Patents

Literature

157results about How to "Affect processing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

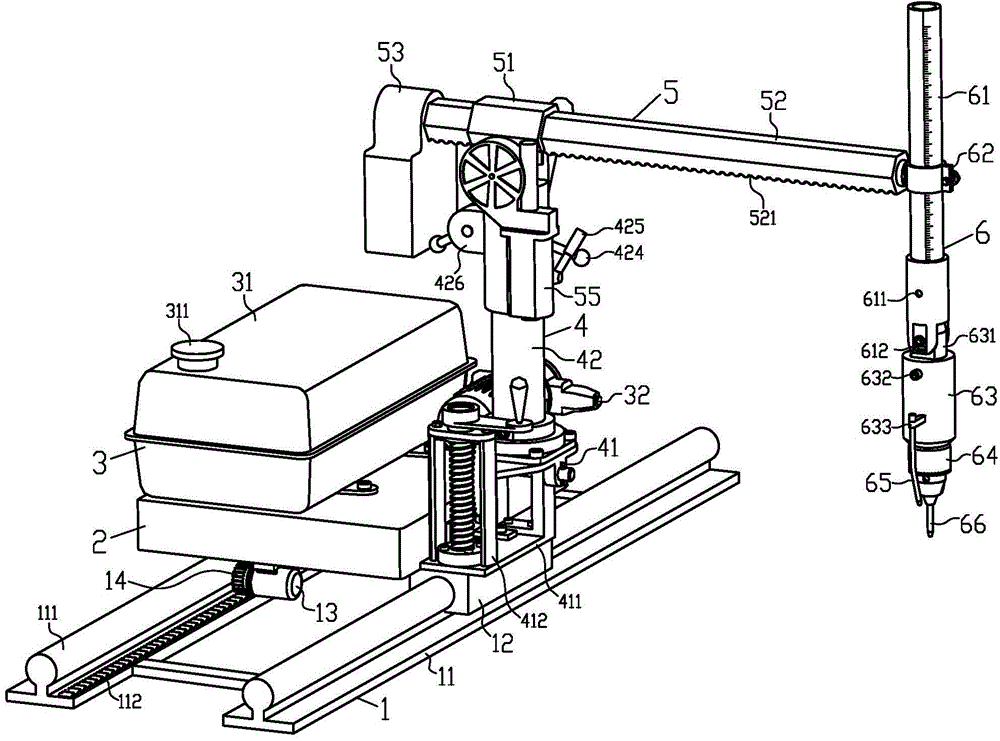

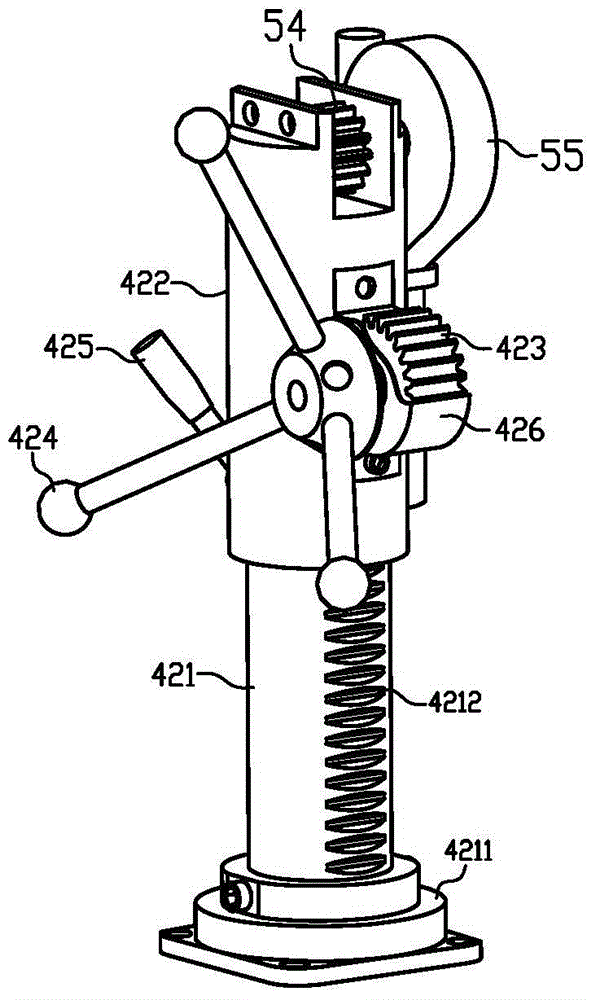

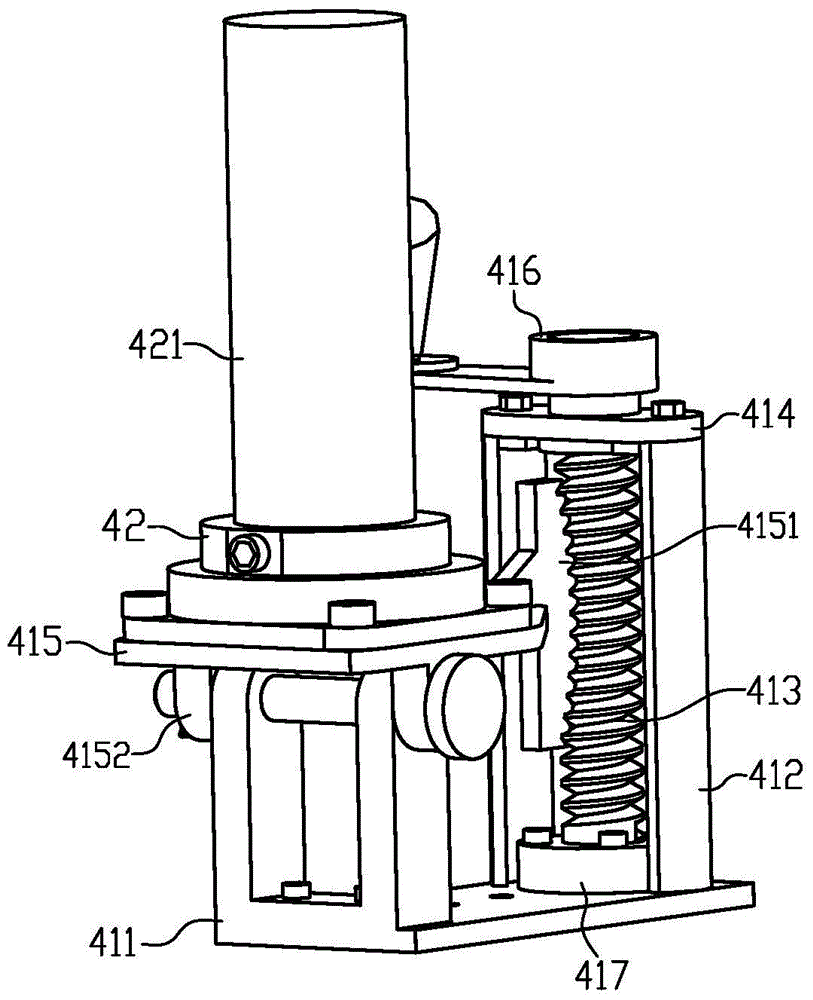

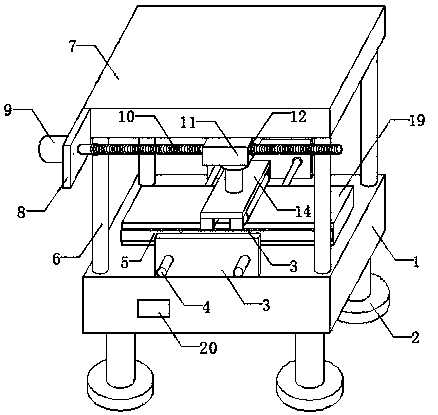

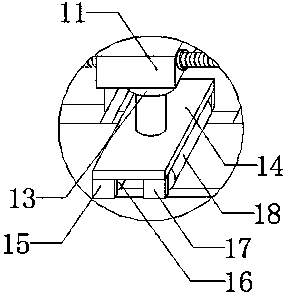

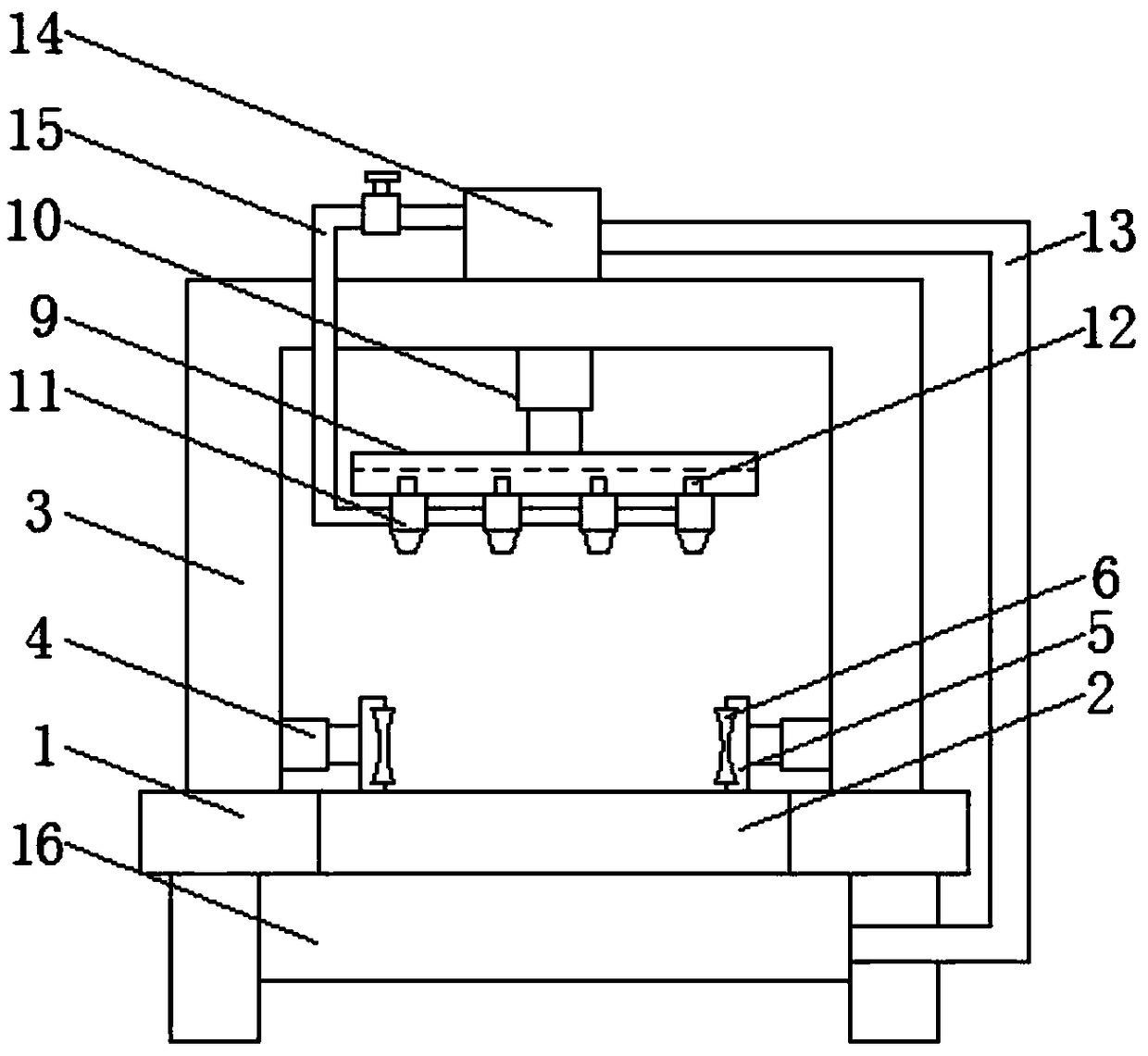

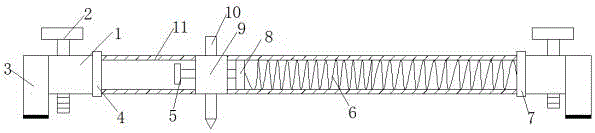

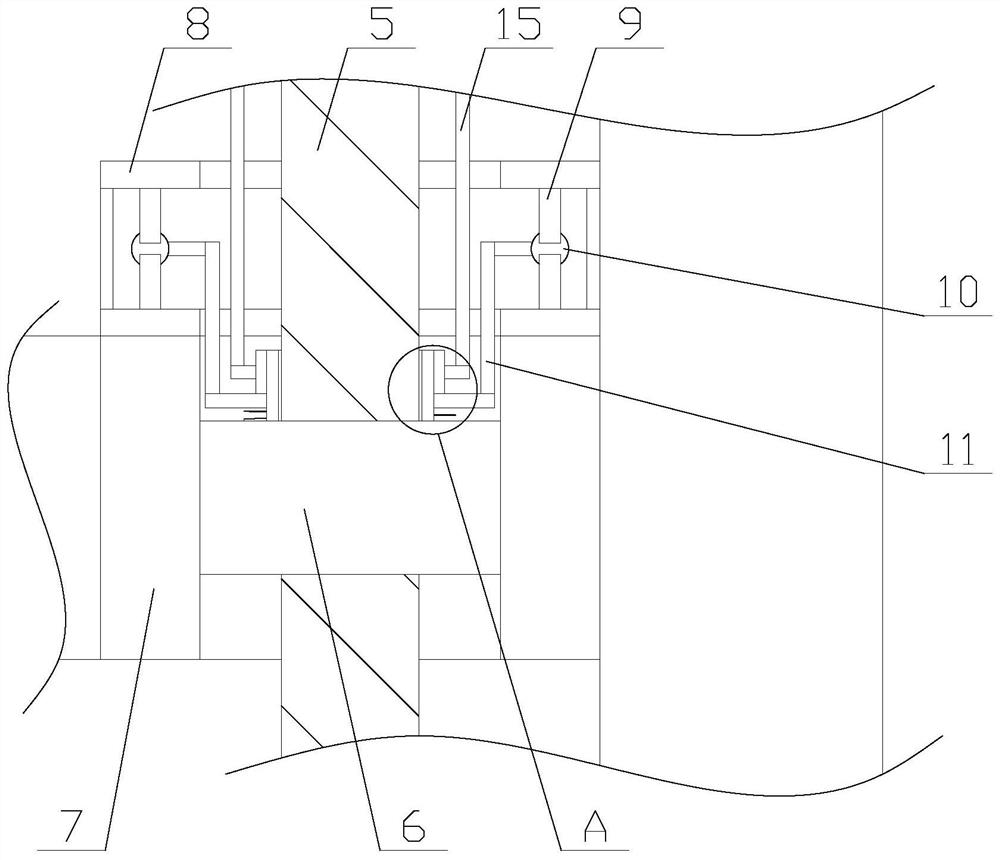

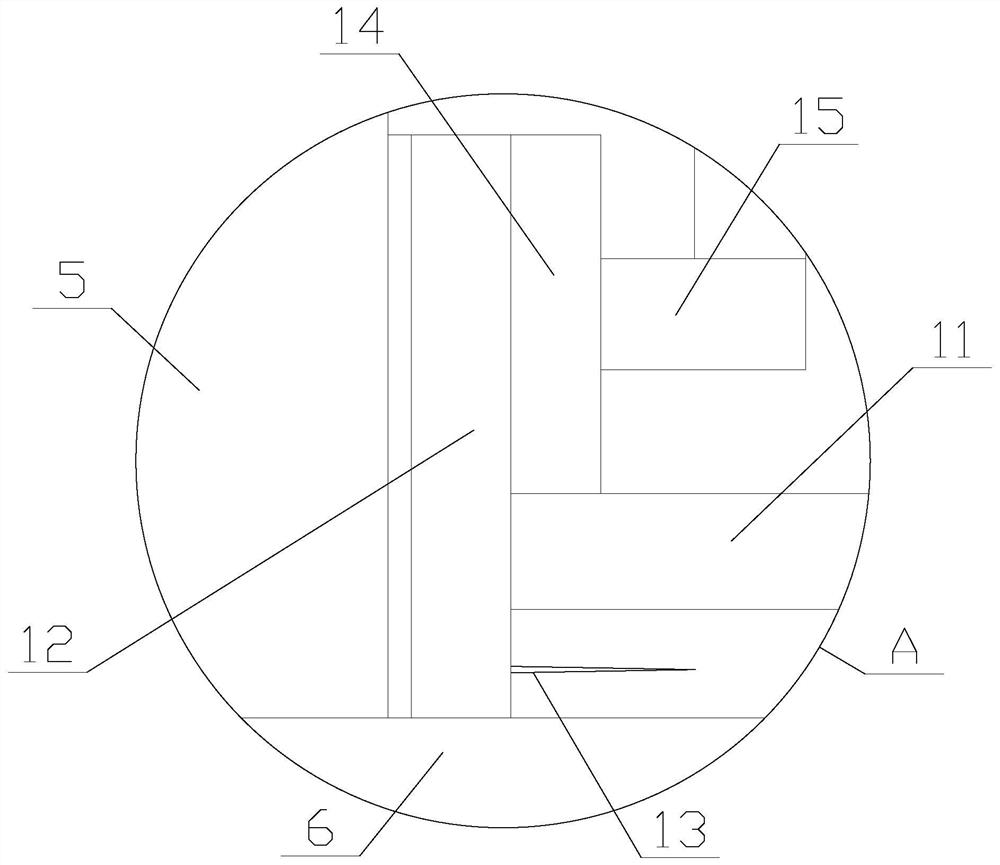

Cutting and processing device for acrylic products

InactiveCN104669334ARealize blanking and cutting functionAdjustable heightMetal working apparatusMotor driveEngineering

The invention discloses a cutting and processing device for acrylic products. The cutting and processing device comprises a self-sliding base, a machine body seat, a cooling system, a two-degree-freedom adjustable upright post, a translating device and a cutter, wherein a balancing weight is arranged inside the machine base seat; the cooling system is arranged on the machine body seat; the two-degree-freedom adjustable upright post is positioned on one side of the machine body seat. According to the cutting and processing device disclosed by the invention, the function of discharging and cutting acrylic materials can be realized, and processing operations of chamfering, routing, trimming and the like for the acrylic products can be finished. By using the cooling system, processed materials and tools can be cooled in real time, so the acrylic materials can be prevented from being bonded on the tools; longitudinal sliding and walking of the self-sliding base and translation of the cutter are respectively finished by motor drive, so the automatic degree is higher; for the cutter, corresponding tools can be changed according to the requirement, and the heights and inclined angles of the tools can be adjusted. The cutting and processing device disclosed by the invention has the advantages of compact and simple structure, stable and reliable work, convenience for operation and maintenance, low cost of an entire machine, high cutting and processing precision and the like.

