Patents

Literature

49results about How to "Good quality finished product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

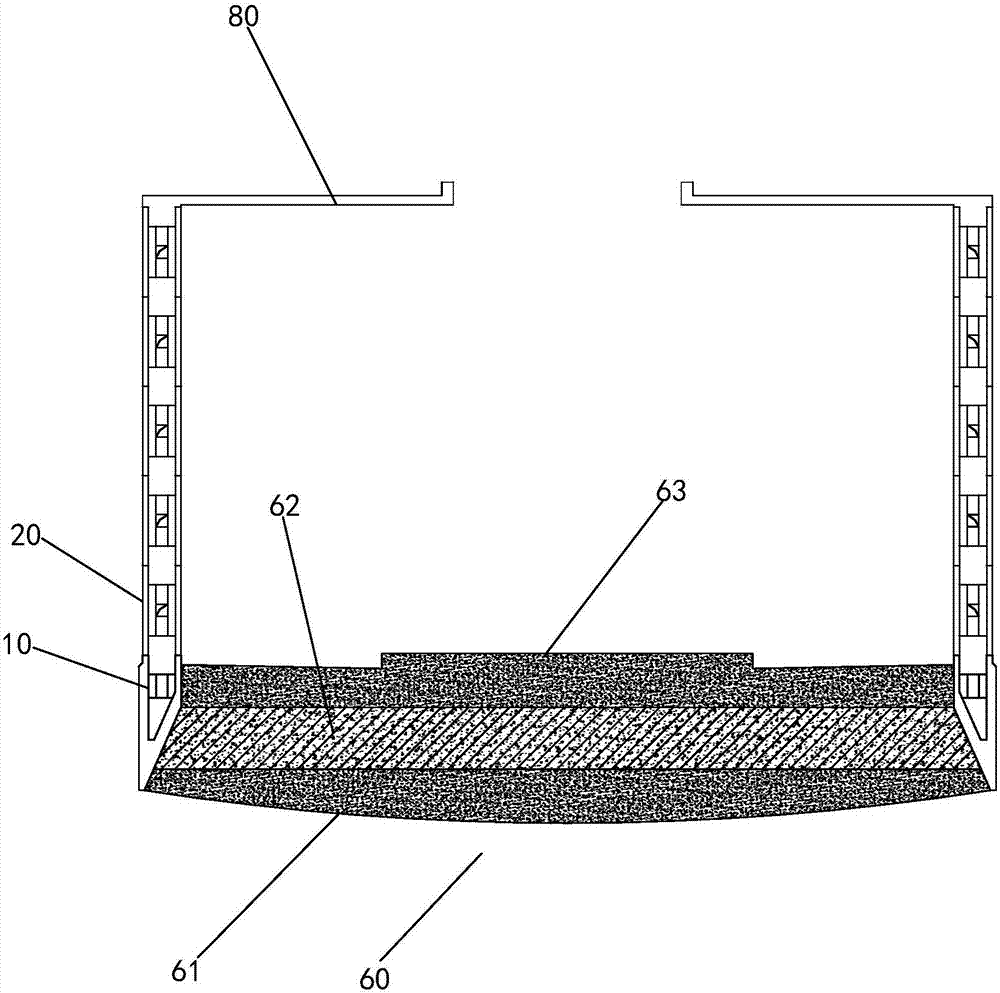

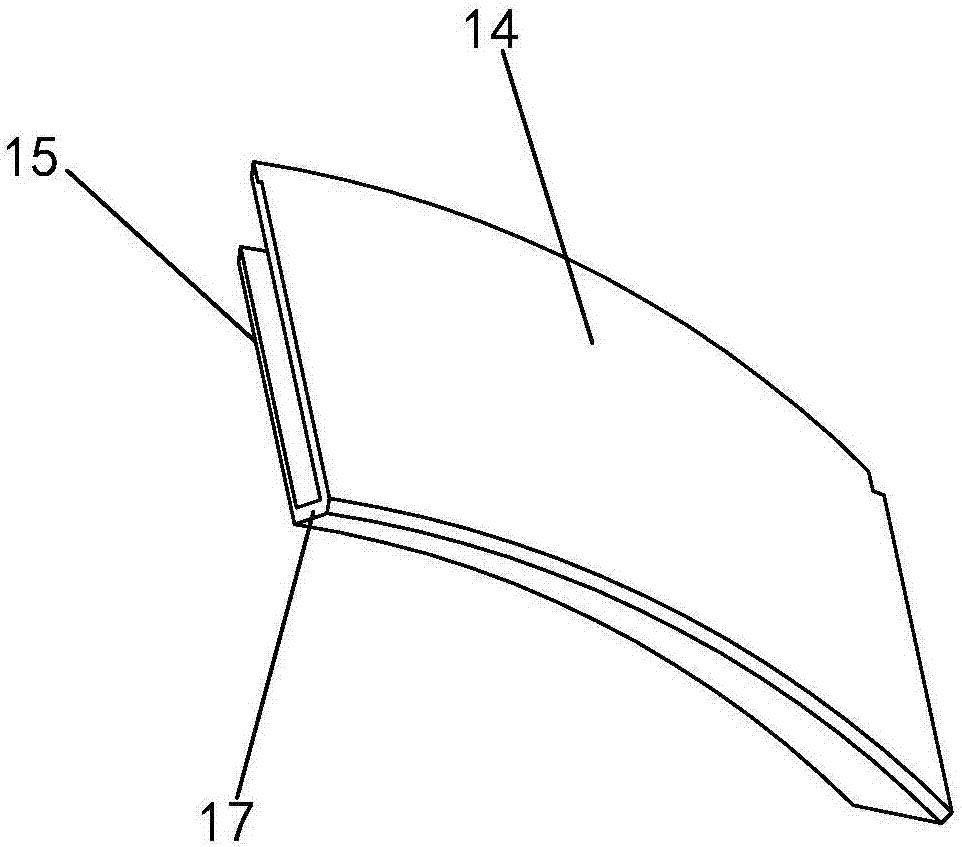

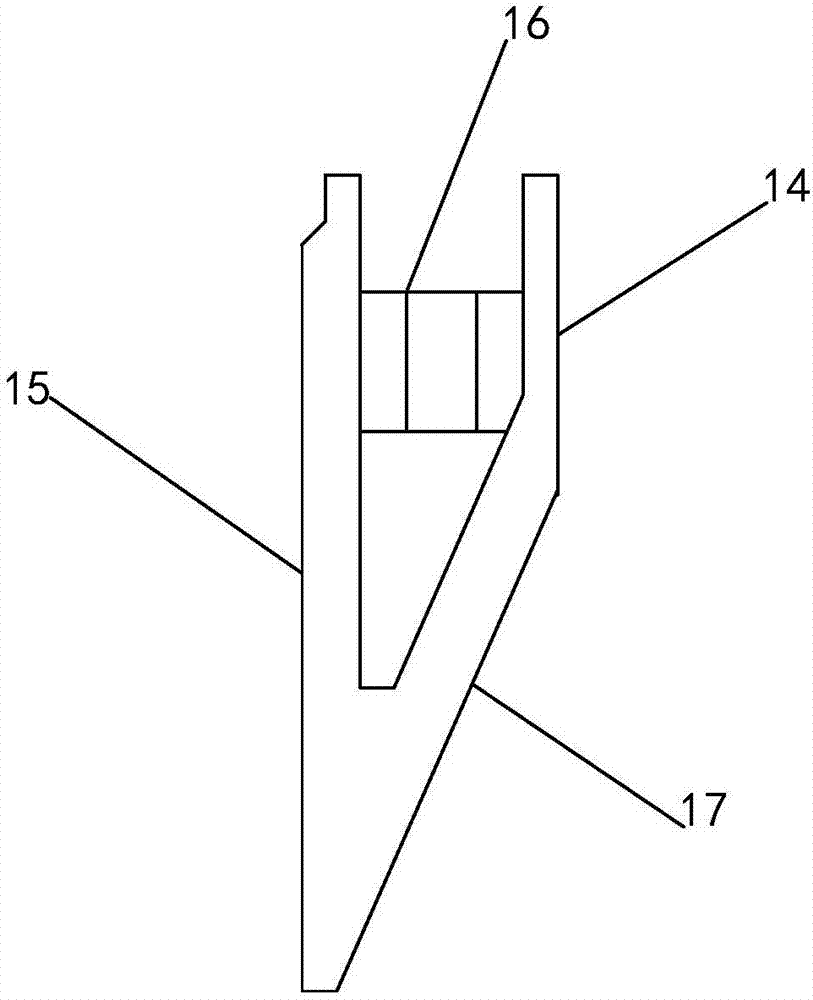

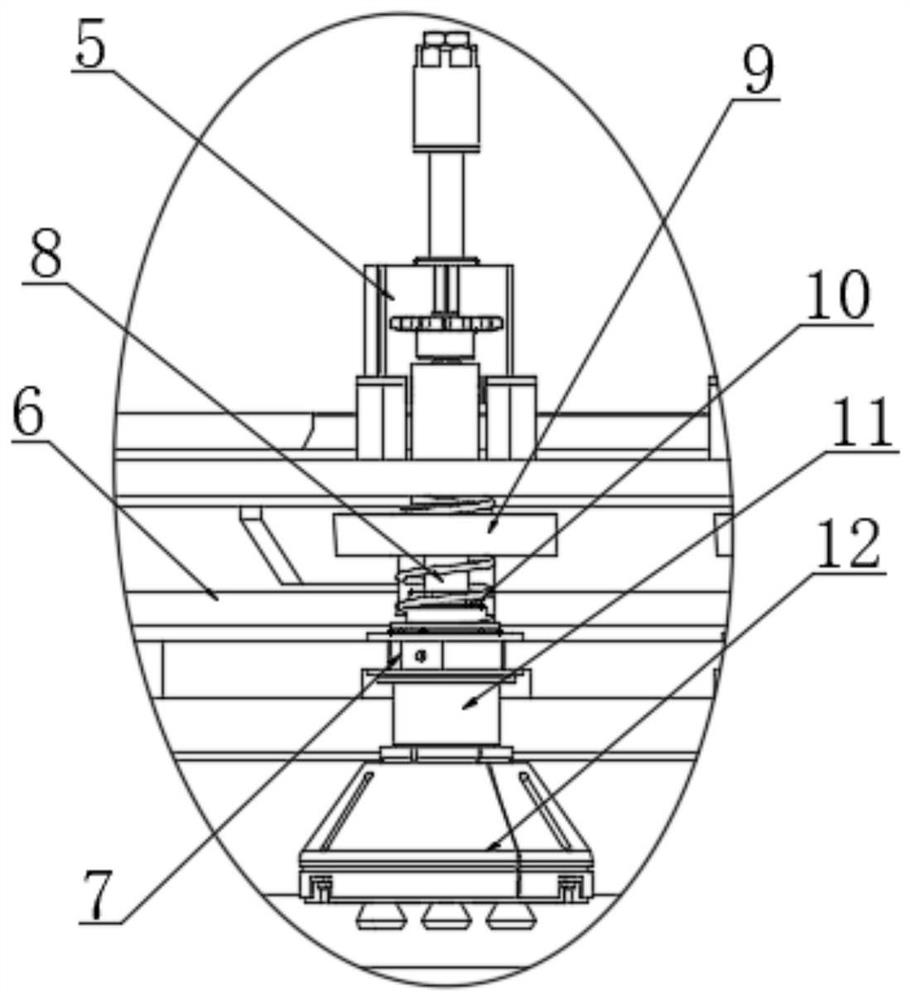

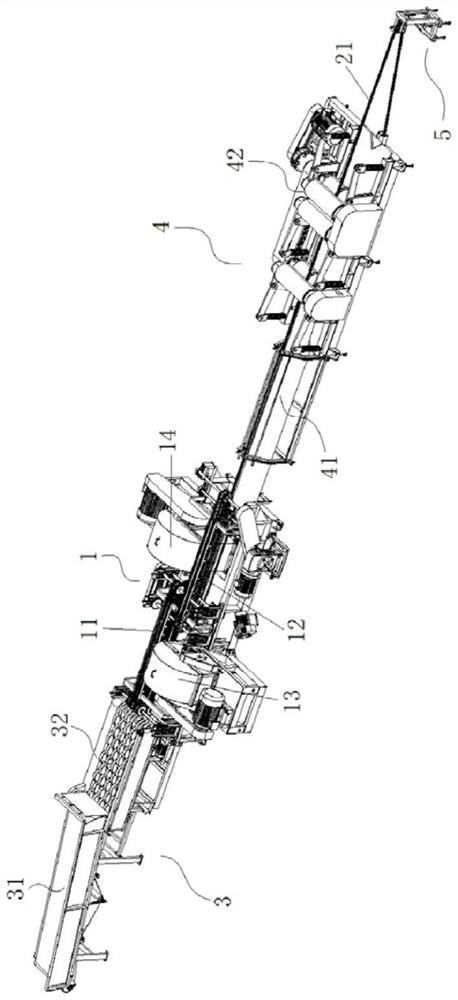

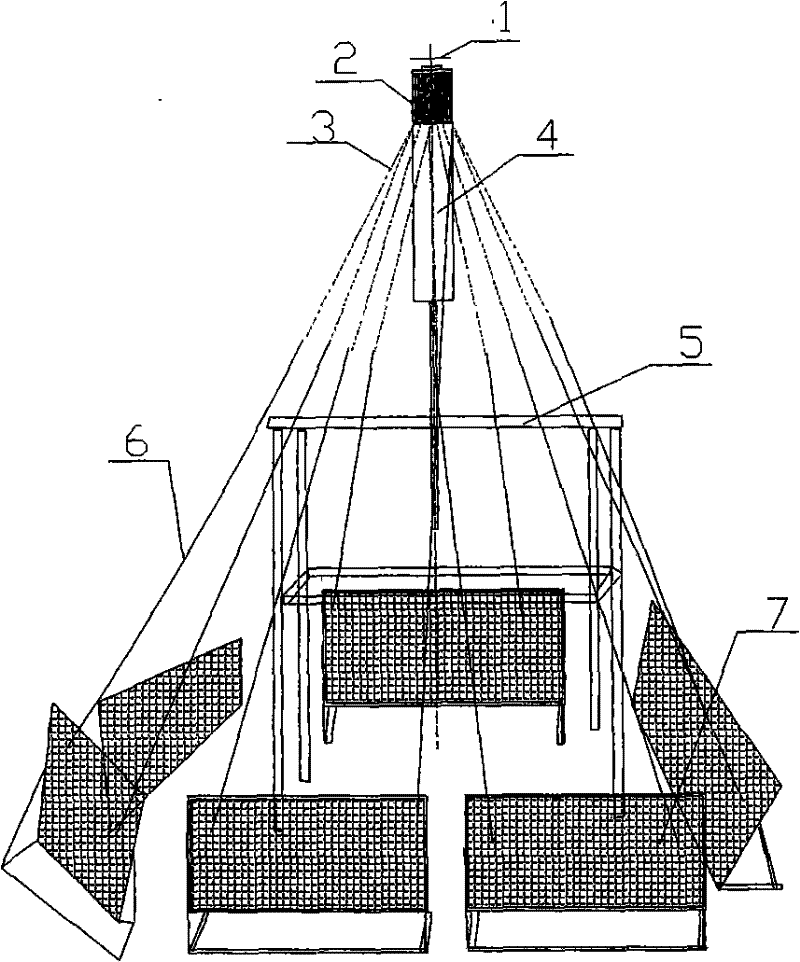

Engineering method of prefabricated and spliced well-sinking type parking garage and parking garage

ActiveCN106854873AShorten the construction periodReduce off-site factorsArtificial islandsUnderwater structuresReinforced concreteEngineering

The invention provides an engineering method of a prefabricated and spliced well-sinking type parking garage and the parking garage. The engineering method comprises the following construction steps that 1, a plurality of blade foot blocks are spliced to form a blade foot layer; 2, reinforced concrete is cast into the inner cavity of the blade foot layer at a time, then soil is excavated from the ground defined by the blade foot layer to make the blade foot layer sink in plate; 3, standard blocks are hoisted to be spliced with the top of an installed shaft, and the adjacent standard blocks are spliced in sequence to form an upper layer of the shaft; 4, reinforced concrete is cast into the inner cavity of a standard layer at a time, soil excavation continues till the shaft in the layer sinks in place; 5, the steps 3 and 4 are repeated to install other layers of the shaft till the shaft sinks to reach preset depth layer by layer; 6, concrete is cast on the bottom surface of the shaft in a layered mode to achieve bottom sealing; 7, a garage parking frame body structure is installed, and the top is sealed. The method adopts prefabrication, site splicing and inner cavity concrete casting, the purposes of shortening a construction period, reducing construction interference and reducing pollution are achieved, the advantages of the mechanical properties of a well-sinking structure are fully utilized, and a timbering process and costs during underground excavation are decreased.

