Patents

Literature

203results about How to "Guaranteed performance and stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for adding rare earth metal into steel to improve performance

The invention relates to the field of manufacturing of high-quality metal materials, in particular to a method for adding rare earth metal into steel to improve the performance. In the smelting process of molten steel, the degree of purity of the molten steel and the degree of purity of the high-purity rare earth metal are strictly controlled; the high-purity rare earth metal is added into a steel ladle; the content of sulfur in the molten steel is below 200 ppm and the total oxygen content is below 40 ppm before the high-purity rare earth metal is added; and the total oxygen content of the added high-purity rare earth metal is below 200 ppm. The method is applicable to the processes such as a converter BOF-ladle refining LF-vacuum degassing RH or VD-continuous casting CC / mold casting MC flow, an electric arc furnace EAF-ladle refining LF-vacuum degassing RH or VD-continuous casting CC / mold casting MC flow and a converter BOF / intermediate frequency furnace GOR / AOD(-ladle refining LF)-continuous casting CC / mold casting MC flow, prepares high-quality carbon structural steel, low alloy steel, medium-high alloy steel, tool and mould steel, bearing steel, spring steel, stainless steel and electrical steel, and solves the bottleneck problems that due to a conventional rare earth adding process, the performance of rolled steel is not stable and a water gap is blocked in the production process.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

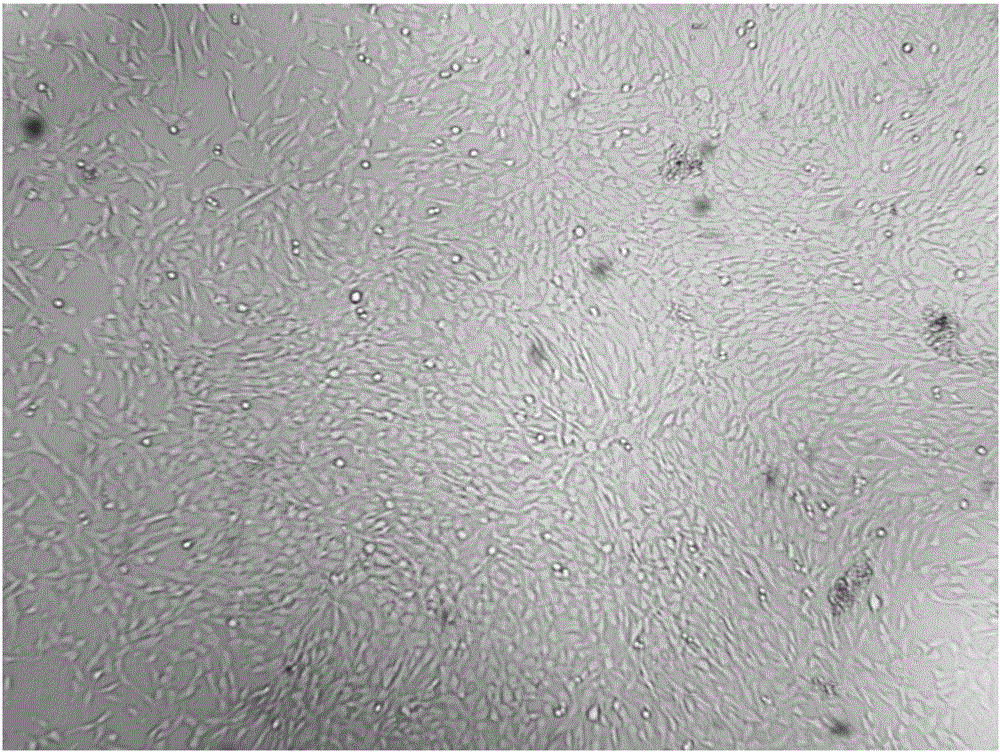

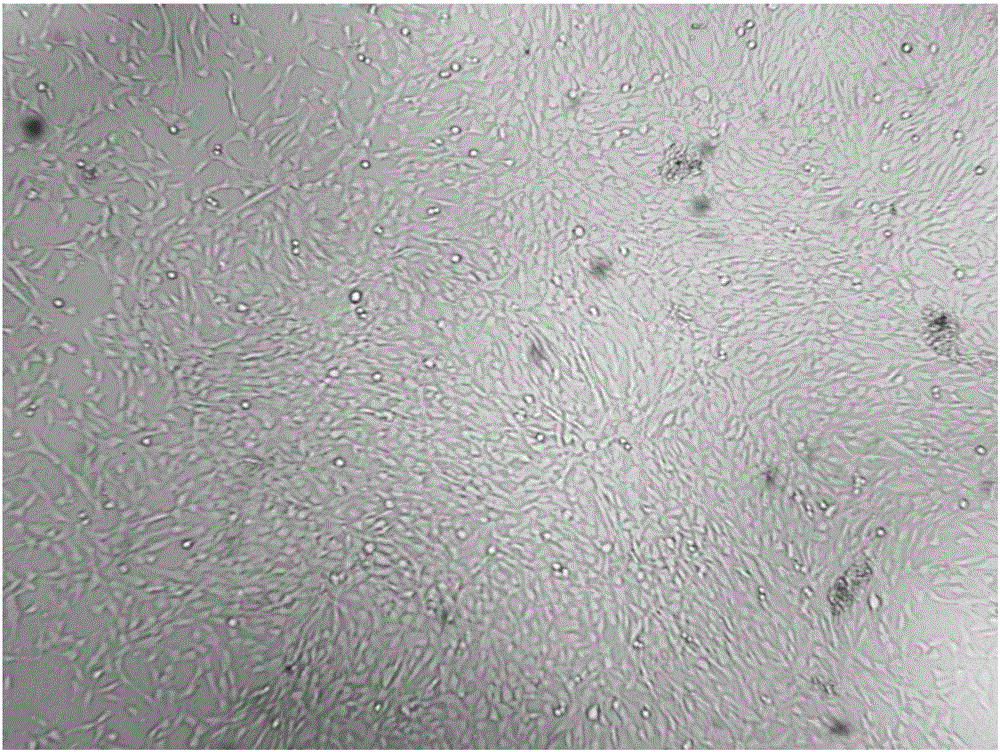

Method for preparing stem cell active factor

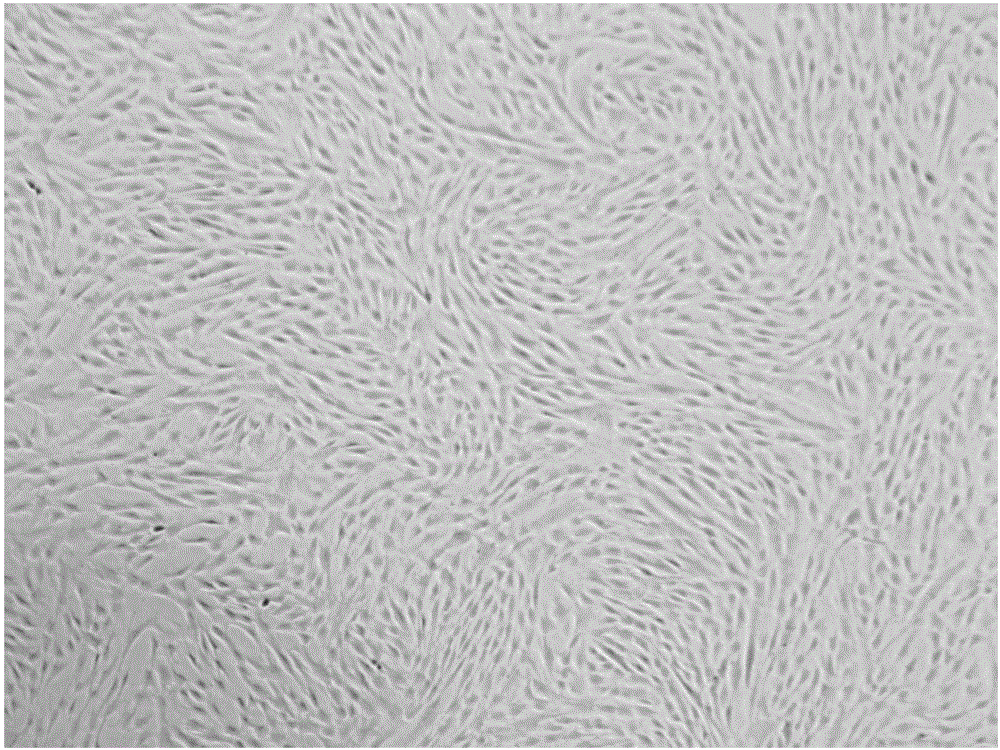

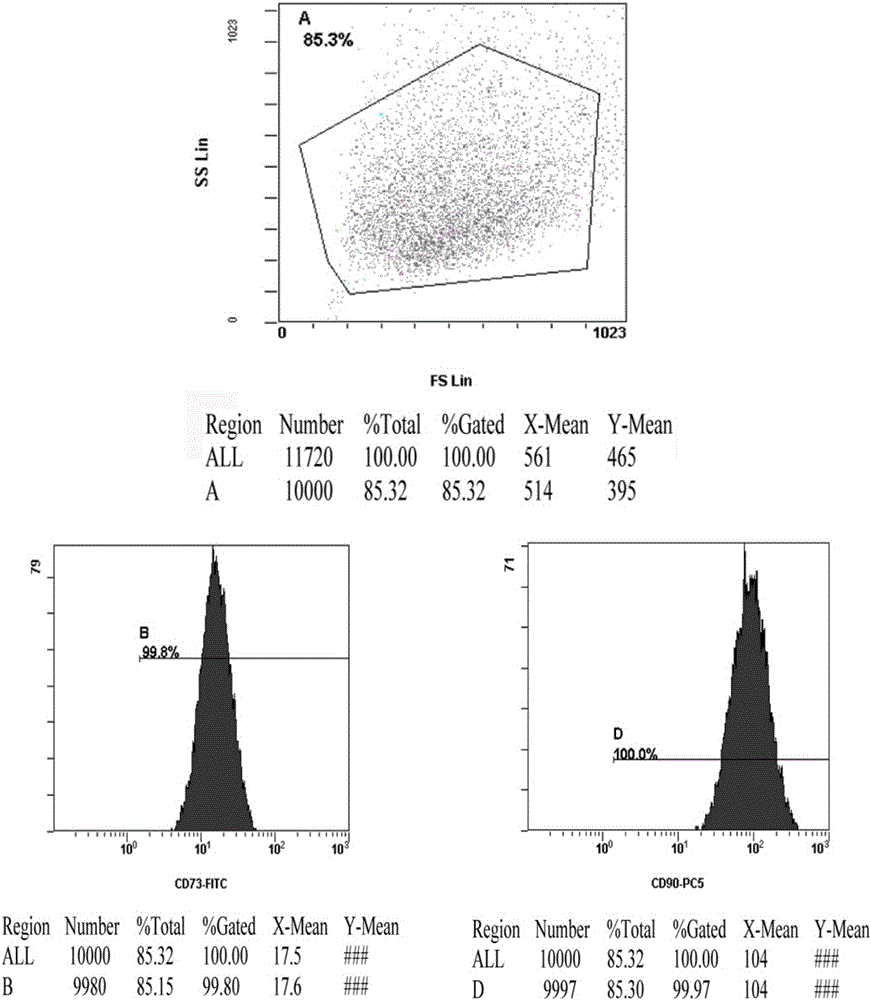

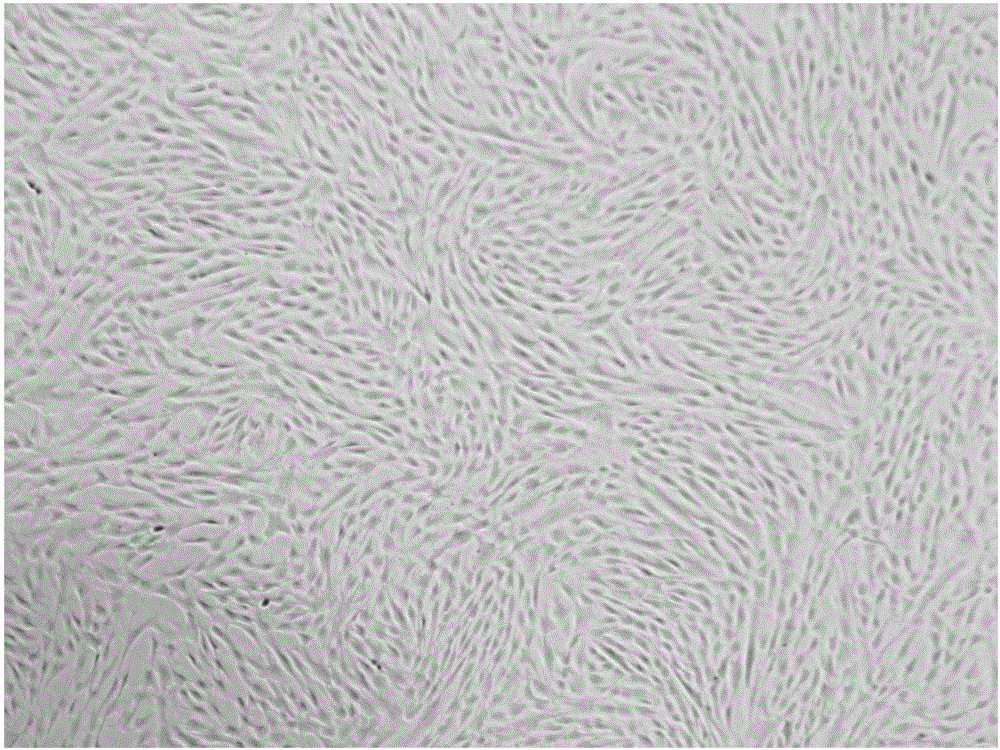

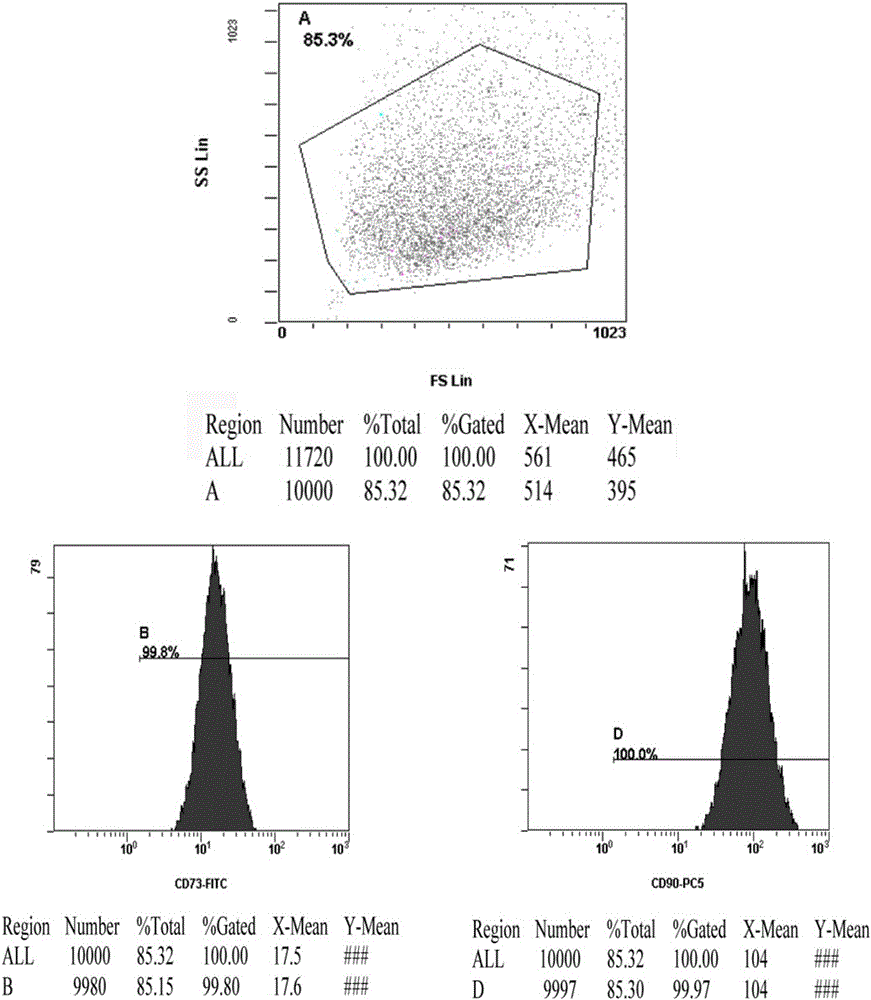

ActiveCN106381284AHomogeneousIn line with biological characteristicsCosmetic preparationsToilet preparationsFreeze-dryingMesenchymal stem cell

The invention relates to a method for preparing a stem cell active factor, and on one hand, in particular relates to a method for preparing the stem cell active factor. The method comprises the following steps of: (1) acquiring umbilical cord placenta derived mesenchymal stem cells; (2) performing cell amplification; (3) performing cell identification detection; (4) preparing the stem cell active factor; and (5) performing optional freeze-drying. Furthermore, the invention relates to a stem cell active factor freeze-dried powder agent prepared by using the method demonstratively. The method provided by the invention has the beneficial effects as shown in the specification of the invention.