Owner:华锻(安徽)机床制造有限公司

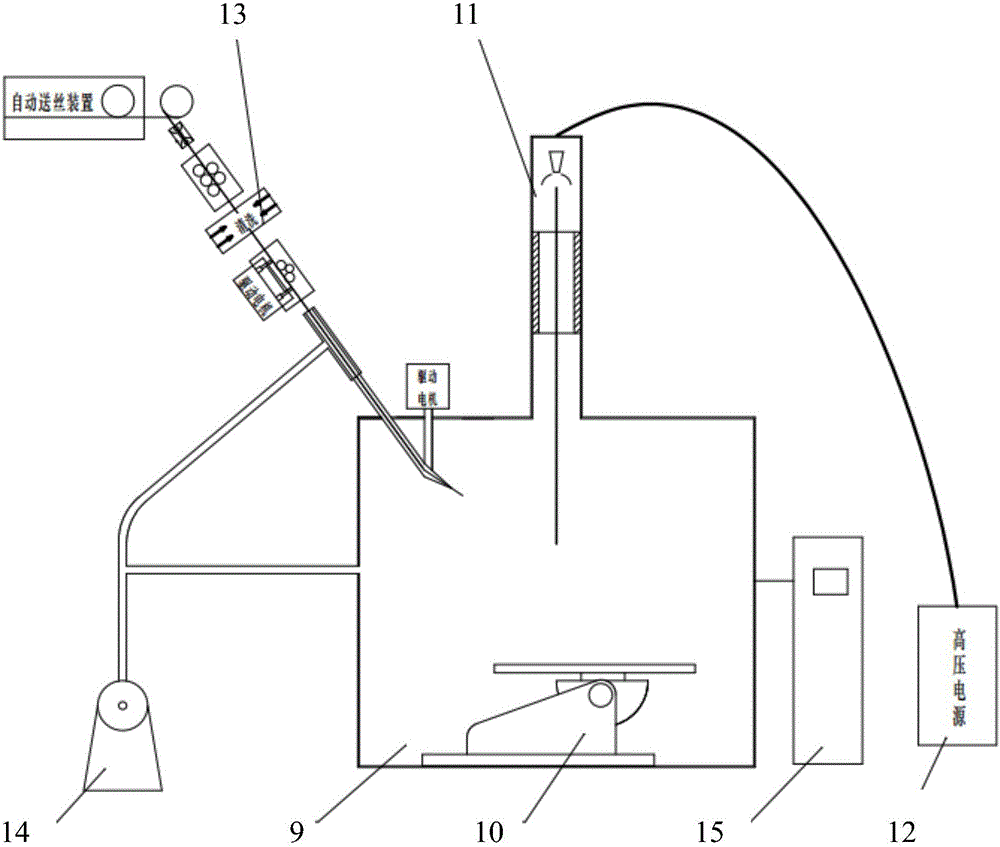

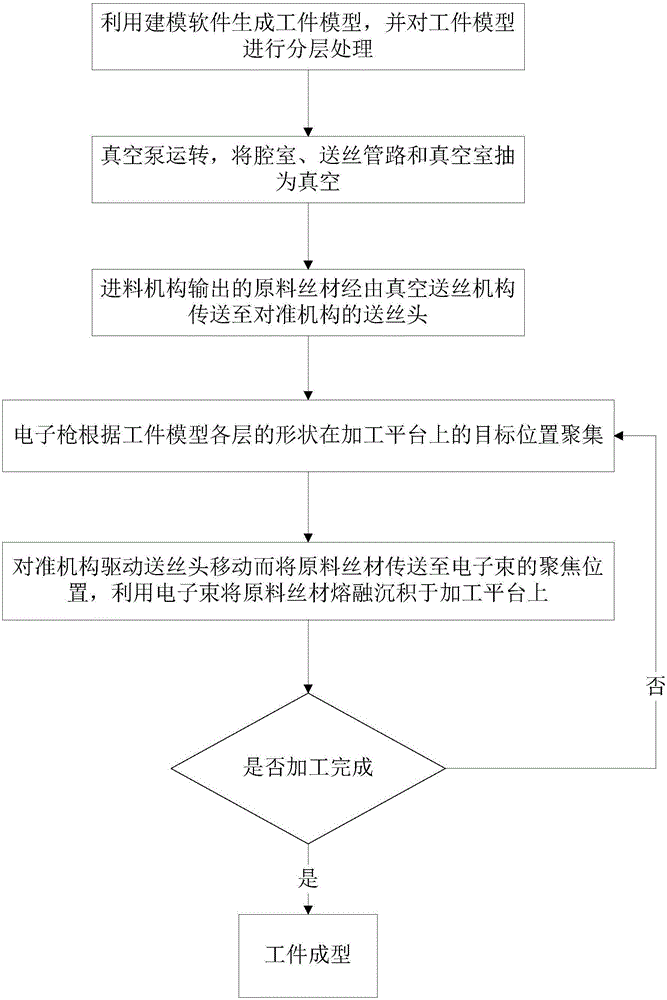

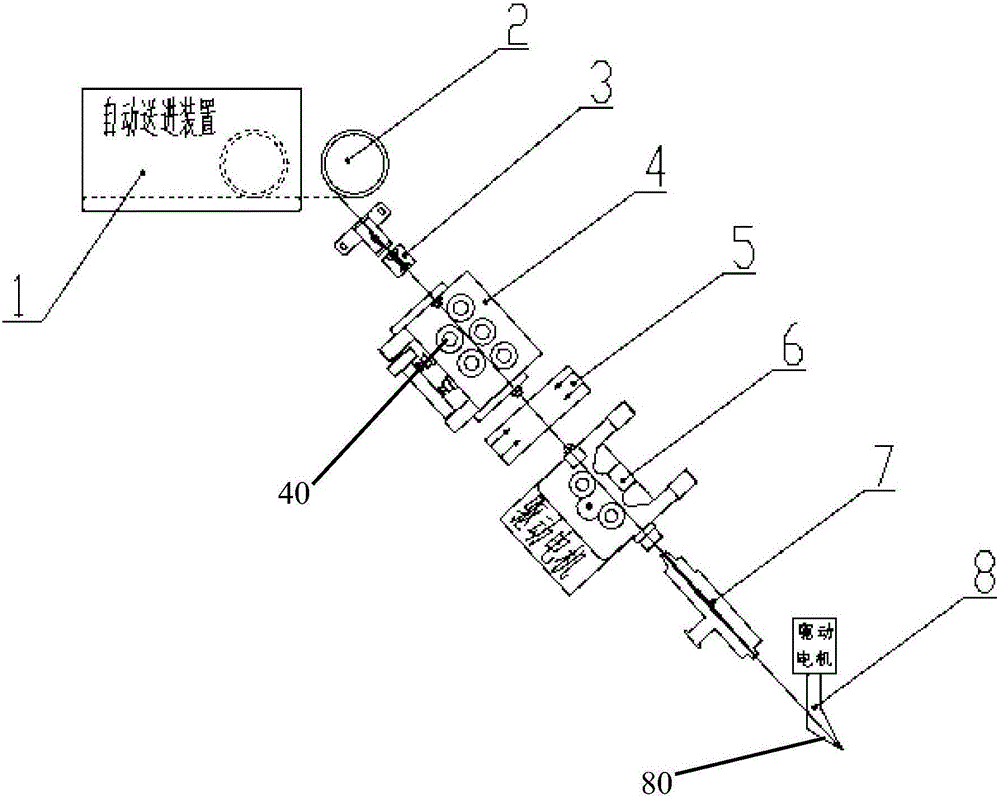

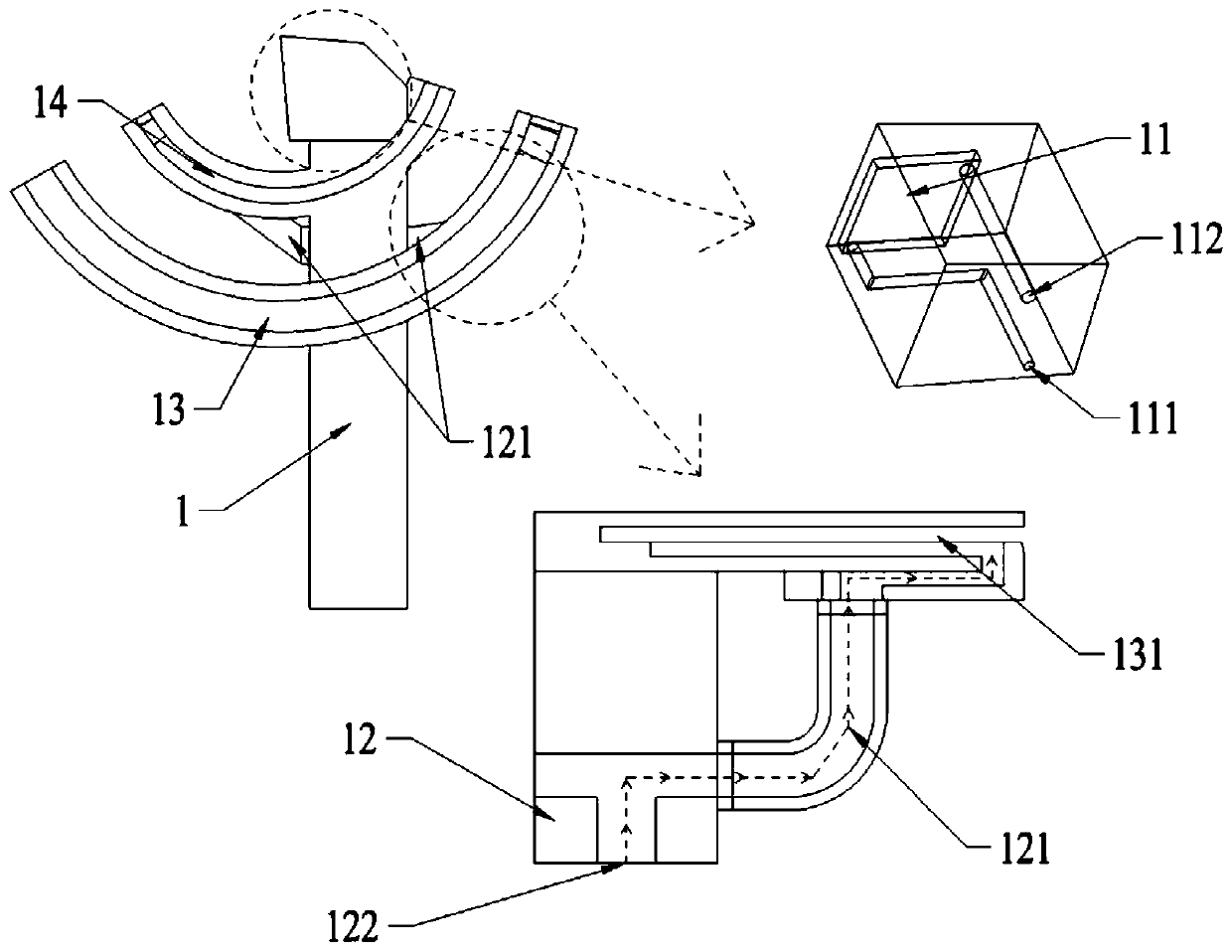

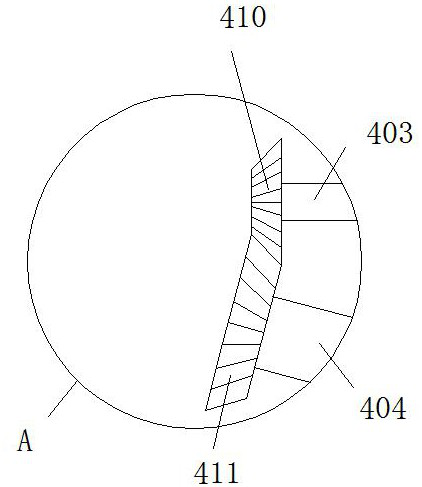

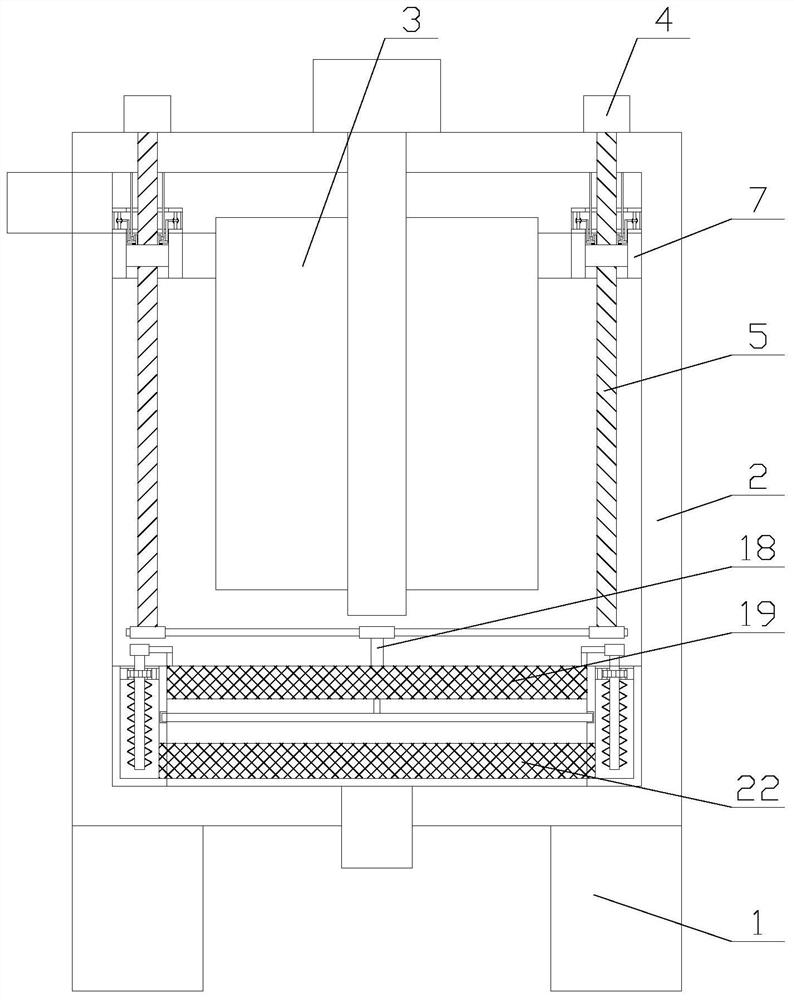

Wire feeding mechanism, wire feeding device and additive manufacturing equipment based on additive manufacturing technology

ActiveCN106001577AAvoid enteringImprove qualityAdditive manufacturing apparatusManufacturing technologyControl system

The invention discloses additive manufacturing equipment. The additive manufacturing equipment comprises a vacuum chamber, an electronic gun, a wire feeding device, a vacuum pump and a master control system; a machining platform is arranged at the bottom of the vacuum chamber; the electronic gun is connected to a high voltage power supply, and an electronic beam output end of the electronic gun faces the machining platform; the wire feeding device is arranged outside the vacuum chamber and comprises a vacuum wire feeding mechanism, the vacuum wire feeding mechanism comprises a shell, a closed cavity is formed inside the shell, a wire feeding pipeline used for conveying raw wires is arranged inside the cavity, the two ends of the wire feeding pipeline penetrate through the shell, the shell is provided with an air nozzle used for vacuumizing the cavity, a plurality of air holes are formed in the wire feeding pipeline, and air inside the wire feeding pipeline is extracted through the air holes; the vacuum pump communicates with the vacuum chamber and the air nozzle through pipelines; the master control system is used for controlling the working states of the electronic gun, the vacuum pump and the wire feeding device. According to the additive manufacturing equipment, the processing efficiency and the processing quality can be effectively improved.

Owner:XIAN ZHIRONG METAL PRINTING SYST CO LTD

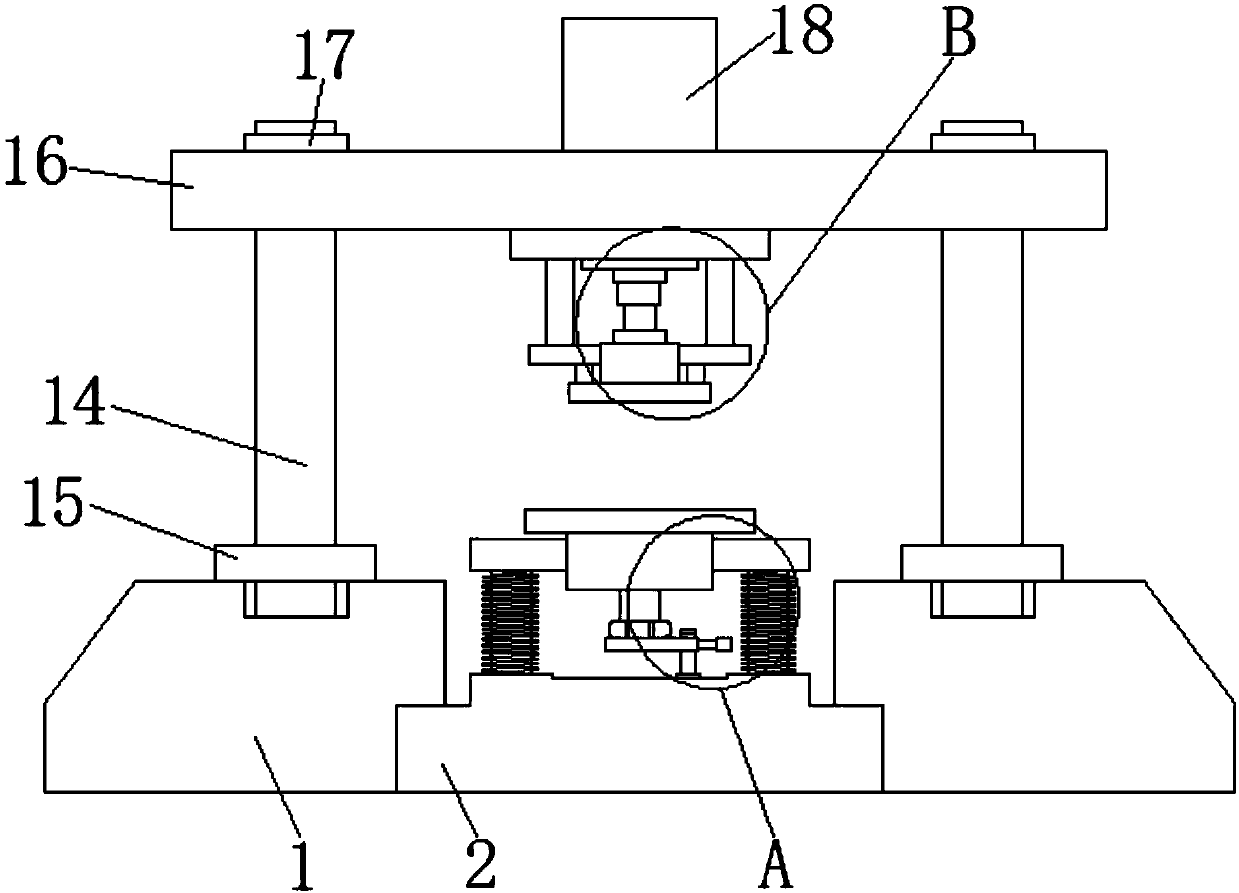

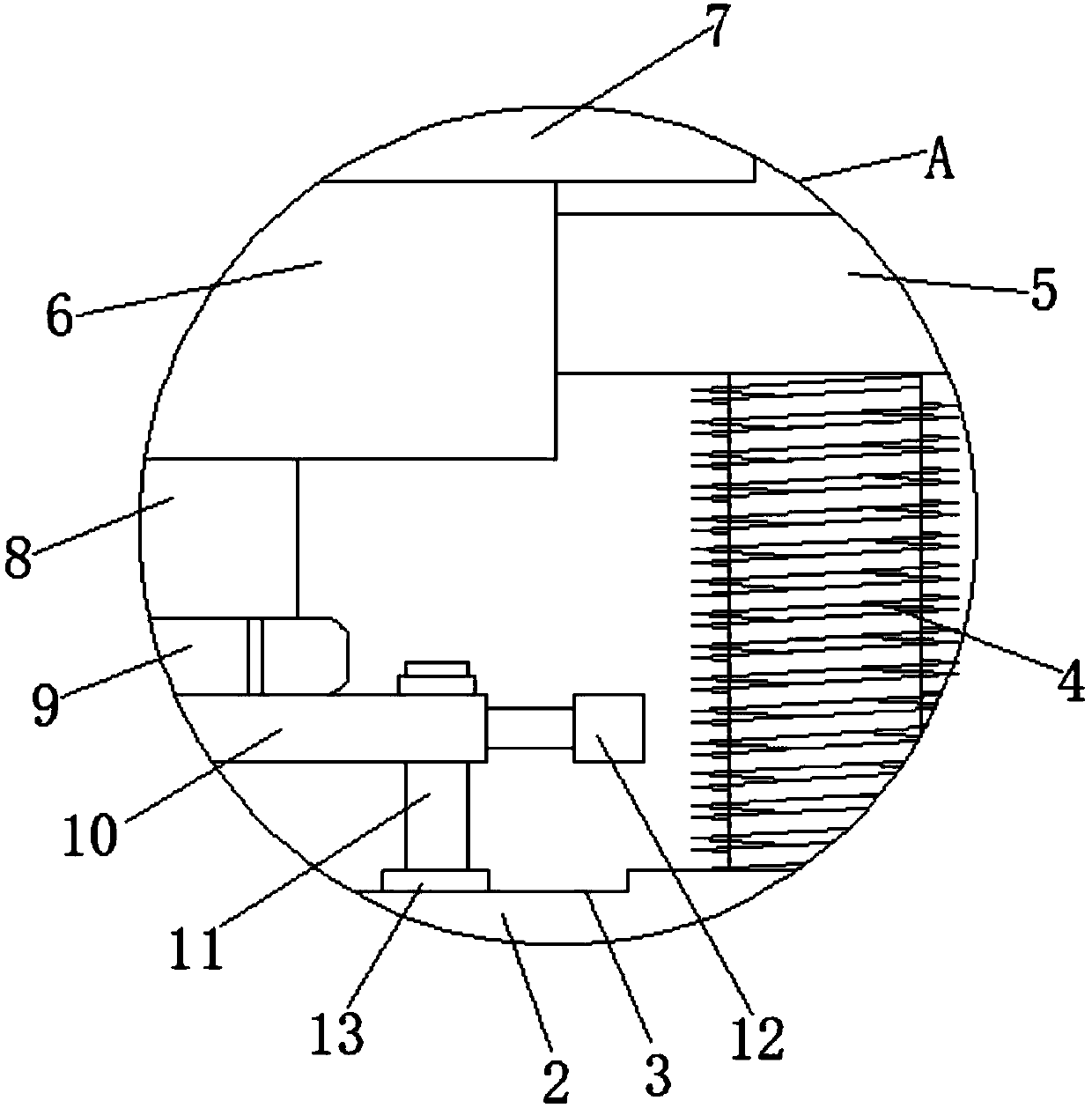

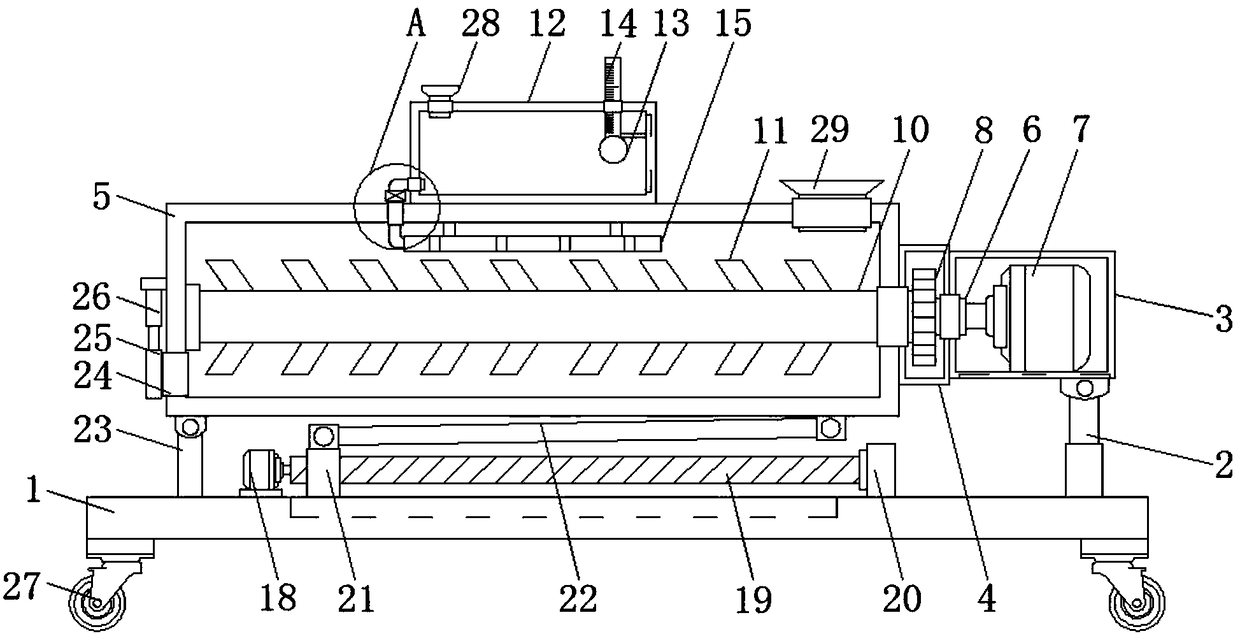

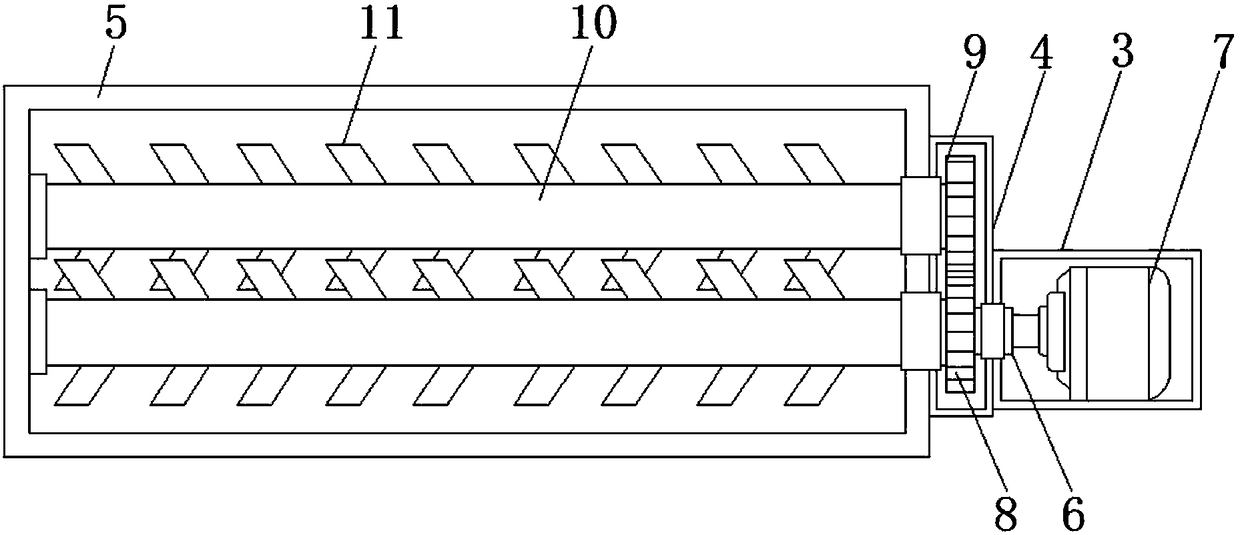

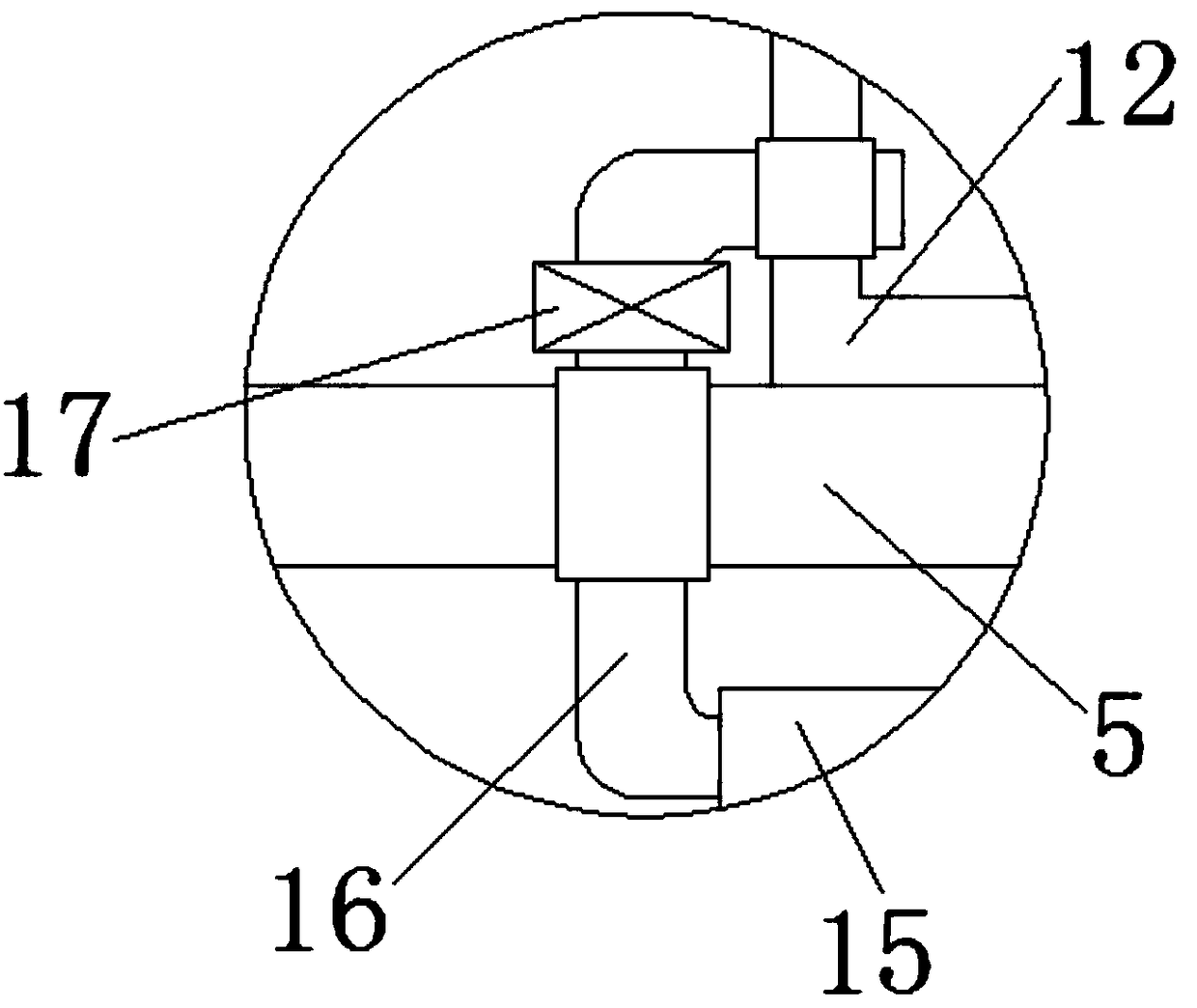

Special aluminum bank rapidly leveling device

InactiveCN108817136AImprove leveling efficiencyEasy to move back and forthMetal-working feeding devicesPositioning devicesAluminiumEngineering

The invention discloses a special aluminum bank rapidly leveling device. The special aluminum bank rapidly leveling device comprises a worktable, the bottom end of the worktable is fixedly provided with four support legs, the top end of the worktable is provided with an aluminum bank, both sides of the top end of the worktable are provided with clamping mechanism, the four corners of the top end of the worktable are fixedly connected with the bottom end of a top plate, and one side of the top late is provided with a driving mechanism. According to the special aluminum bank rapidly leveling device, electric extension bars are arranged to drive clamping boards to move forth and back to conveniently clamp and fix aluminum banks in different sizes and avoid position displacement of the aluminum banks during a leveling process; the transmission shaft of a stepping motor rotatingly drives a screw, which is threadedly connected with a screw nut, to rotate, and through cooperation of a slidinggroove and a slider, drives a connecting block to move forth and back, and then a first press roller and a second press roller can be driven to move on and further level the surface of the aluminum bank.