Owner:中铁科建工程有限公司

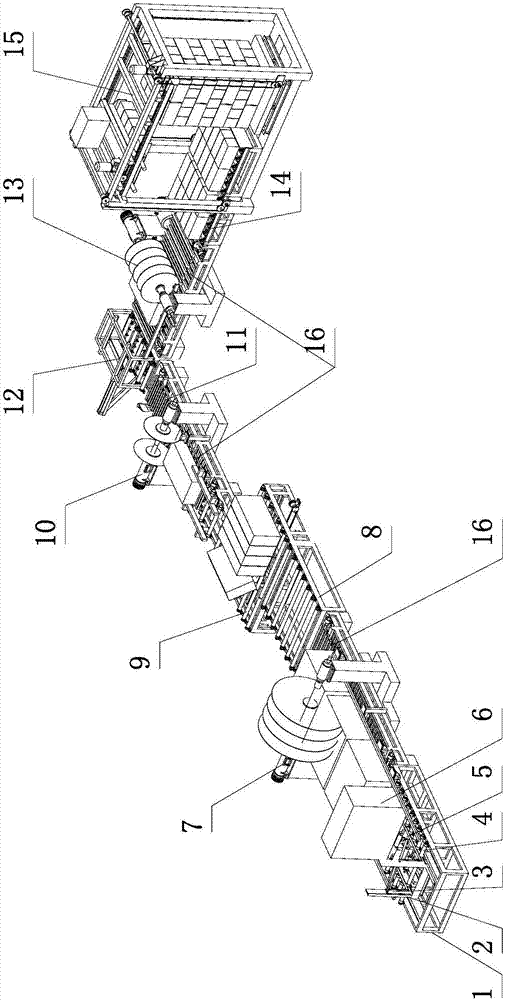

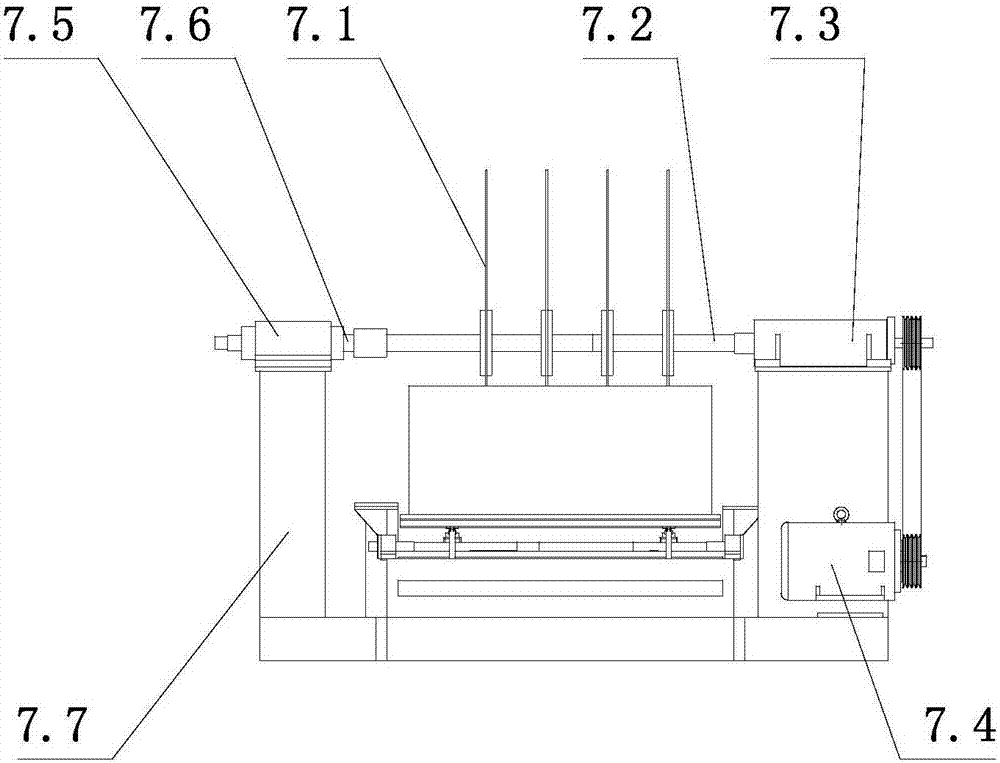

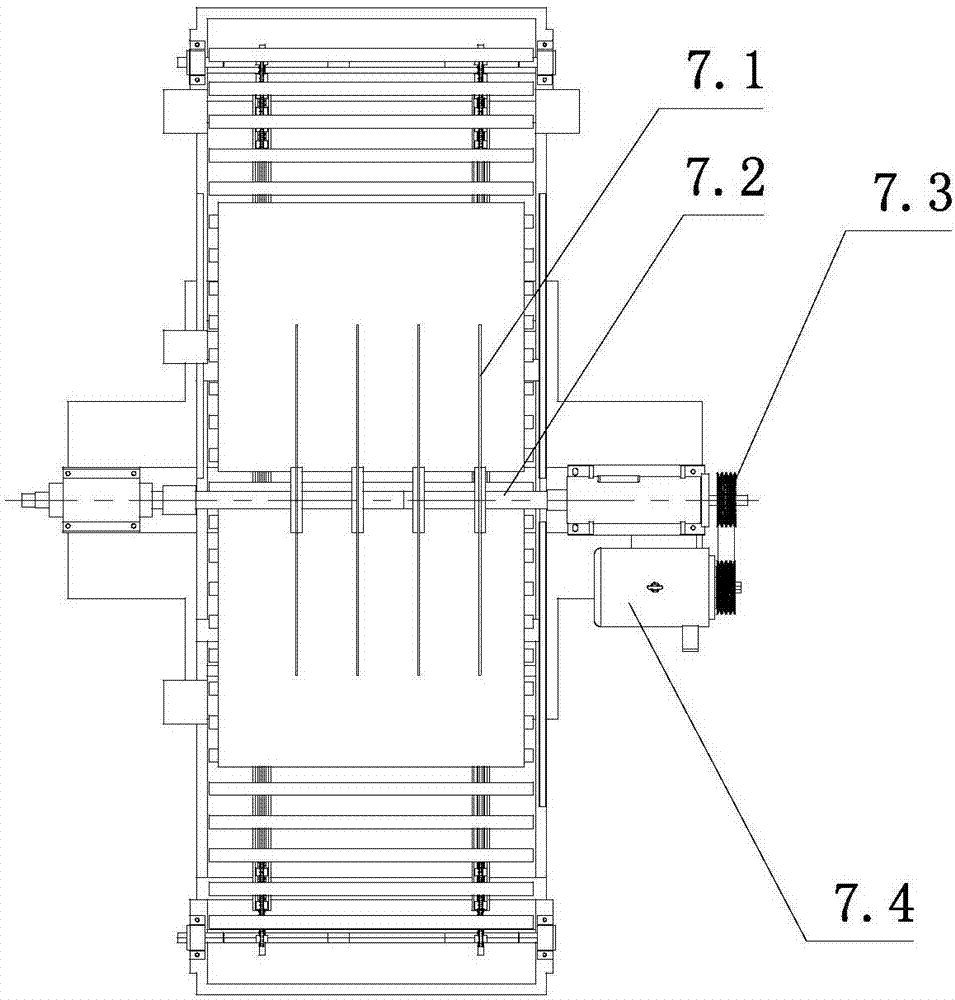

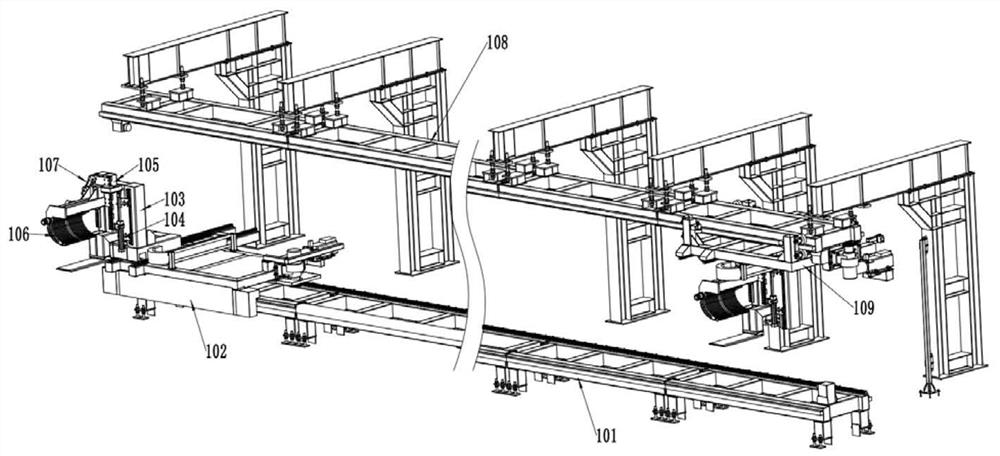

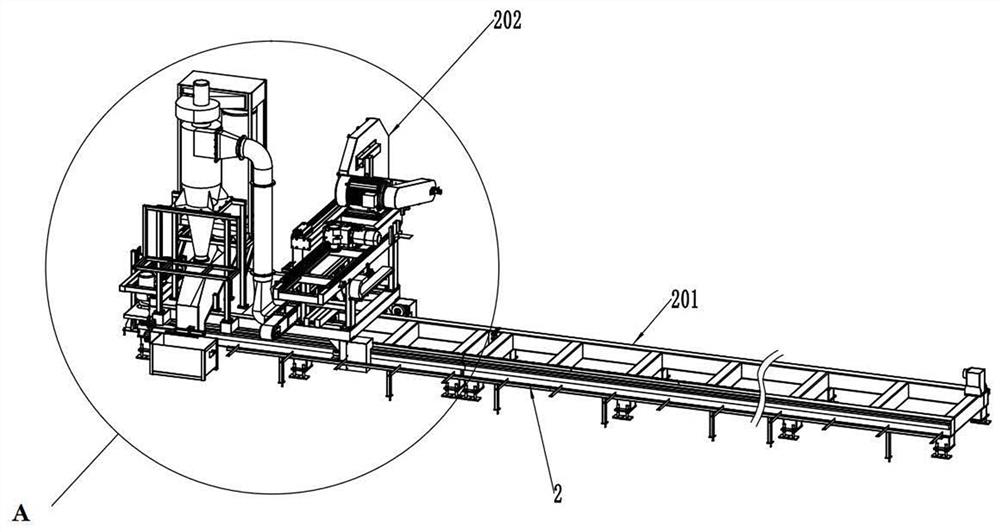

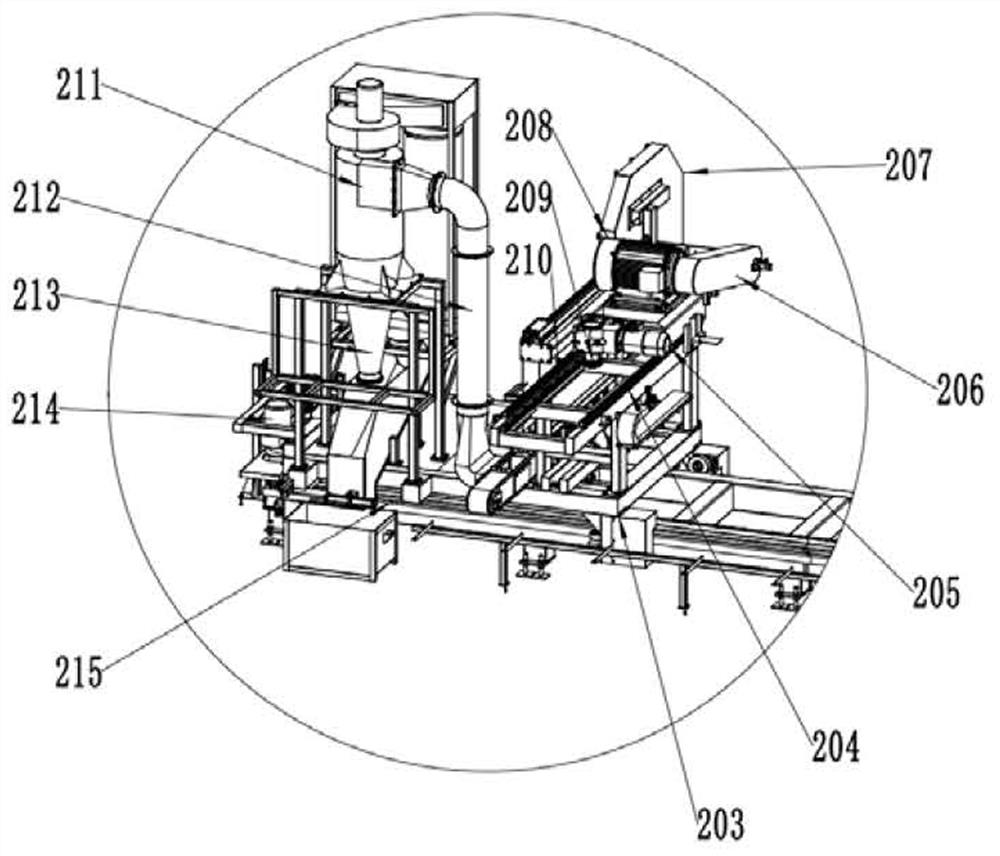

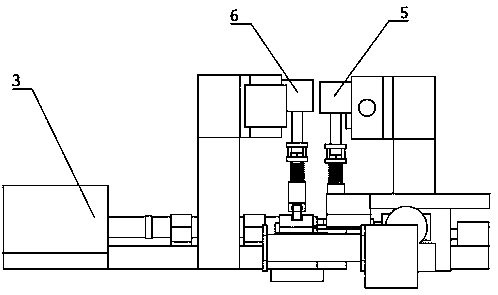

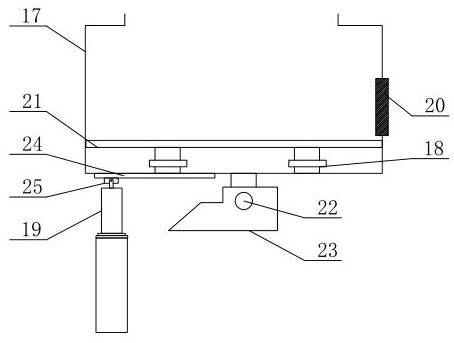

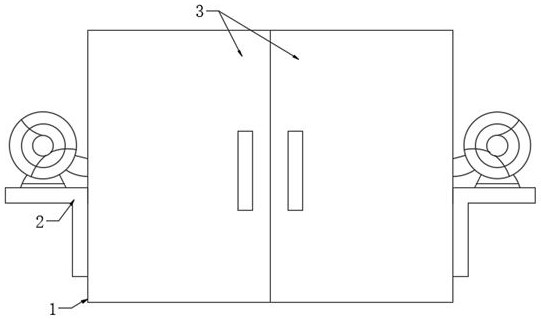

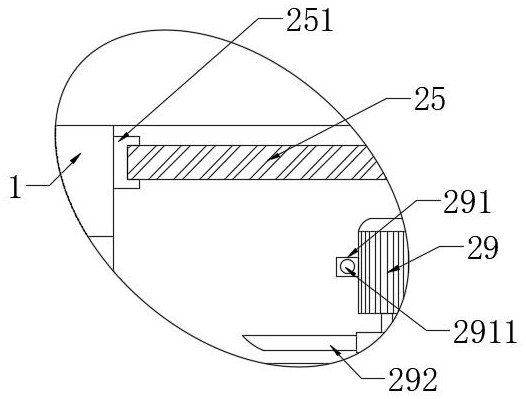

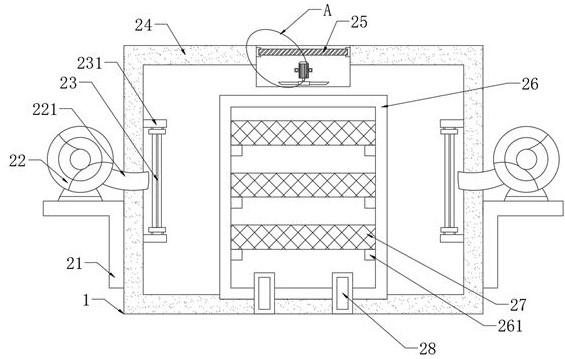

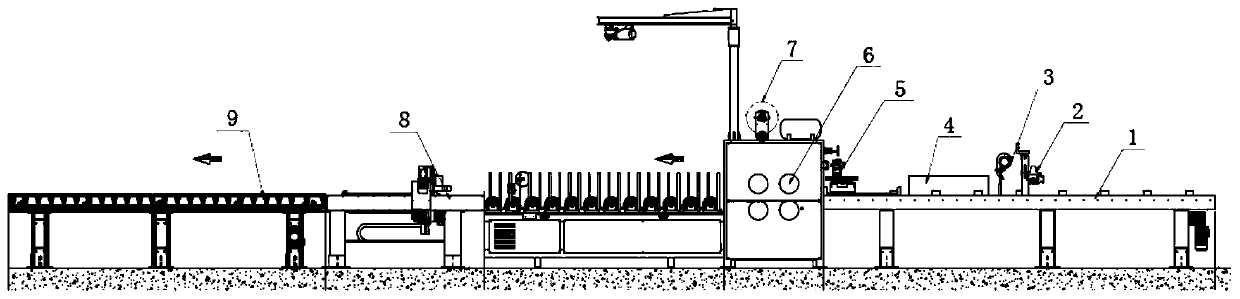

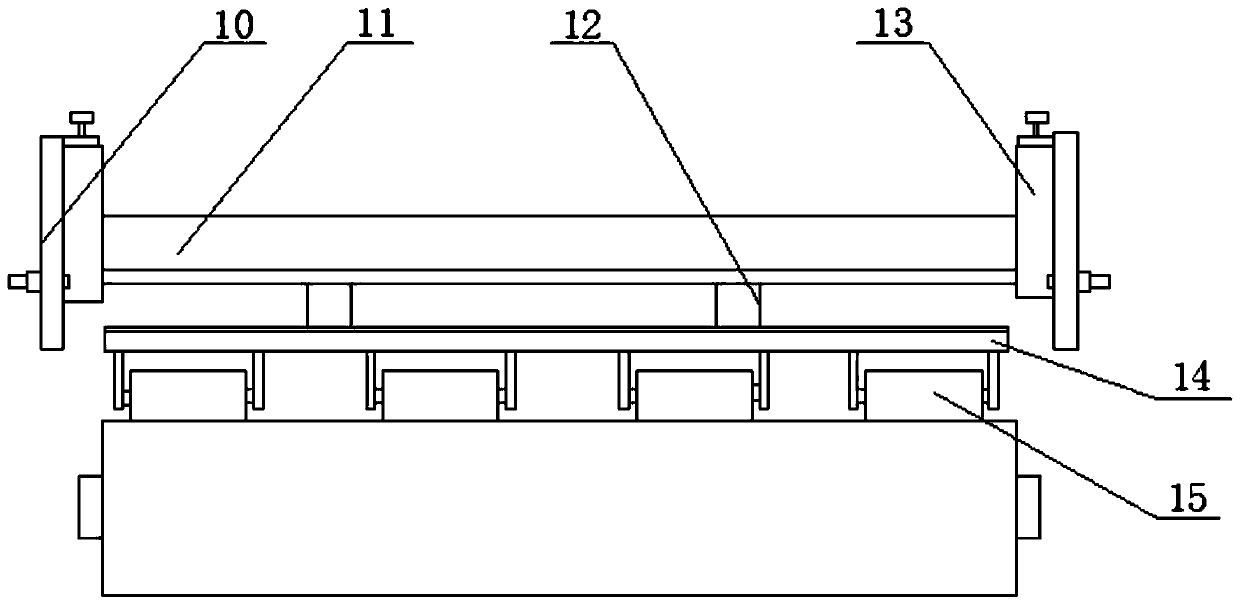

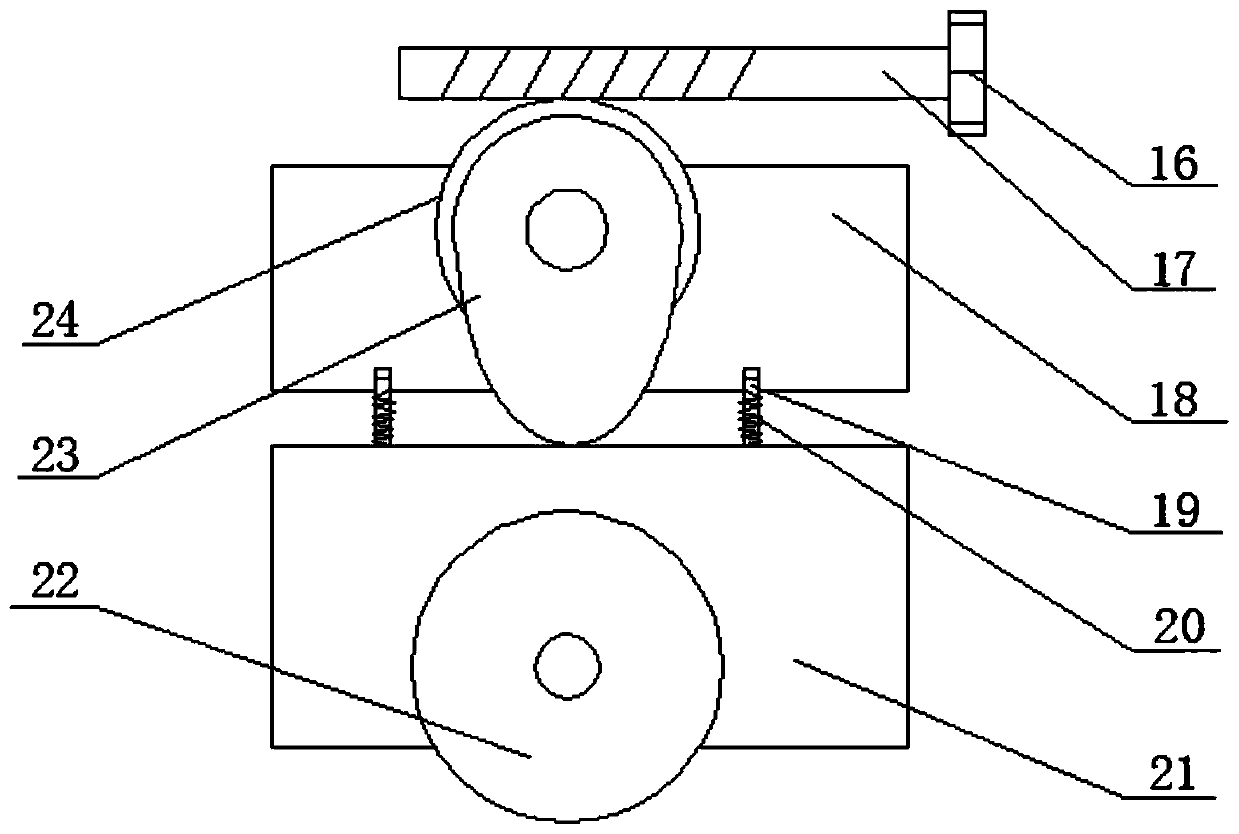

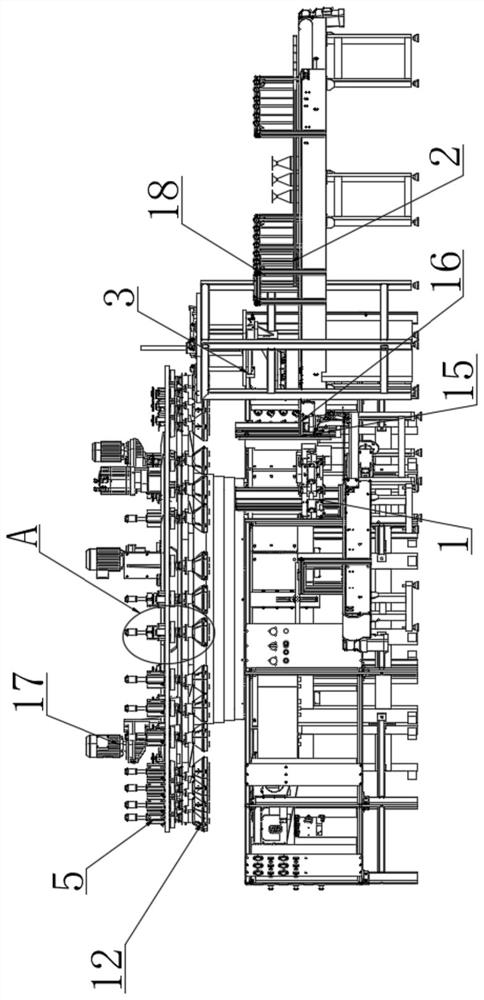

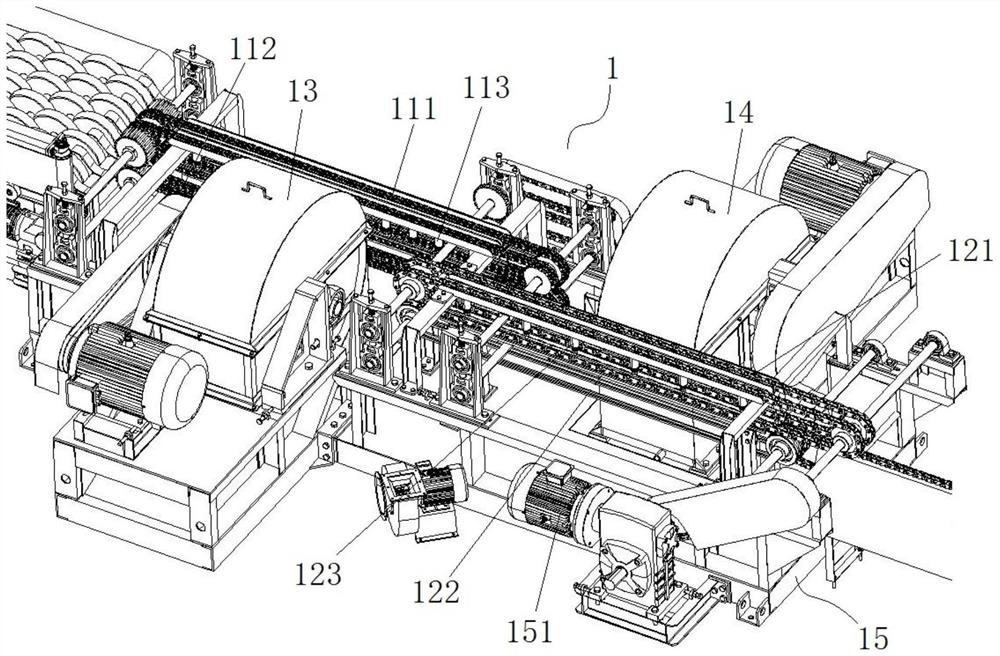

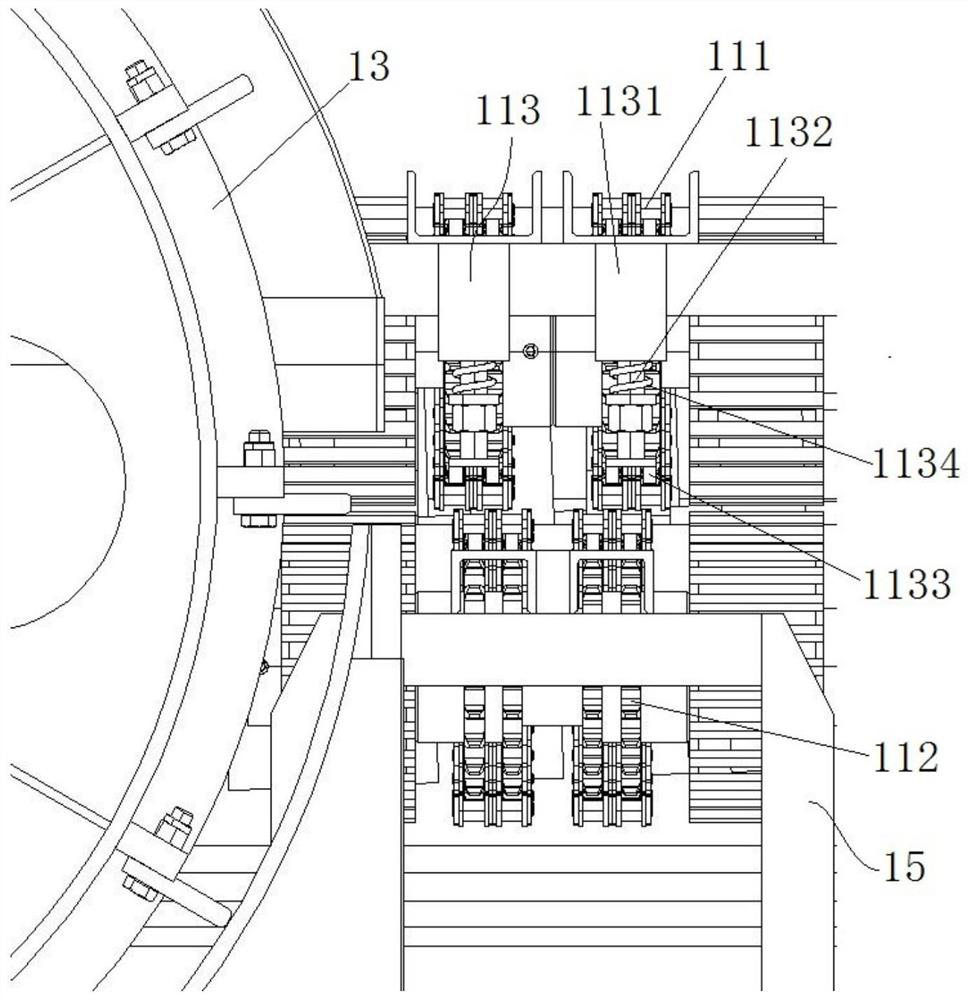

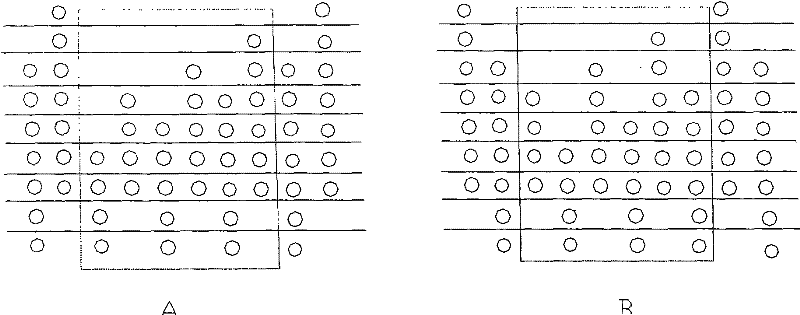

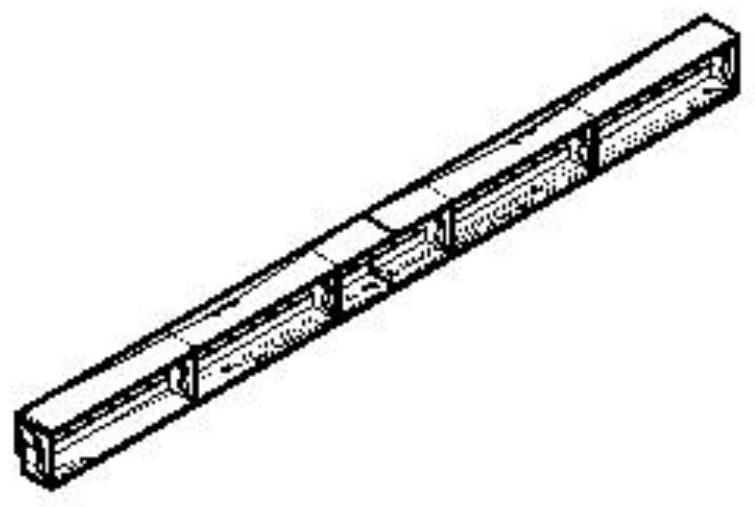

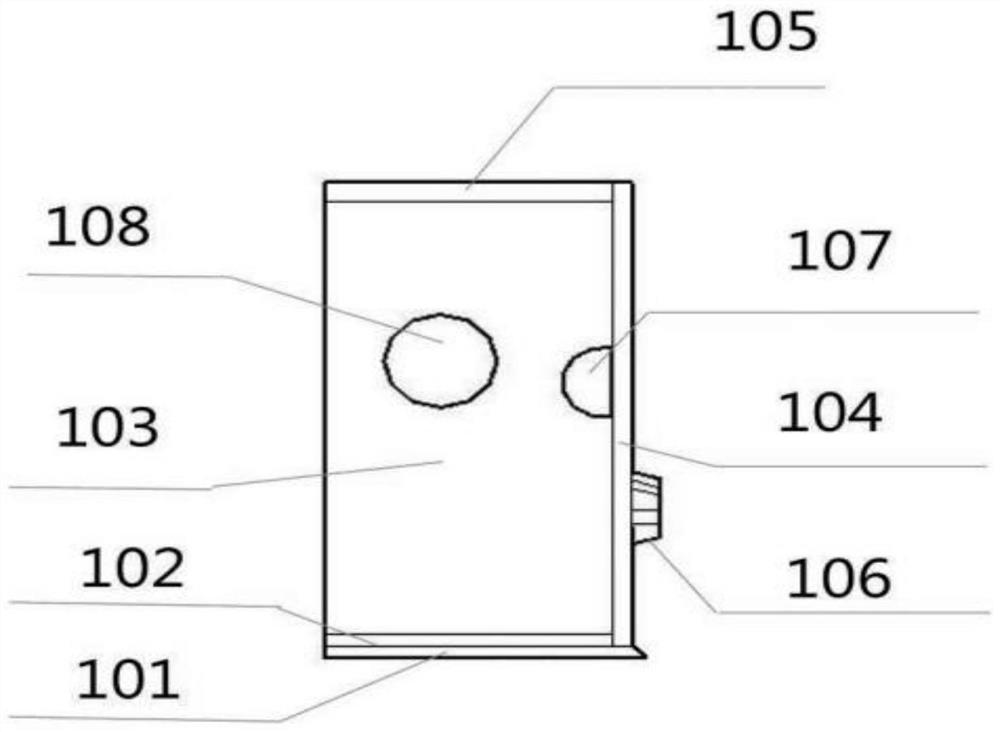

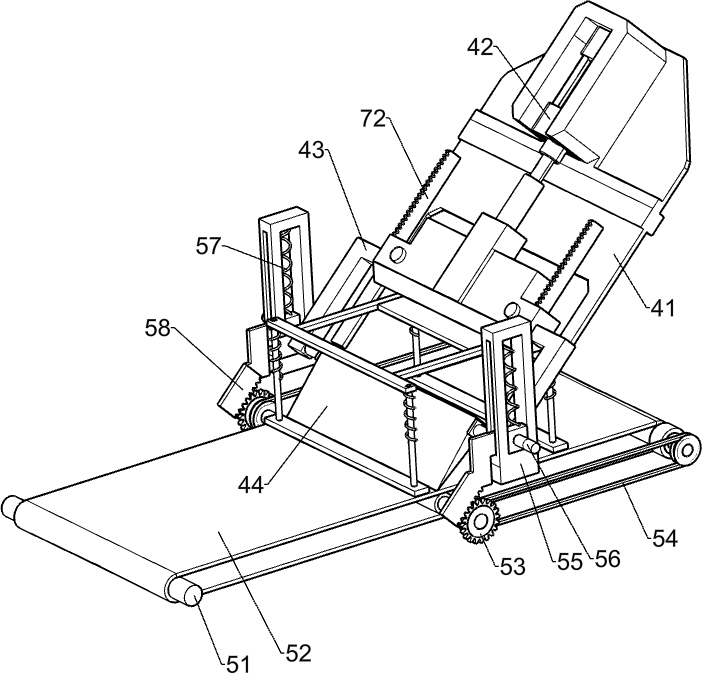

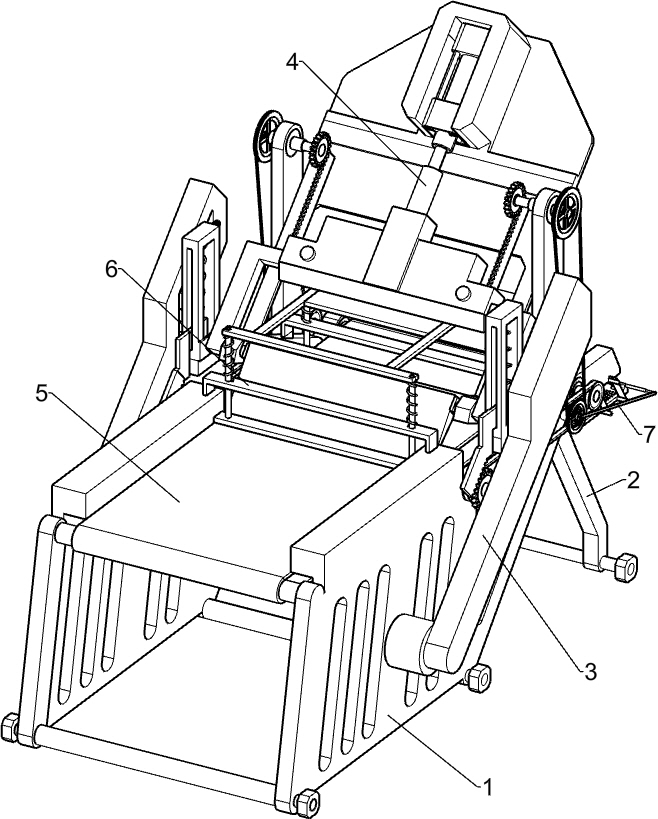

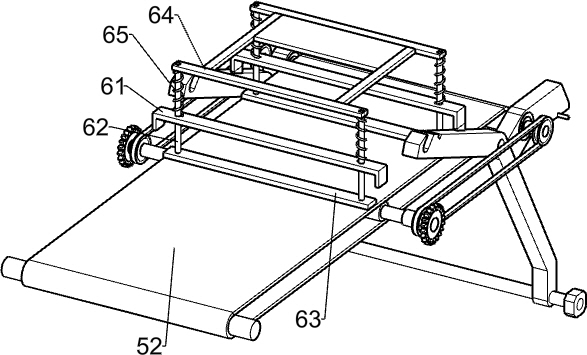

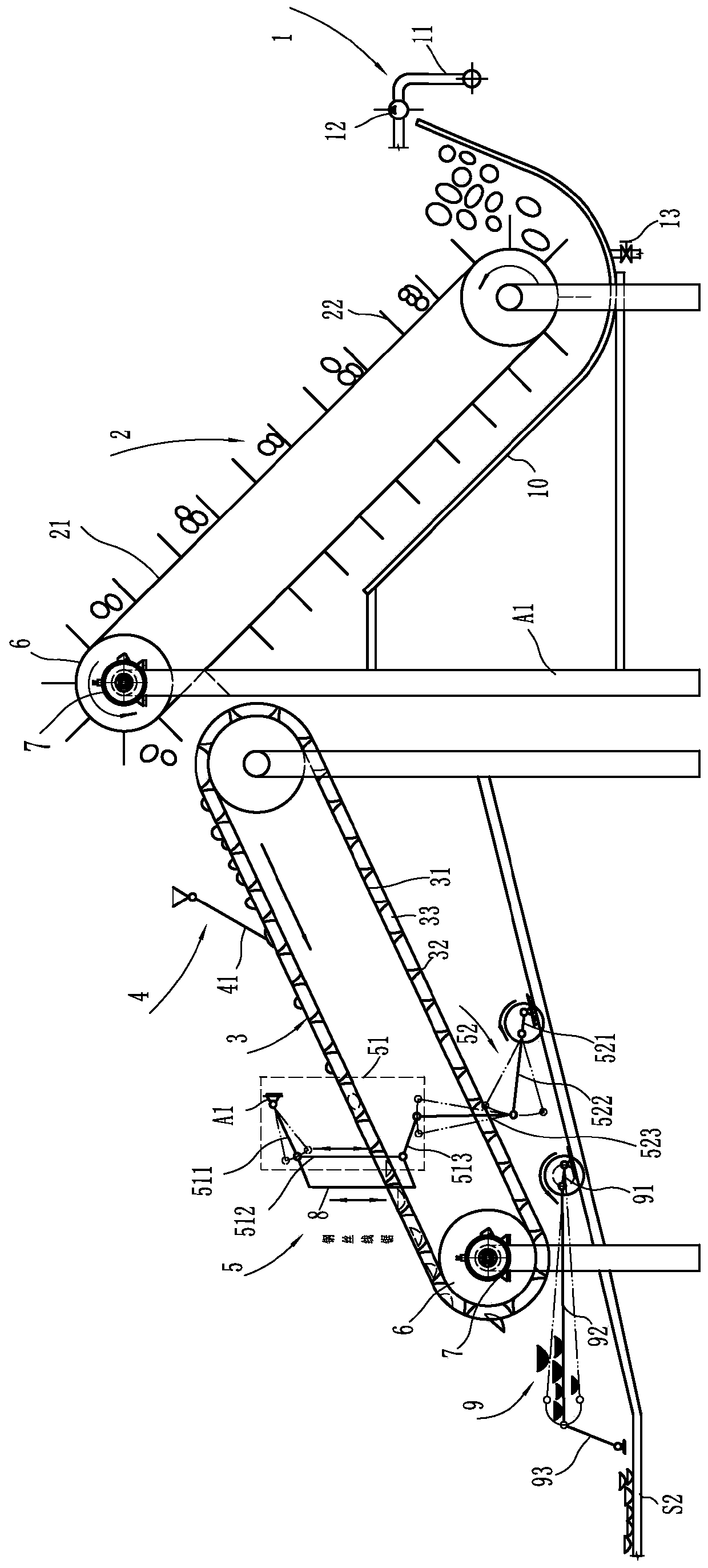

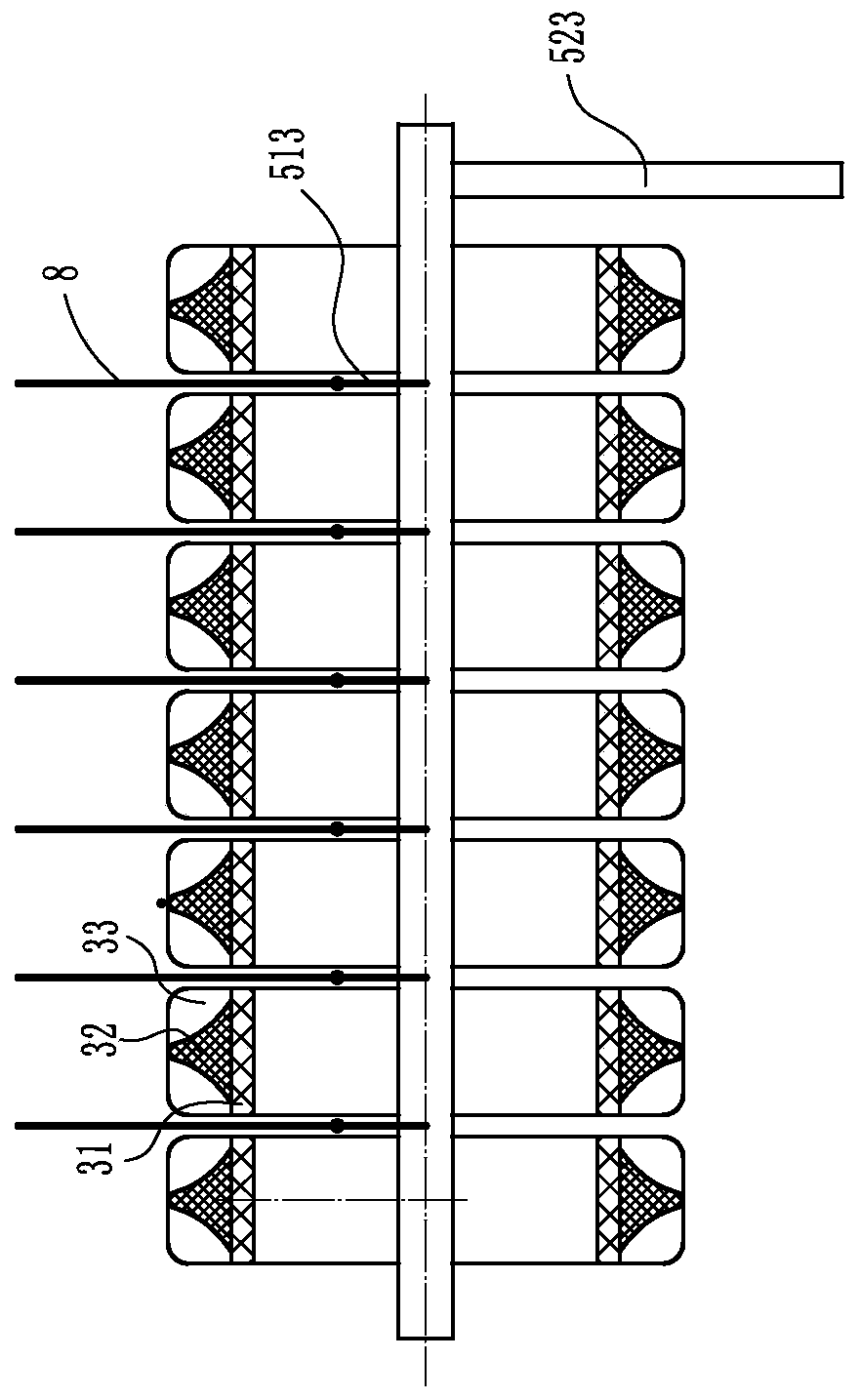

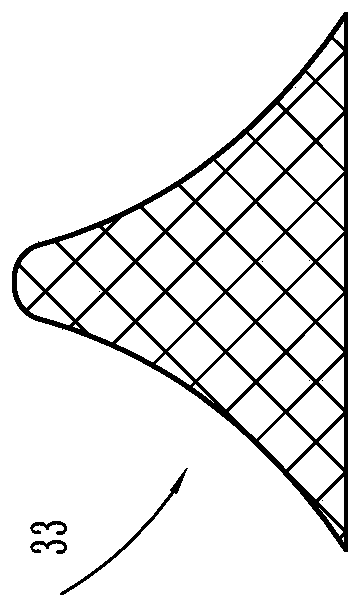

Cutting production line for building blocks

InactiveCN107053443AImprove cutting efficiencyGood quality finished productAuxillary shaping apparatusConveyor partsArchitectural engineeringProduction line

The invention belongs to the field of cutting equipment for building blocks and particularly relates to a cutting production line for the building blocks. The production line comprises a rack and main conveying device arranged on the rack; a No.1 cutting machine, a No.2 cutting machine and a No.3 cutting machine are sequentially arranged on the rack; a transverse distributing and turning mechanism for turning the building blocks by 90 degrees is arranged between the No.1 cutting machine and the No.2 cutting machine; and a reversing mechanism for reversing the building blocks is arranged between the No.2 cutting machine and the No.3 cutting machine. The production line is applicable to cutting of concrete building blocks and building block foam bricks, can perform six-surface cutting on the building blocks automatically, has the high production efficiency and guarantees the appearance quality and the size accuracy of finished products.