Owner:BOYALIFE

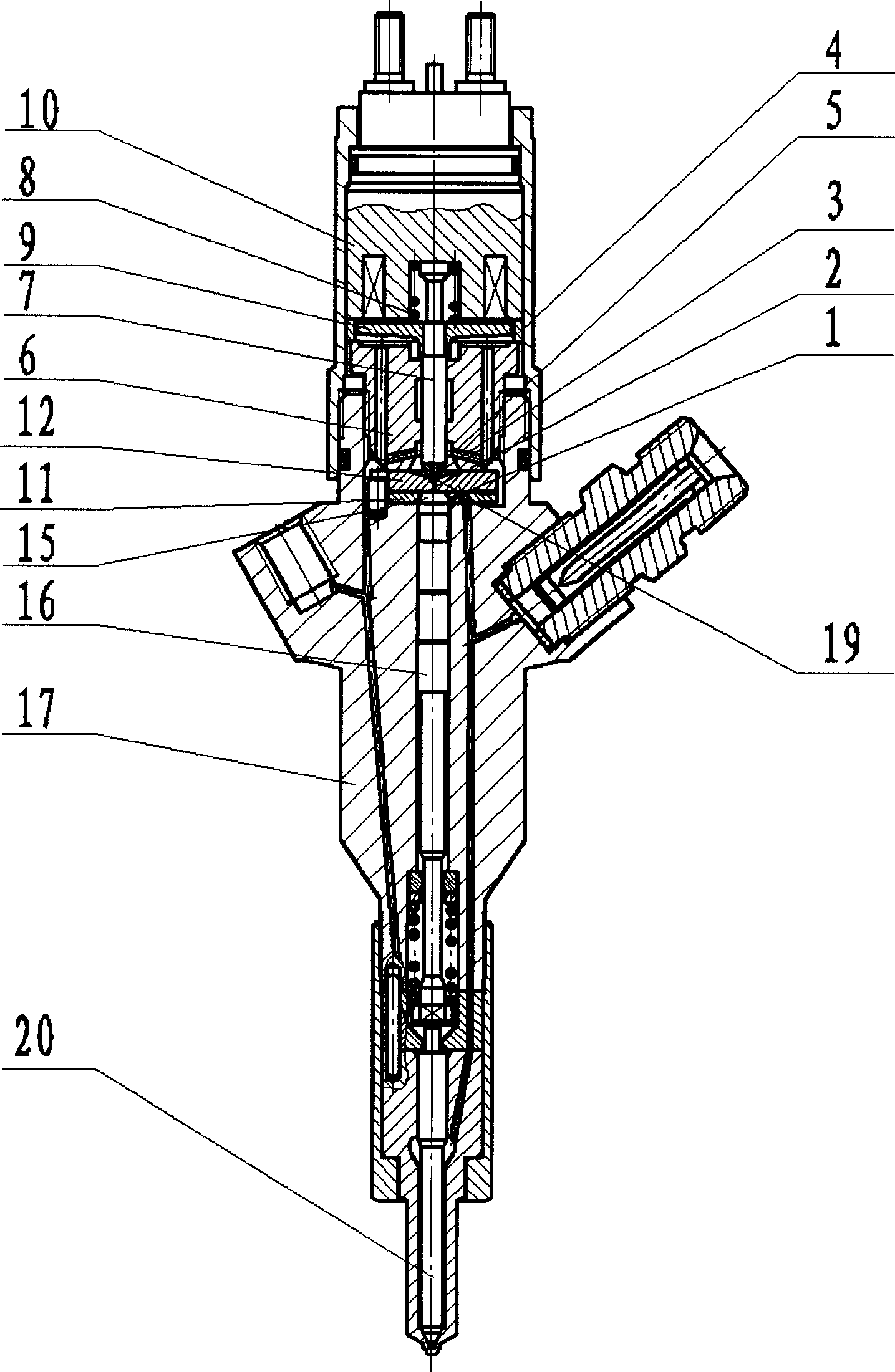

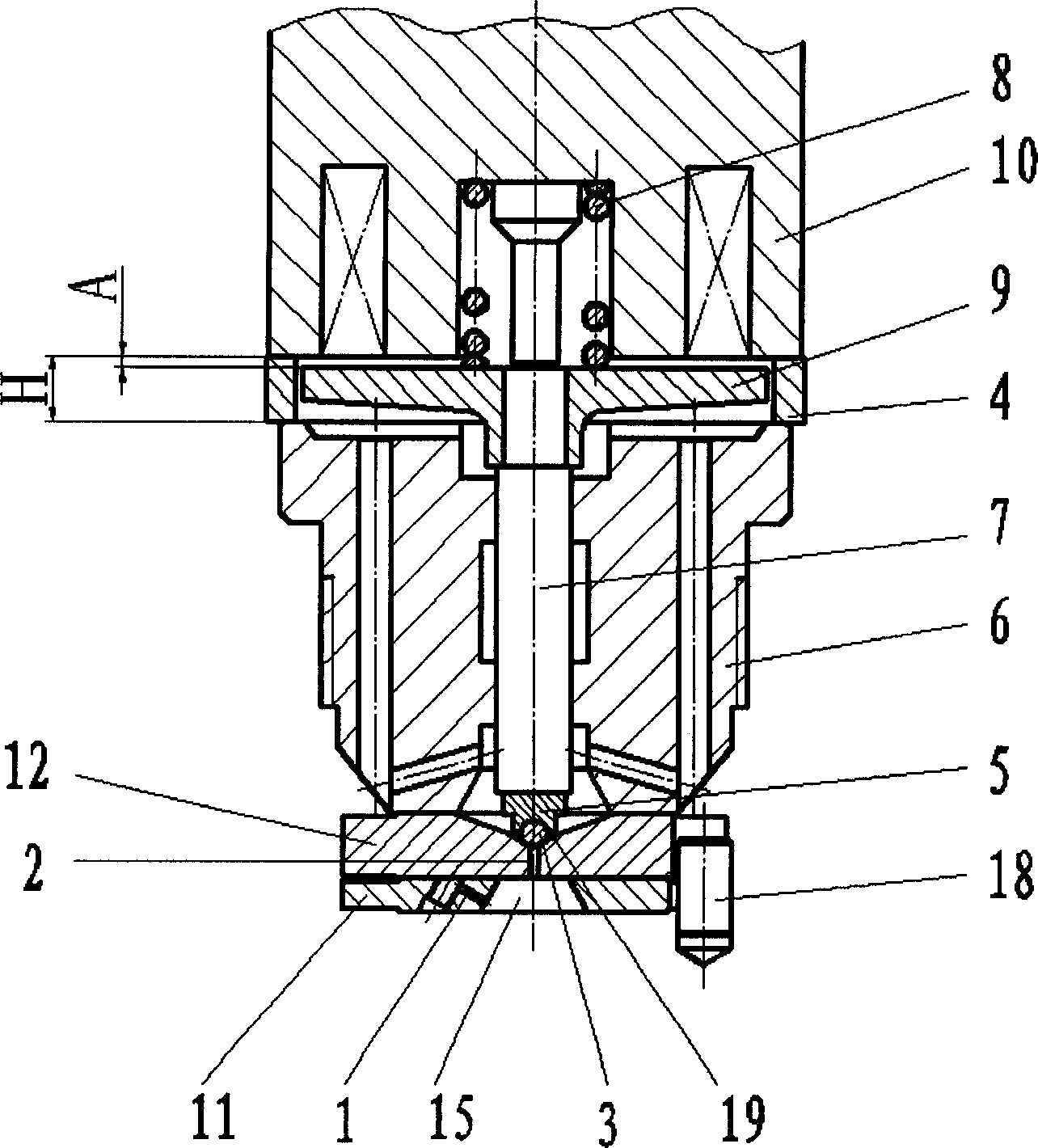

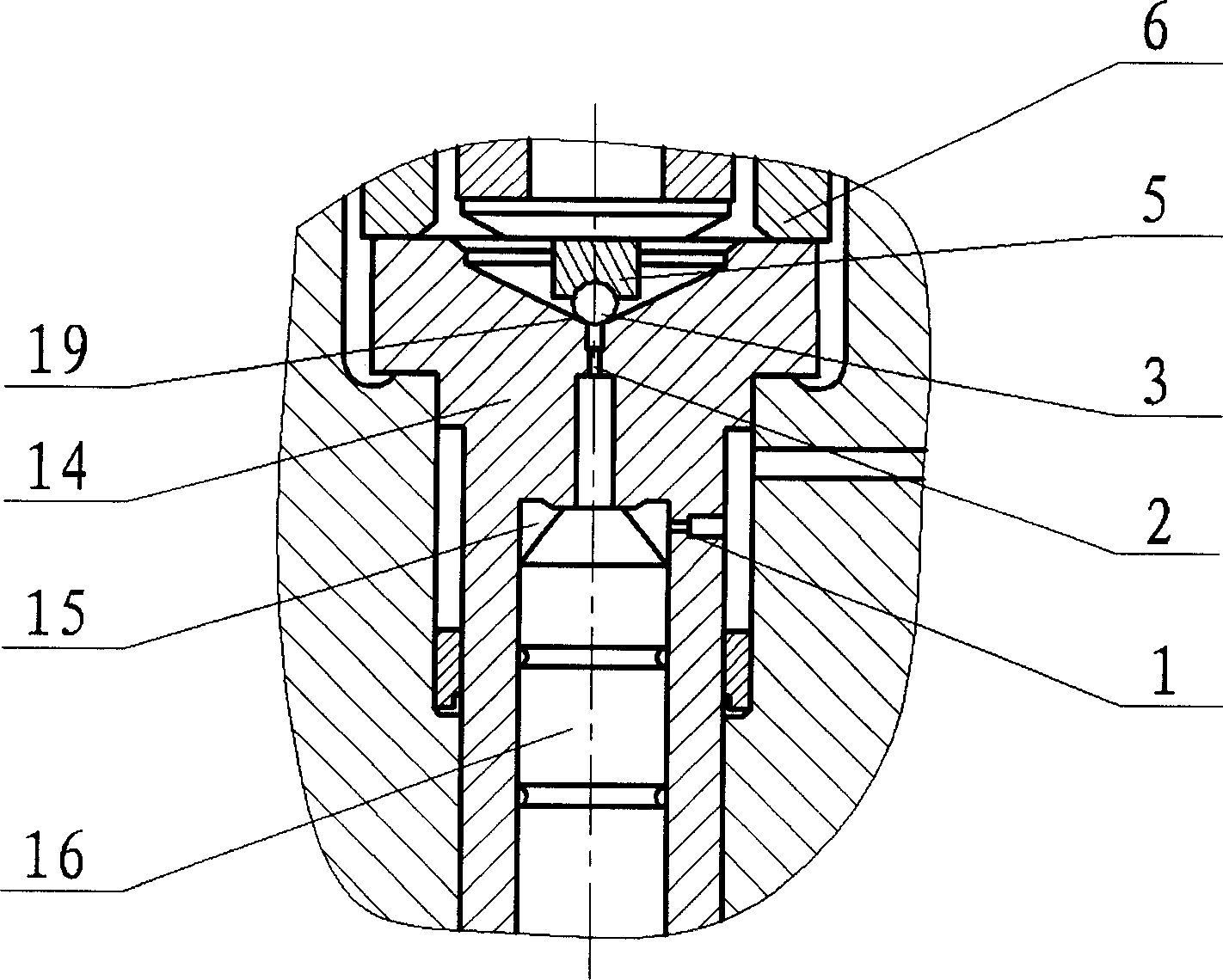

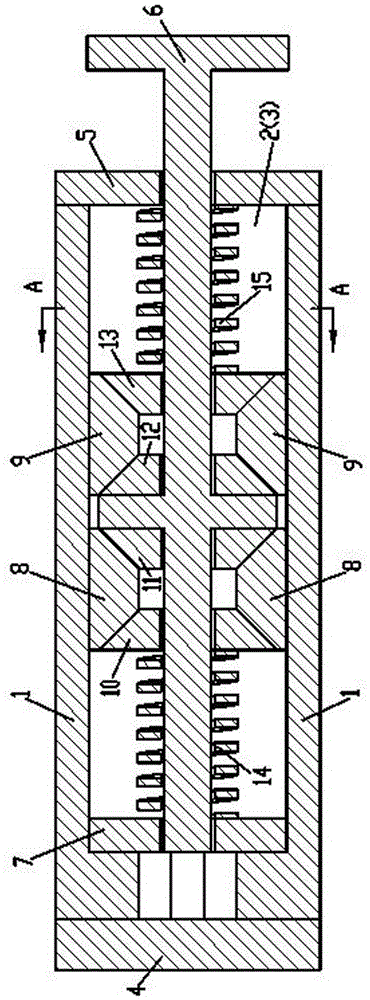

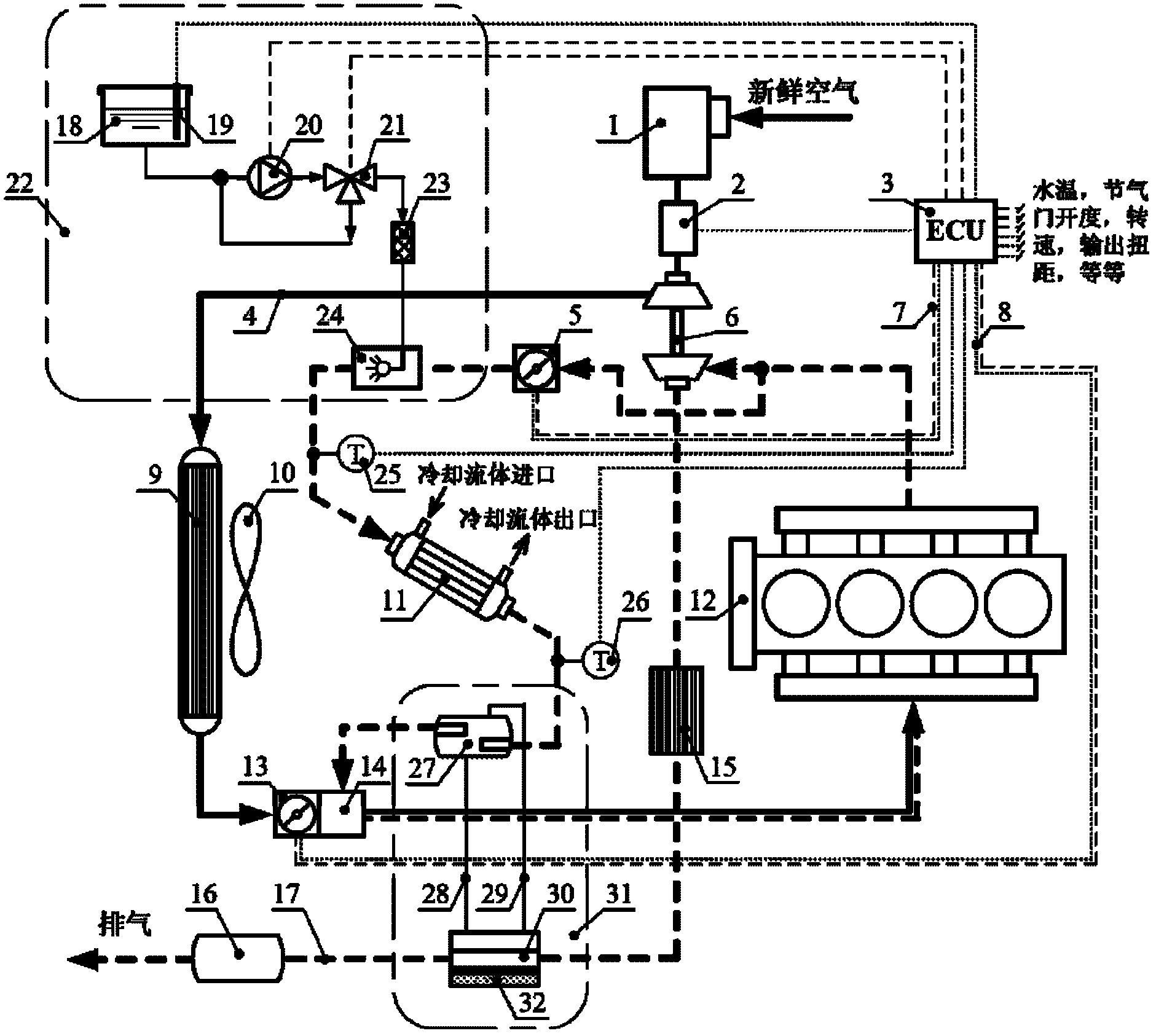

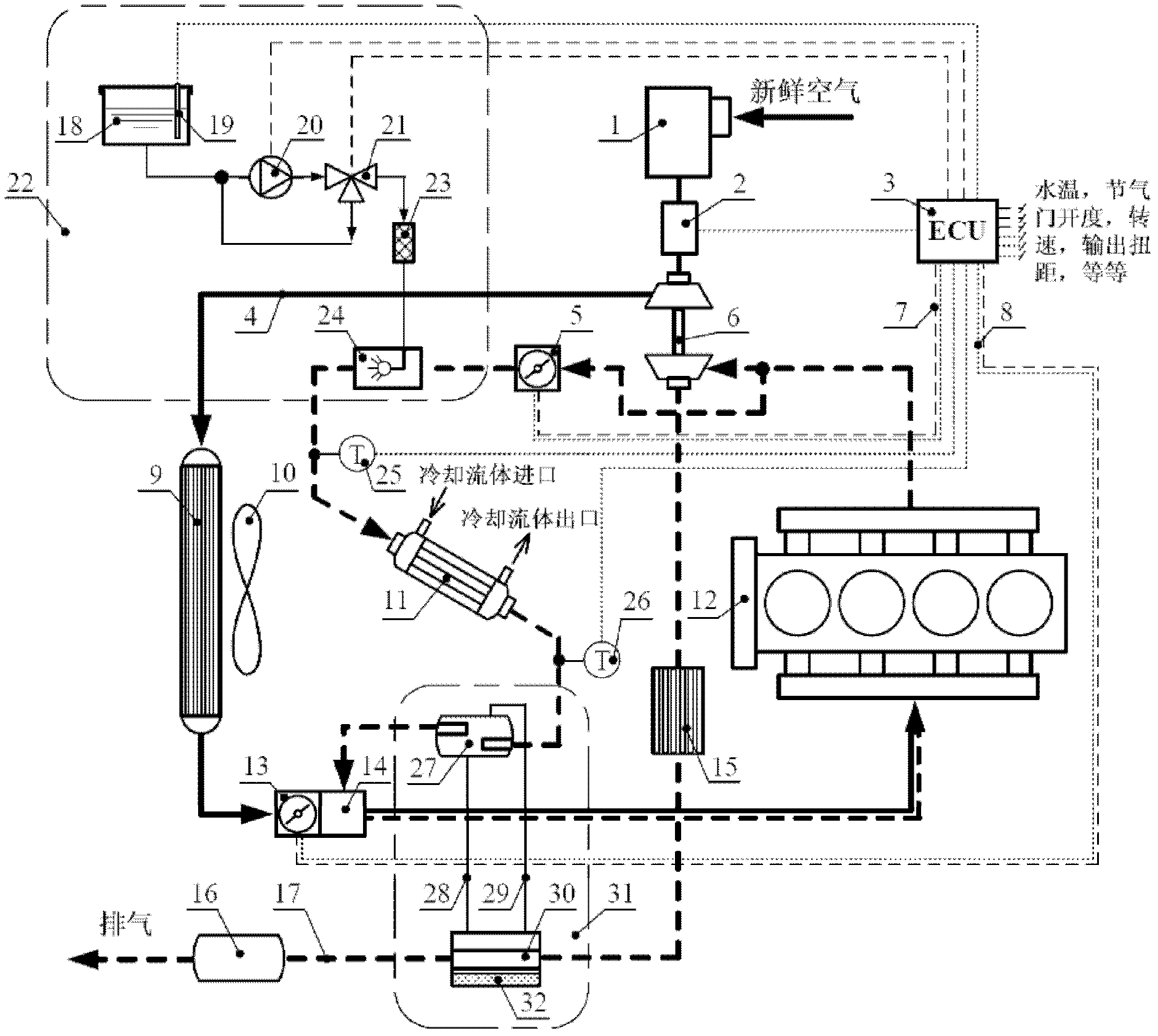

Co-rail oil injection system electric control oil injector

InactiveCN1773098AReduce the difficulty of manufacturing processGuaranteed performance and stabilityFuel injection apparatusMachines/enginesOrifice plateVena contracta diameter

The present invention relates to an electronic-controlled fuel injector of diesel engine common-rail injection system. Its control valve portion structure is characterized by that it has a throttle small orifice plate with fuel inlet orifice, a throttle large orifice plate with fuel-returning orifice and sealed cone and a regulating ring capable of regulating working gap of armature iron.

