Method for continuously producing white carbon black by hypergravity technology

A white carbon black and supergravity technology, applied in the direction of silicon oxide, silicon dioxide, etc., can solve problems such as uneven distribution, long reaction time, and large product particles, to achieve enhanced mass transfer, overcome long reaction time, and uniform performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

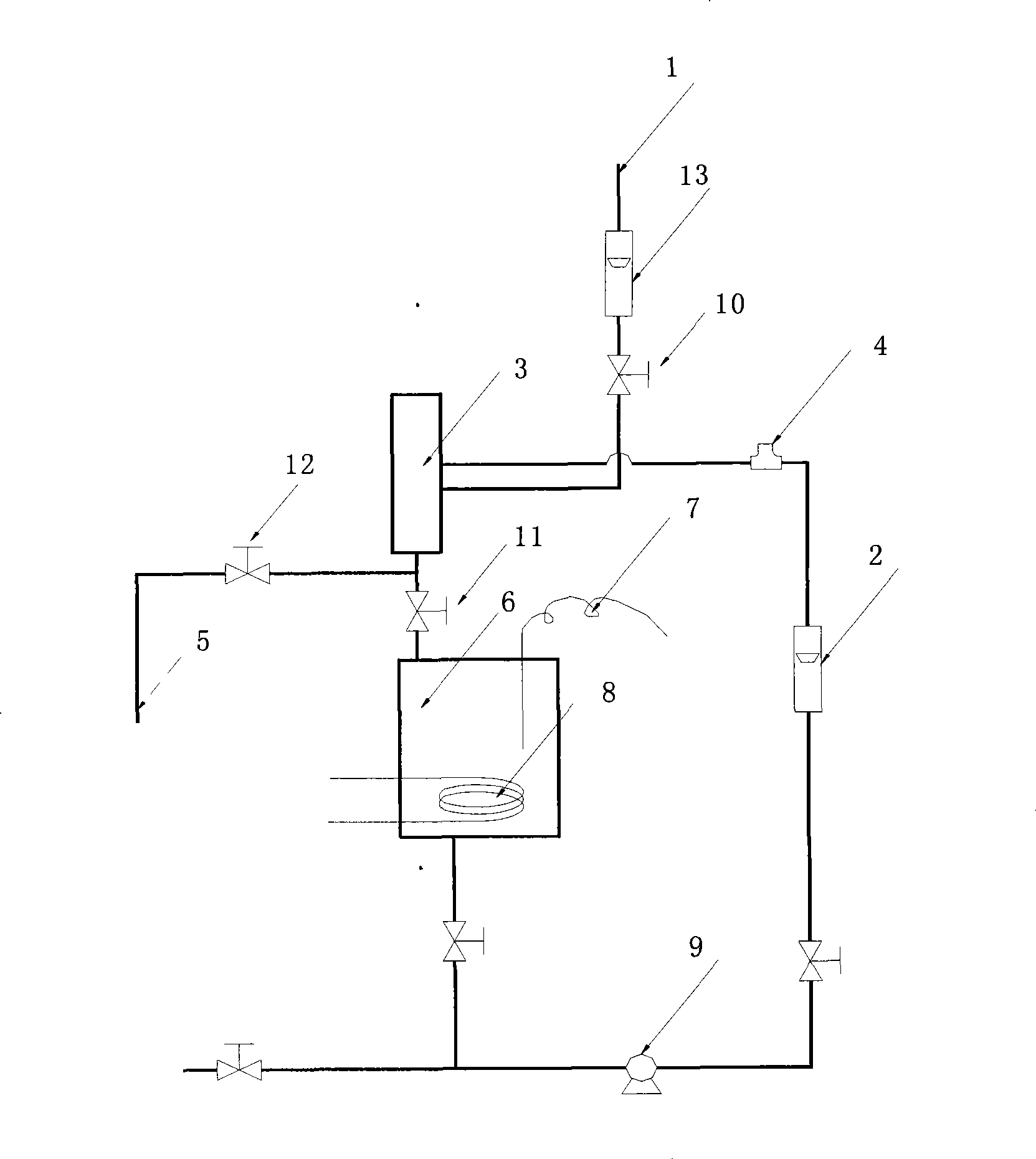

[0026] This embodiment adopts as figure 1 For the shown device, at first prepare a sodium silicate solution with a volume fraction of 10% and a dilute sulfuric acid with a mass fraction of 10%, weigh 150g of sodium chloride, add the sodium chloride and the sodium silicate solution to the barrel 6, and open The heating coil 8 starts heating, and at the same time, the circulation valve 11 is opened, the sulfuric acid addition valve 10 and the outlet valve 12 are closed, and the pipeline pump 9 is turned on, so that the feed liquid circulates in the circulation pipeline and is filtered through the filter net 4, and the rotameter 2 is adjusted. , make it reach 250L / h, turn on the rotary bed 3, and adjust its rotating speed to be 900rpm. After the temperature measured by the temperature probe 7 reaches 75°C, it will automatically keep warm for 10 minutes, then close the heating coil 8, open the outlet valve 12, close the circulation valve 11, open the sulfuric acid adding valve 10,...

