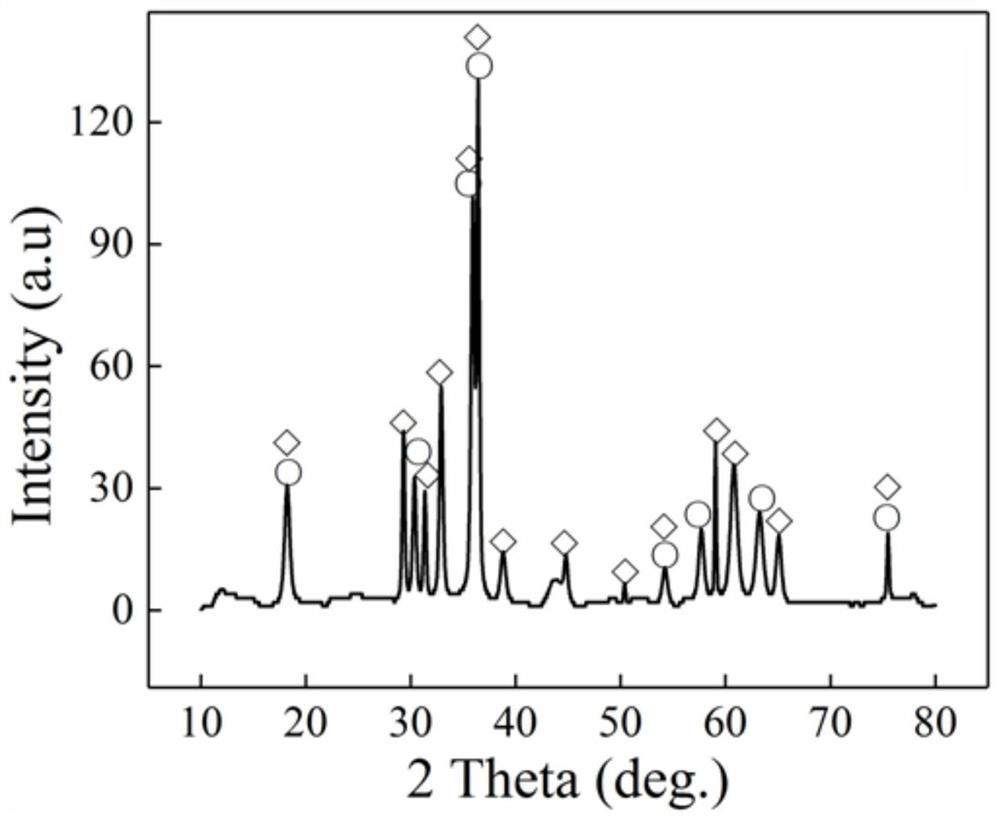

Method for rapidly preparing manganese-cobalt spinel coating through microwave mixed heating

A spinel coating and microwave technology, which is applied to fuel cells, electrochemical generators, electrical components, etc., can solve the problems of uncontrollable manganese-cobalt spinel coating composition, complicated preparation process, and base metal oxidation, etc. Achieve the effects of precise and controllable coating composition, simple preparation process and fast heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

