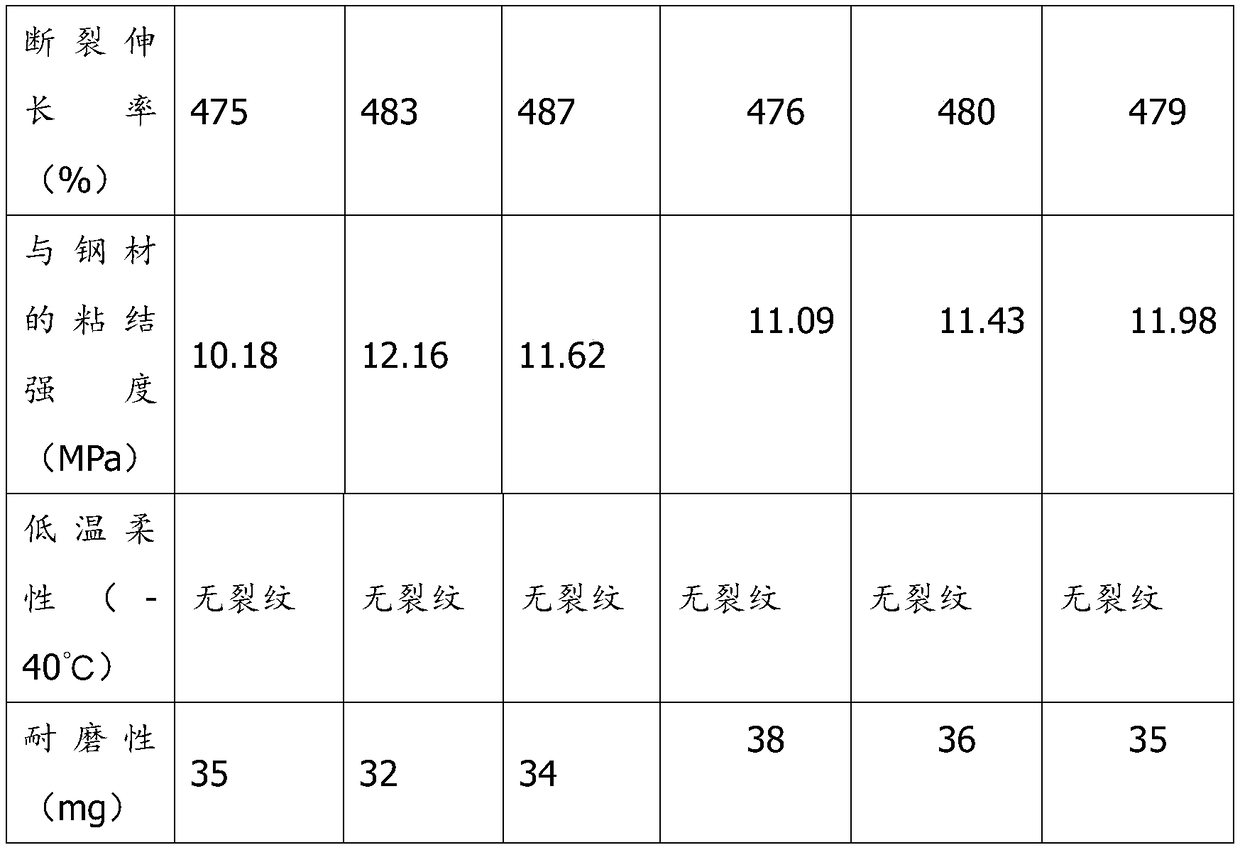

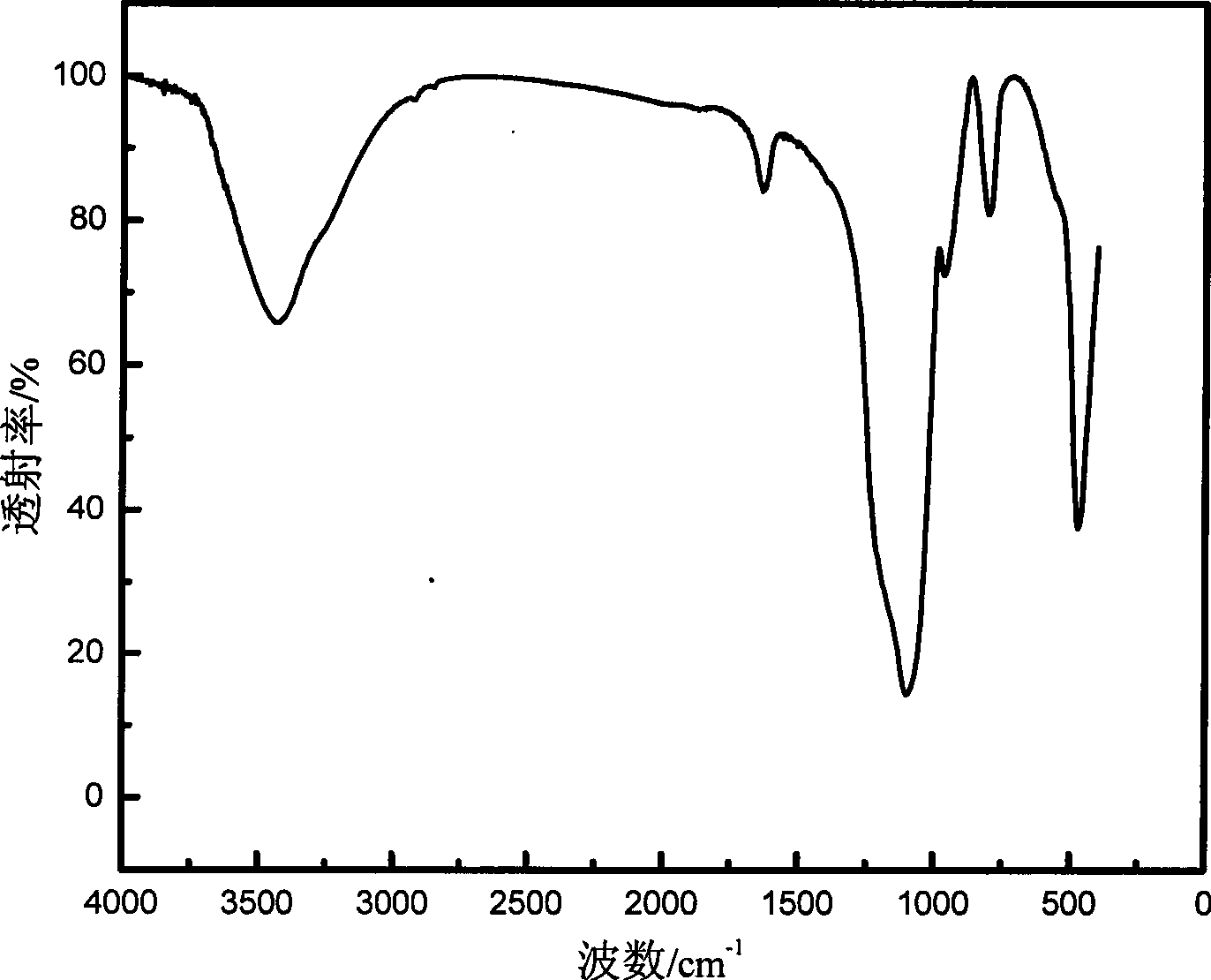

Spraying polyurea elastic anticorrosive paint, and preparation method thereof

ActiveCN109251645AHigh hardnessImprove wear resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsPolyolMechanical property

The invention provides a spraying polyurea elastic anticorrosive paint, and a preparation method thereof. The spraying polyurea elastic anticorrosive paint comprises, by weight, a component A and a component B; the component A comprises 30 to 40 parts of polyether polyol N220, 10 to 20 part of polyether polyol N330, and 30 to 60 part of isocyanate MDI-50; the component B comprises 40 to 60 parts of amine-terminated polyether D-2000, 5 to 10 parts of amine-terminated polyether T-5000, 10 to 20 parts of amino chain extender E-100, and 20 to 30 parts of amino chain extender 6200. The spraying polyurea elastic anticorrosive paint possesses high frequency impact resistance, no shedding or cracking is caused after 2 million times of impacting; the bonding strength is 10Mpa or higher; 3000h saltspray resistance test is passes; the physical strength is high (>=19Mpa), the physical elongation percentage is high (>=450%), the impact resistance is excellent, and the other physical mechanical properties are capable of satisfying requirements in spraying polyureas protection material standard.

