Patents

Literature

43results about How to "Avoid severe oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

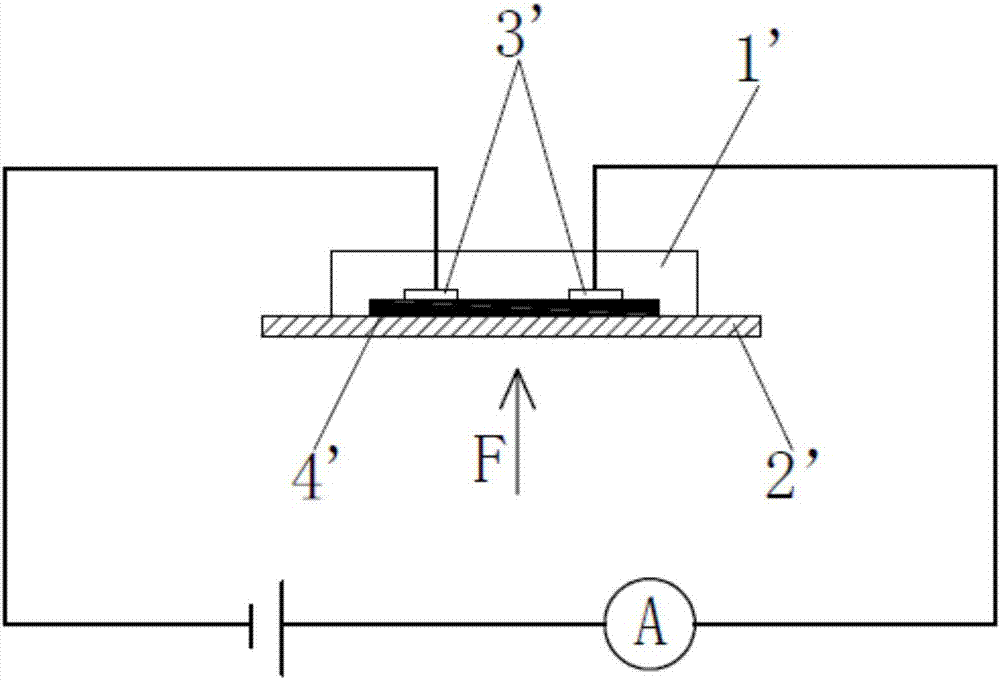

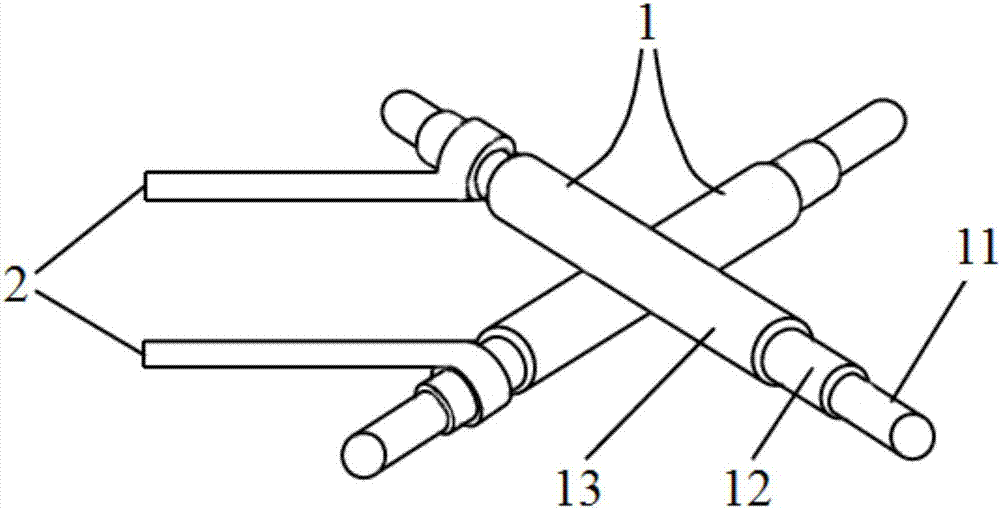

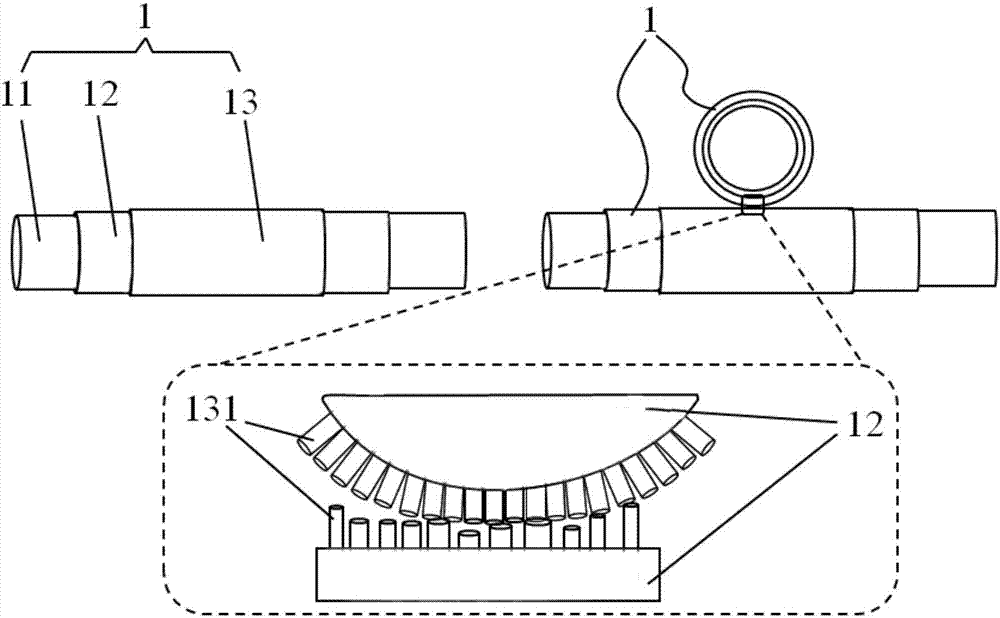

Flexible stress sensor and preparation method thereof

InactiveCN107271084ASmall sizeSolve the problem of difficult miniaturizationMaterial nanotechnologyForce measurementSemiconductor materialsMiniaturization

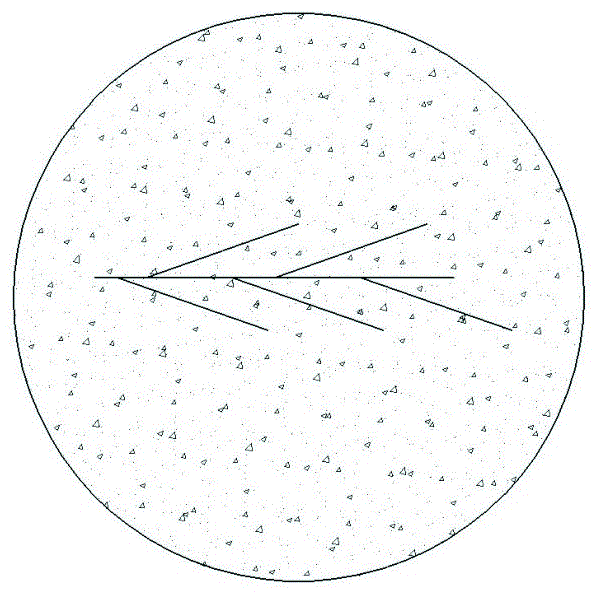

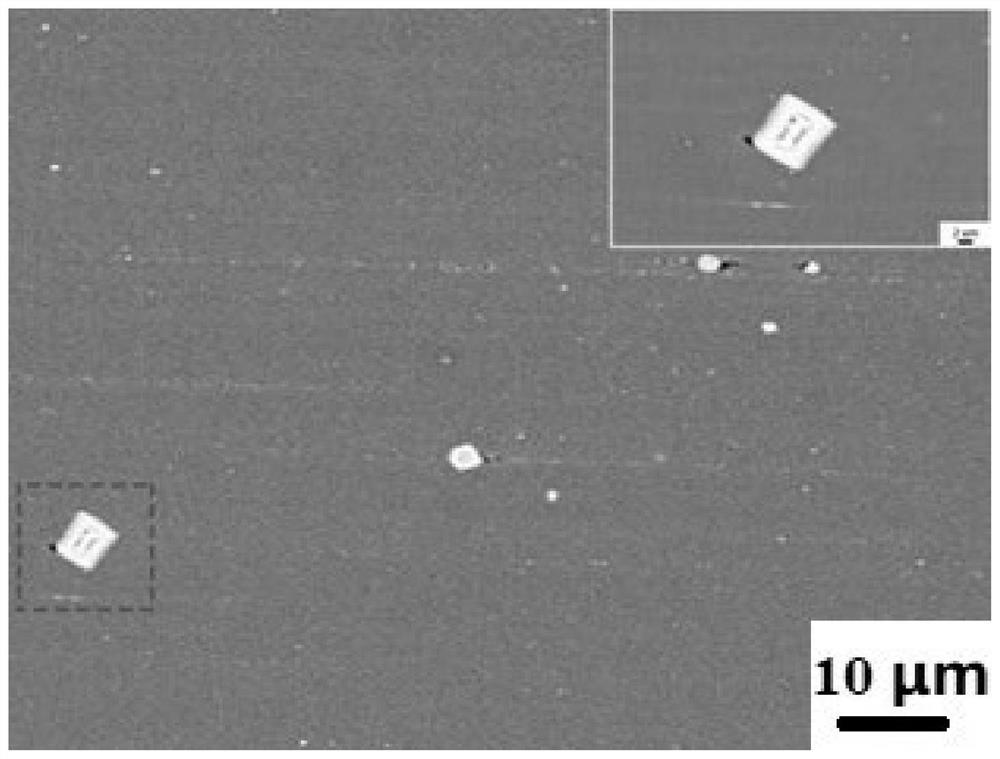

The present invention relates to a flexible stress sensor. The flexible stress sensor comprises two sensing assemblies; each sensing assembly includes a flexible fiber wire and a nanostructured film coating the flexible fiber wire; the flexible fiber wire is made of a conductive material or the surface of the flexible fiber wire is provided with a conductive layer; the nanostructured film is made of a conductive material or a semiconductor material; the two sensing assemblies are cross-stacked; and the nanostructured films of the two sensing assemblies contact with each other at the intersection of the two sensing assemblies. The present invention also relates to a preparation method of the flexible stress sensor. The flexible stress sensor of the invention has the advantages of small size, high resolution, high sensitivity and simple preparation, is suitable for being applied to miniaturized and integrated equipment and can be used for making wearable equipment for detecting human health.

Owner:WUYI UNIV

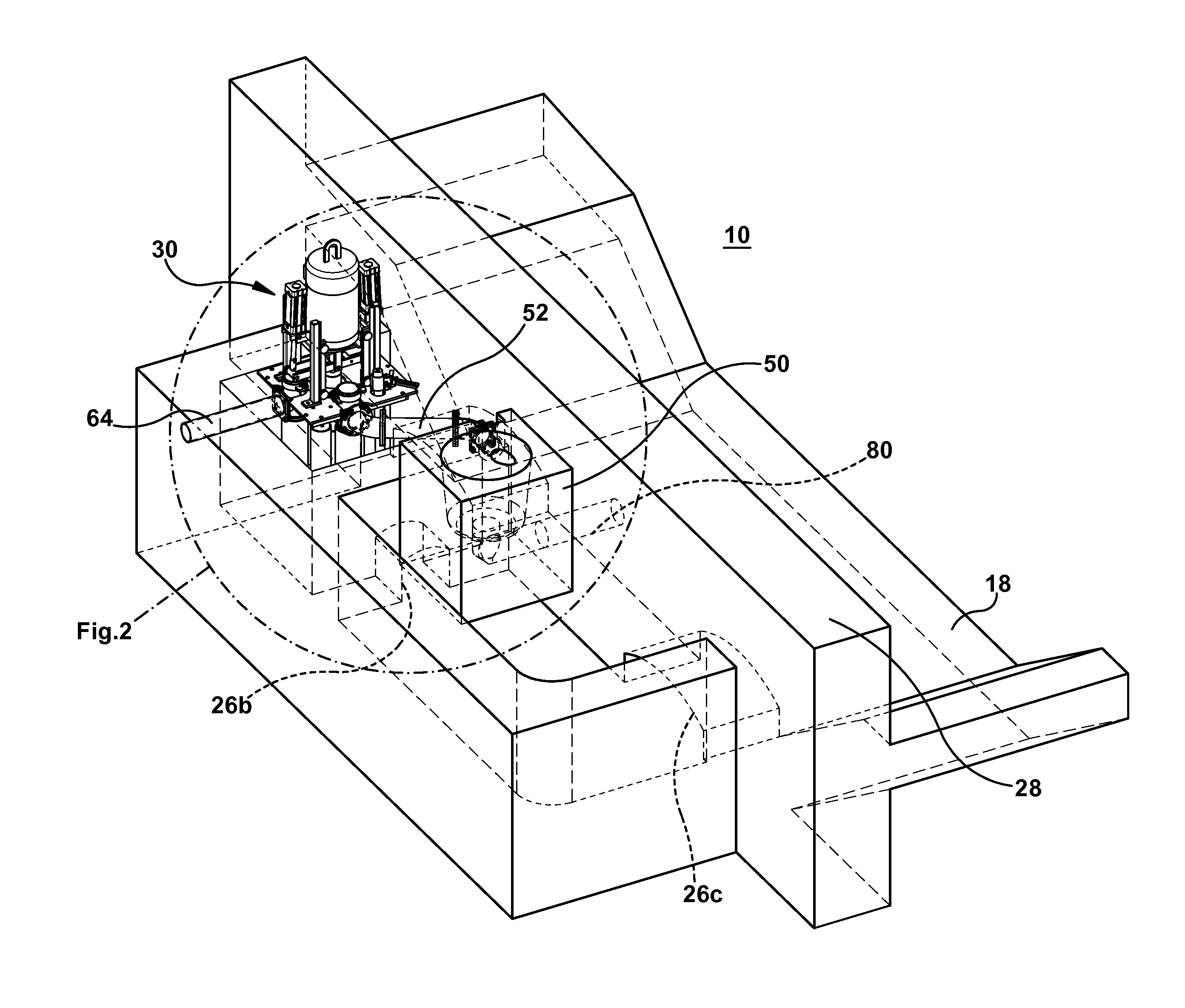

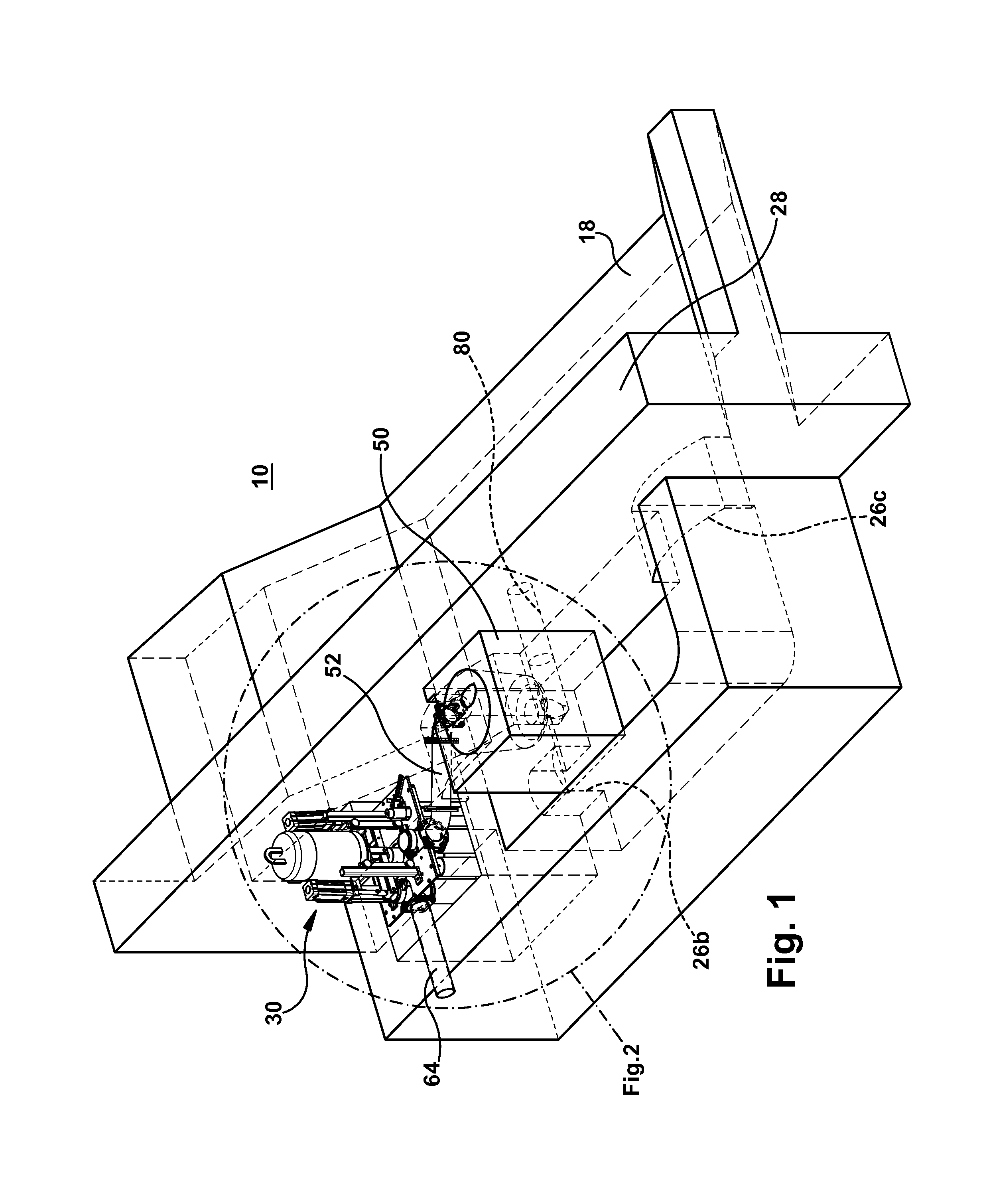

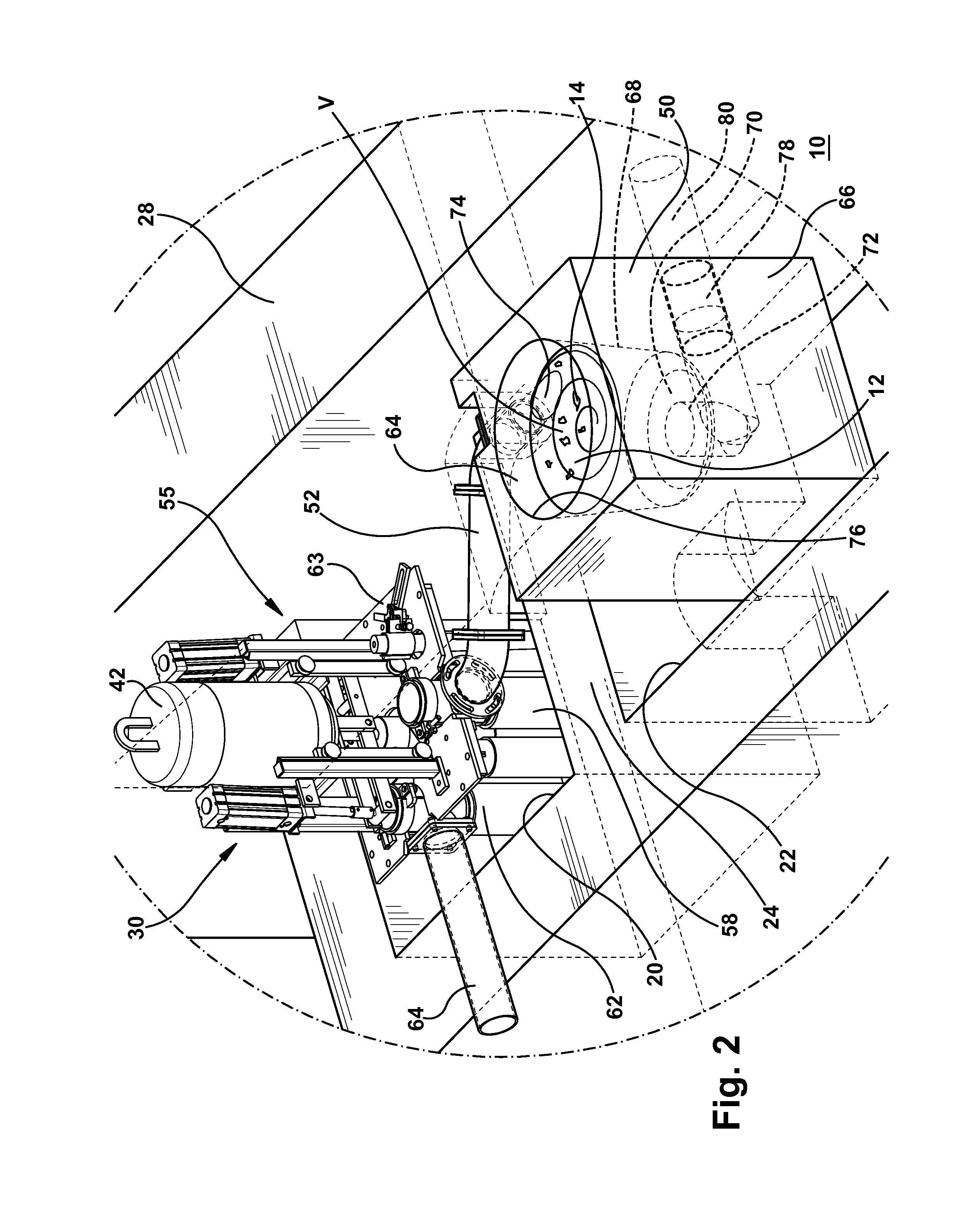

System and method for pumping molten metal and melting metal scrap

ActiveUS9494366B1Tremendous versatilityQuality improvementMelt-holding vesselsStirring devicesMaterials scienceMolten metal

A system for pumping molten metal and melting metal scrap in a furnace that includes a first well that is separated from a second well by a refractory separating wall. The first well and the second well are in fluid communication with a main vessel, the separating wall including a passageway for molten metal. The system includes a pump disposed in the first well for pumping molten metal. A scrap charging vessel is disposed in the second well into which the scrap is added to molten metal contained therein. A conduit extends from the pump over the separating wall. Molten metal pumped from the pump travels from the conduit into the scrap charging vessel.

