A kind of preparation method of iron-copper bonding material

A combination of materials, iron-copper technology, applied in the field of materials, can solve problems such as complex process, affecting bonding strength, unstable yield, etc., to achieve the effect of firm contact surface, protection of alloy performance, and improvement of elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

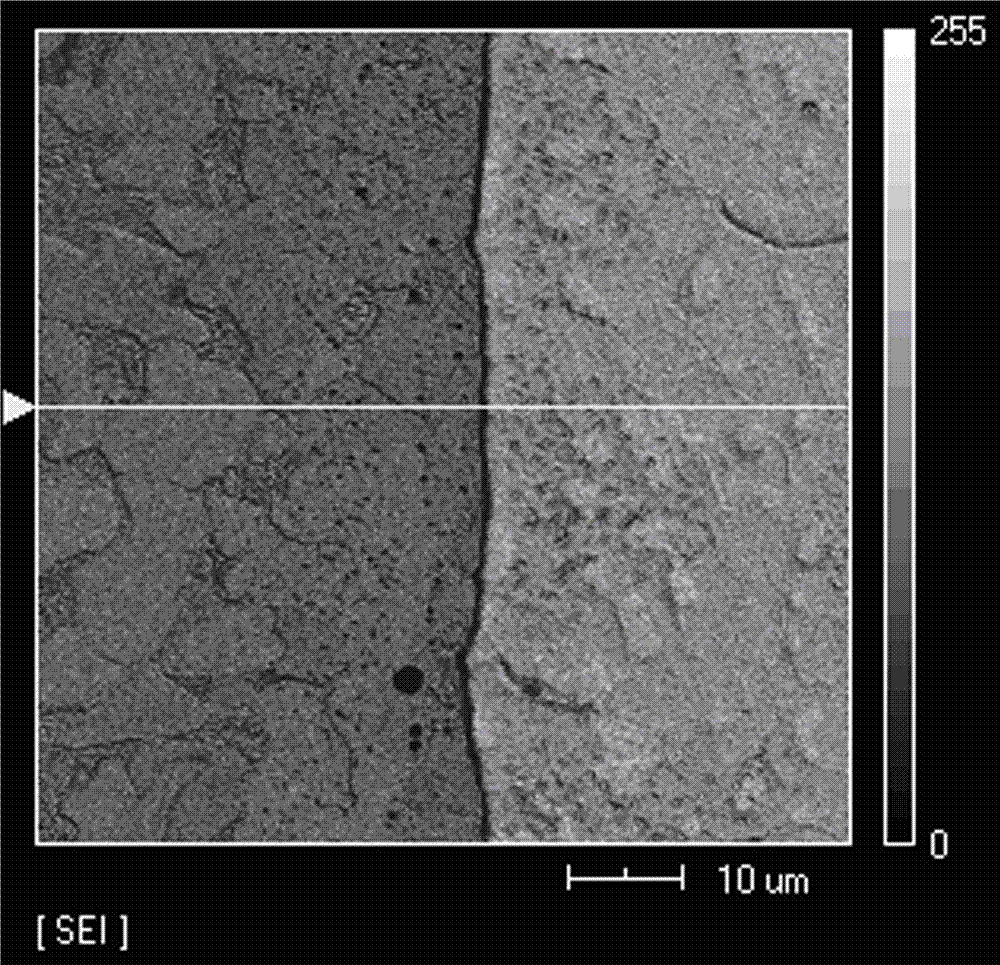

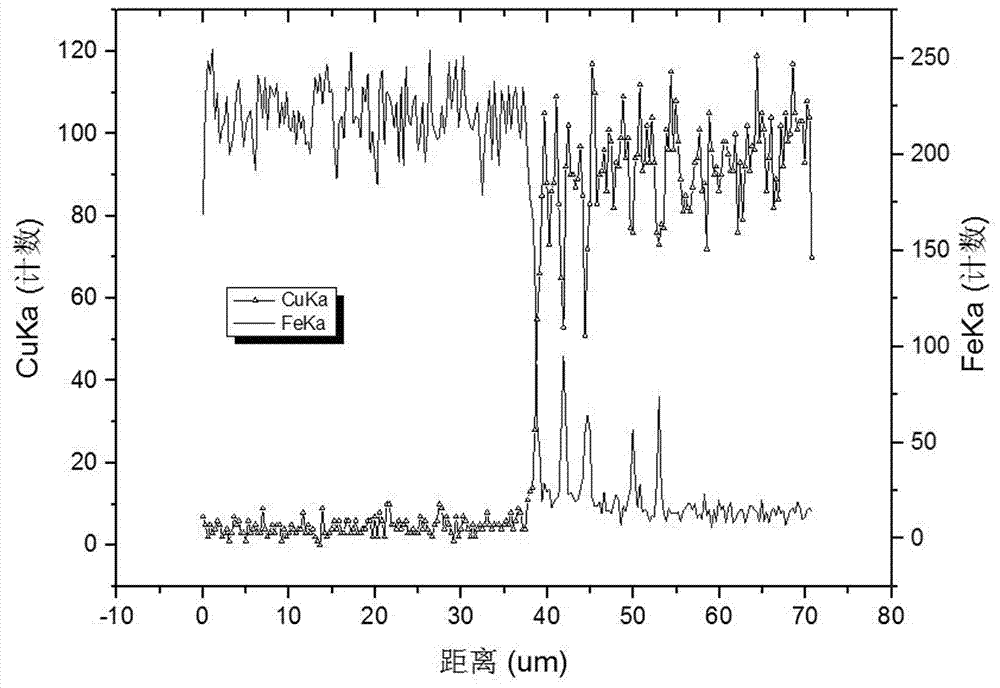

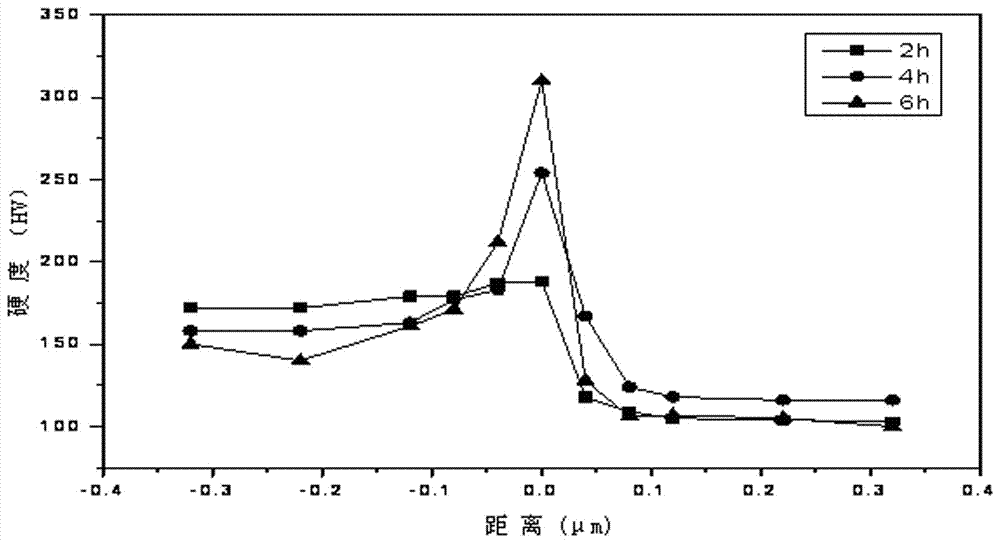

Method used

Image

Examples

Embodiment 1

[0044] Prepare an iron alloy with a weight purity of 99%; process the iron alloy into a drum shape to make an iron drum with a wall thickness of 5mm; remove the oil on the surface of the iron drum;

[0045] Prepare copper alloy raw material electrolytic copper, tin bronze and phosphor copper powder, require the composition of all raw materials to contain Cu56% by weight percentage, and prepare carbonaceous material accounting for 0.5% of the total weight of copper alloy raw material, and the carbonaceous material is charcoal;

[0046] Put the copper alloy raw material and carbonaceous material into the iron drum after mixing. The total volume of the copper alloy raw material and carbonaceous material is 20% of the total volume of the inner space of the iron drum; the iron cover with a round hole in the center is welded and fixed on the iron drum. On the barrel, the round hole communicates with the inside of the iron barrel; then put the iron barrel in a heating furnace, heat it...

Embodiment 2

[0052] Prepare ferroalloy with a weight content of Fe of 98%; process ferroalloy into a barrel shape to make an iron drum with a wall thickness of 10mm; remove surface oil from the iron drum;