Owner:CRRC YANGTZE CO LTD

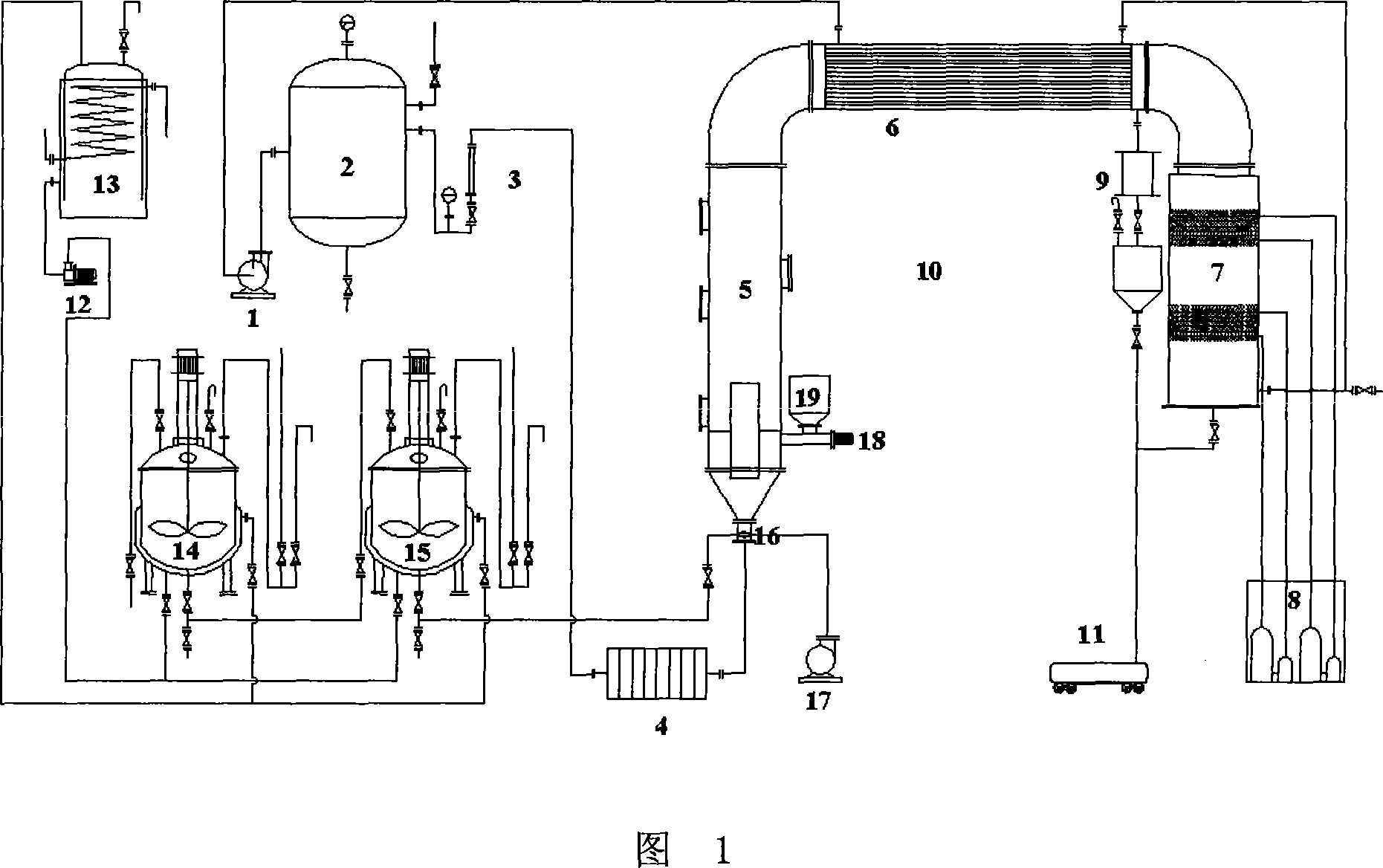

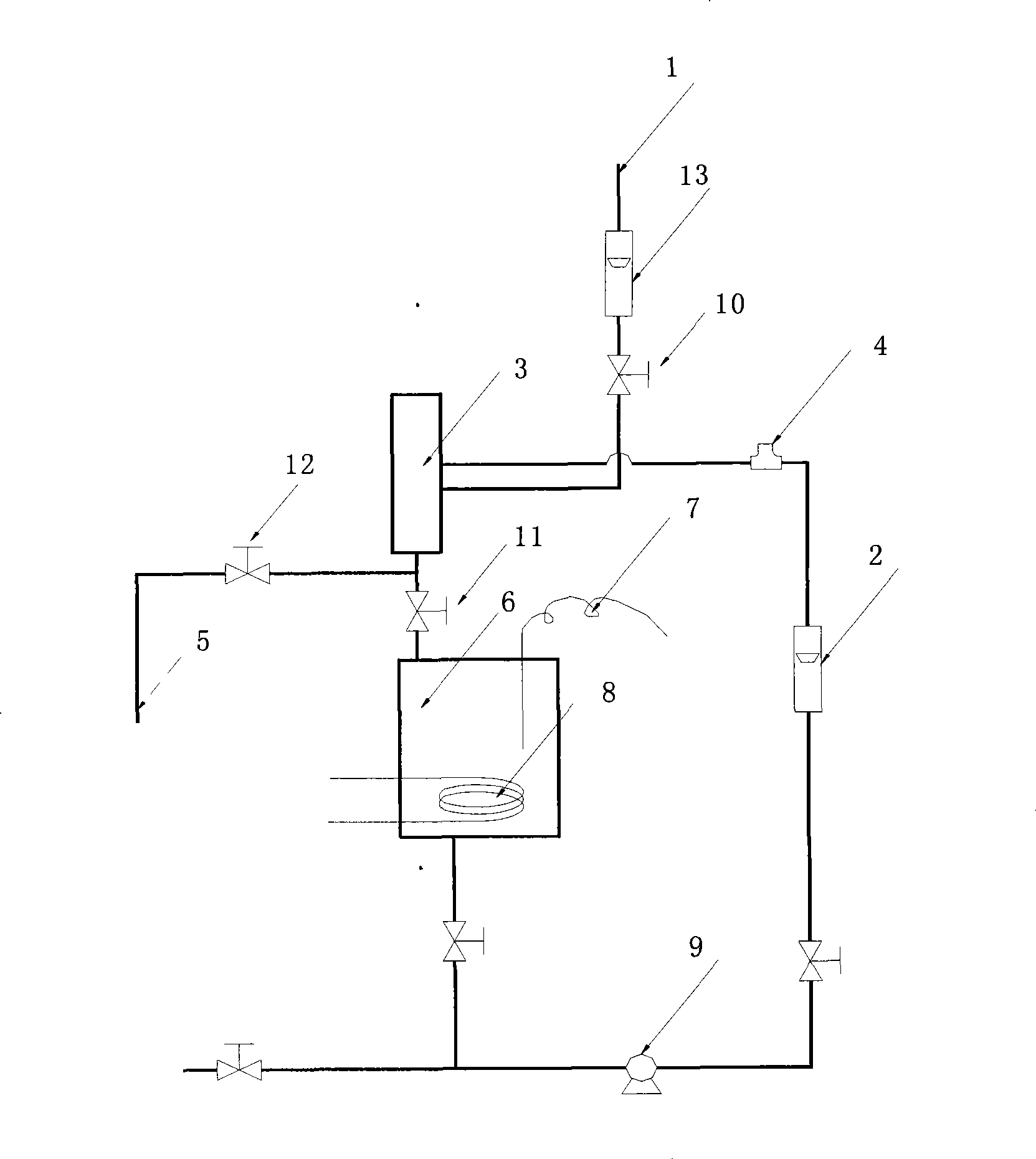

Method for continuously producing white carbon black by hypergravity technology

The invention provides a method for producing white carbon black continuously by using supergravity technique. In a supergravity revolving bed, amorphous superfine white carbon black is produced by using the sulphuric acid sedimentation method through simultaneous continuous feeding and discharging ways. The mechanism of the method is identical with that of the traditional sulphuric acid sedimentation method, both taking sodium silicate as a silicon source, and taking dilute sulphuric acid as an acidulant. The raw material has low cost and is easily available. Meanwhile, the method is combined with the great intensified mass transferring and intensified micro mixing actions of the supergravity revolving bed, and has the advantage that the continuous production can avoid the unstability of the performance of the products in different batches, thereby lowering the production cost, reducing the auxiliary time of assembling, disassembling the equipment and charging and discharging in the intermittent reaction, and having even structure and stable quality.

Owner:BEIJING UNIV OF CHEM TECH

Composite additive and process for producing methanol diesel oil thereof

The invention relates to a preparation method for a compound additive and the methanol diesel oil thereof. The compound additive consists of the components with the following weight percentages: 5 to 20 portions of fatty acid ester, 1 to 25 portions of castor oil acid, 1 to 10 portions of normal butanol, 1 to 25 portions of ethyl acetate, 1 to 10 portions of carbon lauryl alcohol, 1 to 8 portions of cetane number improver, 1 to 8 portions of igniter, 1 to 10 portions of butanone, 1 to 10 portions of heat value increaser, 0.1 to 2 portions of antidetonator, 0.1 to 1 portion of swelling-resistant agent, 0.1 to 1 portion of antiseptic, 1 to 8 portions of antiwear agent as well as 1 to 12 portions of waterproof agent. The methanol diesel oil has the advantages of low cost, excellent performance, good environment protection effect, remarkable economic benefit and convenient popularization.

Owner:王宇

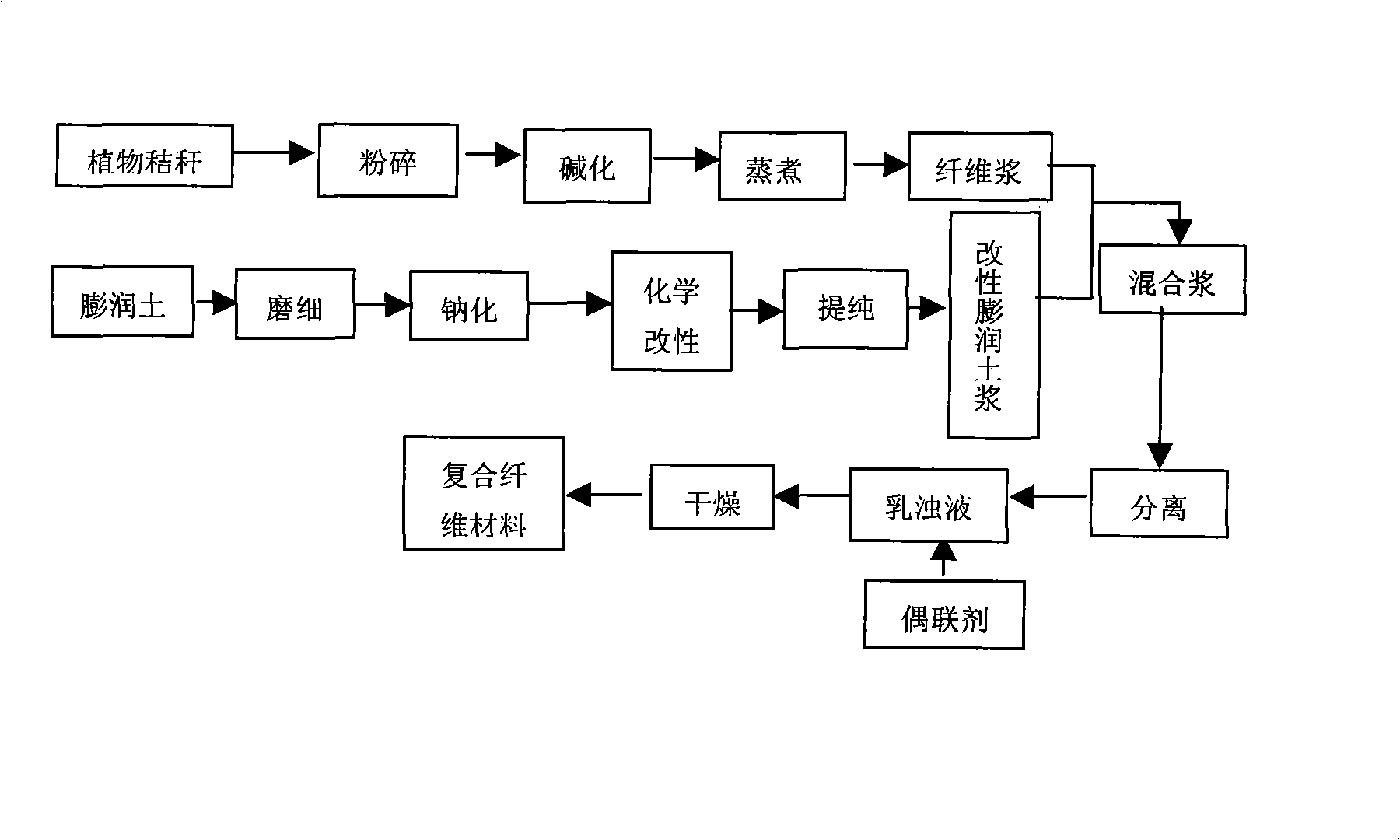

Method of producing stalk composite fiber material for road

InactiveCN101314925AWide range of sourcesSimple preparation processInorganic compound additionFiberRoad surface

