Adhesive for grinding wheel mesh and preparation method thereof

A technology of adhesives and meshes, applied in the direction of adhesives, adhesive types, polymer adhesive additives, etc., can solve the problems of low maximum rotation speed, poor plasticity and brittleness, general bonding effect, etc., and achieve improved Adhesive performance, improvement of brittleness, and the effect of reducing damage to the human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

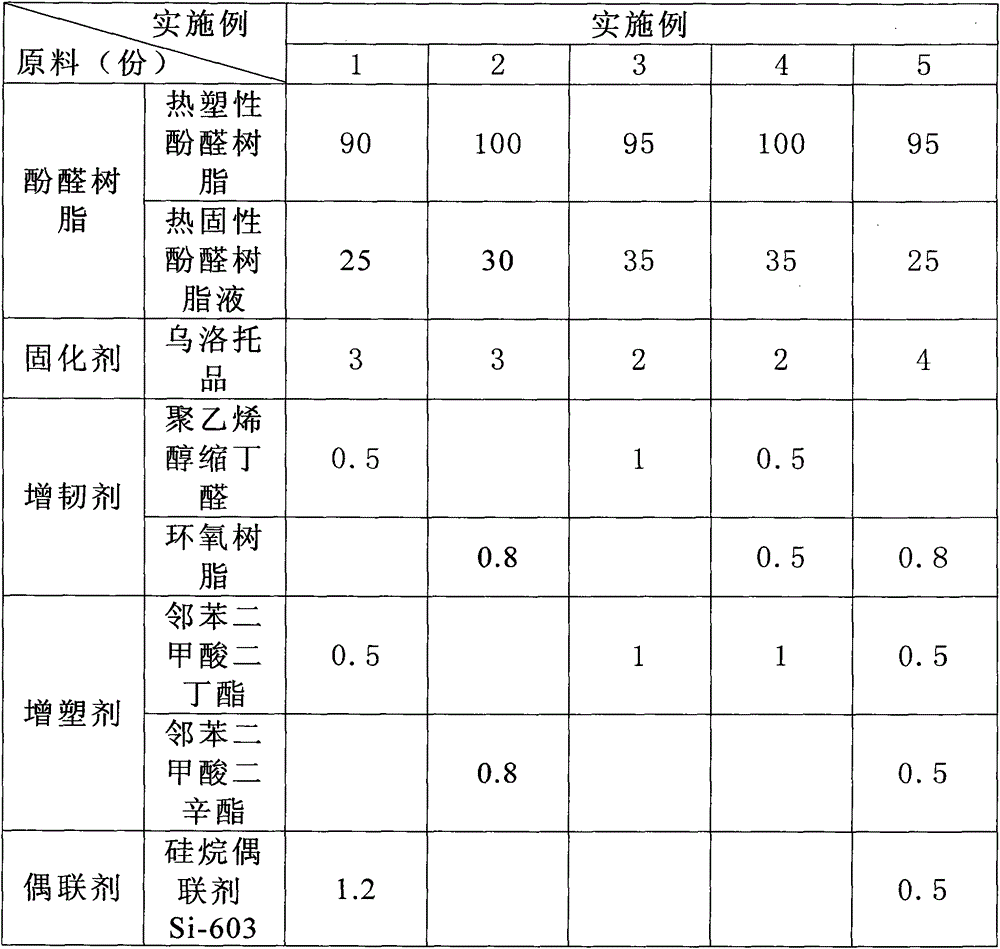

Embodiment 1

[0036] According to the raw material composition and parts by weight in Example 1 in Table 1, 1.2 parts of silane coupling agent Si-603 was added to 25 parts of thermosetting phenolic resin liquid, stirred evenly, and placed for later use. Take 0.5 part of toughening agent polyvinyl butyral and dissolve it in 2 parts of alcohol, fully dissolve it for later use. Then add 80 parts of alcohol into the large mixer, start the mixer to stir, add 90 parts of thermoplastic phenolic resin, stir for about 3 hours, add the prepared thermosetting phenolic resin solution containing coupling agent, and add the prepared Toughening agent and 0.5 parts of plasticizer dibutyl phthalate. After stirring for 3 hours, add 3 parts of curing agent urotropine, rinse the container used above with 3 parts of alcohol, add a stirrer and continue stirring for 4 hours, discharge the material into a barrel and seal it, and obtain an adhesive for grinding wheel mesh.

Embodiment 2

[0038] According to the raw material composition and parts by weight in Table 1, Example 2, 1.2 parts of silane coupling agent DL-602 was added to 30 parts of thermosetting phenolic resin liquid, stirred evenly, and placed for later use. Take 0.8 parts of toughening agent epoxy resin and dissolve it in 4 parts of alcohol, and fully dissolve it for later use. Then add 90 parts of alcohol into the large mixer, start the mixer to stir, add 100 parts of thermoplastic phenolic resin, stir for about 4 hours, add the prepared thermosetting phenolic resin solution containing coupling agent, and add the prepared Toughening agent and 0.8 parts of plasticizer dioctyl phthalate. After stirring for 3 hours, add 4 parts of urotropine as a curing agent, rinse the container used above with 6 parts of alcohol, add a stirrer and continue stirring for 5 hours, discharge the material and seal it in a barrel to obtain an adhesive for grinding wheel mesh.

Embodiment 3

[0040]According to the raw material composition and parts by weight in Example 3 in Table 1, 1.2 parts of silane coupling agent KH-550 was added to 35 parts of thermosetting phenolic resin liquid, stirred evenly, and placed for later use. Take 1 part of toughening agent polyvinyl butyral and dissolve it in 5 parts of alcohol, fully dissolve it for later use. Then add 100 parts of alcohol into the large mixer, start the mixer to stir, add 95 parts of thermoplastic phenolic resin, stir for about 3.5 hours, add the prepared thermosetting phenolic resin solution containing coupling agent, and add the prepared toughener and 1 part plasticizer dibutyl phthalate. After stirring for 4 hours, add 2 parts of urotropine as a curing agent, rinse the container used above with 5 parts of alcohol, add a stirrer and continue stirring for 5 hours, discharge the material and seal it in a barrel to obtain an adhesive for grinding wheel mesh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com