[0053] Prepare copper alloy raw materials tin bronze and phosphor bronze powder, require the composition of all raw materials to contain Cu75% by weight percentage, and prepare carbonaceous material accounting for 1% of copper alloy raw material gross weight, described carbonaceous material is graphite;

[0054] Put the copper alloy raw material and carbonaceous material into the iron drum after mixing. The total volume of the copper alloy raw material and carbonaceous material is 40% of the total volume of the inner space of the iron drum; the iron cover with a round hole in the center is welded and fixed on the iron drum. On the barrel, the round hole is connected with the inside of the iron barrel; then the iron barrel is placed in a heating furnace, heated to 1150 ° C, kept for 40 mi...

Embodiment 3

[0060] Prepare ferroalloy with a weight content of 97% of Fe; process the ferroalloy into a drum shape to make an iron drum with a wall thickness of 20mm; remove surface oil from the iron drum;

[0061] Prepare copper alloy raw material electrolytic copper and tin bronze, require the composition of all raw materials to contain Cu90% by weight percentage, and prepare carbonaceous material accounting for 1.5% of the total weight of copper alloy raw material, and described carbonaceous material is graphite;

[0062] Put the copper alloy raw material and carbonaceous material into the iron drum after mixing. The total volume of the copper alloy raw material and carbonaceous material is 60% of the total volume of the inner space of the iron drum; the iron cover with a round hole in the center is welded and fixed on the iron drum. On the barrel, the round hole is connected with the inside of the iron barrel; then the iron barrel is placed in a heating furnace, heated to 1250 ° C, kep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com