The invention relates to a method for preparing a road used composite straw fibrous material. The preparation method comprises the steps as follows: pulverizing; alkalizing and stewing plant straw to obtain fibrous pulp; mixing the fibrous pulp with bentonite and milling; conducting sodium treatment, chemical modification and purification to obtain modified composite bentonite pulp; separating, drying, etc., to prepare the composite fibrous material. The road used composite straw fibrous material prepared by adopting the method is adopted as an additive and applied in a bituminous mixture, so as to increase the capacity of a bituminous pavement to bear heavy load, prolong endurance life and service life of the pavement. The preparation method adopts the straw and the bentonite as the raw materials, has the characteristics of wide material source, simple process, high utilization rate of resources, low cost, no pollution, etc, eliminates the shortcomings that the existing fibrous material adopts the used newspapers as the raw materials and the printing ink on the newspapers is difficult to be removed completely, solves the problem of unstable properties of mixed materials, and adopts wood as the raw material, thereby increasing the expense of raw materials and reducing production cost.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

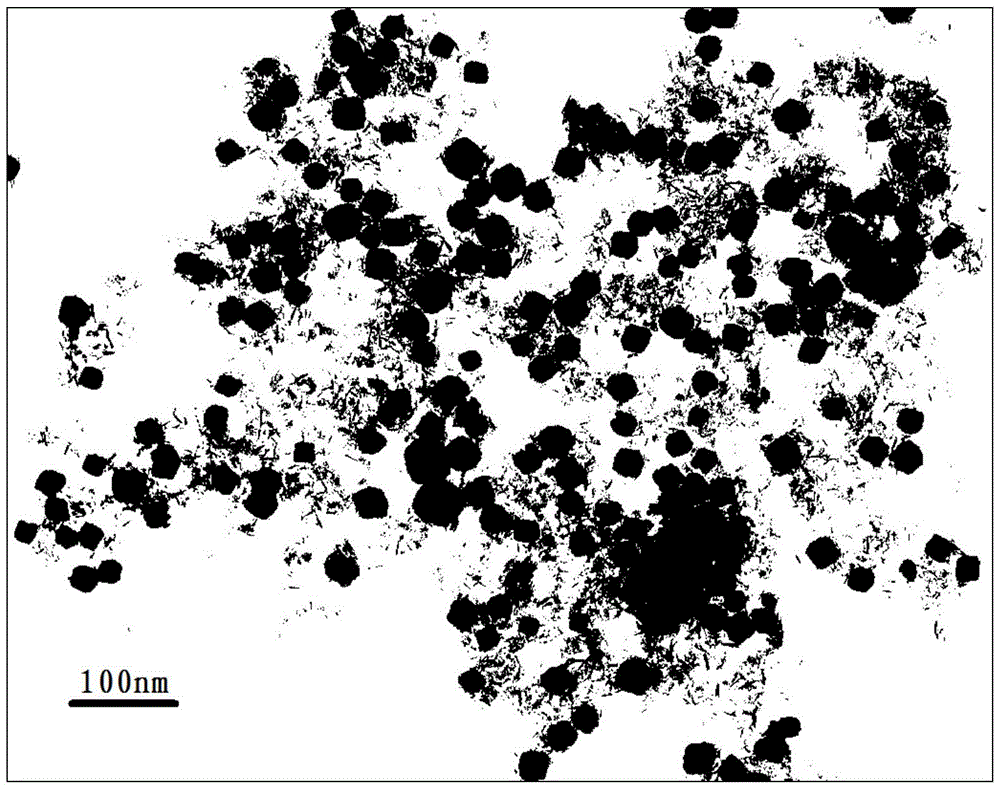

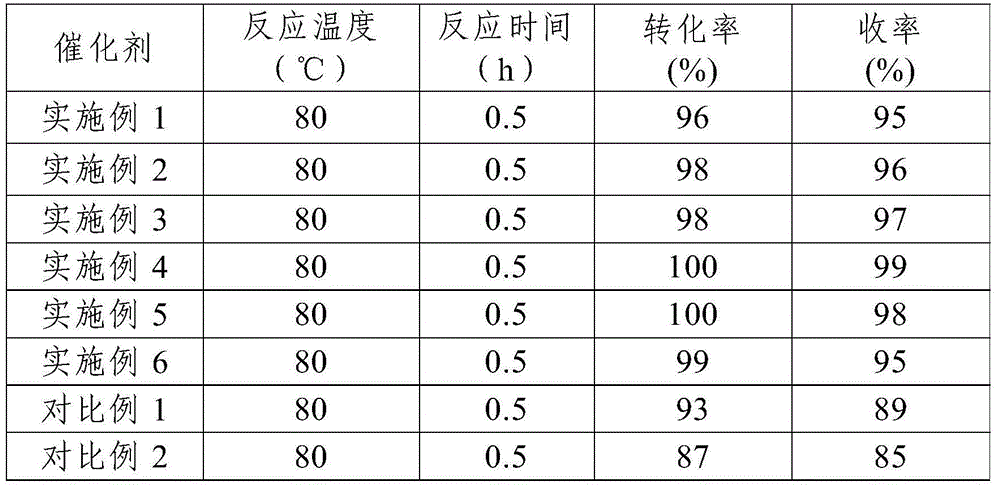

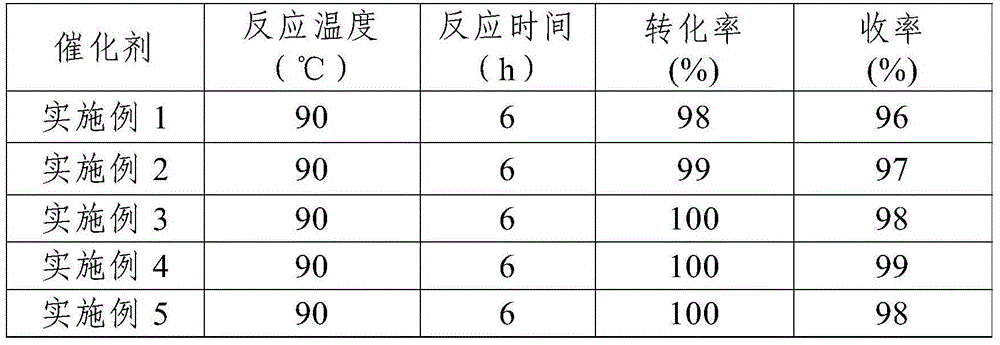

Preparation method for modified palladium-carbon catalyst for Suzuki coupling reaction

ActiveCN104689832AHigh activityEasy to useMetal/metal-oxides/metal-hydroxide catalystsActivated carbonReduction treatment

The invention discloses a preparation method for modified palladium-carbon catalyst for Suzuki coupling reaction. The catalyst is composed of active carbon, and palladium and nickel loaded on the active carbon, wherein the mass percent of the palladium is 5-10%, and the mass percent of the nickel is 0.5-3%. The preparation method for the modified palladium-carbon catalyst for the Suzuki coupling reaction includes steps that 1, preparing nano-nickel sol; 2, preparing active carbon carrier; 3, preparing nickel-containing size; 4, preparing palladium-containing solution; 5, adding the palladium-containing solution to the nickel-containing size, preserving the heat, dipping and filtering to obtain a piece of filter cake; 6, performing reduction treatment, and washing to obtain the modified palladium-carbon catalyst. The modified palladium-carbon catalyst prepared by the method can be used for the Suzuki coupling reaction, and the modified palladium-carbon catalyst has advantages of high reaction activity, high selectivity, good stability and the like; the catalyst is easy to be separated from the product, the catalyst preparation technique is simple, the catalyst can be used repeatedly, the precious metal-palladium is easy to recycle, the pollution and energy consumption are reduced, and the economical benefit and environment significance are important.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

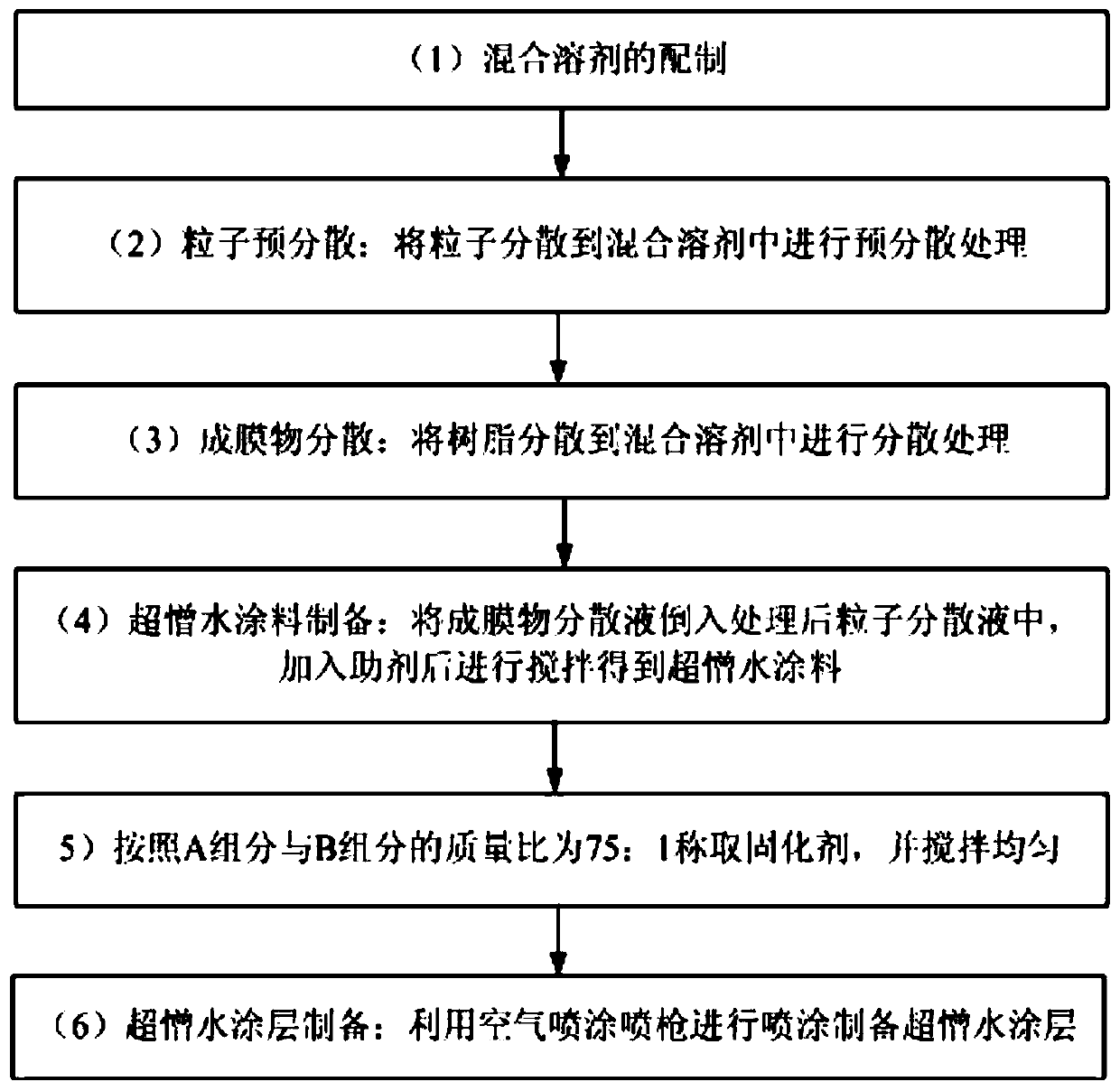

Superhydrophobic coating layer with adjustable particle concentration, and preparation method thereof