Owner:江苏野马电气科技有限公司

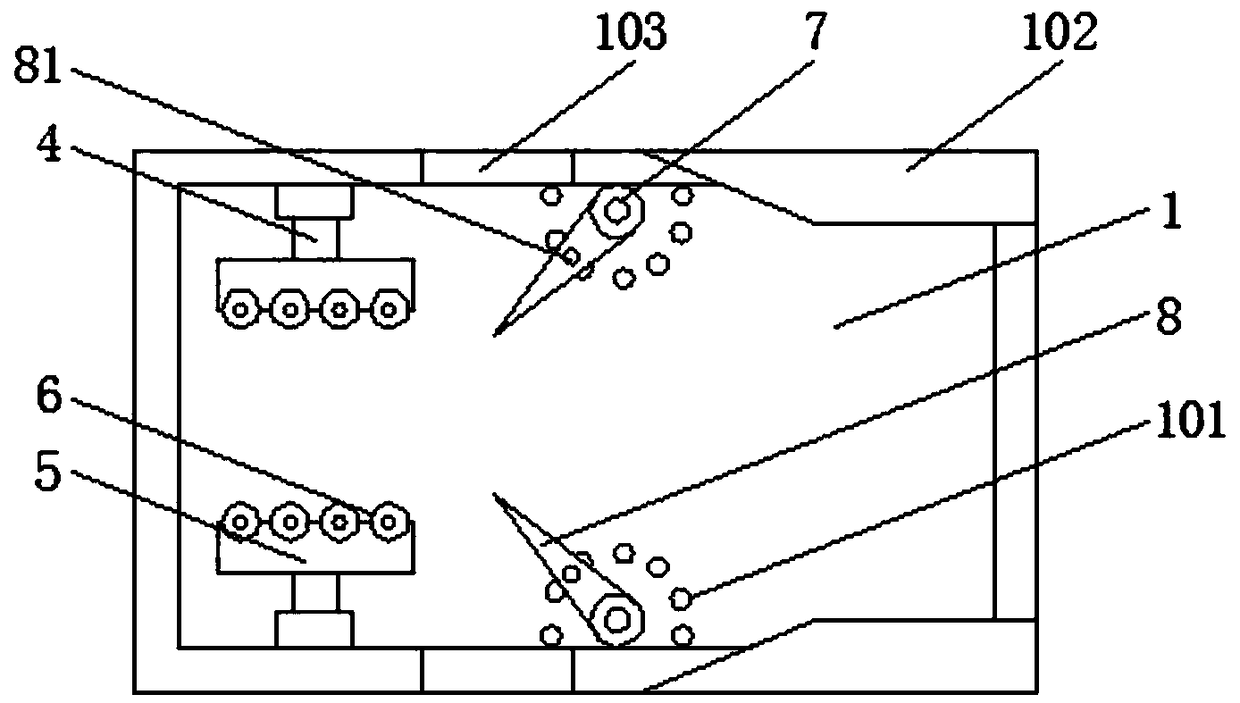

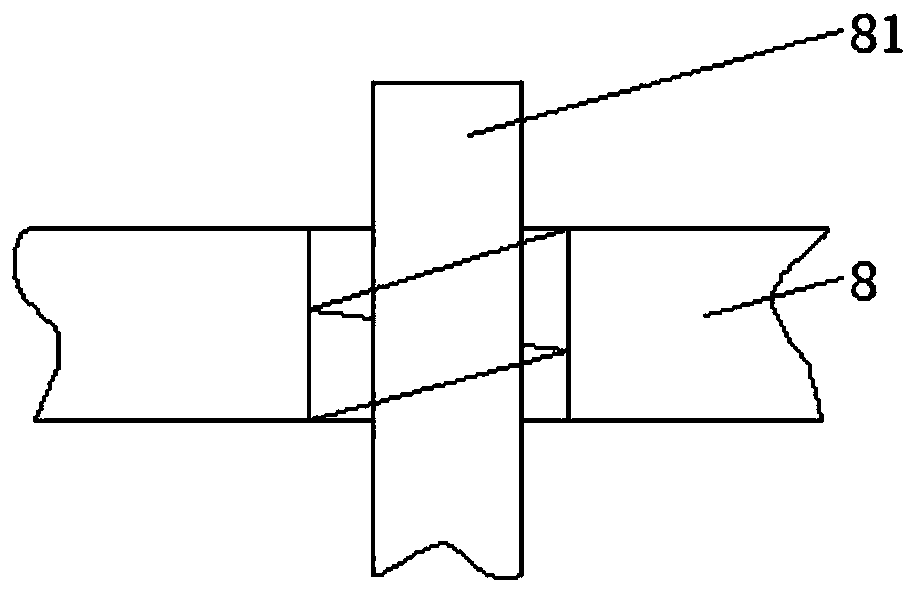

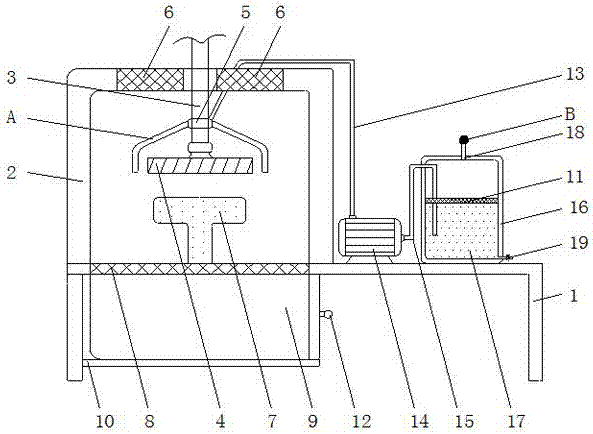

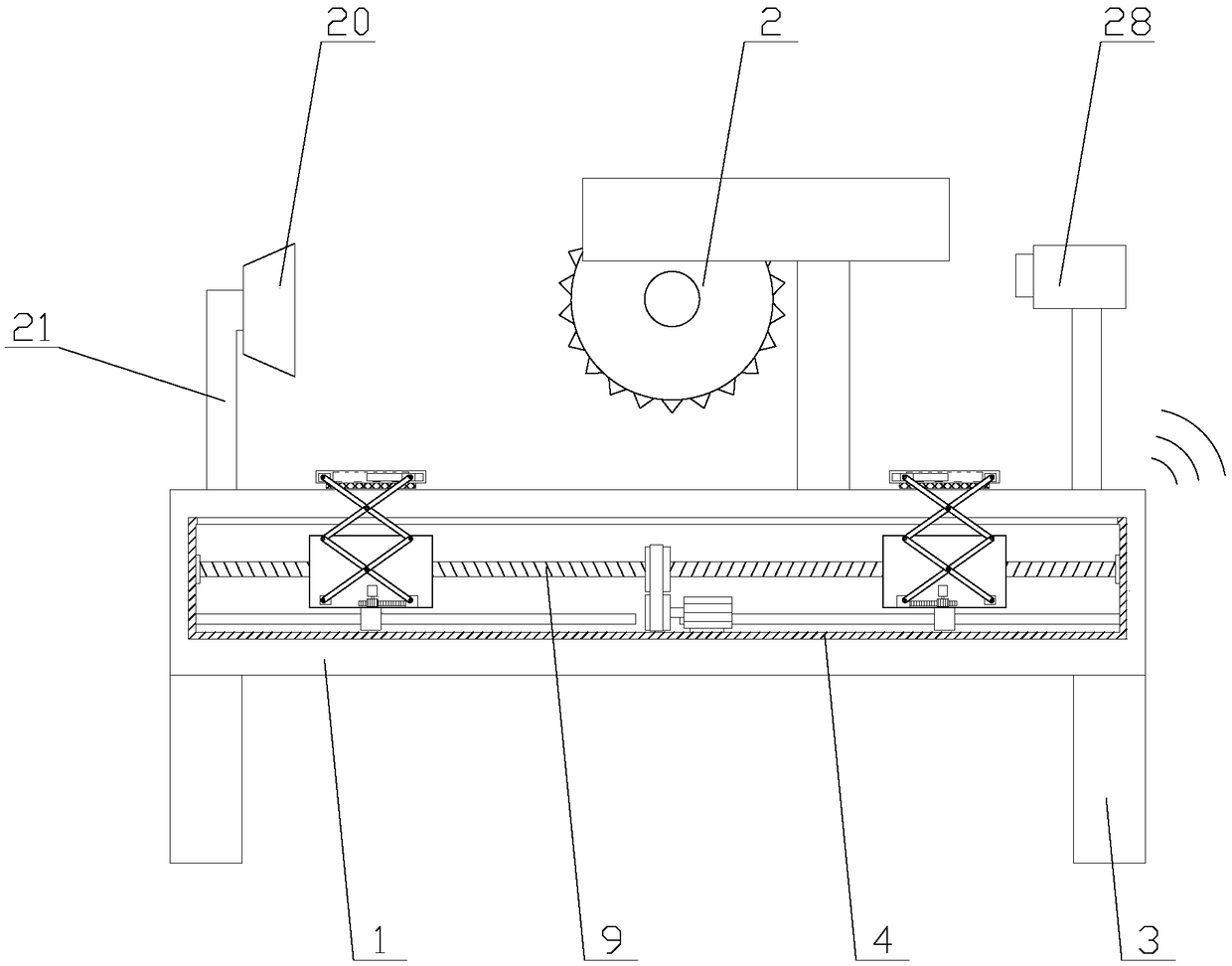

Wood board water cutting device and method having water circulation function

ActiveCN108908523AImpact cleanupReduce cleanupProfiling/shaping machinesStationary filtering element filtersPhysical healthWater storage tank

The invention discloses a wood board water cutting device and method having the water circulation function and belongs to the technical field of wood-working machinery. The wood board water cutting device comprises a working platform. An inner chamber of the working platform is provided with a conveying device. Rotating shafts are arranged in the centers of the outer walls of the left side and theright side of the top of the working platform correspondingly. The front end of each rotating shaft is connected with a guiding plate. A limiting rod is arranged on the outer wall of the top of eachguiding plate. The bottom end of each limiting rod extends to the outer wall of the bottom of the corresponding guiding plate, and the connection position of each guiding rod and the corresponding guiding plate is provided with a groove. By means of the device, chippings generated in the cutting process are flushed into a filter box for centralized treatment through water obtained after cutting, and the problem that the chippings splash everywhere to affect normal work and physical health of people is avoided; the water is separated from the chippings through the filter box, and the chippingscan be treated in a centralized manner conveniently; and meanwhile, the water collected by the filter box is conveyed into a water storage tank for reuse through a water pump, and the water resource is saved.

Owner:浙江博力莫新材料科技有限公司

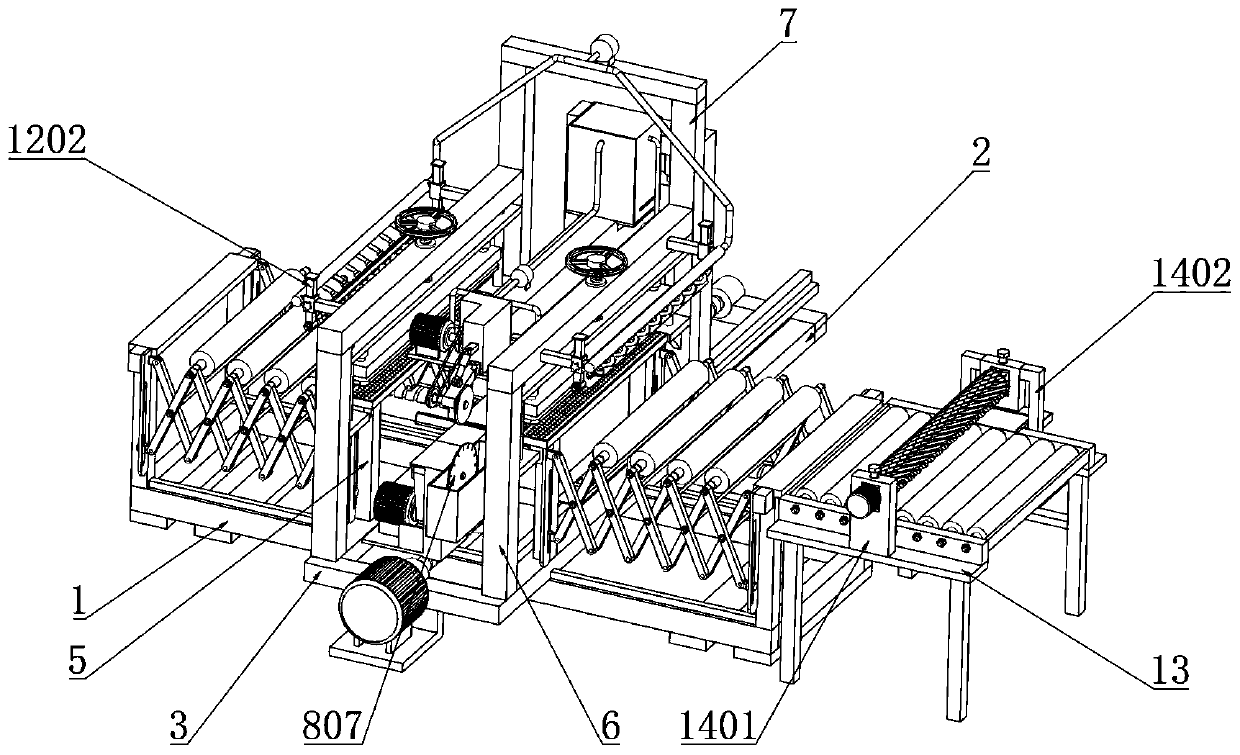

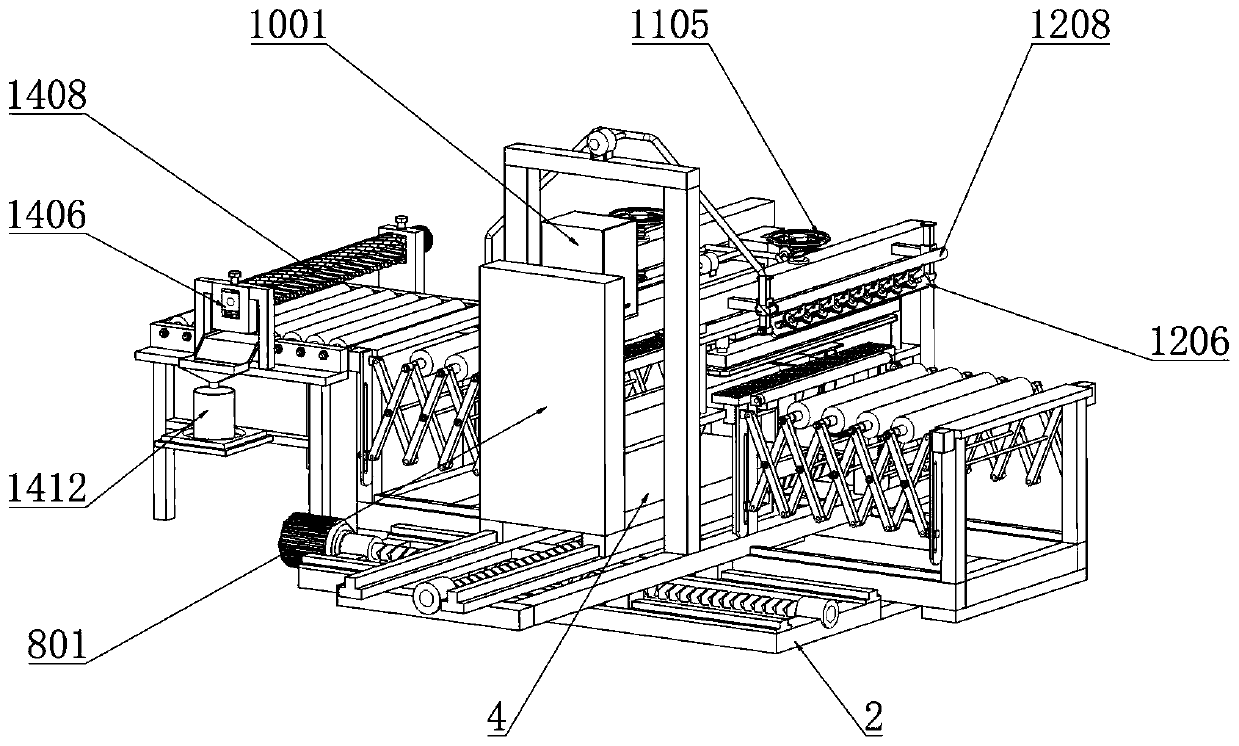

Manufacturing equipment of light-weight, waterproof and environment-friendly composite board

ActiveCN111496543AScientific and reasonable structureEasy to useGrinding machine componentsOther manufacturing equipments/toolsComposite plateIndustrial engineering

The invention discloses manufacturing equipment of a light-weight, waterproof and environment-friendly composite board. The equipment comprises a lower supporting frame. One side of the lower supporting frame is fixedly connected with a side supporting frame. The middle of the top end of the lower supporting frame is movably connected with a middle slide support. The middle of the top end of the middle slide support is movably connected with an upper slide support. Internal supporting frames are fixedly connected to the positions, corresponding to the two sides of the upper slide support, of the top end of the middle slide support correspondingly. One end of the top of the upper slide support is fixedly connected with a cutting and grinding mechanism. According to the manufacturing equipment provided by the invention, a grinding disc is lifted down while the upper slide support moves backwards so that one end surface of the composite board can be ground and chamfered, sharp burrs formed on the side portions of a metal plate on the upper layers of the end surfaces of the composite board are effectively removed, hidden safety hazards in the transporting and using process of the composite board are eliminated, the using safety of the composite board is improved, the two steps of cutting and grinding are completed in the two-way process of the upper slide support, and the production process of the composition board is optimized.

Owner:SHENZHEN LANDUN WATERPROOF ENG

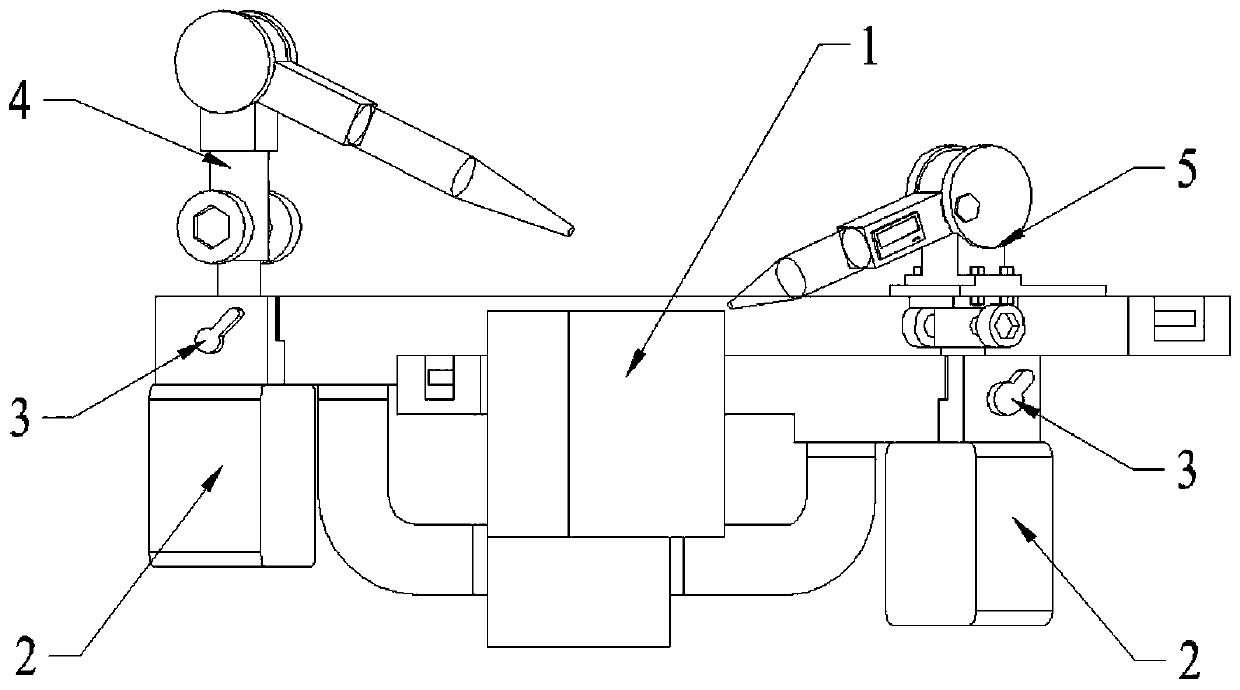

Cooling and chip blowing composite type internal cooling turning tool with adjustable spraying mouths

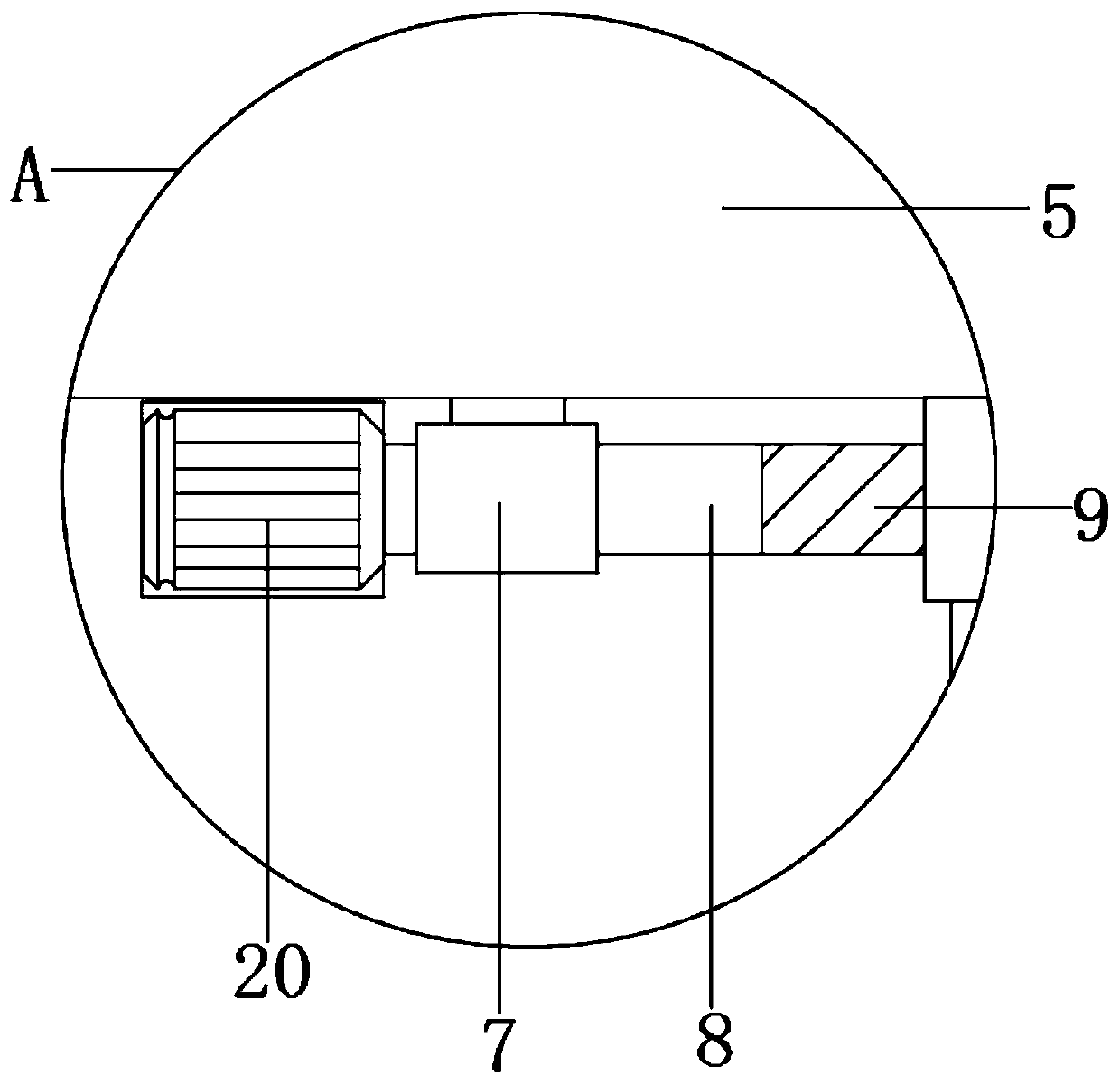

PendingCN110640169AImprove cooling efficiencyAffect processing qualityTurning toolsMaintainance and safety accessoriesEngineeringTool bit

The invention discloses a cooling and chip blowing composite type internal cooling turning tool with adjustable spraying mouths. The internal cooling turning tool comprises an internal cooling turningtool body, an automatic shrinking device, a magnetic clamping seat, an adjustable chip blowing spraying mouth and an adjustable cooling spraying mouth, wherein a cooling liquid internal circulating channel is arranged at a tool head of the internal cooling turning tool body; an atomizing liquid dividing structure, an atomizing liquid groove for chip blowing and an atomizing liquid groove for cooling are arranged on a cutter rod of the internal cooling turning tool body; and the atomizing liquid dividing structure is connected with external spray cooling equipment through an atomizing liquid inlet, and is connected with the atomizing liquid groove for chip blowing and the atomizing liquid groove for cooling through an atomizing liquid external pipe, the adjustable chip blowing spraying mouth is mounted on the atomizing liquid groove for chip blowing, and the adjustable cooling spraying mouth is mounted on the atomizing liquid groove for cooling. According to the cooling and chip blowing composite type internal cooling turning tool with the adjustable spraying mouths, the combination of cooling and auxiliary chip removal can be realized, and the situation that cutting chips are wound around a workpiece and a cutter so as to affect the workpiece can be prevented.

Owner:EAST CHINA JIAOTONG UNIVERSITY

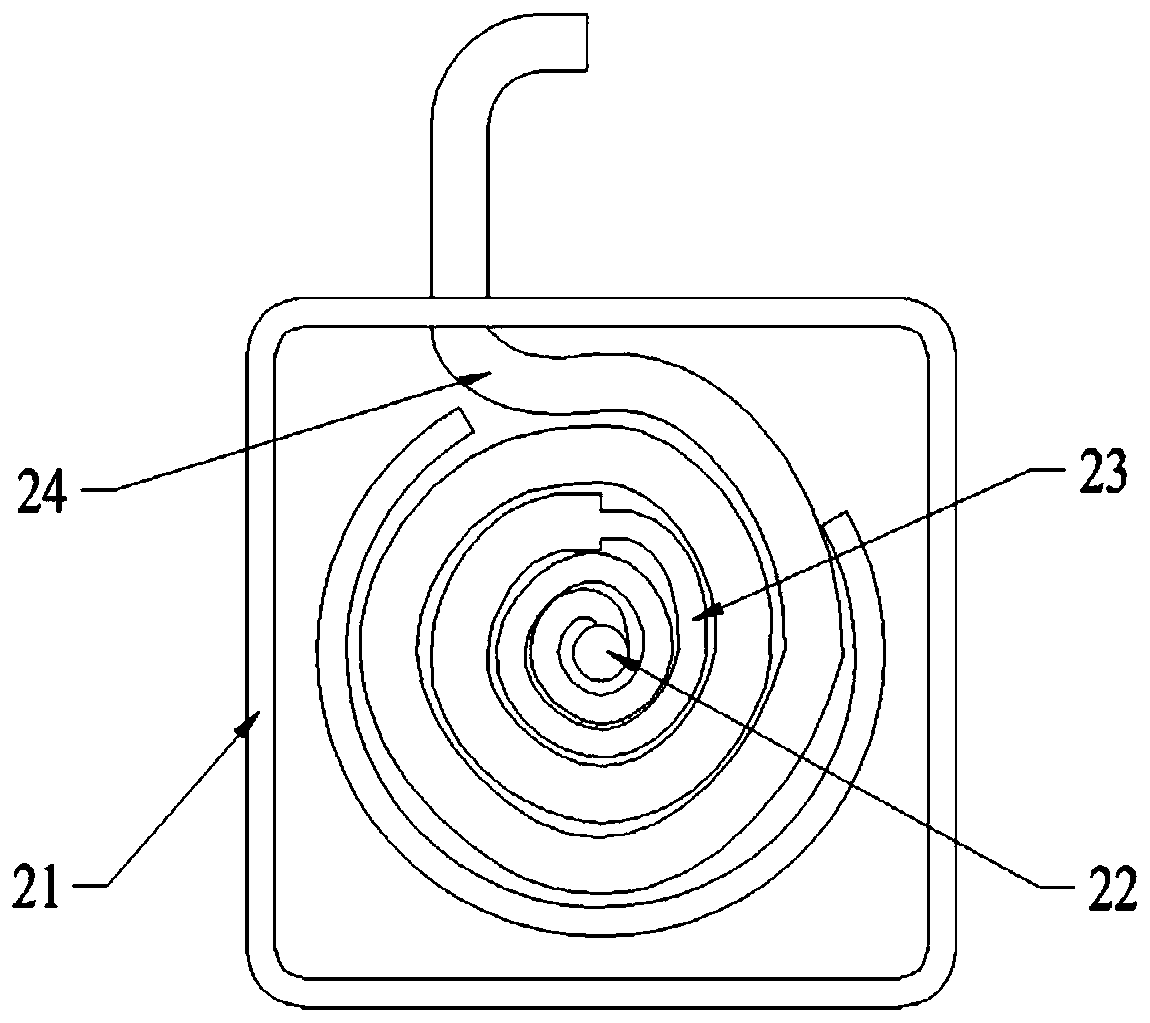

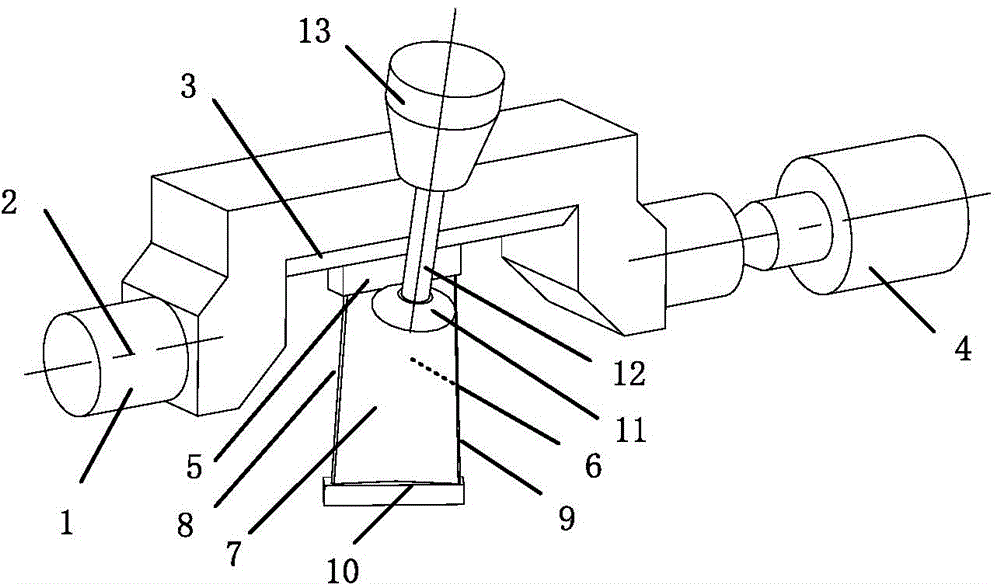

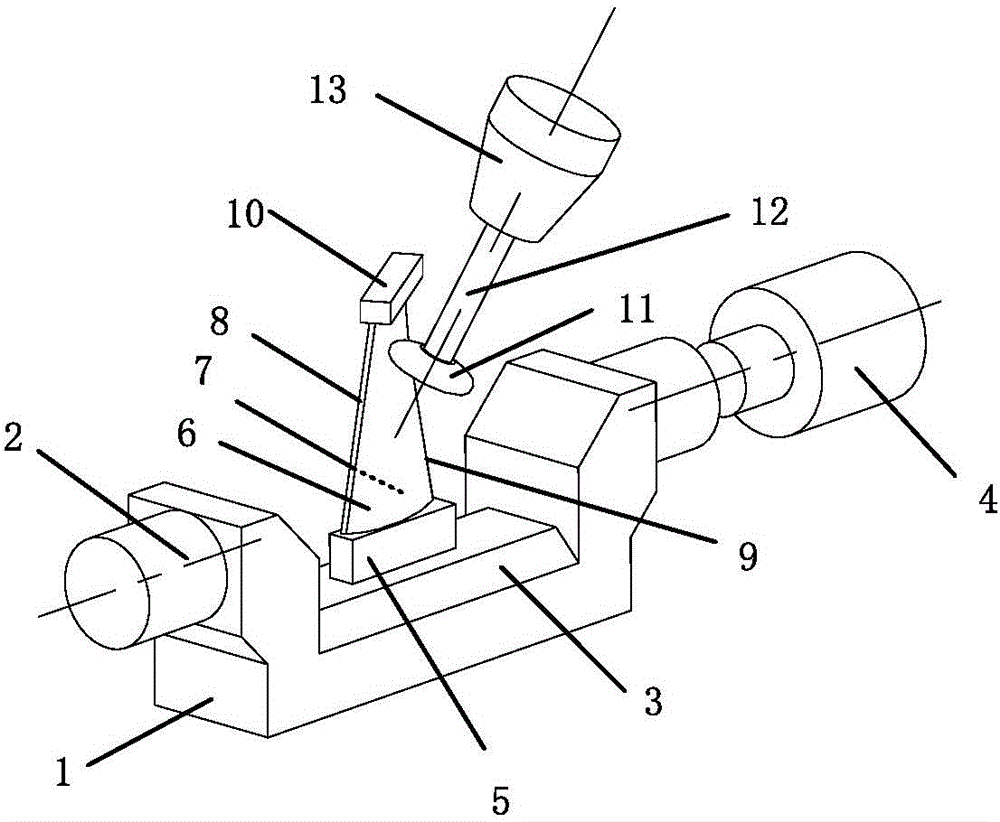

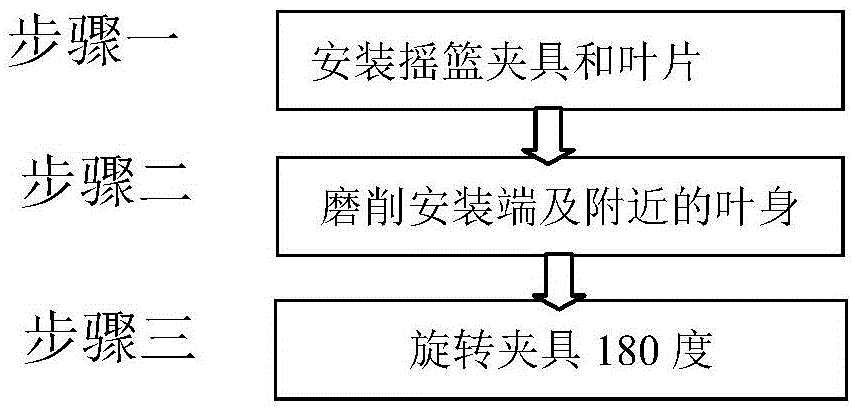

Bi-directional inverted grinding method for full molded surface of blade with two ends having tip shrouds