Owner:BINZHOU XINTONGDA MACHINE CASTING CO LTD

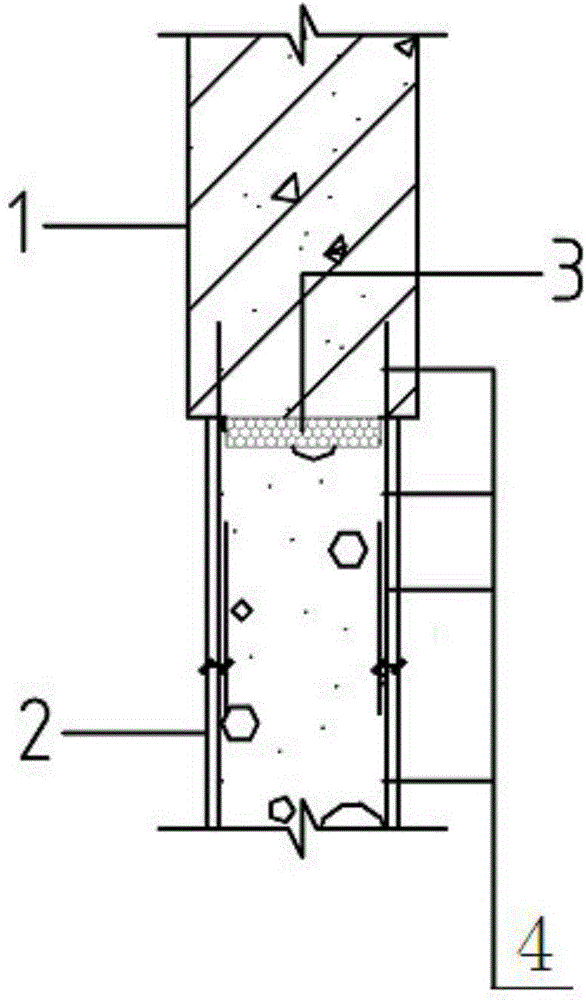

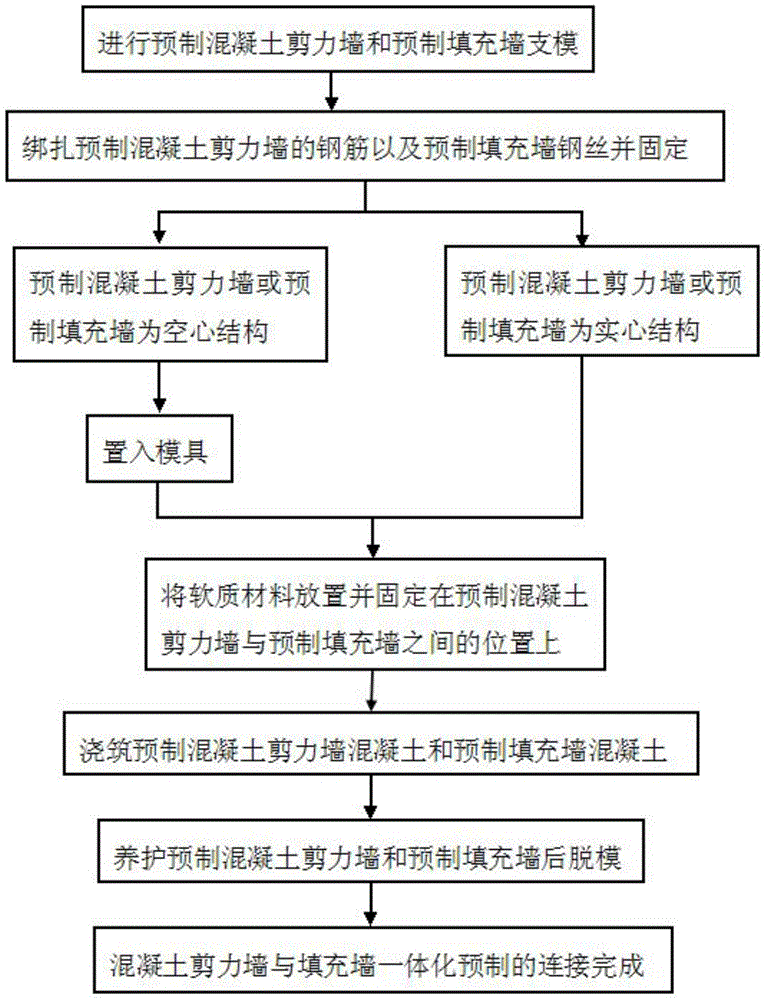

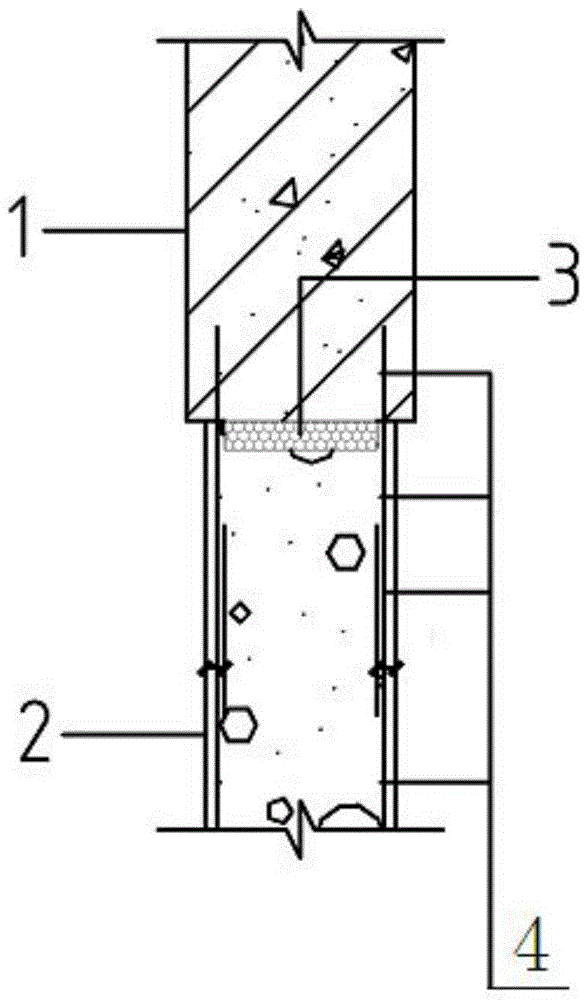

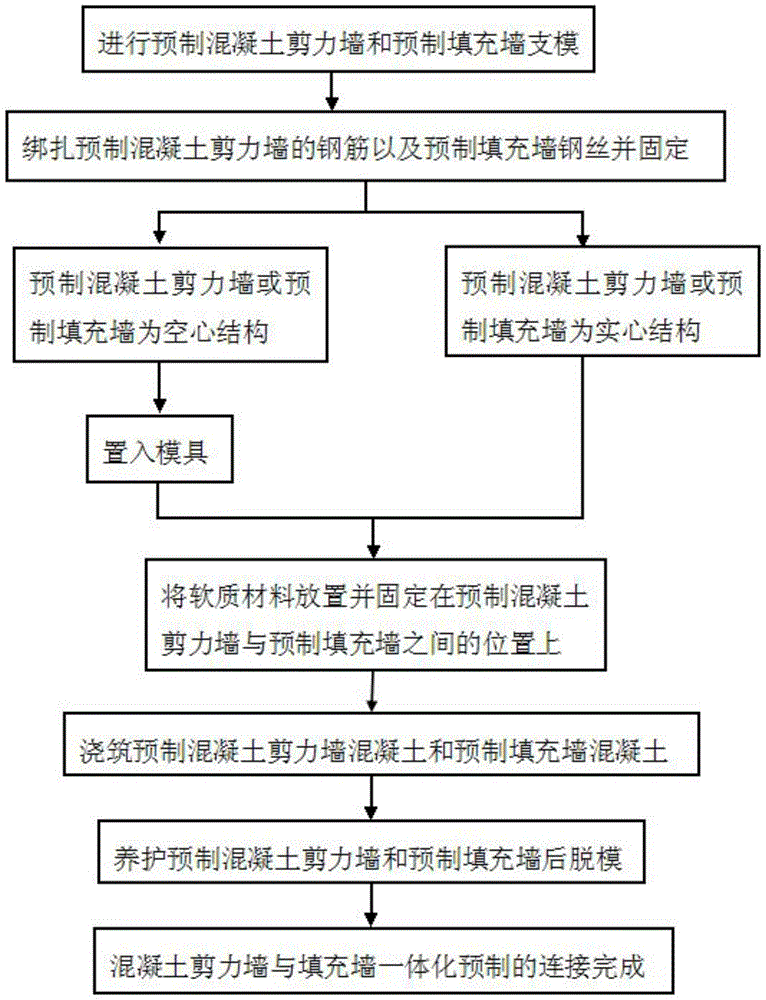

Integrated prefabrication method for connecting concrete shear wall and filler wall

The invention relates to an integrated prefabrication method for connecting a concrete shear wall and a filler wall, and belongs to the technical field of buildings. The integrated prefabrication method comprises a prefabricated concrete shear wall, a prefabricated filler wall, a soft material and prefabricated filler wall steel wires. The integrated prefabrication method is realized through the following steps: carrying out form erecting according to design requirements; binding reinforcing steel bars and steel wires of a wall body; putting corresponding molds into the prefabricated concrete shear wall and the prefabricated filler wall if the prefabricated concrete shear wall and the prefabricated filler wall are hollow; putting the soft material between the prefabricated concrete shear wall and the prefabricated filler wall; pouring wall body concrete for demolding after maintenance. The method can ignore the influence of the filler wall on the lateral-displacement-resistant rigidity of the overall structure, the structure stress is accurate, the force transmission lines are clear, and the reliability of the structure is guaranteed; moreover, the integrated prefabrication method is simple, the production and construction mounting of prefabricated parts are facilitated, the quality and efficiency are improved, the construction cost is reduced, and the method has positive meanings for the development of prefabricated concrete construction.

Owner:凡林装配式建筑科技有限公司

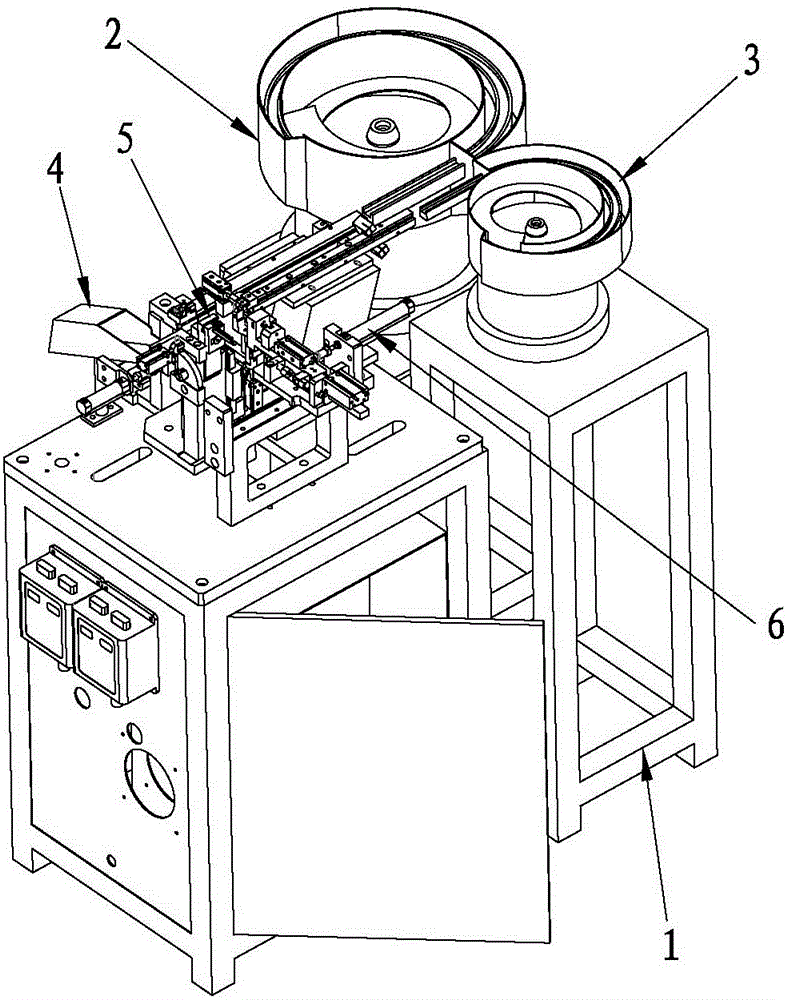

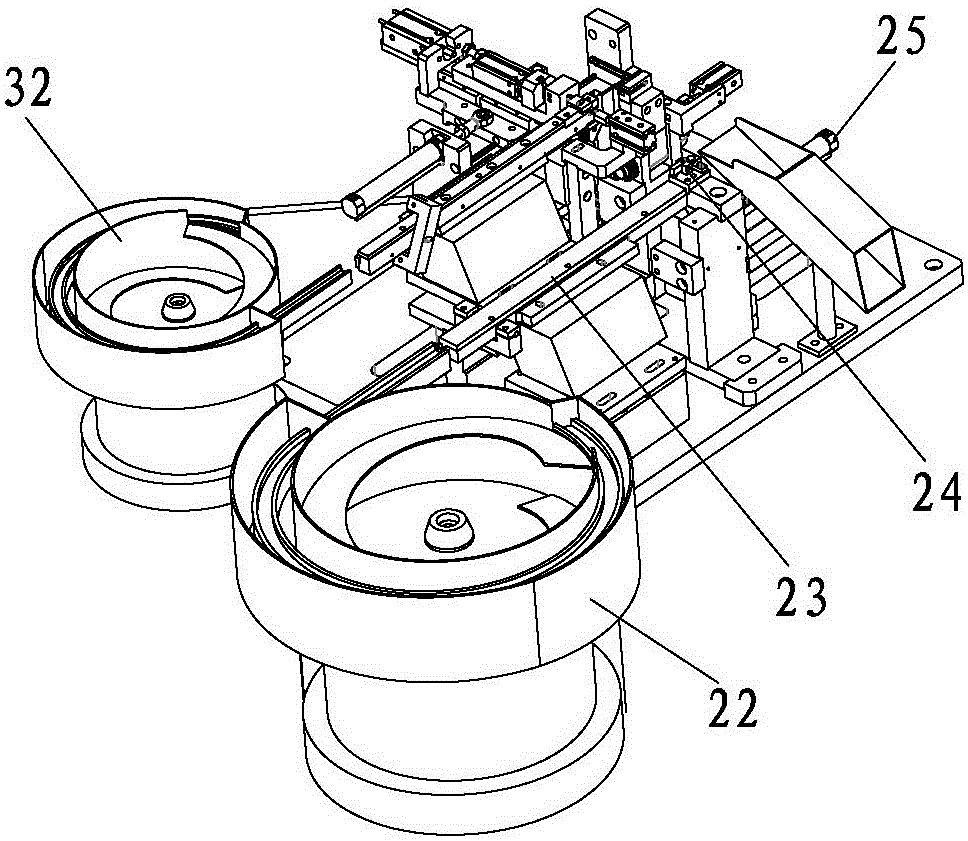

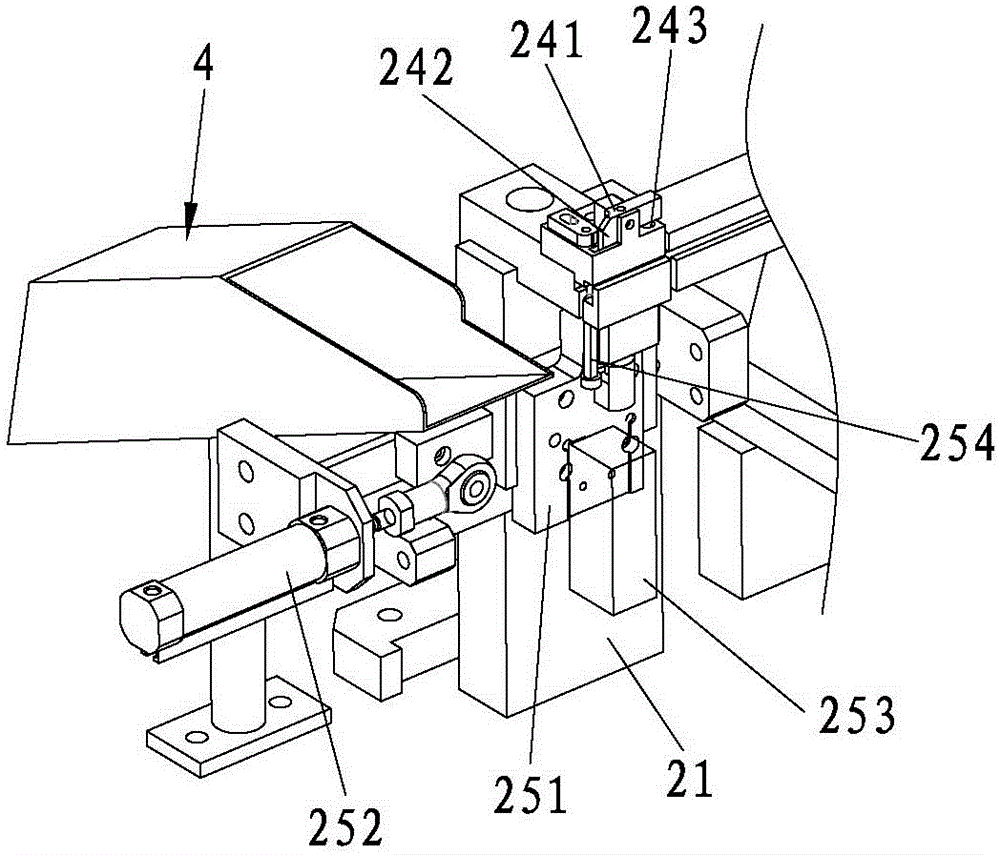

Automatic spring assembling machine

The invention relates to the technical field of fastener assembling equipment, in particular to an automatic spring assembling machine which comprises a bottom platform. The automatic spring assembling machine is characterized in that the bottom platform is provided with a fastener feeding mechanism, a spring feeding mechanism and an overturning assembling mechanism used for receiving fasteners on the fastener feeding mechanism, the output end of the spring feeding mechanism is provided with a conveying mechanism used for conveying springs to the overturning assembling mechanism, and the bottom platform is further provided with a discharging channel used for receiving assembled products of the overturning assembling mechanism. The automatic spring assembling machine has the following advantages that human assistance is not needed in the production process, the production process is fully and automatically completed through equipment, and therefore labor is saved, and the labor cost is reduced; the labor intensity is greatly reduced; and due to the fact that automatic equipment assembling is adopted, the production efficiency is much higher than that of existing artificial assembling or semi-automatic equipment assembling, and the quality of assembled finished products is better.

Owner:广东省春藤实业有限公司

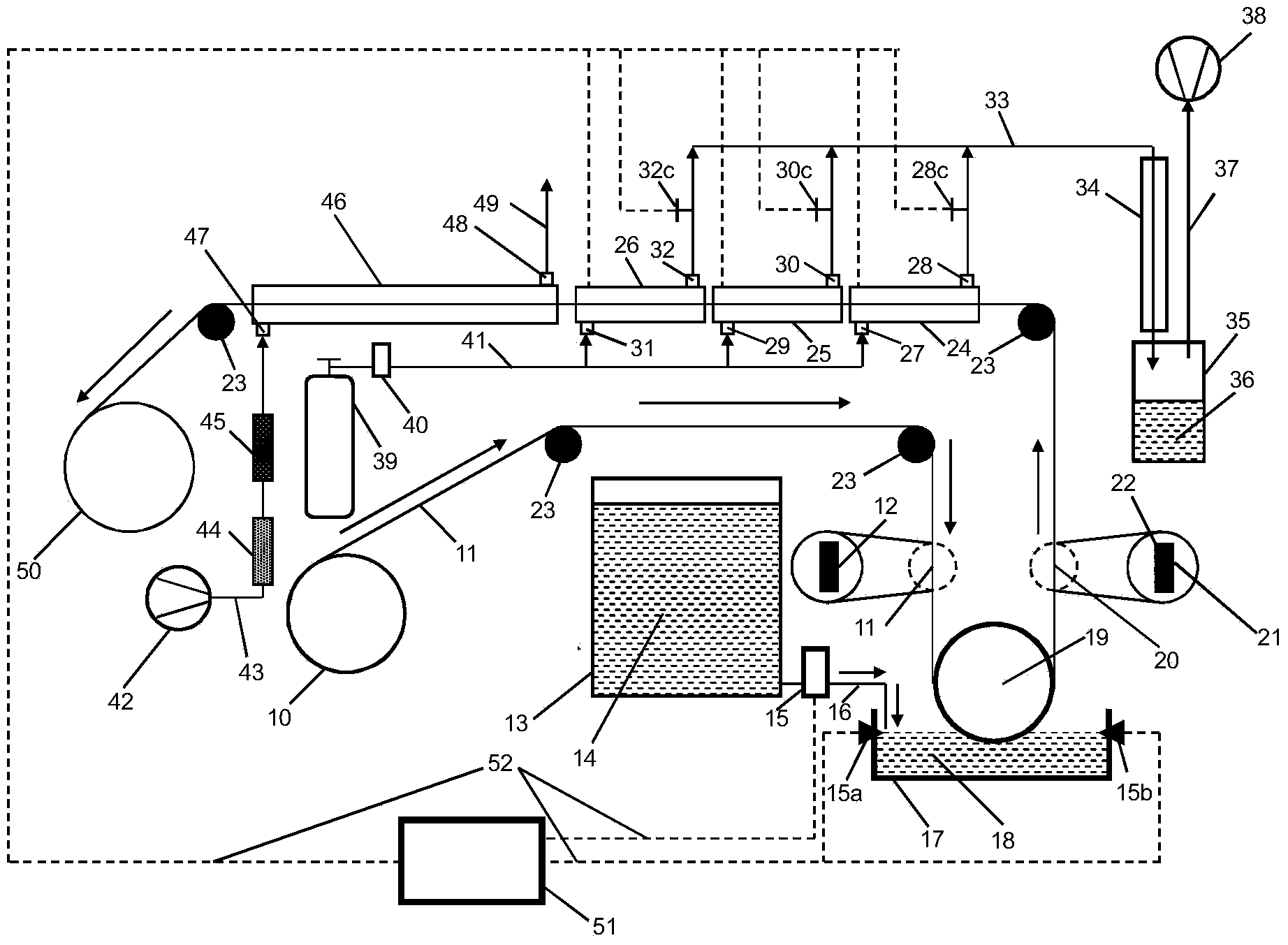

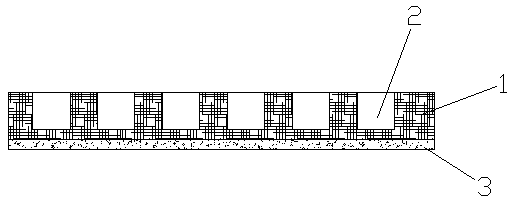

Curtain coating micro dip coating continuous production equipment and method of ultrathin membrane polymer complex film

InactiveCN103446895AIncrease productivityGood quality finished productSemi-permeable membranesSolventChemistry

The invention discloses curtain coating micro dip coating continuous production equipment and a method of an ultrathin membrane polymer complex film, belonging to the technical field of chemical equipment and process. The technical scheme I is that the production equipment provided by the invention comprises a transmission system, a computer control system, a micro dip coating system, a drying system and a solvent recovery system; The technical scheme II is the curtain coating micro dip coating continuous production method of the ultrathin membrane polymer complex film provided by the invention. The equipment and the method provided by the invention have the advantages that the complex film is continuously automatically produced, the production efficiency is high, and the end product quality is good; the uniform and flawless complex film is produced, the temperature, resistance time and vacuum degree and the like of a vacuum drying oven are controlled, and the quality of the complex film is guaranteed; a solvent is recovered, the manufacturing cost is saved, meanwhile, the environmental pollution is stopped, and when output achieves a certain scale, the costs of the continuous production equipment and the method are lower than the batch processing costs.