The invention discloses a superhydrophobic coating layer with an adjustable particle concentration, and a preparation method thereof. The superhydrophobic coating layer is composed of a component A and a component B according to a mass ratio of 75:1; the component A is composed of silicone resin, an organic solvent, silicon oxide, a dispersant, an antifoaming agent and a leveling agent, and the component B is a silicone resin curing agent. The preparation method comprises the following steps: (1) preparing a mixed solvent; (2) pre-dispersing particles; (3) dispersing a film forming matter; (4)preparing a superhydrophobic coating; (5) weighing a curing agent according to the mass ratio of the component A to the component B of 75:1, and performing stirring until uniformity; and (6) preparing the superhydrophobic coating layer. The superhydrophobic coating layer is constructed by using the unmodified particles, and the superhydrophobic effect of the coating layer can be realized within avery wide particle additive amount range without influencing the film-forming property of the coating layer.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Production process of 300sec viscosity nitrocotton

The invention discloses a production process of 300sec viscosity nitrocotton. The process comprises the steps of: first, refined cotton heating: in certain environment, heating refined cotton for a certain period of time; second, refined cotton nitrification: using certain acid to conduct nitrification for certain period of time; third, nitrocotton acid removal: removing acid from the nitrified refined cotton by specific instrument; fourth, nitrocotton boiling washing: subjecting the acid removed nitrocotton to boiling washing through a specific solution; and fifth, nitrocotton dehydration: dehydrating the boiling washed nitrocotton and preliminarily controlling the water content of the nitrocotton. The method provided by the invention can obviously improve the stability, avoids the problem of unstable performance of 2000300sec viscosity nitrocotton, can endure a short period of time of local high temperature, avoids the acid liquid boiling phenomenon caused by local high temperature, and avoids the release of nitrogen dioxide, cannot cause bursting of a nitrocotton holding container, eliminates unnecessary risks, and avoids waste and loss.

Owner:NANTONG TAILIDA CHEM

Method for preparing pyrolytic boron nitride material

InactiveCN107265416AIncrease productivityFast deposition growthNitrogen compoundsBoron nitrideChemical vapor deposition

The invention discloses a method for preparing a pyrolytic boron nitride material. The method comprises the following steps: putting a substrate mold in an air-carrying atmosphere carrying borazine vapor under a vacuum condition, and pyrolyzing borazine which constantly deposits on the depositing surface of the substrate mold by adopting a chemical vapor deposition method to form the pyrolytic boron nitride material. The preparation method of the pyrolytic boron nitride material has the advantages of simple and easily controlled process, low cost, low energy consumption, high yield, environmental friendliness and the like.

Owner:NAT UNIV OF DEFENSE TECH

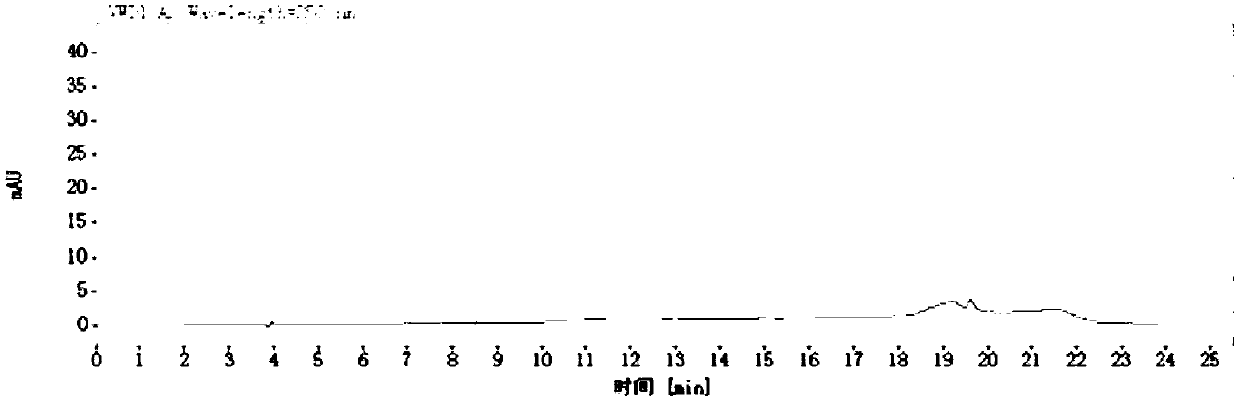

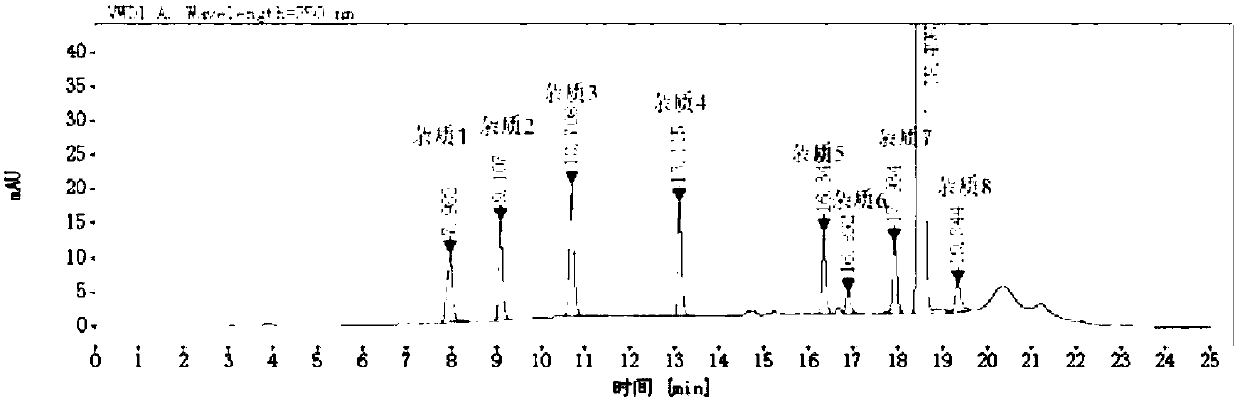

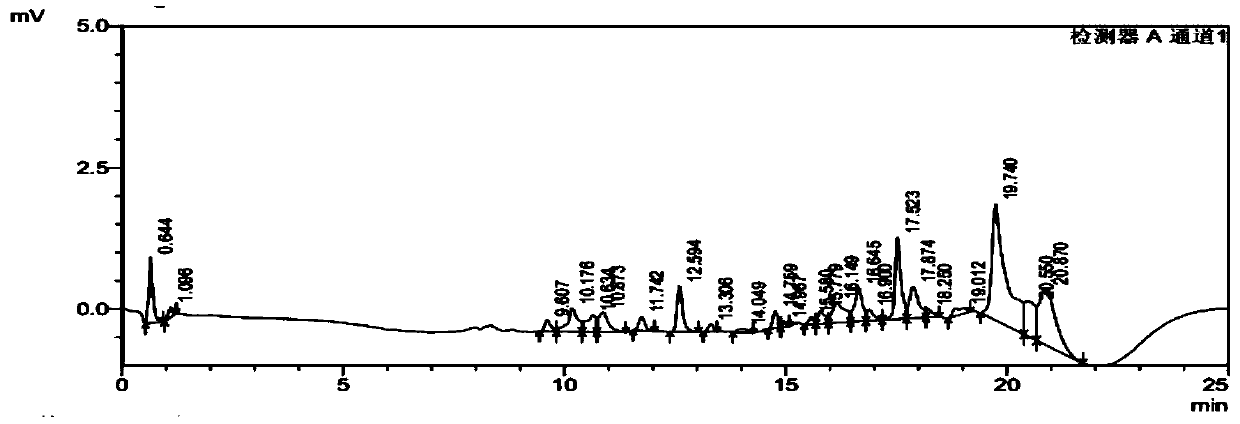

Method for determining rivaroxaban and related substances thereof by using high performance liquid chromatography

The invention provides a method for determining rivaroxaban and related substances thereof by using high performance liquid chromatography, wherein the high performance liquid chromatography comprisesthe following conditions that a stationary phase is octadecylsilane chemically bonded silica,a mobile phase A is selected from a phosphate buffer solution of which the pH value is 5.0-7.0, a citratebuffer solution, an acetate buffer solution or a carbonate buffer solution, a mobile phase B is acetonitrile or methanol, and gradient elution is carried out. The method has the characteristics of good specificity, high sensitivity, good reproducibility, simple post-data processing and the like, especially can solve the problems of interference of a blank solvent, peak pattern difference of individual impurity peaks, low separation degree and the like, and can obtain all contents and related substance analysis results by one-time sample injection.