Owner:WUXI OIL PUMP NOZZLE INST

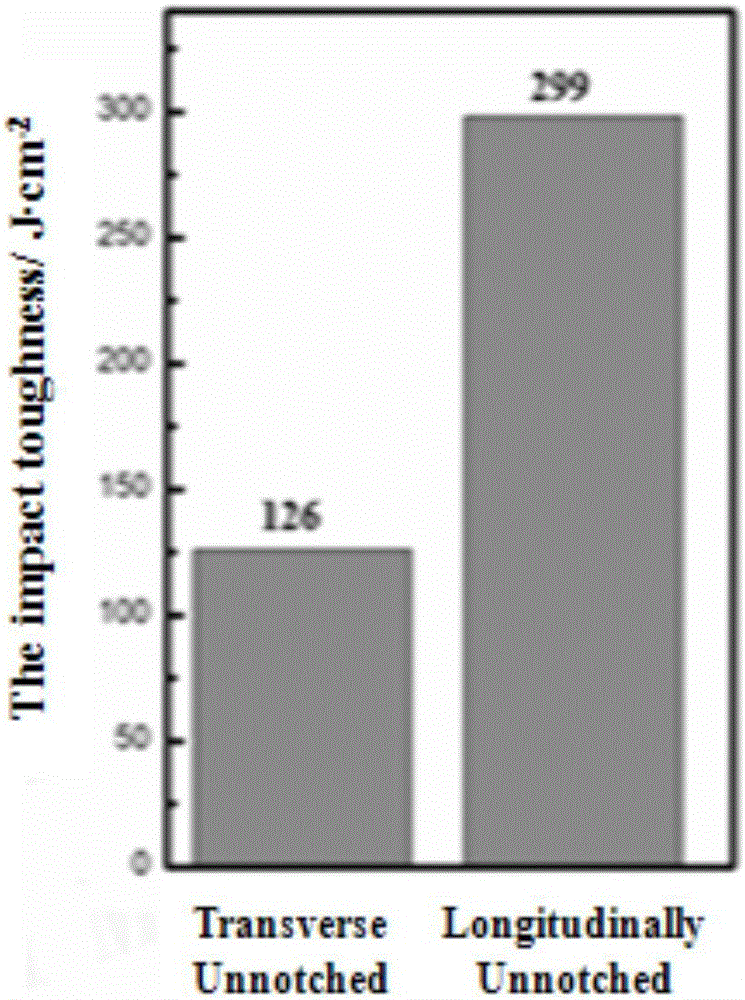

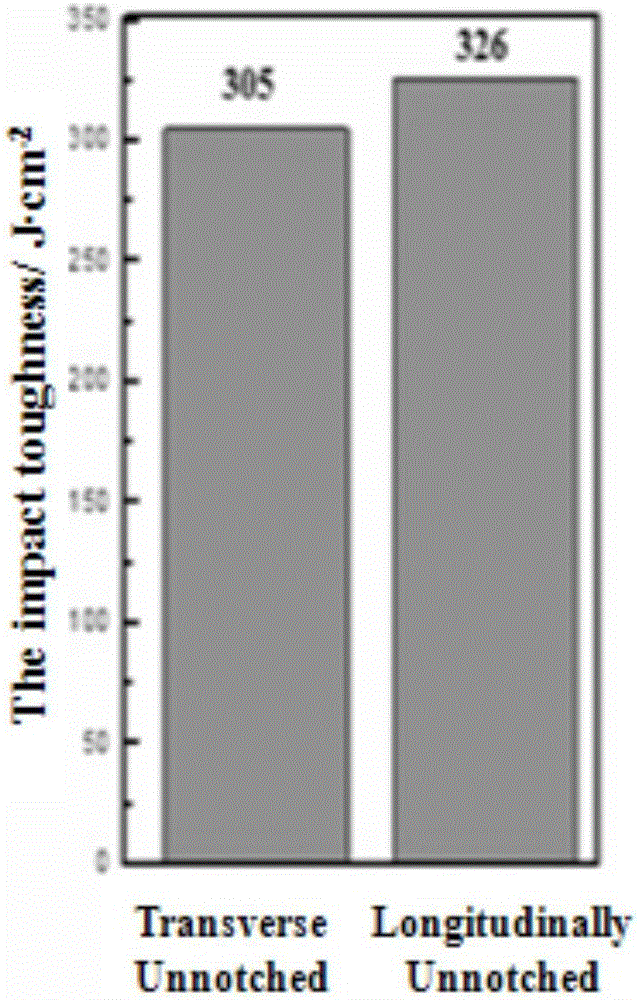

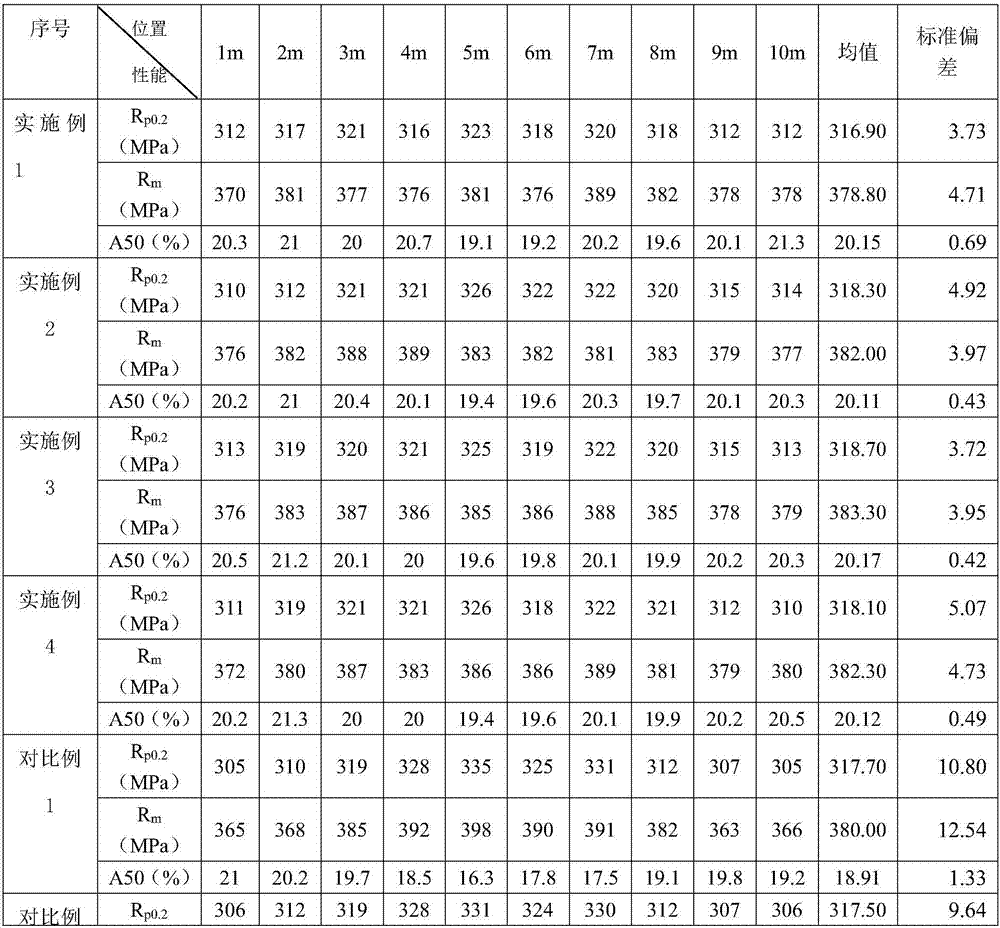

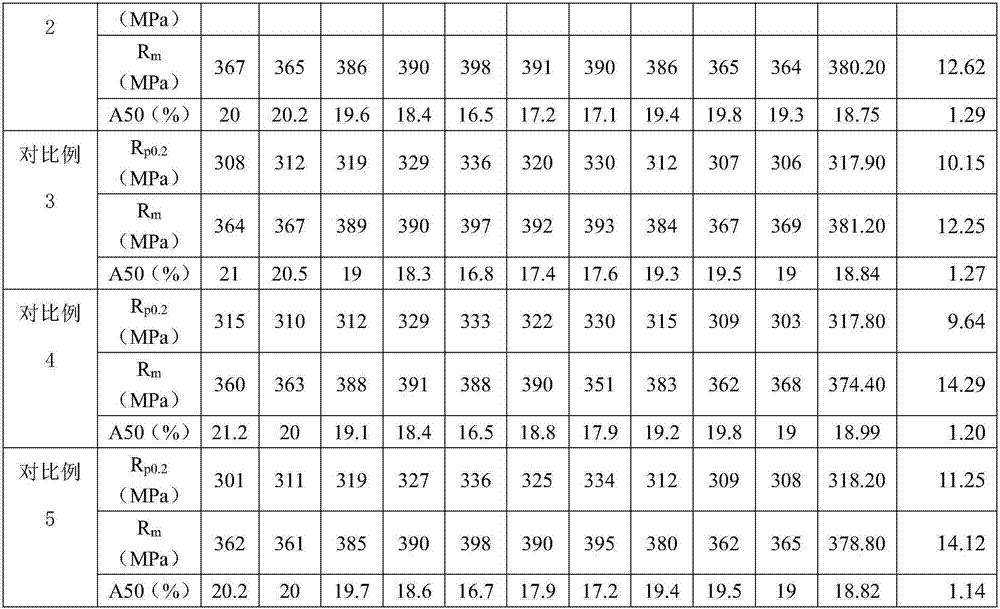

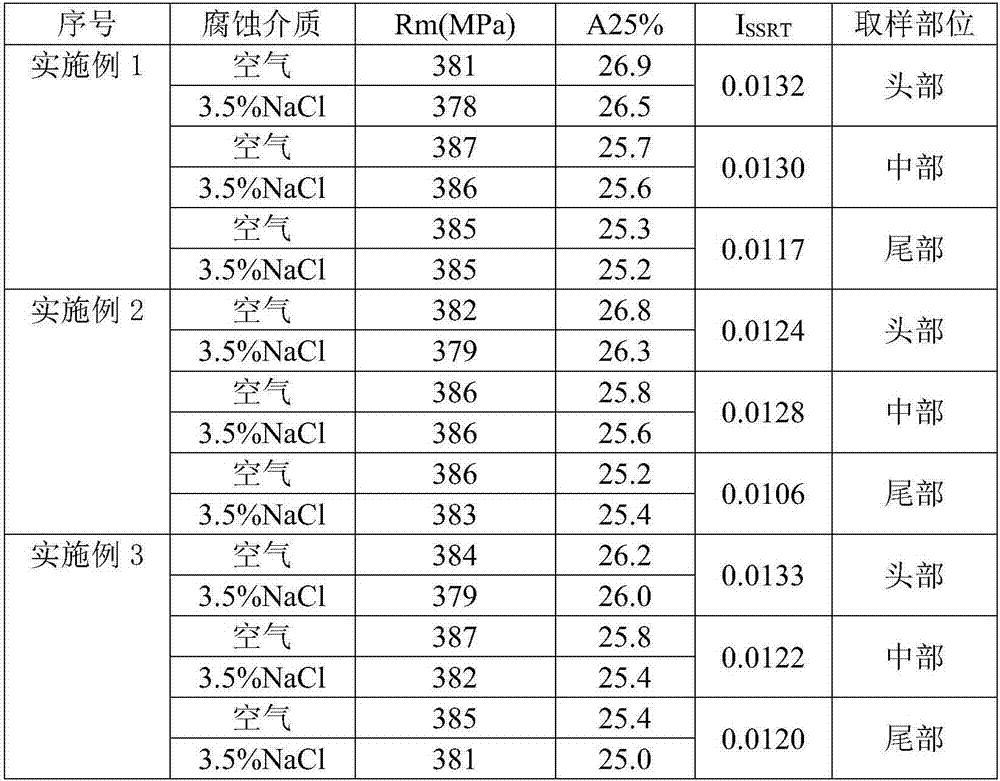

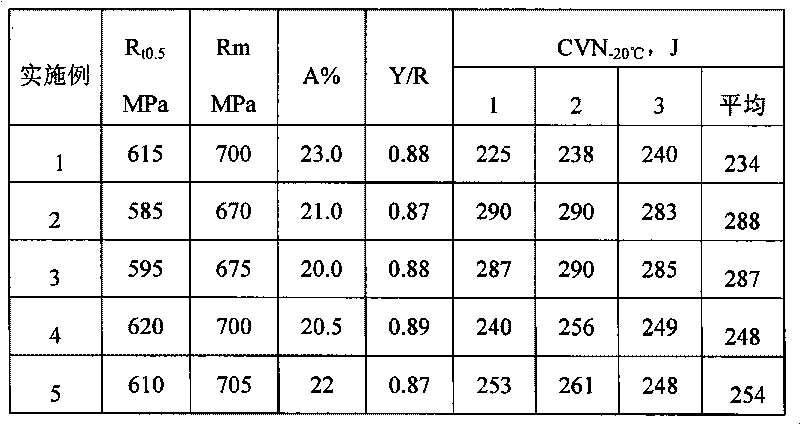

Preparation process of Al-Zn-Mg alloy profile for high-speed train body

The invention relates to a preparation process of a Al-Zn-Mg alloy profile for a high-speed train body. The preparation process comprises the following steps that (1), extruding is carried out; (2), roll bottom continuous solution hardening is carried out; (3), stretching is carried out; (4), plate type three-stage aging oven for aviation aging treatment is carried out; (5), finished product saw cutting is carried out; and (6), packaging and storing are carried out. According to the preparation process of the Al-Zn-Mg alloy profile for the high-speed train body, roll bottom continuous solution hardening and plate type three-stage aging oven for aviation aging treatment are adopted for production, and thermal treatment precision can be greatly improved. Meanwhile, a gradient heating method is adopted during extrusion, the Al-Zn-Mg profile head and tail temperature difference is precisely controlled, the Al-Zn-Mg alloy profile head, middle and tail performance difference is reduced, and therefore the performance stability of the Al-Zn-Mg alloy profile is guaranteed.

Owner:广西南南铝加工有限公司

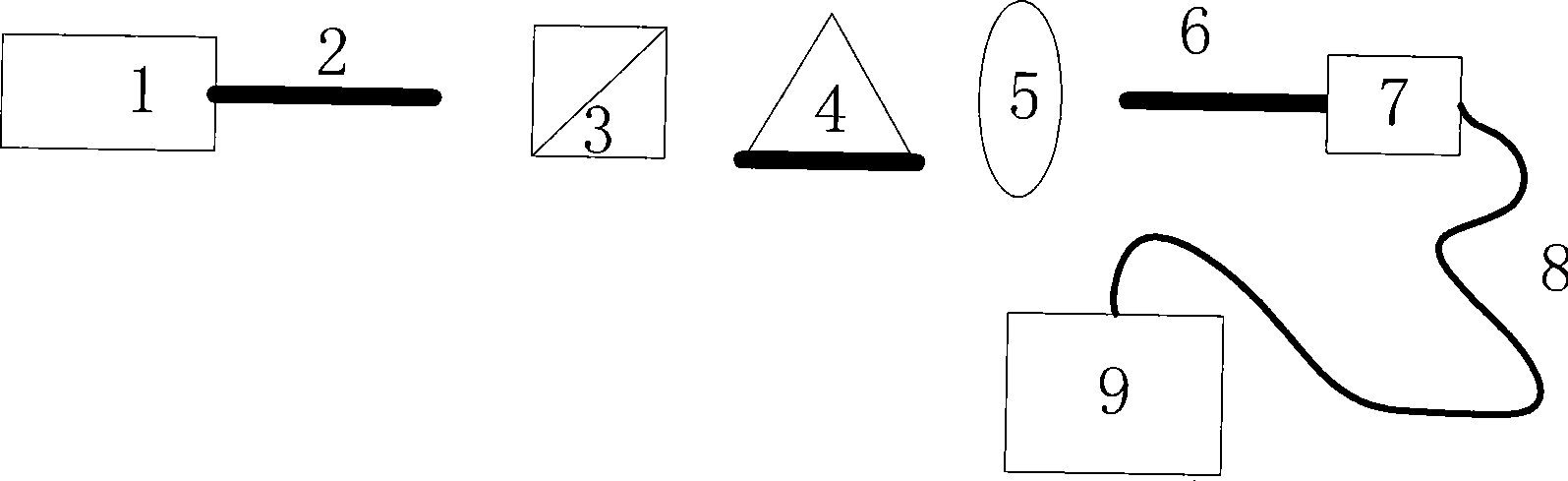

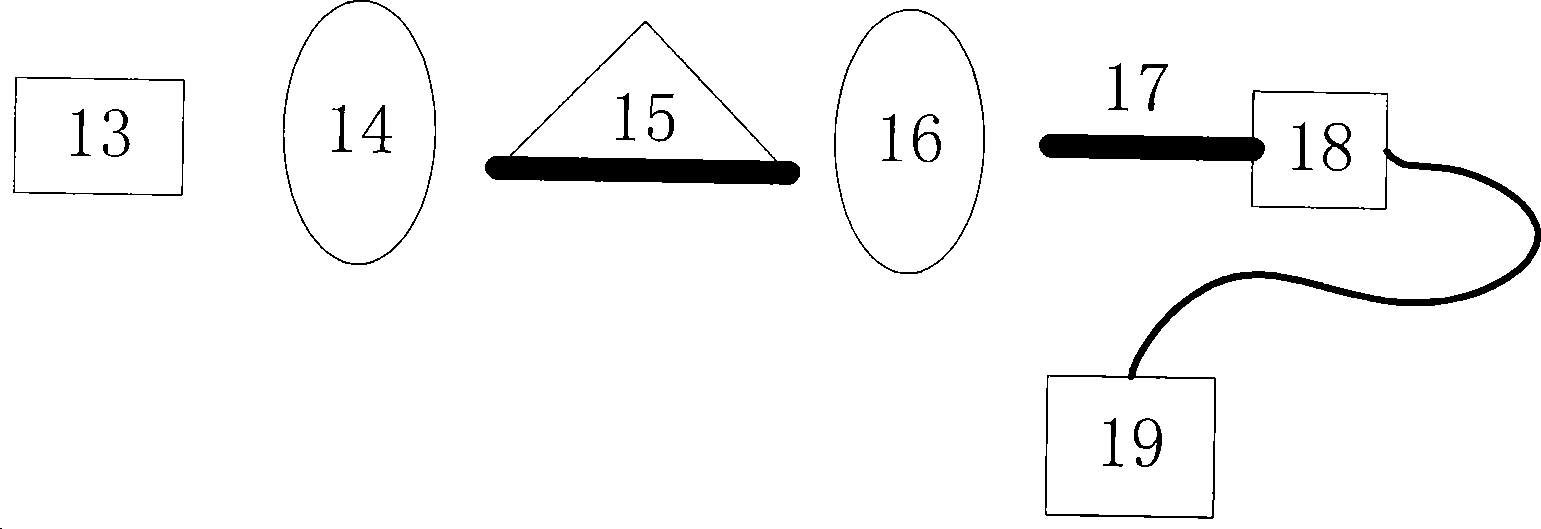

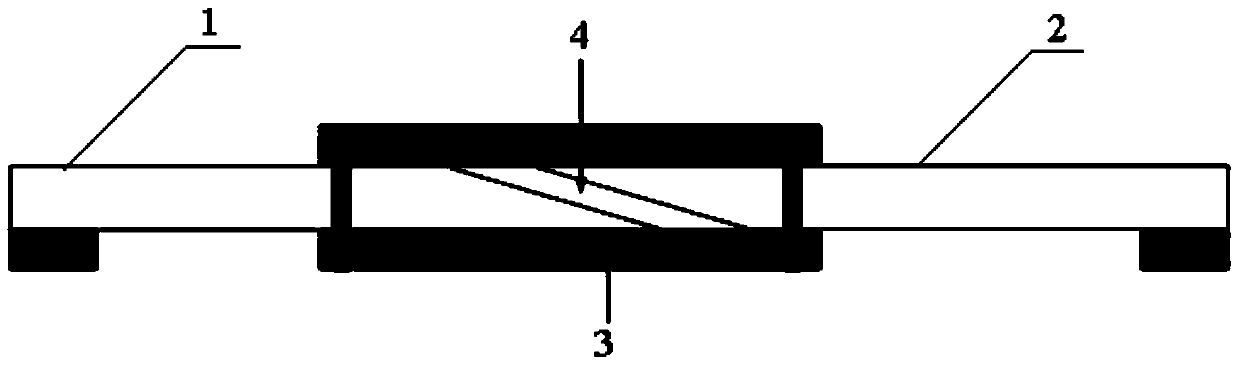

Glass prism SPR sensor detection system based on P polarized light

InactiveCN101477045AImprove throughputHigh sensitivityPhase-affecting property measurementsPrismWavelength modulation

The invention discloses a prism SPR sensor detection system based on P-polarized light, which belongs to the technical field of the prism SPR sensor systems. The prism SPR sensor detection system orderly consists of a light source (1), a multimode optical fiber (2), a prism SPR sensor (4), a convex lens (5), a spectrometer (7) which receives rays transmitted by the convex lens (5) through a multimode optical fiber (6), and a computer (9) connected with the spectrometer (7). The prism SPR sensor detection system is characterized in that a polarization splitting prism (3) with a splitting bandwidth of between 40 and 1000nm is also arranged between the light source (1) and the prism SPR sensor (4). The method ensures that the half-wave widths of resonance wave troughs in a spectrum are reduced, more contributes to the analysis and detection of resonant wavelength parameters in a wavelength modulation method, and is also favorable for improving adhesion phenomenon of various resonance wave troughs of a resonance spectrum detected by a prism distributed measurement system. The prism SPR sensor detection system has the characteristics of simple light path, narrow resonance wave troughs, high detection accuracy, and so on.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Stem cell active factor and lyophilized powder thereof

ActiveCN106344492AHomogeneousIn line with biological characteristicsCosmetic preparationsToilet preparationsGlycineMANNITOL/SORBITOL

The invention relates to a stem cell active factor and lyophilized powder thereof, in particular to a stem cell active factor lyophilized powder on the one hand. The stem cell active factor lyophilized powder comprises a stem cell active factor and a lyophilization protecting agent, and the lyophilization protecting agent is selected from trehalose, mannitol, chitosan, dextran, glycine, arginine and glycine. The invention further relates to a preparation method for preparing the stem cell active factor lyophilized powder. The method has the beneficial effects as described in the specification of the invention.

Owner:BOYALIFE

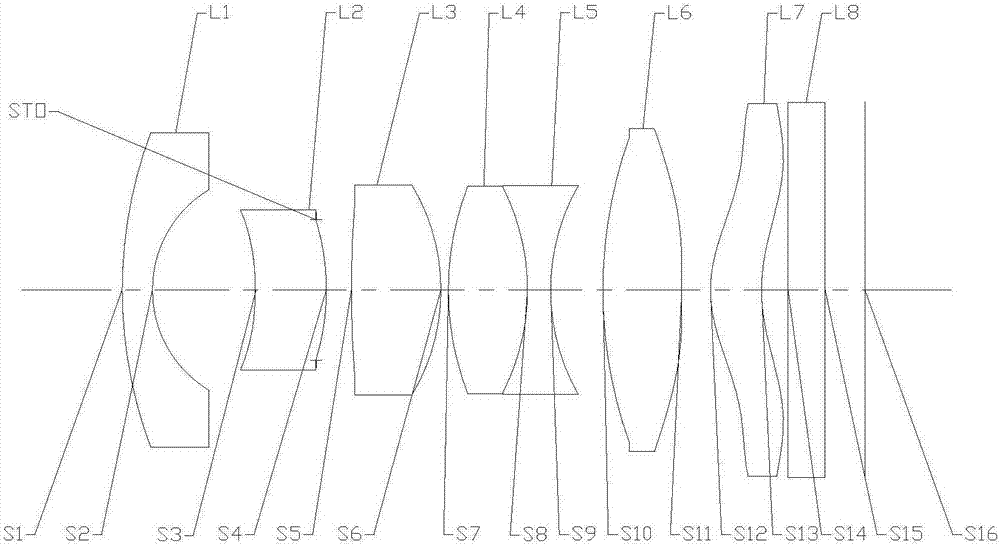

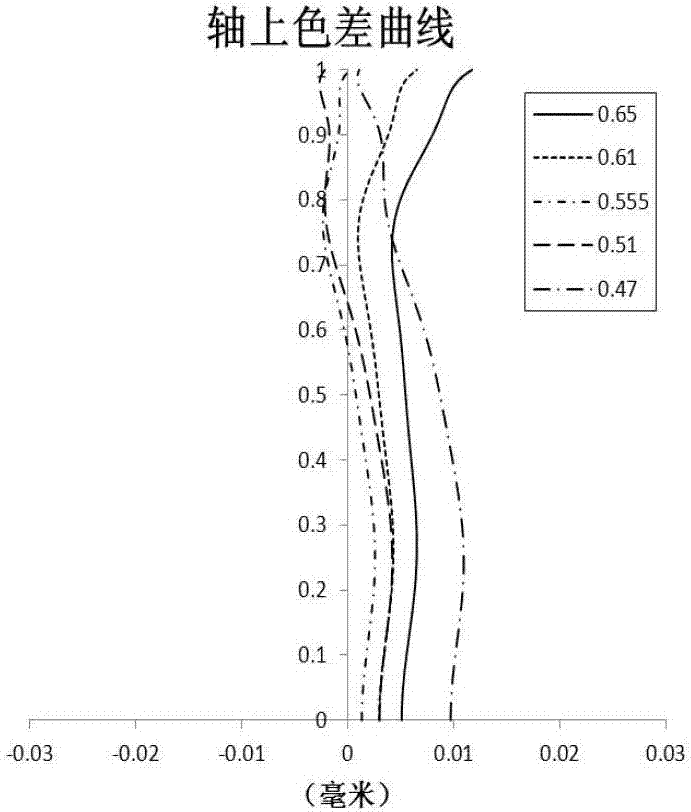

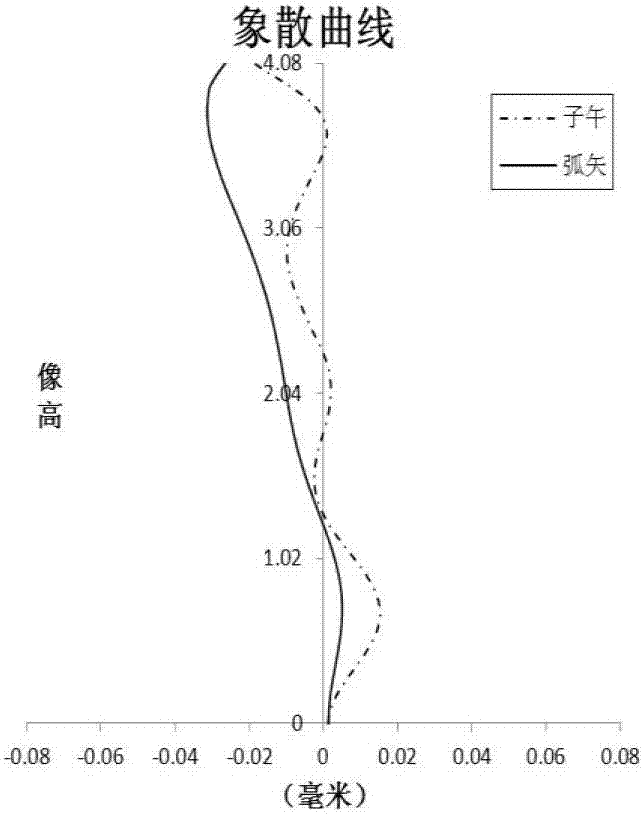

Imaging lens

ActiveCN107065141AReduce Tolerance SensitivityEffective correctionOptical elementsOptical axisImaging lens