ActiveCN104858747AAffect processing qualityImprove processing efficiencyGrinding machinesGrinding work supportsPositive directionAcute angle

Provided is a bi-directional inverted grinding method for a full molded surface of a blade with two ends having tip shrouds. The bi-directional inverted grinding method comprises three steps: step 1, selecting a five-axis linkage machine tool having A / B axes, installing a cradle-like fixture having one end connected to an A axis and driven to rotate by the A axis and having the other end supported by a center hole for ensuring rotation between the cradle-like fixture and the A axis; step 2, selecting a dished circular-ring-surface grinding wheel for machining the blade surface of a blade installing end, a blade root transition surface and a tenon so that an included angel formed between the connecting line from the installing end of the blade to a cantilever end and the positive direction of a machine tool Z axis is an obtuse angle; step 3, enabling the cradle-like fixture to drive the blade to rotate for 180 degrees after the blade body part close to the installing end is finished machining such that the cantilever end of the blade faces upwards and the included angel formed between the blade body direction and the positive direction of the machine tool Z axis is an acute angle, and in the meantime, grinding a blade pot of the blade, a blade back and leading and exhaust edge portions of the blade. In the step 1, some portions of the cradle-like fixture deviate from of the center of the A axis and the center of the blade body draws close to the rotary center of the A axis as much as possible.

Owner:枣庄北航机床创新研究院有限公司

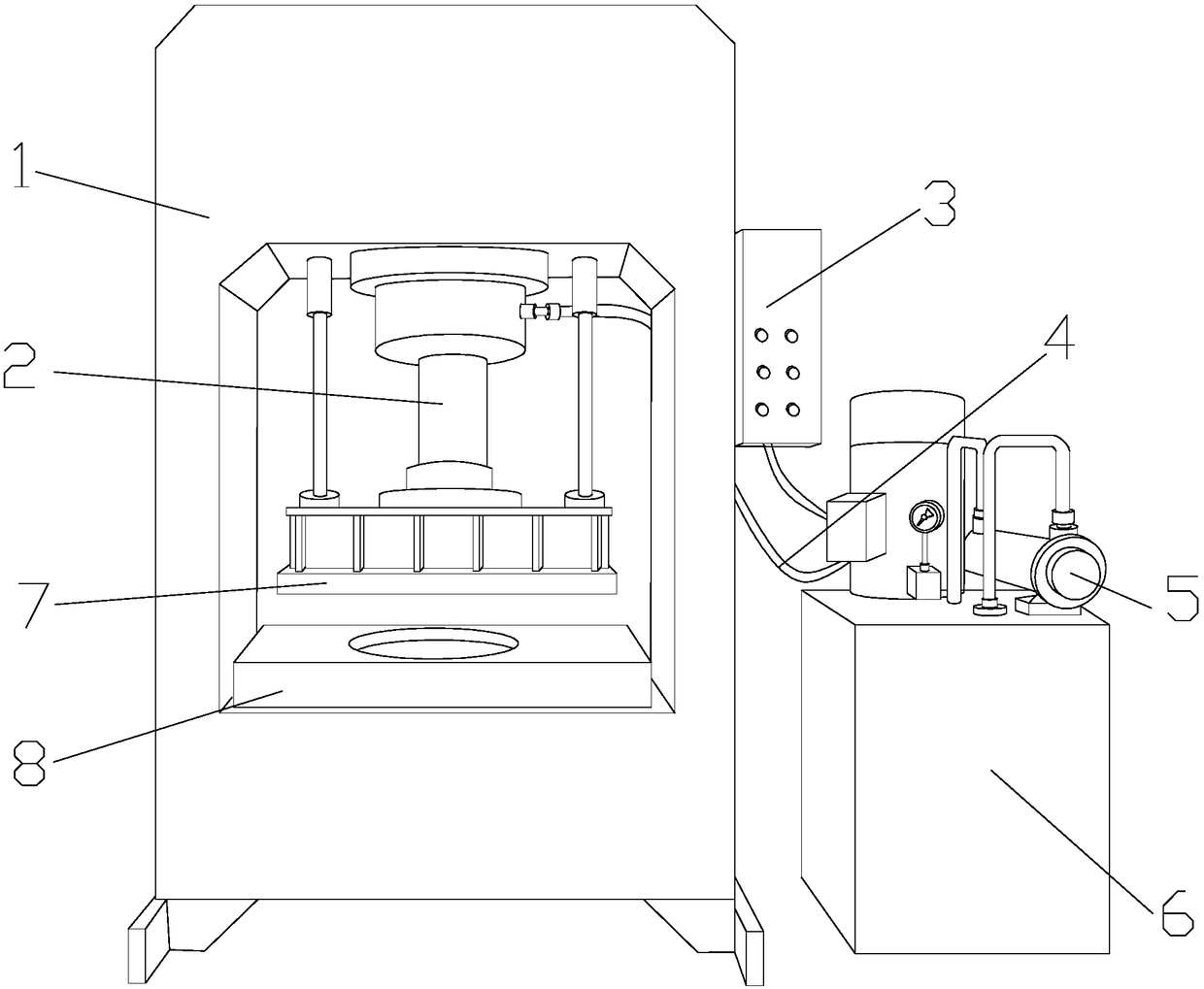

Ceramic sanitary ware moulding press

ActiveCN108356958AAchieve recyclingAffect processing qualityDrying gas arrangementsAuxillary shaping apparatusEngineeringSolid particle

The invention discloses a ceramic sanitary ware moulding press. The moulding press structurally comprises a moulding press shell body, an air pressure cylinder, a moulding press controller, an air delivery pipe, an air pressure tank, an air pressure tank support, a sanitary ware stamping upper mould base and a self-cleaning type sanitary ware stamping lower mould base, wherein the moulding press controller is electrically connected to the other end of the moulding press shell body, the self-cleaning type sanitary ware stamping lower mould base is arranged at the lower end of the inner surfaceof the moulding press shell body, and the sanitary ware stamping upper mould base is arranged on the upper end surface of the self-cleaning type sanitary ware stamping lower mould base. According to the ceramic sanitary ware moulding press, the self-cleaning type sanitary ware stamping lower mould base is arranged, and therefore, the self-cleaning type sanitary ware stamping lower mould base can be automatically cleaned after a ceramic sanitary ware is machined by the ceramic sanitary ware moulding press, the situation that the machining quality of the ceramic sanitary ware is influenced due to residual silt, dust and other solid particles inside the ceramic sanitary ware moulding press is effectively prevented, meanwhile, the situation that manual cleaning is not convenient is also avoided, the machining quality of the moulding press is improved and the practicability is high.

Owner:嘉兴市康立德构件股份有限公司

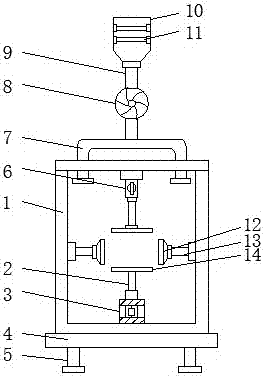

Scrap suction device for polisher

InactiveCN107953262AAffect the running qualityAffect processing qualityPolishing machinesGrinding/polishing safety devicesScrapEngineering

The invention discloses a scrap suction device for a polisher. The scrap suction device comprises a support, a shell is mounted on the support, the upper portion of the shell penetrates a transmissionshaft, a polishing wheel is mounted on the lower portion of the transmission shaft, a bearing is fixedly mounted on the transmission shaft, a rubber scrap suction cover is mounted on the bearing, a scrap suction opening is formed in the rubber scrap suction cover, a placement table is mounted on the lower portion of the polishing wheel, a leakage plate is arranged on the lower portion of the placement table, a scrap collection box is mounted on the lower portion of the leakage plate, a guide rail mounted on the support is arranged on the lower portion of the scrap collection box, the scrap collection box is provided with a handle, and an air inlet pipe is fixedly mounted at the scrap suction opening. According to the scrap suction device for the polisher, the mounted scrap suction cover exhausts and filters dust and scraps generated in machining through an exhaust fan, and suction gas is purified by air purifying preparations and then exhausted to atmosphere, so that the device solvesthe problems that a large quantity of scraps and dust are generated in the machining process, running of the polisher is affected, fitness of workers is harmed, and environments are polluted.

Owner:王变芝

Efficient paint spraying device

InactiveCN107042178AEasy to fixAvoid tiltingLiquid surface applicatorsSpraying apparatusSurface mountingCoupling

The invention discloses a high-efficiency painting device, which includes a support base plate and a fixed plate. A paint spray box is installed on the support base plate. A driving motor is installed at the bottom of the paint spray box. connected, the inside of the paint spraying box is fixed with a telescopic tube, and the telescopic tube is connected with a telescopic rod, and the telescopic rod is connected with the fixed plate through a bearing. The surface of the paint spraying box is provided with a door, and the surface of the door is There is an observation window, a PLC controller and a door handle, and an exhaust fan is fixed on the top of the paint spraying box, and the exhaust fan is connected with a dust conveying pipe, and the connecting pipe is connected with a dust removal tank. In the present invention, the dust in the paint spraying box is extracted into the dust removal tank through the exhaust fan, and the two high-efficiency filter screens in the dust removal tank can basically eliminate the dust, so as to prevent the dust in the dust removal tank from affecting the processing quality of the painting parts and remove dust at the same time The gas discharged from the tank will not pollute the environment.

Owner:TAICANG MIX MACHINERY EQUIP CO LTD

Bottle blow-moulding machine die carrier/mold component

The invention discloses a mold frame / mold assembly of a bottle blowing machine, which comprises a left and a right mold frames and a left and a right molds, wherein the seal compensation device is arranged between a mold and a mold frame and includes recessed sections correspondingly arranged on the outer side wall of the mold and the inner sidewall of the mold frame, and a seal ring arranged on the periphery of the recessed section; the recessed sections can form a closed cavity when the mold frame snap-fits the mold; and an air hole communicating with the sealed cavity is arranged on the mold frame. The mold assembly of the bottle blowing machine obviates the need of moving mold sleeve and static mold sleeve, thus greatly reducing the size of the mold assembly. Accordingly, the number of mold cavities can be increased in single machine, thus improving the production efficiency of single machine. The mold frame / mold assembly is particularly suitable for full-automatic bottle blowing machine with a volume smaller than 600 ml and high requirement for single-machine yield. The mold frame / mold assembly has simpler structure.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

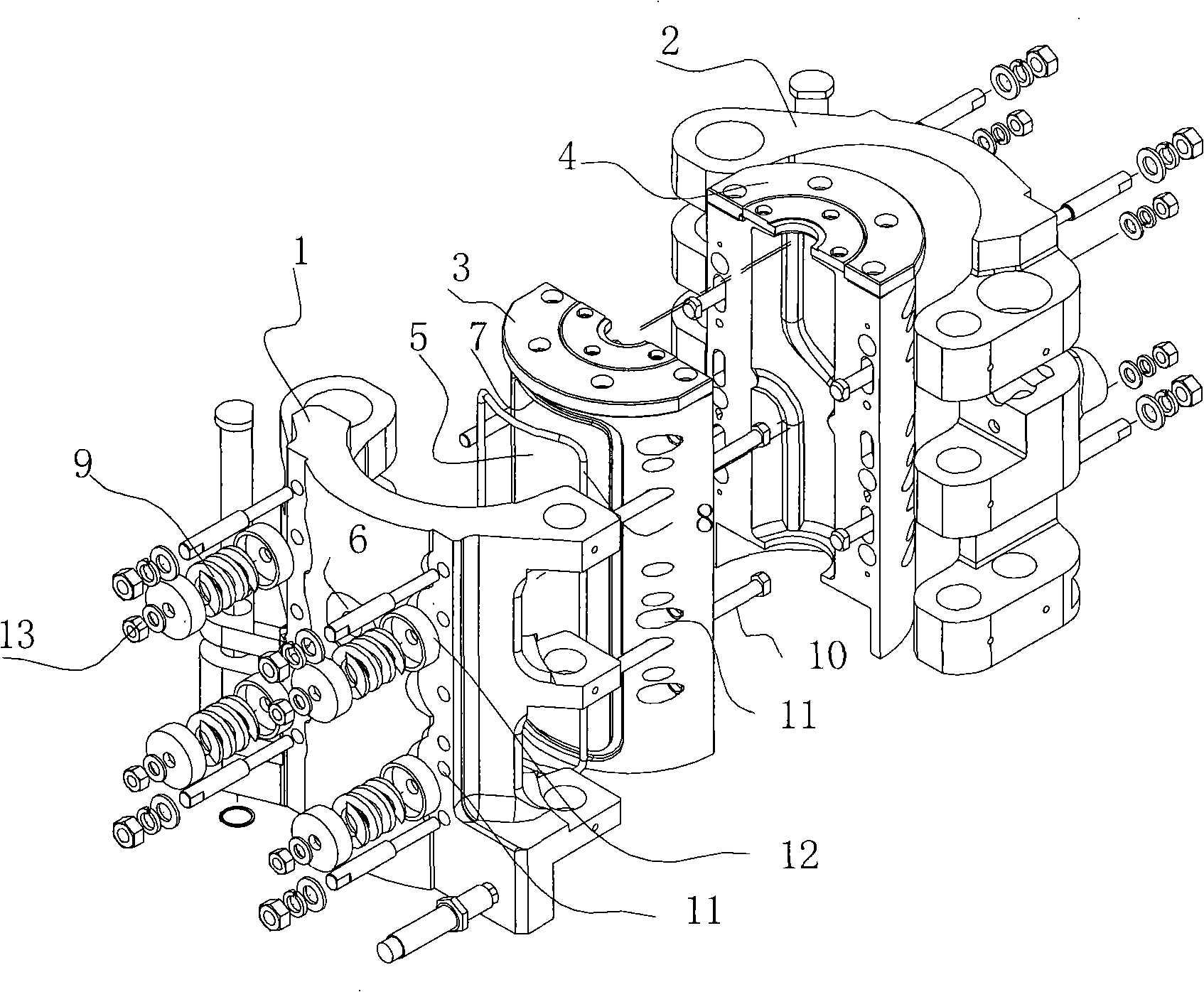

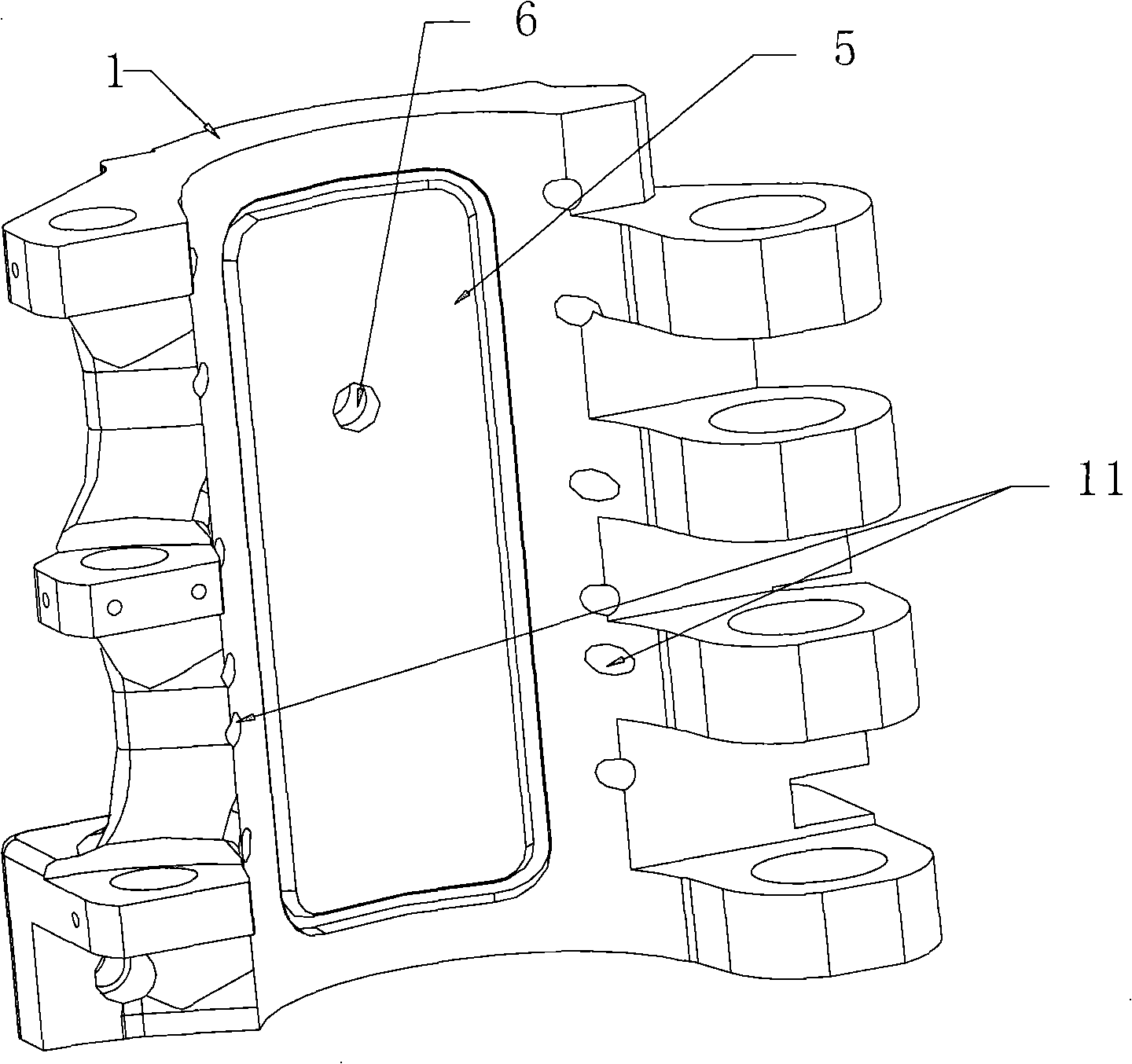

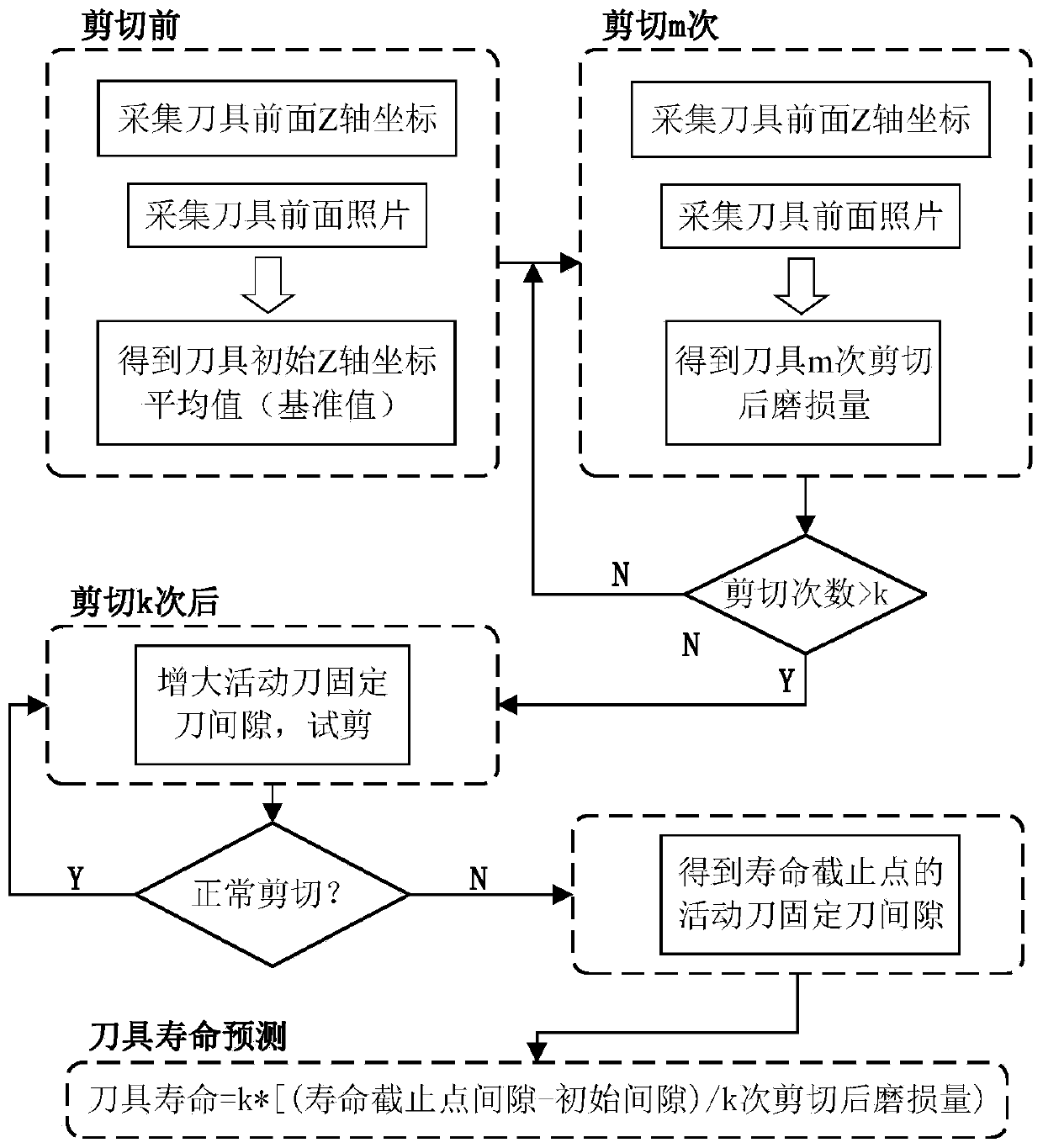

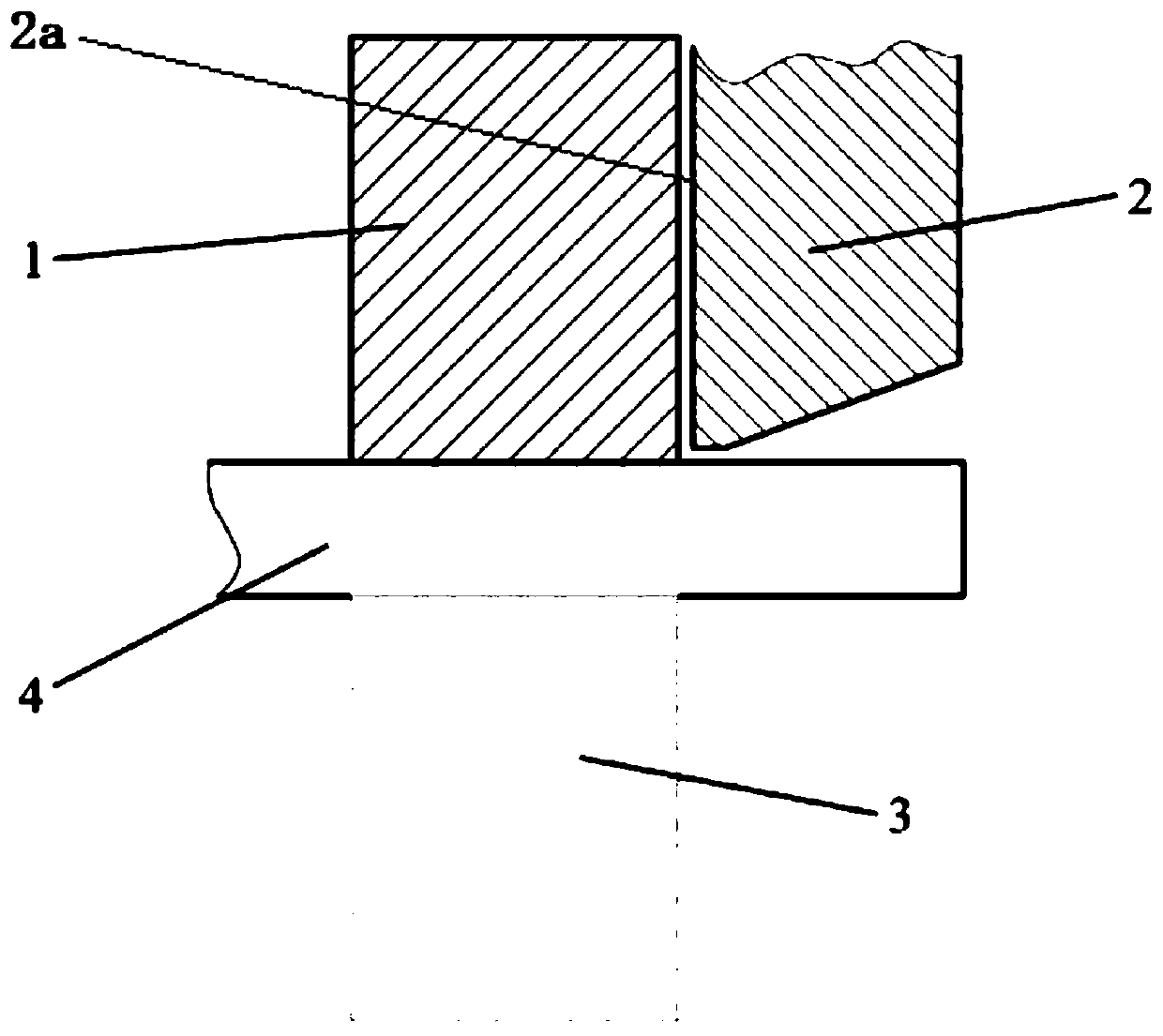

Bar cutting tool life prediction method

ActiveCN109877650AImprove reliabilityReduce economic costsMeasurement/indication equipmentsEngineeringDesign stage

The invention discloses a bar cutting tool life prediction method. The wearing capacity in each time of cutting is obtained by conducting quantitative detection on the wearing capacity of the side face of a movable tool, then the predicted life of a bar cutting tool is obtained according to the difference between the failure spacing distance and the initial spacing distance between a fixed tool and the movable tool, that is to say, the bar cutting tool life prediction method can achieve the technical purpose of obtaining the service life of the tool in the design stage, and the reliability ofthe cutting machine property is improved. Particularly, the bar cutting tool life prediction method has the following advantages that firstly, a full life test does not need to be conducted on the tool, and the characteristics of being low in economical cost, high in prediction speed and high in accuracy are achieved; secondly, a prediction result better conforms to an actual result, and the toollife prediction error is small; and thirdly, the tool life is predicted through the method, the tool can be replaced in advance, the condition that the blank machining quality is influenced due to thefact that the tool is damaged is prevented, and the reliability of a bar cutting machine is improved.