Owner:GRAND LIFE SCI (LIAONING) CO LTD

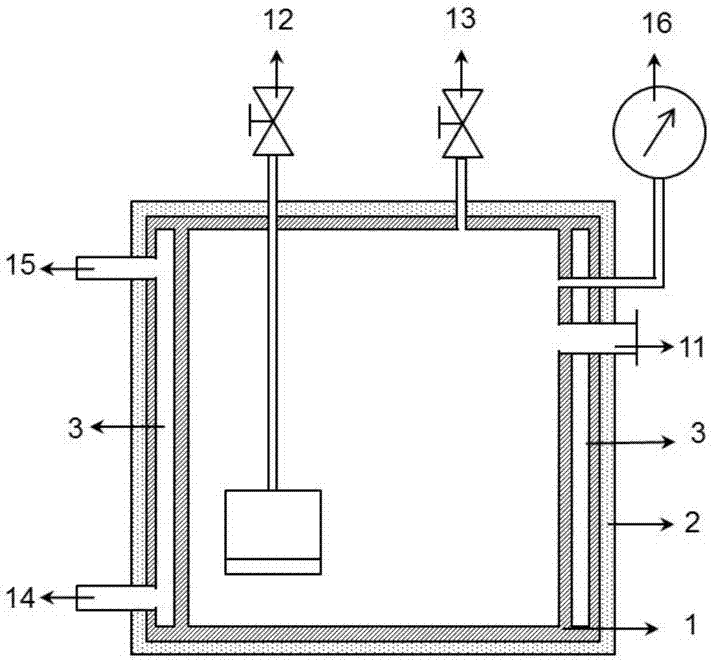

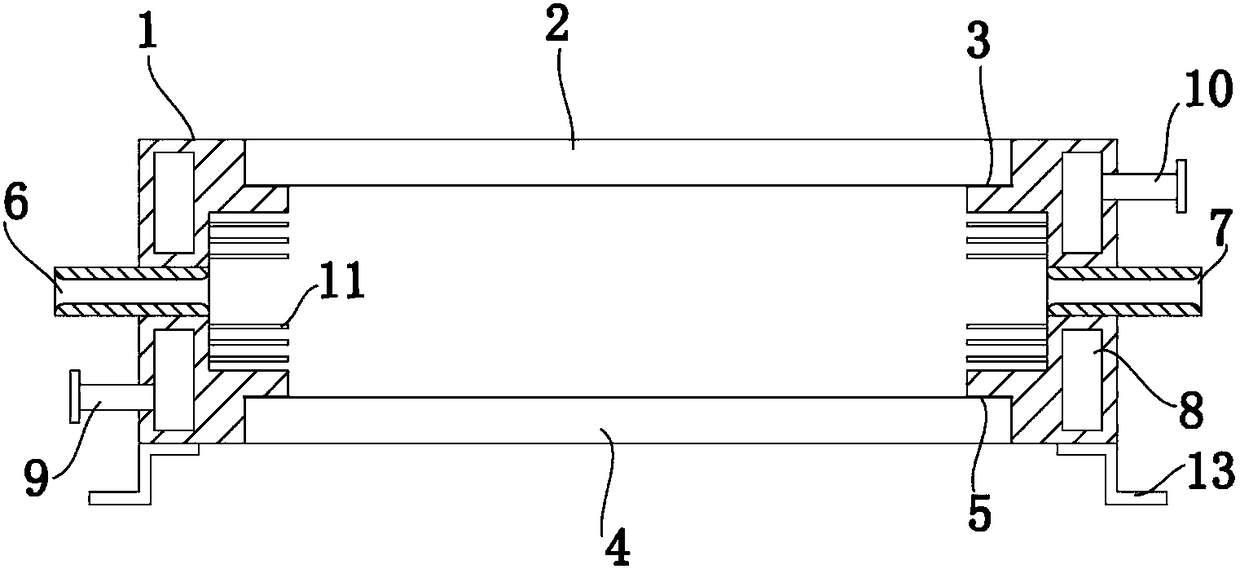

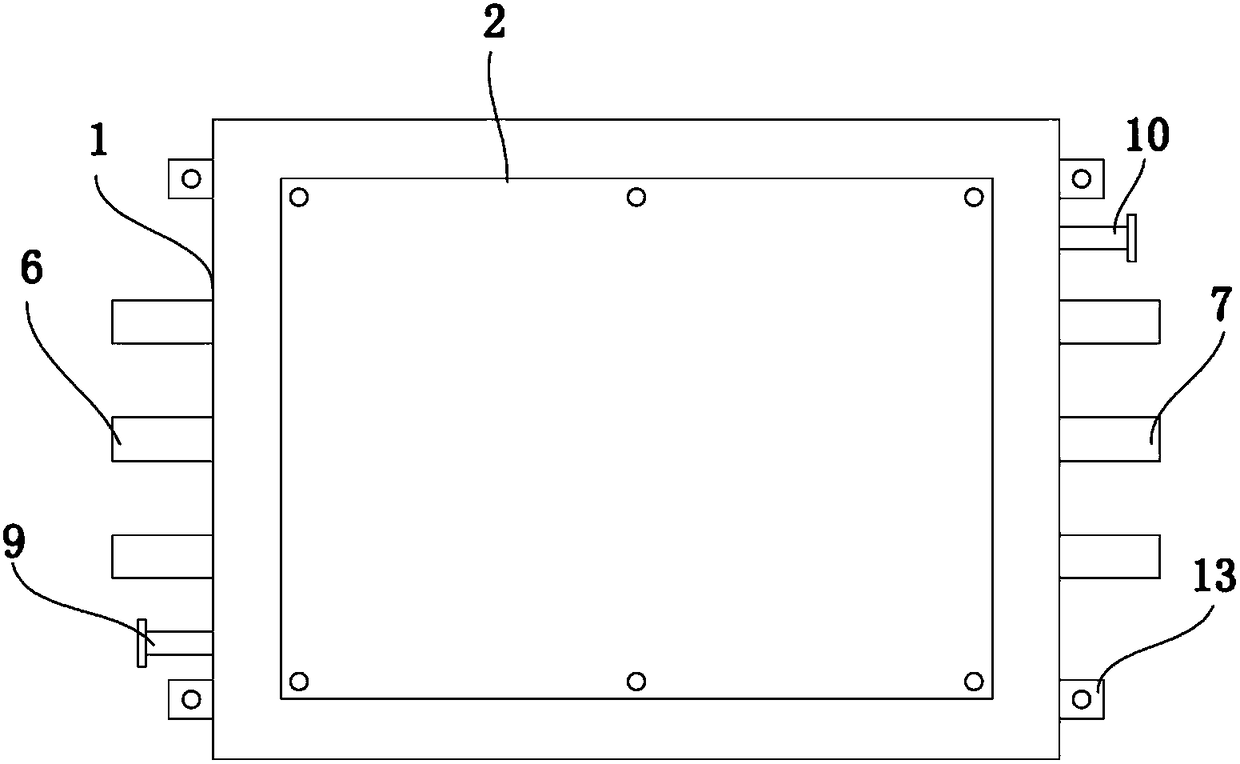

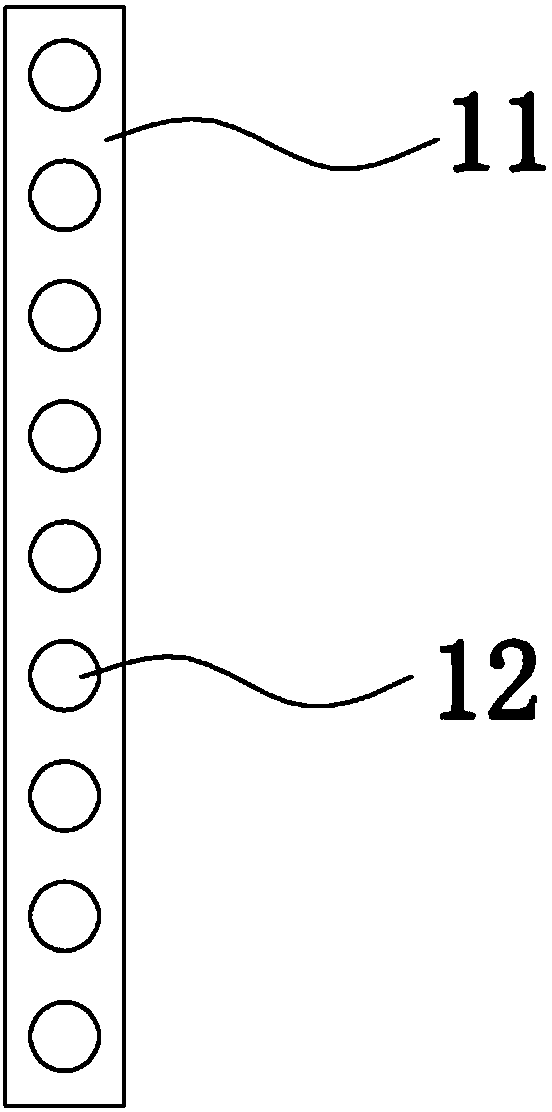

Photovoltaic junction box with heat dissipation structure

InactiveCN108155871AAvoid unstable performanceImprove usabilityPhotovoltaicsPhotovoltaic energy generationEngineeringWater layer

The invention discloses a photovoltaic junction box with a heat dissipation structure, and the junction box comprises a photovoltaic junction box body. The top of the photovoltaic junction box body isprovided with a cover plate, and a contact part of the photovoltaic junction box body with the cover plate is provided with a first sealing strip. The bottom of the photovoltaic junction box body isprovided with a bottom plate, and the inner wall of the photovoltaic junction box body is provided with a cooling water layer. The left side wall of the photovoltaic junction box body is provided witha water incoming pipe which is communicated with the cooling water layer. The right side wall of the photovoltaic junction box body is provided with a water outgoing pipe communicated with the cooling water layer. The left and right side walls of the interior of the photovoltaic junction box body are respectively provided with a thermal conduction piece, and the thermal conduction pieces are arranged uniformly. The left and right sides of the bottom of the photovoltaic junction box body are symmetrically provided with positioning frames. The junction box changes the structure of a conventional photovoltaic junction box, achieves the cooling of the photovoltaic junction box body through a circulating water cooling method, is high in cooling efficiency, and prevents the overtemperature of the junction box from causing the instable performances.

Owner:安徽昱和自动化科技有限公司

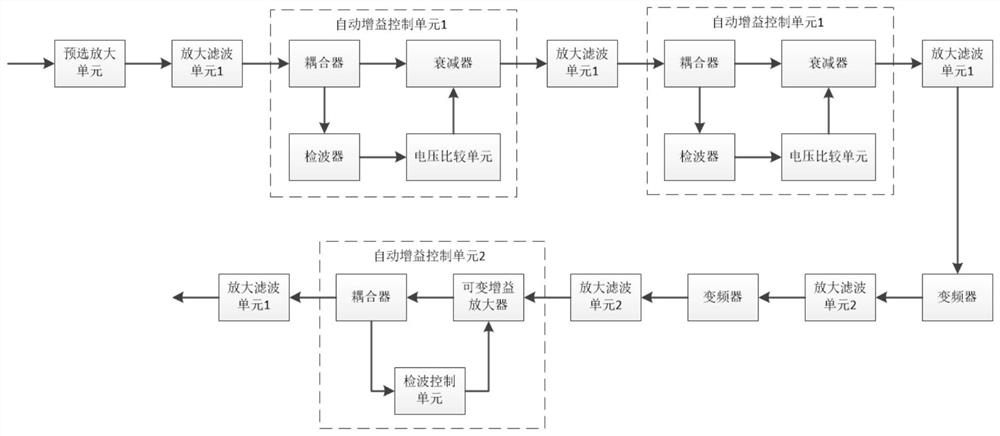

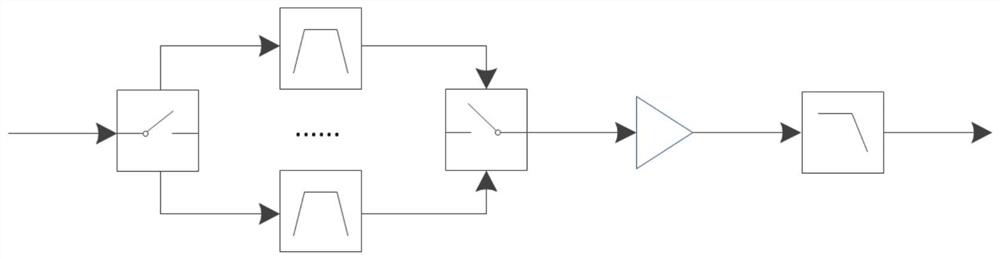

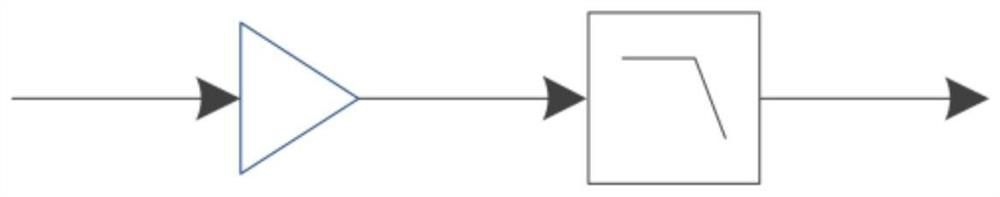

Receiver broadband large-dynamic-range automatic gain control circuit

ActiveCN112564726AImplement Automatic Gain ControlSimple procedureGain controlTransmissionLow noiseConverters