Owner:THUT BRUNO

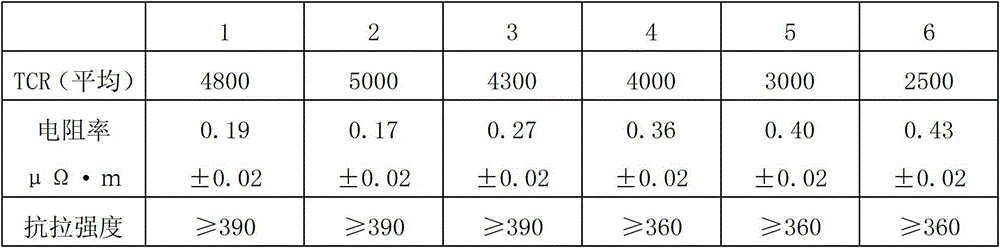

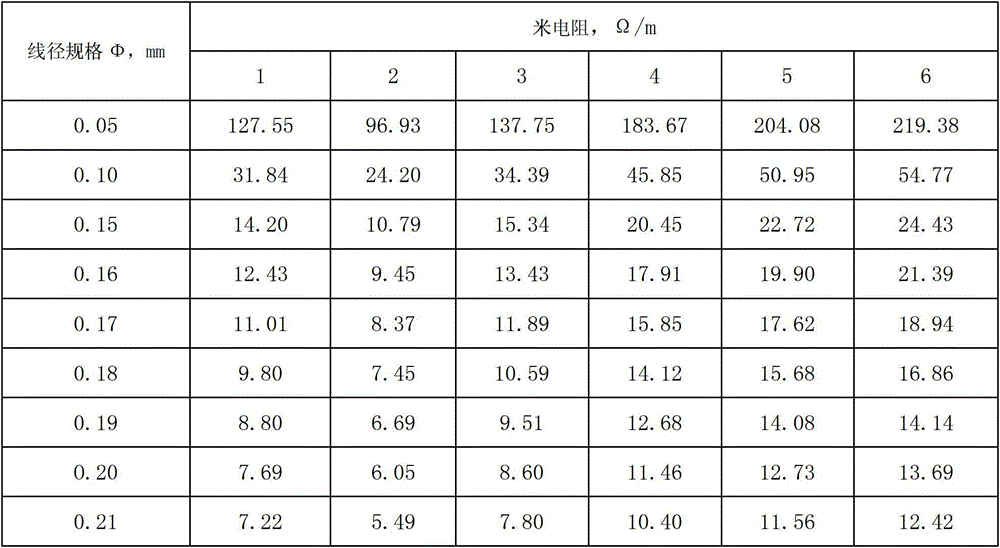

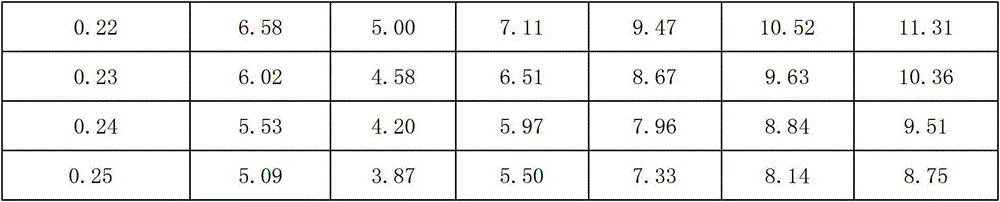

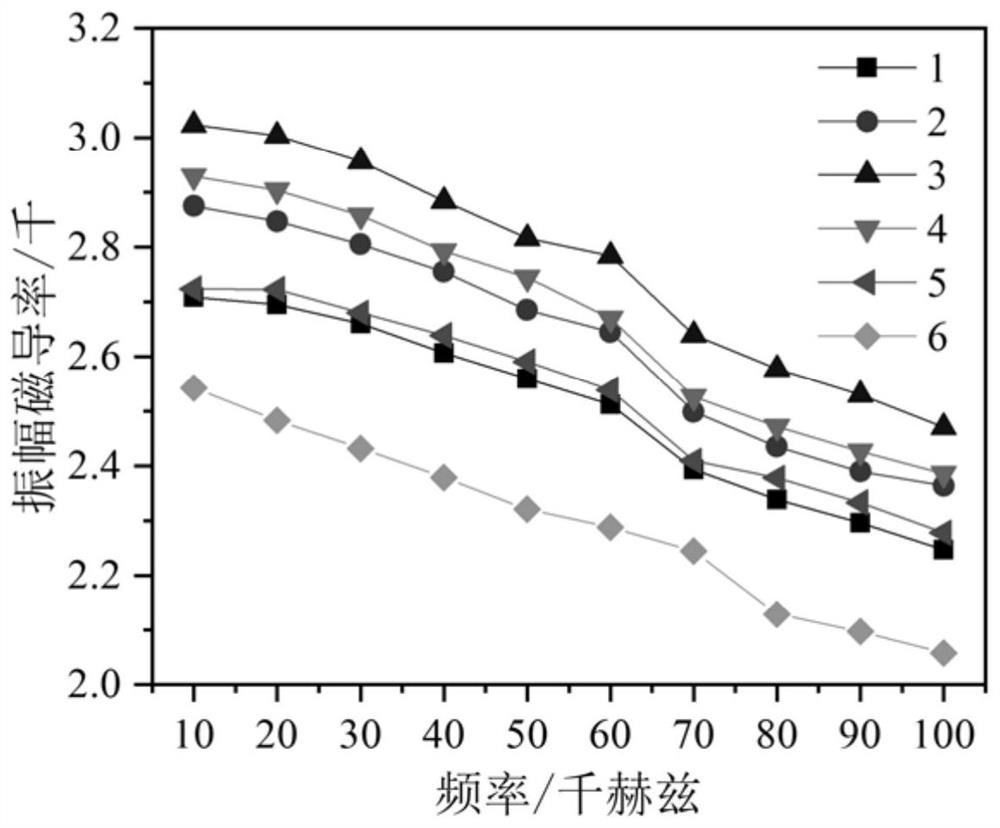

Positive temperature coefficient (PTC) thermal resistance alloy wire and preparation method thereof

ActiveCN103060615AMeet requirements such as more sensitive temperature controlExtended service lifePositive temperature coefficient thermistorsProcess efficiency improvementMisch metalRare earth

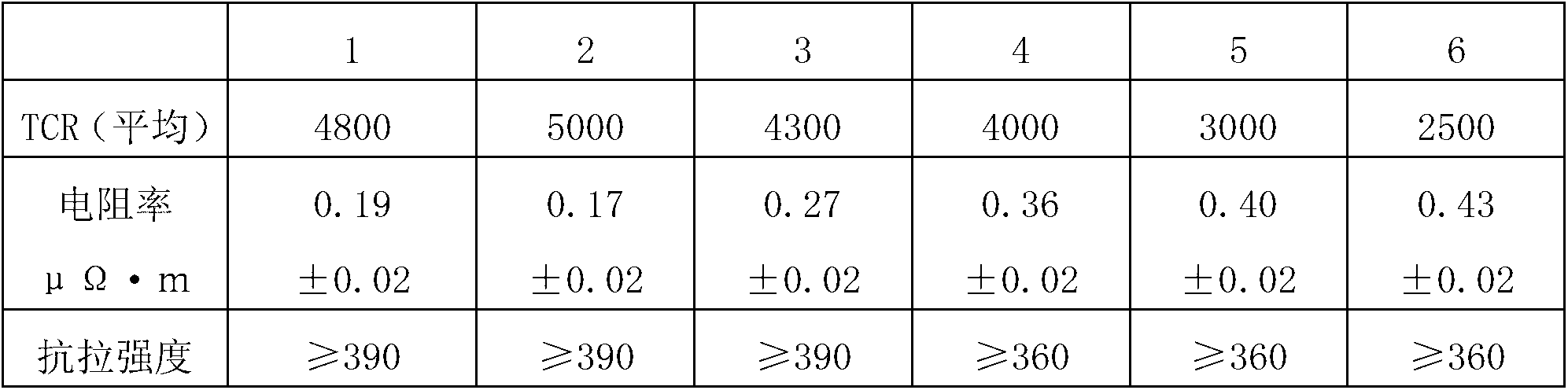

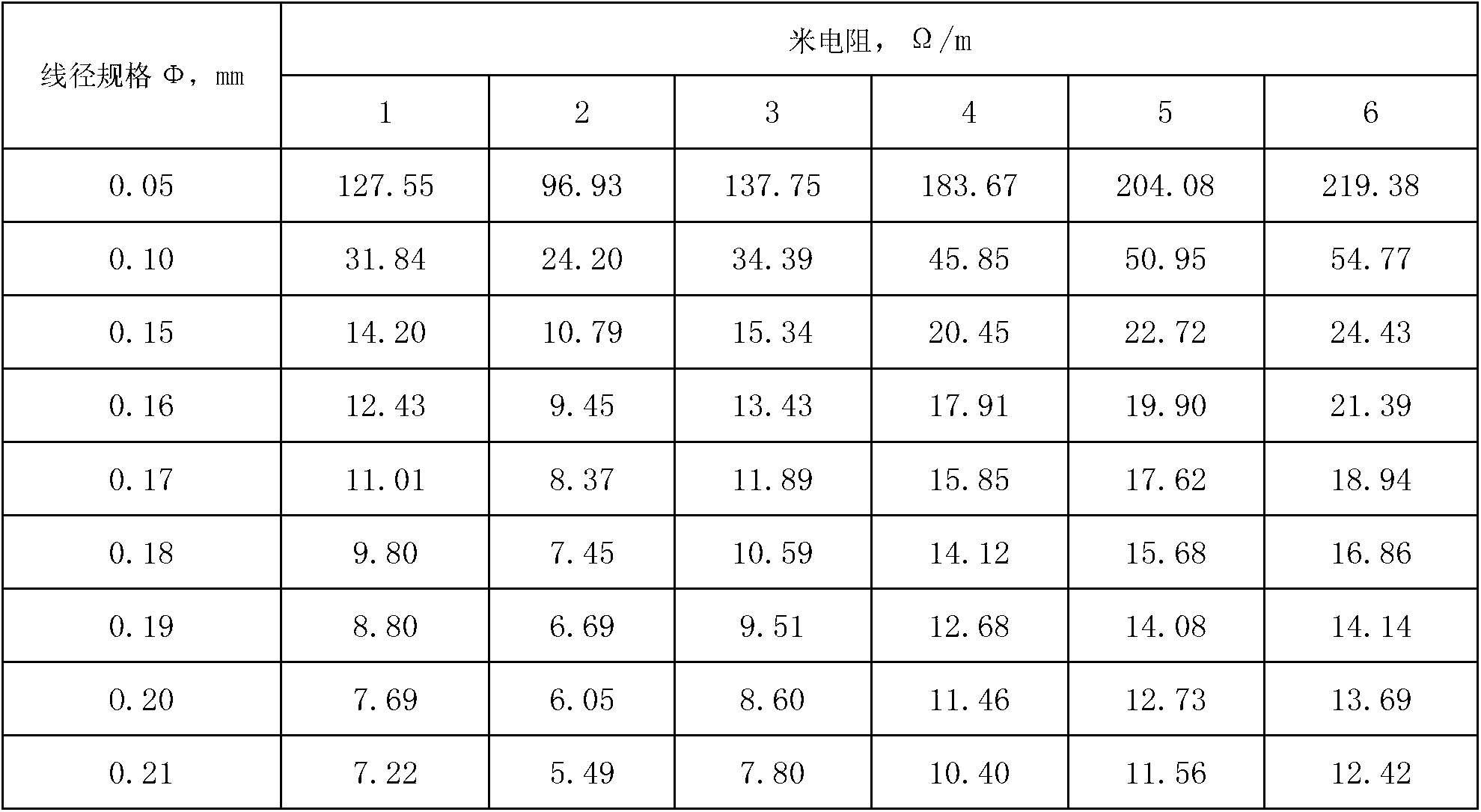

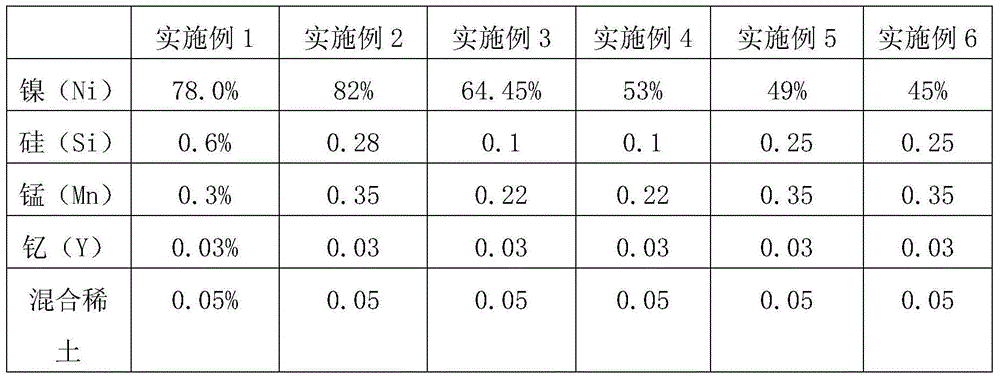

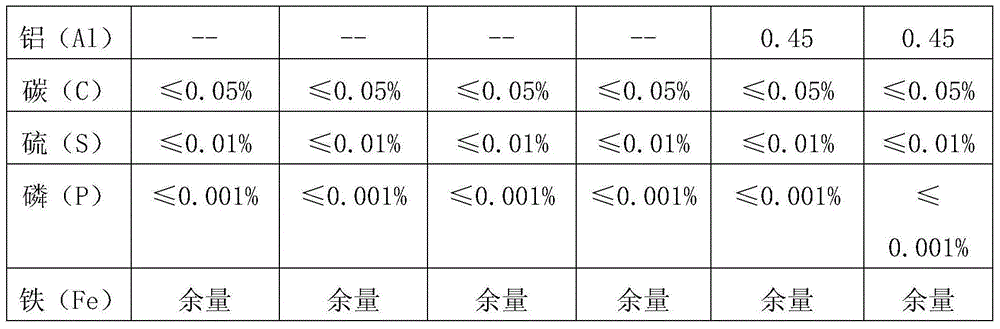

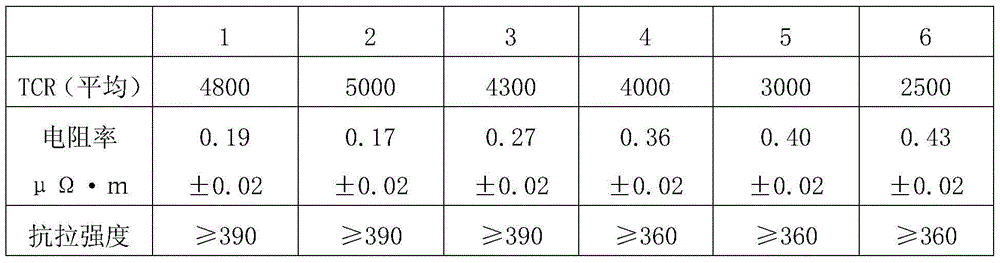

The invention discloses a positive temperature coefficient (PTC) thermal resistance alloy wire and a preparation method thereof. The alloy wire comprises the chemical ingredients by weight percent of 45-82.0% of nickel, 0.1-0.6% of silicon, 0.22-0.35% of manganese, 0.02-0.04% of yttrium, 0.04-0.06% of misch metal, 0.05% or less of carbon, 0.01% or less of sulphur, 0.001% or less of phosphorus and the balance of iron. The mean resistance temperature coefficient at 0-150 DEG C is 2500*10(-6) per DEG C to 5000*10(-6) per DEG C by changing the matching content of the components; the PTC thermal resistance alloy wire of which the resistance temperature coefficient which is urgently needed at present and higher than 3000*10(-6) per DEG C is included; the highest mean resistance temperature coefficient can be 5000*10(-6) per DEG C, and the requirements of more sensitive temperature control of novel electrical equipment can be met.

