Nitrogen protection device and method in laser welding process

A nitrogen protection, laser welding technology, used in laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problem of unqualified product quality, unusable, unequal, avoid serious oxidation, improve corrosion resistance The effect of high performance and simple structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0021] The devices and methods disclosed in the present invention are aimed at the nitrogen protection adopted in the laser welding process of stainless steel pipes, and the welding matrix is stainless steel pipes.

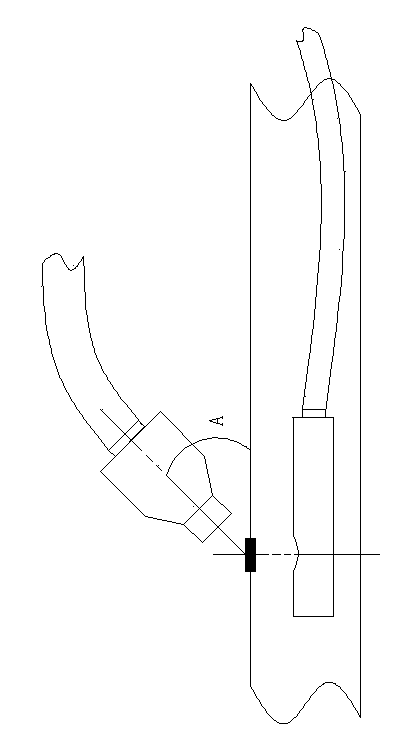

[0022] See attached figure 1 , the device for adding nitrogen protection during the laser welding process includes an external nozzle 3 arranged outside the stainless steel pipe 1 and an internal nozzle 5 arranged inside the stainless steel pipe 1 . Both the nozzle 7 of the external spray head 3 and the spray hole 6 of the internal spray head 5 correspond to the inside and outside of the welding point 2 respectively. The included angle between the center line of the nozzle 7 of the external spray head 3 and the horizontal plane where the welding point 2 is located is 45 degrees, as shown in angle A in the figure. The inner nozzle 5 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com