Owner:CHONGQING UNIV

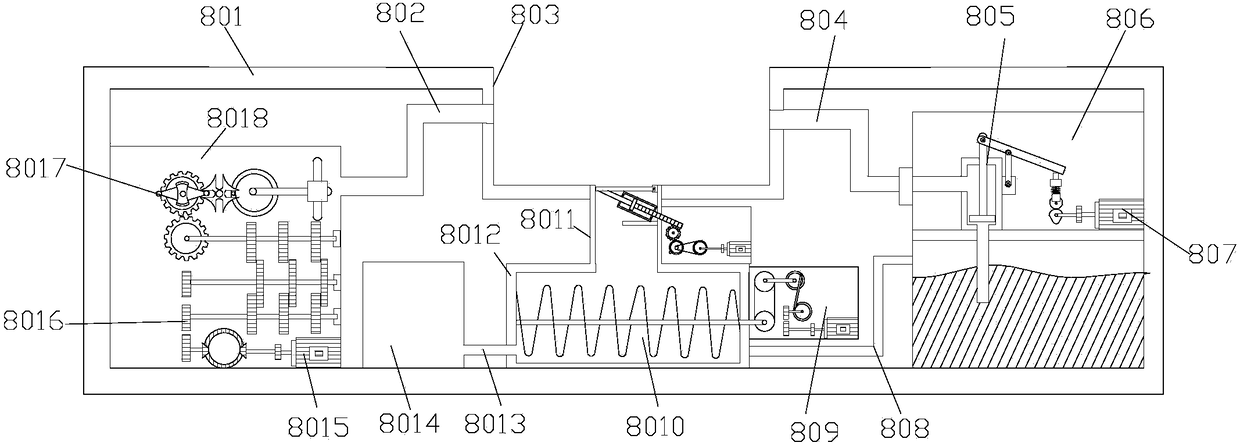

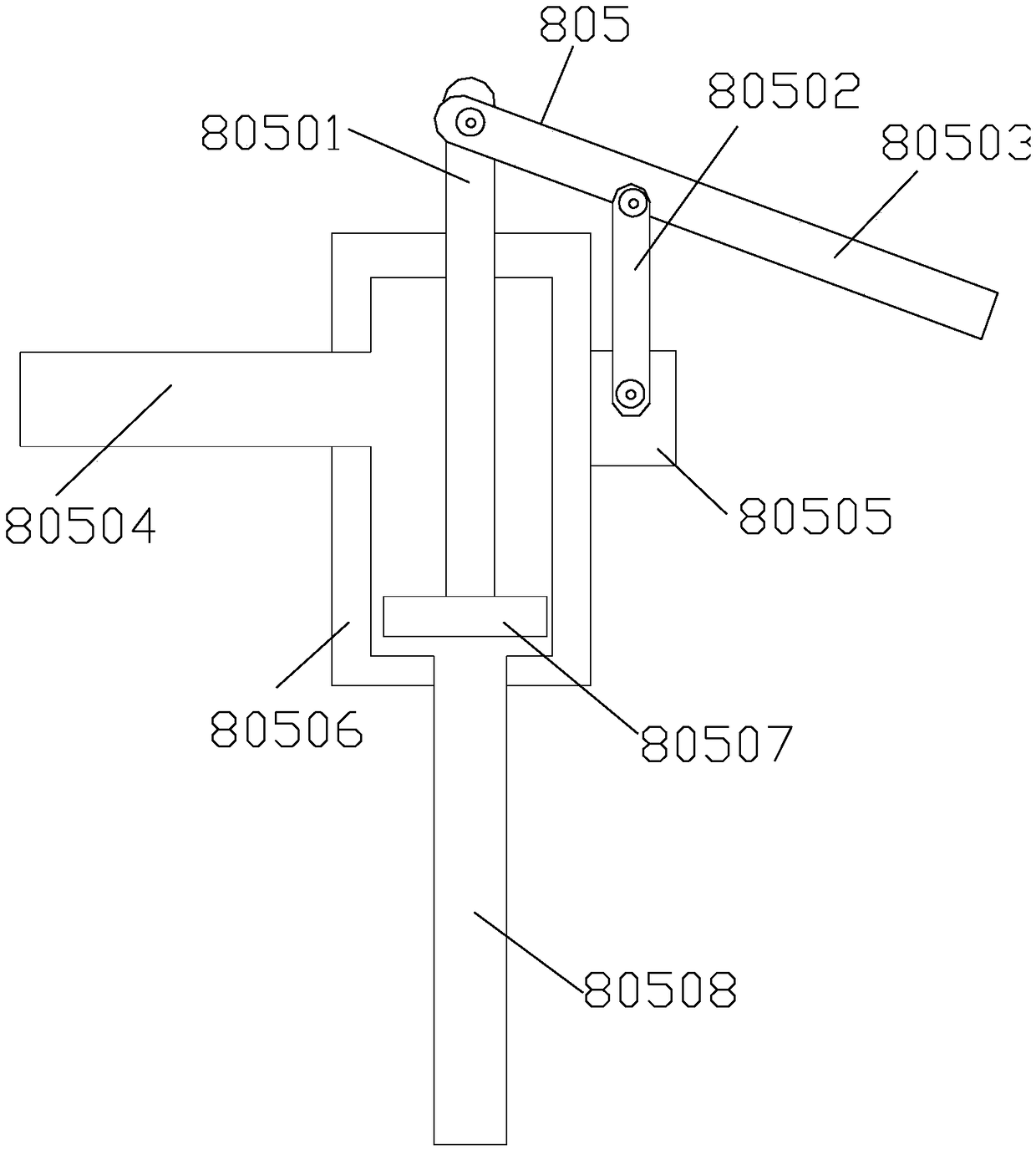

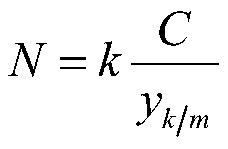

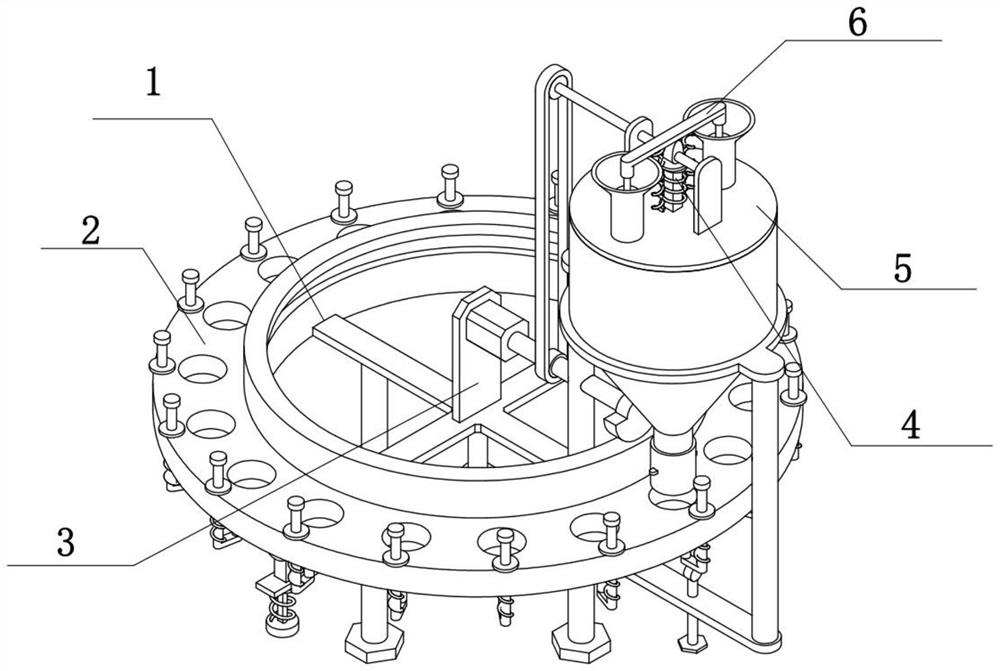

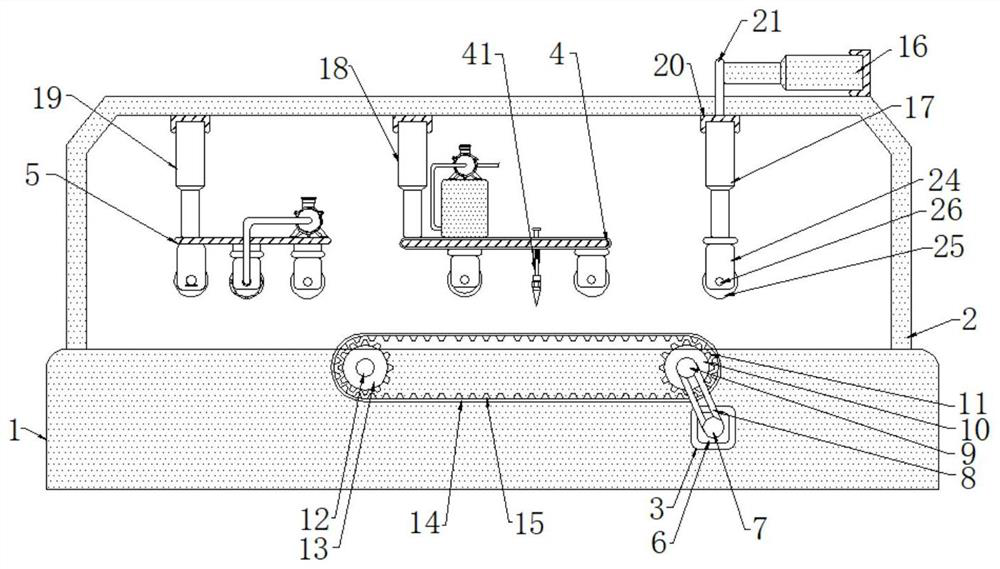

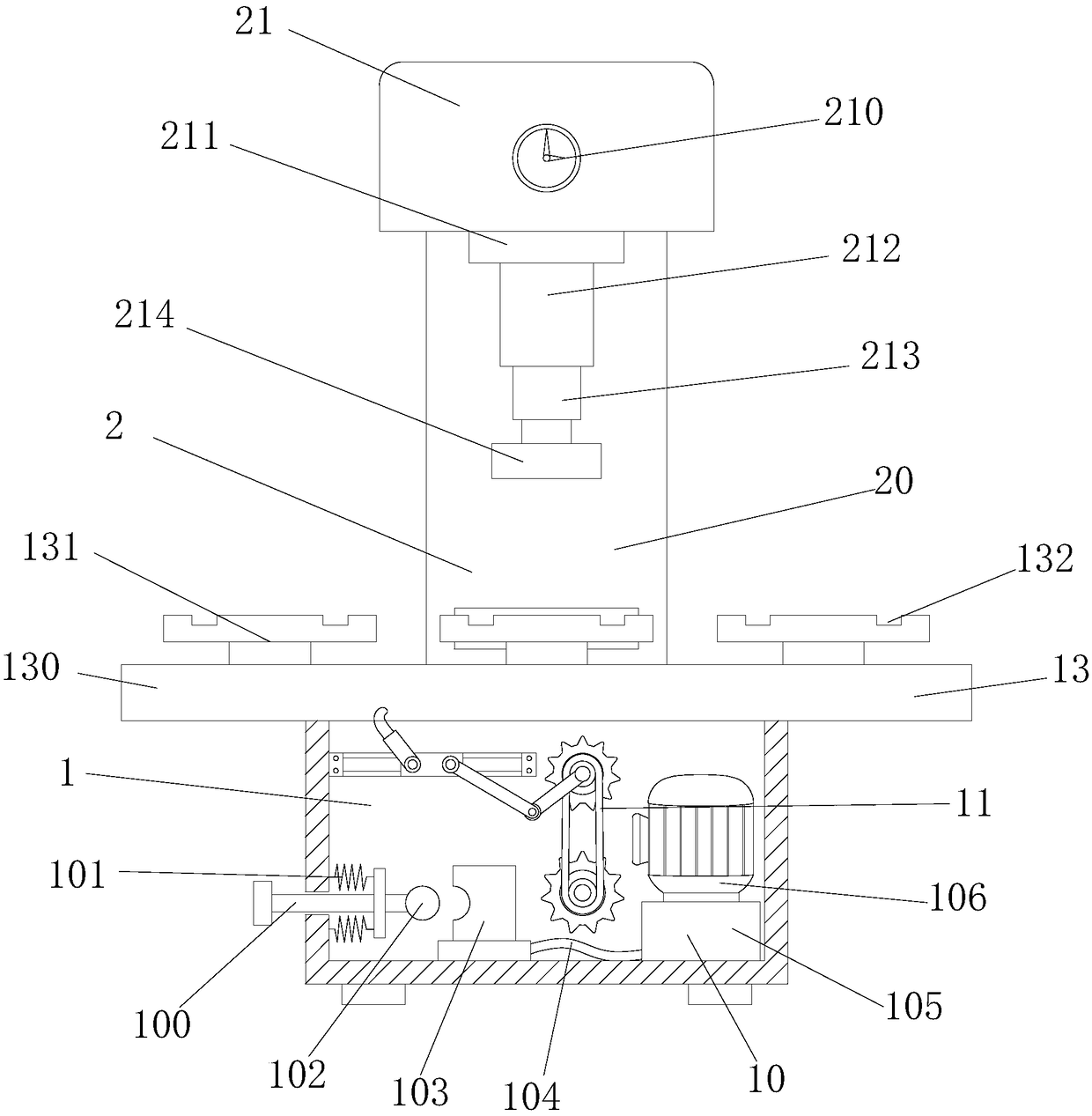

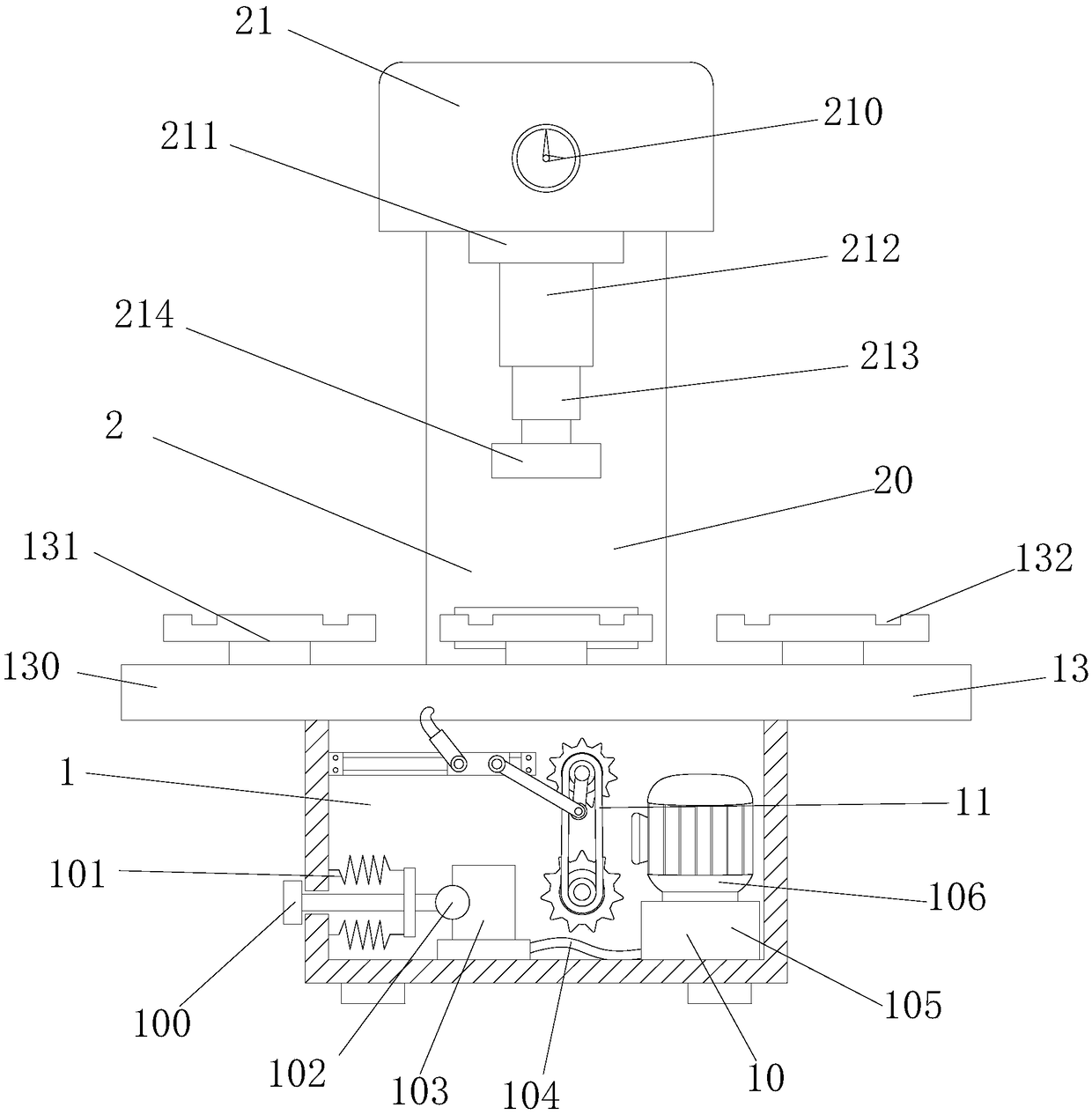

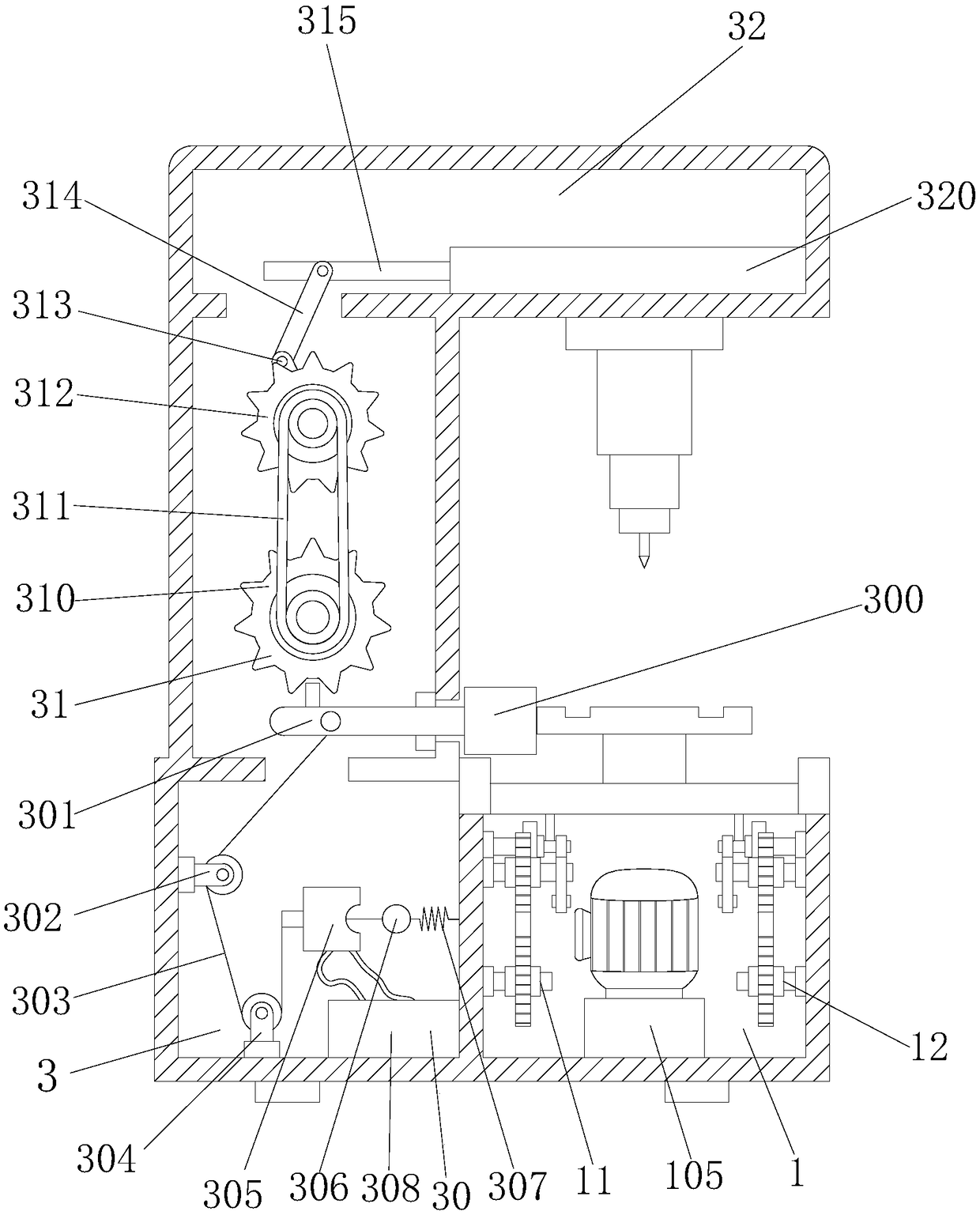

Facial mask forming machine

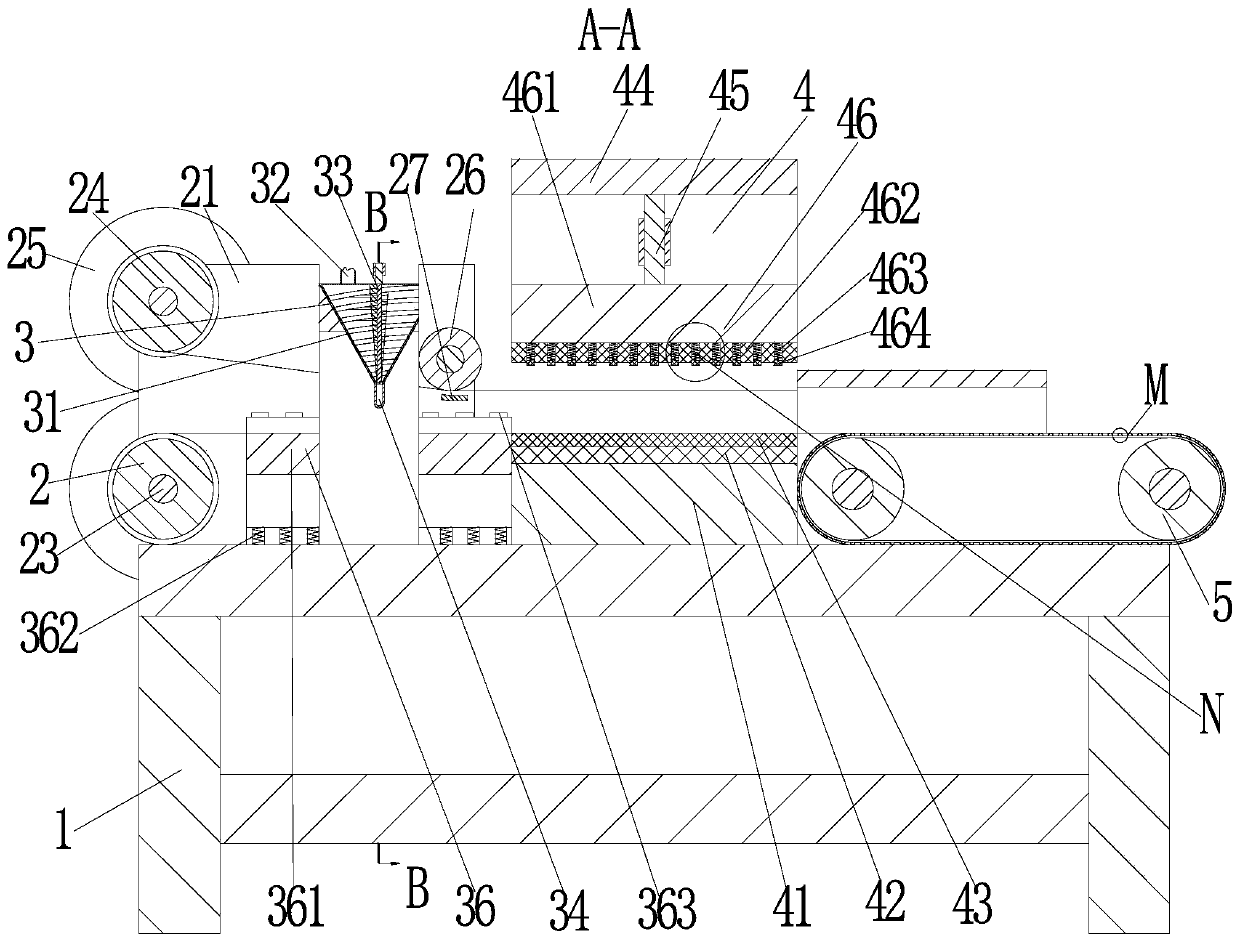

InactiveCN112275628ARealize automatic unloadingGuaranteed molding thicknessCosmetic preparationsSievingMolding machineEngineering

The invention relates to the technical field of cosmetic forming equipment, in particular to a facial mask forming machine which has the advantage of being capable of rapidly conducting facial mask forming production. The facial mask forming machine comprises a supporting discharging assembly, a forming assembly, a driving assembly, a multifunctional assembly, a transmission assembly and a feedingswitch assembly. The forming assembly is rotationally connected with the supporting discharging assembly, the driving assembly is fixedly connected to the supporting discharging assembly, the drivingassembly is fixedly connected to the forming assembly, the multifunctional assembly is connected to the supporting discharging assembly, the transmission assembly is fixedly connected to the supporting discharging assembly, the multifunctional assembly is connected to the transmission assembly, and the feeding switch assembly is connected to the supporting discharging assembly.