Owner:JIANGSU HUAXIN ALLOY

PTC thermistor alloy wire and preparation method thereof

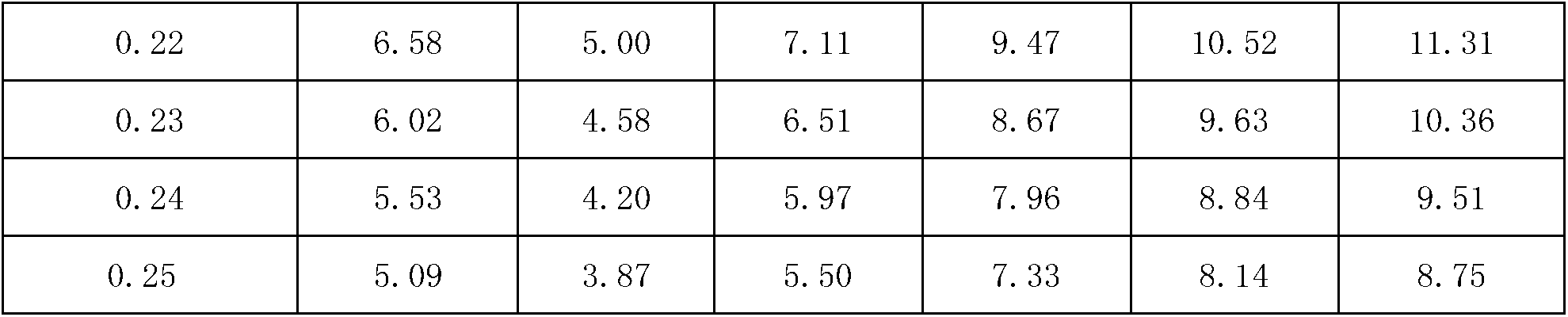

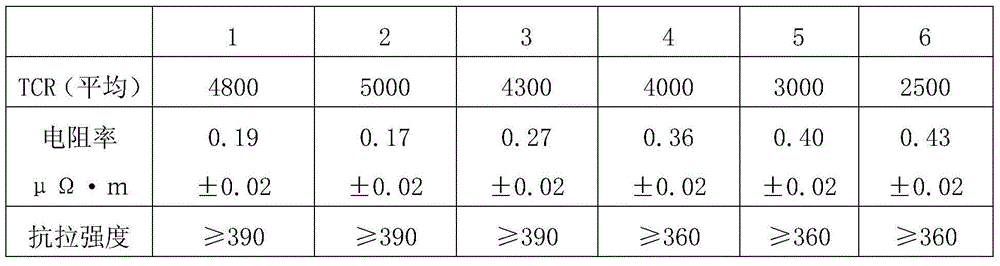

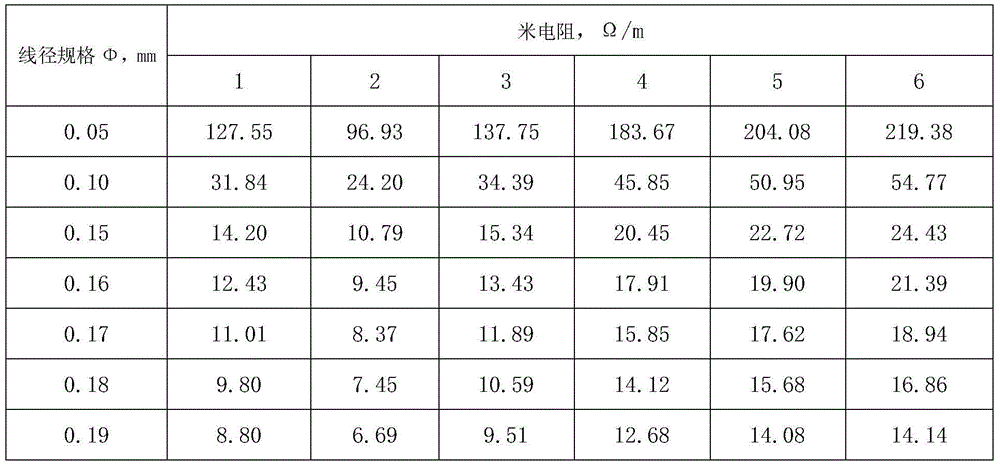

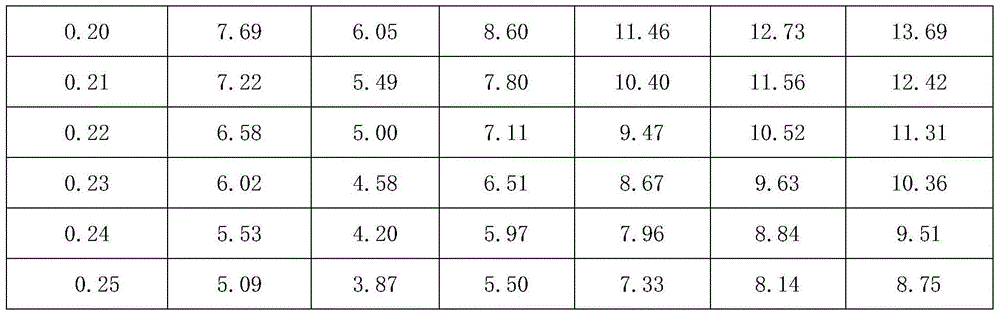

ActiveCN104651666AMeet requirements such as more sensitive temperature controlGuaranteed performance and stabilityPositive temperature coefficient thermistorsRare earthManganese

The invention discloses a PTC thermistor alloy wire and a preparation method thereof. The alloy wire comprises the following chemical components in percentage by weight: 64%-78 % of nickel, 0.1%-0.6% of silicon, 0.22%-0.30 % of manganese, 0.02%-0.04 % of yttrium, 0.04%-0.06 % of mixed rare earth, less than or equal to 0.05 % of carbon, less than or equal to 0.01% of sulfur, less than or equal to 0.001% of phosphorus, and the balance of iron; the average resistance temperature coefficient of the alloy wire at 0 DEG C-150DEG C is 4300*10<-6> / DEG C-4800*10<-6> / DEG C, the resistivity of the alloy wire is (0.19-0.27) + / -0.02mu ohm.m; and the PTC thermistor alloy wire is a PTC thermistor alloy wire with the resistance temperature coefficient of higher than 3000 *10<-6> / DEG C currently needed, thus meeting the requirement on the more sensitive temperature control of new electrical equipment and the like.

Owner:JIANGSU HUAXIN ALLOY

Manufacturing method of PCB large copper surface character

ActiveCN111182738AOptimize the character production processImprove copper surface roughnessPattern printingOther printing apparatusSolder maskSurface oxide

The invention discloses a manufacturing method of a PCB large copper surface character. The method comprises the following steps: preparing a solder mask layer on a production board, and then, carrying out first pickling treatment on the production board; performing silk-screen printing of first surface character ink on the copper surface of one surface of the production board, and pre-curing thefirst surface character ink through pre-baking; carrying out second pickling treatment on the production plate; and performing silk-screen printing of second surface character ink on the copper surface of the other surface of the production board, and thoroughly curing the first surface character ink and the second surface character ink through baking. According to the method, the character manufacturing process is optimized, and before characters are manufactured on the large copper surface, the pickling process is added, so that the copper surface oxide layer obtained after high-temperatureboard baking is removed, the copper surface roughness is increased, the combination area of the copper surface and character ink is increased, and the problem of character dropping of the large coppersurface is solved.

Owner:珠海崇达电路技术有限公司 +1

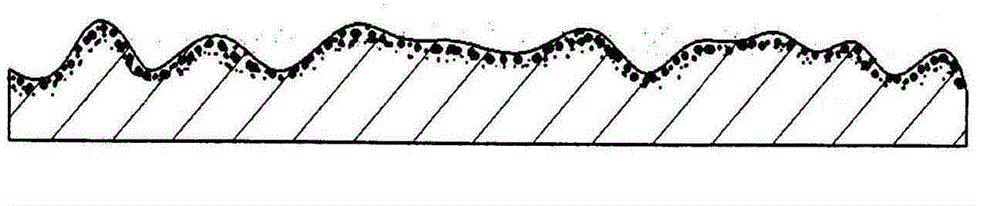

Extrusion method of BMn40-1.5 manganese copper-nickel alloy tube

InactiveCN105013855AAvoid unfavorable factors that are not easy to deformImprove surface qualityCupronickelManganese

The invention discloses an extrusion method of a BMn40-1.5 manganese copper-nickel alloy tube. The method comprises steps as follows: step one, preparation of blanks; step two, primary induction heating; step three, glass powder lubrication; step four, chambering; step five, secondary induction heating; step six, secondary glass powder lubrication; step seven, extrusion forming, wherein the blanks subjected to glass powder lubrication enters an extruder for extrusion forming. By means of the extrusion method of the BMn40-1.5 manganese copper-nickel alloy tube, severe oxidation in the heating process is effectively avoided, adverse factors hindering deformation of the material are avoided, forming of heat cracks in the material forming process is reduced, and the surface quality of a prepared seamless tube is improved. The performance and the size of the seamless BMn40-1.5 manganese copper-nickel alloy tube produced with the method can meet the requirements of a user.

Owner:HANDAN XINXING SPECIAL TUBING CO LTD

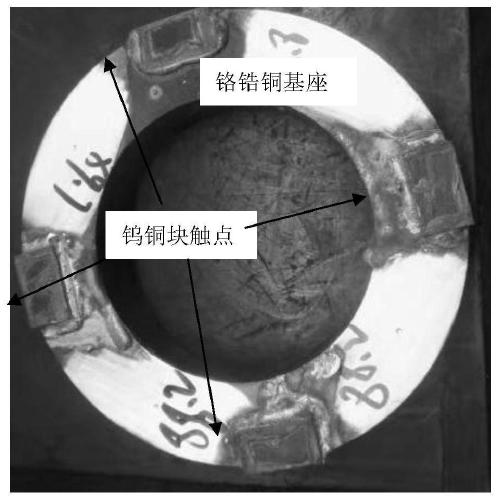

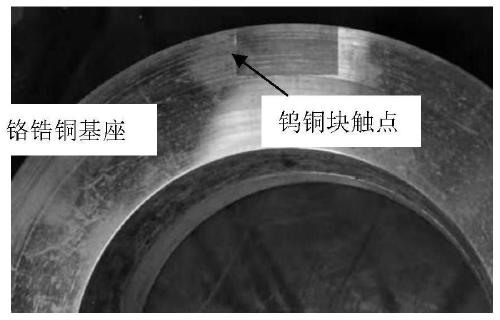

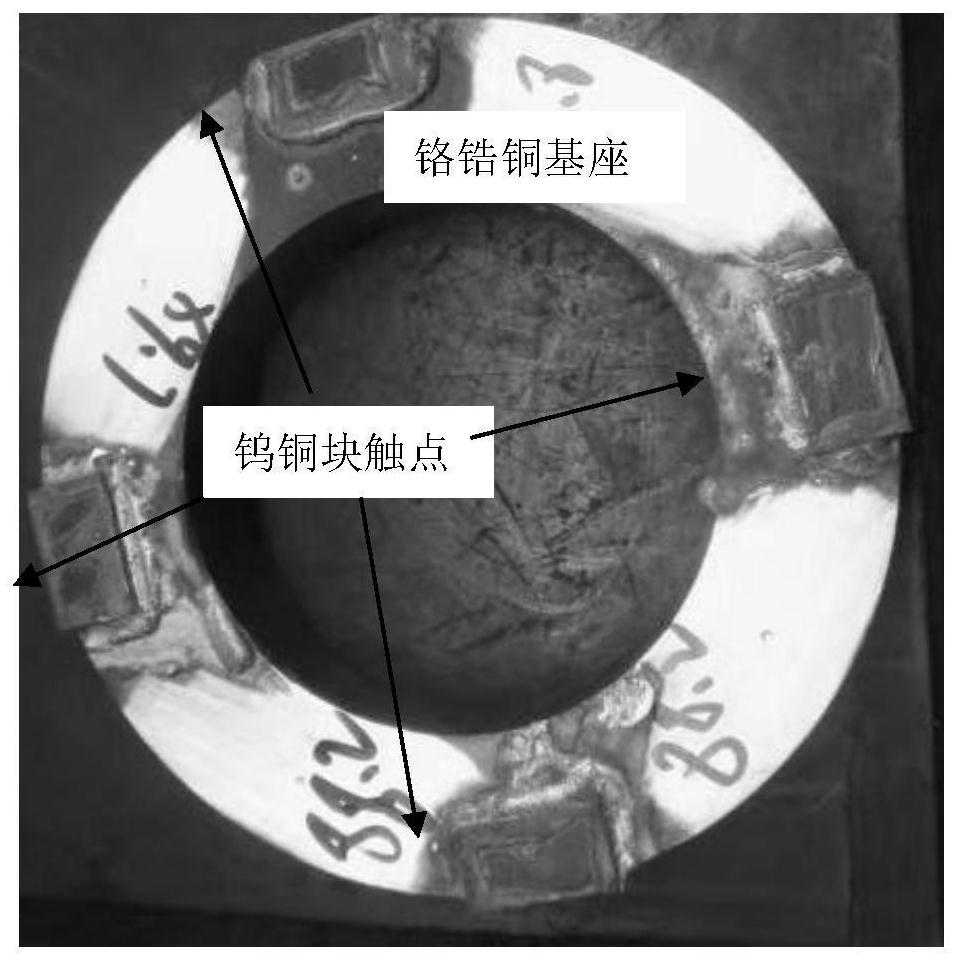

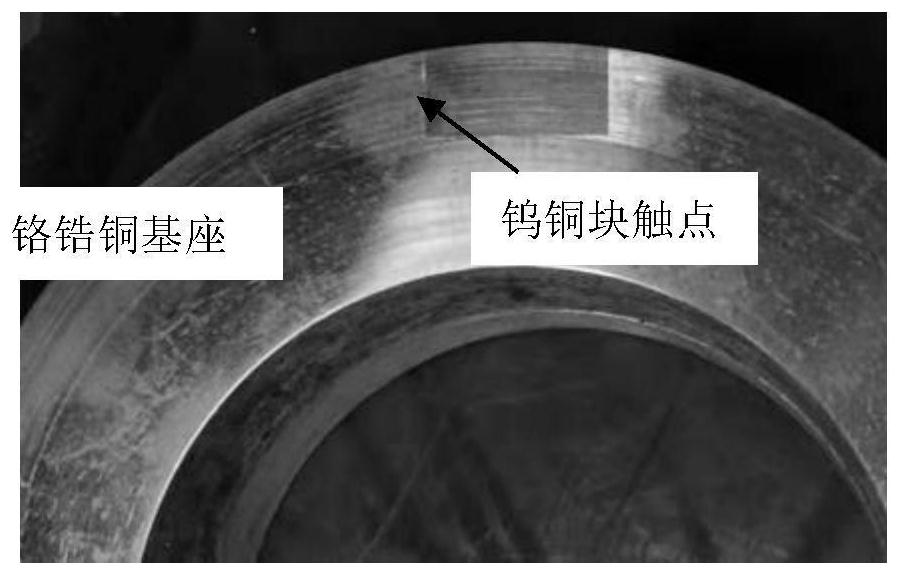

Brazing method of tungsten-copper alloy and chromium-zirconium-copper alloy

ActiveCN111360352AReduce hardnessLow soldering temperatureSoldering apparatusWelding/soldering/cutting articlesUltrasonic assistedCavitation

The invention discloses a brazing method of a tungsten-copper alloy and a chromium-zirconium-copper alloy, and relates to the field of welding. The method aims to shorten the brazing time for the tungsten-copper alloy and the chromium-zirconium-copper alloy, avoid the use of a solder resist, reduce the brazing cost and improve the brazing efficiency. According to the method, the tungsten-copper alloy and the chromium-zirconium-copper alloy are connected by adopting an ultrasonic wave-assisted brazing method, ultrasonic waves are used in the brazing process through a titanium alloy intermediatelayer, and the spreading and wetting of melted brazing filler metal on a brazing surface are promoted by utilizing the acoustic cavitation effect; when the tungsten-copper alloy and the chromium-zirconium-copper alloy are combined and brazed, one of a base metals is moved to promote the discharge of bubbles, and then the ultrasonic wave-assisted brazing process is completed in a short period of time under the low brazing pressure; and in addition, the method can perform brazing in an atmospheric environment, the technical requirements for brazing operators are low, and the brazing efficiencyis high. The invention is applied to the field of brazing.

Owner:SHENYANG JINCHANG LANYU NEW MATERIAL CO LTD

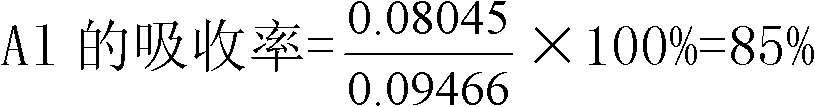

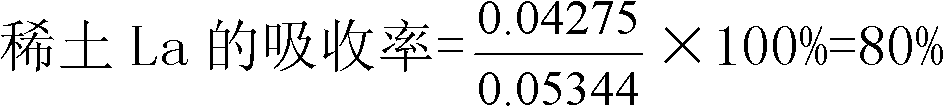

Zn-Al-Mg-RE zinc ingot preparation method

The invention discloses a Zn-Al-Mg-RE zinc ingot preparation method which comprises the following steps: preparing a Zn-Al-Mg-RE ternary intermediate alloy; adding pure Mg in a zinc tank, and dissolving the pure Mg completely; then adding the prepared Zn-Al-RE ternary intermediate alloy in the zinc tank containing the pure Mg, and standing until the Zn-Al-RE ternary intermediate alloy is dissolved completely; and finally pouring a Zn-Al-Mg-RE zinc ingot in a finished product mold. A Zn-Al-Mg-RE quaternary alloy zinc ingot is prepared with low cost rapidly and conveniently by adopting the preparation method, and the yields of Mg and RE elements are improved greatly.

Owner:BAOSHAN IRON & STEEL CO LTD +1

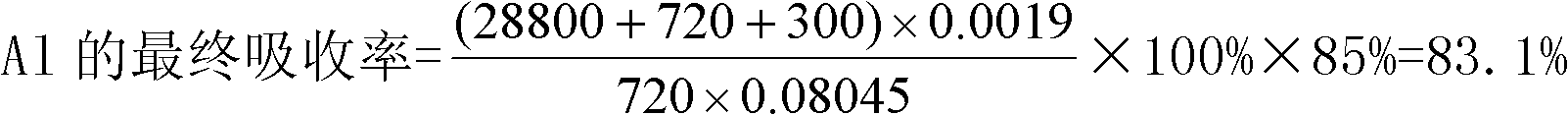

Continuous rotary swaging device and method for producing molybdenum rods or molybdenum alloy rods

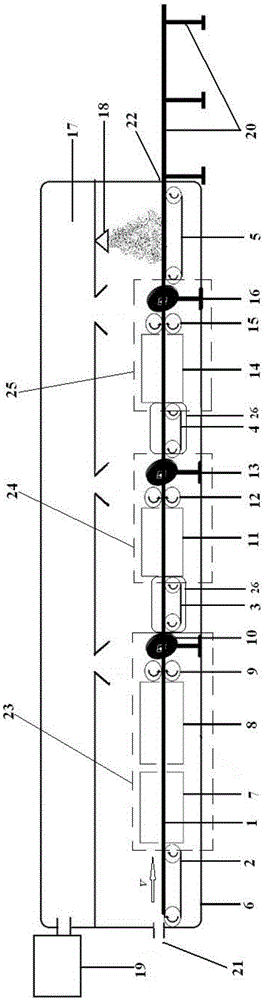

ActiveCN104353769AHigh dimensional accuracyFully automatedForging hammersDirt cleaningThree stageAlloy

The invention discloses a continuous rotary swaging device and method for producing molybdenum rods or molybdenum alloy rods. The continuous rotary swaging device adopts the structure that delivery mechanisms are mounted on a heat-proof and noise-reducing box body, a molybdenum or molybdenum alloy blank is fed from the feed opening of the box body; a molybdenum rod product or a molybdenum alloy rod product is discharged from the discharge opening of the box body; an air extracting mechanism is mounted at the inner top of the box body; the delivery mechanisms adopt a three-stage continuous rotary swaging technology; a spray cooler capable of cooling the molybdenum rods or the molybdenum alloy rods on the fourth delivery mechanism is mounted on the air extracting mechanism above the fourth delivery mechanism. The continuous rotary swaging device has the advantages that the production process is automatic and continuous; the environmental condition of a production field is improved; the problems of oxidation and loss of the product are solved; moreover, the machining dimensional precision of the blank after each machining step is high; the finished product ratio is remarkably improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