Embodiment 2

[0028] Except that following condition changes, all the other conditions are the same as embodiment 1.

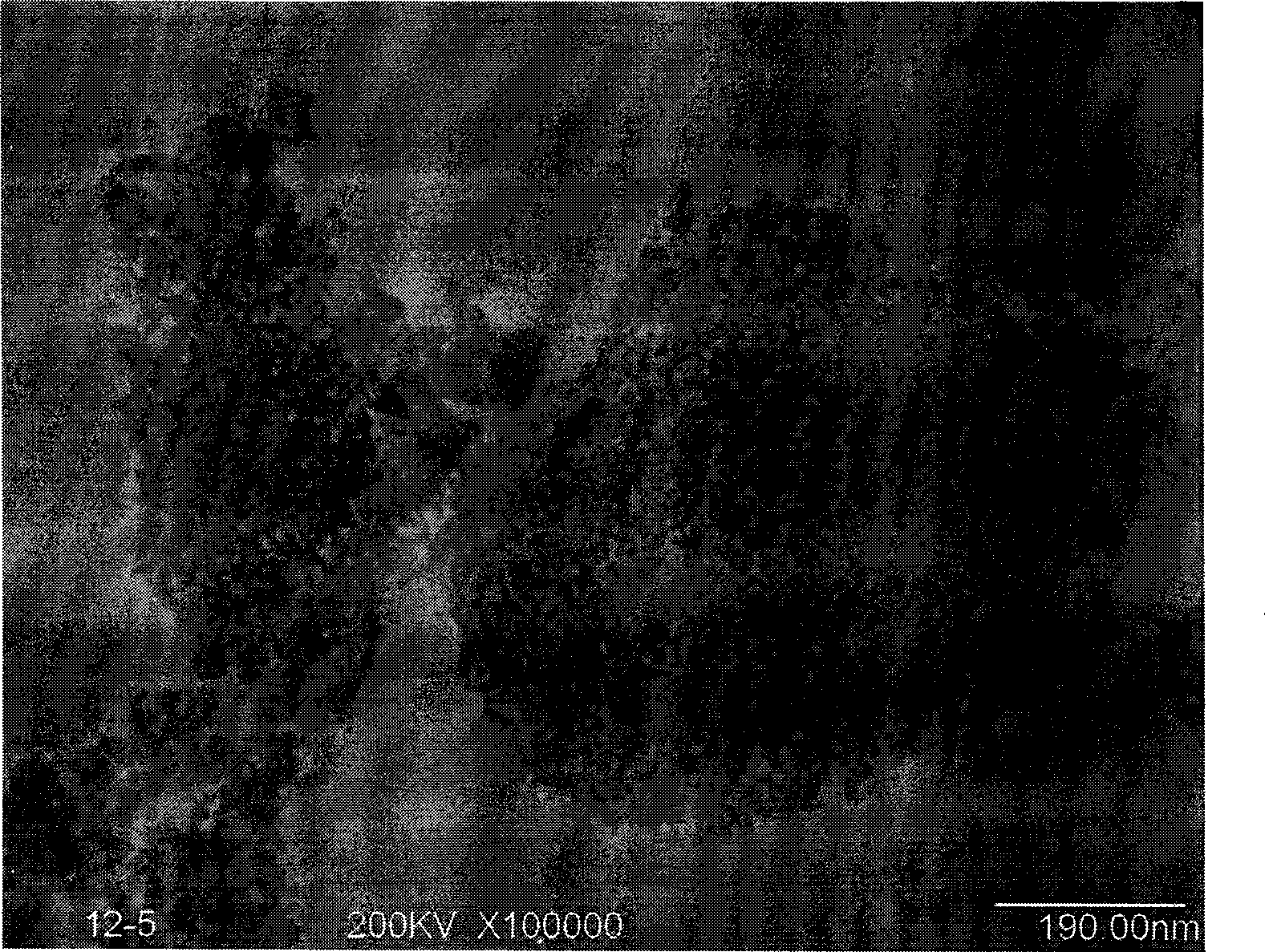

[0029] The mass fraction of dilute sulfuric acid is 20%, and the specific surface area of the obtained white carbon black is 565.2m 2 / g, the DBP oil absorption value is 1.01mL / g, and the average particle size is below 10nm.

Embodiment 3

[0031] Except that following condition changes, all the other conditions are the same as embodiment 1.

[0032] The mass fraction of dilute sulfuric acid is 50%, and the specific surface area of the obtained white carbon black is 525.9m 2 / g, the DBP oil absorption value is 1.19mL / g, and the average particle size is below 10nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com