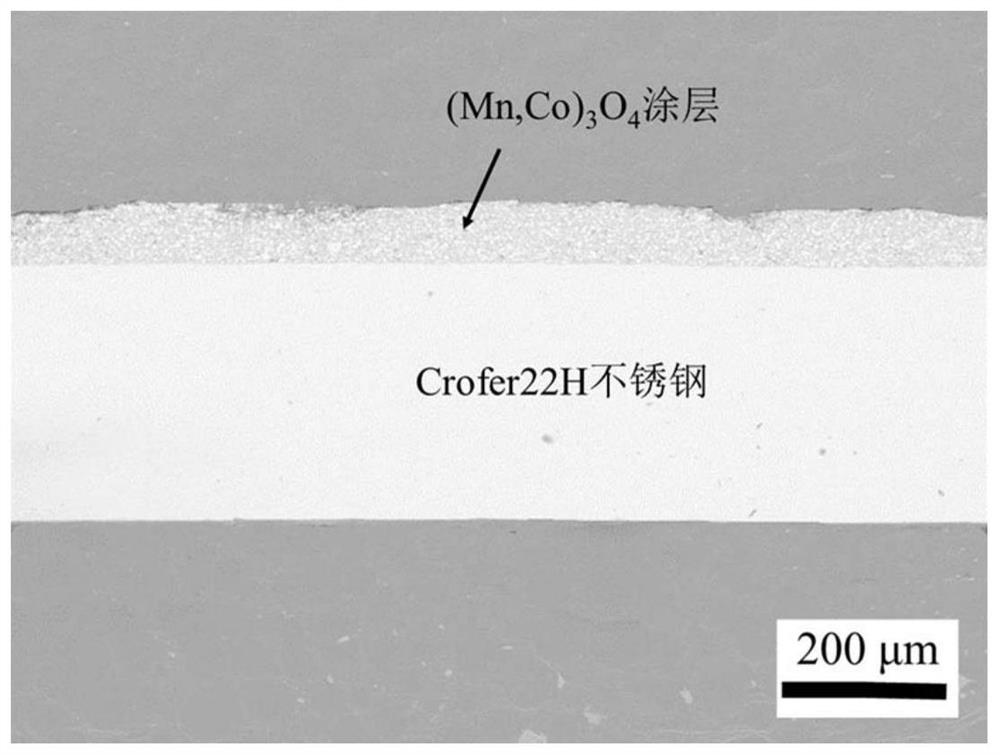

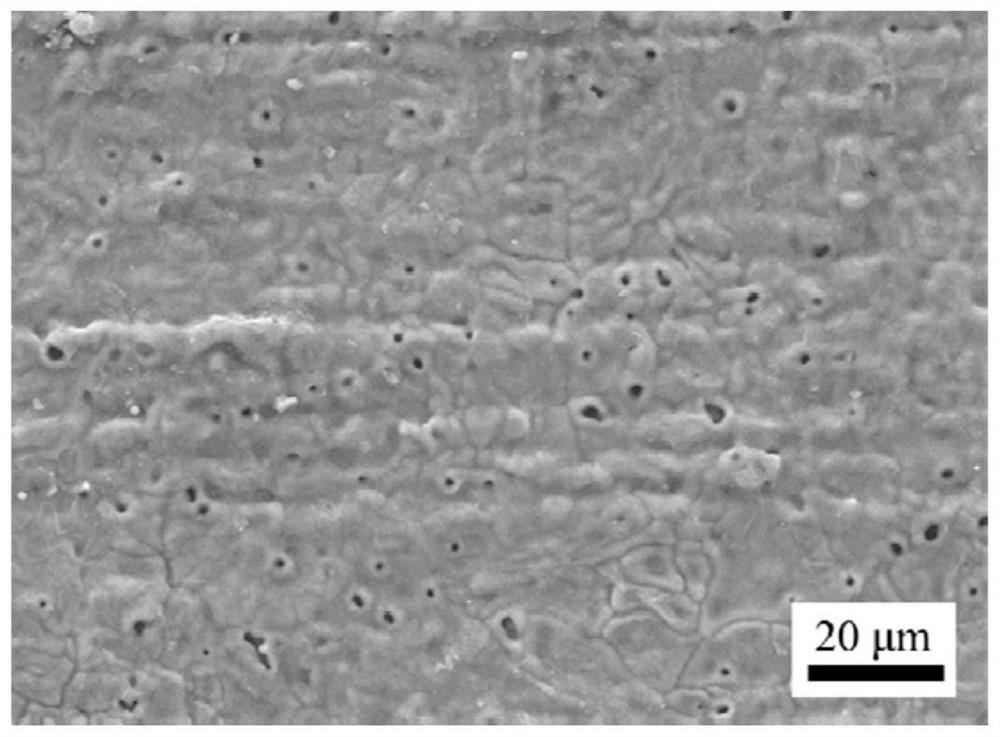

[0021] Specific Embodiment 1: In this embodiment, the method for rapidly preparing manganese-cobalt spinel coating by microwave mixing and heating is implemented according to the following steps:

[0022] 1. Weigh Co powder, MnO 2 Powder and sintering aid powder as raw materials;

[0023] 2. Put the raw materials in step 1 into a ball mill tank for wet ball milling, add absolute ethanol, mix evenly, dry and sieve to obtain a mixed powder;

[0024] 3. Surface treatment of ferritic stainless steel, after sandpaper grinding and ultrasonic cleaning, clean ferritic stainless steel is obtained;

[0025] 4. Evenly smear the mixed powder obtained in step 2 on the surface of clean ferritic stainless steel with a thickness of 50-150 μm, and then place it in a graphite mold for compression molding to obtain stainless steel with a pre-pressed coating;

[0026] 5. Embed the stainless steel with pre-pressed coating in step 4 into the high microwave absorption rate powder in the microwave ...

specific Embodiment approach 2

[0030] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step one, Co powder, MnO 2 The average particle diameter of the powder is 0.5-5 μm.

[0031] In this embodiment, Co powder and MnO 2 The purity of the powder is above 99.9%. Co powder and MnO 2 The powder is spherical or nearly spherical.

specific Embodiment approach 3

[0032] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the Co powder and MnO in step one 2 The amount ratio of powder substance is 1:1 or 1:2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com