Strong antistatic non-woven fabric production device and production method

A technology for a production device and a production method, which is applied to devices for coating liquids on surfaces, textiles and papermaking, heating/cooling fabrics, etc. Mass production and other problems, to achieve the effect of good antistatic effect, saving consumption and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

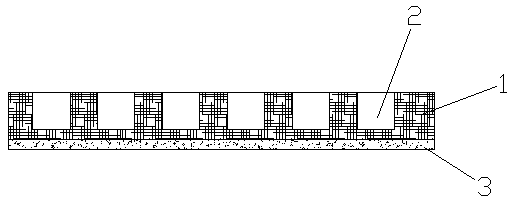

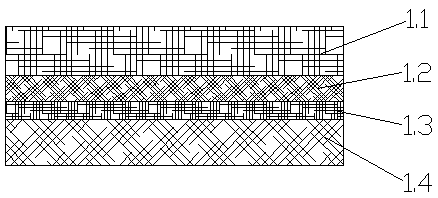

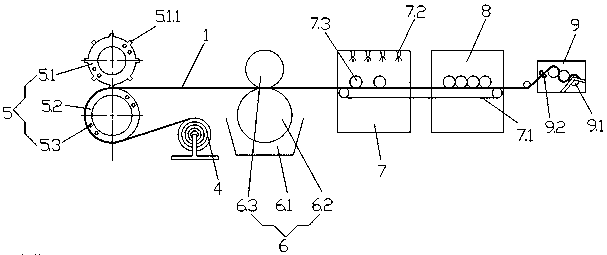

[0033] see Figure 1-2 , a strong antistatic non-woven fabric, comprising a non-woven fabric body 1, the non-woven fabric body 1 is embossed on one side, the embossed side is provided with grooves 2, and the non-embossed smooth roller is coated with antistatic Agent layer 3, the gray cloth of the non-woven fabric body 1 is composed of four layers of non-woven fabrics, and the four-layer non-woven fabrics are the first spunbonded non-woven fabric layer 1.1, the first melt Blown nonwoven layer 1.2, second meltblown nonwoven layer 1.3 and second spunbond nonwoven layer 1.4. Embossing is to improve the strength of non-woven fabric body 1, and single-sided embossing reduces the thickness of non-woven fabric body 1. The static agent is evenly distributed, and the antistatic effect is good. Embossing will reduce the softness of the nonwoven fabric, so the fineness of the first spunbonded nonwoven fabric layer 1.1 and the second spunbonded nonwoven fabric layer 1.4 is controlled bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com