Positive temperature coefficient (PTC) thermal resistance alloy wire and preparation method thereof

A thermistor and alloy wire technology, which is applied in the field of alloy wire, can solve the problems of single variety and no series of products, and achieve the effect of increasing service life and avoiding sulfur corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (Example 1, PTC thermistor alloy wire)

[0035] The chemical composition of the PTC thermistor alloy wire in this embodiment is as follows: 78.0% nickel (Ni), 0.6% silicon (Si), 0.3% manganese (Mn), and 0.02% to 0.04% yttrium (Y). (0.03% in this example), mixed rare earths 0.04% to 0.06% (0.05% in this example), carbon (C) less than or equal to 0.05%, sulfur (S) less than or equal to 0.01%, phosphorus (P) less than Equal to 0.001%, the balance is iron (Fe).

[0036] The average temperature coefficient of resistance of the PTC thermistor alloy wire of the present embodiment is 4800×10 at 0° C. to 150° C. -6 / °C; the accuracy of the temperature coefficient of resistance is ±50×10 -6 / °C; the resistivity of the alloy wire at 20°C is (0.19±0.02) μΩ·m. The tensile strength of soft alloy wire is greater than 390Mpa.

[0037] Since emerging electrical equipment requires more sensitive temperature control and adjustment of resistance elements, the upper limit of the resista...

Embodiment 2 to Embodiment 6

[0055] (Example 2 to Example 6, PTC thermistor alloy wire)