Owner:HUBEI LONGFEIXIANG IND GRP CO LTD +1

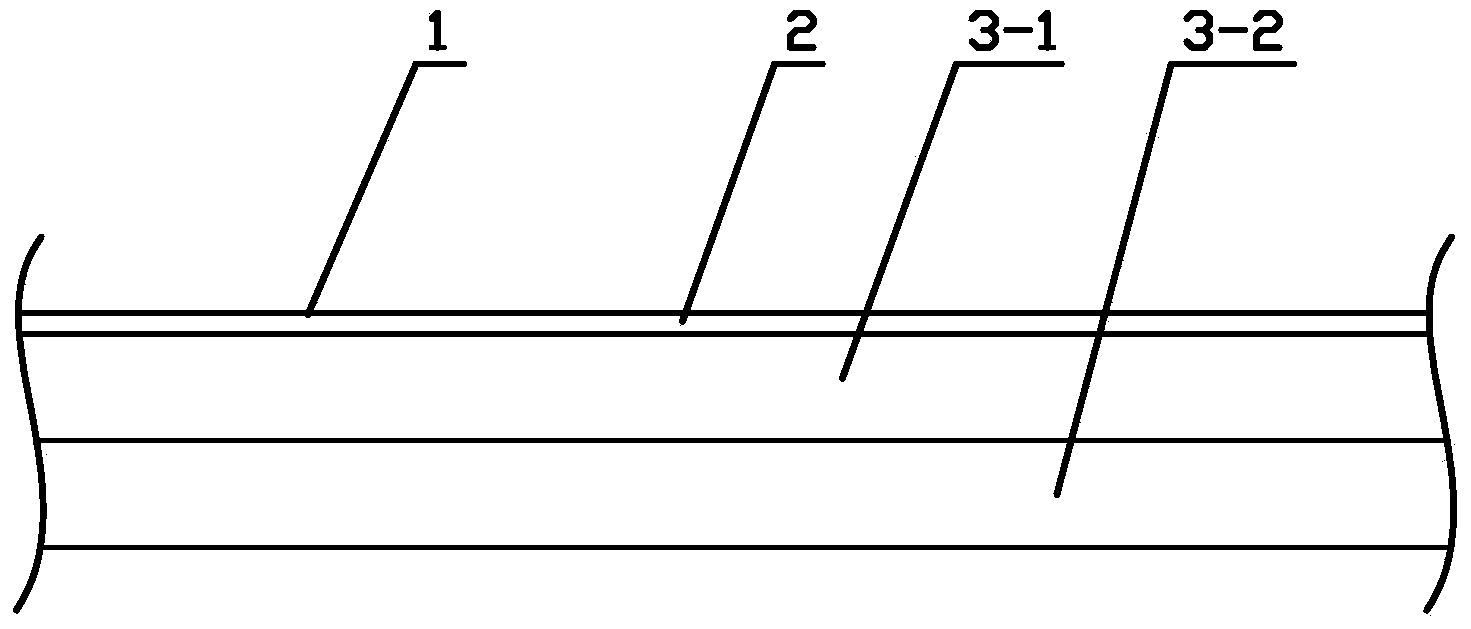

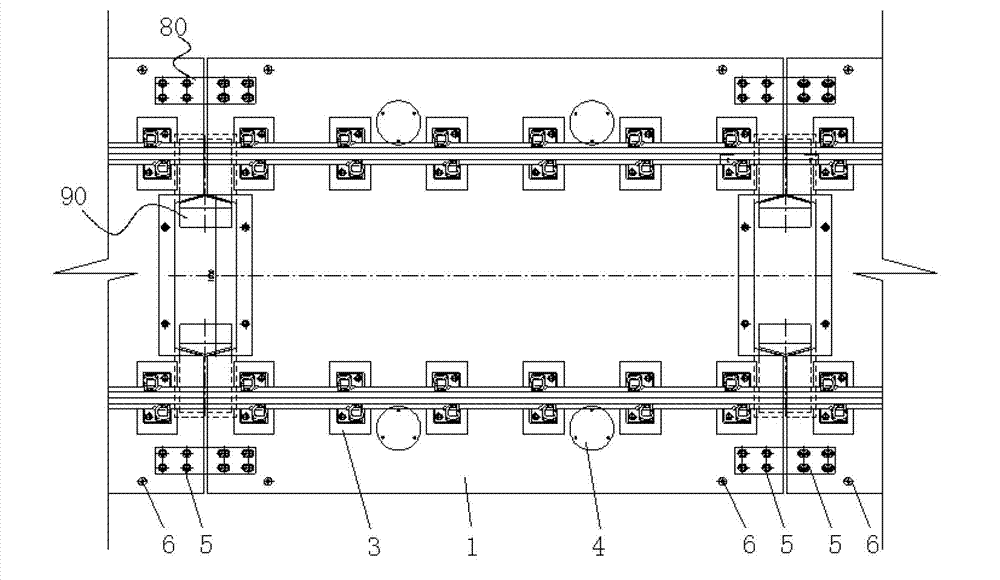

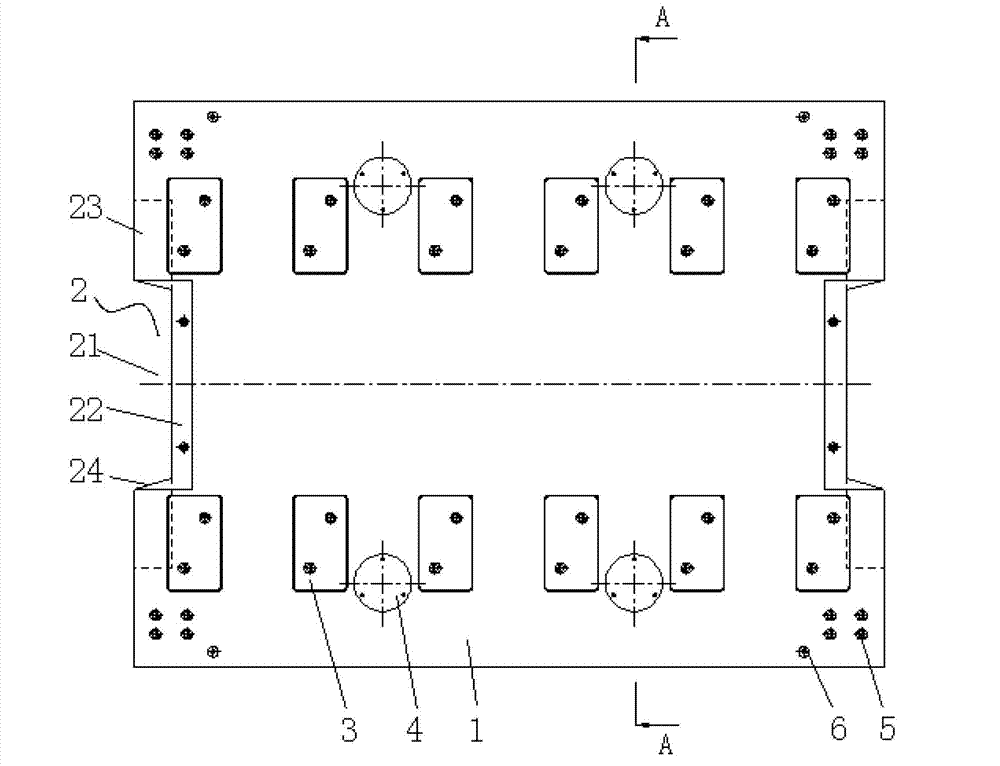

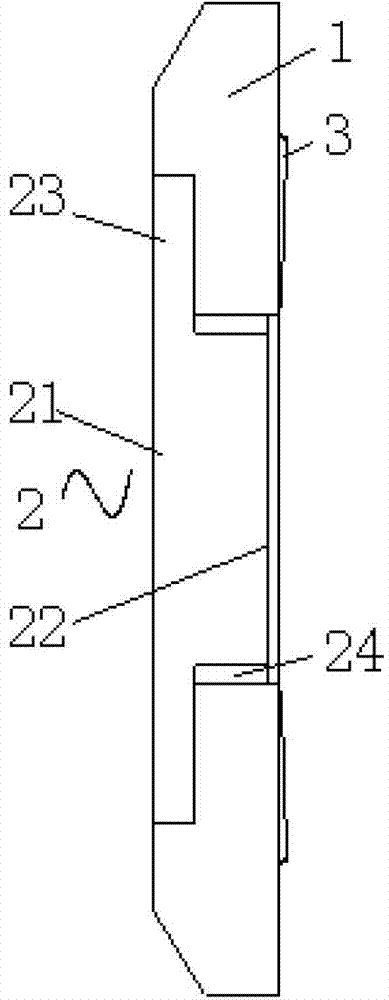

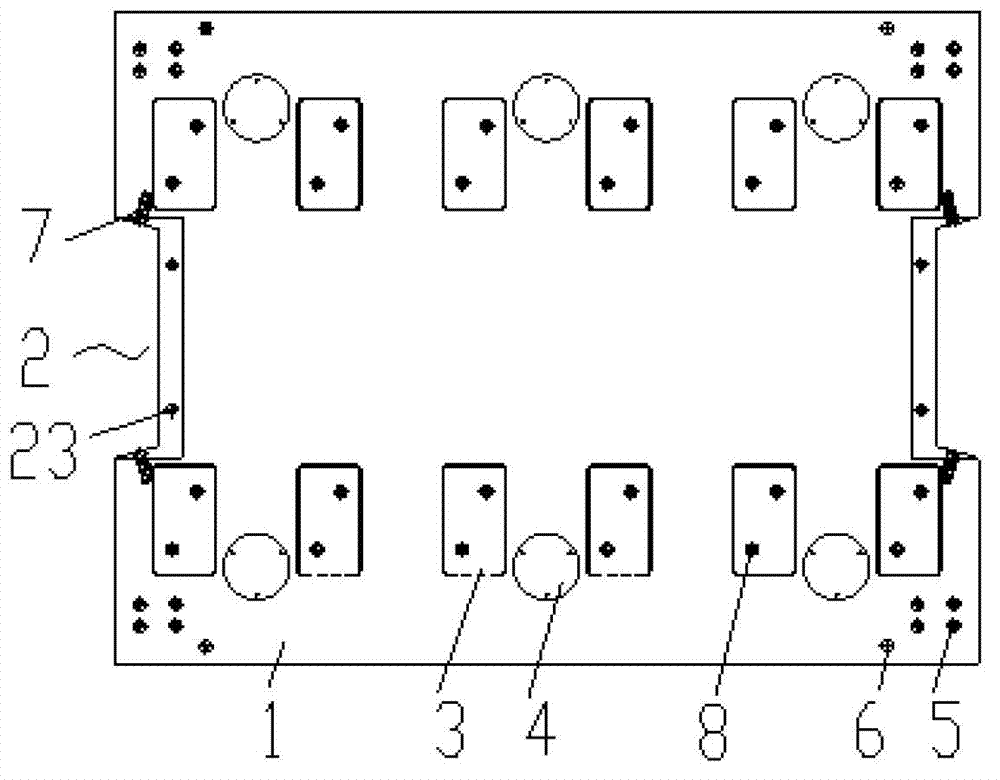

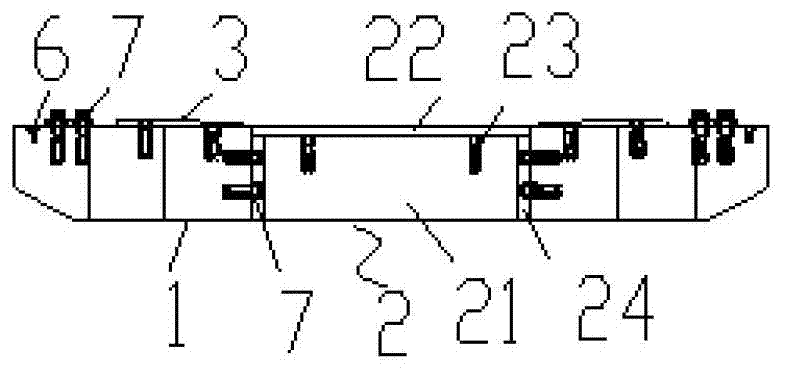

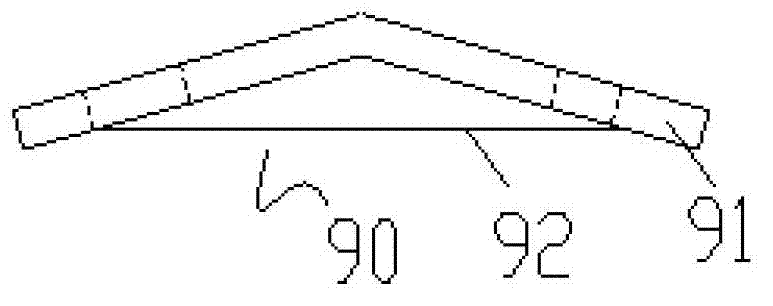

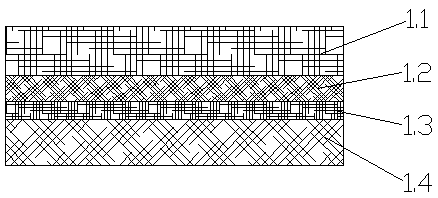

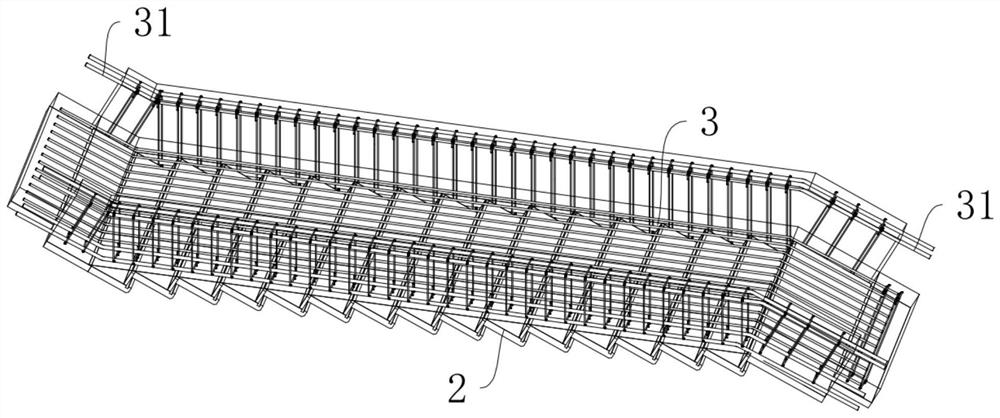

Precast slab assembled floating road bed

ActiveCN102899971AGood maintenance environmentGood quality finished productBallastwayBoard structureBuilding construction

The invention discloses a precast slab assembled floating road bed, which comprises a plurality of precast slabs paved in sequence and a plurality of connecting devices for fixedly connecting two adjacent precast slabs, wherein the connecting devices are used for connecting the precast slabs integrally in sequence to form the assembled floating road bed. Groove structures are respectively arranged at both ends of the main body of the precast slab; a bushing group is arranged at corners on both sides of the main body of the precast slab; and the connecting device comprises a horizontal connecting board structure and a side vibration isolator. Each precast slab in the precast slab assembled floating road bed disclosed by the invention is precast in a factory in a concentrated manner, the finished product is good in quality, and the plurality of precast slabs are assembled when the floating road bed is constructed so that the construction period is short and the efficiency is high; the horizontal connecting board structure in the connecting device is arranged on the surface of the precast slab, and is simple in structure and convenient to use and check; the damaged parts out of work can be replaced; and the floating road bed in settlement state can be adjusted in time.

Owner:BEIJING JIUZHOUYIGUI SHOCK & VIBRATION ISOLATION

Novel precast slab assembled floating track bed

ActiveCN102926294AGood maintenance environmentGood quality finished productBallastwayEngineeringTrack bed

The invention discloses a novel precast slab assembled floating track bed which comprises a plurality of floating track bed precast slabs and a plurality of connecting devices. The floating track bed precast slabs are laid in sequence back and forth. Every two adjacent floating track bed precast slabs are fixedly connected together through the connecting devices. The connecting devices are used for sequentially connecting the plurality of floating track bed precast slabs into a whole to form the assembled floating track bed. Each floating track bed precast slab comprises a precast slab main body, two rows of track bearing platforms, an outer sleeve unit, first sleeve sets, second sleeve sets and third sleeve sets. Two ends portions of the precast slab main body are respectively provided with a groove structure. The first sleeve sets are arranged in the precast slab main body. The second sleeve sets are arranged corner portions of two sides of the precast slab main body. The third sleeve sets are arranged at the track bearing platforms. The novel precast slab assembled floating track bed is fast in assembling and convenient to regulate, substantially decreases operation processes and the construction cycle and multiply improves construction efficiency. When the novel precast slab assembled floating track bed is used in complex areas, due to a replaceable structure, maintenance time is greatly reduced, maintenance cost is decreased, and construction quality and integrity of the floating track bed are guaranteed.

Owner:BEIJING JIUZHOUYIGUI SHOCK & VIBRATION ISOLATION

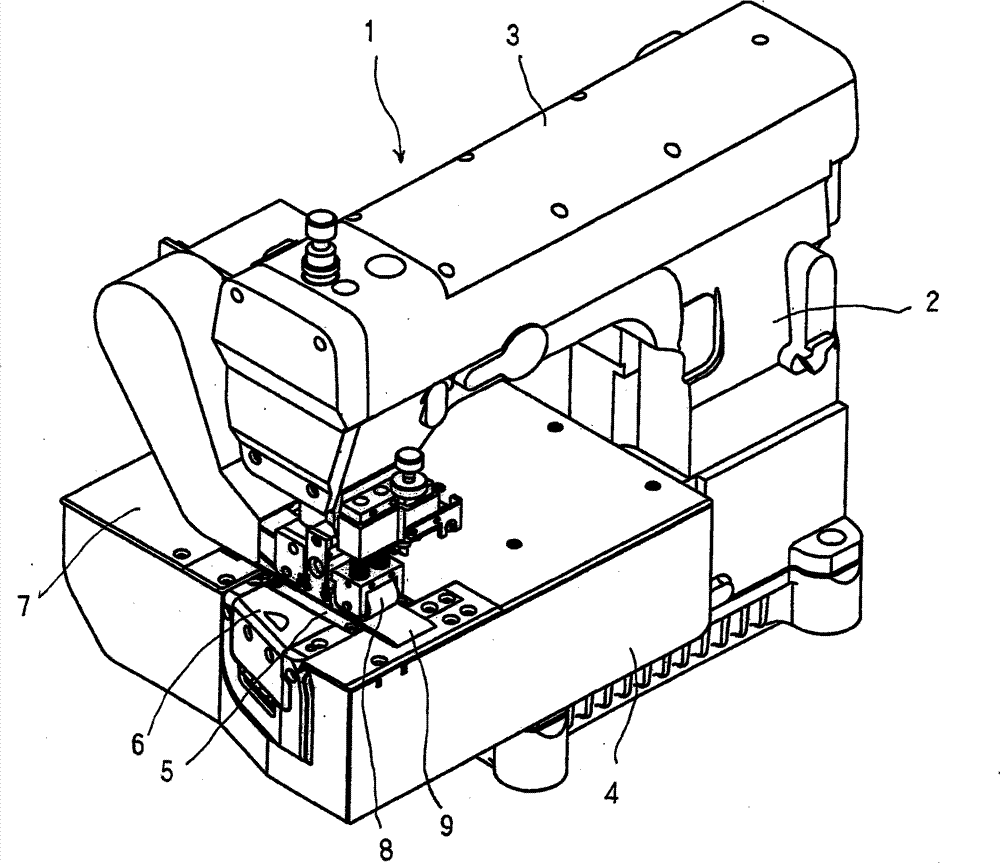

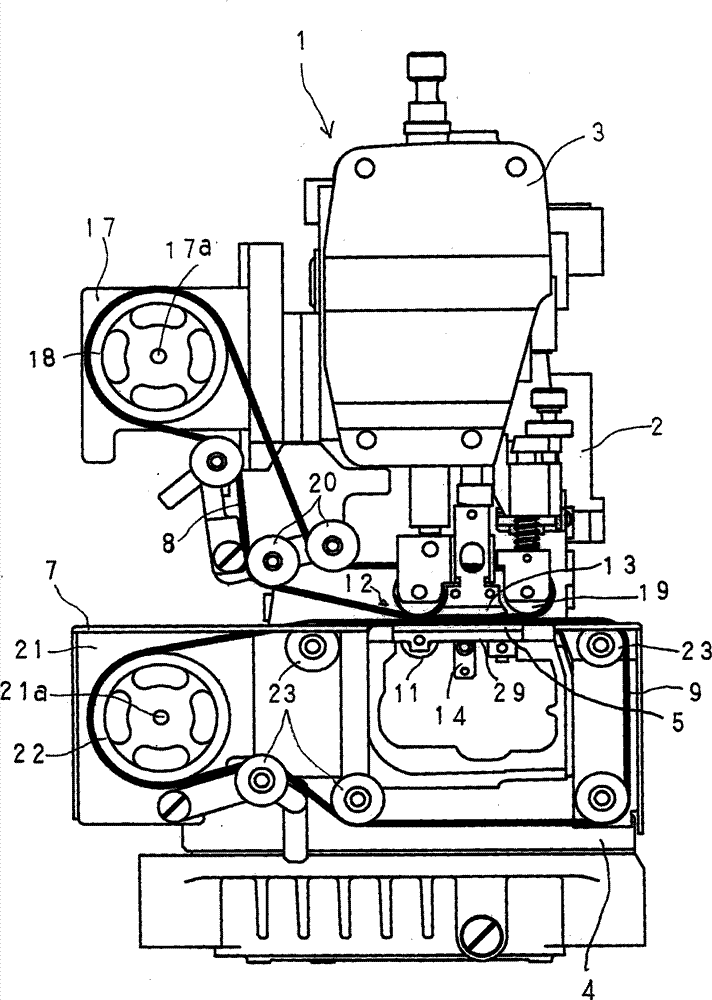

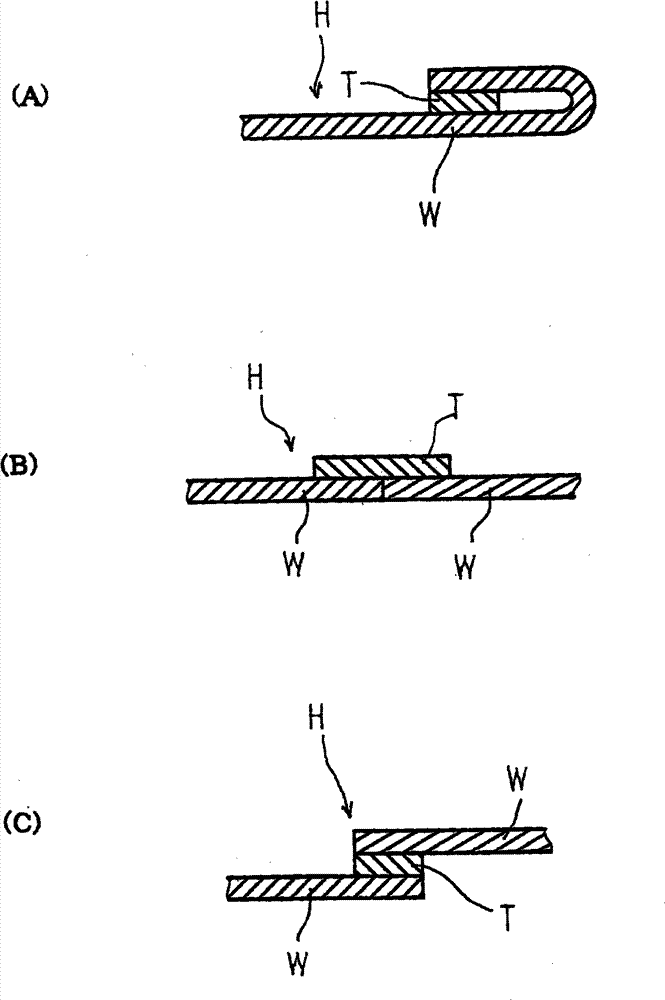

High frequency sewing machine

InactiveCN104512034ASimple structureAvoid scaldingClothes making applicancesElectricityHigh frequency power

A high frequency sewing machine includes a pair of endless belts arranged at upper and lower sides; a pair of rollers arranged at upper and lower sides; an upper electrode having a function of pressing a machined material and a lower electrode opposite to the upper electrode; a high frequency power applying device; a control unit; and a roller lifting mechanism and an electrode lifting mechanism which can perform switching control between a first bonding action mode and a second bonding action mode, in the first bonding action mode, the upper roller and the upper electrode are descended to continuously convey a machined material while high frequency power is continuously applied between the upper and lower electrodes, in the second bonding action mode, the upper roller depart towards the upper side, and at the same time, the upper electrode intermittently rises and falls to convey the machined material while the high frequency power is intermittently applied between the upper and lower electrodes. The high frequency sewing machine can prevent the occurrence of indentations and overheated traces, burning, burnout, and the wavy shape of a fabric, and can also easily and surely bond curvilinear portions.

Owner:YAMATO SEWING MASCH MFG CO LTD

Vegetable bean jelly and preparation method thereof

InactiveCN102461899AHigh nutritional valuePromote absorptionFood preparationNutritive valuesOlder people

The invention discloses a vegetable bean jelly and a preparation method thereof. The vegetable bean jelly solves the problem that the existing bean jelly contains a single nutrient. In preparation of the vegetable bean jelly, vegetable juice is utilized, wherein the weight of the added vegetable juice is 25 to 60% of the total weight of raw materials. Because of utilization of a mass of the vegetable juice, the vegetable bean jelly obtained by the preparation method has a high nutritive value, can be absorbed easily, and is especially suitable for old people who have bad teeth and do not chew vegetables. The preparation method is simple and convenient and can be operated easily. The vegetable bean jelly has good quality, can be stored easily and does not go bad. Mechanized and industrialized production of the vegetable bean jelly can be realized.