The invention discloses an imaging lens, the imaging lens has a total effective focal length f and comprises a fist lens, a second lens, a third lens, a fourth lens, a fifth lens, a sixth lens and a seventh lens which are arranged along the optical axis from the object side to the image side in sequence. The first lens and the fifth lens have negative focal power; the second lens, the fourth lens, the sixth lens and the seventh lens have positive focal power or negative focal power; the third lens has positive focal power, and an effective focal length f3 of the third lens and the total effective focal length f satisfies 1<f3 / f<1.5.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

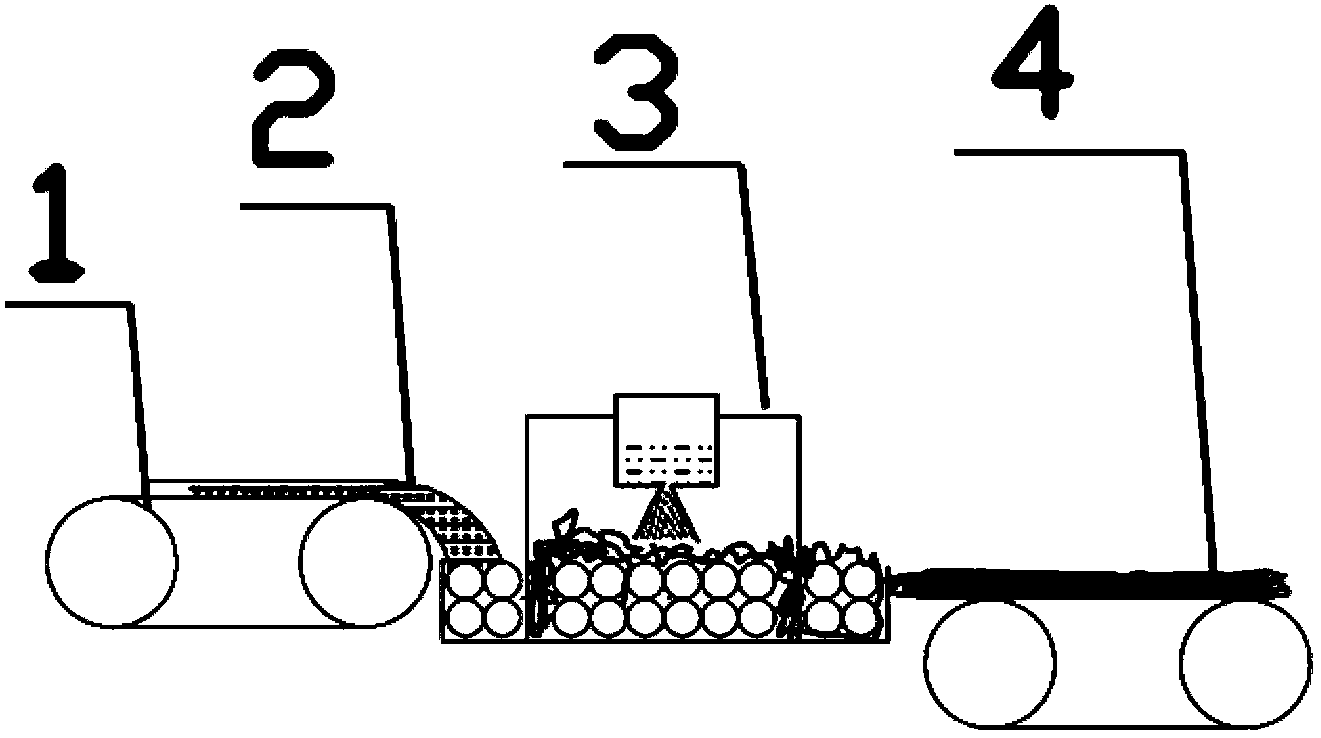

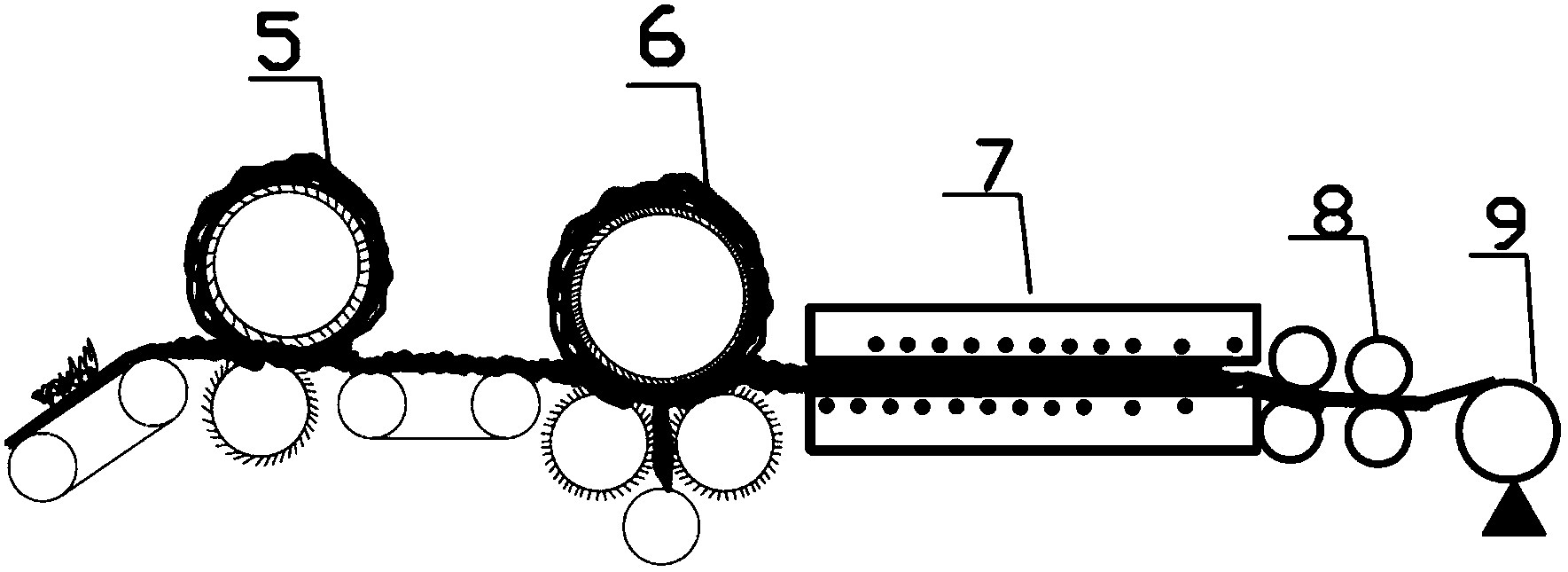

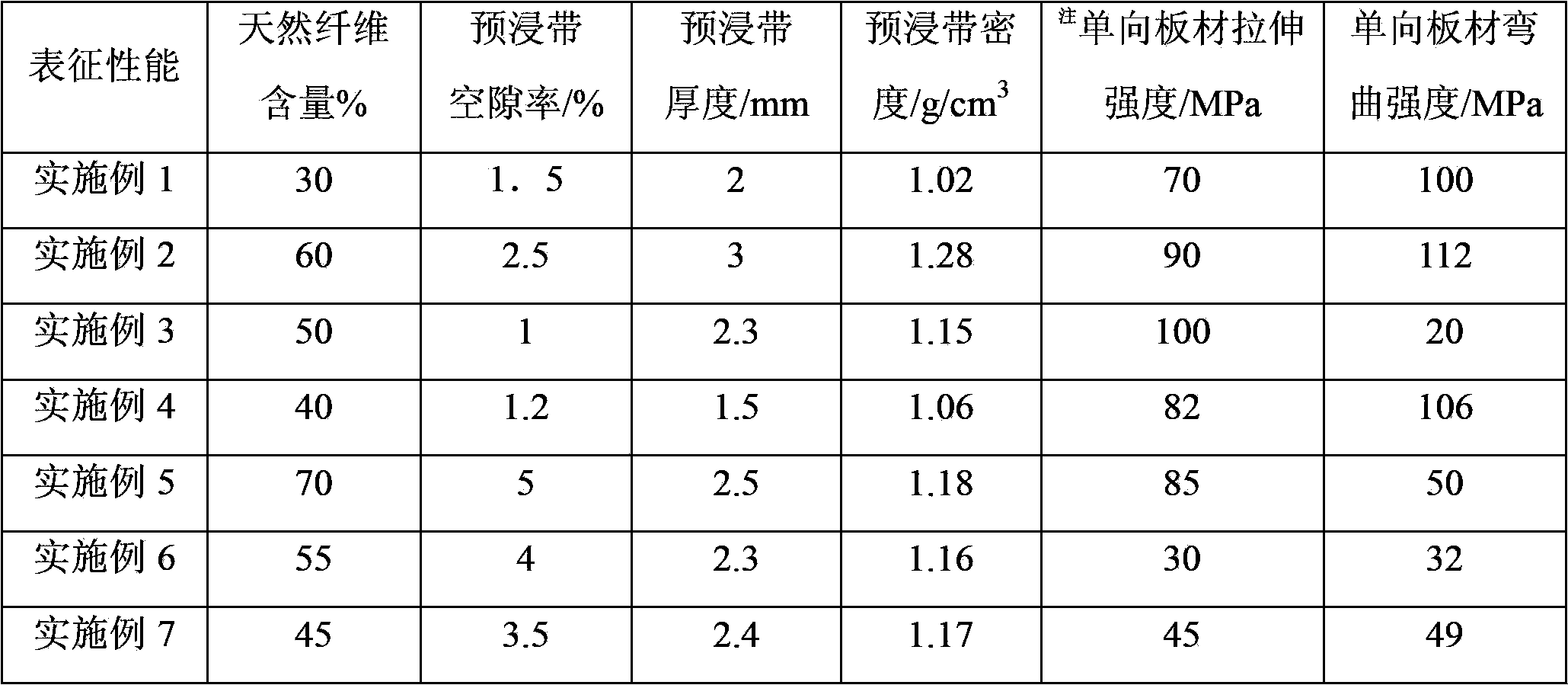

Nature fiber reinforced thermoplastic resin unidirectional prepreg tape and preparation method thereof

The invention belongs to the field of composite material production and preparation, and relates to a fiber reinforced thermoplastic resin unidirectional prepreg tape and a preparation method thereof. The prepreg tape is prepared from the following components, by weight: 30-70 parts of a thermoplastic resin, 30-70 parts of nature fibers, 0-1 part of a coupling agent, and 0-1 part of an emulsion. Compared with the prepreg tape in the prior art, the prepared nature fiber / thermoplastic resin unidirectional prepreg tape of the present invention has the following advantages and beneficial effects that: mechanical strength is high, the prepreg tape can be stored for a long time, the nature fibers are completely impregnated by the resin and are not exposed to the outside so as to maintain the dry state of the material, particularly the nature fibers, the nature fibers are not easily subjected to mildew deterioration, and the porosity is low so as to ensure performance stability of the product. With the method, the width of the reinforcing material and the nature fibers can be limited so as not to cause nature fiber deviation phenomenon during the subsequent production process.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

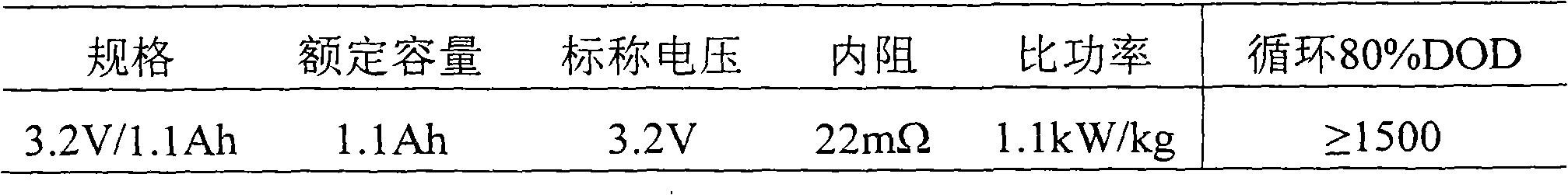

Method for manufacturing gel polymer lithium ion battery

InactiveCN101409366AGuaranteed performance and stabilityReduce side reactions in electrolytesFinal product manufactureSecondary cellsSolventLithium electrode

The invention discloses a manufacture method of a gel polymer lithium ion battery. The active matters of anode slurry are formed by mixing lithium iron phosphate grains with two or more than two grain diameters or shapes; water is used as a solvent for both the anode slurry and cathode slurry; twin planet stirring is adopted, in the mixing method of the anode slurry and the cathode slurry, and primary mixing is carried out 1 to 3 hours; then the mixture is jetted to an ultrasonic mixer by a high pressure pair roller axial extrusion device for carrying out 0.5 to 2 hours of sonic oscillation mixing; a positive plate and a negative plate are coated, dried and then manufactured into the semi-finished product of a lithium battery; after a gel electrolyte precursor is added, a three-section heating polymerizing method is adopted to carry out thermal polymerization on the electrolyte. The manufacture method of a gel polymer lithium ion battery better solves the problem of small areal density of the polar plate of the lithium iron phosphate material; the areal density can be improved by 20 percent and achieve more than 40mg / cm<2>. The air bubble appearing during the traditional slurry mixing process is basically eliminated; the slurry mixing time is shortened; the energy consumption for the working procedure of mixing is reduced and the environment pollution is eliminated.

Owner:JIANGSU SHUANGDENG GROUP

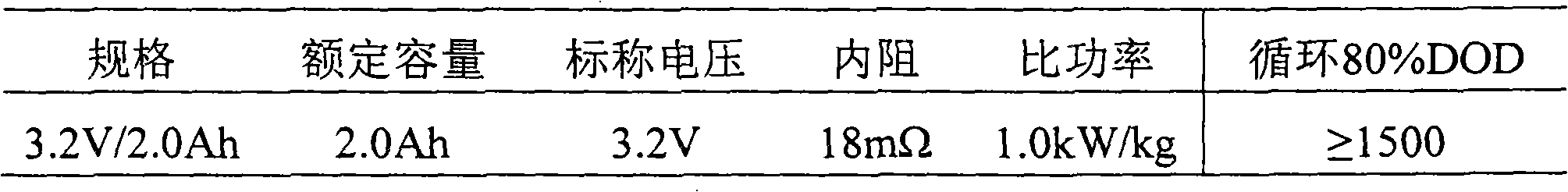

Anti-torsion data power composite cable and manufacturing method thereof

ActiveCN101562062ASimple structureAdvanced technologyPlastic/resin/waxes insulatorsInsulated cablesCapacitanceEngineering

The invention discloses an anti-torsion data power composite cable and a manufacturing method thereof. The composite cable comprises a cable core, an outer jacket, and is provided with a data line core and a power control line core; wherein, the data line core is formed by stranding of quad and positioned in the center of cable, the quad is provided with two insulated cores and drainage lines, and wounded and wrapped with a plastic-aluminum composite strip sub-shielding layer, the data line core is provided with a main shielding layer, the power control line core is formed in a manner that multi-assemble reinforced cores are mounted on the periphery of the data line core, the data line core and the cable core are provided with a composite cushion layer respectively. The invention has the advantages of simple and reasonable structure, advanced technique, high mechanical strength of products, low capacity and low attenuation. The invention is also characterized by strong anti electromagnetic interfere property, shock resistance, fine torsion bending resistance property, oil proofness, chemical solvent resistance, hard wearing, high / low temperature resistance, water erosion resistance, environmental leaching and loss resistance, ensuring stable property of cables in various severe environments so that cable property is reliable and safe.

Owner:BAOSHENG SCI & TECH INNOVATION

WC particle reinforced composite brazing filler metal used for brazing hard alloy and preparation method thereof

ActiveCN104191099AMix well and evenlyGuaranteed mechanical propertiesWelding/cutting media/materialsSoldering mediaSmelting processCemented carbide

The invention provides WC particle reinforced composite brazing filler metal used for brazing hard alloy and a preparation method thereof, and relates to a brazing material and a preparation method thereof. The invention aims to solve the technical problems that a hard alloy brazed joint is easy to wear, relatively low in working strength and poor in wettability. The brazing filler metal provided by the invention is prepared from Al, Ti, Ni, W, Co, Cr, B, Fe, Si powder and WC particles. The preparation method comprises the following steps of weighing of raw materials, mechanical alloying of composite brazing filler metal, smelting and preparing of composite brazing filler metal foils. After going through a ball-milling process, a high-temperature smelting process and an ultrasonic vibrating process, the WC particles generate obvious refining behaviors, so that the dispersivity of WC particle reinforced phases in a brazing filler metal substrate is better, the uniformity of the whole brazing filler metal is improved, and therefore the performance stability of the brazing filler metal is ensured. The invention belongs to the field of brazing filler metal preparation.