Owner:田忠泉

Improved ash-collecting device at furnace mouth of enamelling machine furnace

ActiveCN101968979AEasy to cleanReliable cleaningCable/conductor manufactureEngineeringMechanical engineering

The invention provides an improved ash-collecting device at a furnace mouth of an enamelling machine furnace, by which enamelling ashes can be cleaned conveniently and the processing quality of enamelled wires can be ensured. The improved ash-collecting device comprises a support, and the support is arranged at the furnace mouth of the enamelling machine furnace. The improved ash-collecting device is characterized in that the support is a square support, and the two sidewalls of the square support are provided with openings, ash-collecting boxes are arranged in the openings, and the ash-collecting boxes are closely locked with the square support by lock catches.

Owner:WUXI XIZHOU MAGNET WIRES

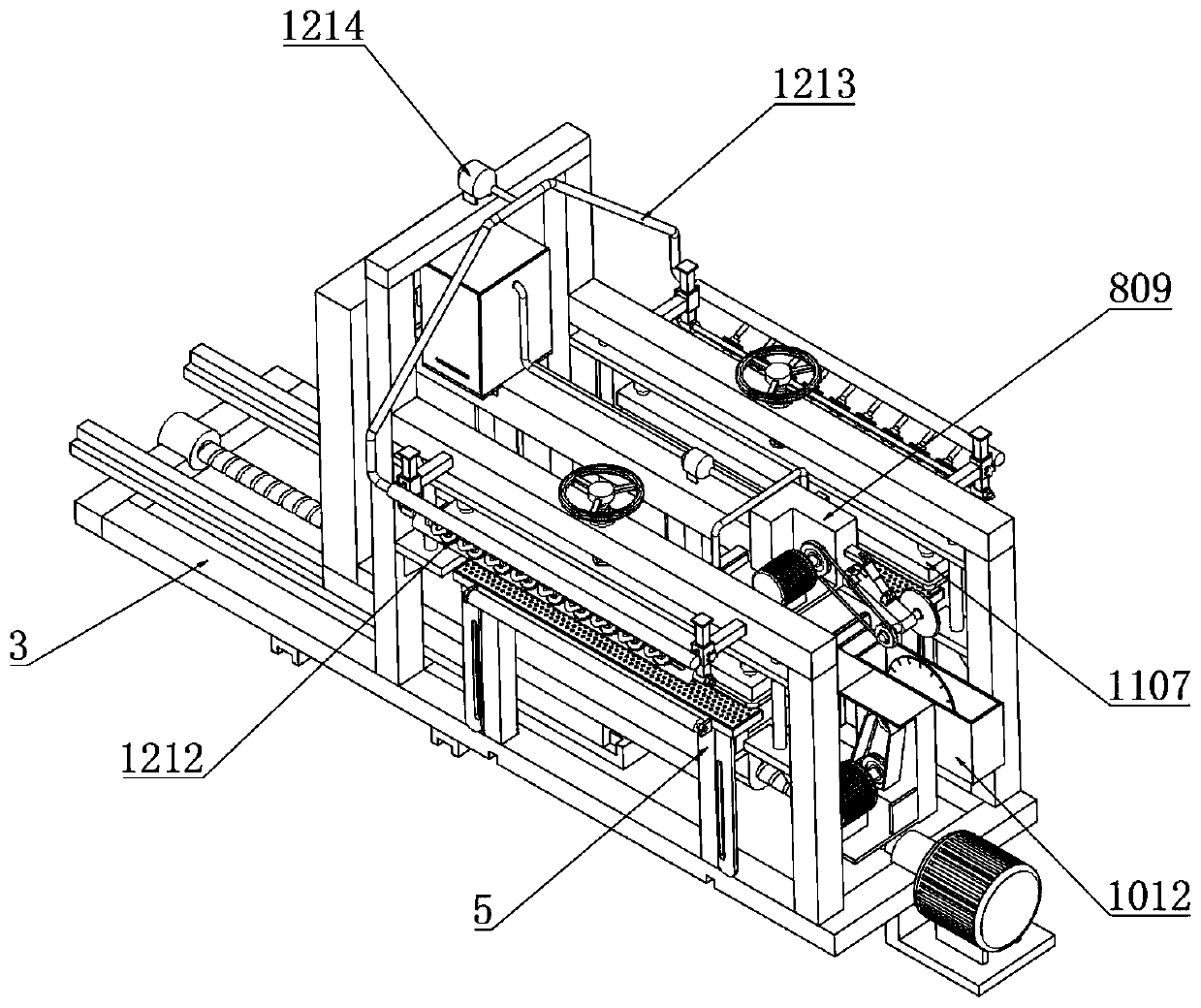

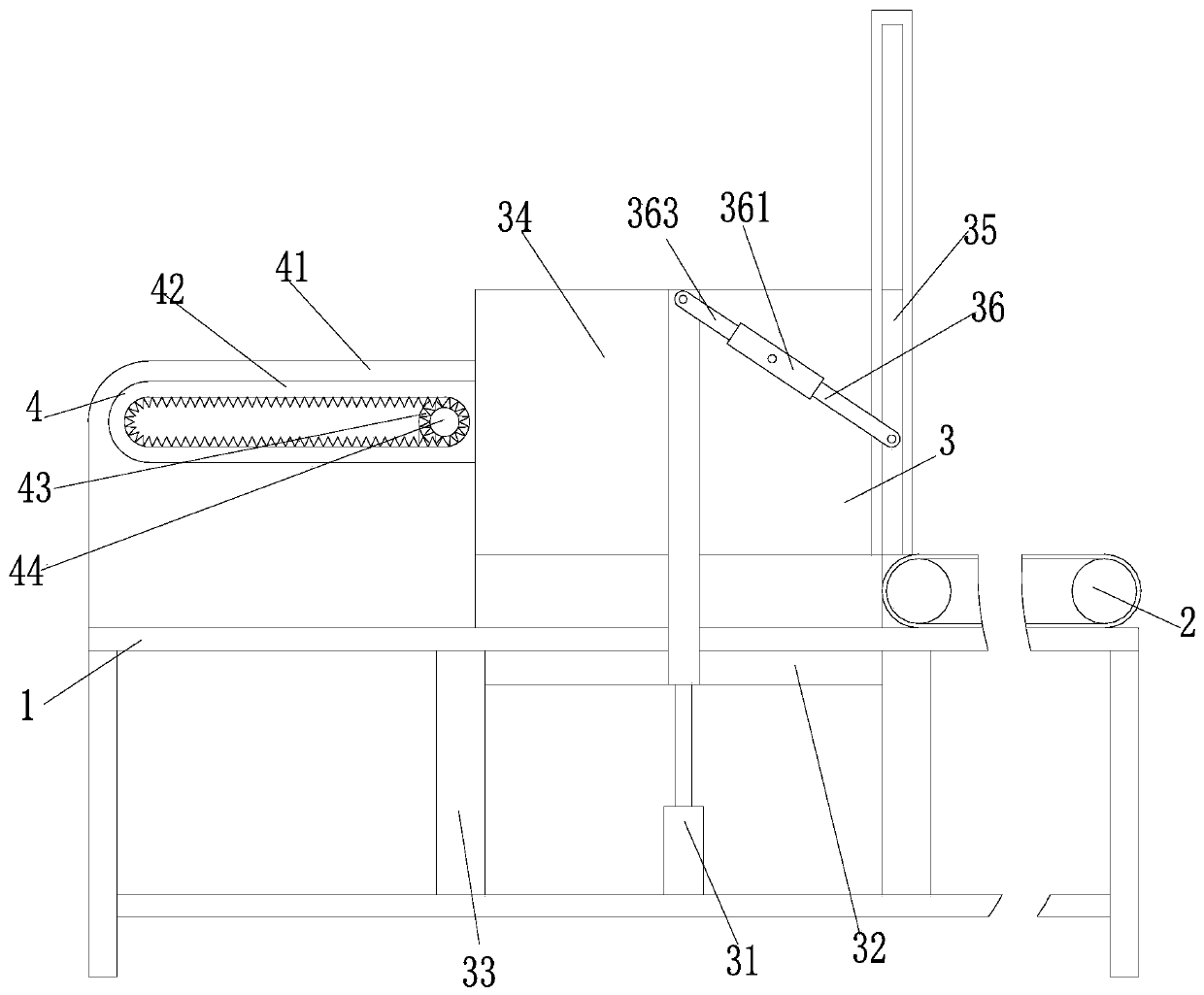

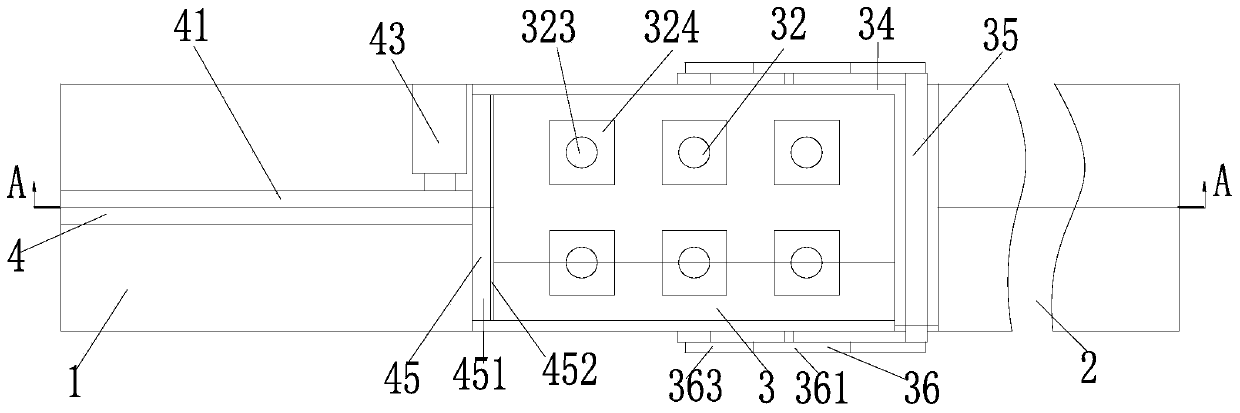

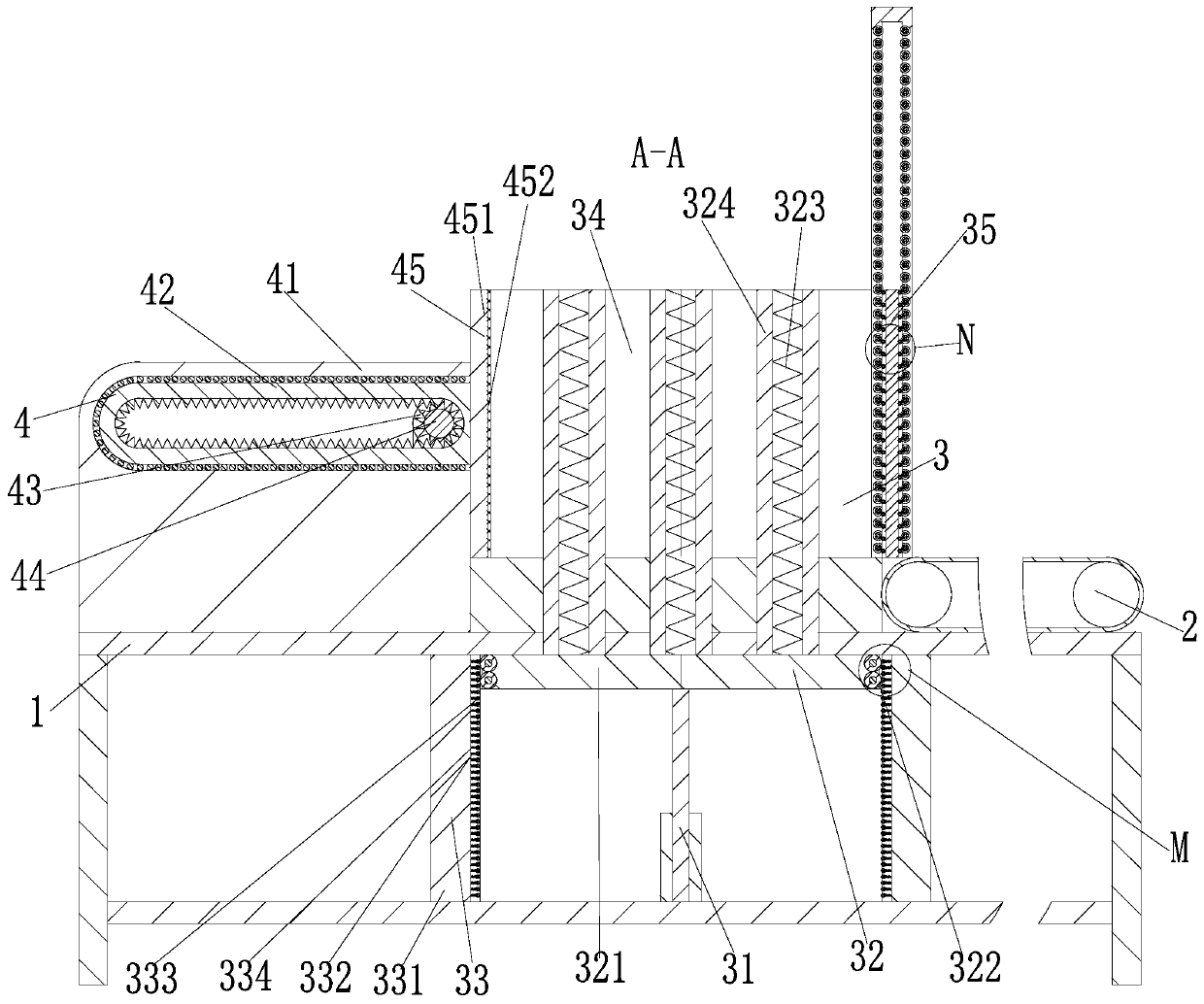

Thermal-insulation concrete block preparing and forming machine and preparing method

ActiveCN110815513AQuality improvementImprove surface qualityMouldsAuxillary shaping apparatusMolding machineStructural engineering

The invention relates to a thermal-insulation concrete block preparing and forming machine and a preparing method. The thermal-insulation concrete block preparing and forming machine comprises a workbench, a belt-type conveyor, a forming device and a block pushing device, wherein the belt-type conveyor is installed on the upper end face of the right side of the workbench, the forming device is installed in the middle of the workbench, and the block pushing device is installed on the upper end face of the left side of the workbench. The forming device comprises a telescopic support, a mold coreframe, a mold core track, a forming frame, a baffle and a connecting rod. According to the thermal-insulation concrete block preparing and forming machine, through the forming device and the block pushing device, the mold core frame vertically pushes out the forming frame, so that the purpose of improving the quality of concrete blocks is achieved; moreover, a toothed plate drives a push plate topush the concrete blocks out of the forming frame, and the purpose of improving the surface quality of the concrete blocks is furthermore achieved; and through threaded rods, mold core pillars are convenient to detach and replace, so that the purpose of expanding the application range of the concrete block preparing machine is achieved.

Owner:山东铭城环保新材料科技有限公司 +1

Shearing equipment with wrinkle removing function for non-woven fabric processing and method

ActiveCN111979750AAvoid displacementReduce cut qualityMechanical cleaningPressure cleaningStructural engineeringNonwoven fabric

The invention discloses shearing equipment with the wrinkle removing function for non-woven fabric processing, and belongs to the technical field of non-woven fabric processing equipment. The shearingequipment comprises a workbench, a fixing frame is arranged at the top of the workbench, a second electric telescopic rod, an electric hydraulic rod and a third electric telescopic rod are arranged in an inner cavity of the fixing frame from right to left, top bases are arranged at the tops of the second electric telescopic rod, the electric hydraulic rod and the third electric telescopic rod, afirst U-shaped frame is arranged at the bottom of the second electric telescopic rod, a winding roller is arranged in an inner cavity of the first U-shaped frame, the first U-shaped frame is rotationally connected with the winding roller through a first rotating shaft, a shearing assembly is arranged at the bottom of the electric hydraulic rod, a winding assembly is arranged at the bottom of the third electric telescopic rod, and the periphery of a right shaft is sleeved with a driving roller. The shearing device for non-woven fabric processing can conduct fixed-width shearing on non-woven fabric and can iron and remove wrinkles of the non-woven fabric after shearing so as to guarantee the processing quality of the non-woven fabric.