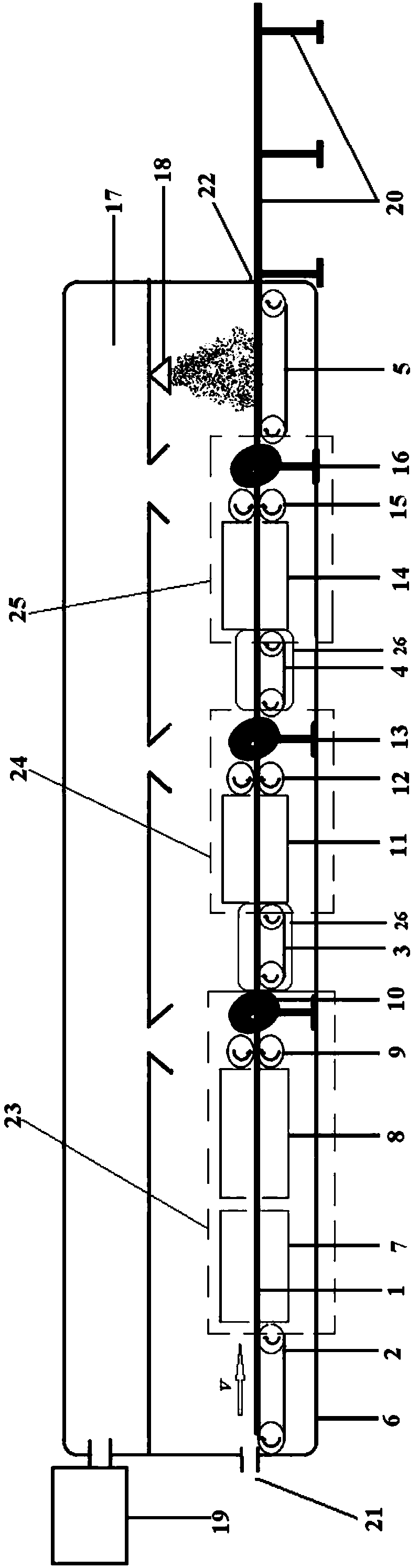

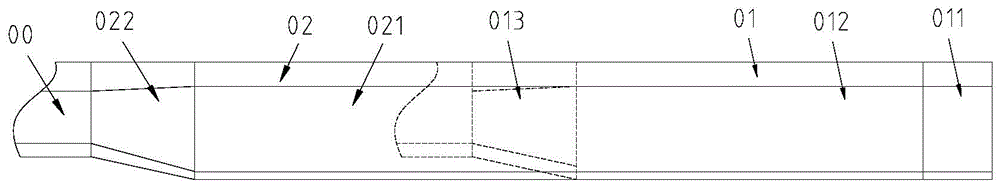

Forging and pressing method of steel rail heel and three-position molding die used thereby

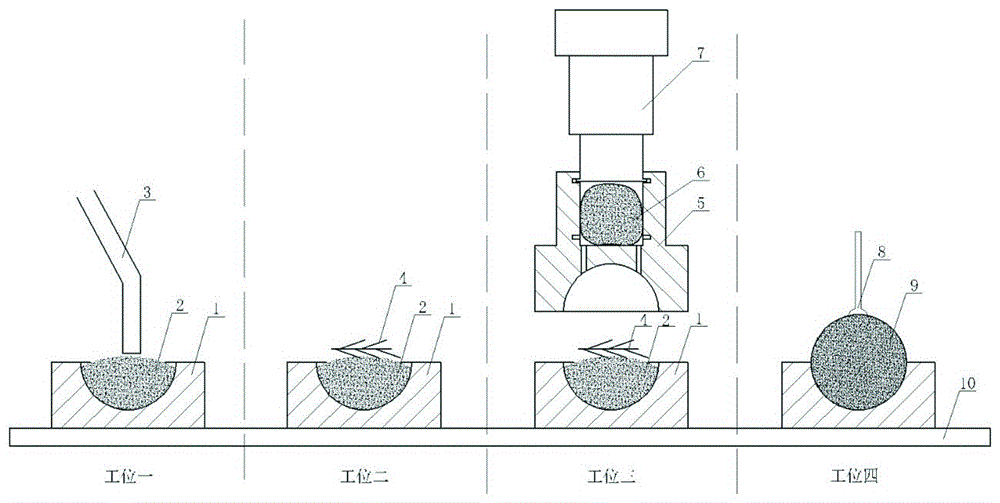

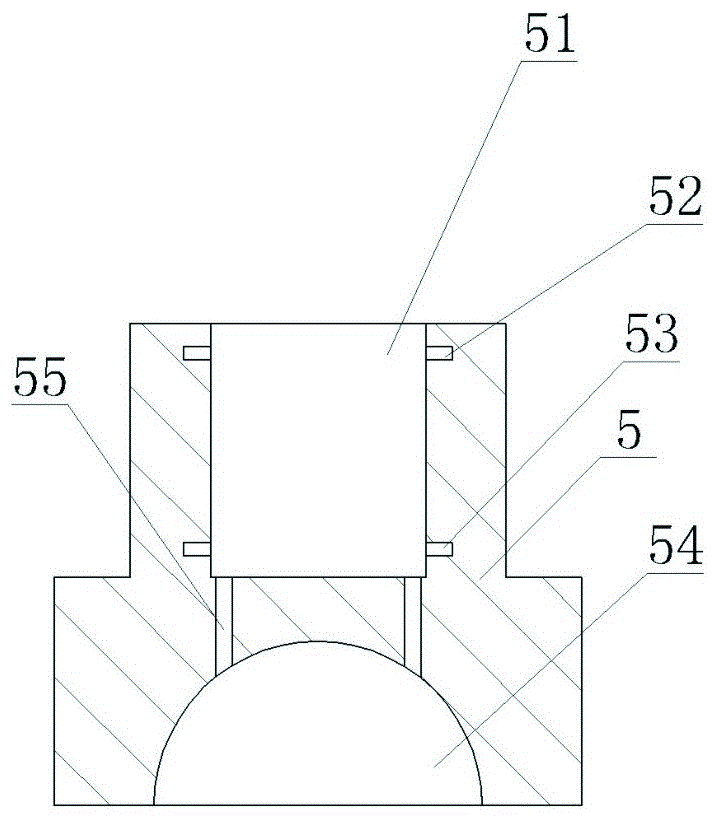

ActiveCN104550593AQuality assuranceEnsure the quality is qualifiedForging/hammering/pressing machinesMaterials scienceHeel

The first purpose of the invention is to provide a forging and pressing method of steel rail heel; a steel rail heel comprises a pre-forging heel and a final forging heel; the pre-forging heel comprises a first section, a second section, and a third section; the final forging heel comprises a fourth section and a fifth section; the method specifically comprises the following steps: implementing a first stage forging and pressing after heating the first section, the second section and the third section, wherein the first two sections are molded by forging and pressing, the third section is pre-deformed; and implementing a second stage forging and pressing after heating the last three sections. The provided forging and pressing method adopts a measure of molding twice, thereby being able to solve the defect that the size of the molded final forging heel is unqualified, as well as greatly reducing the molding force in the entire steel rail heel product molding process. The second purpose of the invention is to provide a three-position molding die with a simple integral structure; a second upper die section inside a pre-forging rail molding cavity and a first pre-forging insert inside a final forging molding cavity are both in detachable structures, thereby meeting different requirements to the three-position molding die in the twice forging and pressing process; the three-position molding die is convenient to be assembled, and strong in practicability.

Owner:CHINA RAILWAY CONSTR HEAVY IND

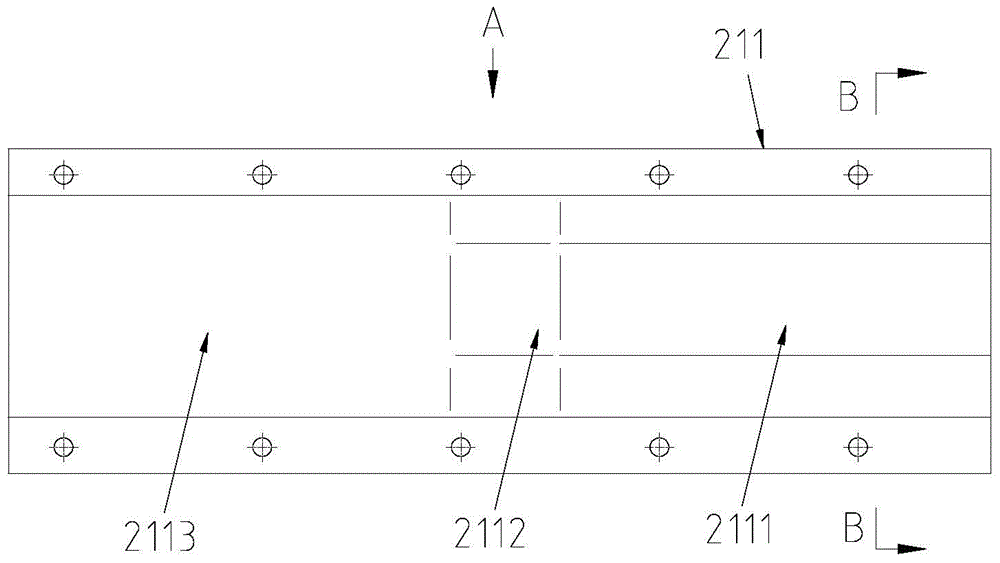

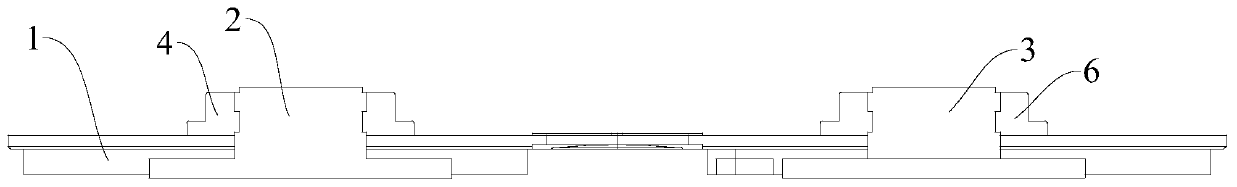

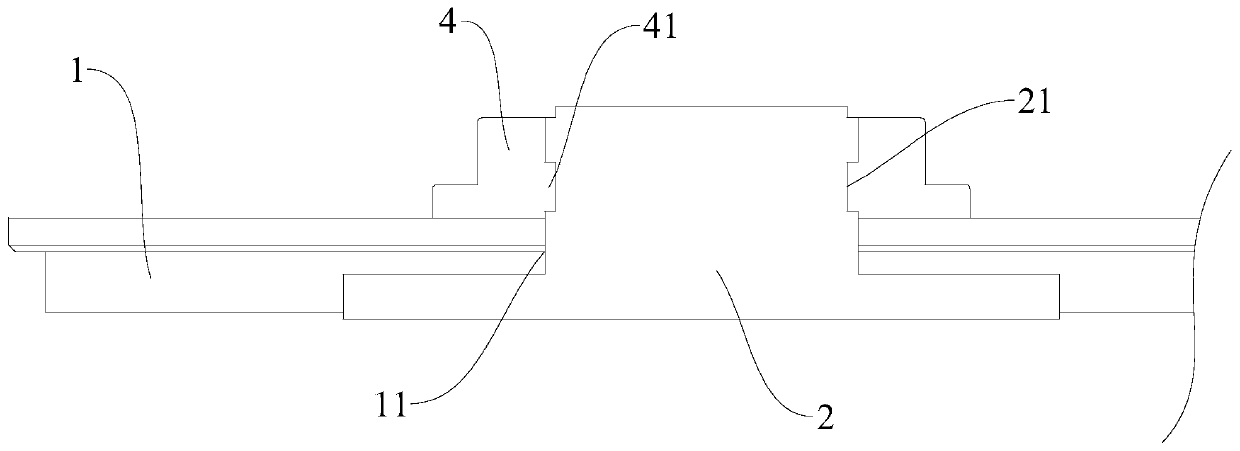

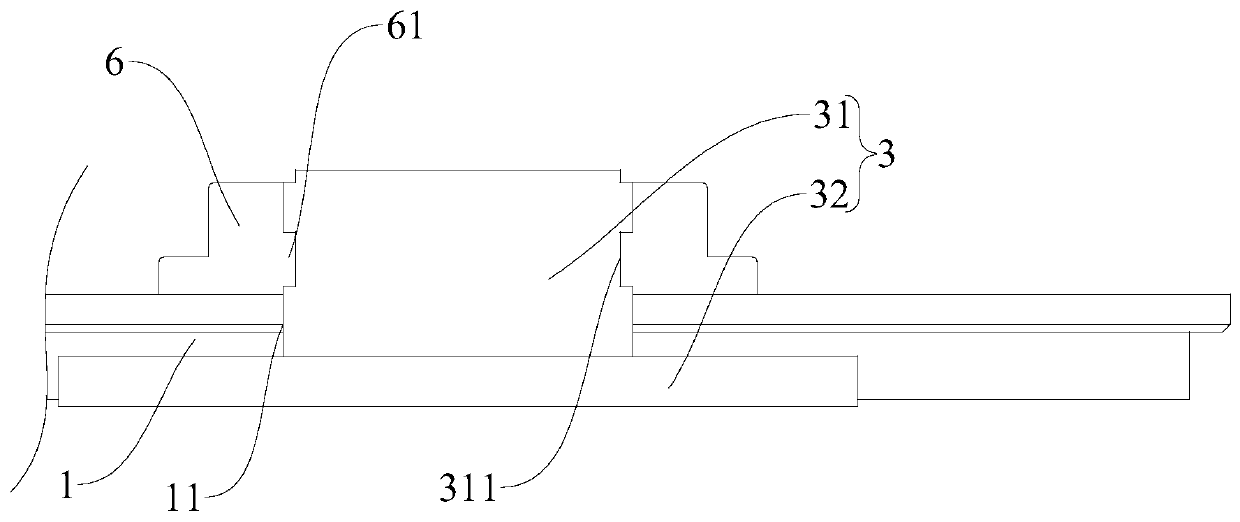

Power battery cover plate

PendingCN111276664AExtended service lifeLight in massSmall-sized cells cases/jacketsCell lids/coversPower batteryStructural engineering

The invention discloses a power battery cover plate. The power battery cover plate comprises a top cover, a positive pole and a negative pole. The positive pole is an aluminum pole. The positive poleis connected to the top cover through a positive injection molding part or riveted to the top cover through a positive pressing block. The negative pole comprises an aluminum part and a copper part, one part of the aluminum part penetrates out of the upper side wall of the top cover, the copper part is located on the lower portion of the top cover, and the negative pole is connected to the top cover through a negative injection molding part or riveted to the top cover through a negative pressing block. According to the power battery cover plate, the part, exposed out of the top cover, of the negative pole column is prevented from being seriously oxidized, the service life of the negative pole column and the whole power battery cover plate is prolonged, the connecting structure between thepole column and the top cover is simplified, the positive pole column and the negative pole column are convenient to install, and the mass of the whole power battery cover plate is reduced.

Owner:SHENZHEN KEDALI IND CO LTD

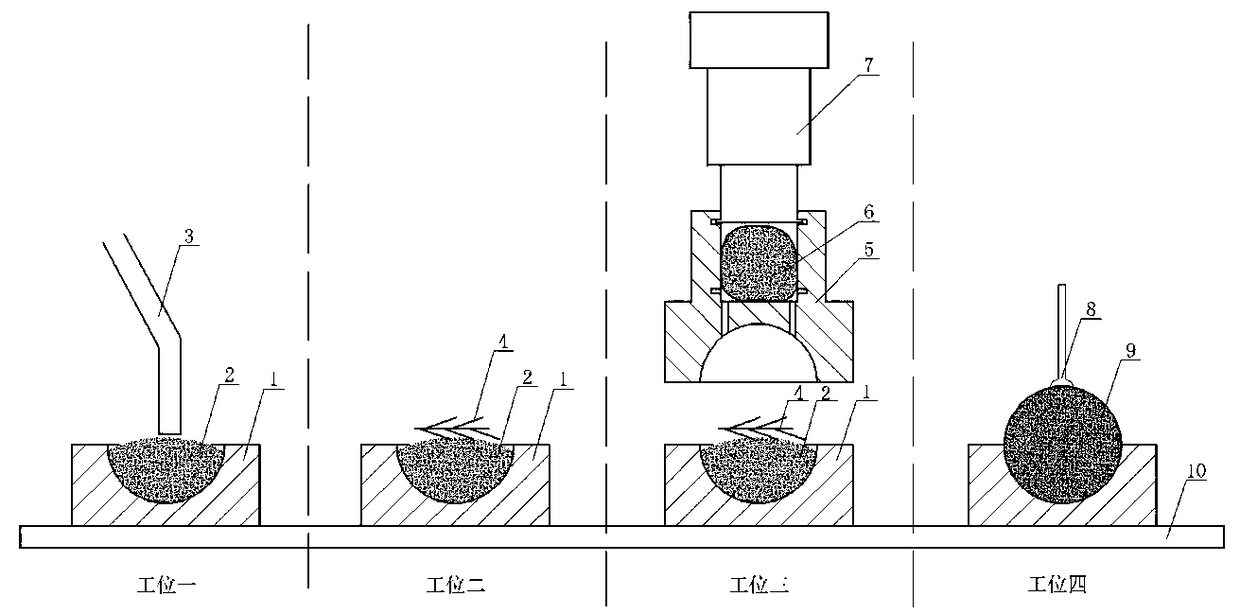

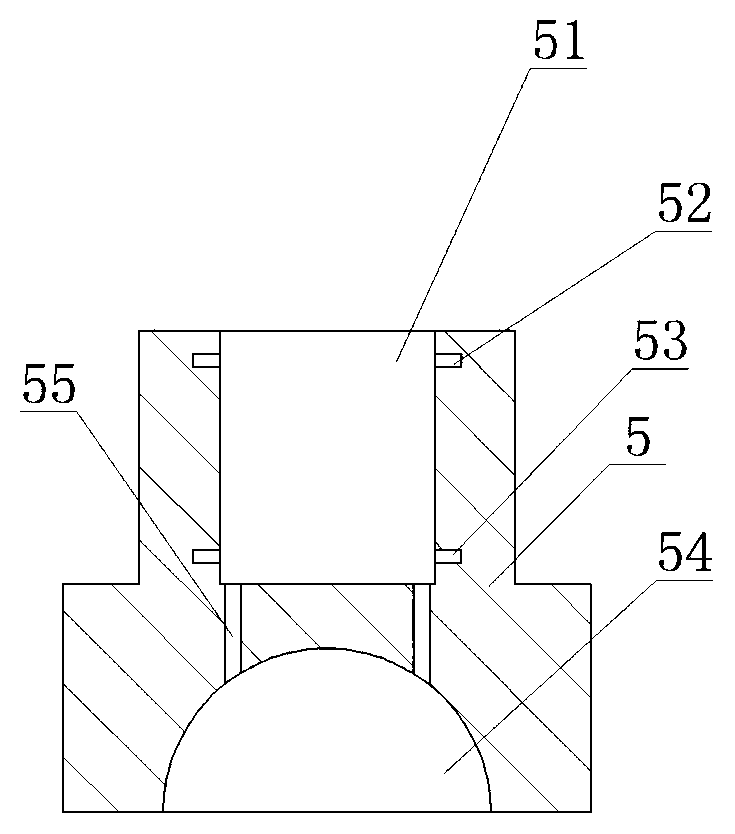

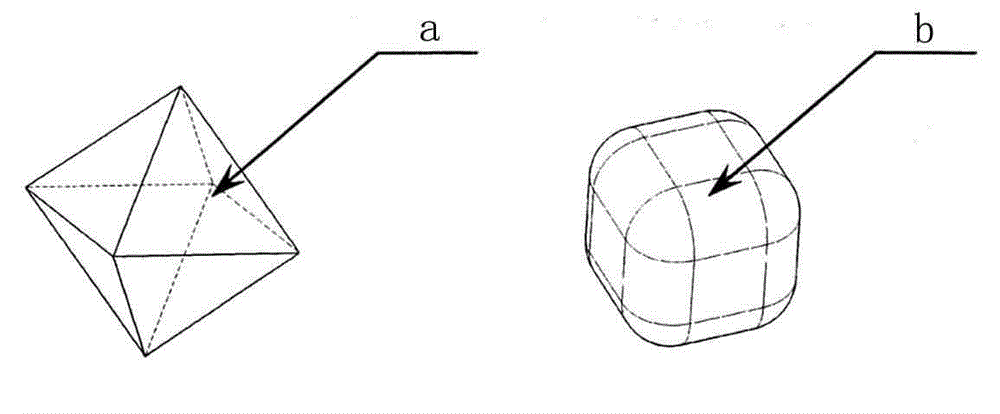

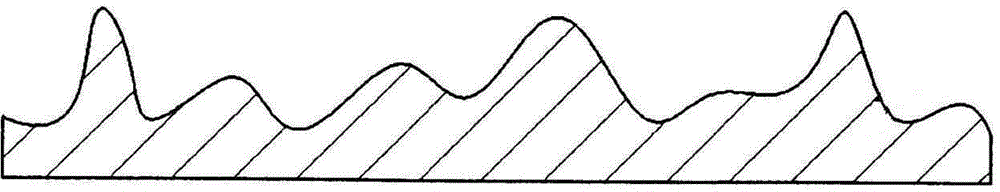

Ceramic ball with in-built alpha+beta titanium alloy skeleton and preparation method thereof

The invention provides a ceramic ball with an in-built alpha+beta titanium alloy skeleton. The ceramic ball is composed of an alpha+beta titanium alloy prepared skeleton with an integrated structure, and a ceramic ball body wrapped outside of the skeleton, and is manufactured in manners of integrated lamination and high-temperature sintering, wherein the total volume of the alpha+beta titanium alloy skeleton accounts for 3 to 5% of the volume of the ceramic ball; the size of the alpha+beta titanium alloy skeleton in the longest direction is smaller than 70% of the external diameter of the ceramic ball; and the ceramic ball body is prepared from an alumina based ceramic material. The invention also discloses a preparation method for the ceramic ball. The preparation method comprises procedures like batching, ball milling, spray granulation, aging in a stock bin, profiling processing, high-temperature sintering, powder-cleaning and polishing, and finished-product drying; and specifically, a great amount of improvements in the procedures of profiling processing and high-temperature sintering are performed. The ceramic ball with the in-built alpha+beta titanium alloy skeleton has better integrality and is insusceptible to breaking; meanwhile, the preparation method enables industrial production of the ceramic ball with the in-built alpha+beta titanium alloy skeleton to be possible through the improvements in the procedures of profiling processing and high-temperature sintering.