The invention discloses a receiver broadband large-dynamic-range automatic gain control circuit, which belongs to the technical field of radio frequency communication and comprises one pre-selection amplifying unit, four amplifying and filtering units 1, two amplifying and filtering units 2, two frequency converters, two automatic gain control units 1 and one automatic gain control unit. The receiver is of a superheterodyne structure, and uses a secondary frequency conversion scheme. The pre-selection amplifying unit comprises a filter bank composed of a switch and a band-pass filter, a low-noise amplifier and a low-pass filter. The amplifying and filtering unit 1 comprises a primary amplifier and a low-pass filter. The amplifying and filtering unit 2 comprises a primary amplifier and a band-pass filter. The automatic gain control unit 1 comprises a coupler, a detector, a voltage comparison unit and an attenuator. The automatic gain control unit 2 comprises a coupler, a detection control unit and a variable gain amplifier.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

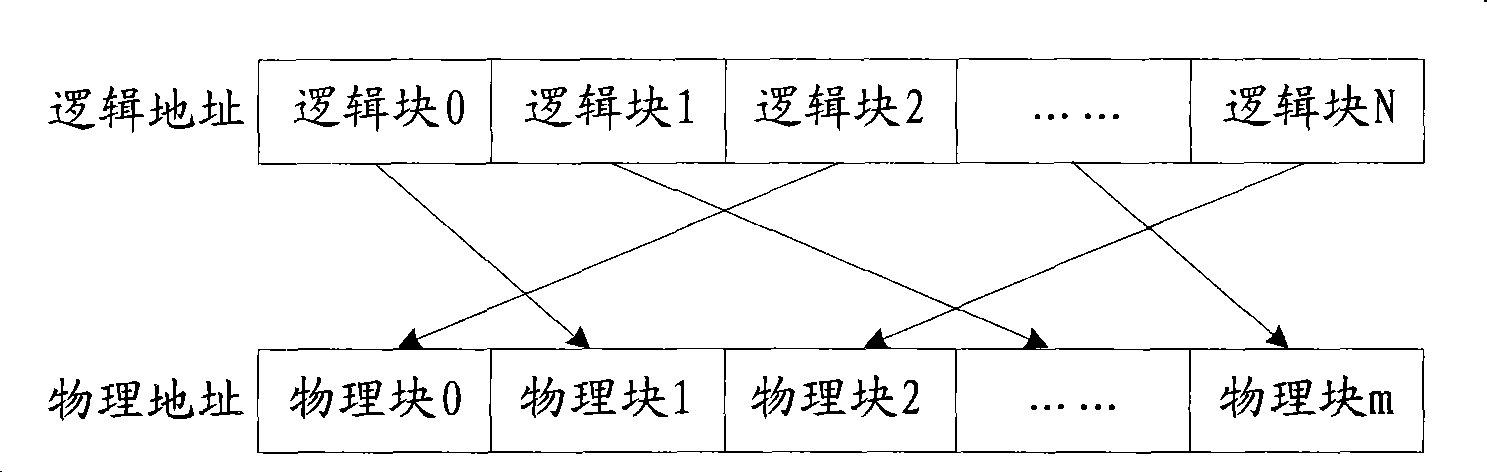

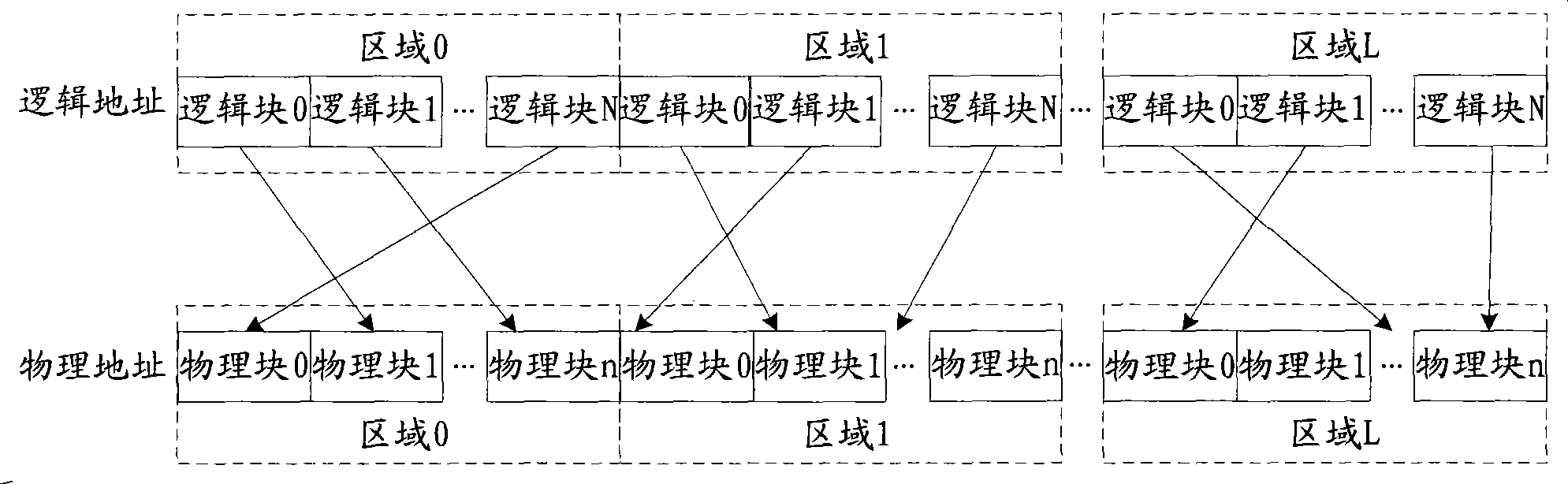

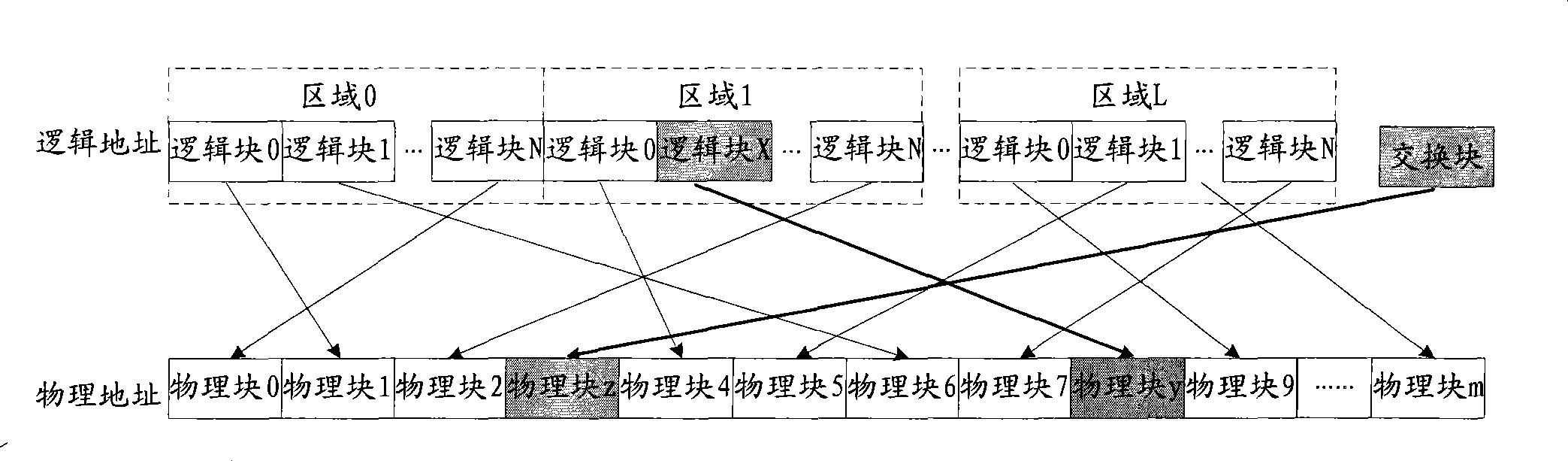

Storage medium management method

ActiveCN101436159AEliminate the problem of uneven wearAvoid unstable performanceMemory adressing/allocation/relocationCapacitanceComputer engineering

The invention provides a method for managing a storage medium. The method comprises: step one, logical addresses are managed in subareas; and the corresponding relation between at least one region logical address and at least one physical address is established; step two, the corresponding relation between at least one region logical address and at least one physical address is loaded in a memory; and step three, according to the corresponding relation between at least one region logical address and at least one physical address, an accessing command is executed. In the method, the logical address of the storage medium is divided into a plurality of regions; each region respectively organizes a contrast table, thereby realizing the completion of managing the large-capacitance storage medium through occupying less memory; the method also utilizes an exchange block to realize mutual exchange of physical blocks among the regions, thereby solving the problem of unbalanced abrasion among the regions and simultaneously avoiding the problem of unstable performance caused by the transferring of data of the whole region; and the method is safe, stable and easy to realize.

Owner:NETAK TECH KO LTD

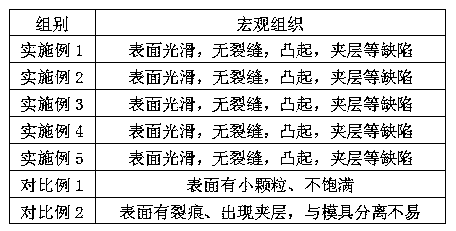

Hot forging and molding process for oxygen free copper material

ActiveCN103706741AAvoid unstable performanceAvoid damageMetal-working apparatusCombustionLubrication

The invention discloses a hot forging and molding process for oxygen free copper materials. The hot forging and molding process is different from the traditional cold extrusion process in prior art. According to this process, a hot forging method is adopted to process the oxygen free copper materials and process parameters including a preheating temperature of moulds, a heating temperature of materials, and a lubrication oil component are ensured. The hot forging and molding process can be used to prepare precise oxygen free copper components which are smooth on surface, good in performance, and qualified in combustion. The process steps are simple to operate and applicable to industrialization promotion, the finished product rate is high, and all the parameters of products are excellent.