Owner:金少军

Epoxy resin terrazzo mixing proportion

The invention relates to an epoxy resin terrazzo which is characterized by being prepared by evenly blending the following raw materials according to the specific weight: 6.0-6.5 kg / m<3> of epoxy resin, 1.2-1.3 kg / m<3> of curing agent, 0.5-1.0 kg / m<3> of flour, 100-160 kg / m<3> of industrial salt, 1320-1640 kg / m<3> of stones, 10-30 kg / m<3> quartz sand, 450-670 kg / m<3> glass, and 10-30 kg / m<3> of luminous powder. Compared with the prior art, the epoxy resin terrazzo has the advantages that the quality of terrace is obviously improved, and the construction process is more environment-friendly. The epoxy resin terrazzo has good application prospects at the places of supermarkets and the like which lay emphasis on the decoration effect.

Owner:ZHONGTIAN CONSTR GROUP

Rear auxiliary machine equipment of extruding machine

PendingCN113263334AImprove processing efficiencyHigh degree of automationOther manufacturing equipments/toolsEngineeringMachine

The invention discloses rear auxiliary machine equipment of an extruding machine. The equipment comprises quenching equipment, a traction machine, hot saw equipment, a cooling bed, a straightening machine, a finished product saw feeding shaft channel, finished product saw equipment and a sizing table which are arranged on the rear portion of the extruding machine in the profile discharging machining direction. A formed profile is dragged out from the extruding machine through a dragger, is quenched and cooled by the quenching equipment, is cut by the hot saw, is further cooled by the cooling bed, is straightened and corrected by the straightening machine, and is output after being cut into the required length by the finished product saw and the sizing table, so that the overall automation degree of the equipment is high, the quality of the finished product is excellent, reliability is high, the profile machining efficiency is improved, and the market space is wide.

Owner:FOSHAN TONGRUN THERMAL ENERGY TECH

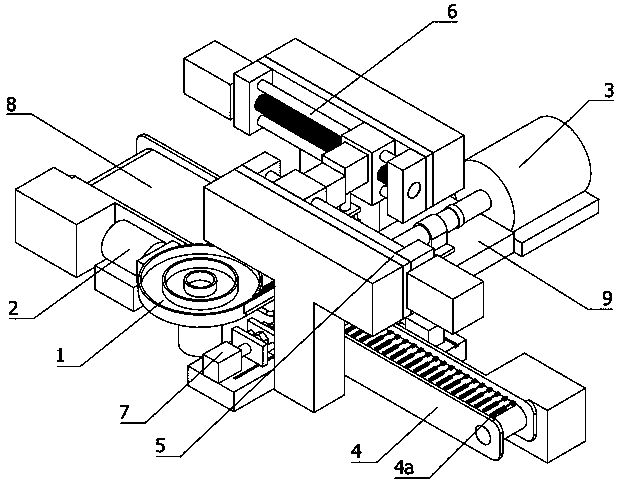

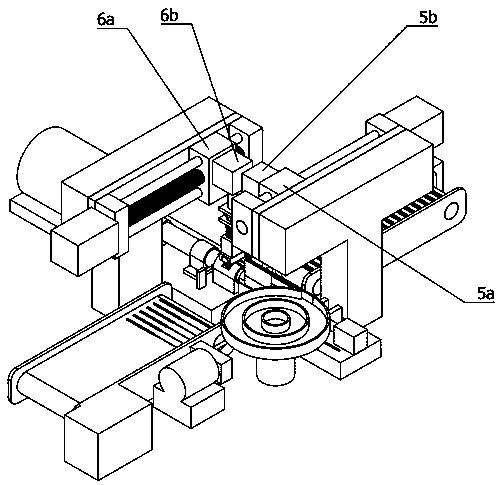

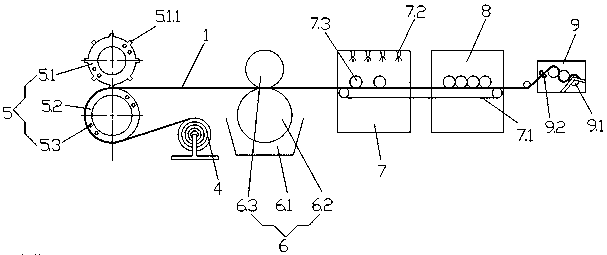

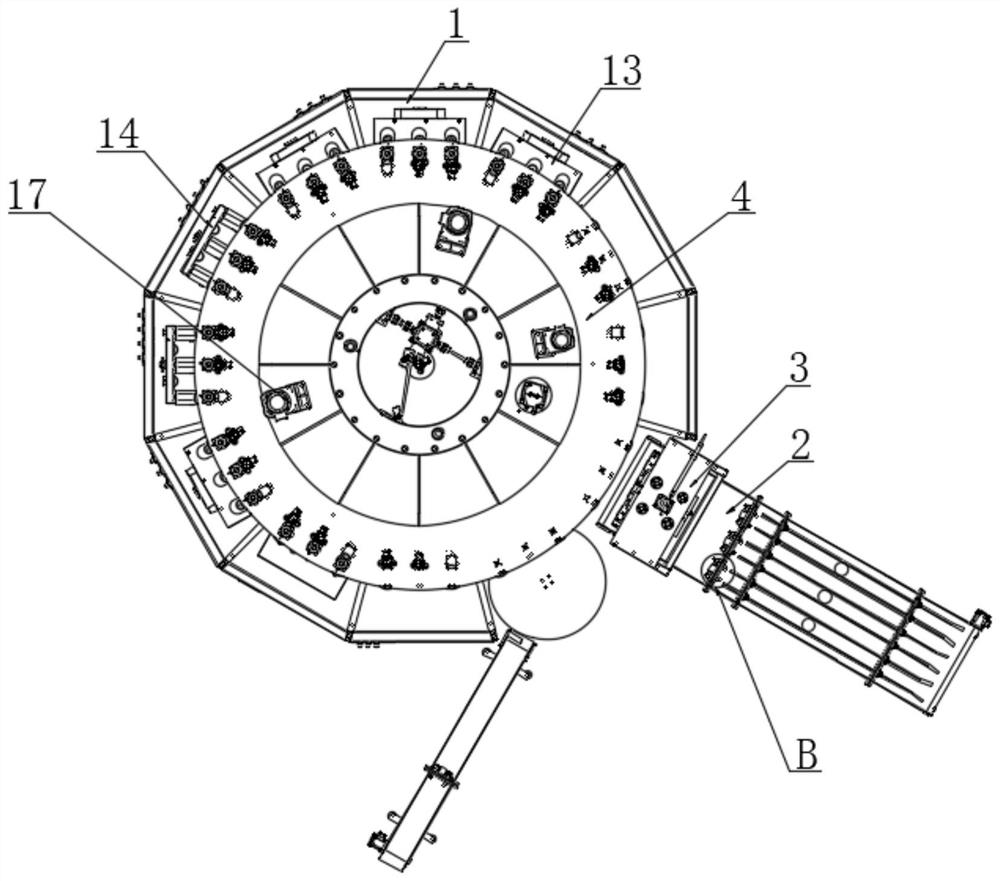

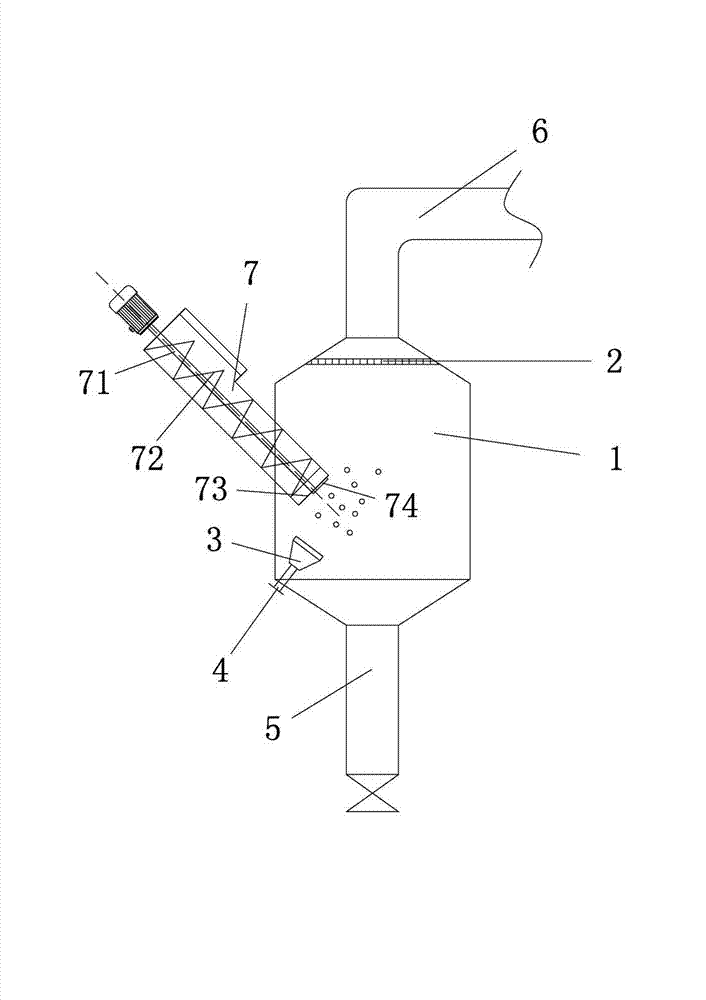

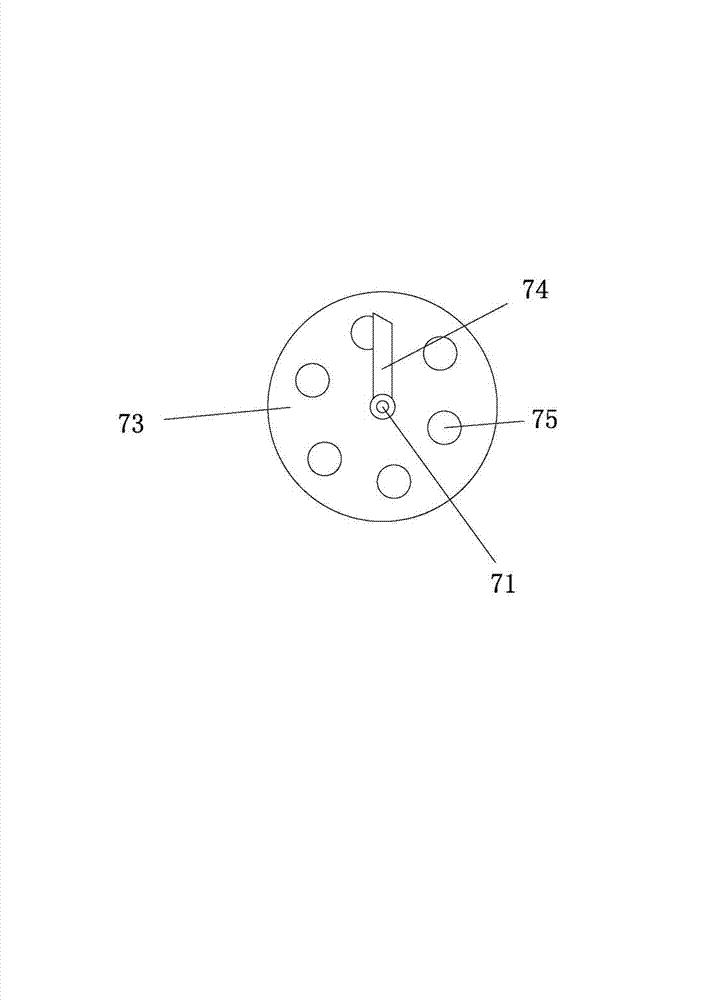

Automatic assembling equipment of needles with spring holders for acupuncture and moxibustion

ActiveCN111112995ASame rotation angleArranged in an orderly mannerMetal working apparatusPhysical medicine and rehabilitationEconomic benefits

The invention relates to the technical field of automatic assembling, in particular to automatic assembling equipment of needles with spring holders for acupuncture and moxibustion. The automatic assembling equipment comprises a vibration feeding mechanism, a jet feeding mechanism, an indexing mechanism, a first linear conveying mechanism, a feeding robot, a discharging robot, an inserting mechanism, a second linear transportation mechanism, a rack and a controller, wherein the output end of the vibration feeding mechanism is sequentially connected with the input end of the jet feeding mechanism, the output end of the jet feeding mechanism is sequentially connected with the input end of the indexing mechanism, the first linear transportation mechanism is arranged on one side of the indexing mechanism, the feeding robot, the discharging robot and the inserting mechanism are all fixedly connected with the rack and are all distributed around the indexing mechanism, and the structures of the horizontal moving parts and vertical moving parts of the feeding robot and the discharging robot are identical. According to the scheme, the manpower is saved, the assembling efficiency is high, the economic benefit is good, positioning is accurate, and the quality of a finished product is excellent.

Owner:SHENZHEN MATERNITY & CHILD HEALTHCARE HOSPITAL

Strong antistatic non-woven fabric production device and production method

PendingCN110438718AReduce dosageRoller coating evenlyMechanical cleaningLiquid surface applicatorsAntistatic agentEngineering

The invention relates to a strong antistatic non-woven fabric production device. After a non-woven fabric body is unwound from an unwinding mechanism, the non-woven fabric body sequentially passes anembossing device, a roller coating device, a hot air blasting device, a cooling device and a winding device. Antistatic agents are uniformly applied in a roller coating manner, dosage of the antistatic agents is reduced, antistatic effects are good, a finished non-woven fabric is good in barrier property, softness and quality, and the surface of the non-woven fabric is smooth.

Owner:江阴金凤特种纺织品有限公司

A connection method of integrated prefabrication of concrete shear wall and filling wall

ActiveCN104831829BReduce consumptionGuaranteed reliabilityWallsArchitectural engineeringSoft materials

A connection method for integrated prefabrication of concrete shear walls and infill walls, which belongs to the technical field of construction, including prefabricated concrete shear walls, prefabricated infill walls, soft materials, and prefabricated infill wall steel wires, and is realized through the following steps: According to the design Formwork is required; wall reinforcement and steel wires are bound; if precast concrete shear walls and prefabricated infill walls are hollow, corresponding molds should be placed; soft materials between precast concrete shear walls and prefabricated infill walls should be placed; pouring The wall concrete is demoulded after curing. The present invention can ignore the impact of the filling wall on the anti-sway stiffness of the overall structure, the structural force is clear, the force transmission route is clear, and the reliability of the structure is guaranteed; at the same time, the integrated prefabrication method is simple, which is convenient for the production, construction and installation of prefabricated components, and improves It improves the quality and efficiency, reduces the construction cost, and has positive significance for the development of prefabricated concrete buildings.

Owner:凡林装配式建筑科技有限公司

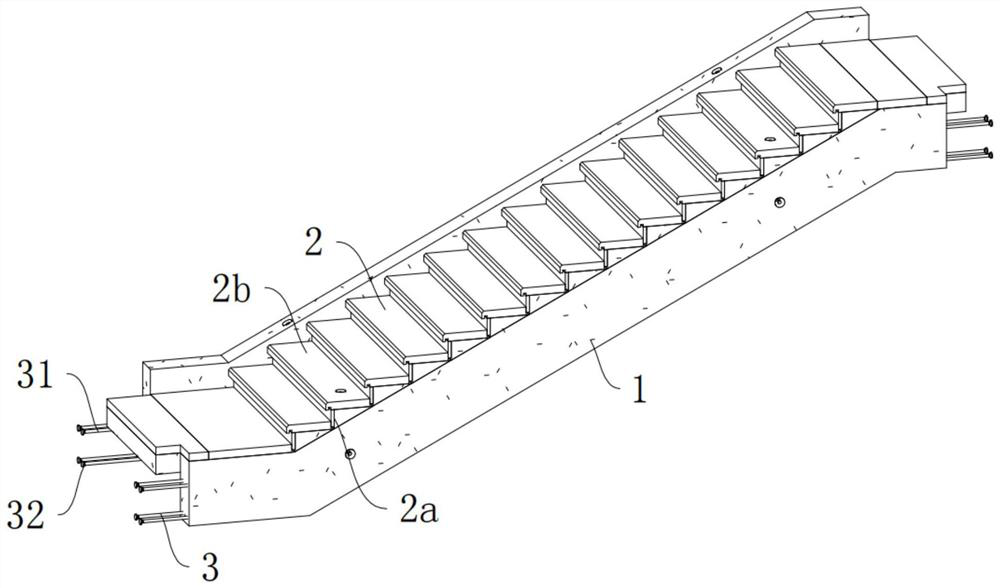

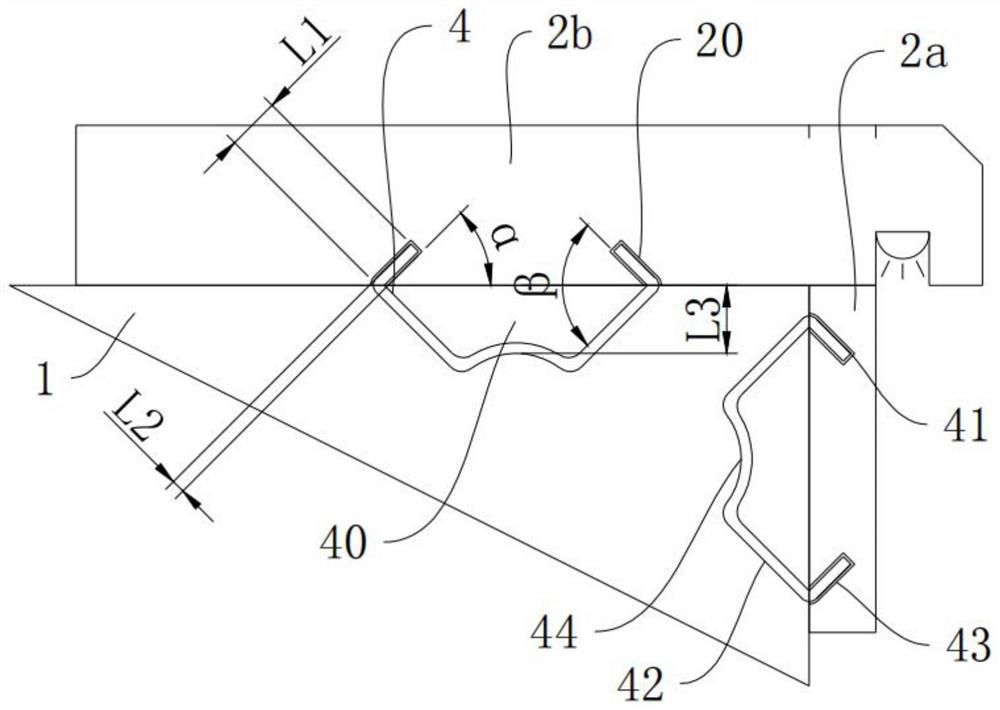

Prefabricated stair and production and construction method thereof

The invention discloses a prefabricated stair and a production and construction method thereof, and belongs to the field of prefabricated stairs, the production and construction method comprises the following steps: assembling a bottom die: assembling the bottom die into a standard kicking surface height and a tread height of stone reverse hitting, and reserving a stone thickness for the kicking surface height; the back face of the stone is coated with a waterproof interface agent, anchoring holes are drilled in the stone and filled with a binding agent, claw nails are fixed to the anchoring holes of the stone, filling holes are formed between the claw nails and the back face of the stone, and then the front face of the stone is positioned at the corresponding tread and kicking face positions of the bottom die; waterproof sealing treatment is carried out on the appearing joints; mounting a reinforcement cage: hoisting the reinforcement cage to the bottom die; assembling a side mold; pouring concrete; the prefabricated stair comprises a stair body, stone and a reinforcement cage. According to the prefabricated stair and the production and construction method thereof, the stone and the stair body are firmly connected, the integrality is good, the waterproofness is good, the environmental applicability is high, field installation is easy, and the influence on the installation environment is small.

Owner:中铁科建预制科技有限公司

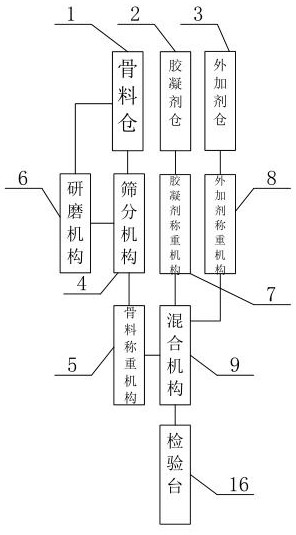

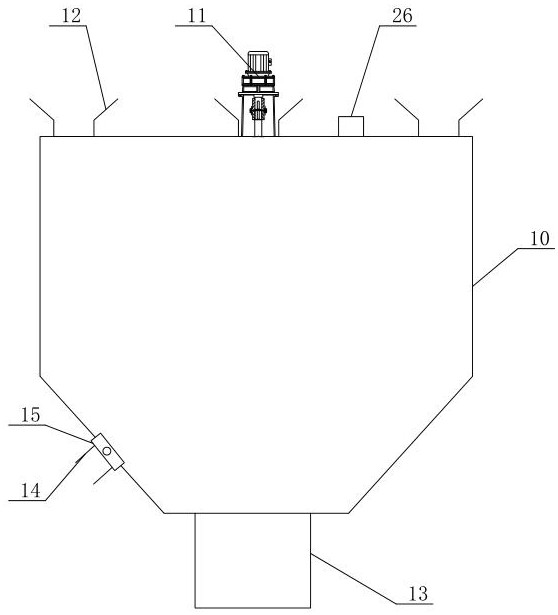

Dry-mixed mortar production system

ActiveCN112976315AQuality assuranceSave materialSolid waste managementCement mixing apparatusProcess engineeringMixing tank

The invention discloses a dry-mixed mortar production system which comprises an aggregate bin, a gelling agent bin and an additive bin, wherein electric discharging gates are arranged on a discharging hole in the bottom of the aggregate bin, the discharging hole of the aggregate bin communicates with a screening mechanism, a fine discharging hole of the screening mechanism communicates with an aggregate weighing mechanism; a discharging hole of the gelling agent bin communicates with a gelling agent weighing mechanism, a discharging hole of the additive bin communicates with an additive weighing mechanism, the mixing mechanism comprises a mixing tank and a stirring device installed in the mixing tank, and feeding holes are formed in the positions, corresponding to the aggregate weighing mechanism, the gelling agent weighing mechanism and the additive weighing mechanism, of the upper portion of the mixing tank; and a finished product outlet and an inspection outlet are formed in the bottom of the mixing tank, an electric valve is arranged on the inspection outlet, and the inspection outlet communicates with an inspection table through a sixth conveying mechanism. The dry-mixed mortar production line has the advantages of material saving, automatic effect and high quality of finished products, and is mainly used for production of dry-mixed mortar.