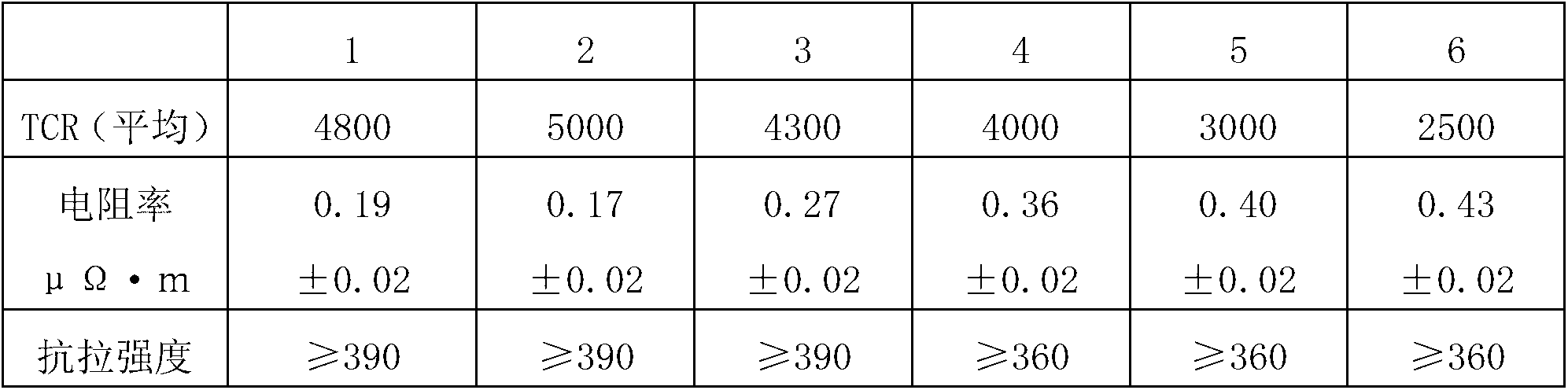

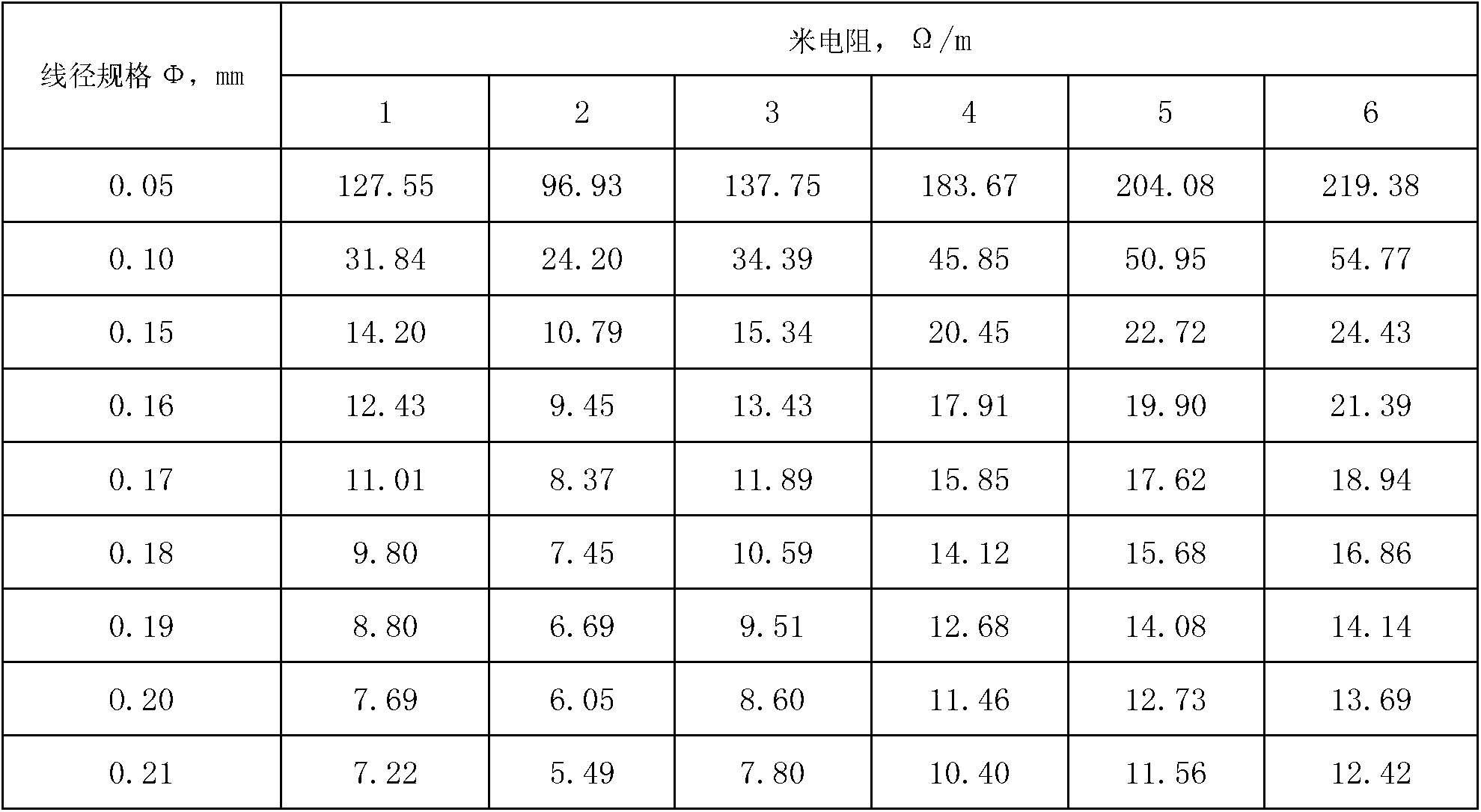

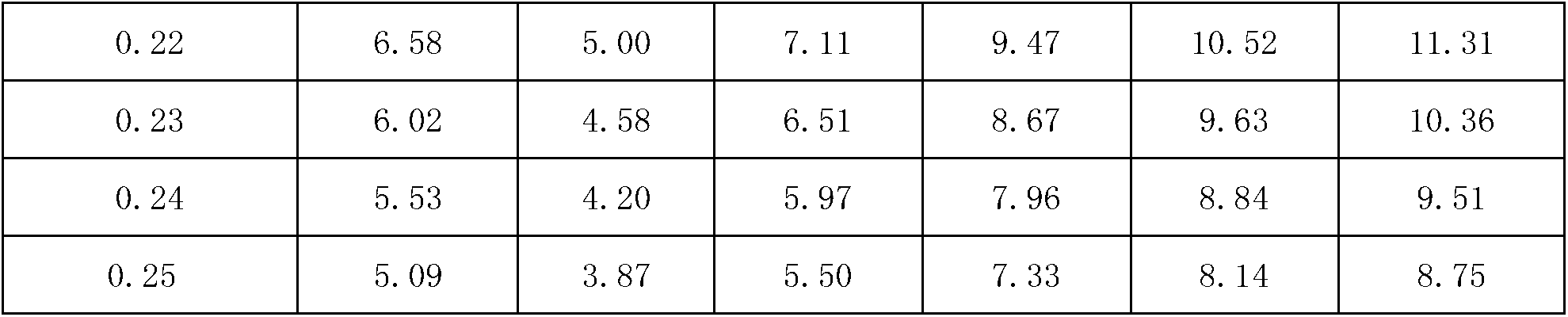

[0056] The chemical composition of the PTC thermistor alloy wire of embodiment 2 to embodiment 6 is shown in Table 3 by weight percentage:

[0057] Table 3 Embodiment 1 to Embodiment 6

[0058]

Example 1

Example 2

Example 3

Example 4

Example 5

Example 6

Nickel (Ni)

78.0%

82%

64.45%

53%

49%

45%

Silicon (Si)

0.6%

0.28

0.1

0.1

0.25

0.25

Manganese (Mn)

0.3%

0.35

0.22

0.22

0.35

0.35

Yttrium (Y)

0.03%

0.03

0.03

0.03

0.03

0.03

misch earth

0.05%

0.05

0.05

0.05

0.05

0.05

Aluminum (Al)

--

--

--

--

0.45

0.45

Carbon (C)

≤0.05%

≤0.05%

≤0.05%

≤0.05%

≤0.05%

≤0.05%

Sulfur (S)

≤0.01%

≤0.01%

≤0.01%

≤0.01%

≤0.01%

≤0.01%

Phosphorus (P)

≤0.001%

≤...

Embodiment 7

[0074] (Example 7, the preparation method of PTC thermistor alloy wire)

[0075] The preparation method of the PTC thermistor alloy wire of the present embodiment specifically comprises the following steps:

[0076] ① Preparation of raw materials: Nickel is No. 1 electrolytic nickel Ni-1 whose standard is GB6516; silicon is primary crystalline silicon Si-1 whose standard is GB2881; manganese is electrolytic manganese DJMn99.5 whose standard is GB3418; yttrium is Q The rare earth metal yttrium Y-3 of / HUAC23; the mixed rare earth is the mixed rare earth RECe-45 with the standard of GB / T4153; the iron is the raw material pure iron DT3 with the standard of GB / T9971;

[0077] ②Vacuum melting:

[0078] The equipment used for vacuum smelting is the EG-25 vacuum induction furnace intermediate frequency equipment produced by Shanghai Electric Furnace Factory, of which:

[0079] a. The motor power of the frequency conversion unit is 60 kilowatts, the motor is three-phase, the generat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com