Steel for induction heating syphon for oil gas transportation and method for producing hot rolled slab thereof

A technology of induction heating and pipe bending, applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of unstable performance and high production cost, and achieve the advantages of reduced production cost, good comprehensive performance, and reduced production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below by way of examples.

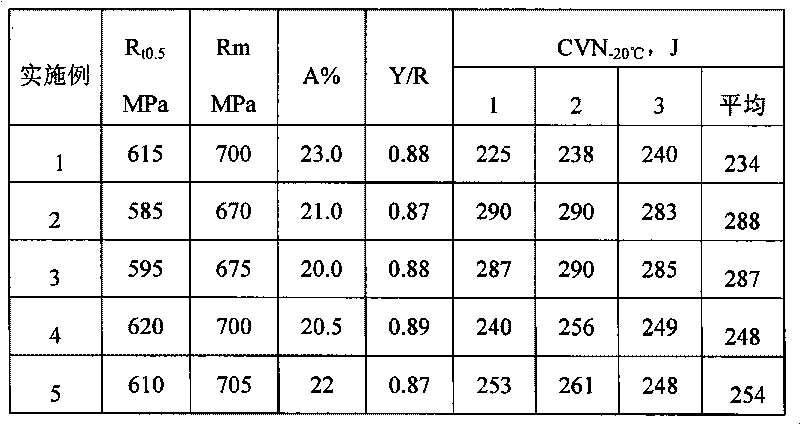

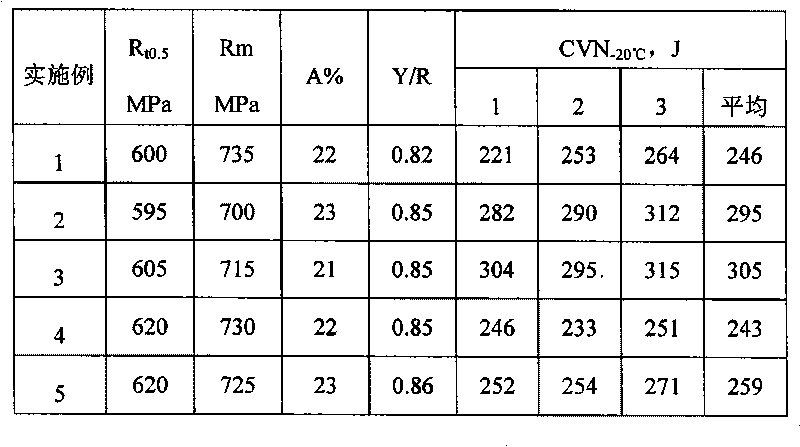

[0020] The chemical composition of the embodiment of the present invention is shown in Table 1. The rolling process of the corresponding embodiment is shown in Table 2. The performance test results are shown in Table 3. The properties after quenching and tempering heat treatment are shown in Table 4.

[0021] Table 1 Chemical Composition of Steel for Induction Heating Elbows Used in Economical Oil and Gas Transportation in Embodiments of the Invention

[0022] Example

C

Si

mn

P

S

Ni

Ti

Nb

V

als

1

0.08

0.24

1.72

0.008

0.002

0.18

0.015

0.05

0.04

0.023

2

0.09

0.26

1.70

0.008

0.002

0.19

0.020

0.05

0.03

0.04

3

0.06

0.28

1.77

0.006

0.002

0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com