Forming method of 2.5-dimensional weaving revolving solid composite material

A molding method and composite material technology, applied in the field of manufacturing and molding, can solve the problems of uneven resin flow, difficulty in mold sealing, and high cost, and achieve the effects of good finished product quality, stable glue flow, and diverse resin systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

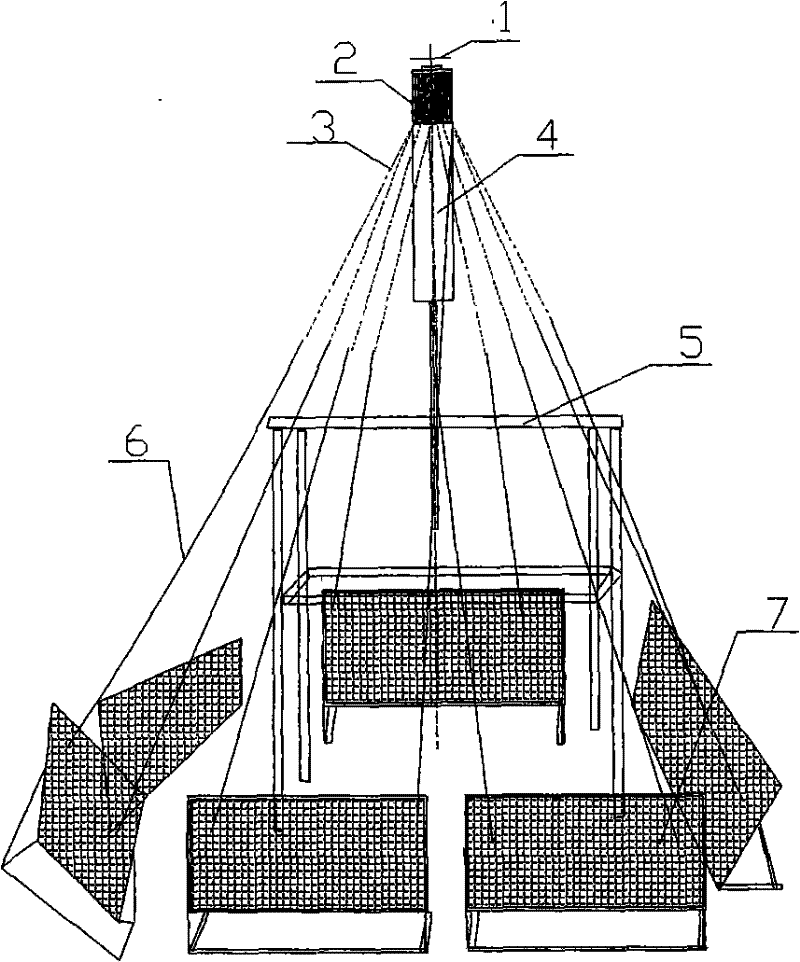

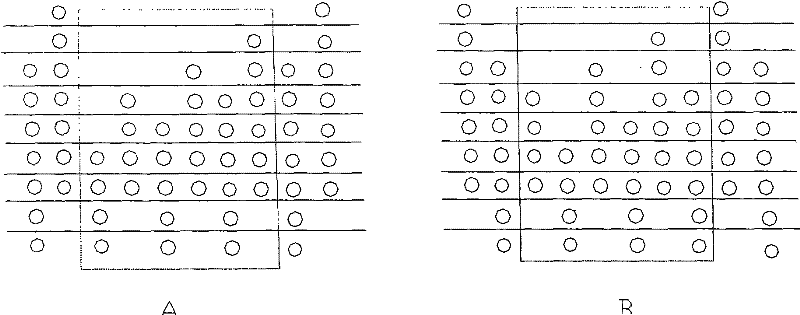

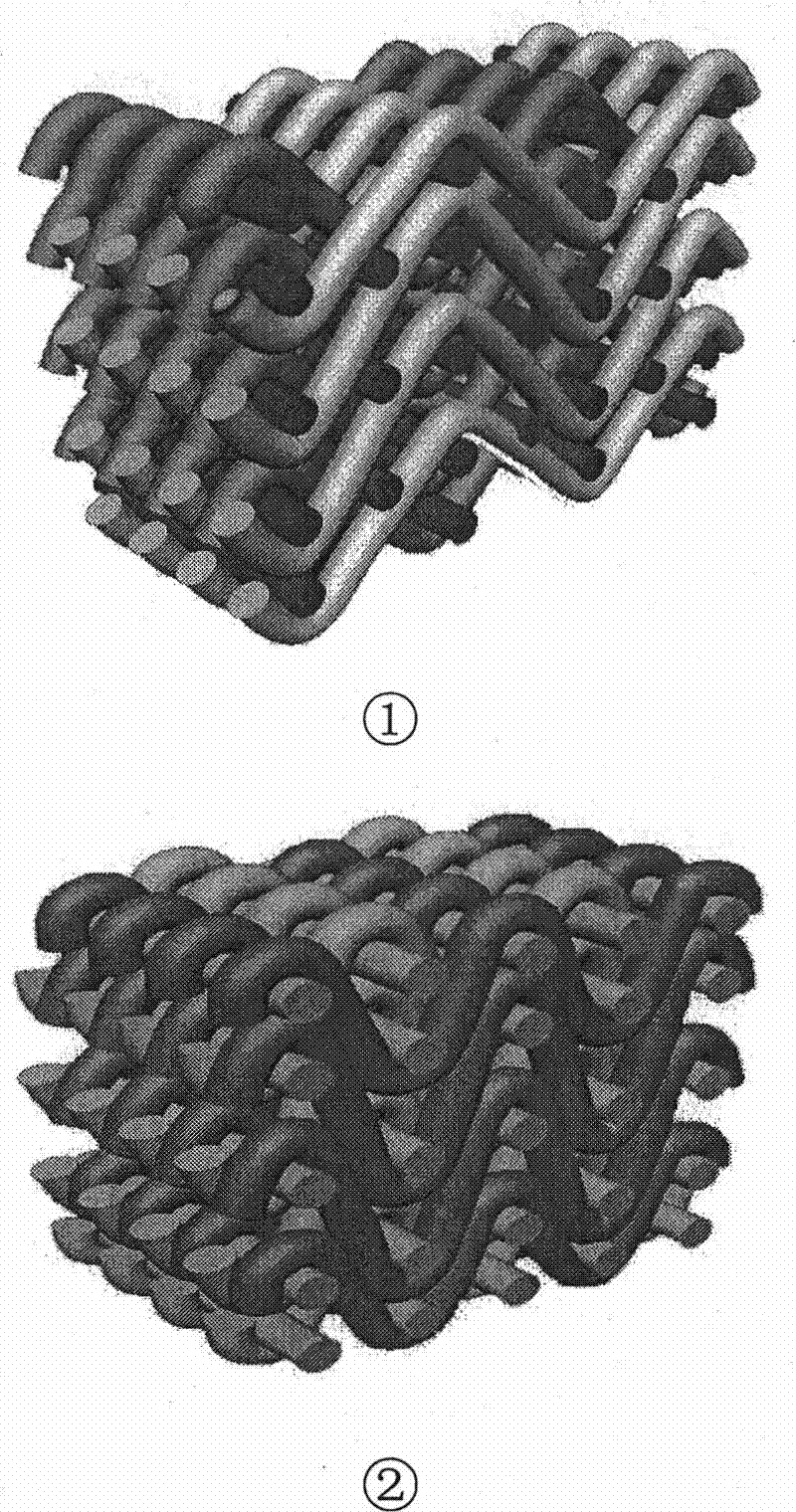

[0031] figure 1 Shown is a schematic diagram of a 2.5D (dimension) weaving rotary fabric weaving equipment. The simple 2.5D knitting machine consists of a knitting square machine, an operating platform, a mold bracket, and a mold. First design the forming mold of the rotary fabric and the tooling of the fixed mold. The weaving mold can be designed in a conical shape, a truncated cone shape, and a circular tube shape. The mold material can be selected from steel, wood, graphite, and nylon, which can be selected according to actual needs. design. The 2.5D knitting machine is used to weave the rotary fabric. The 2.5D knitting machine is composed of a simple square knitting machine. The simple square knitting machine is designed to be composed of a liftable sliver frame and a non-liftable sliver frame. The moving sliver and the non-moving sliver are a group and separated Arrangement, the whole square machine is composed of several groups of slivers, and the warp capacity of each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com