Owner:瑞安市兴源塑料制品有限公司

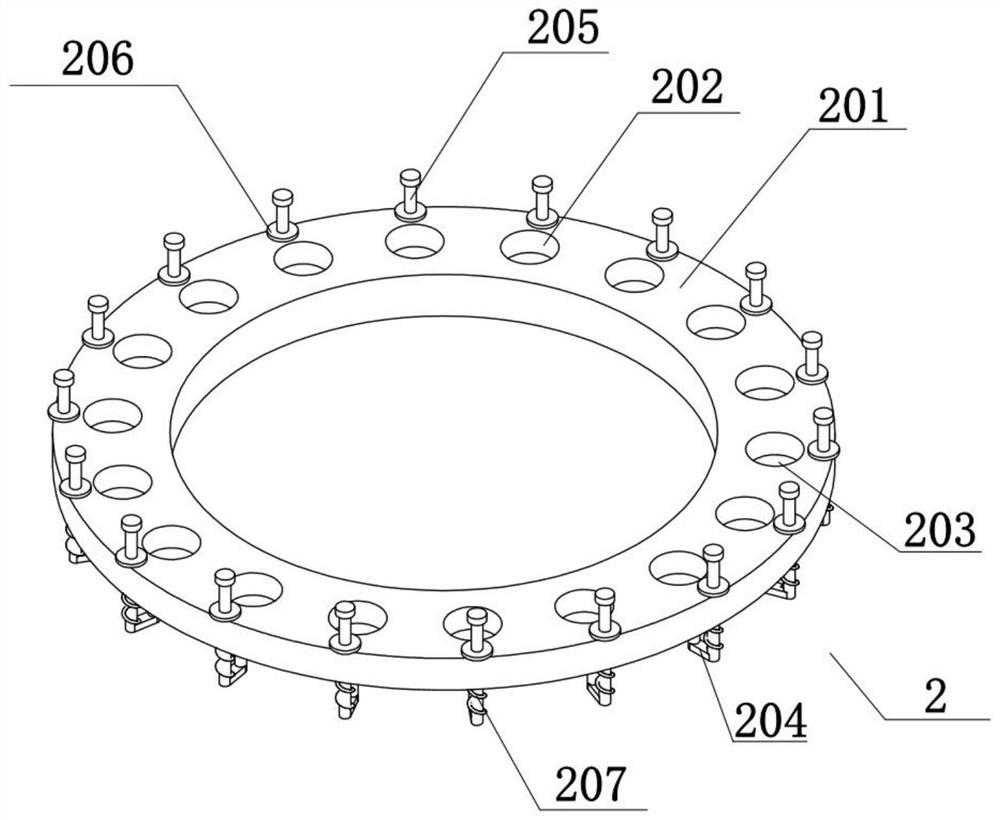

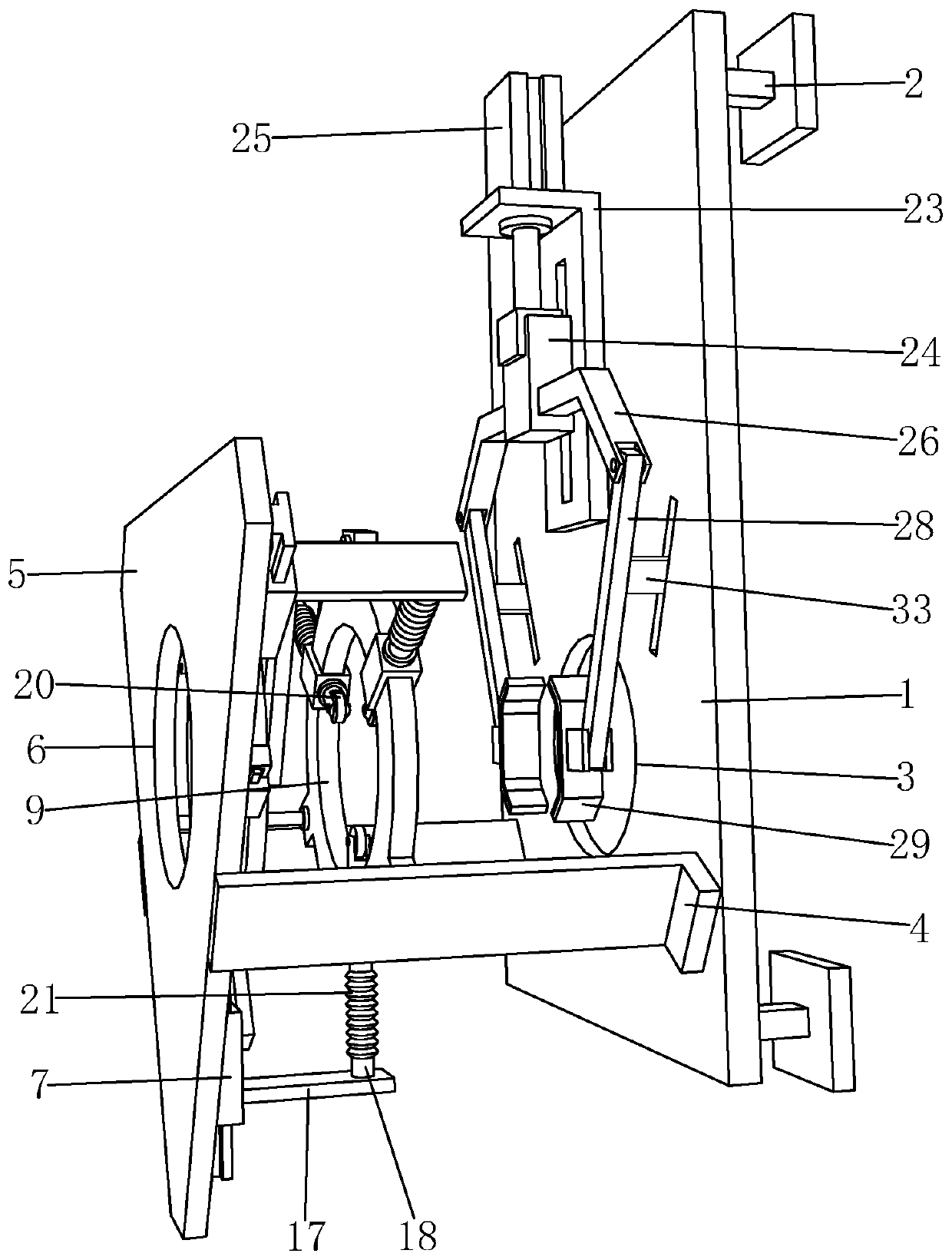

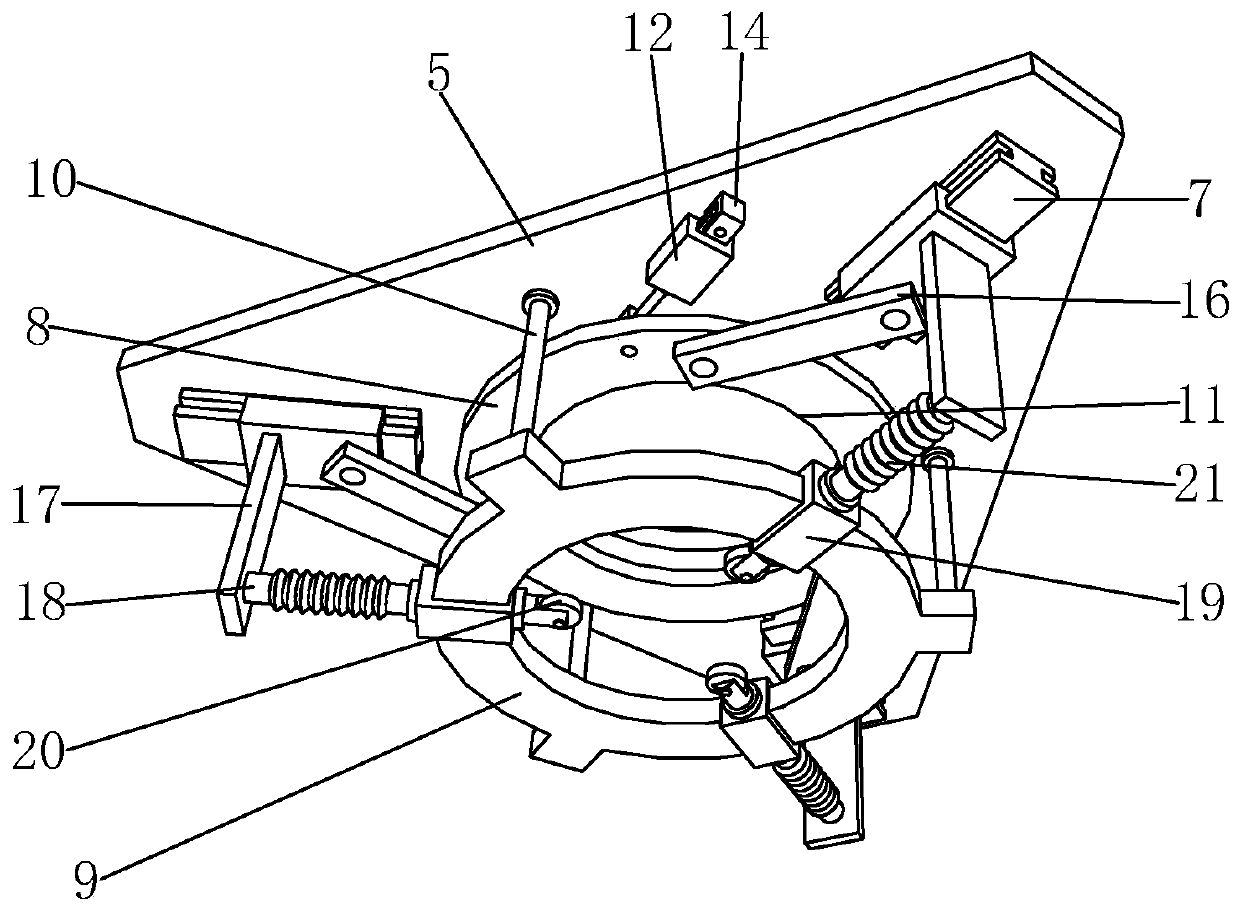

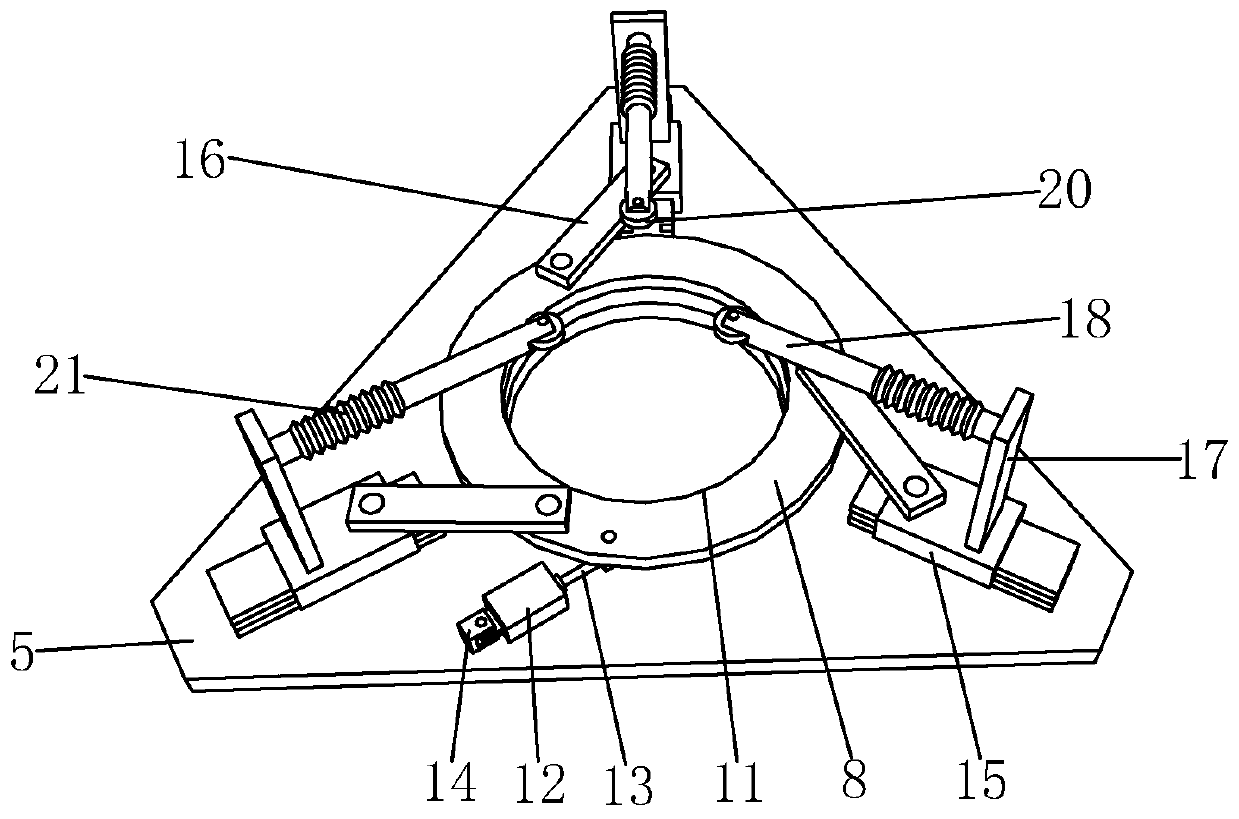

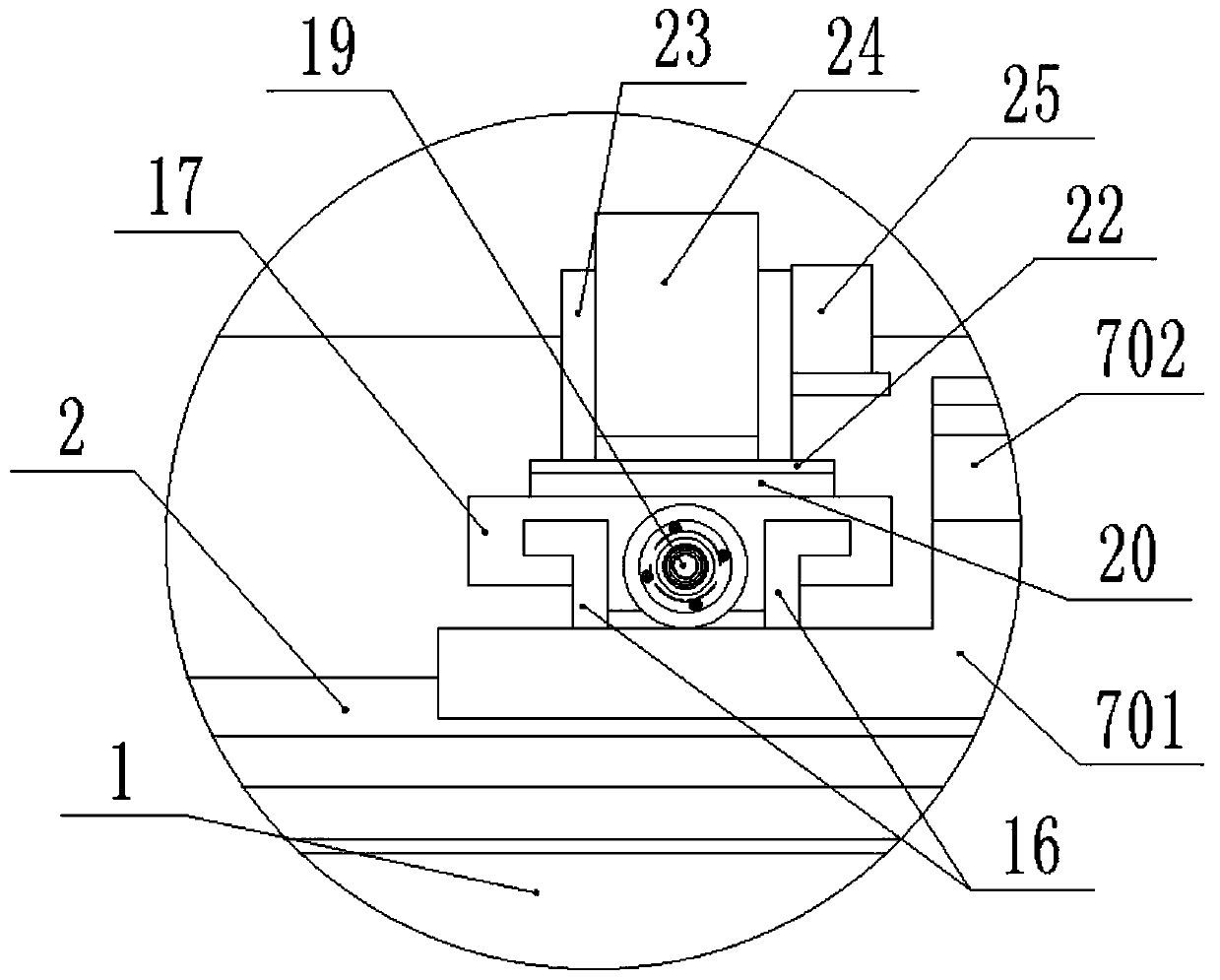

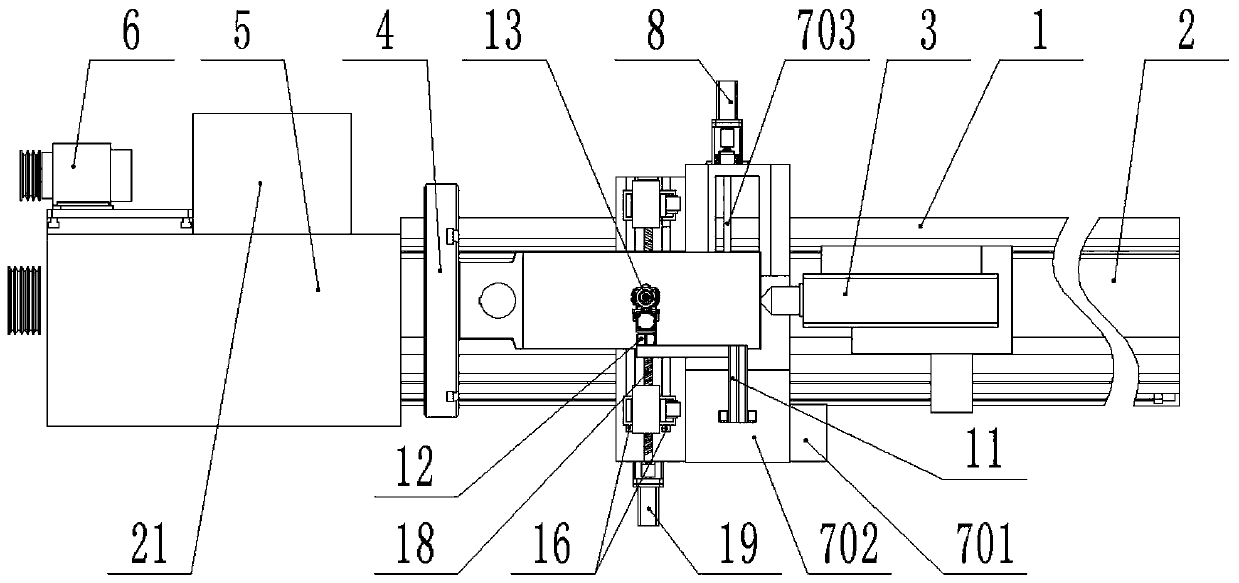

Clamping platform for hardware pipe machining

The invention discloses a clamping platform for hardware pipe machining. The clamping platform for hardware pipe machining comprises a workbench. A holding groove is formed in the workbench, and supporting frames are arranged on the workbench. A triangular plate is arranged between the supporting frames, a fixing through hole is formed in the center of the triangular plate, and fixing guide railsand a driving mechanism are arranged on the bottom surface of the triangular plate. A locating disc is arranged below the triangular plate, a clamping ring is arranged below the locating disc, and supporting columns are arranged between the clamping ring and the triangular plate. A holding through hole is formed in the locating disc. One end of the driving mechanism is connected with the locatingdisc. Sliding blocks are connected to the fixing guide rails in a sliding mode, transmission rods are connected between the sliding blocks and the locating disc, and the driving mechanism is connectedwith the locating disc. Fixing plates are arranged on the sliding blocks, and clamping rods are arranged on the fixing plates. Fixing clamping bases are distributed on the clamping ring in a surrounding mode, the clamping rods pass through the fixing clamping bases, and a clamping wheel is connected with one end of each clamping rod. The clamping platform for hardware pipe machining is novel in structure and convenient to use, can be suitable for hardware pipes with different pipe diameters, is broad in application range and firm to clamp and fix, and facilitates various kinds of machining operation.

Owner:浙江缔鹏实业有限公司

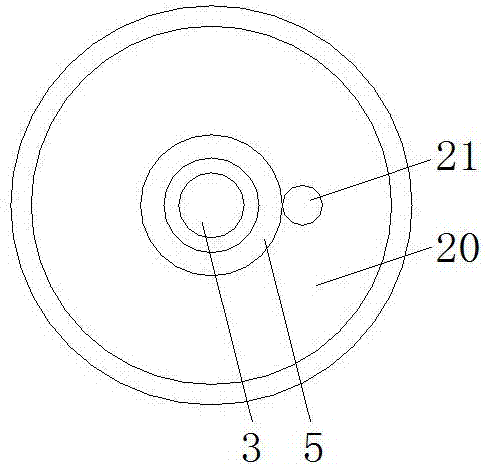

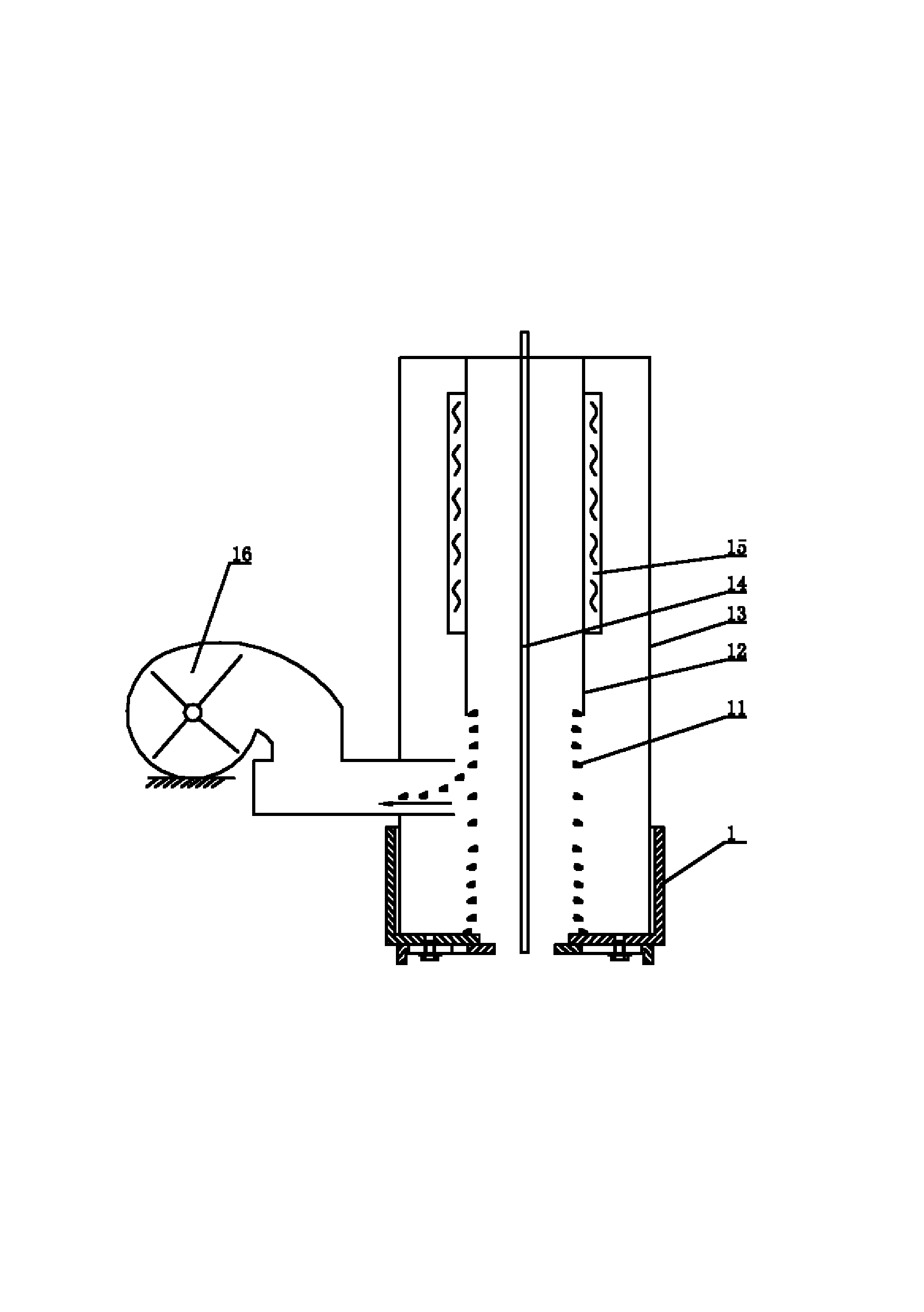

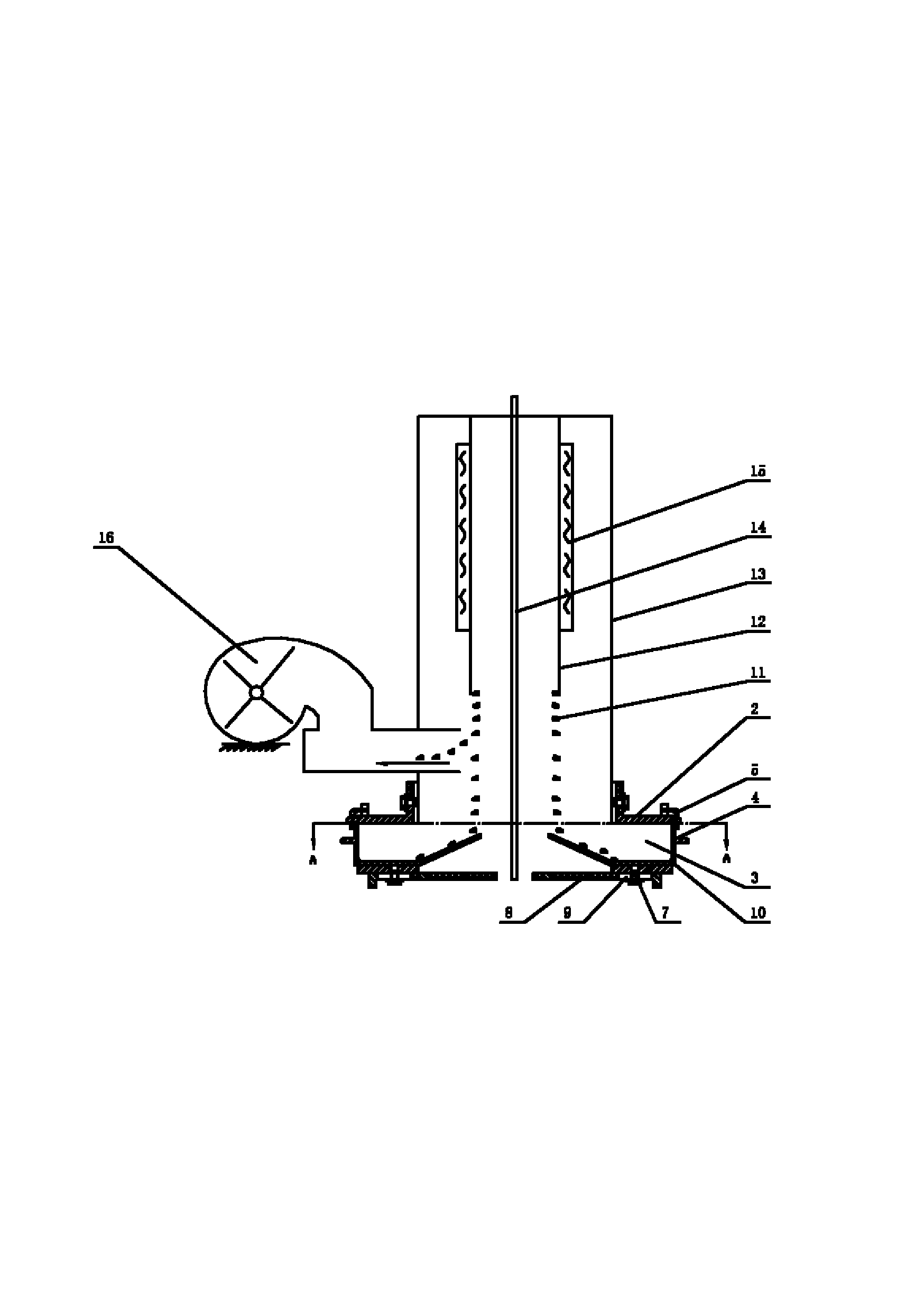

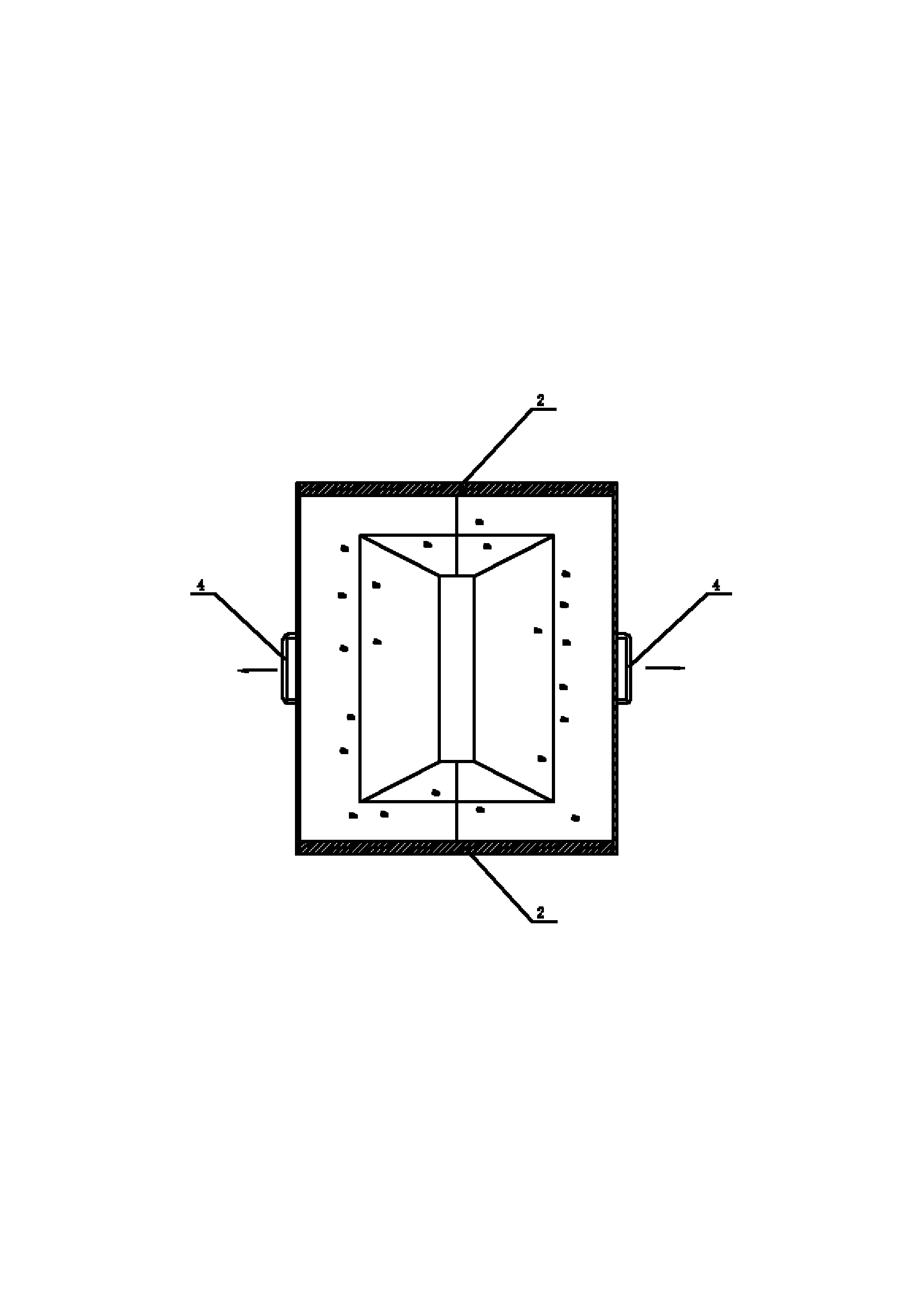

Machining device for center hole of motor heat dissipation wheel of new energy automobile

InactiveCN111745181AAffect processing qualityPlay a supporting rolePositioning apparatusMaintainance and safety accessoriesNew energyElectric machinery

The invention relates to the technical field of new energy automobiles, and particularly discloses a machining device for a center hole of a motor heat dissipation wheel of a new energy automobile. The machining device for the center hole of the motor heat dissipation wheel of the new energy automobile comprises a base and further comprises a fixing mechanism, a punching mechanism and a chipping cleaning mechanism; the fixing mechanism is arranged on the base and comprises vertical plates, a long groove and a L-shaped plate, the vertical plates are symmetrically and fixedly connected to the top of the base, the long groove is formed in the base, and the L-shaped plate is fixedly connected to the left side of the base; and the punching mechanism is arranged above the fixing mechanism. According to the machining device for the center hole of the motor heat dissipation wheel of the new energy automobile, a clamping plate is driven to move through two first hydraulic telescopic rods, so that a heat dissipation wheel is clamped, and a supporting block plays a supporting role; a motor drives a punching drill bit to rotate, punching of the heat dissipation wheel is achieved, meanwhile, fan blades are finally driven to rotate through the motor, and therefore chippings generated by punching are blown down into a collecting box, the effect of conveniently cleaning chippings is achieved,and the chippings are prevented from adhering to the heat dissipation wheel to affect the machining quality of the heat dissipation wheel.

