Spraying polyurea elastic anticorrosive paint, and preparation method thereof

An anti-corrosion coating and elastic technology, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of high strength, average impact resistance, and easy occurrence of hollowing of sprayed polyurea protective materials, so as to improve the flow rate. The effect of flattening performance, improving tensile strength, and improving softness performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] On the other hand, based on the same inventive concept, the embodiment of the present application provides a preparation method of the polyurea elastic anticorrosion coating, comprising the following steps:

[0048](1) Add the polyether polyol into the reaction kettle, dehydrate under the vacuum condition of 100-140°C and vacuum degree of 0.06-0.1MPa until the moisture is qualified; then turn off the vacuum pump, lower the temperature to 50-70°C, add MDI- 50, mix evenly, slowly raise the temperature to 80-90°C, react at constant temperature for 1-3h, take a sample to measure the NCO content, after reaching the set result, cool down to 40-50°C and discharge to obtain the A component.

[0049] (2) Mix the amino chain extender, additives, amino-terminated polyether, and color paste, put them into the reaction kettle, vacuum dehydrate at 100-140°C, and filter the material after the moisture test is qualified to obtain the B component.

[0050] (3) When using, use a spraying...

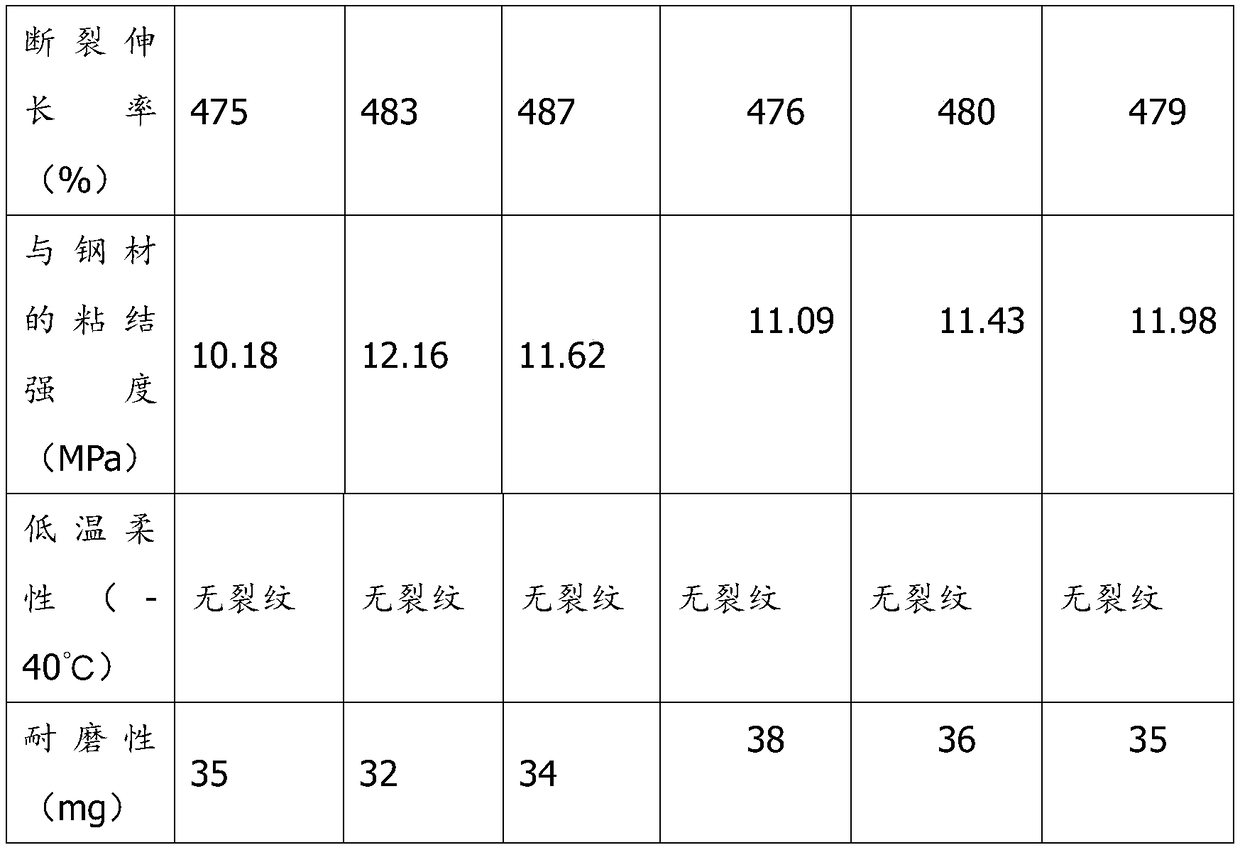

Embodiment 1

[0054] According to the proportion by mass, 40 parts of polyether polyol (N220) and 10 parts of polyether polyol (N330) produced by Jiangsu Jinqi Company were added to the reaction kettle, and dehydration was carried out at 120°C and vacuum degree of 0.08MPa for 2h to Moisture is acceptable. Then turn off the vacuum pump, lower the temperature to 60°C, add 49 parts of isocyanate (MDI-50) produced by Yantai Wanhua Company, and 1 part of stabilizer, mix well, slowly heat up to 80°C, and react at constant temperature for 2 hours. Take samples to measure the NCO content, reaching After the set result is 13-16%, the temperature is lowered to 40°C and the material is discharged to obtain the A component.

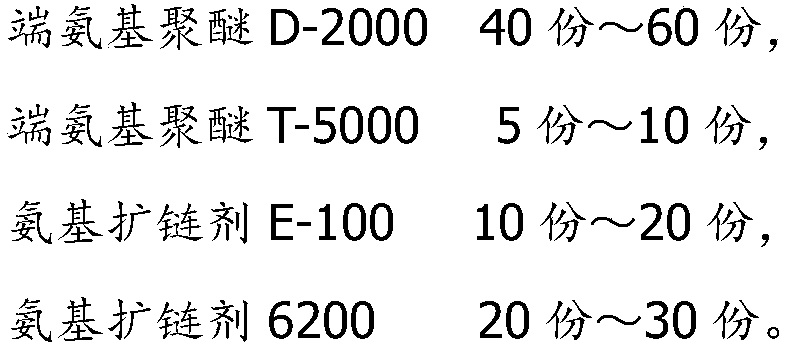

[0055] According to the ratio by mass, 54 parts of amino-terminated polyether (D-2000) produced by American Huntsman Company, 5 parts of amino-terminated polyether (T-5000), 1 part of auxiliary agent, and amino chain extender produced by American Yabao Company 12 parts of (E-100)...

Embodiment 2

[0058] According to the proportion by mass, add 36 parts of polyether polyol (N220) and 12 parts of polyether polyol (N330) produced by Jiangsu Jinqi Company into the reaction kettle, and dehydrate for 2 hours at 120°C and vacuum degree of 0.08MPa until the moisture content is acceptable. Then turn off the vacuum pump, lower the temperature to 60°C, add 50.5 parts of isocyanate (MDI-50) produced by Yantai Wanhua Company, and 0.5 parts of stabilizer, mix well, slowly heat up to 80°C, react at constant temperature for 2 hours, and take samples to measure the NCO content. After reaching 13% to 16% of the set result, cool down to 40°C and discharge to obtain the A component.

[0059] According to the proportion by mass, 52 parts of amino-terminated polyether (D-2000) produced by Huntsman Company of the United States, 6 parts of amino-terminated polyether (T-5000) and 0.5 parts of additives, amino chain extension products produced by Yabao Company of the United States Mix 15 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com