Owner:SHANDONG TIANHUI GRINDING WEAR TECH DEV CO LTD

Nitrogen protection device and method in laser welding process

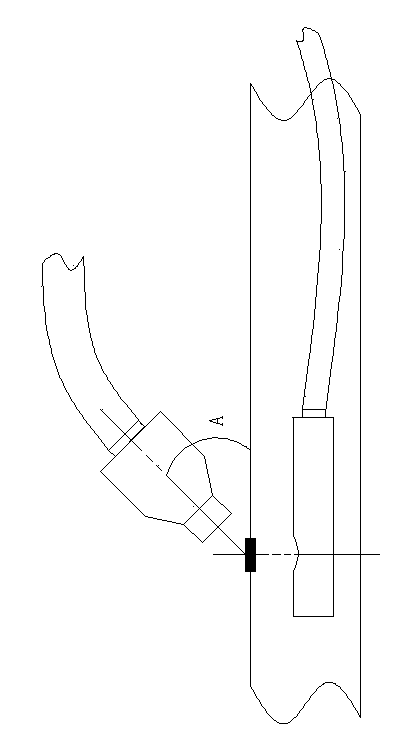

InactiveCN103639596AReal-time protectionAvoid severe oxidationWelding/soldering/cutting articlesLaser beam welding apparatusLiquid nitrogen containerNitrogen

A nitrogen protection device in the laser welding process adopts the structure that nozzles are connected with nitrogen supply conducts, and the nozzles comprise an external nozzle and an internal nozzle. The concrete operation method comprises the following steps: the nozzles are simultaneously arranged inside and outside a welding point of a stainless steel tube; the external nozzle and the internal nozzle are respectively connected with a liquid nitrogen container through the nitrogen supply conducts; the internal and external nozzles are opened at first to allow nitrogen to be jetted on the welding point, and then a laser welding machine is started; the nitrogen supply quantities of the internal and external nozzles are determined by the welding speed and the power of the laser welding machine, and after welding is finished, the laser welding machine is stopped at first and then the internal and external nozzles are closed. The nitrogen protection device has a simple structure and can protect the welding point in real time in the laser welding process of the stainless steel tube so as to prevent the welding point from serious oxidation, guarantee the internal and external brightness of the tube and improve the corrosion resistance, and all detections show that the tube welding quality is high; the nitrogen protection method is simple to operate, saves both time and labor and can be conveniently used by welders of all levels.

Owner:TANGSHAN FENGNAN HUAXIN SUS SUPER CONTROL PIPE

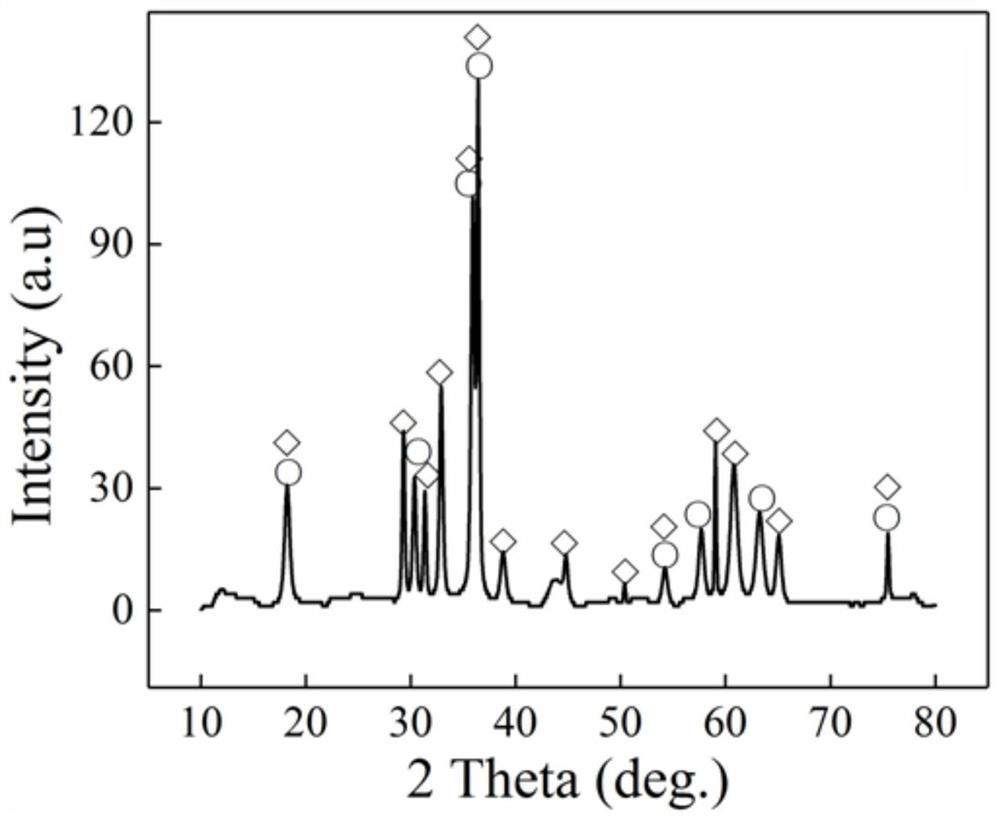

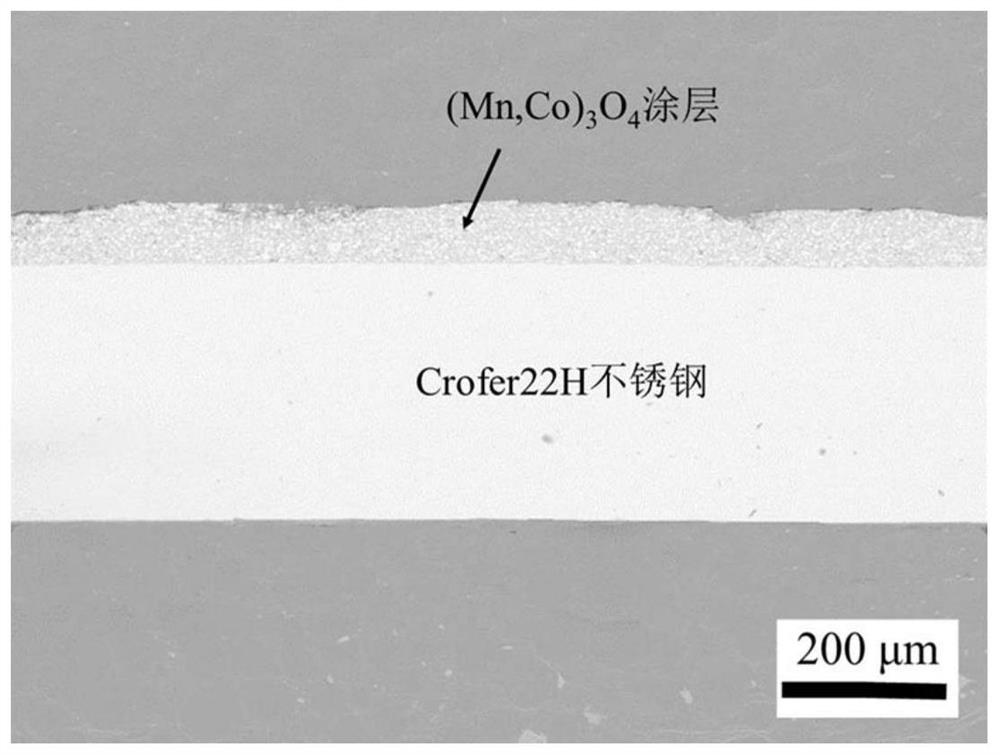

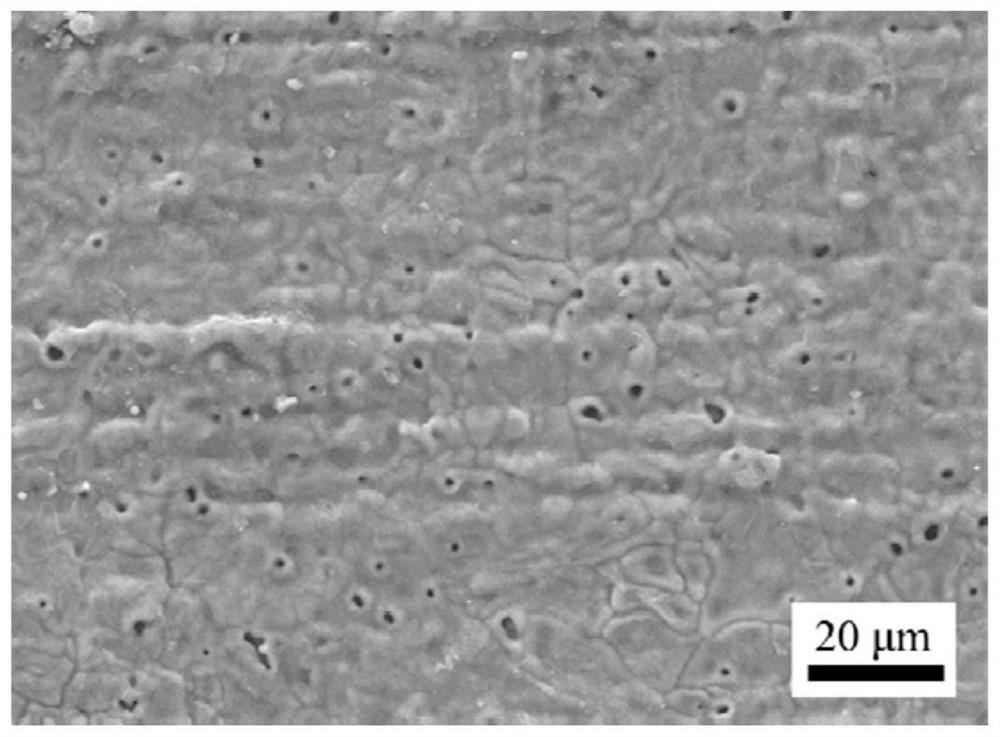

Method for rapidly preparing manganese-cobalt spinel coating through microwave mixed heating

PendingCN112939575AGood repeatabilityLow relative permittivityFuel cellsAir atmosphereCompression molding

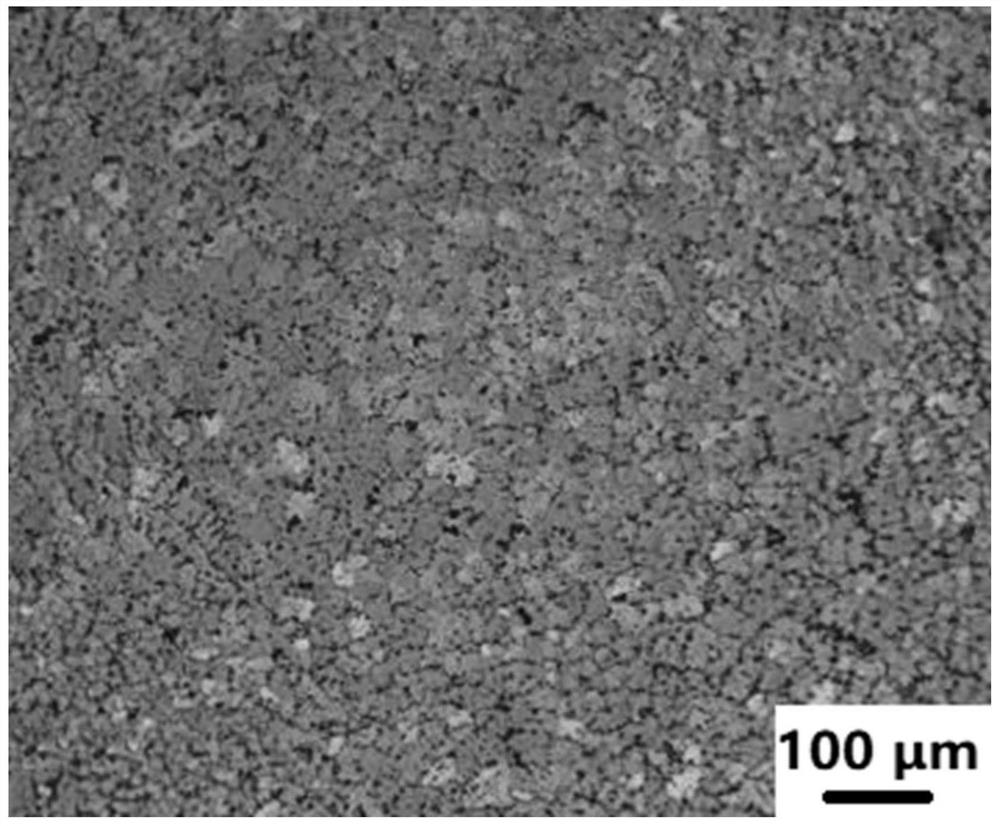

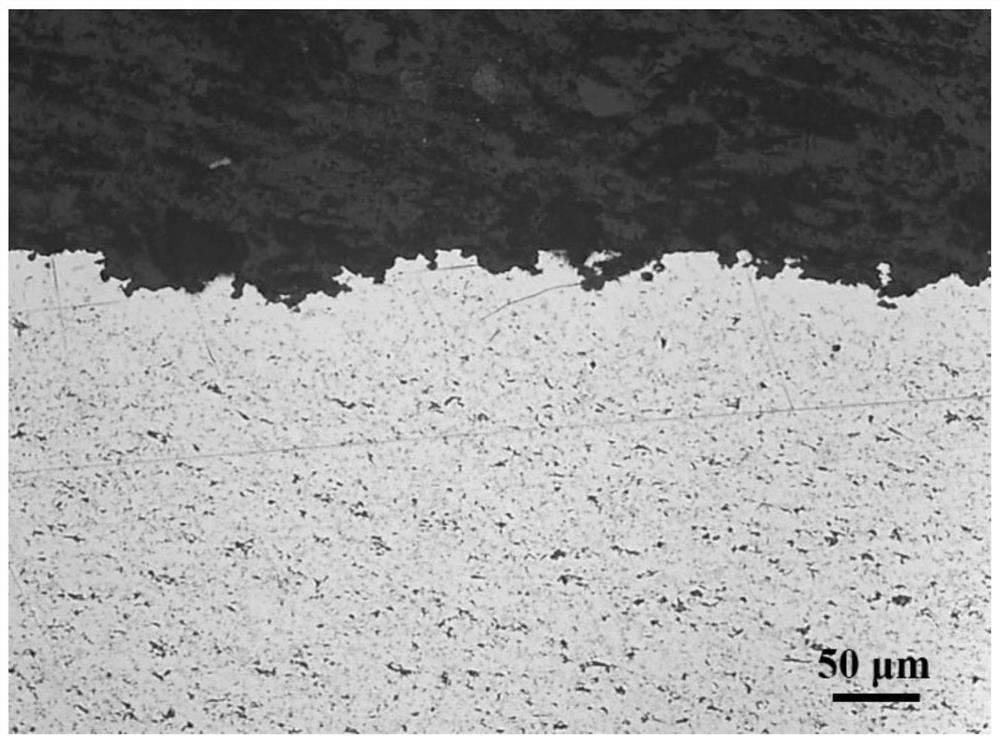

The invention discloses a method for rapidly preparing a manganese-cobalt spinel coating through microwave mixed heating, relates to the technical field of microwave processing and metal surface modification, and aims at solving the problems that components are uncontrollable, the preparation process is tedious, base metal is seriously oxidized and the like when the manganese-cobalt spinel coating is prepared through a traditional technology. The method for preparing the manganese-cobalt spinel coating comprises the following steps: 1, weighing Co powder, MnO2 powder and sintering aid powder as raw materials; 2, placing the raw materials in a ball-milling tank for wet ball-milling treatment; 3, carrying out surface treatment on the ferritic stainless steel; 4, evenly smearing the mixed powder on the surface of the ferritic stainless steel, and performing compression molding; and 5, imbedding the stainless steel attached with the prepressing coating in the high-microwave-absorptivity powder in the microwave sintering furnace, and performing sintering and heat preservation in the air atmosphere. The manganese-cobalt spinel protective layer is prepared by adopting a microwave mixed heating method, the heating rate is high, the heating efficiency is high, the sintering temperature is greatly reduced, the sintering time is shortened, overall uniform heating is realized, and the internal stress of the coating is small.

