All-solid-state quantum dot sensitized solar cell and preparation method thereof

A technology for quantum dot sensitization and solar cells, which is applied in the field of preparation of all-solid-state quantum-dot-sensitized solar cells and all-solid-state quantum-dot-sensitized solar cells, can solve problems such as unstable performance and difficult packaging, and achieve low cost, Overcome the effects of unstable performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

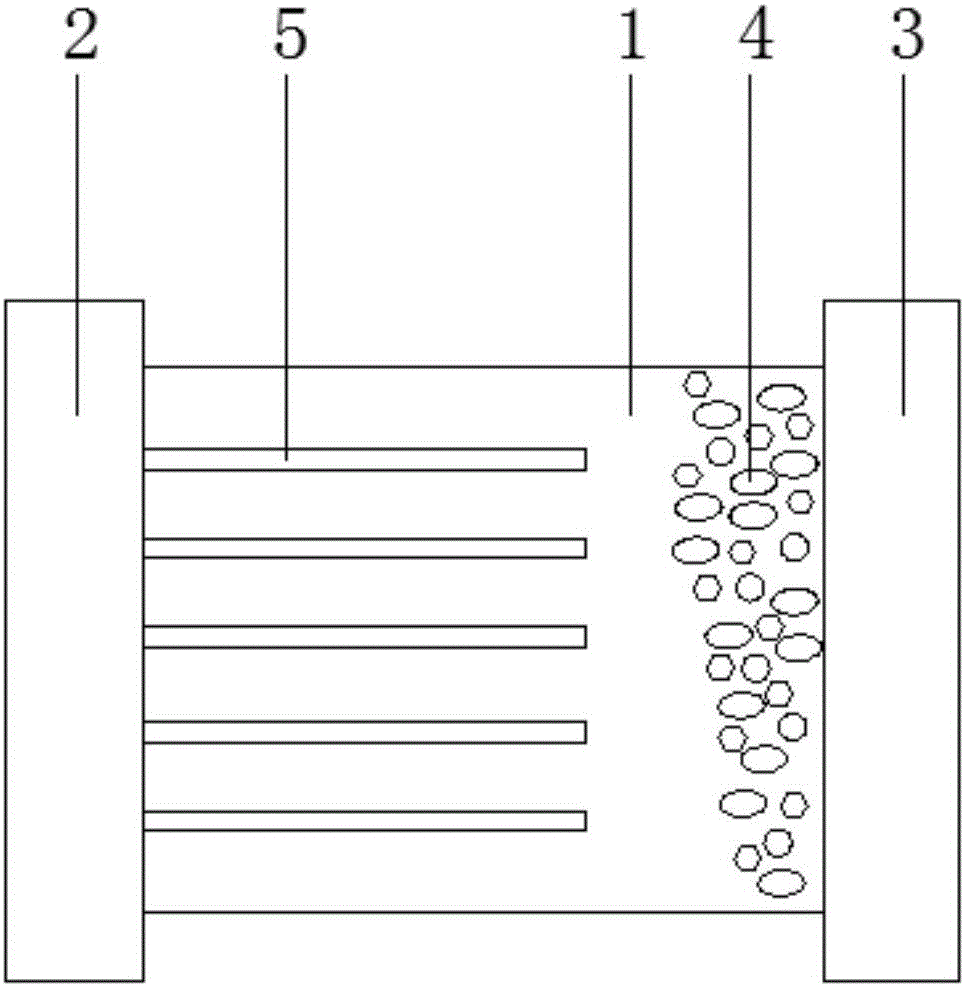

[0042] A preparation method of an all-solid-state quantum dot sensitized solar cell of the present invention comprises the following steps:

[0043] Step 1, preparing ZnO nanowire arrays on conductive glass 2

[0044]Step 1.1, prepare the precursor solution of the ZnO seed layer, use the precursor solution of the ZnO seed layer on one side of the conductive glass 2, and prepare the ZnO seed layer by spin coating and heat treatment process, wherein the spin coating speed is 3000-4500r / min, the temperature of the heat treatment process is 300-350°C, and the thickness of the ZnO seed layer is 50-100nm;

[0045] The precursor solution of the ZnO seed layer is specifically: add 16.46g of zinc acetate to the mixed solution of 4.5ml of monoethanolamine (MEA) and 100ml of ethylene glycol methyl ether, then magnetically stir for 30min under 60°C hydrothermal conditions, and then in 30 Aging in a constant temperature box at ℃ for 24h;

[0046] Step 1.2, put the ZnO seed layer in step...

Embodiment 1

[0066] (1) Preparation of photoanode 5

[0067] Prepare the precursor solution of the ZnO seed layer: add 16.46g of zinc acetate to a mixed solution of 4.5ml of monoethanolamine (MEA) and 100ml of ethylene glycol methyl ether, then magnetically stir for 30min under water heat at 60°C, and then in 30°C Aged for 24 hours in a constant temperature box.

[0068] Prepare solution a: add KBH with a molar ratio of 1:1 to the methanol solution 4 Powder and SeO 2 Powder, heated and reduced to obtain solution a.

[0069] Use the precursor solution of ZnO seed layer on one side of conductive glass 2, prepare ZnO seed layer by spin coating method and heat treatment process, wherein spin coating speed is 3000r / min, the temperature of heat treatment process is 300 ℃, obtains the ZnO seed layer The thickness is 50nm; the ZnO seed layer is placed in NaOH and Zn(NO 3 ) 2 Mix the solution and grow ZnO nanowire arrays in a water bath at 80 °C; alternately immerse the ZnO nanowire arrays in ...

Embodiment 2

[0078] (1) Preparation of photoanode 5

[0079] Prepare the precursor solution of the ZnO seed layer: add 16.46g of zinc acetate to a mixed solution of 4.5ml of monoethanolamine (MEA) and 100ml of ethylene glycol methyl ether, then magnetically stir for 30min under water heat at 60°C, and then in 30°C Aged for 24 hours in a constant temperature box.

[0080] Prepare solution a: add KBH with a molar ratio of 1.2:1 to the methanol solution 4 Powder and SeO2 Powder, heated and reduced to obtain solution a.

[0081] Use the precursor solution of the ZnO seed layer on one side of the conductive glass 2 to prepare the ZnO seed layer by spin coating and heat treatment process, wherein the spin coating speed is 3800r / min, and the temperature of the heat treatment process is 320°C to obtain the thickness of the ZnO seed layer is 80nm; the ZnO seed layer is placed in the molar concentration ratio of 1:1 hexamethylenetetramine and Zn(NO 3 ) 2 Mix the solution and grow ZnO nanowire ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com