Owner:哈尔滨瀚霖科技开发有限公司

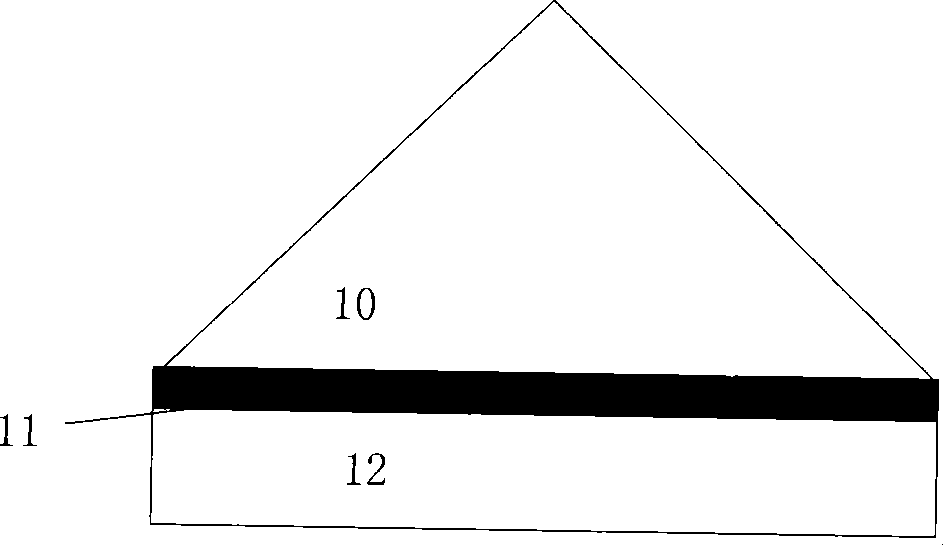

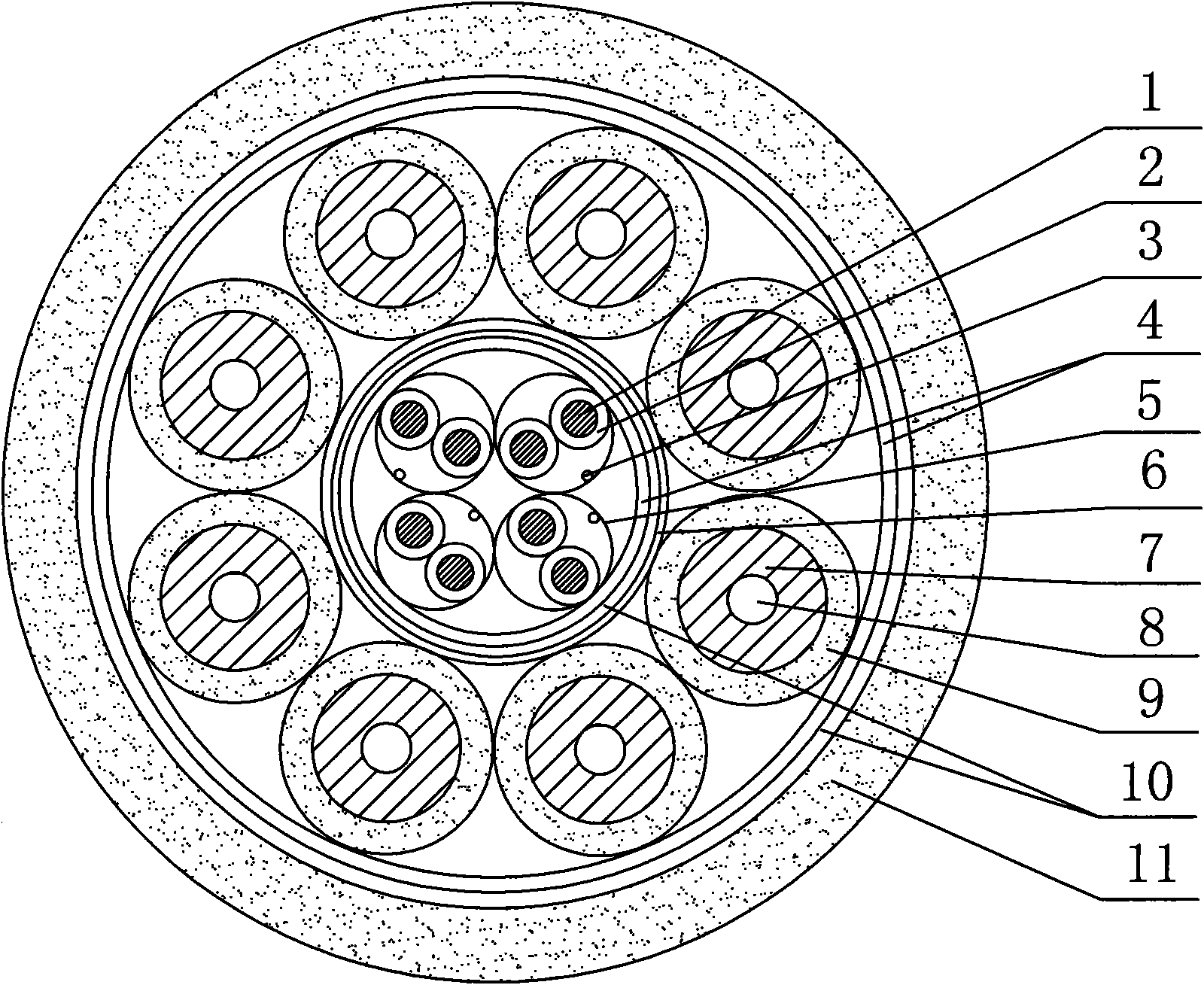

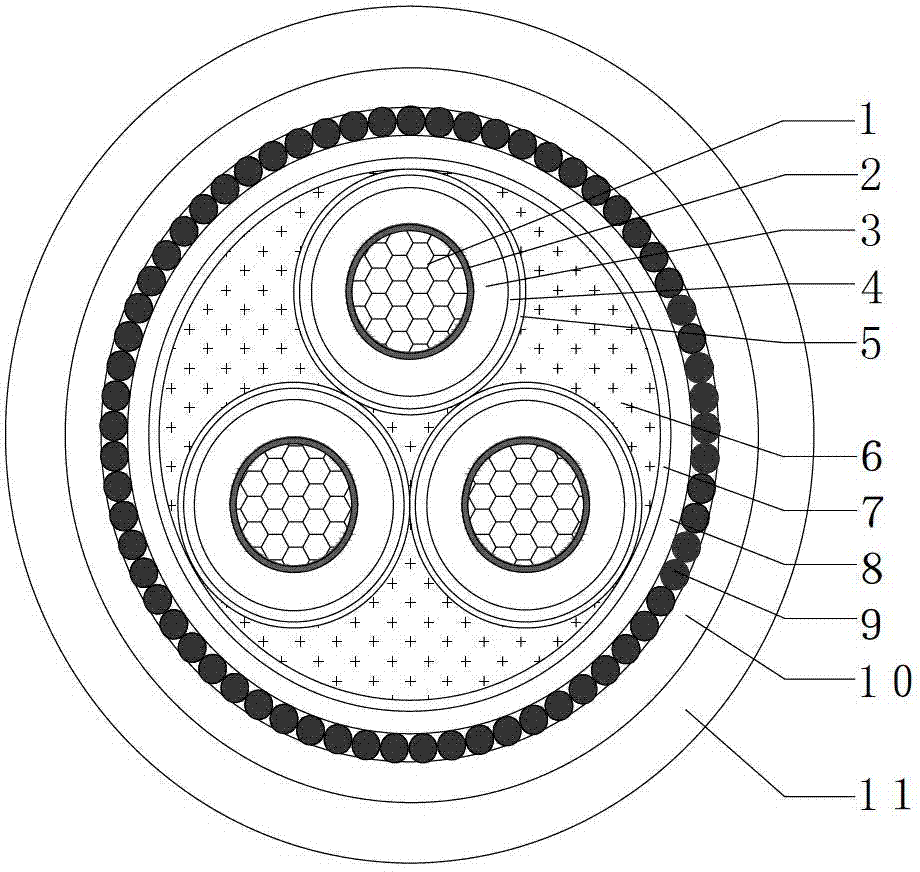

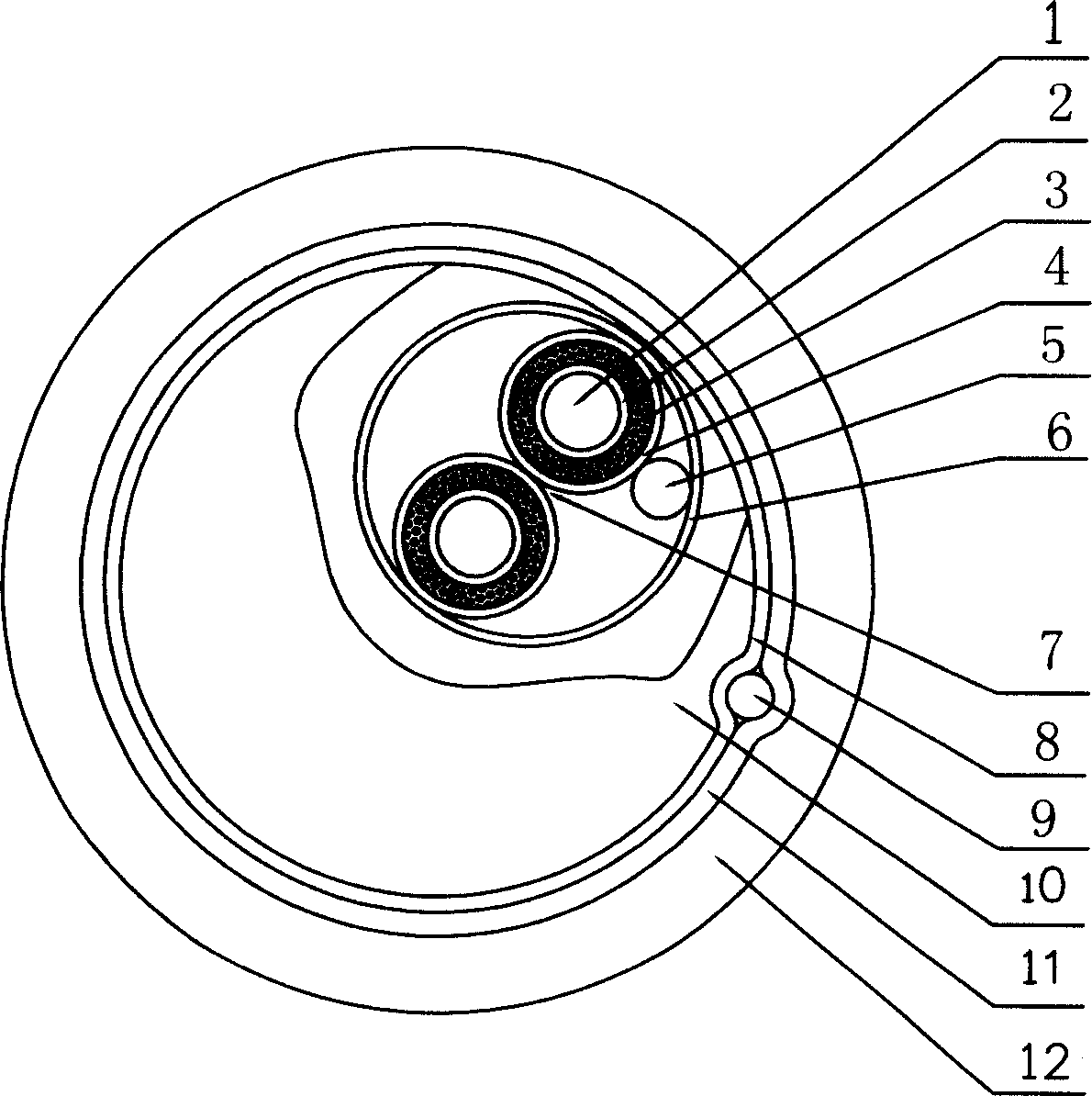

Waterproof greasy-dirt-resisting 10 kV middle-voltage transducer cable and method

ActiveCN102969069AWaterproofWaterproof and oil-resistantPower cables with screens/conductive layersCable/conductor manufactureElectrical conductorLow voltage

The invention relates to a waterproof greasy-dirt-resisting 10 kV middle-voltage transducer cable and a method. The waterproof greasy-dirt-resisting 10 kV middle-voltage transducer cable is characterized by consisting of a conductor 1, a conductor shield 2, a cross linked polyethylene insulating layer 3, an insulating shielding layer 4, a split-phase shielding layer 5, a filling waterproof rope 6, a lapping waterproof belt 7, an insulation sleeve 8, a combined shielding layer 9, an aluminum plastic adhesion comprehensive protection layer 10 and a butyronitrile compound outer casing layer 11. The manufacturing process comprises the following steps of: (1) pulling by a single line and annealing; (2) twisting and pressing; (3) carrying out co-extrusion insulation on the conductor shielding layer, the insulating layer and the insulating shielding layer; (4) mounting the split-phase shielding layer; (5) carrying out a partial discharge test; (6) cabling; (7) mounting the insulation sleeve; (8) mounting the combined shielding layer; (9) mounting the aluminum plastic adhesion comprehensive protection layer; and (10) mounting the butyronitrile compound outer casing layer. According to the waterproof greasy-dirt-resisting 10 kV middle-voltage transducer cable provided by the invention, the insulation core wire gives up the 3+3 design normally used in a low-voltage transducer and uses a concentric conductor structure; the shielding layer uses two types including split-phase shielding and combined shielding; and a double-layer combined protection structure consists of a waterproof layer and a greasy dirt layer.

Owner:南洋电缆集团泰州有限公司

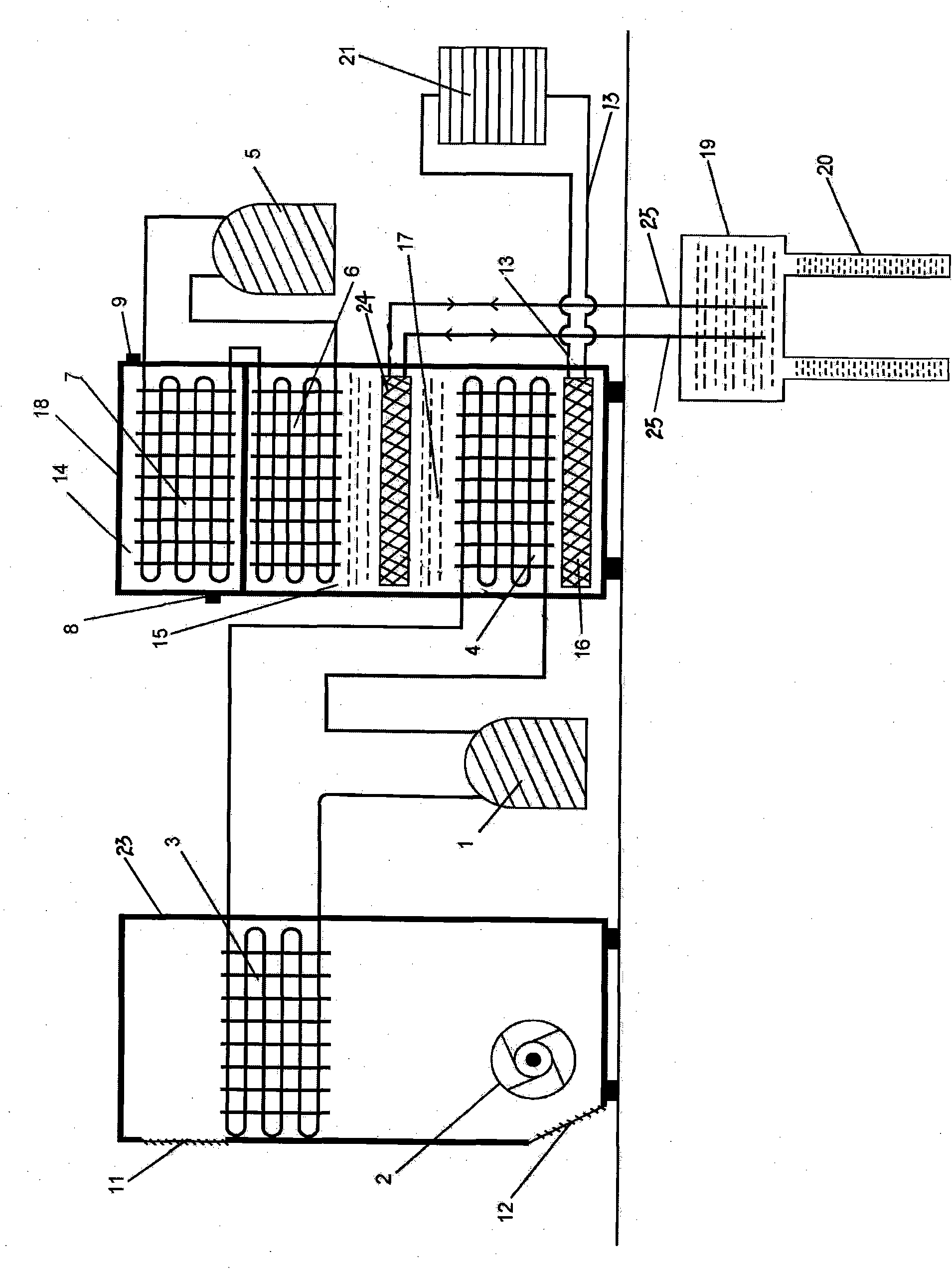

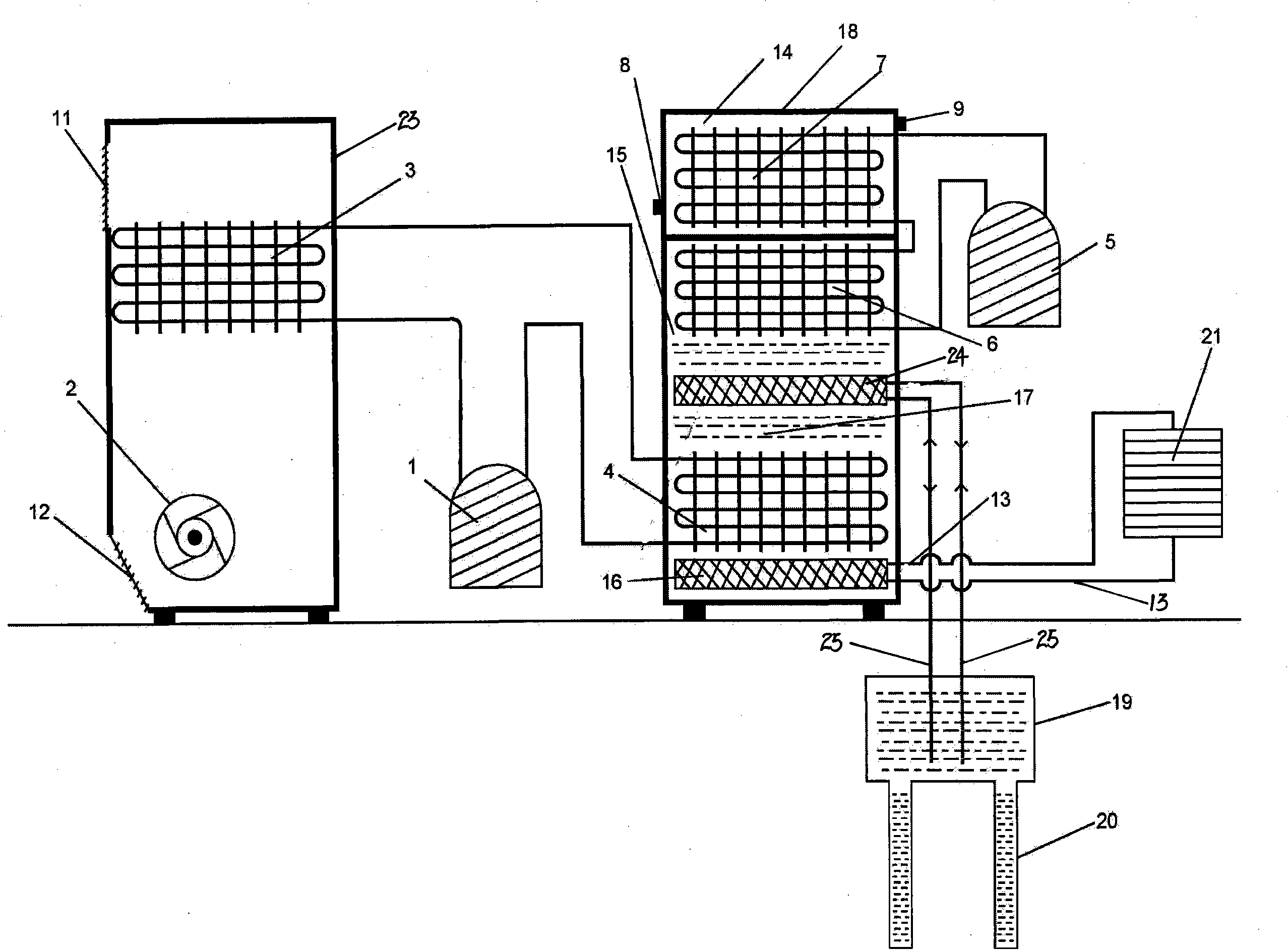

Water-cooled air conditioning and water heating system

InactiveCN101858669AReduce power consumptionAvoid dirtSolar heating energyOther heat production devicesEngineeringAir conditioning

The invention discloses a water-cooled air conditioning and water heating system. The system comprises an indoor heat exchanger, an outdoor heat exchanger, a condenser, an evaporator, a compressor, an engine block and an air conditioning accessory, wherein the engine block comprises an outdoor unit and an indoor unit; the compressor comprises an air conditioning compressor and a hot water compressor which are both positioned outside the engine block; the indoor heat exchanger is positioned in the indoor unit and communicated with the indoor environment; the outdoor heat exchanger, the condenser and the evaporator are positioned in the outdoor unit; the outdoor unit is partitioned into a heat exchange water tank and a hot water tank; the condenser is positioned in the hot water tank; both the outdoor heat exchanger and the evaporator are positioned in the heat exchange water tank; the indoor heat exchanger, the outdoor heat exchanger, the air conditioning compressor and the air conditioning accessory are connected through pipelines to form a set of circulating pipeline; and the condenser, the evaporator and the hot water compressor are connected through the pipelines to form another set of circulating pipeline. By taking water as a heat exchange medium, the system fulfils the aim of energy saving; and the system further comprises a renewable energy resource heat exchange device so as to realize high-efficiency mutual conversion among solar energy, a geothermal (cold) source and air energy and continuous recycling.