Owner:JIANGXI AUDY BRASSWORK

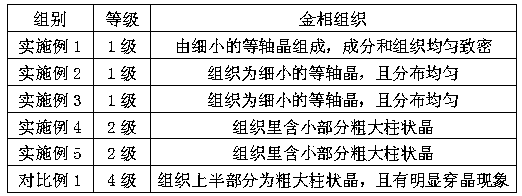

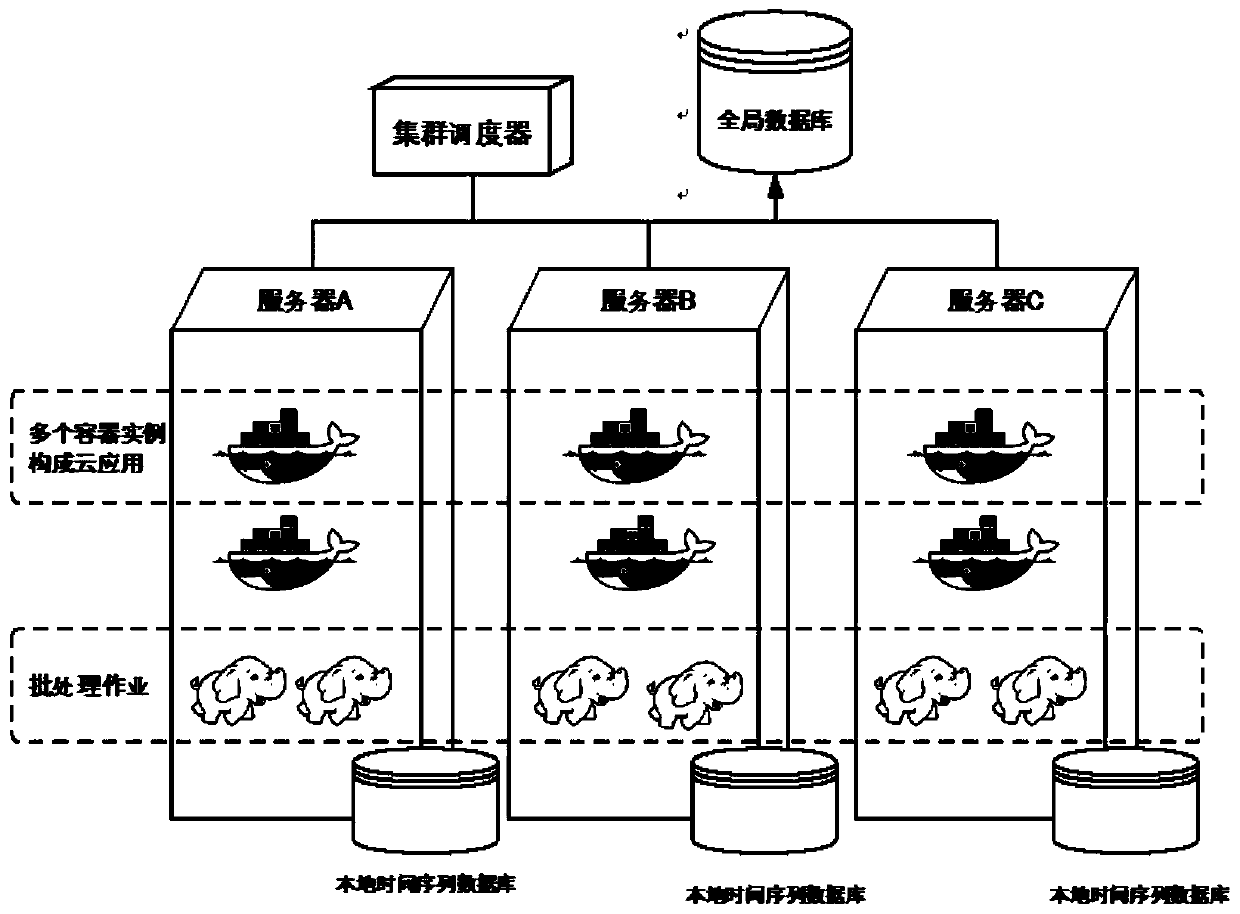

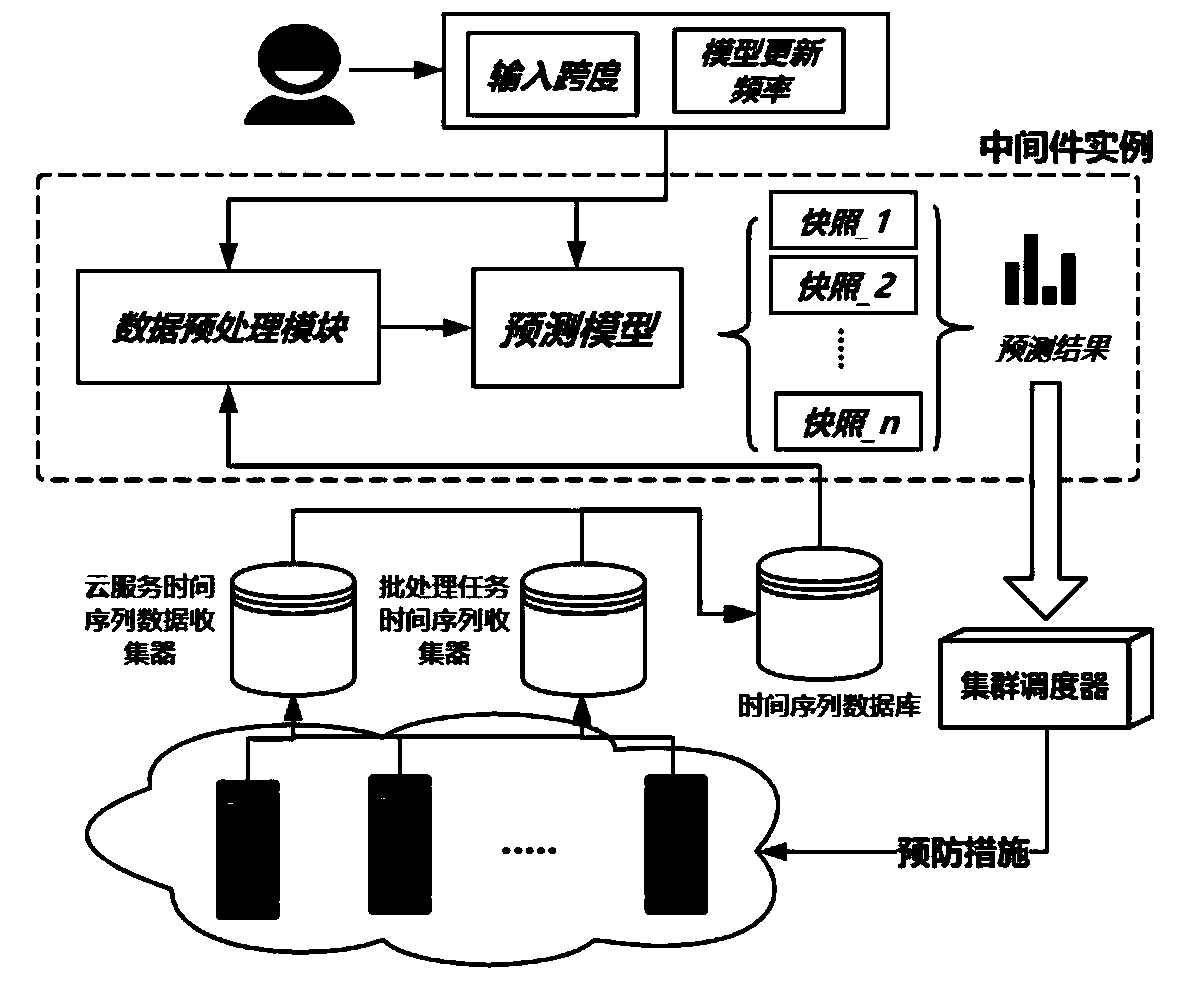

CPI index-based cloud service performance intelligent prediction method and device

ActiveCN110191015AGood forecastAvoid unstable performanceData switching networksBatch processingData mining

The invention discloses a CPI index-based cloud service performance intelligent prediction method and device. The method comprises the steps of obtaining various time series data about batch processing tasks and cloud services and time spans thereof; pre-processing the time sequence data based on the time span to obtain a pre-processing result; inputting the preprocessing result into a pre-trainedSnapLSTM prediction model to obtain a CPI prediction value; and carrying out weighted average on the CPI prediction value according to a pre-acquired verification error weight to obtain a CPI prediction result. According to the CPI index-based cloud service performance intelligent prediction method and device provided by the invention, modeling prediction is carried out on the performance of thecloud service under mixed deployment starting from the CPI index, the prediction effect is good, and an operation and maintenance engineer can be effectively helped to determine the trend of the service performance.

Owner:SUN YAT SEN UNIV

All-solid-state quantum dot sensitized solar cell and preparation method thereof

ActiveCN106328381AAvoid unstable performanceGood reproducibility for large area preparationLight-sensitive devicesFinal product manufactureAll solid stateLiquid state

The invention discloses an all-solid-state quantum dot sensitized solar cell which comprises conductive glass and a copper substrate. The conductive glass is opposite to the copper substrate, the space between the conductive glass and the copper substrate is filled with solid electrolyte, a photo-anode is arranged on the conductive glass and positioned on one side of the solid electrolyte, a copper-based Cu2S nano-sheet counter electrode is arranged on the copper substrate and positioned on the other side of the solid electrolyte, and the photo-anode is a CdS / CdSe quantum dot sensitized ZnO nanowire array photo-anode. By synthesizing and heating the solid electrolyte with good conductivity, the microstructure gap between the ZnO nanowire array photo-anode and the copper-based Cu2S nano-sheet counter electrode is sufficiently filled with the solid electrolyte, the problems of unstable performance of a liquid quantum dot sensitized solar cell and electrolyte omission in the package process are solved, and the all-solid-state quantum dot sensitized solar cell is simple in preparation process, low in cost, good in large-area preparation repeatability and excellent in use value.

