Preparation method for modified palladium-carbon catalyst for Suzuki coupling reaction

A palladium-carbon catalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of poor catalytic effect of chlorinated aromatics and cannot be recycled and reused , increase cost and other issues, to achieve the effect of improving catalyst activity, improving reusable performance, and increasing metal dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The modified palladium carbon catalyst for the Suzuki coupling reaction in this embodiment consists of an activated carbon carrier and an active component loaded on the activated carbon carrier, wherein the active component is palladium and nickel; the mass percentage of palladium in the catalyst is 5%. , the mass percentage of nickel is 0.5%;

[0032] The preparation method of present embodiment catalyst comprises the following steps:

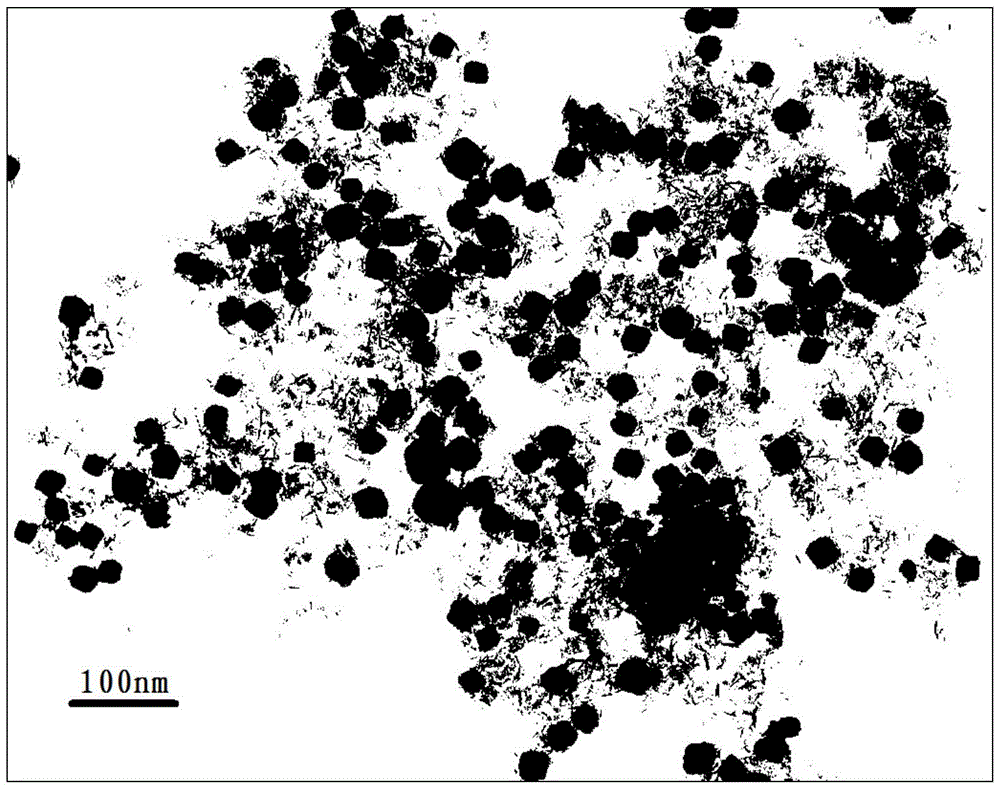

[0033] Step 1. Under the condition of 60°C and continuous stirring, firstly mix 4gNiCl 2 ·6H 2 A mixture of O and 0.67g polyvinylpyrrolidone (PVP) was dissolved in 80mL of distilled water to obtain solution A, then 80mL of absolute ethanol was added to obtain solution B, and then 3mL of hydrazine hydrate was slowly added dropwise to solution B to obtain nano-nickel sol , and its TEM photo is shown in figure 1 ,Depend on figure 1 It can be seen that nickel does exist in nanoscale sol state;

[0034] Step 2, the particle size is 38μm...

Embodiment 2

[0040] The modified palladium carbon catalyst for the Suzuki coupling reaction in this embodiment consists of an activated carbon carrier and an active component loaded on the activated carbon carrier, wherein the active component is palladium and nickel; the mass percentage of palladium in the catalyst is 5%. , the mass percentage of nickel is 1%;

[0041] The preparation method of present embodiment catalyst comprises the following steps:

[0042] Step 1. Under the condition of 40°C and continuous stirring, firstly mix 4.2gNi(OAc) 2 4H 2 A mixture of O and 1.4g polyvinylpyrrolidone (PVP) was dissolved in 55mL of distilled water to obtain solution A, then 55mL of absolute ethanol was added to obtain solution B, and then 6.5mL of hydrazine hydrate was slowly added dropwise to solution B to obtain nano-nickel Sol;

[0043] Step 2, the particle size is 38μm ~ 74μm, the specific surface area is 1000m 2 The gac / g is placed in boiling mass percent concentration of 5% sodium car...

Embodiment 3

[0049] The modified palladium-carbon catalyst for the Suzuki coupling reaction in this embodiment consists of an activated carbon carrier and an active component loaded on the activated carbon carrier, wherein the active component is palladium and nickel; the mass percentage of palladium in the catalyst is 7.5% , the mass percentage of nickel is 2%;

[0050] The preparation method of present embodiment catalyst comprises the following steps:

[0051] Step 1. Under the condition of 50°C and continuous stirring, first mix 5.0gNi(NO 3 ) 2 ·6H 2 A mixture of O and 2.5g of polyvinylpyrrolidone (PVP) was dissolved in 50mL of distilled water to obtain solution A, then 50mL of absolute ethanol was added to obtain solution B, and then 8.0mL of hydrazine hydrate was slowly added dropwise to solution B to obtain nano-nickel Sol;

[0052] Step 2, the particle size is 38μm ~ 74μm, the specific surface area is 1200m 2 The activated carbon per g is placed in boiling mass percent concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com