Owner:HARBIN INST OF TECH

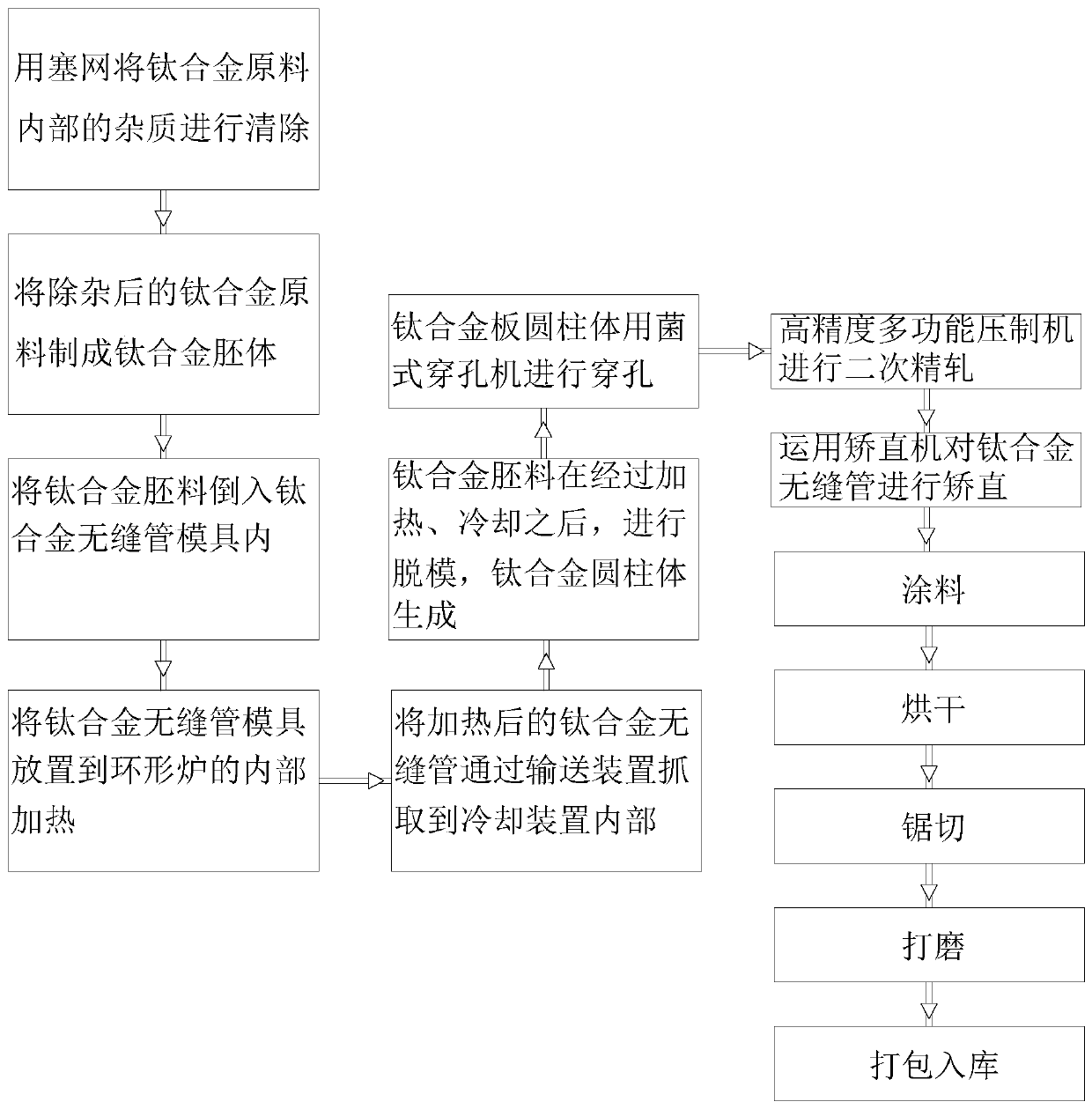

Production process of hot-rolled large-caliber thin-wall titanium alloy seamless tube

InactiveCN110586653AReduce consumptionReduce power consumptionMetal rolling arrangementsHydrogenAdditive ingredient

The invention relates to the technical field of titanium alloy seamless tubes and discloses a production process of a hot-rolled large-caliber thin-wall titanium alloy seamless tube. The technologicaloperation process of the production process mainly comprises the following steps of A, an operator removes impurities in a titanium alloy material through a clogging screen; B, manufacturing the impurity removed titanium alloy material into a titanium alloy blank; C, pouring the titanium alloy blank into a seamless tube mold; D, just placing the titanium alloy seamless tube mold into an annular furnace to be heated; E, grabbing the heated titanium alloy blank seamless tube into a cooling device through a conveying device; F, conducting demolding after titanium alloy ingredients are subjectedto heating and cooling to generate a solid titanium alloy cylinder; and G, conducting fixing on the solid titanium alloy cylinder through a machining lathe. Through the production process of the hot-rolled large-caliber thin-wall titanium alloy seamless tube, the problems that titanium has a reaction with carbon, hydrogen, nitrogen and oxygen at high temperature, the organization structure of thetitanium is changed, the physical and chemical characteristics of the titanium are affected and the using requirements can be hardly met are solved.

Owner:XINPENGYUAN INTELLIGENT EQUIP GRP

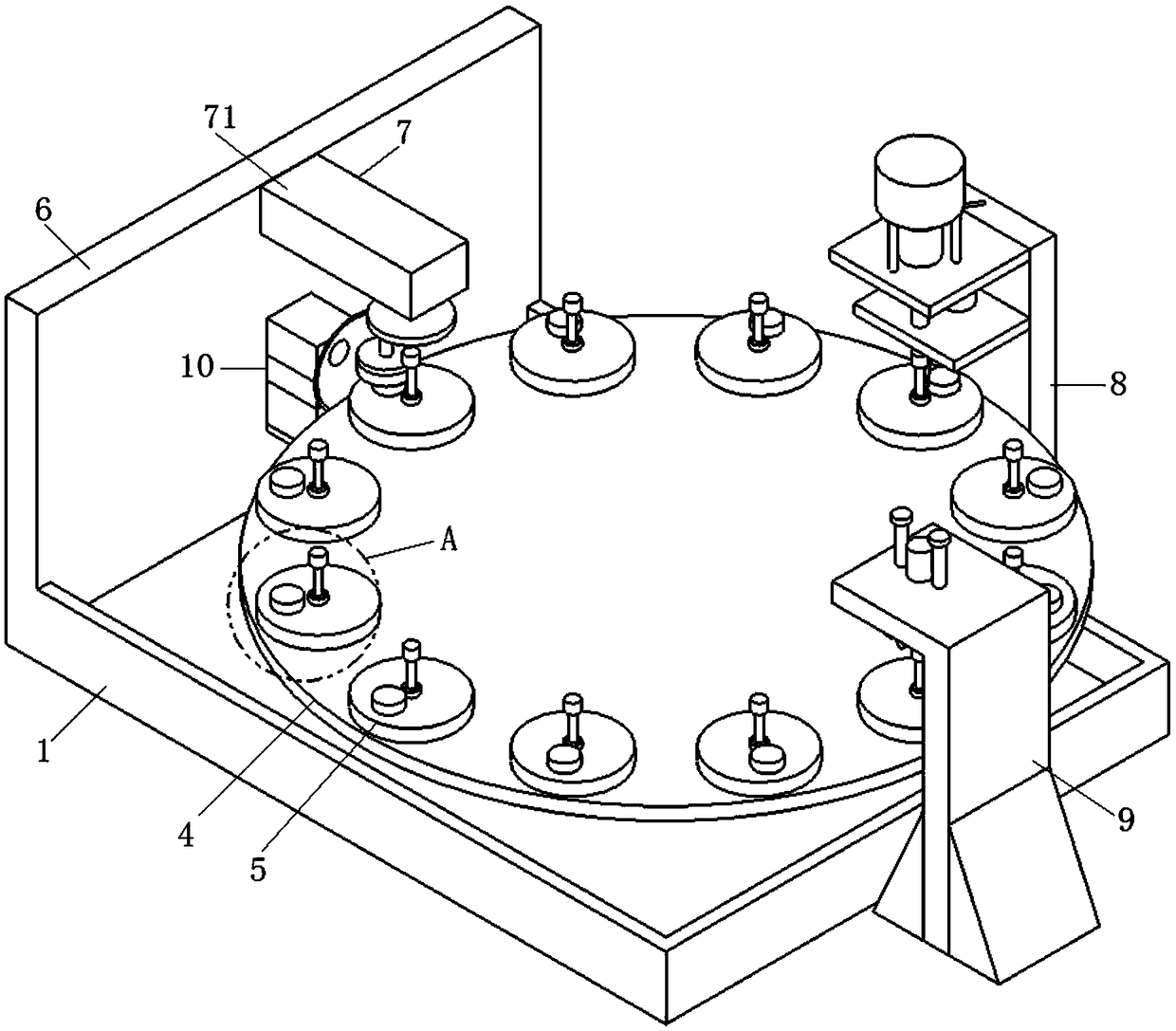

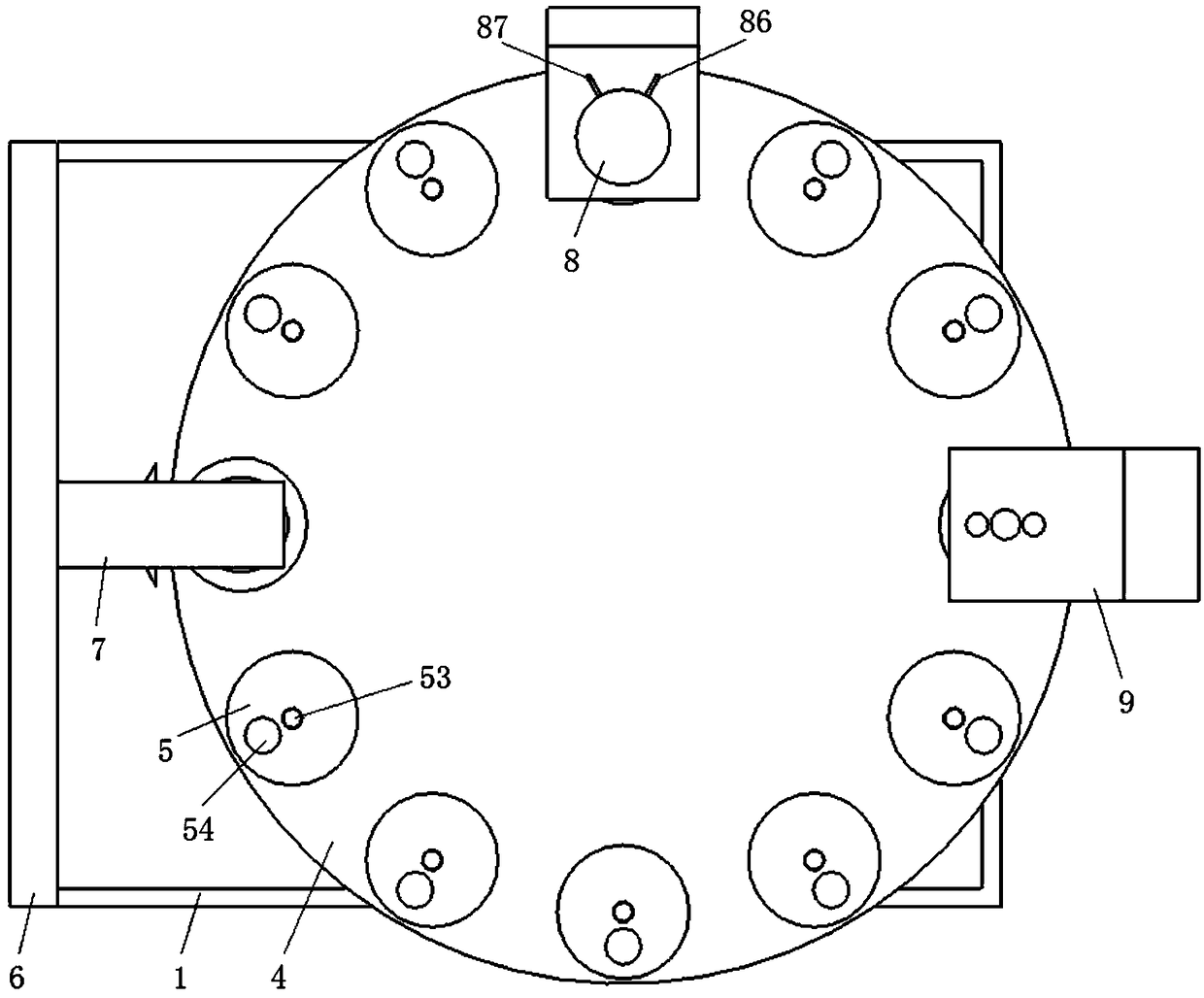

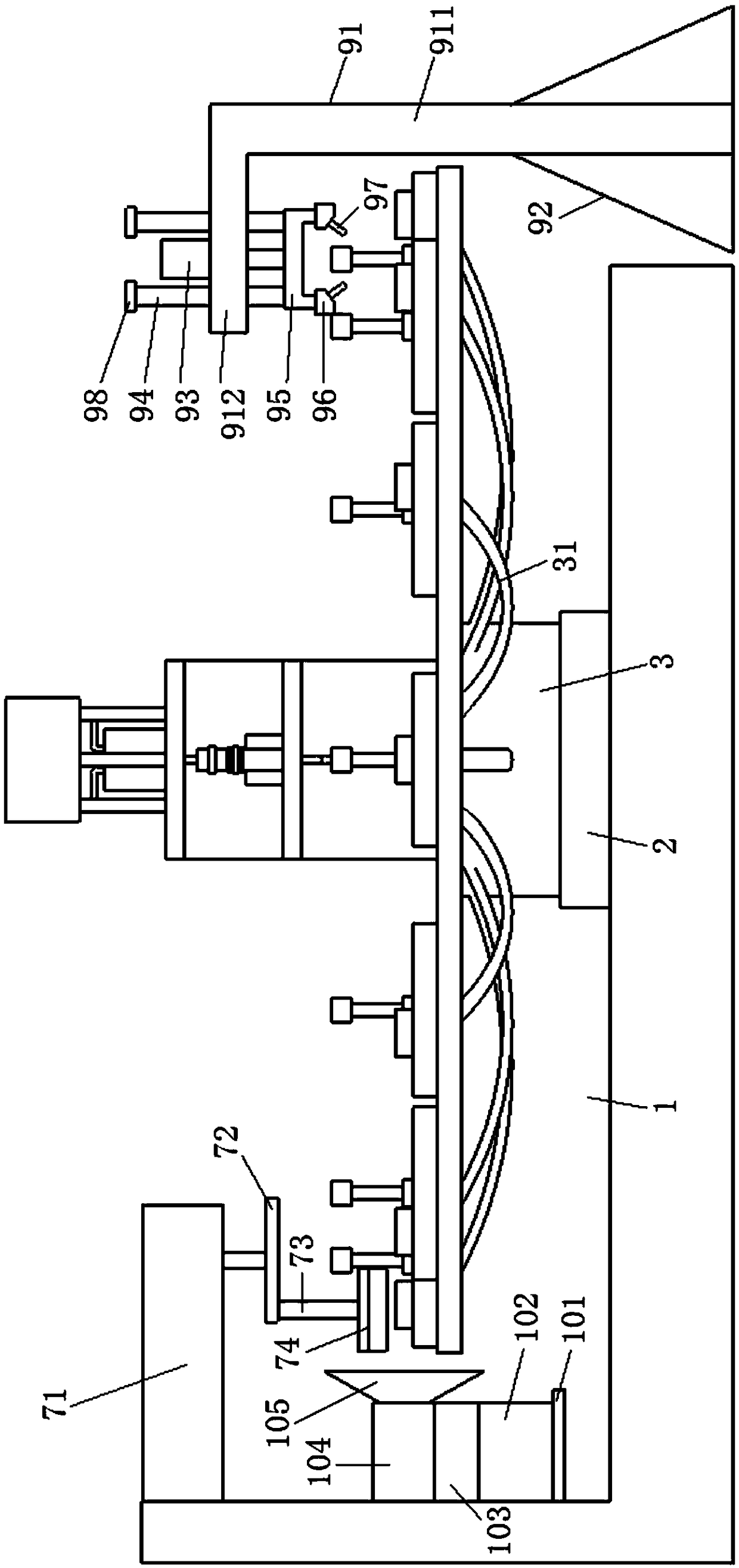

Welding equipment with smearing mechanism for exhaust pipes of upper shells of air-conditioning compressors

ActiveCN108856957AImprove cleanlinessRealize automatic stirringMetal working apparatusSoldering auxillary devicesElectricityNitrogen

The invention discloses welding equipment with a smearing mechanism for exhaust pipes of upper shells of air-conditioning compressors. The welding equipment comprise a bearing pond and controllers. Abase, a nitrogen supply device and a worktable are sequentially arranged in the bearing pond from bottom to top, a plurality of base plates are arranged on the worktable, clearing stations, smearing stations and welding stations are arranged on the bearing pond, a support plate is arranged at the end, which is close to the clearing stations, of the bearing pond, a clearing mechanism and a dust collection mechanism are arranged on the support plate, the smearing mechanism is arranged on the side, which is close to the smearing stations, of the bearing pond, a welding mechanism is arranged on the side, which is close to the welding stations, of the bearing pond, gas outlet assemblies are arranged on the base plates and are connected with the nitrogen supply device by nitrogen delivery pipes,nitrogen electromagnetic valves are arranged between the nitrogen supply device and the nitrogen delivery pipes, and stepper motors, the nitrogen electromagnetic valves, the nitrogen supply device, the clearing mechanism, the smearing mechanism and the welding mechanism are electrically connected with the controllers. The welding equipment has the advantages that that welding paste can be automatically smeared by the welding equipment, accordingly, the smearing efficiency can be improved, and the brightness of the exhaust pipes and the upper shells can be guaranteed.

Owner:芜湖美奥机械科技有限公司

PTC thermistor alloy wire with high resistance temperature coefficient and preparation method of PTC thermistor alloy wire

ActiveCN104651667AMeet requirements such as more sensitive temperature controlExtended service lifePositive temperature coefficient thermistorsMisch metalRare earth

The invention discloses a PTC thermistor alloy wire with a high resistance temperature coefficient and a preparation method of the PTC thermistor alloy wire. The PTC thermistor alloy wire comprises the following chemical components in percentage by mass: 78%-82% of nickel, 0.28%-0.60% of silicon, 0.30%-0.35% of manganese, 0.02%-0.04% of yttrium, 0.04%-0.06% of misch metal, not more than 0.05% of carbon, not more than 0.01% of sulphur, not more than 0.001% of phosphorus and the balance of iron; the mean resistance temperature coefficient of the alloy wire at 0-150 DEG C is 4800*10<-6> DEG C to 5,000*10<-6> DEG C; and the specific resistance of the alloy wire is (0.17-0.19)+ / -0.02muohm.m. The alloy wire disclosed by the invention is currently needed alloy wire with a relatively high resistance temperature coefficient; and the mean resistance temperature coefficient can be up to 5,000*10<-6> DEG C, and meets relatively sensitive temperature control requirements of emerging electric equipment.

