Production process of hot-rolled large-caliber thin-wall titanium alloy seamless tube

A production process and technology for titanium alloys, applied in metal rolling and other directions, can solve the problems of affecting physical and chemical properties, difficult to meet the requirements of use, low yield, etc., to achieve flexible and reliable adjustment, shorten the transfer time, and improve the yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

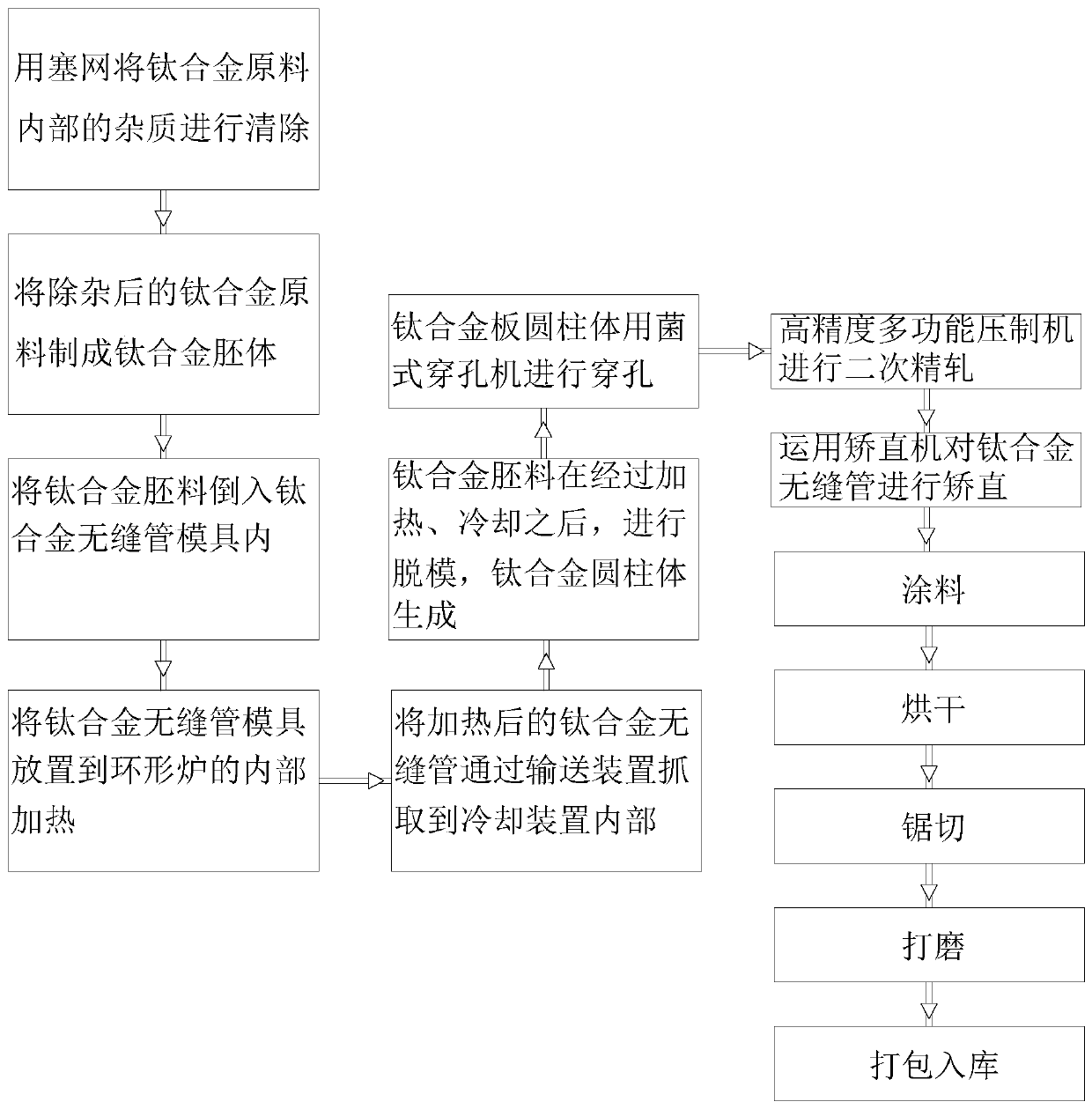

[0042] Such as figure 1 As shown, the present invention provides a technical solution: a production process of hot-rolled large-diameter thin-walled titanium alloy seamless pipe, and its process operation flow is mainly divided into the following steps:

[0043] A. First, the operator uses the plug net to remove the impurities inside the titanium alloy raw material;

[0044] B. Secondly, the titanium alloy raw material after the impurity removal is made into a titanium alloy body;

[0045] C. Subsequently, the titanium alloy blank is poured into the titanium alloy seamless pipe mould;

[0046] D. Next, just place the titanium alloy seamless pipe mold inside the ring furnace for heating;

[0047] E. Grab the heated titanium alloy seamless pipe into the cooling device through the conveying device;

[0048] F. Titanium alloy ingredients are demolded after heating and cooling, and solid titanium alloy cylinders are formed;

[0049] G. The titanium alloy cylinder is then fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com