Owner:河源普天能源科技有限公司

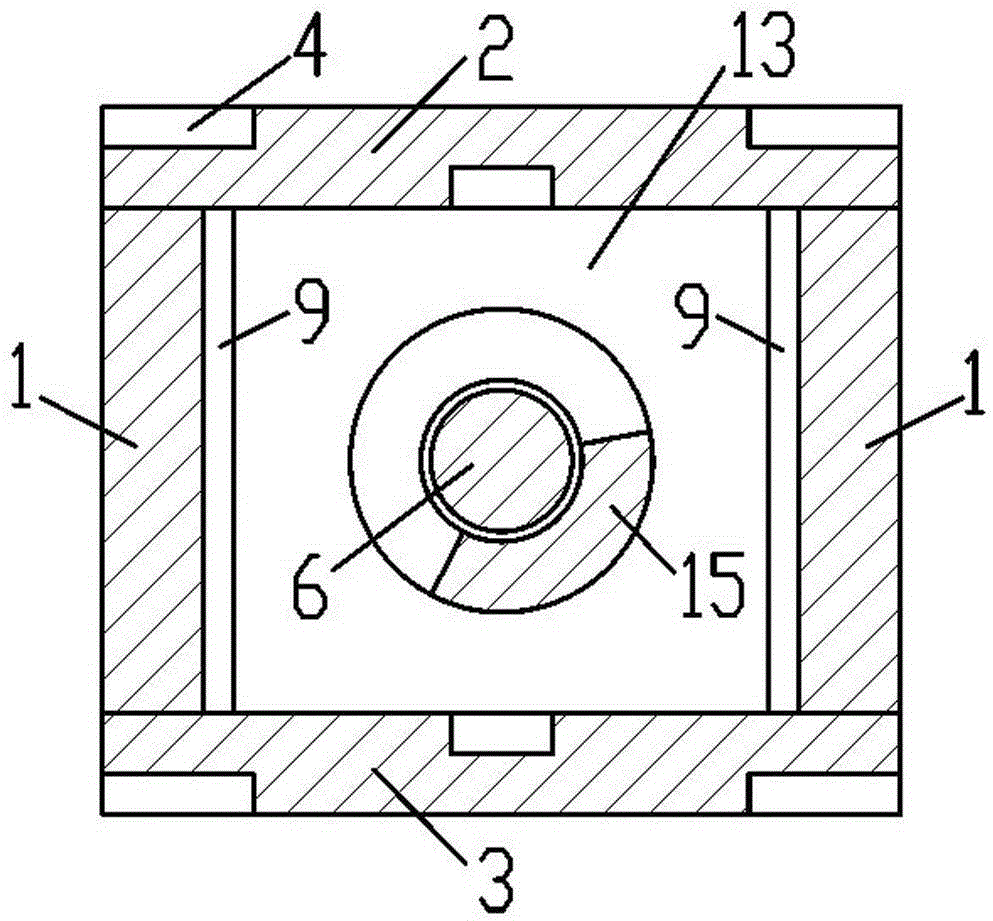

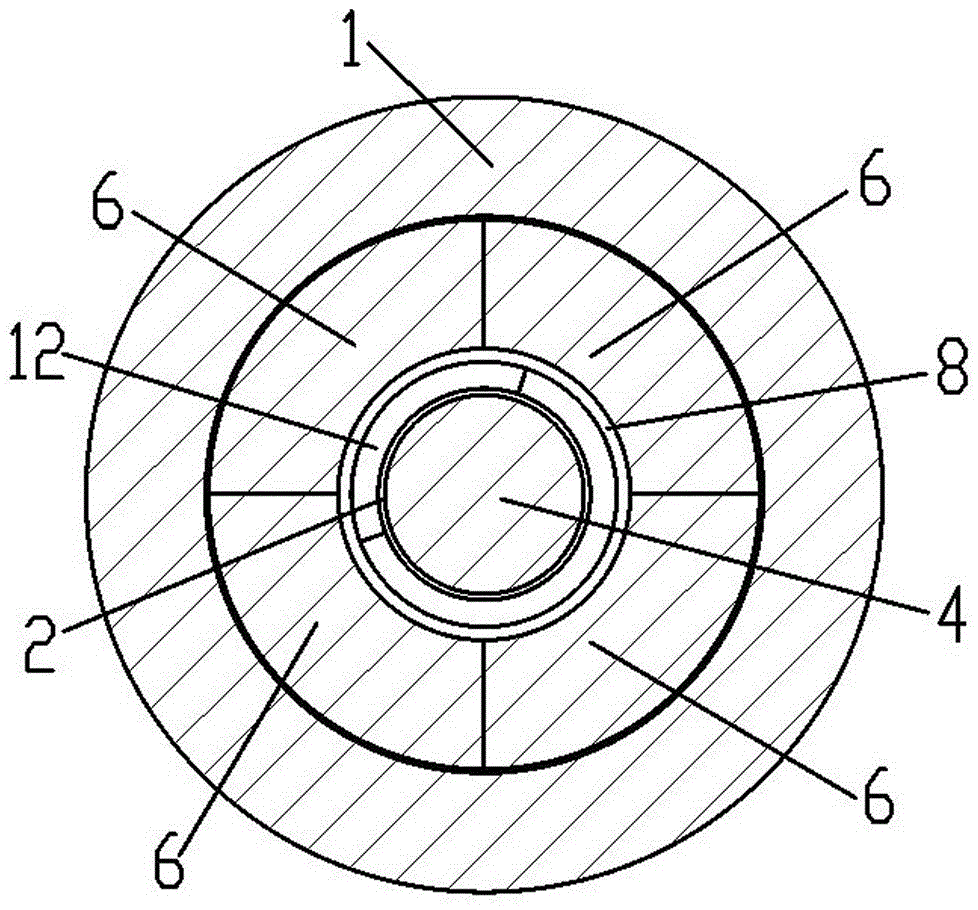

Dual-compressed-spring flat plate type-centripetal variable friction damper

InactiveCN105387115AGuaranteed performance and stabilityLow costShock absorbersViscous dampingClassical mechanics

The invention relates to a dual-compressed-spring flat plate type-centripetal variable friction damper which comprises two friction plates, two fixed plates, two end plates, a positioning plate, wedge sliding friction blocks, an extrusion wedge block, a middle connecting shaft and two compressed springs. The two friction plates, the two fixed plates, the two end plates and the positioning plate form a plate-type cavity. A variable friction device is arranged inside the cavity. The variable friction device is composed of a pair of friction assemblies, the pair of compressed springs and the middle connecting shaft. Each wedge sliding friction block comprises a friction face and two slopes. The extrusion wedge block comprises an upper slope and a lower slope. The extrusion wedge block with the two opposite slopes and the two wedge sliding friction blocks form one friction assembly. The damper has the advantage of complex damping, the complex damping force linearly changes along with transformation amplitude, viscous damping force linearly changes along with deformation velocity, a friction interface is stable in performance, and the cost performance is better.

Owner:BEIJING UNIV OF TECH

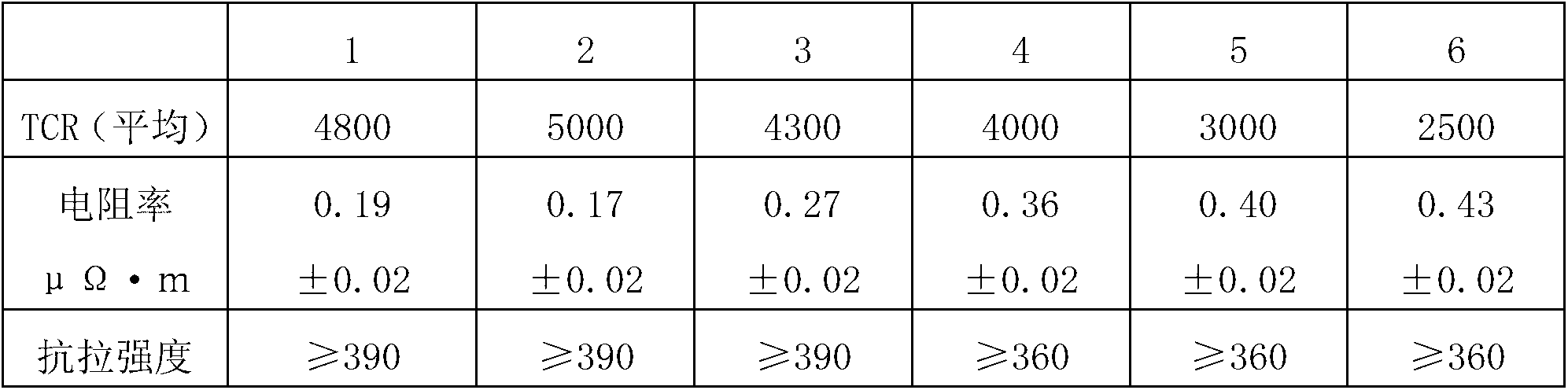

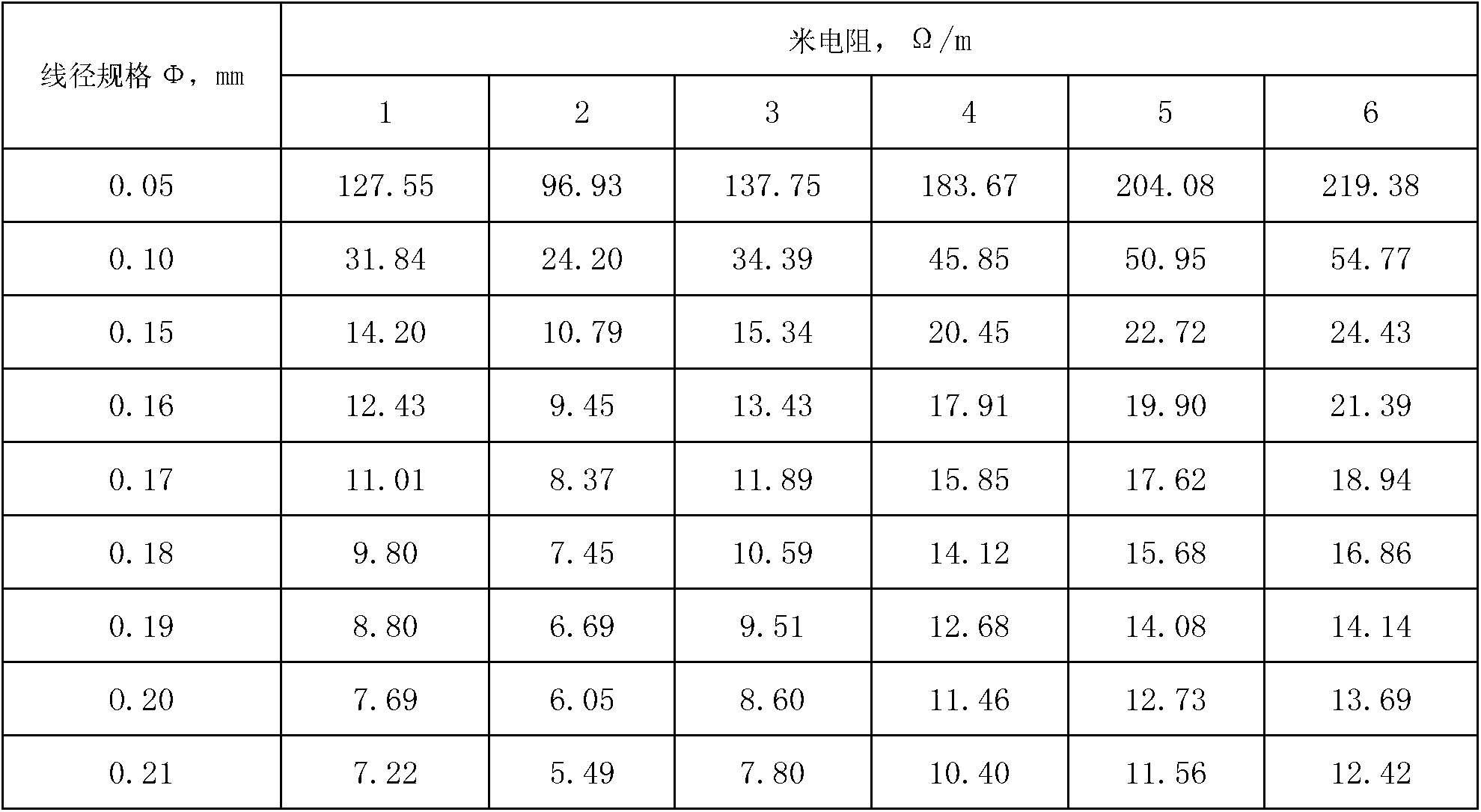

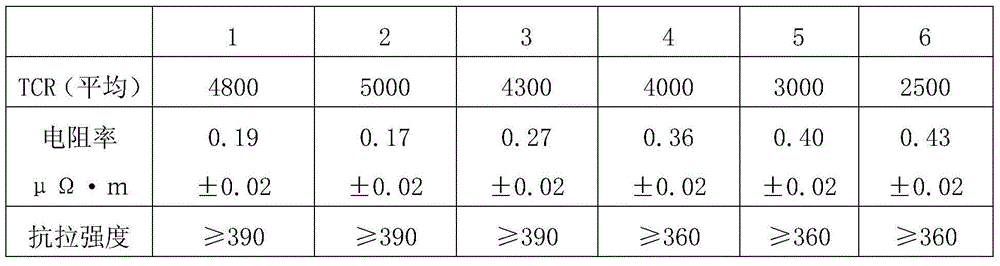

Positive temperature coefficient (PTC) thermal resistance alloy wire and preparation method thereof

ActiveCN103060615AMeet requirements such as more sensitive temperature controlExtended service lifePositive temperature coefficient thermistorsProcess efficiency improvementMisch metalRare earth

The invention discloses a positive temperature coefficient (PTC) thermal resistance alloy wire and a preparation method thereof. The alloy wire comprises the chemical ingredients by weight percent of 45-82.0% of nickel, 0.1-0.6% of silicon, 0.22-0.35% of manganese, 0.02-0.04% of yttrium, 0.04-0.06% of misch metal, 0.05% or less of carbon, 0.01% or less of sulphur, 0.001% or less of phosphorus and the balance of iron. The mean resistance temperature coefficient at 0-150 DEG C is 2500*10(-6) per DEG C to 5000*10(-6) per DEG C by changing the matching content of the components; the PTC thermal resistance alloy wire of which the resistance temperature coefficient which is urgently needed at present and higher than 3000*10(-6) per DEG C is included; the highest mean resistance temperature coefficient can be 5000*10(-6) per DEG C, and the requirements of more sensitive temperature control of novel electrical equipment can be met.

Owner:JIANGSU HUAXIN ALLOY

Magnetic ink and preparation method for ink-jet printing flexible electromagnetic wave absorption film

The invention discloses magnetic ink, and relates to an electronic material technology. The magnetic ink comprises a solvent and a solute, wherein the solvent consists of ethanol, isopropanol and deionized water in a volume ratio of A: B: C, wherein A is more than or equal to 1 and less than or equal to 4, B is more than or equal to 1 and less than or equal to 3, and C is more than or equal to 6 and less than or equal to 12; the solute comprises nano magnetic granules, dispersant, connecting agent, surfactant, wetting agent and defoaming agent; the mass ratio of the nano magnetic granules to the dispersant is x: y, wherein x is more than or equal to 4 and less than or equal to 25, and y is more than or equal to 1 and less than or equal to 3; the ratio of the solvent: the connecting agent: the surfactant: the wetting agent: the defoaming agent is a: b: c: d: e, wherein a is more than or equal to 86.95 and less than or equal to 99.199, b is more than or equal to 0.3 and less than or equal to 5, c is more than or equal to 0.5 and less than or equal to 5, d is more than or equal to 0 and less than or equal to 3, and e is more than or equal to 0.001 and less than or equal to 0.05; and the ratio of the mass of the nano magnetic granules to the volume of the solvent is 0.002 to 0.02 gram per milliliter. The method realizes low-cost production of the large-area electromagnetic wave absorption film and preparation of flexible wave absorption films with high output graph precision, clear graph boundary, uniform distribution and various complex components and images.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

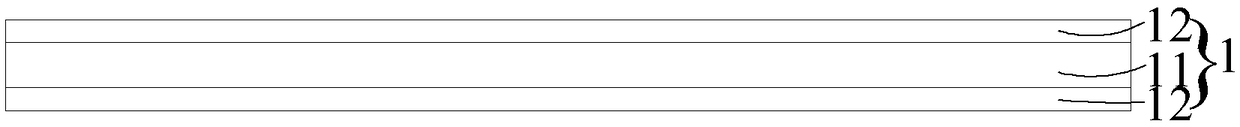

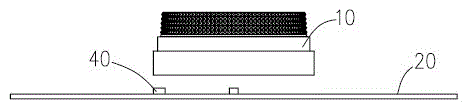

Novel aramid-paper-based copper-clad plate and preparation method thereof

InactiveCN109082944AImprove conductivityHigh peel strengthSpecial paperPaper/cardboardPaper basedThermal expansion

The invention relates to the technical field of copper-clad plates, in particular to a novel aramid-paper-based copper-clad plate and a preparation method thereof. The novel aramid-paper-based copper-clad plate comprises a substrate and copper foil and is characterized in that the substrate is formed by stacking a plurality of prepregs, and the copper foil is stacked to at least one surface of thesubstrate; each prepreg comprises modified para-position aramid paper and resin composite layers stacked to at least one surface of the aramid paper; the copper foil is adhered to the surface of theresin composite layers through glue. The aramid-paper-based copper-clad plate is good in stripping strength, small in density, excellent in dielectric property and thermal expansion coefficient, and the good thermal conductivity of the aramid-paper-based copper-clad plate can greatly expand the application range of the copper-clap plate.

Owner:LONGPONT

Knob

InactiveCN102722214AExtended service lifeGuaranteed performance and stabilityControlling membersEngineeringElectrical and Electronics engineering

The invention relates to a knob, which comprises an operation cap, a circuit board arranged behind the cap, a plurality of magnetic particles, and a plurality of magnetic sensors, wherein the magnetic particles basically adopt a rotating center of the operation cap as a circular center and are uniformly and fixedly arranged on an inner side of the operation cap; and the magnetic sensors also basically adopt the rotating center of the operation cap as a circular center and are arranged on the circuit board. When the operation cap is rotated, the magnetic particles are rotated along with the rotation of the operation cap; and the magnetic sensors are used for sensing magnetic field variation generated when the magnetic particles are rotated. Physical independence, i.e. non-contact is realized between an operation structure of the knob and an operation signal receiving device; the defect of physical abrasion caused by physical contact can be overcome; and the service life of the knob is prolonged, and the performance stability of industry is ensured. In addition, the knob is flexible, the operation feel cannot be affected by the receiving device, the positioning requirement of product assembly is reduced, and the productivity is improved.

Owner:HUIZHOU DESAY SV AUTOMOTIVE

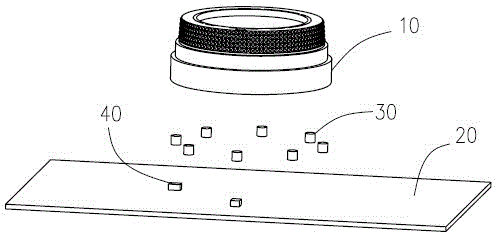

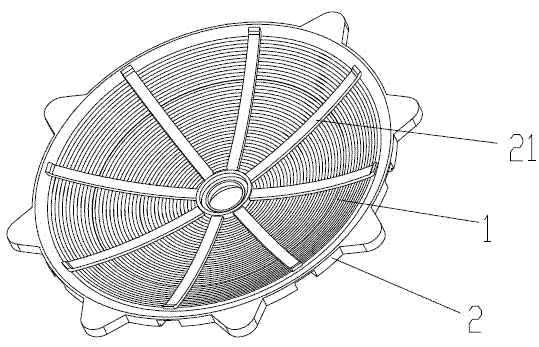

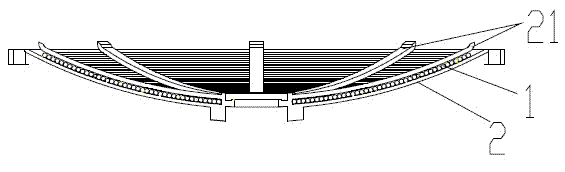

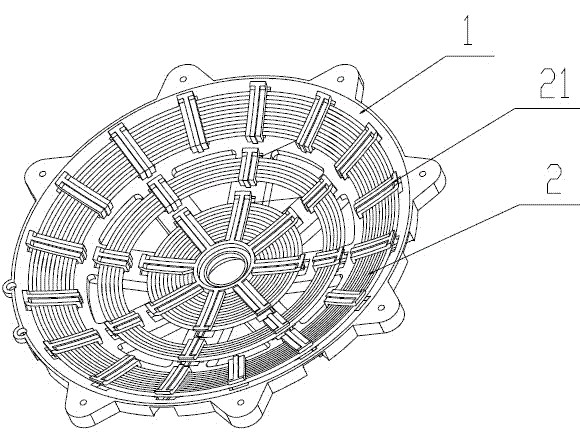

Coil disc of electromagnetic oven

ActiveCN102523643AGuaranteed performance and stabilityImprove performanceCoil arrangementsCoil procedureEngineering

The invention discloses a coil disc of an electromagnetic oven, comprising a coiling bracket and coil windings arranged on the coiling bracket, wherein the coiling bracket is provided with a plurality of wire buckles which are distributed in a ring shape and are convenient for winding fixed enamelled wires; and the coil windings are formed by winding of the enamelled wires which penetrate through the wire buckles distributed in a ring shape. The coil disc is characterized in that due to adoption of the structure with wire buckles, adhesive-less winding on the coiling bracket can be realized, and no matching of a coiling mold is needed, so that the coiling procedure is greatly simplified, the safe and convenient effects are achieved, the production efficiency is improved and the manufacturing cost is saved. Especially for multiple circles of windings, the coil disc can realize accurate coiling of multiple windings and ensures that the distance among wire rings is constant all the time, thus ensuring the performance stability of the coil disc in batch production. According to the coil disc, not only can the manual fast and accurate coiling be realized and is the operation simple and convenient, but also the high-speed coiling also can be realized by matching of simple mechanical equipment, and the requirement for corresponding equipment is lower, the production efficiency is greatly improved and the manufacturing cost is reduced. The coil disc is ingenious in design and is convenient and practical.