Owner:山西大地华基建材科技有限公司

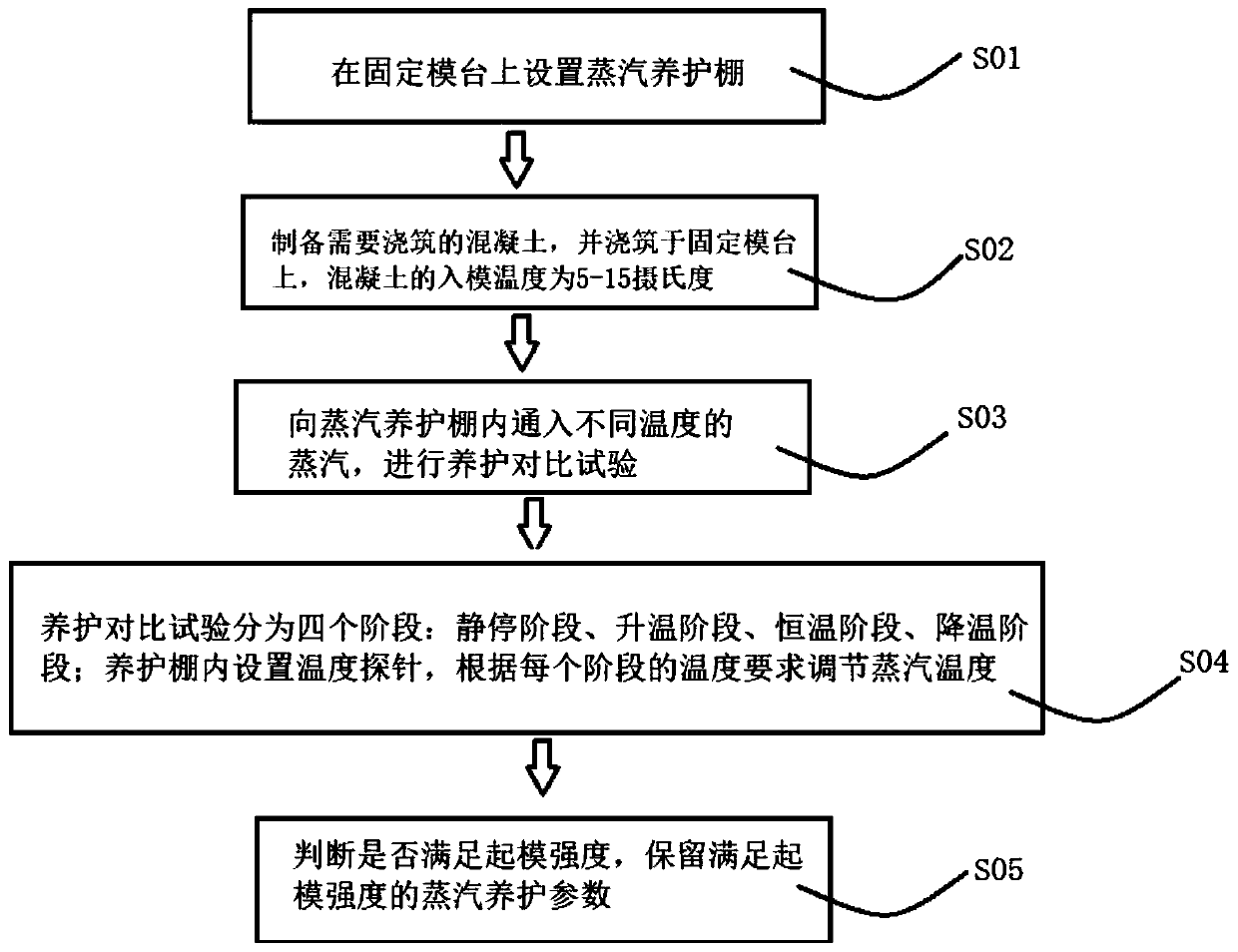

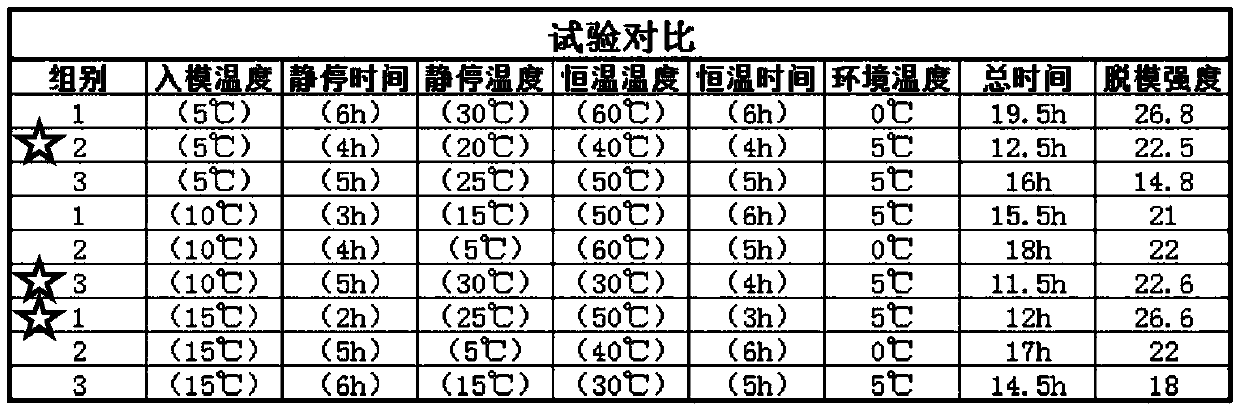

Test method and device for acquiring steam curing parameters of prefabricated part at low temperature and steam curing method

InactiveCN110962224AOptimal Steaming ParametersGood quality finished productCeramic shaping apparatusThermodynamicsProcess engineering

The invention belongs to the technical field of building prefabricated part improvement, and discloses a test method and device for acquiring the steam curing parameters of a prefabricated part at a low temperature and a steam curing method. The test method comprises the following steps: arranging a steam curing shed on a fixed mold platform; preparing concrete to be poured, and pouring the concrete onto the fixed mold platform, wherein the pouring temperature of the concrete is 5 to 15 degrees centigrade; introducing steam with different temperatures into the steam curing shed, and performinga curing comparison test which is divided into four stages including a standing stage, a heating stage, a constant-temperature stage and a cooling stage; arranging a temperature probe in the curing shed, and adjusting the temperature of the steam according to the temperature requirement in each stage; and determining whether the stripping strength is satisfied or not, and keeping the steam curingparameters satisfiying the stripping strength. The method specifies better steam curing parameters for different pouring temperatures (5, 10 and 15 degrees centigrade) of concrete at a low temperature, shortens the steam curing time, improves the mold turnover rate and reduces the steam curing cost.

Owner:ZHONGTIAN CONSTR GROUP +1

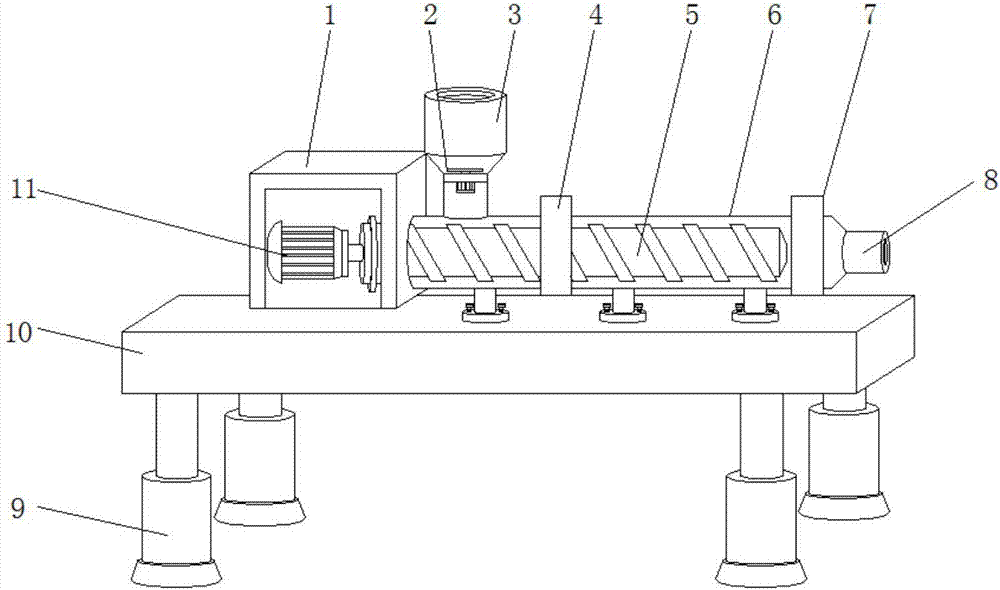

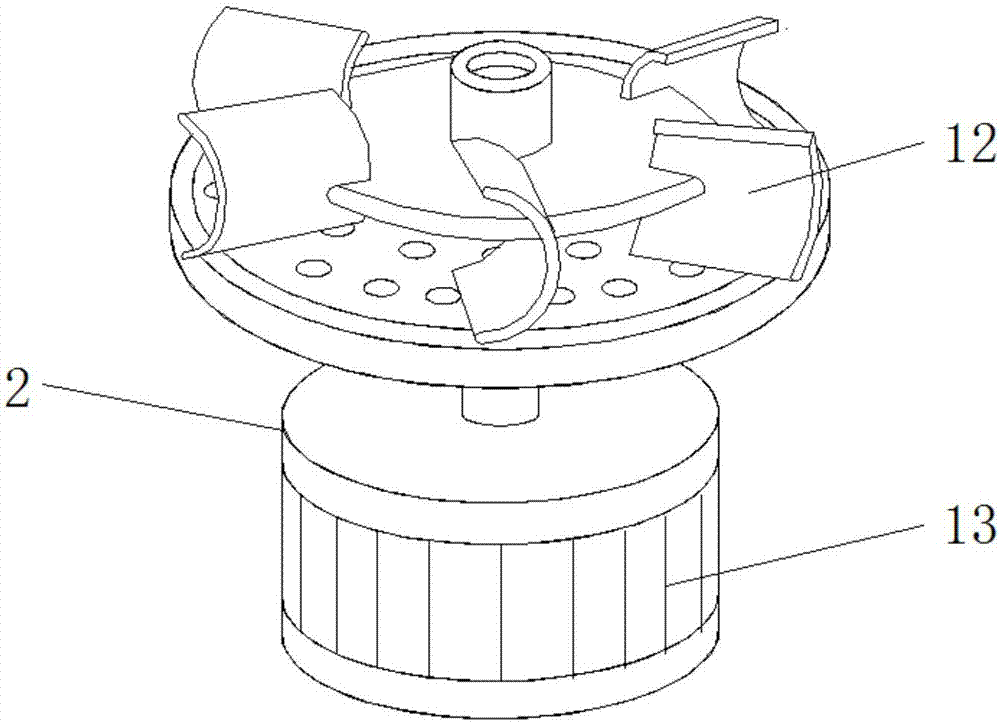

Double filter plate on-line type spiral extruder

PendingCN107877822AEasy Extrusion Hybrid MoldingGood quality finished productEngineeringDouble filtration

The invention discloses a double filter plate on-line type spiral extruder. The double filter plate on-line type spiral extruder comprises a power device protection box and a supporting plate, the power device protection box is fixedly installed at the upper end of the supporting plate, and an electromotor is fixedly installed in the power device protection box; supporting legs are fixedly installed at the four corners of the lower end of the supporting plate, a heating barrel is fixedly installed at one end of the power device protection box; a screw rod is rotatably installed in the heatingbarrel, a first filter device is fixedly connected with the middle of the heating barrel in an inserted mode, and a second filter device is connected with the end, deviating from the power device protection box, of the heating barrel in an inserted mode; and a feeding hopper is fixedly installed at the upper end of the heating barrel, a stirring device is connected with the interior of the feedinghopper in a clamped mode, a second electromotor is fixedly installed at the bottom end of the stirring device, and a stirring gear is rotatably installed on the upper portion of the second electromotor. According to the double filter plate on-line type spiral extruder, it can be ensured that the extrusion quality and the molding rate are better in the using process through double filtration arrangement.