Owner:SHAANXI UNIV OF TECH

Method for producing high-strength finishing rolling threaded steel bar by online hardening and tempering technology

ActiveCN101514390BSavings on off-line temperingReduce manufacturing costTemperature control deviceIncreasing energy efficiencyInduction heaterHigh intensity

Owner:YINGKOU JIULONG FINE SCREW

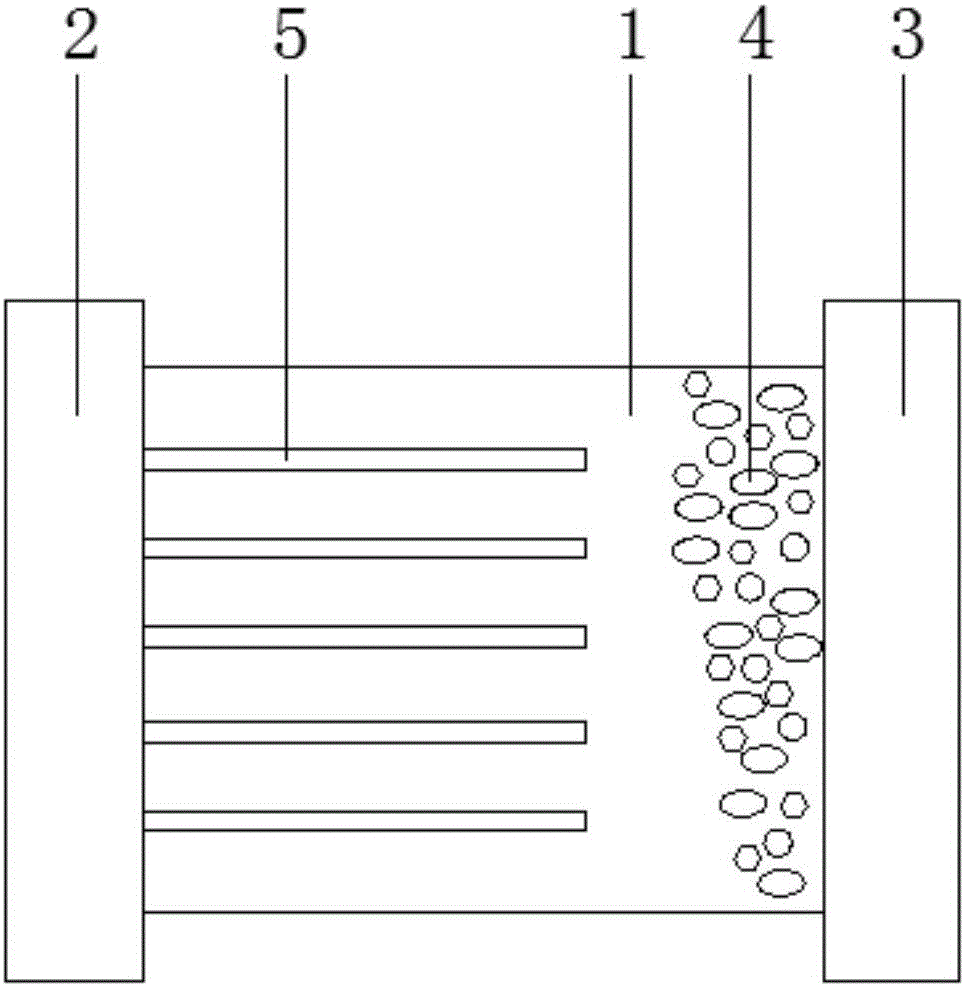

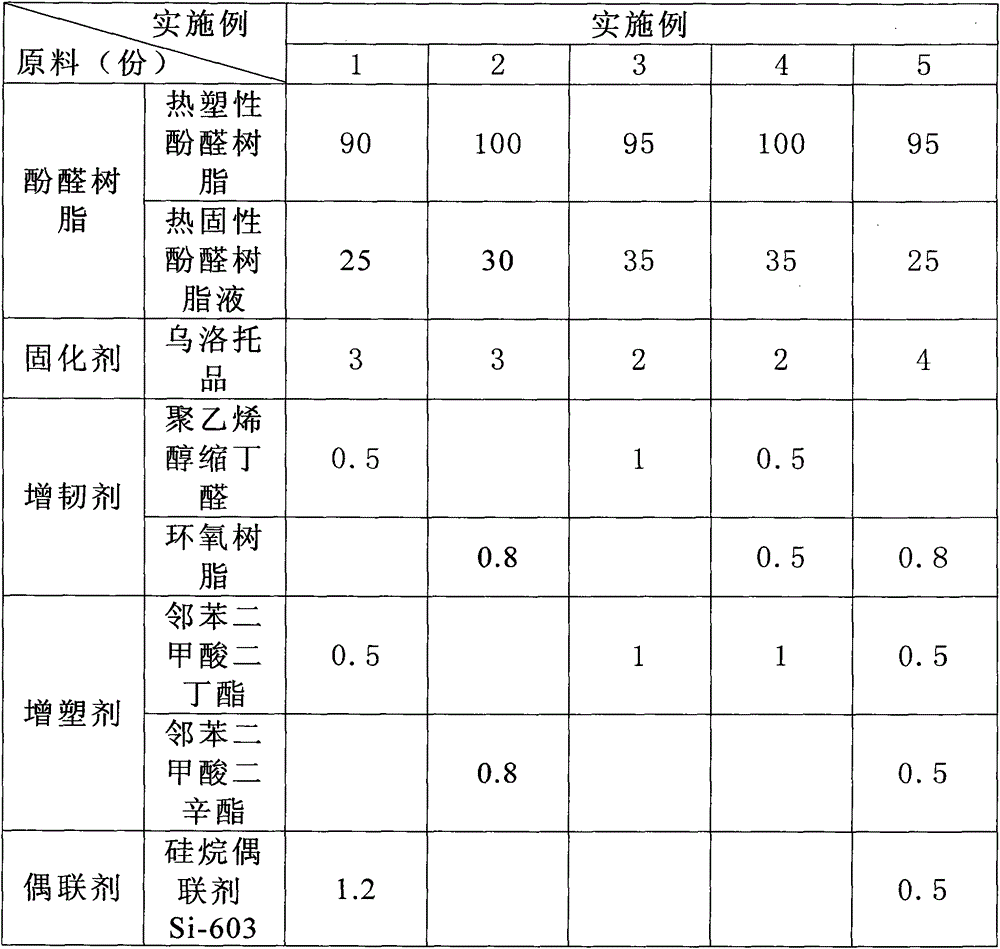

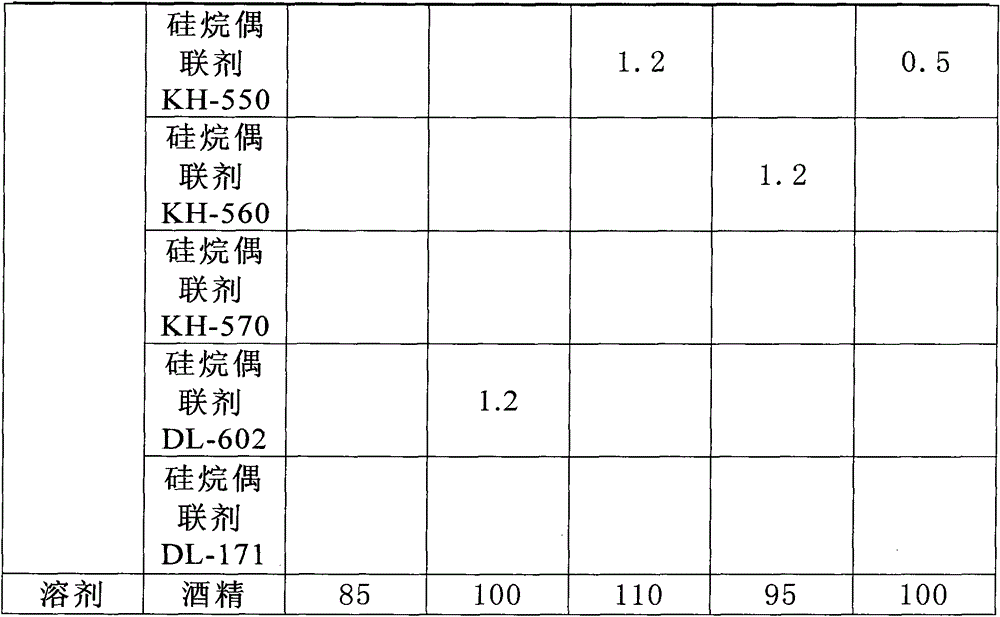

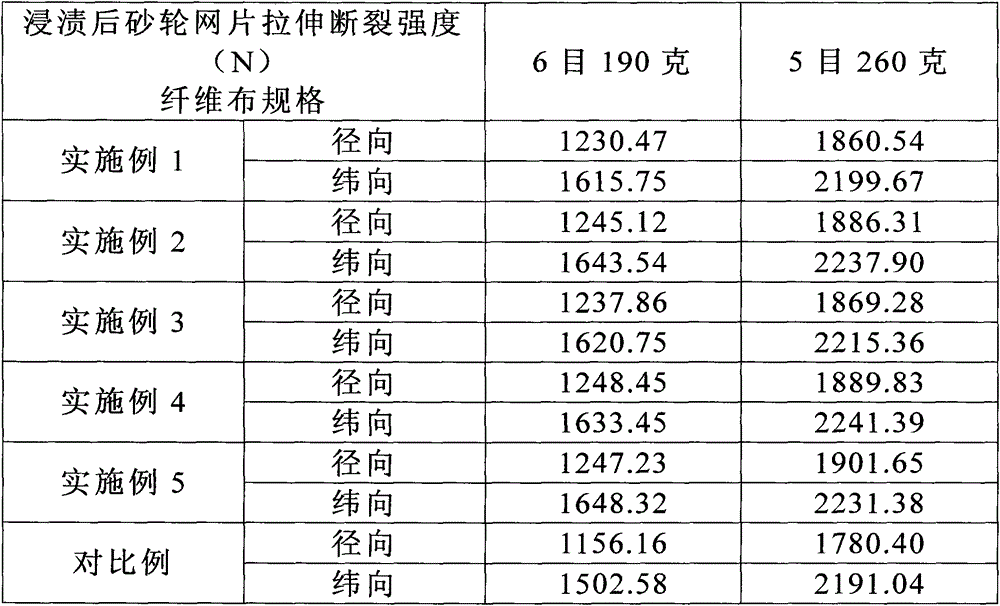

Adhesive for grinding wheel mesh and preparation method thereof

ActiveCN103481210BImprove brittlenessHigh strengthNon-macromolecular adhesive additivesAbrasion apparatusAlcoholPlasticizer

The invention relates to an adhesive for grinding wheel meshes and a preparation method of the adhesive. The adhesive comprises 80-110 parts of thermoplastic phenolic resin, 1-6 parts of curing agent, 20-40 parts of thermosetting phenol resin liquid, 60-140 parts of alcohol, 0.5-2 parts of flexibilizer, 0.5-2 parts of coupling agent and 0.5-2 parts of plasticizer. The preparation method includes adding the alcohol into a stirrer, adding the thermoplastic phenolic resin whiling stirring, stirring for 3-4 hours, adding the thermosetting phenol resin liquid containing the coupling agent, the plasticizer and the flexibilizer containing the alcohol after phenolic resin blocks are totally dissolved, stirring for 3-4 hours prior to adding the curing agent, and continue stirring for 4-6 hours to obtain the adhesive. The adhesive prepared by the method can be ready-to-use and ready-to-prepare and is good in stability pollution and mainly used for impregnation of the grinding wheel meshes, pollution and waste are reduced, brittleness of the grinding wheel mashes, strength and adhesive performance are improved, and accordingly wear resistance of grinding wheels is improved, highest rotation speed of the grinding wheel is increased, and service life of the grinding wheel is improved.

Owner:NINGBO DAHUA GRINDING WHEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com