Owner:JIANGSU HUAXIN ALLOY

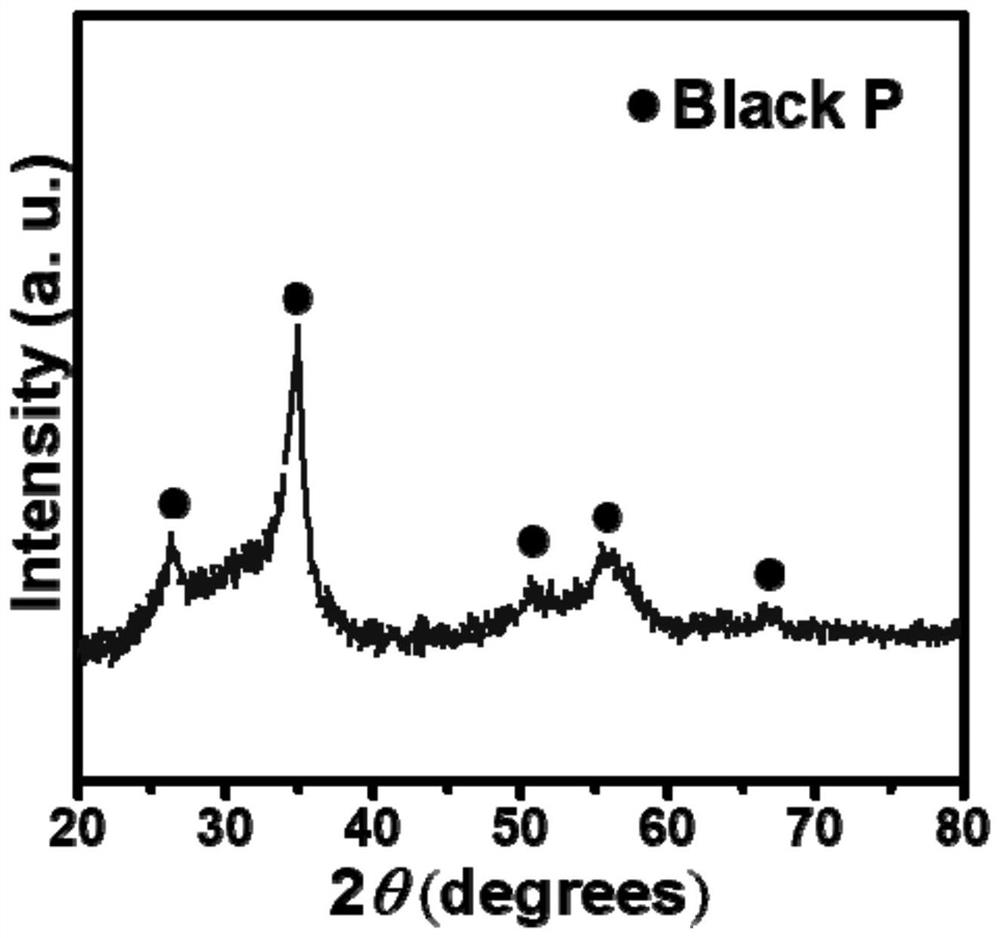

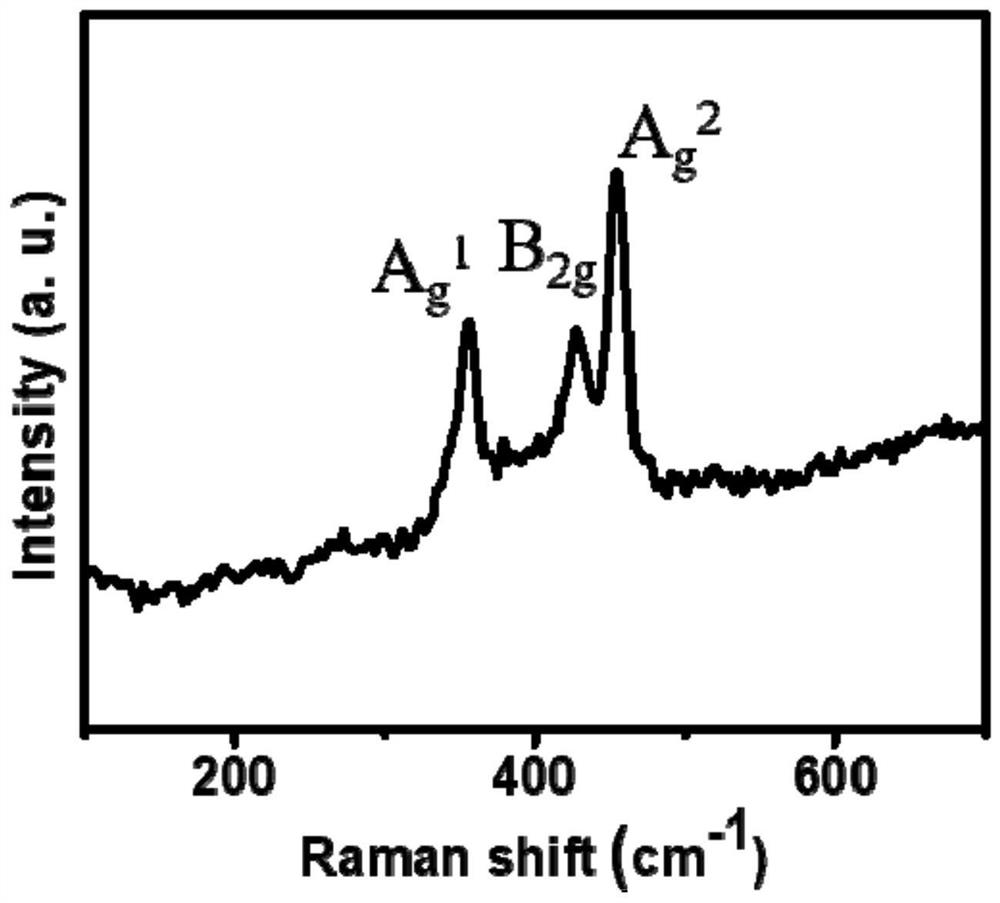

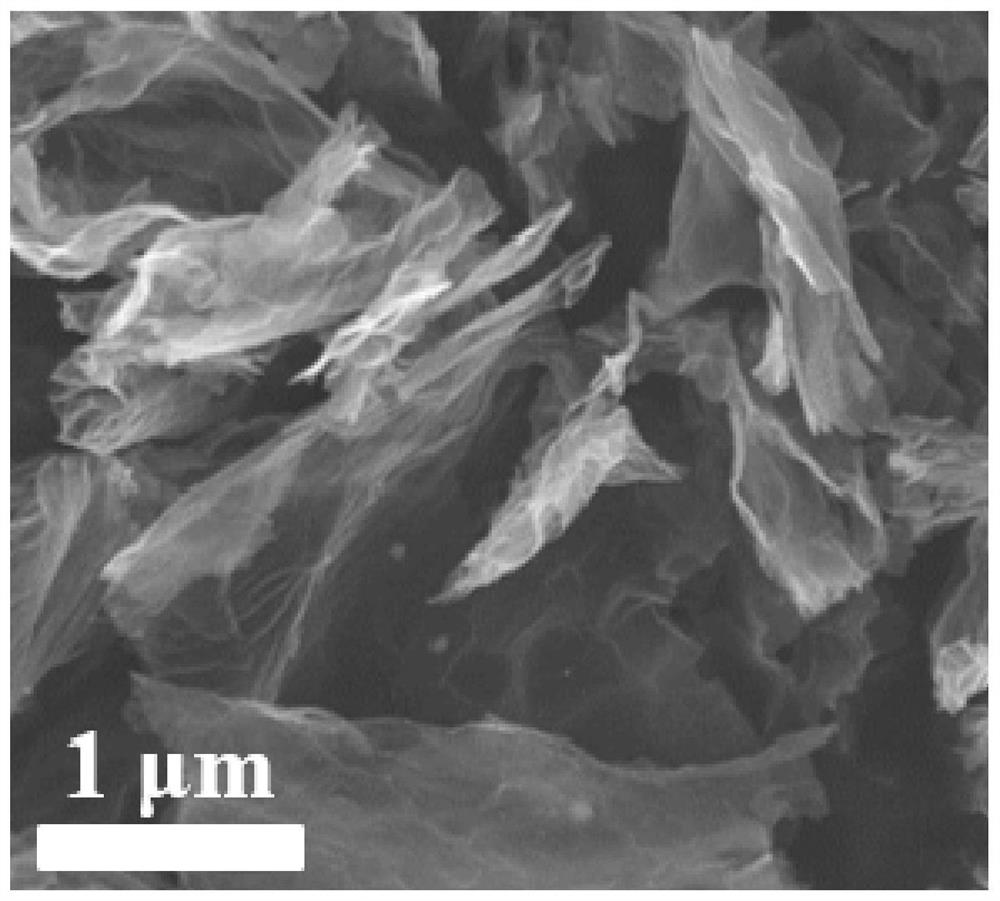

Synthetic method of porous black phosphorus nanosheet for negative electrode material of ion battery

ActiveCN113336206AExcellent peelabilityAvoid severe oxidationNegative electrodesNanotechnologyElectrical batteryPhysical chemistry

The invention discloses a synthesis method of a porous black phosphorus nanosheet for an ion battery negative electrode material, and belongs to the technical field of synthesis of nano materials. The invention aims to solve the problems that the synthesis conditions of the existing black phosphorus material are harsh, the two-dimensional black phosphorus nanosheet needs complex ultrasonic stripping, the construction method of the porous black phosphorus nanosheet is complex, and the pore diameter is too large. The preparation method comprises the following steps: 1, carrying out ball milling on phosphorus trichloride, anhydrous zinc chloride and metal sodium to obtain a ball-milled mixture; 2, carrying out cleaning, centrifugal separation and vacuum drying on the ball-milled mixture to obtain the porous black phosphorus nanosheet. The method is used for synthesizing the porous black phosphorus nanosheet of the negative electrode material of the ion battery.

Owner:HARBIN ENG UNIV +1

Positive temperature coefficient (PTC) thermal resistance alloy wire and preparation method thereof

ActiveCN103060615BMeet requirements such as more sensitive temperature controlGuaranteed performance and stabilityPositive temperature coefficient thermistorsProcess efficiency improvementMisch metalRare earth

The invention discloses a positive temperature coefficient (PTC) thermal resistance alloy wire and a preparation method thereof. The alloy wire comprises the chemical ingredients by weight percent of 45-82.0% of nickel, 0.1-0.6% of silicon, 0.22-0.35% of manganese, 0.02-0.04% of yttrium, 0.04-0.06% of misch metal, 0.05% or less of carbon, 0.01% or less of sulphur, 0.001% or less of phosphorus and the balance of iron. The mean resistance temperature coefficient at 0-150 DEG C is 2500*10(-6) per DEG C to 5000*10(-6) per DEG C by changing the matching content of the components; the PTC thermal resistance alloy wire of which the resistance temperature coefficient which is urgently needed at present and higher than 3000*10(-6) per DEG C is included; the highest mean resistance temperature coefficient can be 5000*10(-6) per DEG C, and the requirements of more sensitive temperature control of novel electrical equipment can be met.

Owner:JIANGSU HUAXIN ALLOY

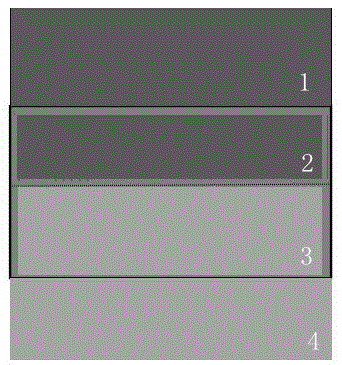

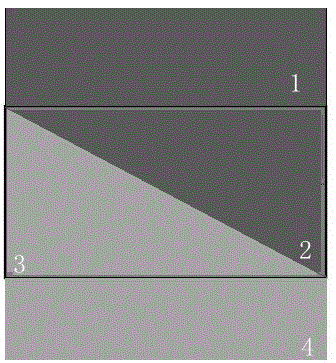

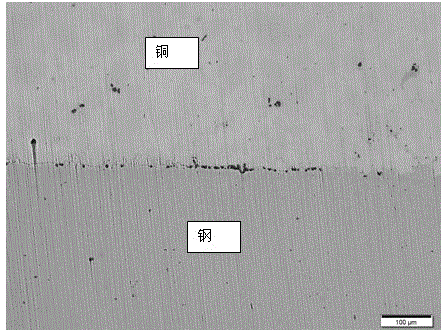

Copper and steel bimetal bridging welding method

InactiveCN103753042AEfficient weldingEasy to standardize operationWelding/soldering/cutting articlesWelding apparatusHeating furnaceMetal

The invention belongs to the technical field of metal welding, and particularly relates to a copper and steel bimetal bridging welding method. The method includes firstly adding copper material and charcoal into a steel drum, then placing the steel drum in a heating furnace to form flux inside, placing the steel drum with the flux into a centrifuge, turning on the centrifuge to rotate in the speed of 400 to 800 rpm, allowing the flux to cool till solidifying as copper alloy, allowing the middle of the copper alloy to form a sump, obtaining a bimetal drum, then placing the bimetal drum into casting sand to cool till room temperature, obtaining a bimetal combined drum, rolling, extruding, tensioning, forging and cutting the bimetal combined drum, obtaining a steel and copper welding bridge, welding steel to be welded to the steel side of the welding bridge, welding copper to be welded to the copper side of the welding bridge, and finishing steel and copper welding. According to the technical scheme, the atomically-bound copper and steel bimetal serves as a bridge, copper and copper, steel and steel can be welded easily, and copper and steel bimetal welding can be realized.

Owner:NORTHEASTERN UNIV

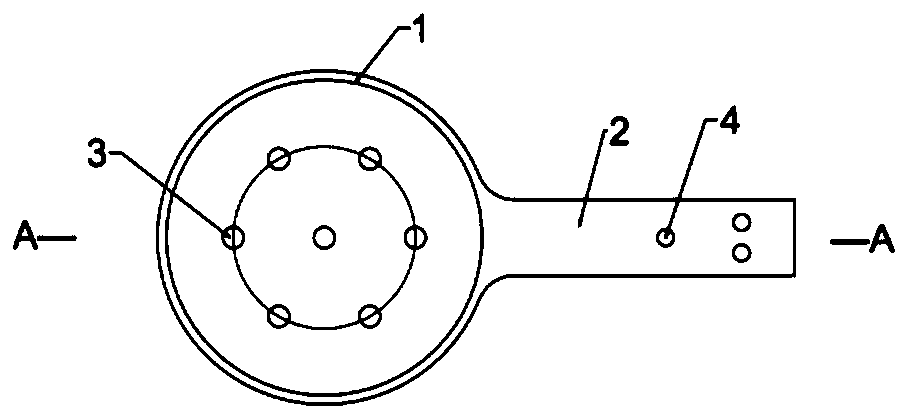

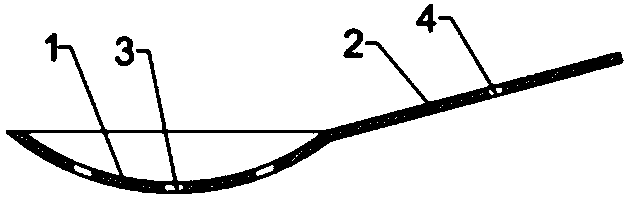

High-temperature-resistant antioxidant niobium alloy slag ladle used for nonferrous metal smelting and slagging

InactiveCN110340341ASolve the problem of melting lossAvoid problems that reduce the quality of aluminum productsCasting cleaning apparatusSlagNonferrous metal

The invention discloses a high-temperature-resistant antioxidant niobium alloy slag ladle used for nonferrous metal smelting and slagging. The slag ladle is of a spoon-shaped structure, and comprisesa ladle body (1) and a ladle handle (2), wherein leakage holes (3) are formed in the bottom of the ladle body; the ladle body and the ladle handle are manufactured from a high-temperature-resistant antioxidant niobium alloy which is Nb-1Zr; and an MoSi2 high-temperature-resistant antioxidant coating material is sprayed to the surface of the ladle body and the surface of the ladle handle. The high-temperature-resistant antioxidant niobium alloy slag ladle disclosed by the invention is not liable to melt, is long in service life, can be used in a circulating mode by many times, reduces tool consumption and manufacturing and maintaining cost, can prevent molten iron from mixing into molten aluminum to reduce aluminum product quality, and is high in slag removal efficiency.

Owner:鹤庆溢鑫铝业有限公司

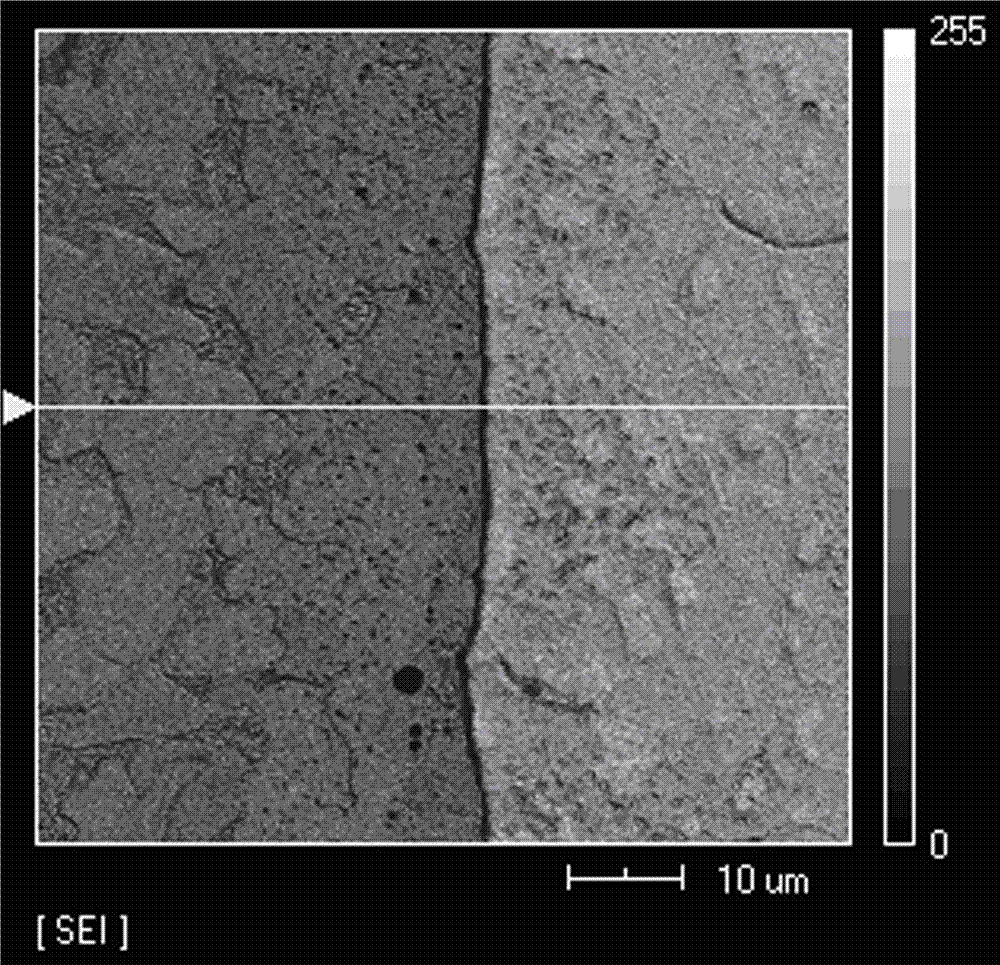

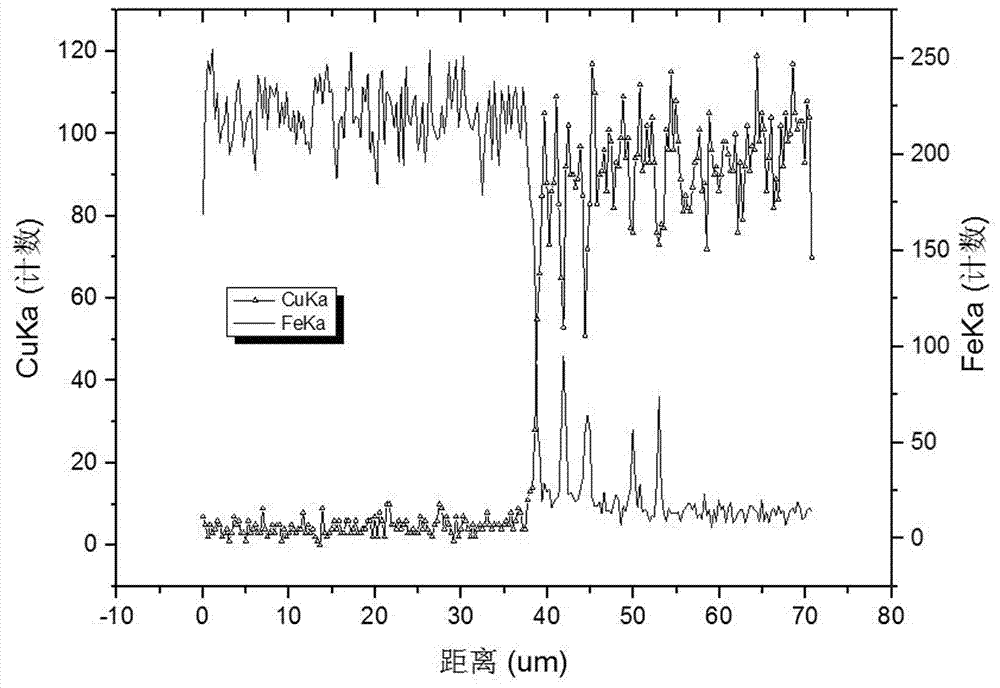

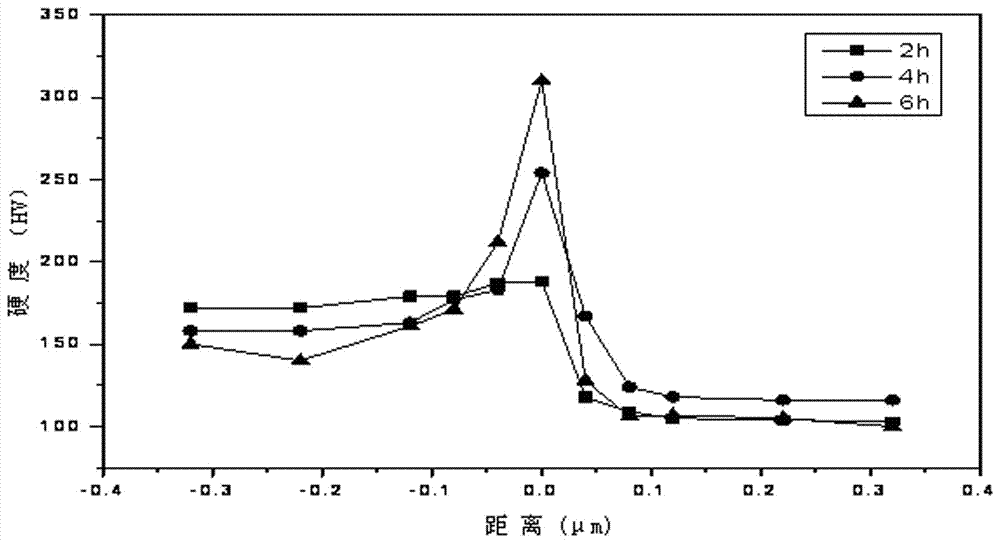

A kind of preparation method of iron-copper bonding material

An iron-copper bonded material and a preparation method thereof, belonging to the field of material technology, are formed by combining two metals, one metal is an iron alloy, and the other metal is a copper alloy; the joint of the two metals is in the form of atomic bonding; the preparation The method is: (1) process the iron alloy into an iron drum; (2) prepare the copper alloy raw material and carbonaceous material; (3) put the copper alloy raw material and carbonaceous material into the iron drum, and weld the iron cover on the iron drum , placed in a heating furnace, heated to form a melt; (4) centrifuged in a centrifuge until it is completely solidified into a copper alloy; placed in casting sand and cooled to room temperature; (5) cut along the vertical direction of the axis to obtain a double Metal disc; (6) Rolled into ring-shaped bimetallic sheet. The iron-copper bonding material in the present invention can be applied in bridging welding of dissimilar metals, high-temperature automatic protection of nuclear power plants, automatic control devices in unmanned environments, microgravity electric rotor connectors, and the like.

