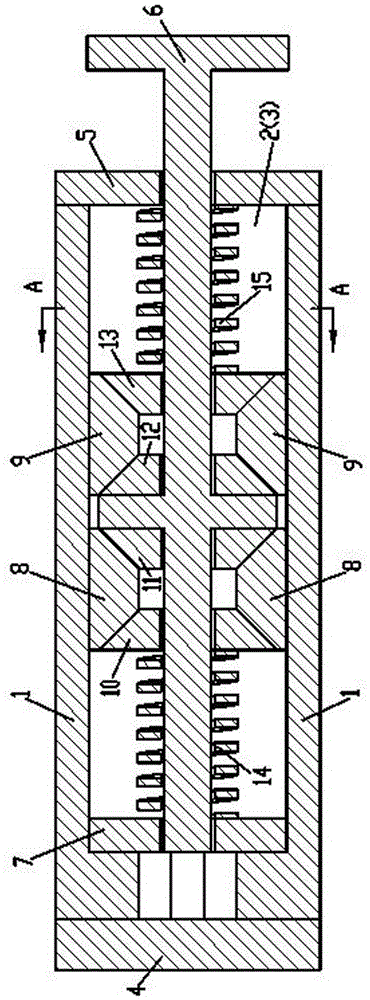

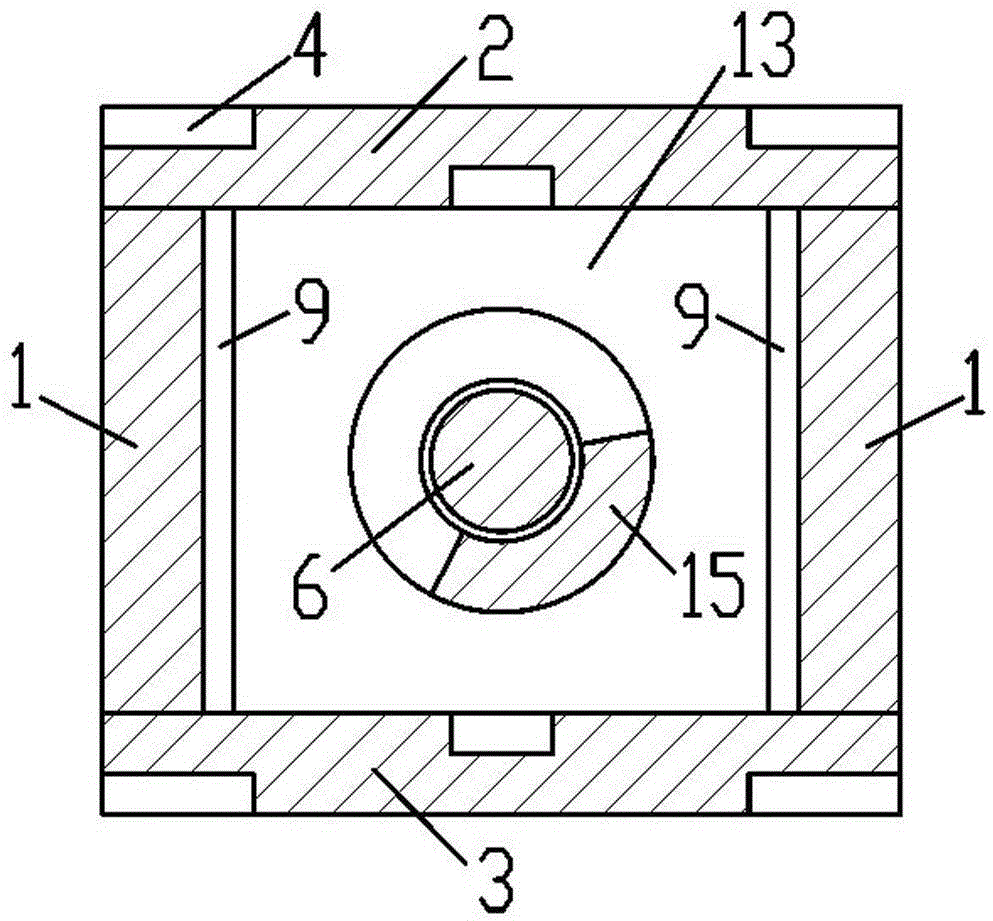

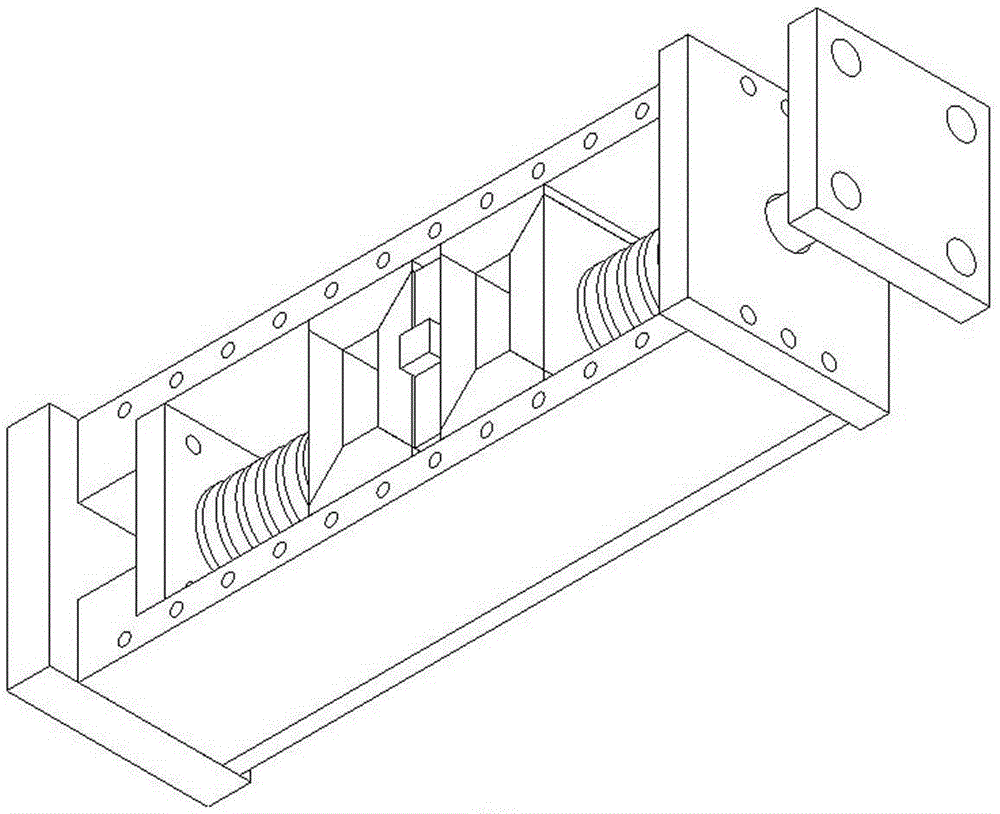

Dual-compressed-spring flat plate type-centripetal variable friction damper

A variable friction, flat-plate technology, applied in the direction of spring/shock absorber, shock absorber, shock absorber, etc., can solve the problems of damper complex damping friction interface performance stability, etc., to achieve the effect of ensuring performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In order to improve the load-carrying capacity and deformation capacity of the damper and prolong the service life of the compression spring, the compression spring used is a die spring made of high-performance chromium alloy spring steel , height 50mm, outer diameter 30mm, inner diameter 15 (16) mm, stiffness 35 (100) N / mm, friction assembly length 36 mm, width 59 mm, two sets of compression springs and friction assemblies work sequentially in the actual test , improving its anti-fatigue ability. The plate cavity, end plate, intermediate connecting shaft, extruded wedge block and wedge-shaped sliding friction block are all made of high-performance steel, and the friction surface is specially treated to ensure that the friction coefficient between the wedge-shaped sliding friction block and the inner wall of the friction plate reaches A certain value meets the design requirements. The slope angle of the wedge block adopts π / 4. The total length of the cavity is 237mm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com