Owner:MIDEA GRP CO LTD

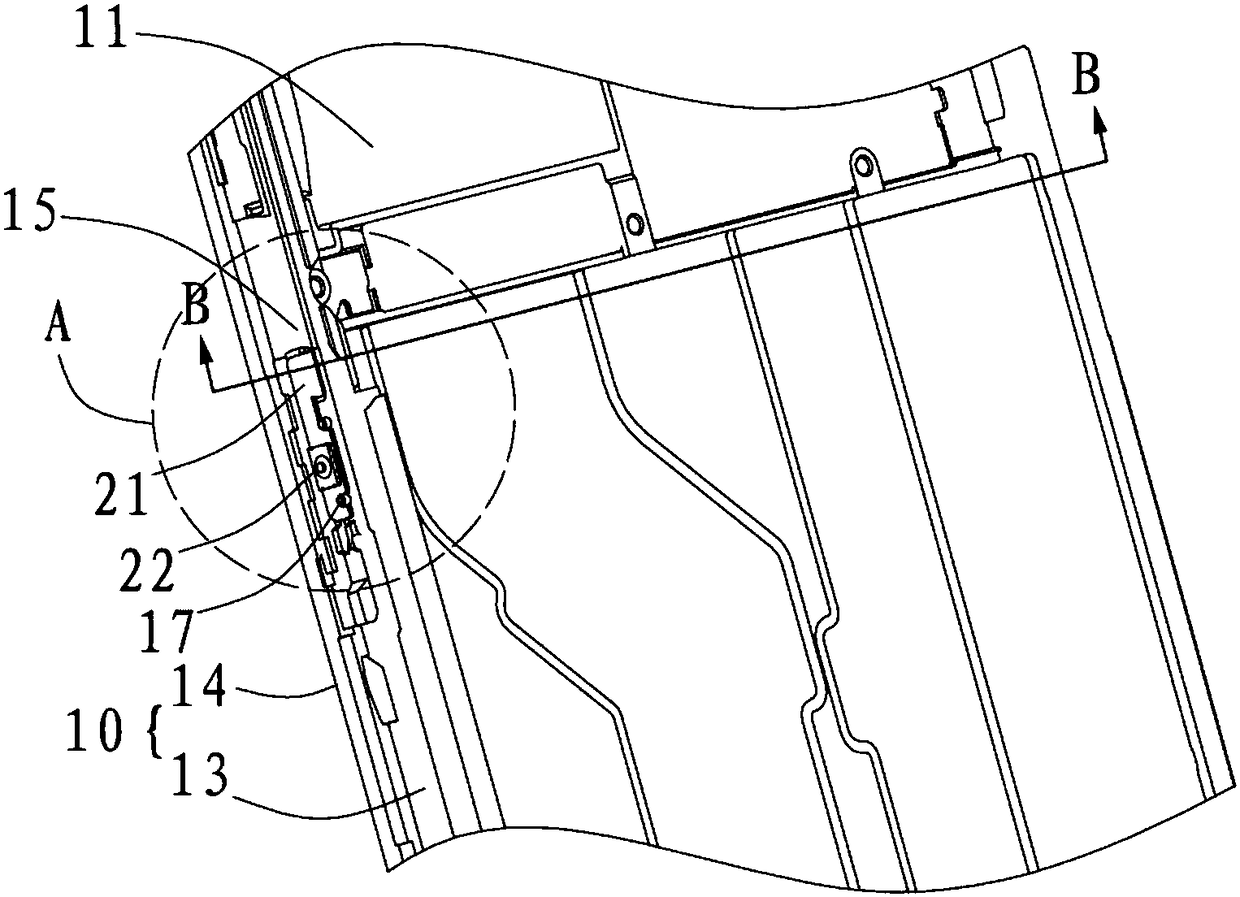

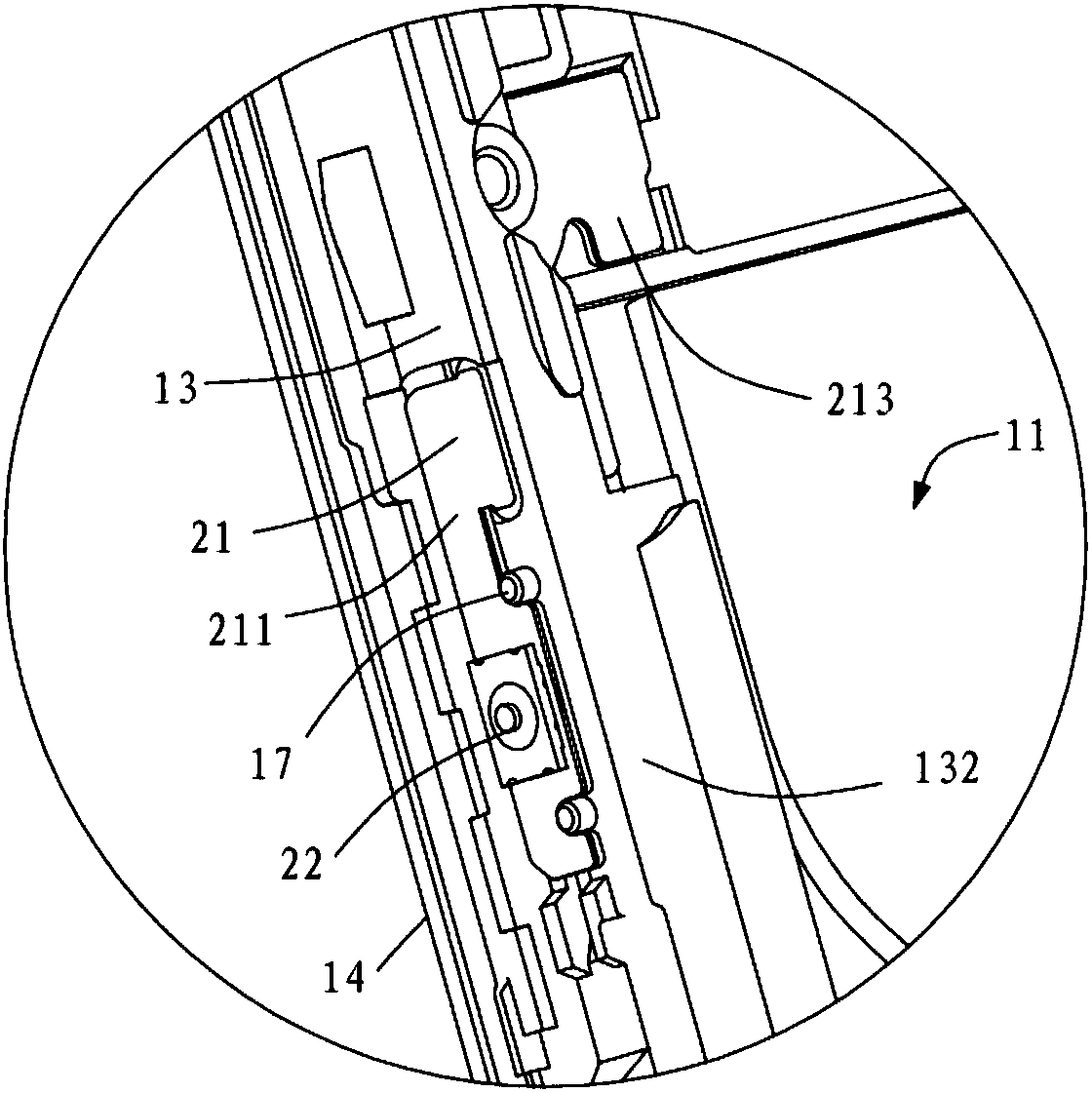

Electronic device

InactiveCN108512971AImprove sealingImprove waterproof performanceTelephone set constructionsFlexible circuitsElectronic equipment

The invention provides an electronic device. The electronic device comprises a front housing and a key assembly, wherein a containing cavity is formed in the front housing, the front housing is provided with a through hole, and the through hole is communicated with a containing cavity; the key assembly comprises a flexible circuit board, a key and a sealing element, wherein the flexible circuit board comprises a first section, a second section and a third section which are connected in sequence; the first section is arranged on one side, deviating from the containing cavity, of the front housing; the key is fixed on the first section and electrically connected with the first section, and the second section is contained in the through hole; the sealing element is sealed between the second section and the inner peripheral wall of the through hole, and the third section is contained in the containing cavity. The electronic device has better waterproof performance.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Environment protection digital type high-precise meter cable

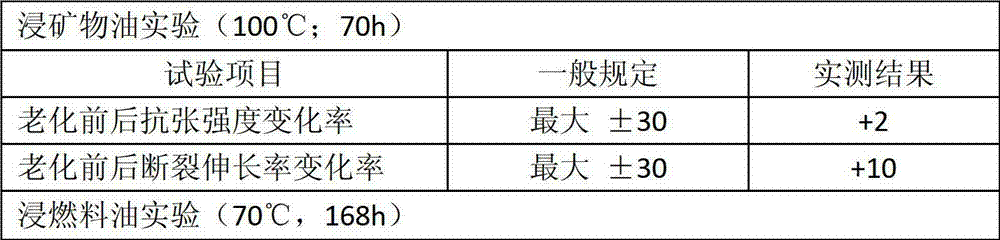

InactiveCN1687997AGuaranteed performance and stabilityOil resistantInsulated cablesInsulated conductorsElectrical conductorInsulation layer

This invention relates to a data precision instrument cable. An insulation layer of expanded PE material in skin-foam-skin co-extrusion is set on the conductor to form a core of the cable, multiple pair-groups of pair wires with pair twist screen layers are set in the core, each set wire is set with a conduction wire, the cable core is set with a gird, a general screen layer and an outer sheathing are set on it orderly and a conduction lead is set between them.

Owner:BAOSHENG SCI & TECH INNOVATION

Natural fiber composite board, and manufacturing method and application thereof

InactiveCN103849019AAdjustable longitudinal lengthMeet the length requirementVegetal fibresNatural fiberUltimate tensile strength

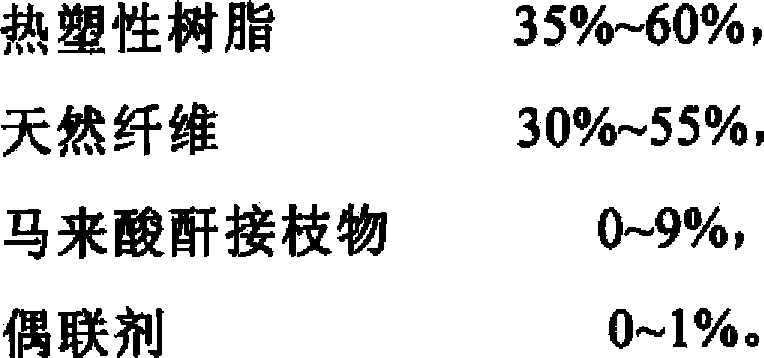

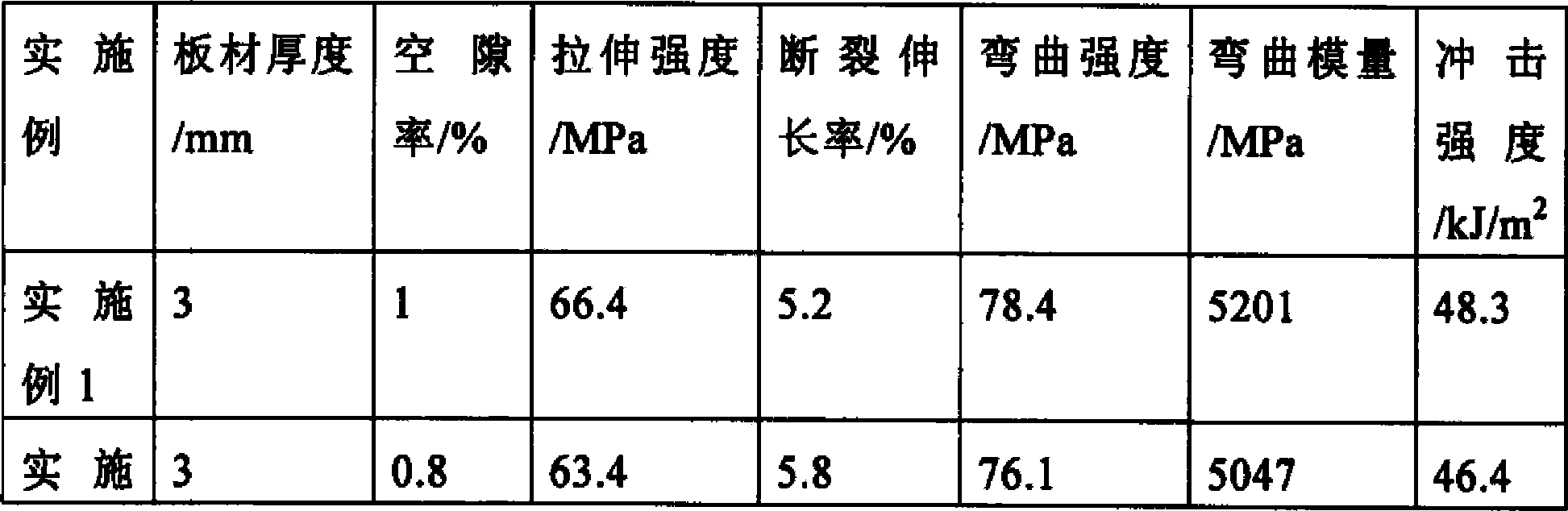

The invention relates to a natural fiber composite board and a manufacturing method and application thereof. The natural fiber composite board is prepared from the following raw materials by weight: 35 to 60% of a thermoplastic resin, 30 to 55% of a natural fiber, 0 to 9% of maleic anhydride graft and 0 to 1% of a coupling agent. The procedures consisting of mixing, washing and starching, weaving, desizing and hot pressing are carried out so as to form a natural fiber reinforced thermoplastic resin board which is used for manufacturing of a mobile phone protective shell, an IPAD shell, a musical instrument, a box or a helmet. Compared with the prior art, the natural fiber composite board provided by the invention has the advantages of great strength, stable performance, effectively controllable thickness direction, etc.

Owner:HEFEI GENIUS NEW MATERIALS

On-line spray descaling method and system for diesel engine exhaust gas recirculation cooler

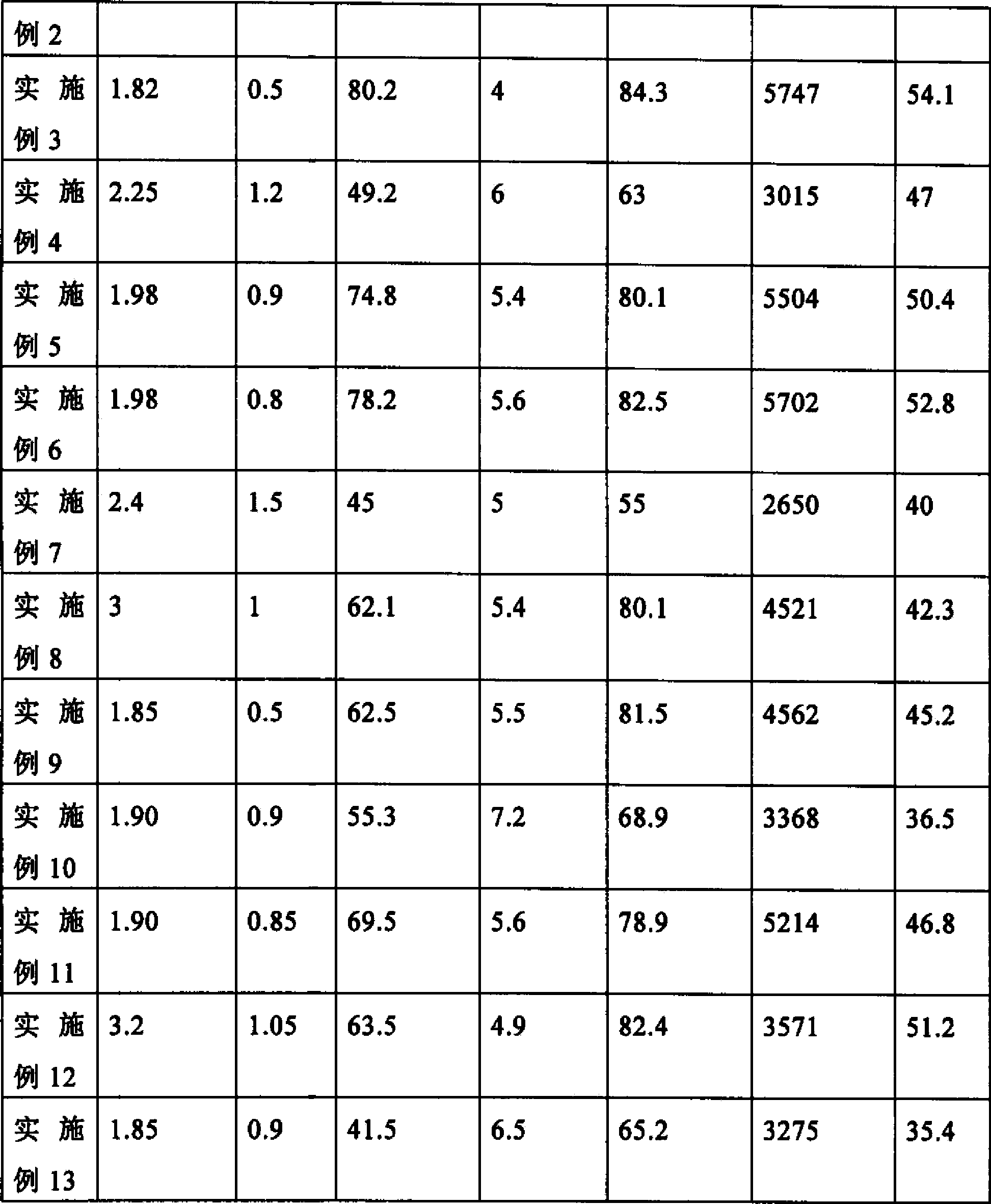

ActiveCN102278241ASolve corrosiveGuaranteed performance and stabilityInternal combustion piston enginesNon-fuel substance addition to fuelWater vaporExhaust gas recirculation

The invention discloses an on-line spraying method and an on-line spraying system for an exhaust gas recirculation cooler of a diesel engine. In the method, according to the actual operation condition of the diesel engine and the exhaust gas recirculation cooler, an on-line spraying descaling system is controlled by an electronic control unit (ECU), and atomized descaling liquid is sprayed to an inlet on the hot side of the exhaust gas recirculation cooler, so that recycling exhaust gas with high moisture content is in the saturated state; and water vapor is condensed and collected on the hotside wall surface of the cooler and outflows, so that the on-line cleaning of the hot side wall surface of the exhaust gas recirculation cooler is realized, the problems of low performance and corrosion in the long-term using process of the exhaust gas recirculation cooler are solved, and the maintenance of the exhaust gas recirculation system is simplified.

Owner:ZHEJIANG YINLUN MACHINERY

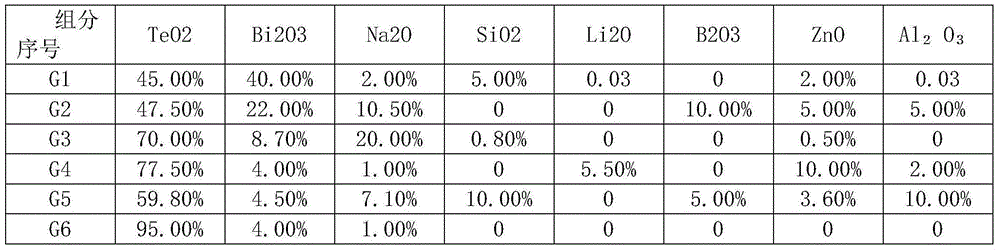

Glass powder, positive silver paste, and preparation methods therefor

ActiveCN106504814AImprove photoelectric conversion efficiencyImprove solderabilityNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteLead glass

The invention provides glass powder, positive silver paste, and preparation methods therefor. The glass powder consists of the following components by percentage: 45%-95% of TeO2, 4-40% of Bi2O3, 1-20% of Na2O, 10% of B2O3, ZnO, Al2O3 and SiO2 or less, and 5.5% of LiO2 or less. The positive silver paste comprises the above glass powder. The glass powder is in a Te-Bi-M glass system, wherein M is alkali metal, such as Li, Na, K and so on. The system employs a non-lead compound, thereby achieving the lead-free glass powder, meeting the demands of environment protection, and also improving the applicability of the high-sheet-resistance technology. Therefore, the positive silver paste is prepared through the no-lead glass powder, and can achieve the lead-free glass powder. The methods can effectively increase the sintering temperature through controlling the addition volume of the alkali metal, guarantee the performance stability of a product, improve the weldability and tension force of a grid line, effectively improve the photoelectric conversion efficiency of a silica-based battery, and enables the silver paste to be as good or even better than the positive silver paste in the market currently.

Owner:SHANGHAI TRANSCOM ELECTRONICS TECH

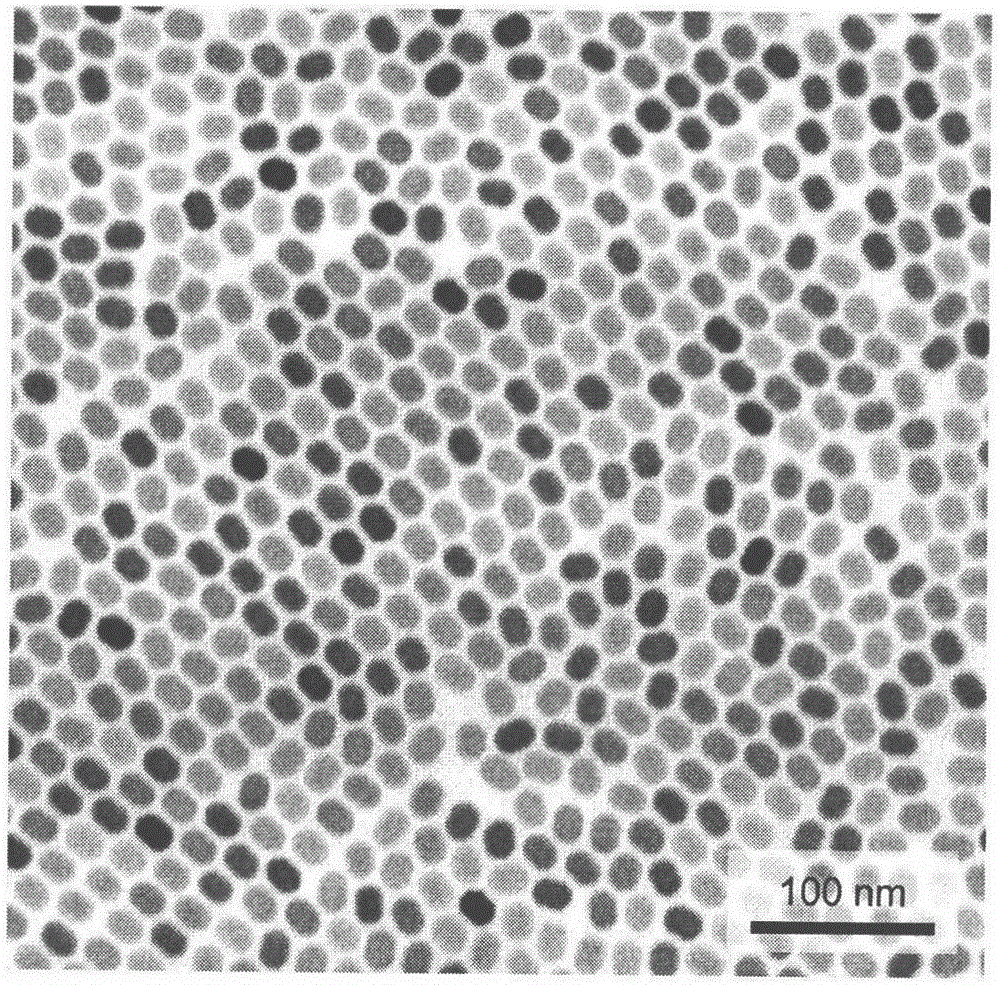

Spherical styrene-butadiene rubber for 3D printing and preparation method thereof

ActiveCN105504174AFulfil requirementsNarrow particle size distributionAdditive manufacturing apparatusRubber materialPolymer science

The invention relates to a spherical styrene-butadiene rubber material for 3D printing. The material is characterized in that a structural core is polystyrene microspheres; the material is prepared from, by weight, 5-20 parts of polystyrene microspheres, 60-80 parts of butadiene monomers, 20-30 parts of styrene monomers, 0.2-1 part of an emulsifying agent, 0.02-0.5 part of an initiator, 0.02-0.1 part of a terminating agent and 80-120 parts of a filling material. Styrene-butadiene rubber latex is prepared through a seeding emulsion polymerization method in which the polystyrene microspheres serve as the core and the polystyrene microspheres, the butadiene monomers and the styrene monomers are grafted and copolymerized, the styrene-butadiene rubber latex and the filling materials are coagulated into powder, the particle size is 10-100 micrometers, particle size distribution is narrow, performance is uniform and stable, and the spherical styrene-butadiene rubber material can be directly applied as a 3D printing material.

