High-temperature-resistant antioxidant niobium alloy slag ladle used for nonferrous metal smelting and slagging

A non-ferrous metal, high temperature resistant technology, used in metal processing equipment, mechanical cleaning, manufacturing tools, etc., can solve the problems of large slag scoop burning, increased tool use cost, reduced aluminum product quality and other problems, to avoid production trouble and waste. Large, improve the ability and efficiency of slag removal, solve the effect of easy melting loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

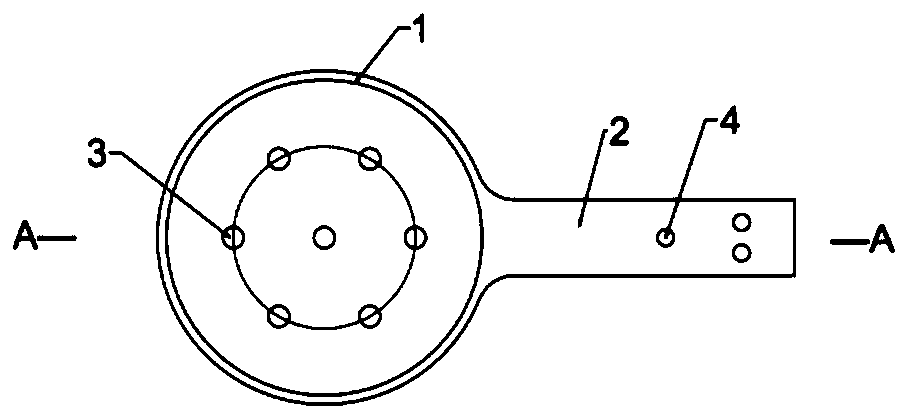

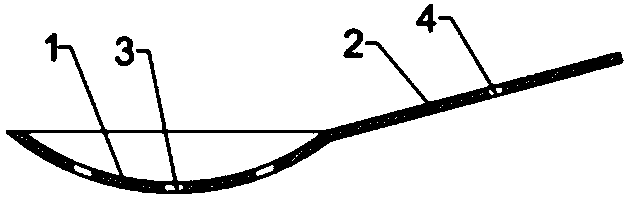

[0012] Such as figure 1 , figure 2 As shown, a high-temperature-resistant and anti-oxidation niobium alloy slag scoop for non-ferrous metal smelting slag removal, the slag scoop is a spoon-shaped structure, including a scoop body 1 and a scoop handle 2, and a leak hole 3 is opened at the bottom of the scoop body, The outer end of the scoop handle is processed with a mounting hole 4 that can be externally extended to extend the scoop handle, so that the slag scoop can be replaced and used, and the welding process is omitted. In this embodiment, the design length of the scoop handle is 200mm, so as to avoid contact with the molten metal surface during operation and be burned and melted. The outer end of the scoop handle is provided with three Φ11 mounting holes for bolt connection to lengthen the scoop handle. A plurality of leak holes 3 are provided at the bottom of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com