Owner:福清市洪裕塑胶有限公司

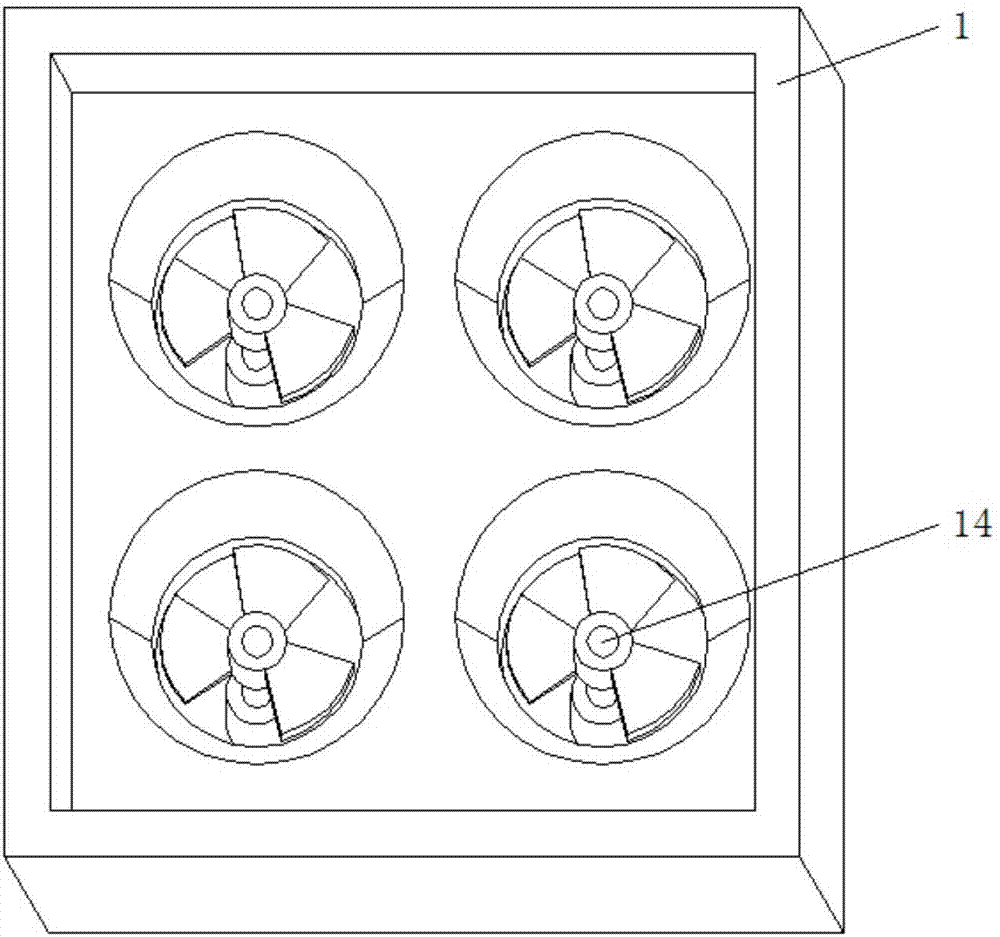

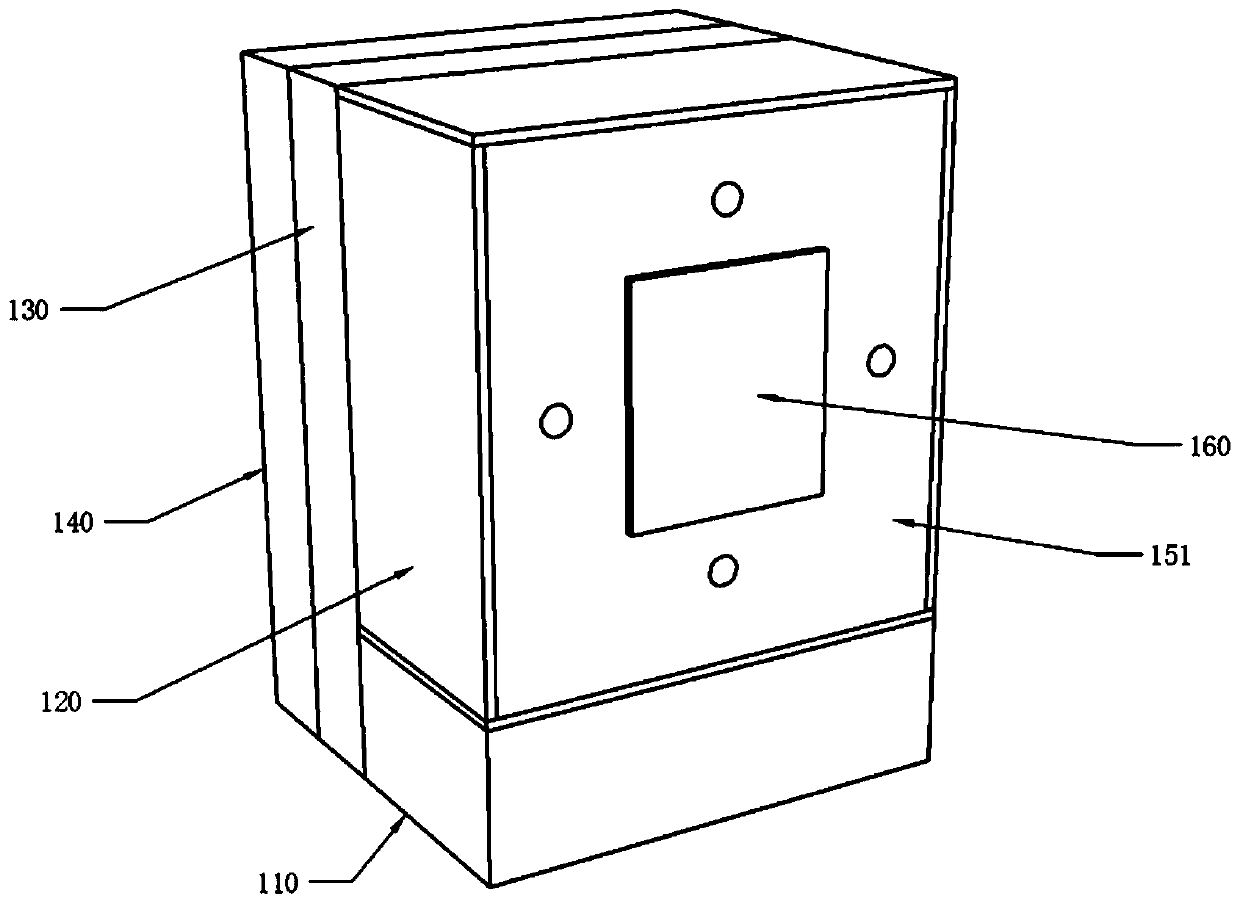

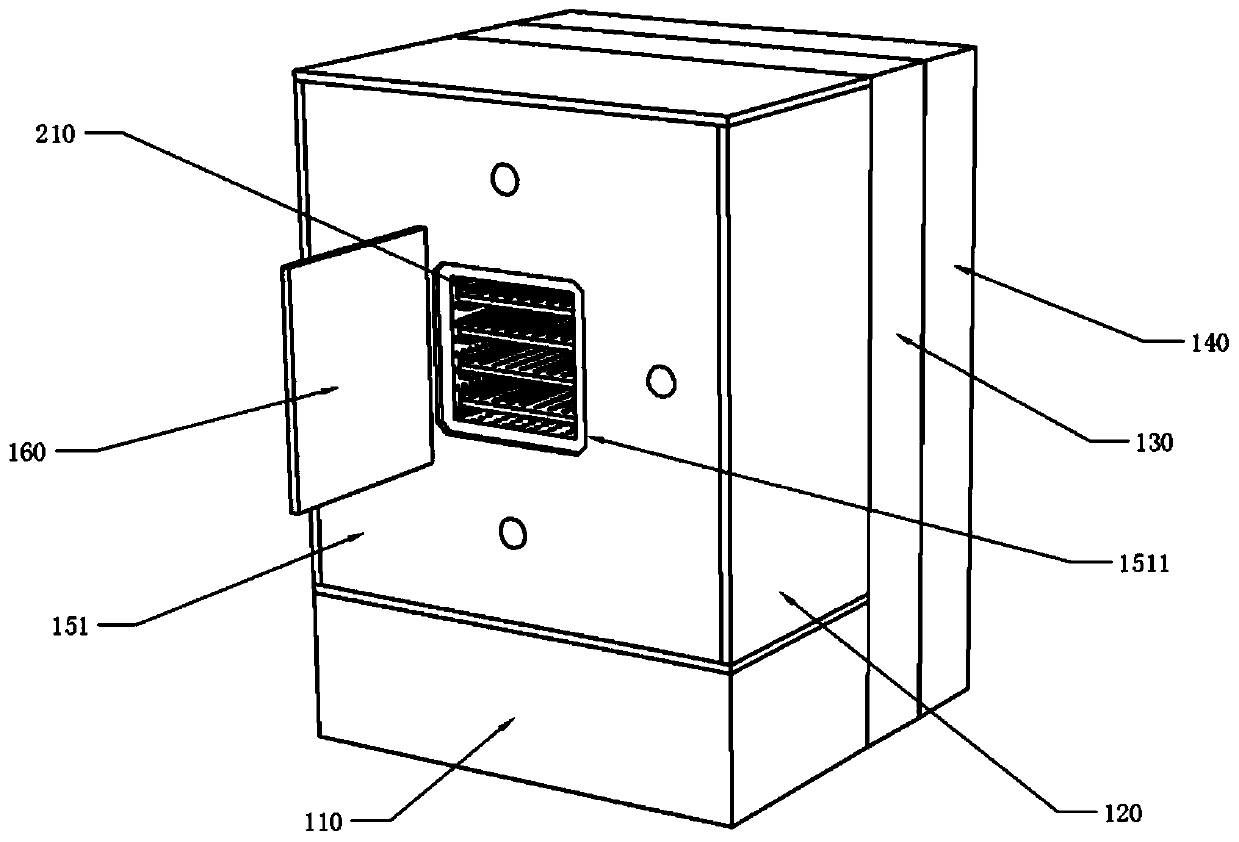

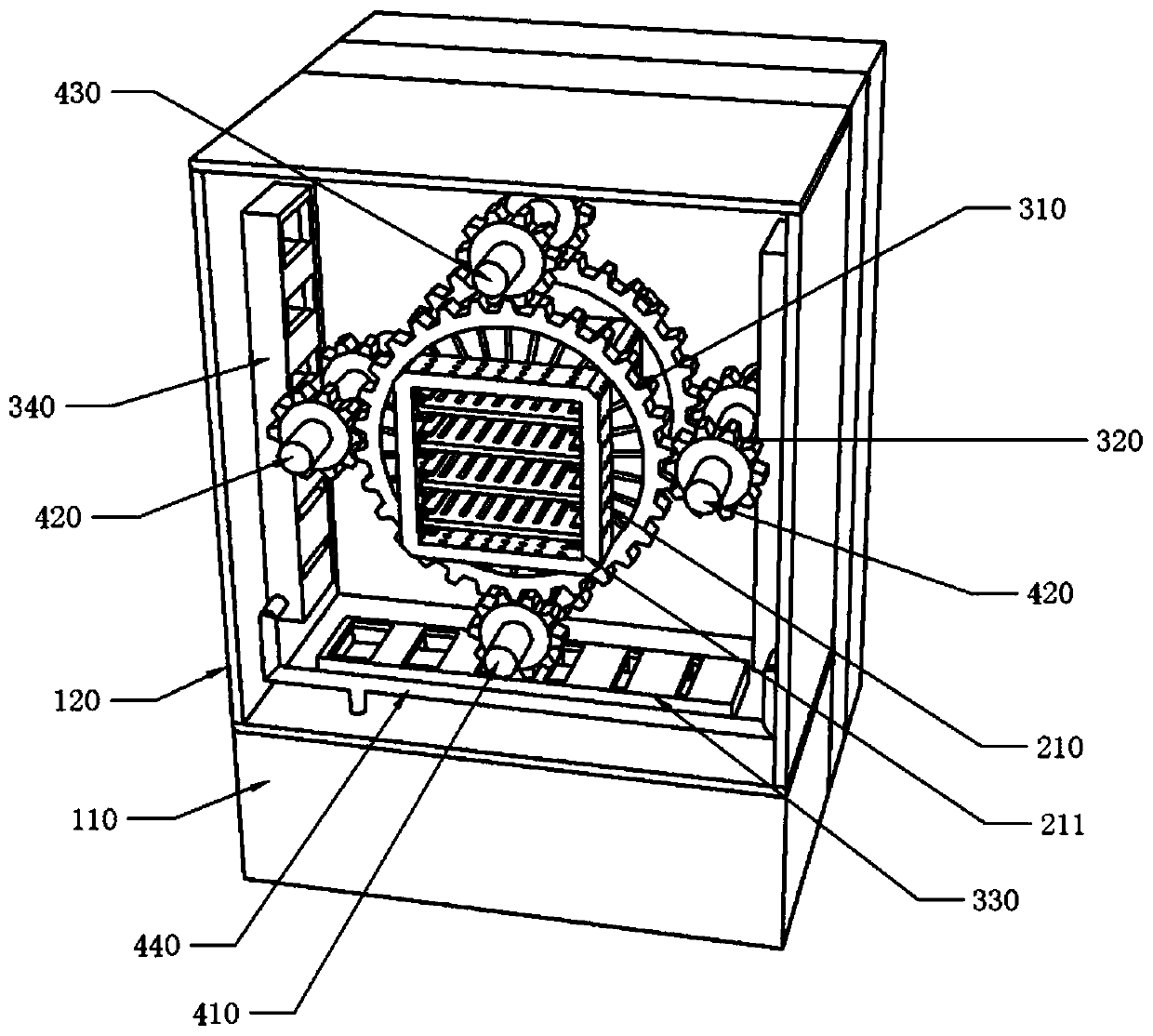

Rotating mechanism and rotating plate baking machine thereof

ActiveCN110341293AIncrease process flexibilityGood quality finished productCombination devicesGas treatmentSmall teethEngineering

The invention discloses a rotating mechanism and a rotating plate baking machine thereof. The rotating mechanism comprises a rotating shell, a heating cavity is arranged in the rotating shell, and a plurality of through flow guide holes are formed in the rotating shell; a plurality of supports are arranged in the heating cavity and used for fixing a printing plate; a rotating big tooth is fixed onthe rotating shell and is in meshing transmission with rotating small teeth arranged on a first shaft body, second shaft bodies and a third shaft body respectively; one end of the first shaft body penetrates through a rear panel and is fixedly assembled with an output shaft of a rotating motor; the first shaft body, the second shaft bodies and the third shaft body are uniformly distributed in thecircumferential direction of the rotating big teeth by taking the axis of the rotating big teeth as the center; and the two second shaft bodies pass through the rear panel and are respectively assembled and fixed with a brake cylinder. The printing plate can rotate, so that the printing plate integrates two modes of a vertical mode and a horizontal mode, and can rotate in the baking process, andthe printing plate can be baked at any angle.

Owner:CHONGQING YIXI BRAND PLANNING CO LTD

Soaking tea hot air drying process

PendingCN112273457ASolve the problem of uneven heating and different drying degreesImprove drying uniformityPre-extraction tea treatmentAir blowerTea leaf

The invention provides a soaking tea hot air drying process which comprises a drying box, an air blower, a ceramic electric heating pipe, waterproof cotton, a stainless steel cart, pulleys and a fan;the air blower is arranged on the left side of the outer end face of the drying box, the ceramic electric heating pipe is arranged on the left side of the inner wall of the drying box, and the stainless steel cart is arranged in the middle in the drying box. Pulleys are arranged on the lower end face of the stainless steel cart, the interior of the drying box is filled with waterproof cotton, a draught fan is arranged on the upper side of the inner wall of the drying box, and the process solves the problems that according to an existing tea leaf hot air drying box, air is supplied from one side, tea leaves are dried through refraction, tea leaf heating is uneven, and the drying degrees are different. The structure is reasonable. Through uniform hot air, uniform and stable drying of the tealeaves is achieved, and the finished product quality is better.

Owner:贵州湄潭兰馨茶业有限公司

Ultra-light fiberboard compounding process and compounding device

PendingCN111591006AFlat surfaceReduce surface blemishesLamination ancillary operationsLaminationDust controlMechanical engineering

The invention discloses an ultra-light fiberboard compounding process and a compounding device. A fiberboard is placed in a coating machine, the fiberboard and a coating film are pressed and formed after being heated, then coating is conducted, the heating temperature is 100-130 DEG C, the workshop environment temperature is 15-25 DEG C, the humidity is 30% + / -2%, the pressure during pressing is set to be 15-20 MPa, and the pressing time is not shorter than 35 s. According to the invention, the fiberboard and the coating film can be compounded through low-temperature setting; the coating machine is provided with a liftable and movable hairbrush dust removal device, so that the dust removal effect of fiberboards with different thicknesses can be met; and a gluing device is provided with a gap adjusting device, so that the distance between glue rollers can be slightly and accurately adjusted to adapt to gluing of fiberboards with different thicknesses. The compounding device is uniform in gluing, thorough in dust removal, suitable for compounding fiberboards with different thicknesses, good in finished product quality, not prone to product edge warping and the like.

Owner:绍兴欣亚行汽车配件有限公司

Laser cracking-off machine applied to goblet production

PendingCN114105449AImprove processing efficiencyGood quality finished productGlass blowing apparatusPhysicsEngineering

The invention discloses a laser cracking-off machine applied to goblet production, the laser cracking-off machine comprises a feeding assembly and a cracking-off machine body, the feeding assembly comprises a conveying belt and a feeding mechanical gripper communicating with the surface of the cracking-off machine body, and the surface of the cracking-off machine body is rotationally connected with a workbench. According to the laser cracking-off machine applied to goblet production, glass cups are conveyed through the conveying belt, spacing adjustment is conducted, then the glass cups are conveyed to the position below the three-jaw clamping air cylinder through the feeding mechanism to be clamped, cracking-off and grinding operation is conducted in sequence, a plurality of procedures can be combined together through the multi-station design, and the production efficiency is improved. The machining efficiency is greatly improved, the finished product quality is good, a jacking air cylinder is started to downwards extrude a bearing plate, so that the bearing plate compresses an extension spring to drive a lifting rod to move downwards in a connecting sleeve, the glass cup abuts against the surface of a grinding position, and operation is more convenient.

Owner:蚌埠马克韦尔机械设备有限公司

Hemp scraping device and plant fiber extraction equipment

PendingCN113136626AAffect the clamping effectStable and reliableMechanical fibre separationPlant fibreMechanical engineering

The invention belongs to the technical field of plant fiber extraction, and provides a hemp scraping device and plant fiber extraction equipment. The hemp scraping device mainly comprises a first hemp pressing chain group and a second hemp pressing chain group, wherein a first hemp scraping knife ball and a second hemp scraping knife ball are arranged corresponding to the first hemp pressing chain group and the second hemp pressing chain group, the raw material output end of the first hemp pressing chain group is connected with the raw material input end of the second hemp pressing chain group; the first hemp pressing chain group and the second hemp pressing chain group are arranged along the length direction of a straight line, and the projection of the raw material output end of the first hemp pressing chain group and the projection of the raw material input end of the second hemp pressing chain group on the straight line are overlapped. According to the hemp scraping device and plant fiber extraction equipment, the process integration of hemp scraping processing can be realized, the hemp scraping efficiency can be improved, the hemp scraping quality can be guaranteed, and the production economic benefits of plant fiber extraction can be improved.

Owner:ZHANJIANG WEIDA MACHINERY IND

Method for granulation of bakelite powder under hot melt state and equipment thereof

The invention relates to a method for granulation of bakelite powder under a hot melt state and equipment thereof. The method for granulation of bakelite powder under a hot melt state includes: heating the bakelite powder into a molten coagulum form, adding the bakelite powder in a molten coagulum form into a screw extruder to extrude it into strips and cutting the strips into granules, and then carrying out cooling so as to obtain granular products. The extrusion granulation method of bakelite powder under a hot melt state realizes one-step molding, and the granules are very uniform and have no need for screening. Aircurrent rapid cooling is achieved, the finished products have good quality, and the production efficiency is high. Thus, the outdated traditional cold state granulation methods, which are characterized by first melting, solidification and then crushing of bakelite powder, low screening efficiency, and high dust environment pollution, are completely changed.

Owner:ZHEJIANG HANGMO SYNTHETIC MATERIAL

Artware and manufacture method thereof

The invention provides artware and a manufacture method thereof, and relates to the technical field of artware processing and manufacture. The manufacture method of the artware includes pouring modified immature soil into a mold for molding, and removing the mold to obtain the artware. The modified immature soil mainly comprises immature soil, adhesives, fillers and optional aids. Strength and plasticity of the immature soil are optimized through the adhesives and the fillers. The manufacture method of the artware has the advantages of simplicity, low cost and environment protection since theimmature soil serves as the main material. The artware has the advantages that the simple and natural property of the immature soil can be given to the artware, natural beauty of natural materials ispursued, natural texture of the materials is displayed fully, and the artware is endowed with more culture and inspiration.

Owner:土上(北京)建筑设计咨询有限公司

Manufacturing process of self-luminous PVC automobile foot pad

The invention discloses a manufacturing process of a self-luminous PVC automobile foot pad, which is characterized by comprising the following steps: (1) proportioning raw materials according to the following parts by weight: preparing 80-120 parts of polyvinyl chloride SG-5, 50-70 parts of a plasticizer (DOP), 2-3 parts of a composite stabilizer and 5-8 parts of luminous powder; (2) pouring the above raw materials into a high-speed mixer and conducting stirring for 5-10 minutes; (3) when the stirring time is 3-6 minutes, adding 3-5 parts of polyethylene glycol, and then continuously conducting stirring; (4) after the stirring is completed, pouring the 5-8 parts of luminous powder into the above system and conducting stirring for 10-15s; (5) after fully stirring, putting the mixed raw materials into an injection molding machine for injection molding to obtain a semi-finished product; and (6) after the semi-finished product is cooled, removing the waste edge of the semi-finished productafter injection molding to obtain the finished product. The manufacturing process has the following beneficial effects: the manufacturing process of the self-luminous PVC automobile foot pad materialcan make the fluorescent powder evenly distributed and improve the final quality of the fluorescent soft PVC material.

Owner:浙江沃尔德汽车用品有限公司

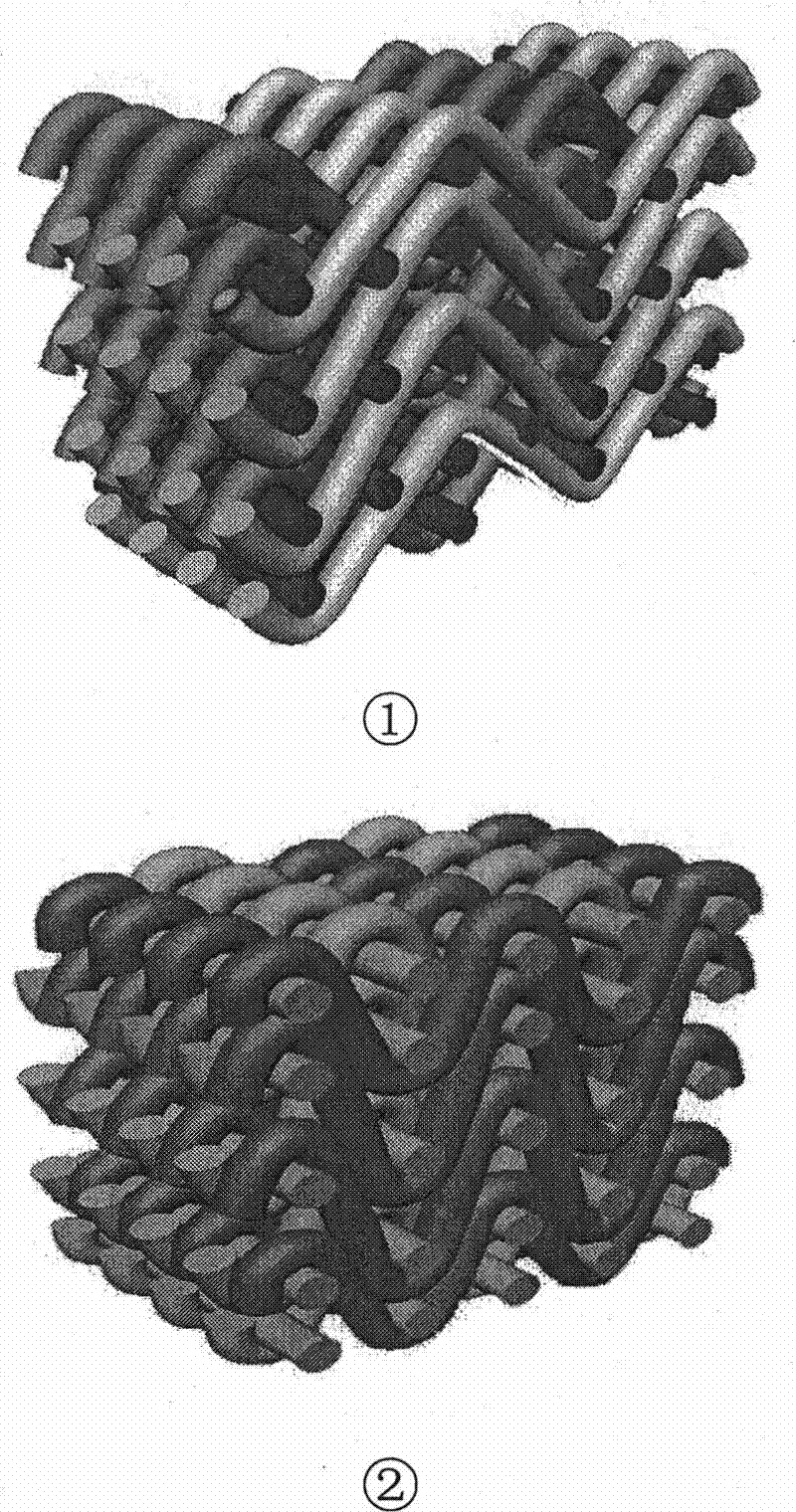

Forming method of 2.5-dimensional weaving revolving solid composite material

The invention relates to a forming method of a 2.5-dimensional weaving revolving solid composite material, which belongs to the technical field of manufacturing formation and comprises the following processes of: (1) weaving by using at least four simple weaving square machines by a radioactive yarn adding method; (2) weaving fabric with changed cross section from a smaller end to a larger end and evenly hanging warp yarns in the circumferential direction of weft yarns according to different changes of mould diameters; (3) vertically putting the revolving solid fabric into a mould; (4) injecting glue into multiple channels from bottom to top and monitoring glue injecting pressure in real time for ensuring stable glue injecting loading; (5) judging that the glue is completely injected by glue outlets which is also an observation port; (6) closing the last glue outlet and maintaining the pressure of a mould cavity; and (7) curing and treating. The method and corresponding forming equipment have low cost, simple operation, quick compounding, even injection of glue liquid, adjustable pressure, diversity of resin systems and good product quality.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

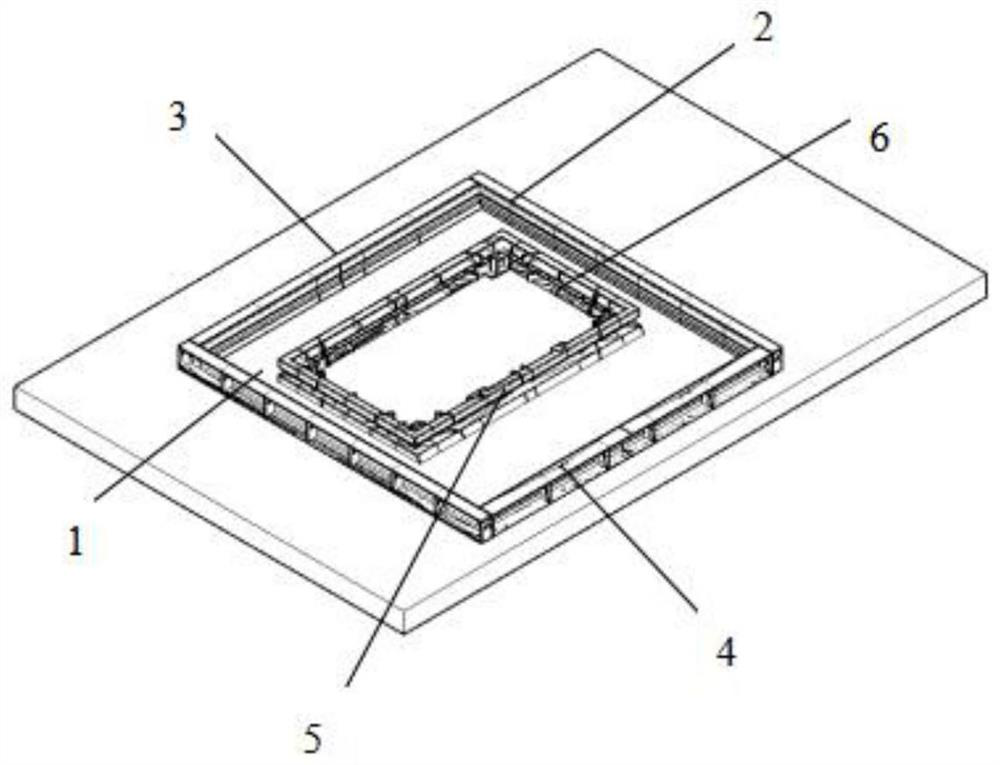

A pc wall panel mold with pre-embedded window frames and pre-embedded waterproof adhesive strips for prefabricated buildings

ActiveCN110978255BAccurate to ensure the embedded precisionReduce labor costsMouldsArchitectural engineeringWall plate

The invention discloses a PC wall panel mold with pre-embedded window frames and pre-embedded waterproof adhesive strips for prefabricated buildings, which belongs to the technical field of building moulds, and includes a mold table and a structure of sequentially connecting the ends installed on the mold table Rectangular frame PC wall panels with pre-embedded waterproof strips and decompression space on the left end side formwork, PC wall panels with pre-embedded waterproof strips and external low and internal high structure water-stop molding top side formwork, with pre-embedded waterproof strips The right end side formwork of the PC wall panel and the PC wall panel lower end side formwork with pre-embedded waterproof adhesive strips and low outer and inner high structure water-stop molding. The invention realizes the production of PC wall panels with pre-embedded window frames and pre-embedded waterproof adhesive strips for prefabricated buildings; it has high precision, easy assembly and operation, no need to punch holes for the large bottom formwork platform, and no need for truss trucks when removing the formwork Cooperate, easy to operate, save component production labor and machine cost and low mold cost.

Owner:安徽企服工业技术有限公司

Traditional Chinese medicine cutting and beveling machine

PendingCN112847477AGood quality finished productIncrease productivityMetal working apparatusMedicinal herbsEngineering

The invention relates to a beveling machine, in particular to a traditional Chinese medicine cutting and beveling machine. The technical problem of the invention is to provide the traditional Chinese medicine cutting and beveling machine, which has a dust shaking function and can automatically convey medicinal materials. According to the technical scheme, the traditional Chinese medicine cutting and beveling machine comprises a bottom frame, rear supports, rails, a cutting mechanism and a transmission device, wherein the rear supports are symmetrically arranged on the right side of the bottom frame, the rails are arranged on the front side and the rear side of the lower portion of the bottom frame, the cutting mechanism is arranged on the upper portions of the rear supports, and the transmission device is arranged on the inner side of the bottom frame and located below the cutting mechanism. According to the traditional Chinese medicine cutting and beveling machine provided by the invention, traditional Chinese medicines are manually placed on the transmission device by people, the cutting mechanism is started, the medicinal materials are subjected to rapid bevel cutting under the action of the up and down movement of the cutting mechanism, the quality of finished products obtained after the medicinal materials are cut is good, and the production efficiency is higher.

Owner:钟小生

Segment-cutting and sun-drying system for dried tomatoes

ActiveCN110179146AAffect processing qualityGood quality finished productClimate change adaptationMetal working apparatusBiochemical engineeringTransfer mechanism

The invention discloses a segment-cutting and sun-drying system for dried tomatoes. A tomato segment-cutting device is movable on sun-drying tables, moving parts are arranged on both sides of the sun-drying tables for bearing the tomato segment-cutting device, and the moving parts move on movement-guiding parts. The tomato segment-cutting device includes a body frame, a cleaning mechanism, a transferring mechanism, a conveying mechanism, a spreading mechanism, a cutting mechanism and a placing mechanism, and scattered equipment for workshop-cleaning-transportation-segment cutting-transportation-placing in the traditional tomato processing operation process is integrated into a set of operation equipment. The operation system can be used to realize the effect of integrating the following steps: tomato charging-tomato segment cutting-even placing on the sun-drying tables, thus avoiding the problems of consuming time, consuming labor, high cost and affecting the quality of processed driedtomatoes, etc. caused by two times of loading, transporting and transferring in the traditional processing process of dried tomatoes, and has characteristics that the operation system is high in automation degree, time-saving, labor-saving, low in cost, high in production efficiency and excellent in quality of finished products of dried tomatoes.

Owner:SHIHEZI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com