Owner:台州科金中高技术转移有限公司

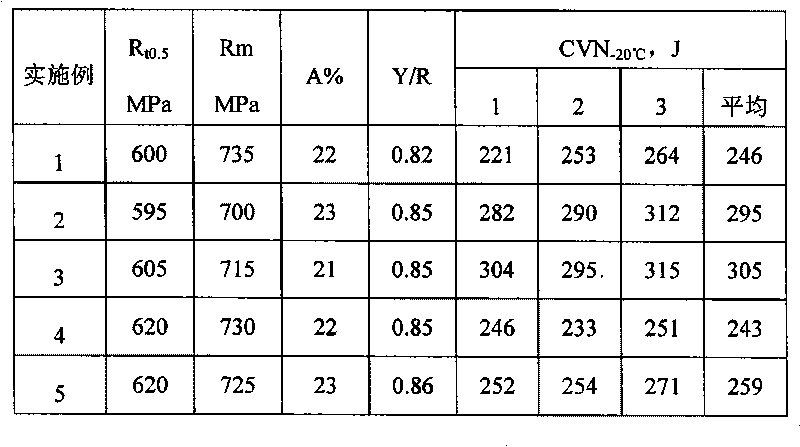

Steel for induction heating syphon for oil gas transportation and method for producing hot rolled slab thereof

InactiveCN101736196AGuaranteed performance and stabilityReduce the content of precious alloying elementsTemperature control deviceMetal rolling arrangementsHeating temperatureCooling temperature

The invention provides steel for an economic-type induction heating syphon for oil gas transportation and a method for producing a hot rolled slab thereof. The steel comprises the following compositions: 0.06 to 0.11 percent of C, 0.15 to 0.30 percent of Si, 1.50 to 1.80 percent of Mn, 0.03 to 0.06 percent of Nb, 0.010 to 0.025 percent of Ti, 0.010 to 0.045 percent of Als and the balance of iron and inevitable impurities. The production method comprises smelting, external refining, continuous casting, and rolling; in the rolling process, the heating temperature of a continuous casting blank is between 1,100 and 1,150 DEG C; the rough rolling temperature is between 960 and 1,000 DEG C; the deformation of each pass is over 15 percent; the finish rolling temperature is between 780 and 920 DEG C; the accumulated deformation is 55 to 75 percent; a cooling speed after rolling is between 15 and 35 DEG C / s; and the final cooling temperature is between 400 and 550 DEG C and then air cooling is carried out. Under the condition of not increasing production procedure, the method reduces the production cost by reducing the content of a noble alloy element and optimizing a production process, ensures that a steel plate reaches the steel standard of the X80-level induction heating syphon, and also ensures the performance stability after a material is subjected to heat treatment.

Owner:ANGANG STEEL CO LTD

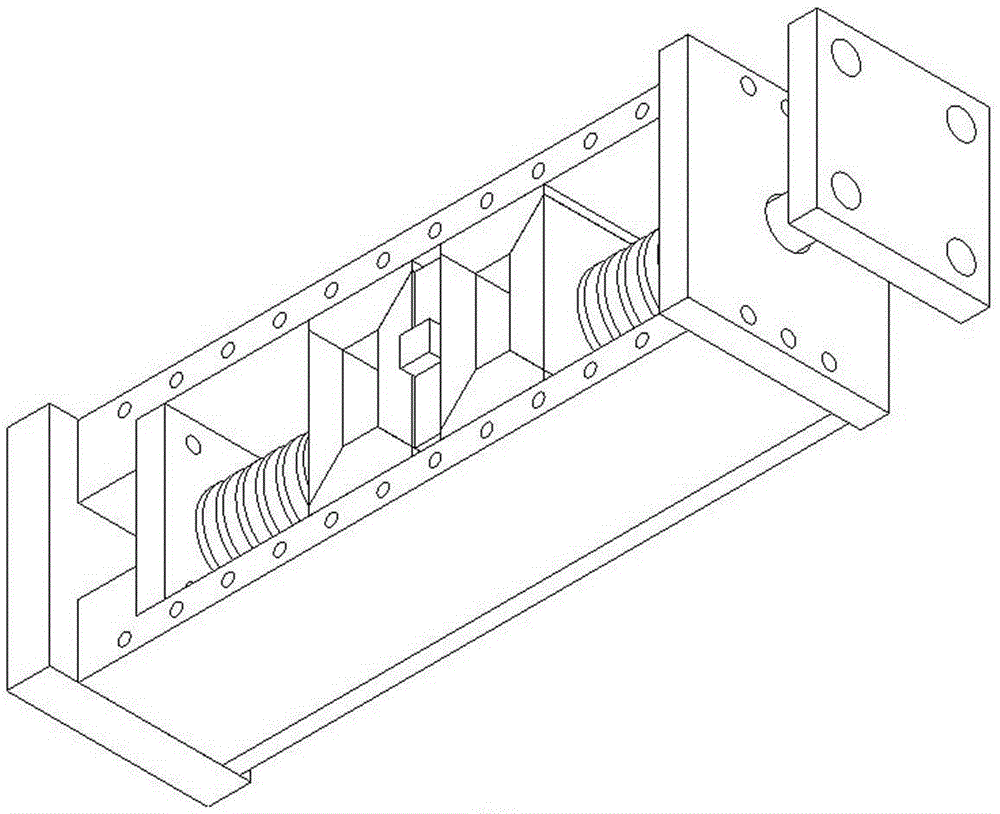

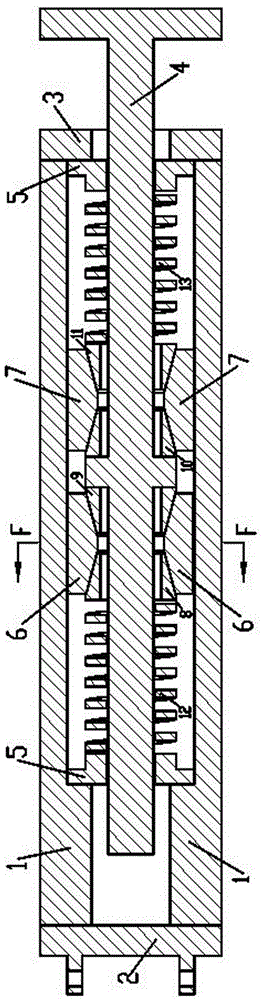

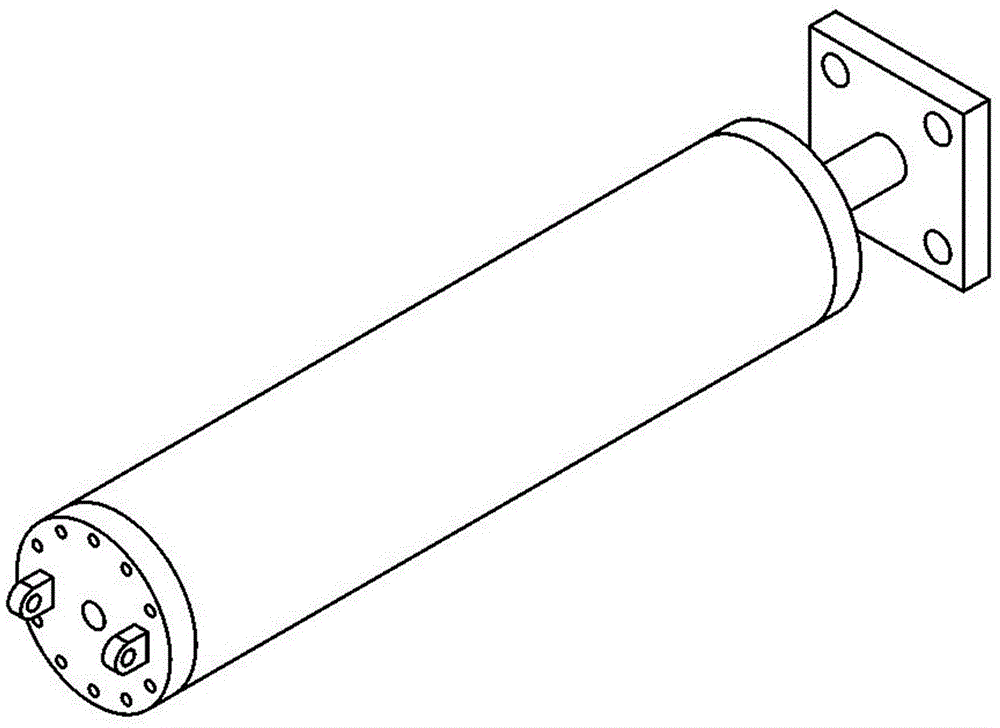

Double-compressed-spring cylinder centripetal friction-variable damper with complex damping feature

InactiveCN105604203AGuaranteed performance and stabilityReduced performance and stabilityShock proofingViscous dampingEngineering

The invention relates to a double-compressed-spring cylinder centripetal friction-variable damper with the complex damping feature. The double-compressed-spring cylinder centripetal friction-variable damper comprises a friction sleeve, two sleeve outer stop blocks, a middle sliding shaft, a sliding-shaft positioning stop block, two friction assemblies and two compressed springs. The friction sleeve and the two sleeve outer stop blocks define a circular cylindrical cavity. Each wedge-shaped sliding friction block comprises a quadrant-shaped friction face and two quadrant-shaped slopes. Each pressing wedge-shaped block comprises a circular slope. The four wedge-shaped sliding friction blocks define a cylinder, and every two pressing wedge-shaped blocks with the opposite slopes form one friction assembly. The sliding-shaft positioning stop block, the compressed springs, the pressing wedge-shaped blocks and the sleeve outer stop block on the right side are arranged on the middle sliding shaft in a sleeving mode. The cavity is divided by a circular baffle in the middle of the middle sliding shaft into a left part and a right part. The damper has the complex damping feature, complex damping force is linearly changed along with the deformation amplitude, viscous damping force is linearly changed along with the deformation speed, the friction interface is stable in performance, and the cost performance is good.

Owner:BEIJING UNIV OF TECH

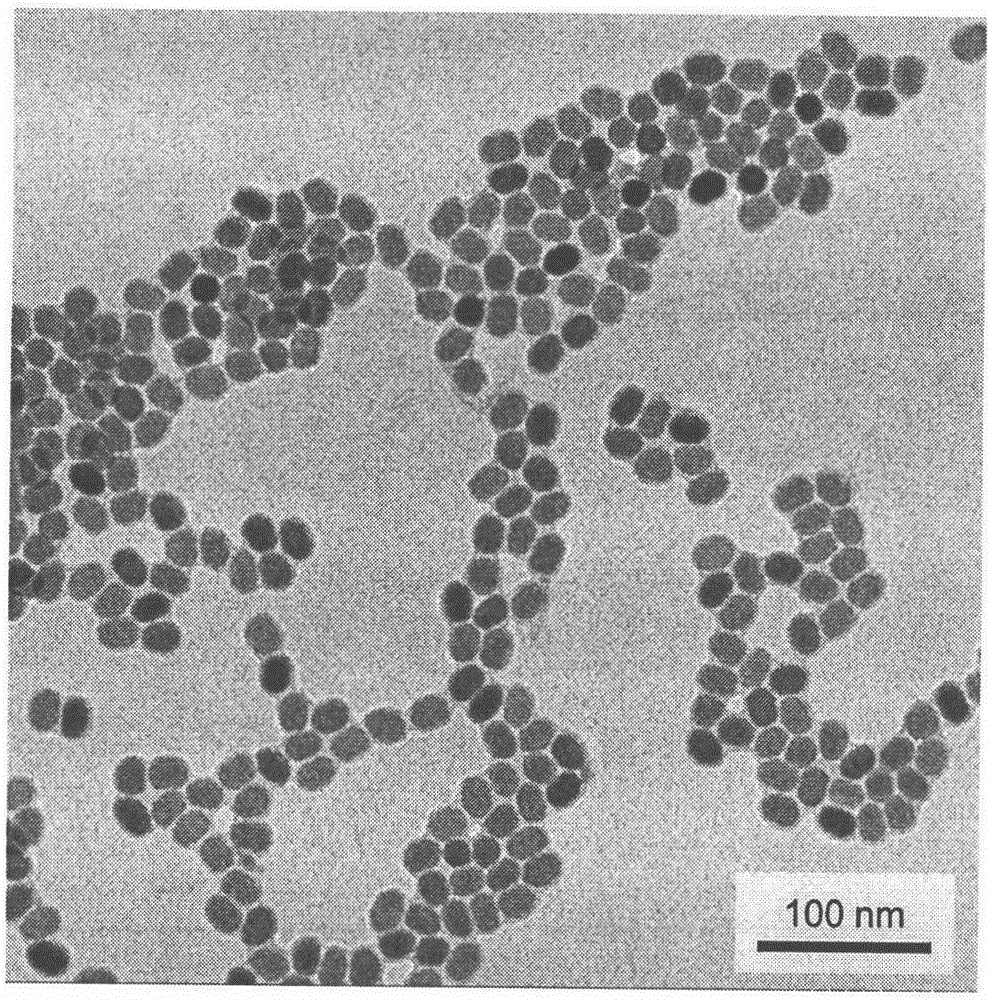

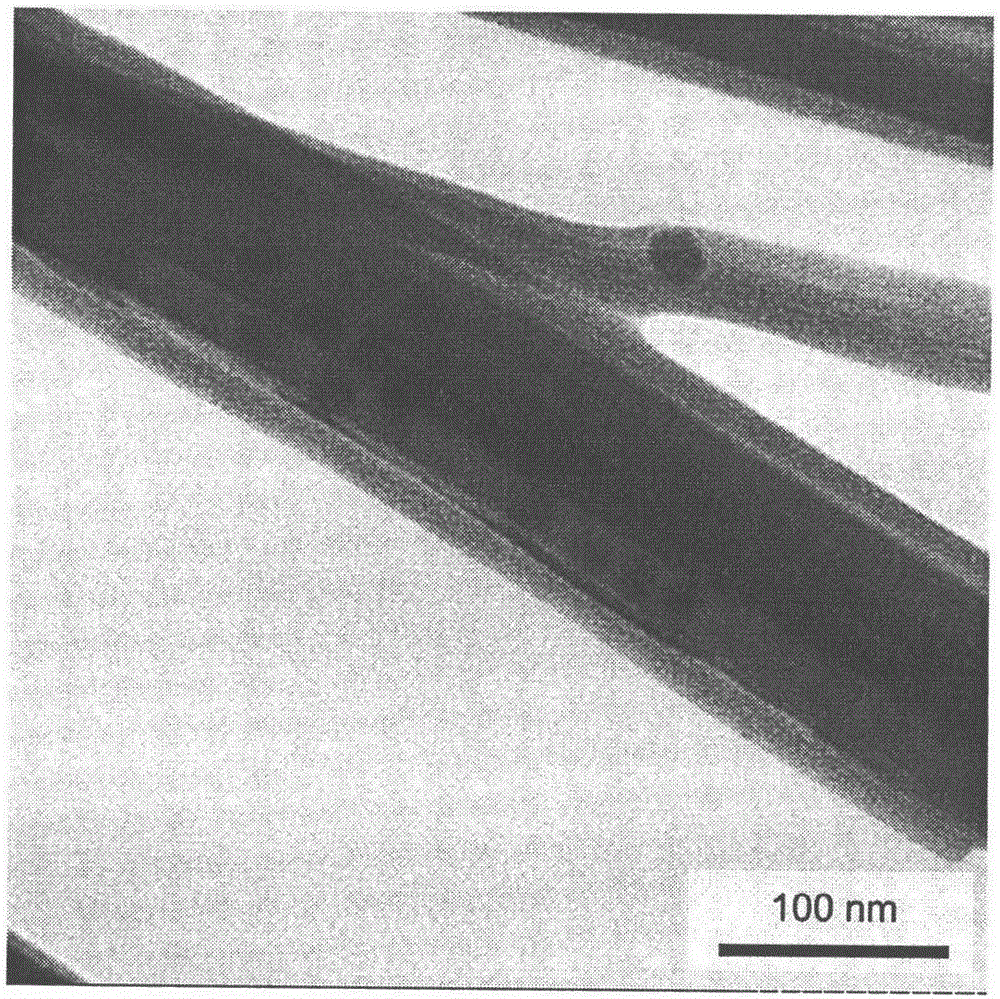

Method for preparation of composite material by embedding nanoparticles into perovskite nanowire

InactiveCN106064831AGuaranteed performance and stabilityOvercoming Phase Splitting ProblemsMaterial nanotechnologyTitanium dioxideNanowireMaterials science

The invention discloses a method for preparation of a composite material by embedding nanoparticles into a perovskite nanowire. The specific method includes: firstly, preparing nanoparticles with regular shape and uniform size; then dispersing the pretreated nanoparticles uniformly into an aqueous solution of cysteine, adding an inorganic salt of lead into the solution to prepare a nanoparticle embedded perovskite precursor nanowire; at room temperature, adding a mixed solution of haloid acid and halogen methanamine salt into the precursor nanowire so as to form an organic / inorganic hybrid material finally. The method has the advantages of artful design, mild reaction conditions, simple operation, high yield and easy mass preparation, and has broad application prospects in preparation of novel hybrid nanomaterials based on perovskite.

Owner:NANJING UNIV OF TECH

PTC thermistor alloy wire and preparation method thereof

ActiveCN104651666AMeet requirements such as more sensitive temperature controlGuaranteed performance and stabilityPositive temperature coefficient thermistorsRare earthManganese

The invention discloses a PTC thermistor alloy wire and a preparation method thereof. The alloy wire comprises the following chemical components in percentage by weight: 64%-78 % of nickel, 0.1%-0.6% of silicon, 0.22%-0.30 % of manganese, 0.02%-0.04 % of yttrium, 0.04%-0.06 % of mixed rare earth, less than or equal to 0.05 % of carbon, less than or equal to 0.01% of sulfur, less than or equal to 0.001% of phosphorus, and the balance of iron; the average resistance temperature coefficient of the alloy wire at 0 DEG C-150DEG C is 4300*10<-6> / DEG C-4800*10<-6> / DEG C, the resistivity of the alloy wire is (0.19-0.27) + / -0.02mu ohm.m; and the PTC thermistor alloy wire is a PTC thermistor alloy wire with the resistance temperature coefficient of higher than 3000 *10<-6> / DEG C currently needed, thus meeting the requirement on the more sensitive temperature control of new electrical equipment and the like.

Owner:JIANGSU HUAXIN ALLOY

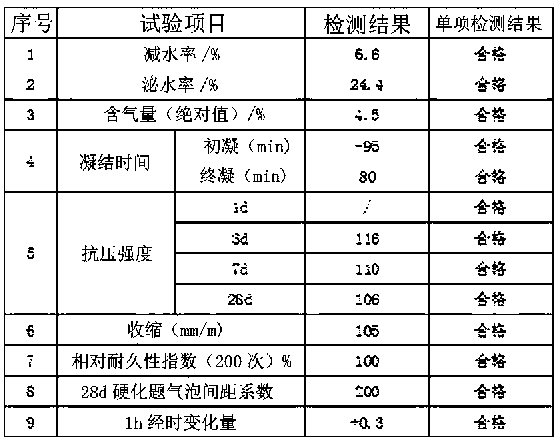

Efficient water reducer of concrete

The invention provides an efficient water reducer of concrete, relates to an admixture applied to concrete, particularly relates to an efficient air-entraining water reducer of concrete and also relates to a preparation method of the water reducer. The efficient water reducer of concrete is mainly prepared from modified naphthalene sulfonate, lignosulfonate, sodium sulfate, flyash, triethanolamine, sodium gluconate, sodium dodecyl benzene sulfonate, silicon resin polyether emulsions and sodium nitrite. The invention aims to prepare a simple, easily operable and high-performance water reducer with an air entraining function based on the current situation of various water reducers on the market at present. The water reducer is mainly characterized in that an air entraining agent is added into the water reducer; the air entraining agent is characterized by entraining micro, uniform and stable air into a system; the air is added into the water reducer, so that the probably-used water amount is same when mixing the concrete through the water reducer; meanwhile, the workability of the concrete can be effectively improved; the slump degree is improved; and the strength of the concrete inuse can be effectively enhanced.

Owner:云南森博混凝土外加剂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com