Owner:NORTHEASTERN UNIV LIAONING

A kind of brazing method of tungsten-copper alloy and chromium-zirconium-copper alloy

ActiveCN111360352BReduce hardnessLow soldering temperatureSoldering apparatusWelding/soldering/cutting articlesUltrasonic assistedTitanium alloy

A brazing method for tungsten-copper alloy and chromium-zirconium-copper alloy, which relates to the field of welding. The purpose of the invention is to shorten the welding time of tungsten-copper alloy and chromium-zirconium-copper alloy, avoid the use of solder resist, reduce welding cost, and improve welding efficiency . The invention adopts the method of ultrasonic-assisted brazing to connect tungsten-copper and chromium-zirconium-copper alloy, and uses the ultrasonic wave in the welding process through the titanium alloy intermediate layer to promote the spreading and wetting of the melted solder on the welding surface by using the acoustic cavitation effect . When tungsten-copper alloy and chromium-zirconium-copper alloy are welded together, one of the base metals is moved to promote the discharge of air bubbles, and then the ultrasonic-assisted brazing process is completed in a short period of time under a lower welding pressure. In addition, the present invention can Welding in the atmospheric environment has low technical requirements for welding operators and high welding efficiency. The invention is applied in the field of welding.

Owner:SHENYANG JINCHANG LANYU NEW MATERIAL CO LTD

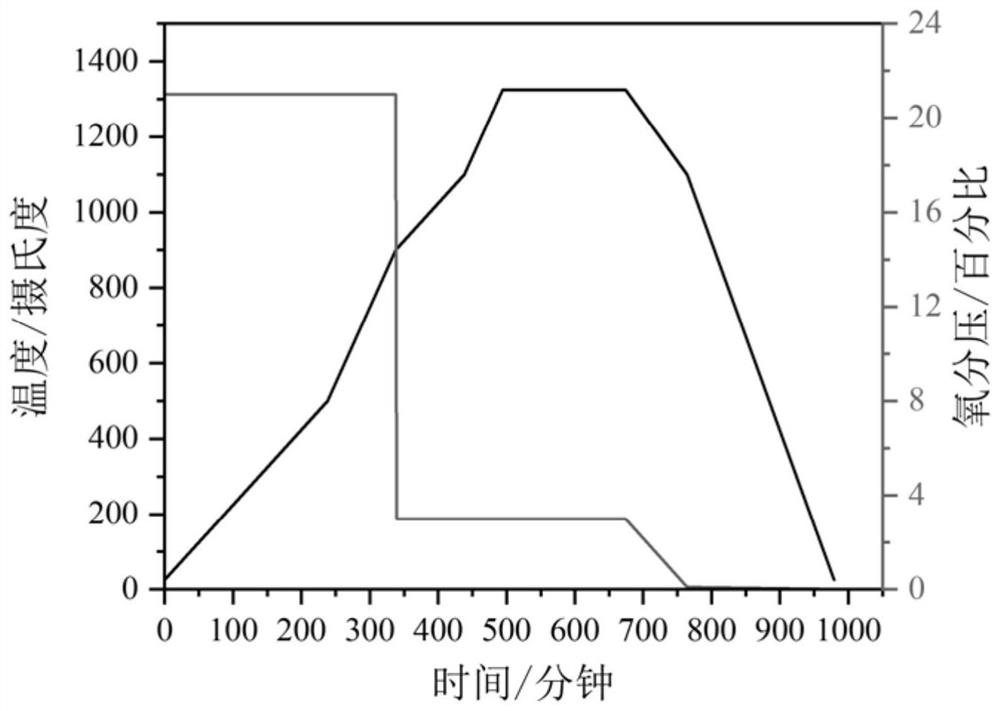

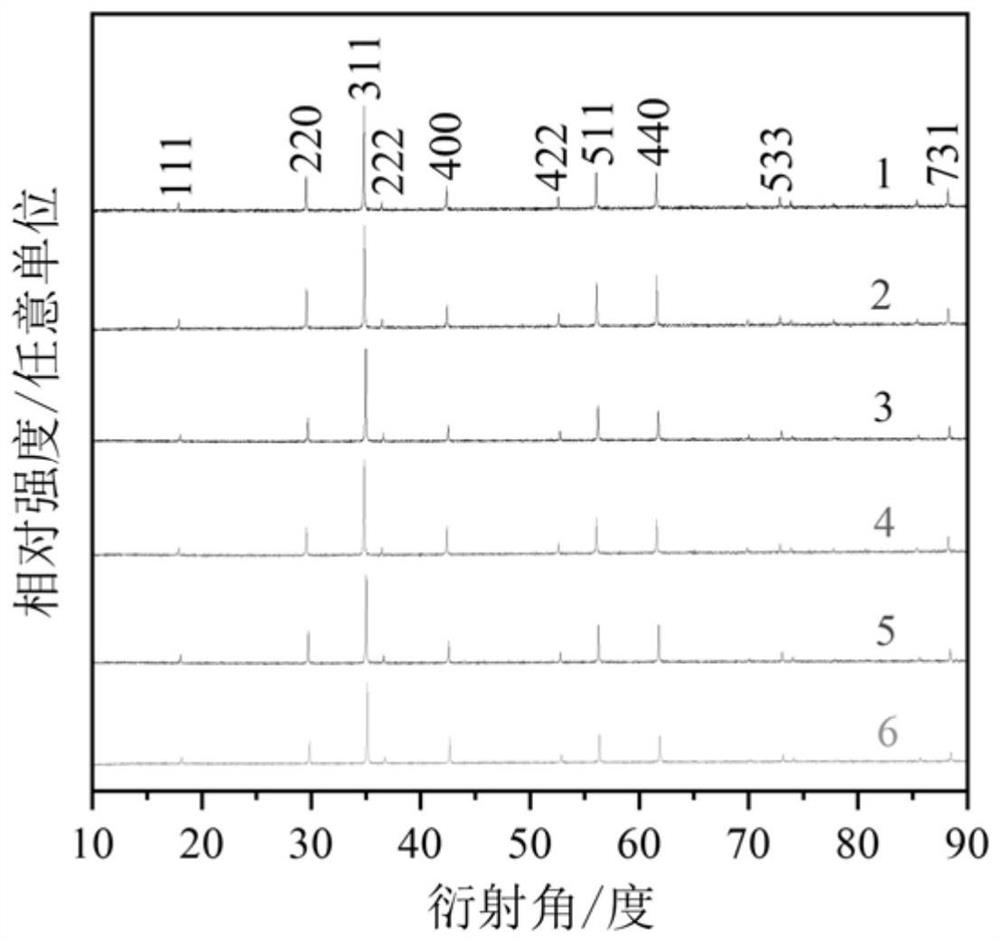

Oxygen partial pressure controlled sintering method for preparing manganese zinc ferrite from secondary materials

ActiveCN108484153BReduce dosageReduce Zn volatilizationInorganic material magnetismThermal insulationManganese

The invention belongs to the field of magnetic materials, and discloses an oxygen partial pressure control sintering method for preparing manganese zinc ferrite through a re-grinding material. The method comprises the following steps: heating a manganese zinc ferrite re-grinding material compacted blank obtained through pretreatment at room temperature to 900 DEG C; feeding nitrogen for replacement when the temperature is risen to 900 DEG C, adjusting the oxygen partial pressure to be 0.5 to 15 percent, stopping feeding the nitrogen, continuously rising the temperature to sintering temperatureto perform thermal insulation sintering, keeping the obtained oxygen partial pressure till a thermal insulation sintering stage is stopped, and sealing a sintering cavity at the thermal insulation sintering stage; finally performing cooling in a flowing nitrogen condition, so as to obtain a sintering product. The method has the advantages that nitrogen is not required to be continuously fed at asecond temperature rising stage and the thermal insulation sintering stage, the dosage of nitrogen required during sintering is greatly saved, the preparation cost is reduced, and the obtained soft magnetic property is obviously better than that of the manganese zinc ferrite prepared through a common sintering method through the control of the sintering oxygen partial pressure.

Owner:SOUTH CHINA UNIV OF TECH

A copper-steel bimetal bridge welding method

InactiveCN103753042BEfficient weldingAchieve weldingWelding/soldering/cutting articlesWelding apparatusRoom temperatureHeating furnace

Owner:NORTHEASTERN UNIV LIAONING

Al-Mg alloy welding wire and preparation method thereof

ActiveCN114589430AAvoid WeldingAvoid heat cracksWelding/cutting media/materialsSoldering mediaCorrosion resistantDuctility

The invention discloses an Al-Mg alloy welding wire and a preparation method thereof. The Al-Mg alloy welding wire comprises the following components in percentage by weight: 4.0%-4.5% of Mg, 1.2%-2.0% of Zn, 0.1%-0.15% of Cr, 0.1%-0.25% of Mn, 0.2%-0.4% of Si, 0.10%-0.15% of Ti, 0.05%-0.2% of Sc, 0.05%-0.2% of Zr, 0.05%-1.5% of late transition metal and the balance of aluminum. The Al-Mg alloy welding wire of some examples is low in melting point and good in base metal wettability, the strength can reach 423 Mpa, the ductility can reach 13.3%, the mechanical property is excellent, and meanwhile the Al-Mg alloy welding wire further has excellent corrosion resistance. The method can be used for welding various high-strength aluminum alloys, pseudo soldering, insufficient soldering and hot cracks of weldments are effectively avoided, and the comprehensive mechanical property of a welded joint is remarkably improved.

Owner:中力鸿(深圳)新材料科技有限公司

A continuous swaging device and method for manufacturing molybdenum rod or molybdenum alloy rod

ActiveCN104353769BHigh dimensional accuracyFully automatedForging hammersDirt cleaningThree stageAlloy

The invention discloses a continuous swaging device and method for manufacturing molybdenum rods or molybdenum alloy rods. The transmission mechanism is installed in a box capable of heat insulation and noise reduction. The product molybdenum rod or molybdenum alloy rod is sent out from the outlet of the box body; the top of the box body is equipped with an exhaust mechanism, and the transmission mechanism adopts a three-stage continuous swaging process, and the ventilation mechanism above the fourth transmission mechanism A spray cooler capable of cooling the molybdenum rod or molybdenum alloy rod on the fourth conveying mechanism is installed on the mechanism. The continuous swaging device of the present invention is used to manufacture molybdenum rods or molybdenum alloy rods, which realizes the automation and continuity of the production process, improves the environmental conditions of the production site, and solves the problems of oxidation and loss of products. The processing size precision is high, and the yield rate is significantly improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

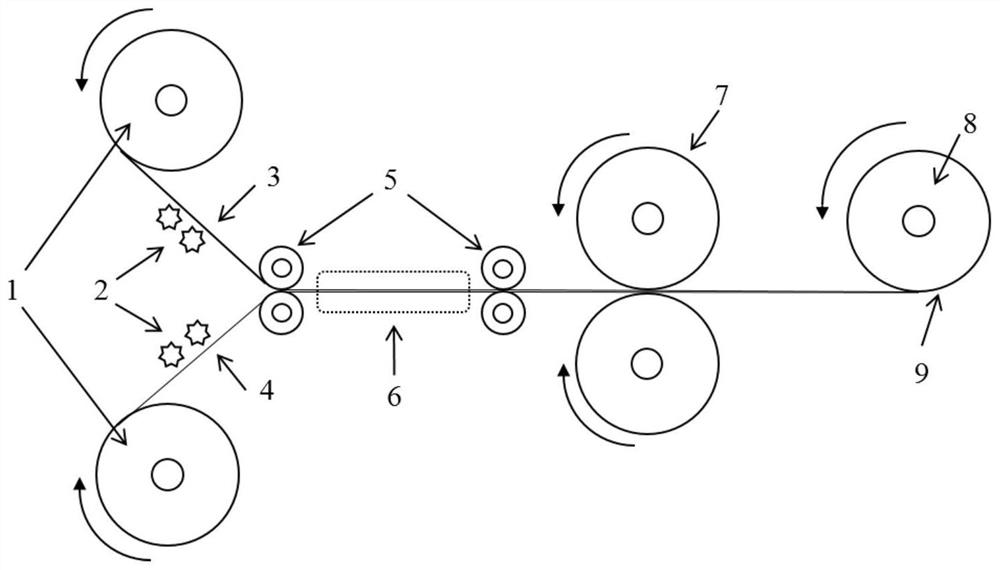

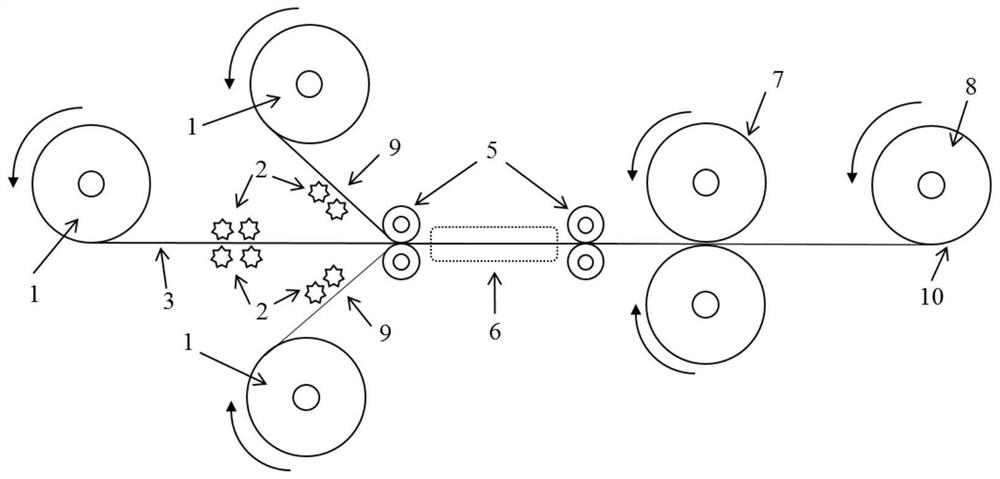

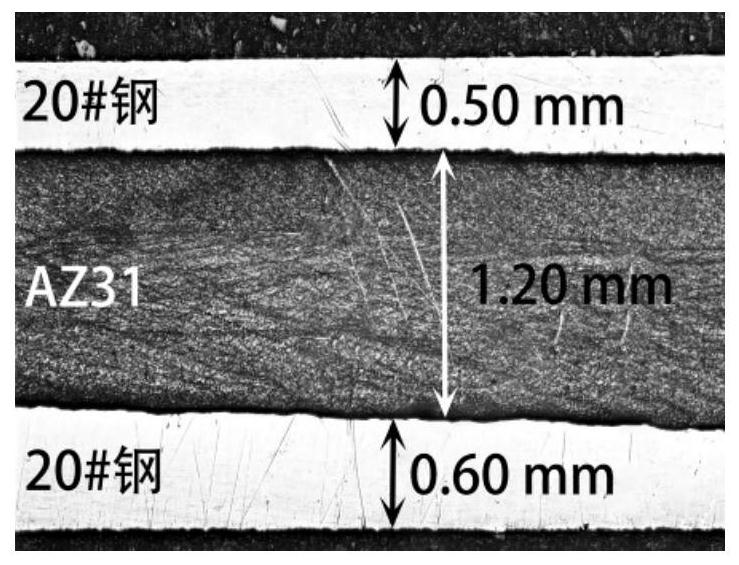

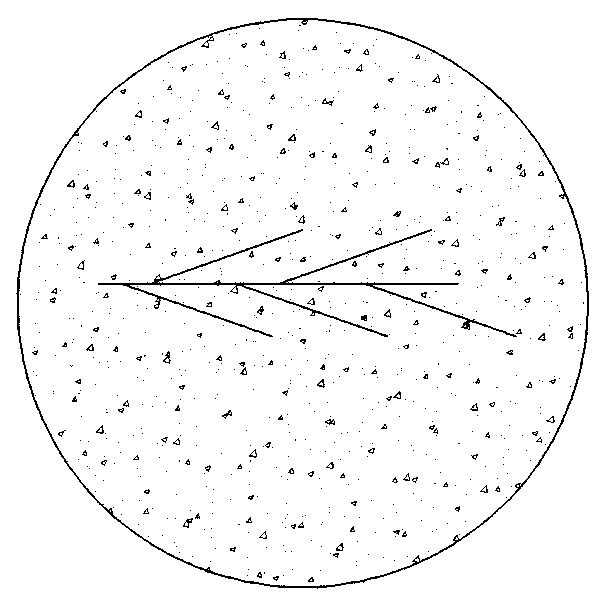

Low-cost and high-efficiency preparation method of steel/magnesium laminar composite plate strip

ActiveCN113319145APromote interdiffusionRealize the combinationFurnace typesHeat treatment furnacesMaterials preparationComposite plate

The invention discloses a low-cost and high-efficiency preparation method of a steel / magnesium laminar composite plate strip, and belongs to the technical field of metal laminar composite material preparation. The method comprises the following steps of firstly, softening and annealing steel and magnesium plate strip blanks, mechanically grinding the surfaces to be compounded of the steel and magnesium plate strip blanks, carrying out steel / magnesium laminated assembly, heating at 150 DEG C-300 DEG C, carrying out pre-rolling compounding to obtain a steel / magnesium pre-compounded plate strip, carrying out stress relief annealing, mechanically grinding the surfaces to be compounded of the steel / magnesium pre-compounded plate strip and the magnesium plate strip blank, carrying out (steel / magnesium) / magnesium laminated assembly, heating at 310 DEG C-400 DEG C, carrying out final rolling compounding to obtain the steel / magnesium final composite plate strip, and finally, carrying out diffusion annealing to obtain the steel / magnesium laminar composite plate strip. According to the technical scheme, high-strength metallurgical bonding between magnesium and steel can be achieved, and the method is particularly suitable for preparing the steel / magnesium laminar composite plate strip with the large size and the large coil weight, and the magnesium layer of the steel / magnesium laminar composite plate strip is far thicker than the steel layer.

Owner:UNIV OF SCI & TECH BEIJING

A ceramic ball with a built-in α+β titanium alloy skeleton and its preparation method

Owner:SHANDONG TIANHUI GRINDING WEAR TECH DEV CO LTD

A method of improving brazing welding strength

ActiveCN103273156BPromote wettingEasy to spreadSoldering apparatusUltimate tensile strengthFiller metal

The invention discloses a method for improving brazing strength. According to the technical scheme, the method includes the steps of (1) preparation of ceramic particles for adhering metal nanopowder of used brazing filler metal: selecting appropriate ceramic particles according to actual brazing conditions, and preparing the ceramic particles for adhering the metal nanopowder in the used brazing filler metal; (2) brazed surface treatment: performing degreasing and surface oxide removal on a brazed surface, then enabling impact and friction to be generated between the brazed surface and the ceramic particles adhering the metal nanopowder by a shot blasting or vibration method, enabling the brazed surface to have different roughness heights, and coating a metal layer on the brazed surface; and (3) brazing: combining inert gas shielding and heat preservation processes to complete brazing. By the aid of the spot blasting or vibration method, brazed surface quality and brazing filler metal flowability are improved, evenness, diffusion depth and concentration of the brazing filler metal in the whole brazing area are improved, and further brazing connection strength is improved.

Owner:SHENYANG AIRCRAFT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com