Owner:孙雪峰

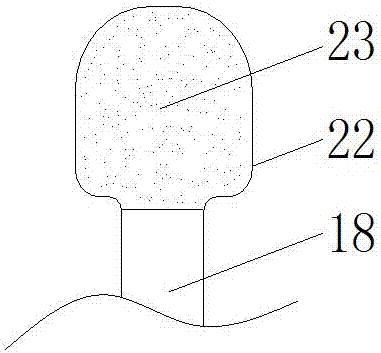

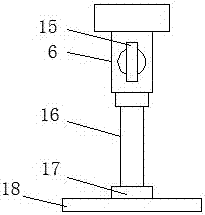

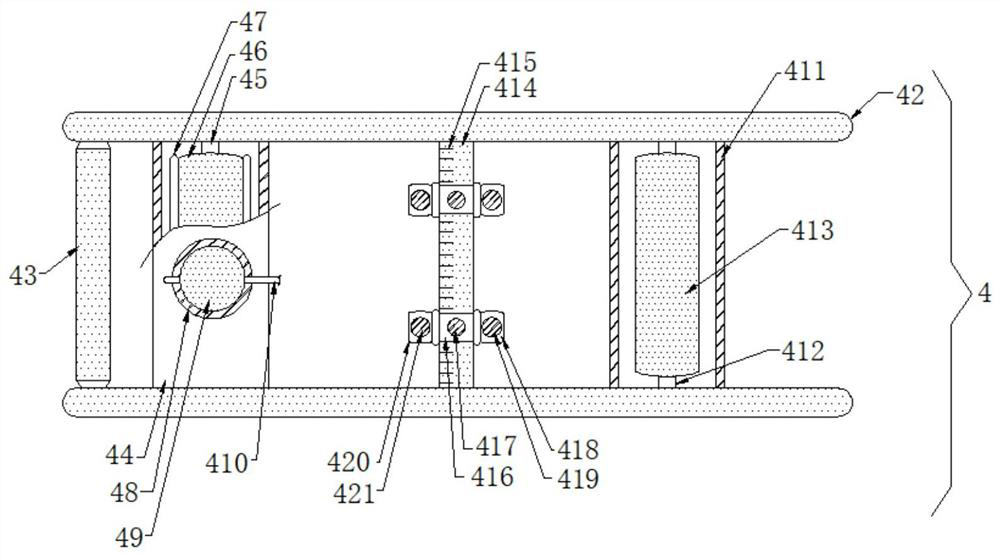

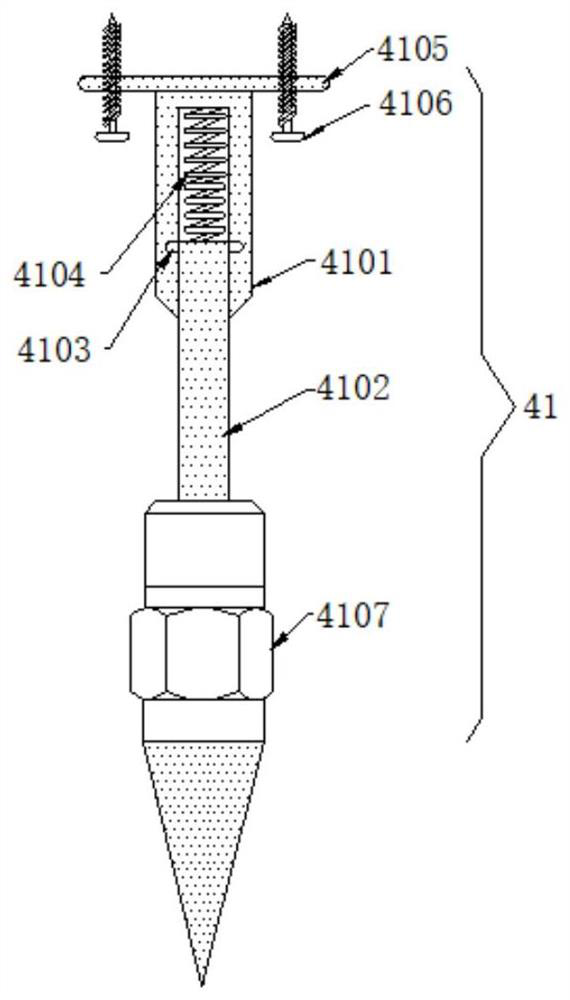

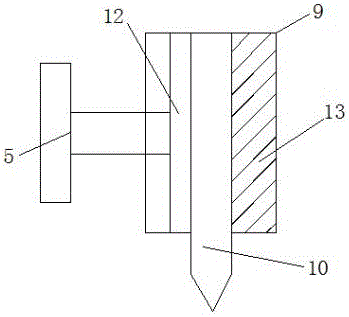

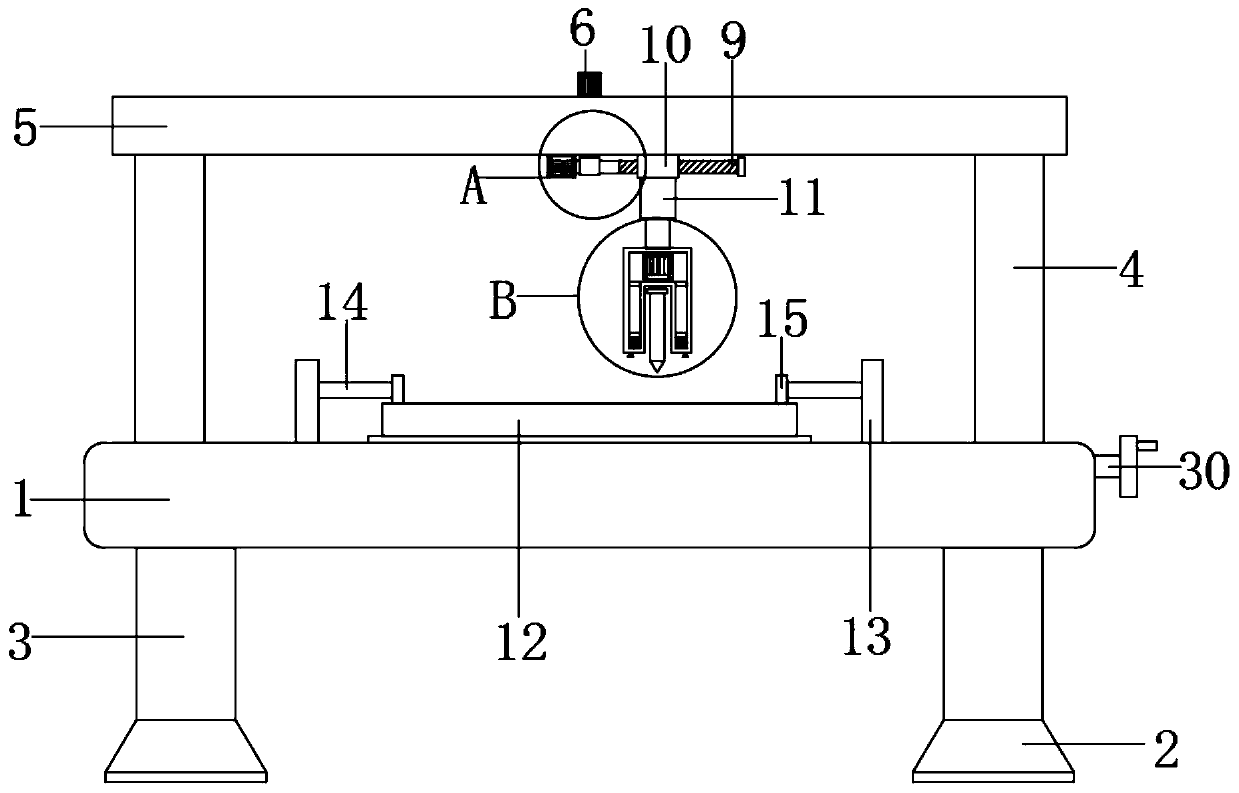

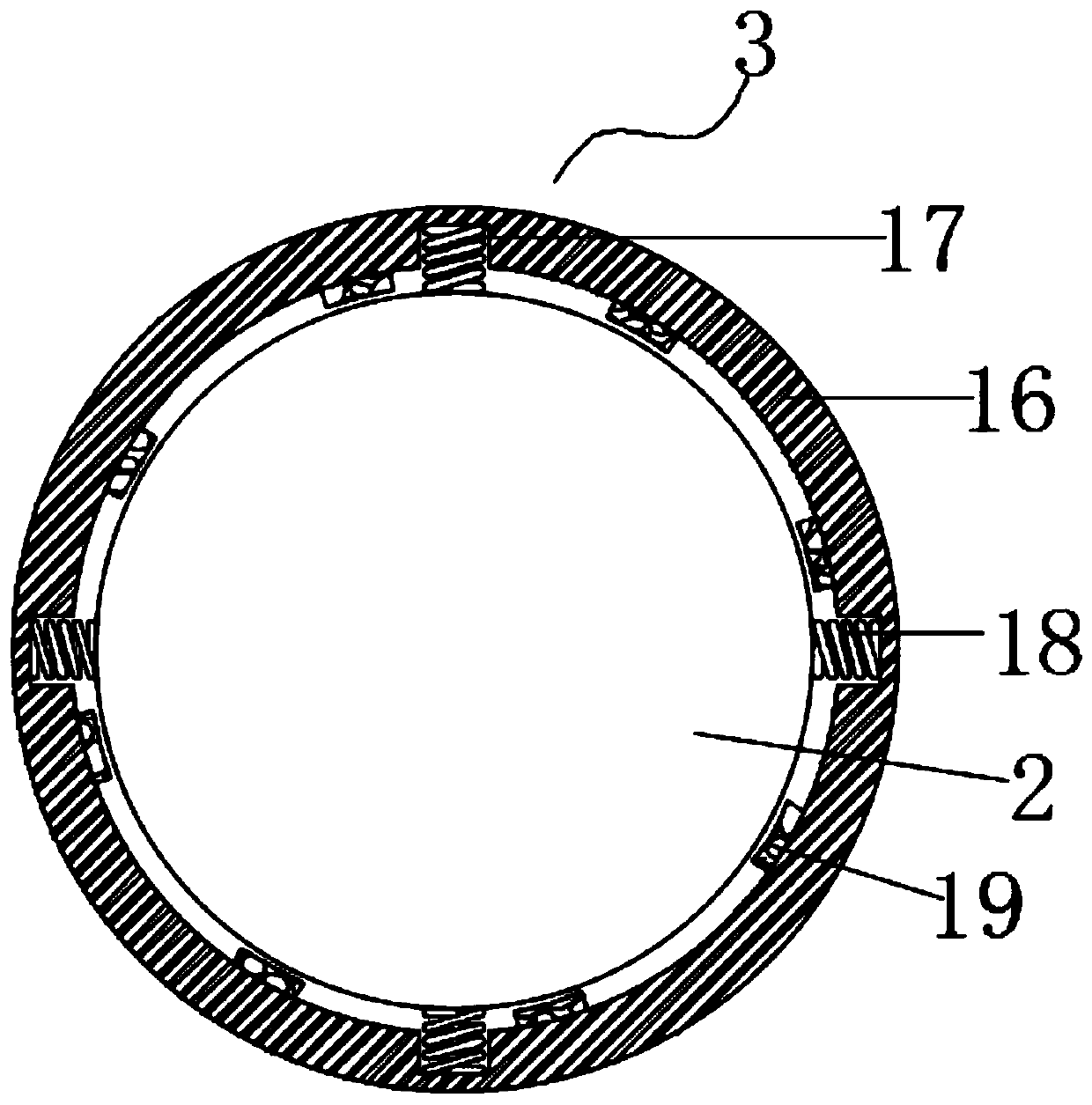

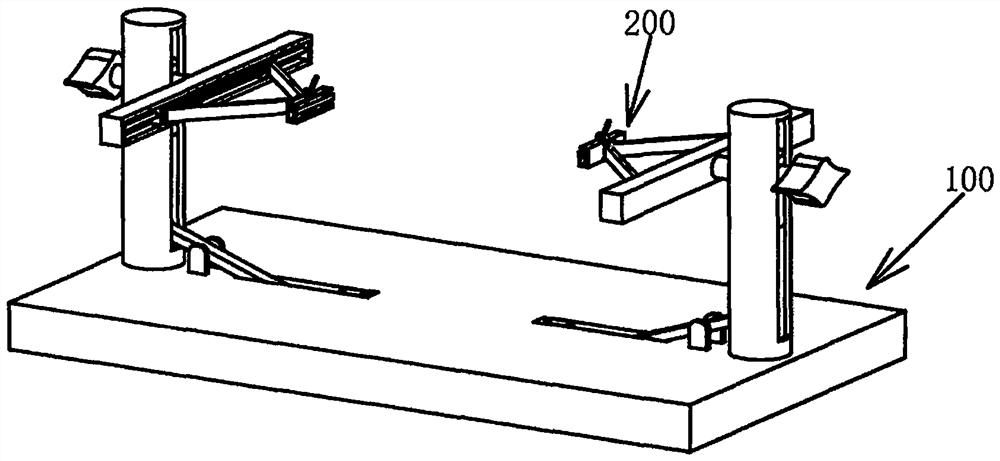

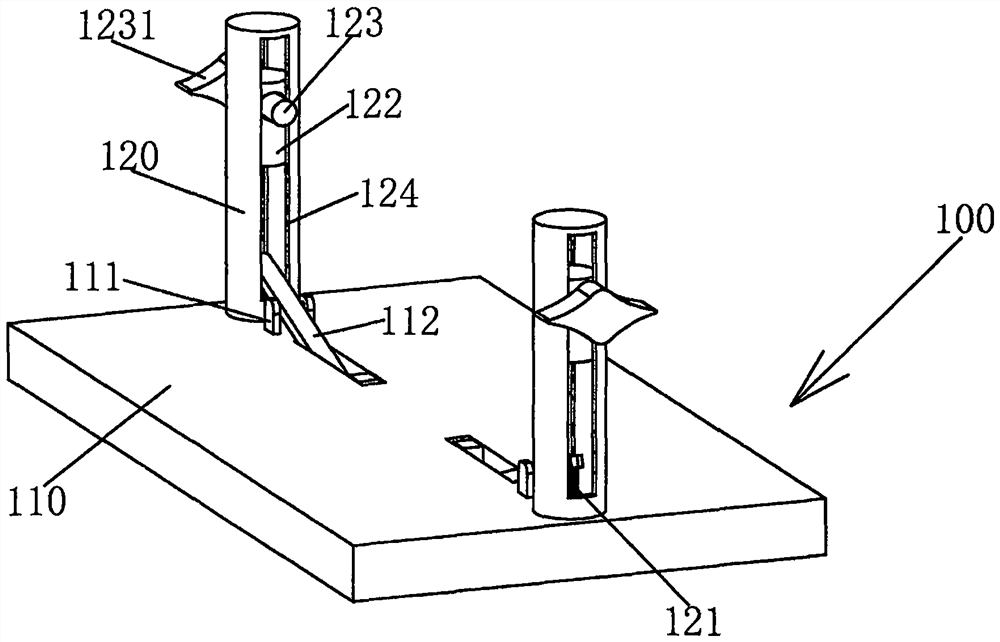

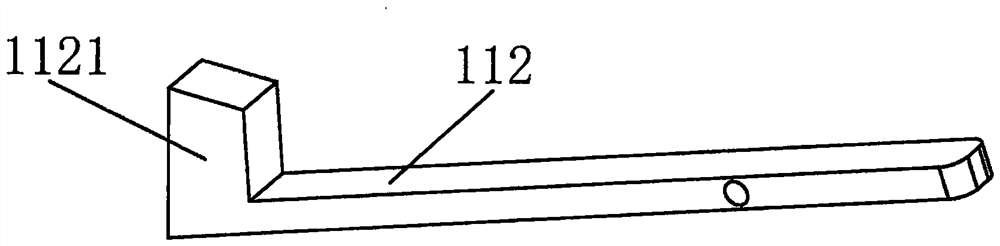

Small and precise lineation device

InactiveCN106041872AHeight adjustableNo marking errorOther workshop equipmentEngineeringMechanical engineering

Owner:WUXI FUMEI LIGHT ALLOY TECH

Milling machine with stabilizing mechanism for machining

InactiveCN111069667AReduce vibrationAffect processing qualityMilling machinesLarge fixed membersElectric machineryEngineering

The invention discloses a milling machine with stabilizing mechanism for machining in technical field of machining. The milling machine comprises a workbench, supporting legs are fixedly connected tothe lower end of the workbench, stabilizing mechanisms are arranged on the outer sides of the supporting legs correspondingly, fixing plates are fixedly connected to the two sides of the upper end ofthe workbench correspondingly, the upper ends of the fixing plates are fixedly connected to a top plate, a first motor is arranged in the middle of the upper end of the top plate, the power shaft endof the first motor is fixedly connected to a fixed sleeve, a positioning rod is rotationally connected into the fixed sleeve and is in threaded connection with a threaded sleeve, an electric telescopic rod is fixedly connected to the lower end of the threaded sleeve, the lower end of electric telescopic rod is fixedly connected with machining mechanism, and an object carrying platform is fixedly connected to the middle of the upper end of the workbench. Vibration generated in the horizontal direction of the workbench can be buffered through a stabilizing mechanism, the workbench can be stablyplaced on the ground, the position of the machining mechanism can be adjusted through a positioning rod so as to meet the machining requirements of different positions, and chippings generated duringmachining can be adsorbed through fan, and unified cleaning is facilitated.

Owner:丽水市翔隆自动化设备制造有限公司

Clamping tool for producing and welding computer component

InactiveCN112338315AAffect processing qualityAffect processing efficiencyWelding/cutting auxillary devicesAuxillary welding devicesMachiningPhysics

The invention relates to the technical field of electronic machining, in particular to a clamping tool for producing and welding a computer component. The clamping tool comprises a supporting mechanism and a clamping mechanism, wherein the supporting mechanism comprises a bottom plate and cylinders, and the top surface of the bottom plate is sequentially, symmetrically and fixedly connected with two first rotating bases and two cylinders with the respective of the vertical central plane of the bottom plate. According to the clamping tool for producing and welding the computer component, one ends of pressing plates penetrate through arc-shaped notches, the bottom surfaces of the pressing plates are fixedly connected with one ends of reset springs, the other ends of the reset springs are fixedly connected with the bottom surfaces of inner cavities of the cylinders, the other ends of the pressing plates are fixedly connected with convex blocks, when sliding columns move downwards and makecontact with the pressing plates, the convex blocks make contact with the middle of the bottom surface of a circuit board, the circuit board can be placed stabler, when the circuit board needs to beturned over after the sliding columns ascend, the convex blocks move downwards into the bottom plate, and therefore the situation that the long sides of the circuit board abut against the convex blocks in a rotating process due to the fact that the width of the circuit board is larger is avoided, and safe and high-quality machining of the circuit board is guaranteed.

Owner:CHONGQING COLLEGE OF ELECTRONICS ENG

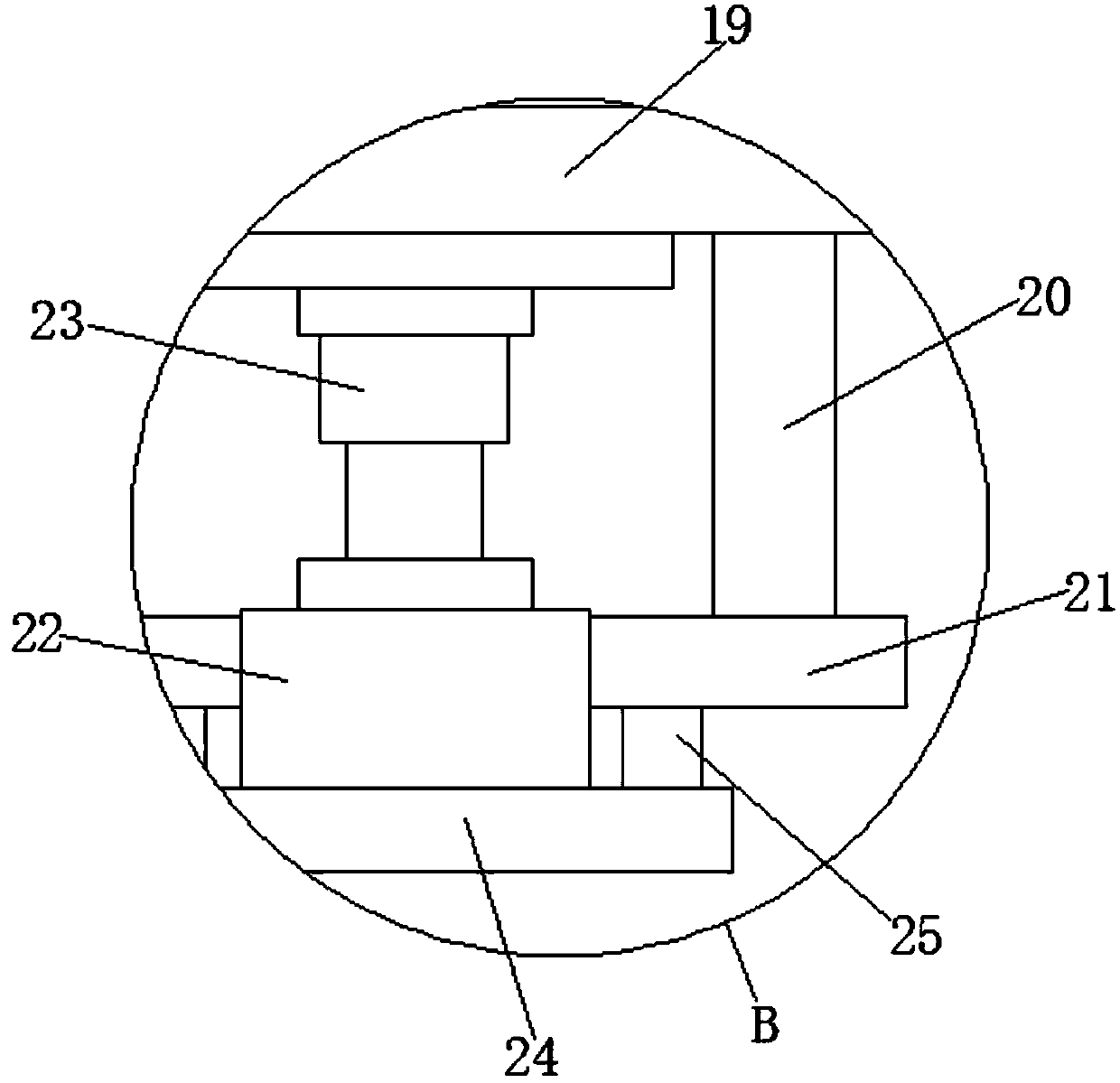

Valve stamping method with adjustment and use being convenient

InactiveCN107812819AEasy to adjustEasy to useShaping toolsMetal-working feeding devicesEngineeringMachining process

The invention relates to the technical field of valve processing, and discloses an easy-to-adjust and easy-to-use valve stamping method. The cooperating use of block (13) can when the situation of displacement occurs in the process of object processing, can rotate the movement of slide block (13) by adjusting handle (12), thereby drives the movement of storage plate (7), can It is convenient for the user to adjust the object, and at the same time, it can prevent the user from being hurt, effectively improves the practicality and safety, and can meet the needs of the user. By setting the positioning plate (19), the support frame (20), and the stamping seat (21), the limit sleeve (22) and the air cylinder (23) can be used together to reduce the force on the stamping seat (21) during use, and play a buffer role to prevent the stamping seat (21) from The force received is too large, which affects the processing quality of the object, and solves the problem that it is inconvenient to move when the workpiece is displaced during the processing process, resulting in a reduction in the processing quality.

Owner:楼浩伟

Stone cutting equipment with raw material fixing function

InactiveCN108638349APrevent shock shiftImprove practicalityWorking accessoriesStone-like material working toolsPhysical healthFiltration

The invention relates to stone cutting equipment with a raw material fixing function. The stone cutting equipment with the raw material fixing function comprises a main body, a cutting device and a bracket and also comprises a fixing mechanism and a dedusting mechanism, wherein the fixing mechanism comprises a shell, a moving assembly and a fastening assembly; the dedusting mechanism comprises a suction nozzle, a connecting pipe, an air pump, a purification chamber, a filtration chamber and a spray nozzle. According to the stone cutting equipment with the raw material fixing function, the position of a rubber block can be moved through the fixing mechanism to fix stones of different sizes. Compared with existing stone cutting equipment, the condition that the cutting precision is reduced and the processing quality is affected as stones vibrate and deviate in the processing course is prevented. Moreover, the saw web damaged extent is reduced, and the service life of the equipment is prolonged. The stone cutting equipment with the raw material fixing function can absorb dust through the dedusting mechanism. Compared with the existing stone cutting equipment, the construction environment is improved, the influence of dust on physical health of people is reduced, and the practicality and reliability of the stone cutting equipment are improved greatly.

Owner:福建奕圣科技有限公司

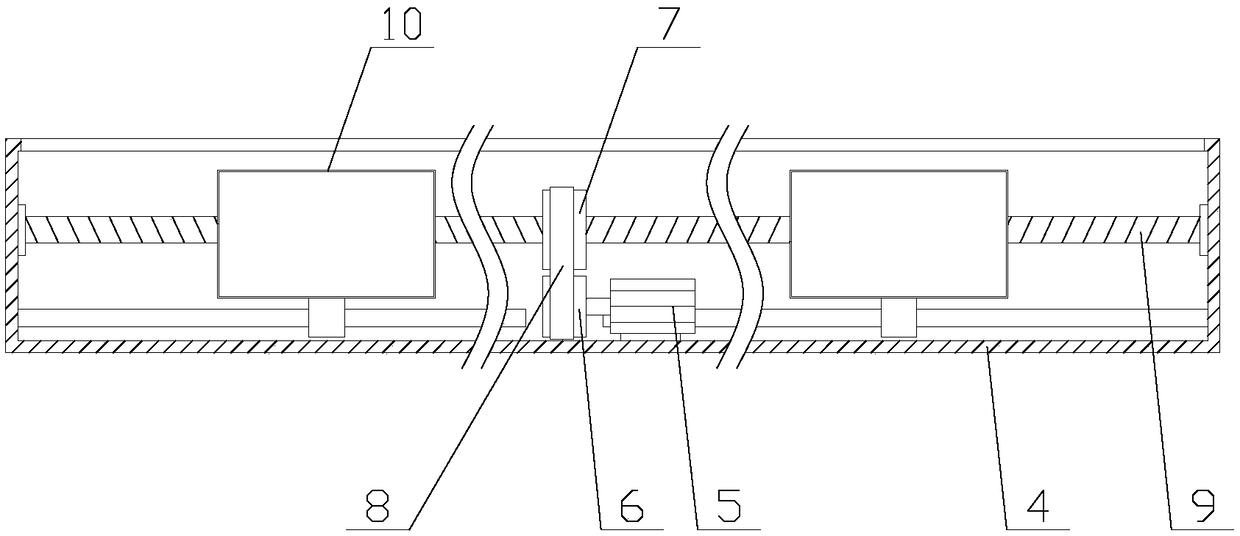

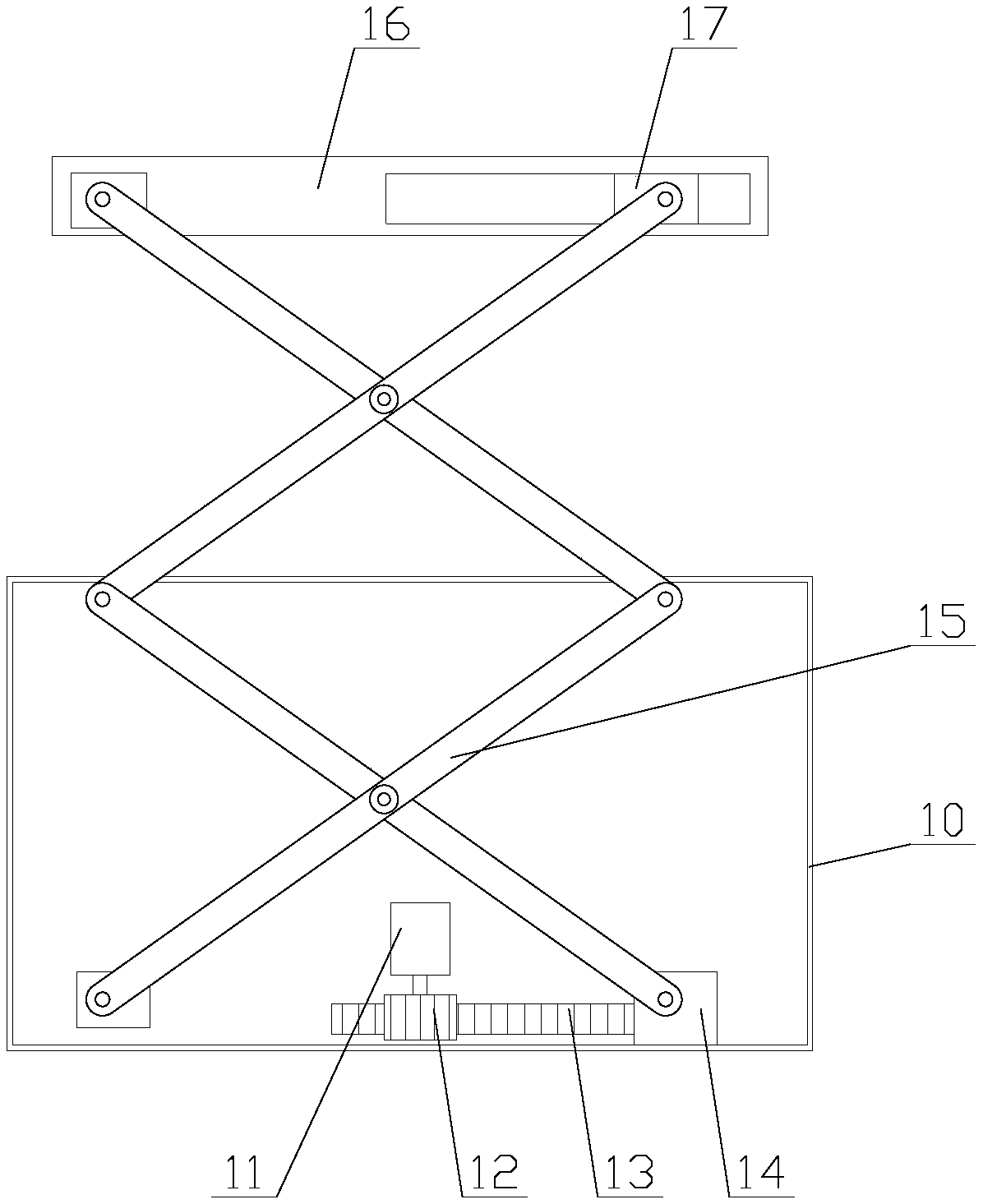

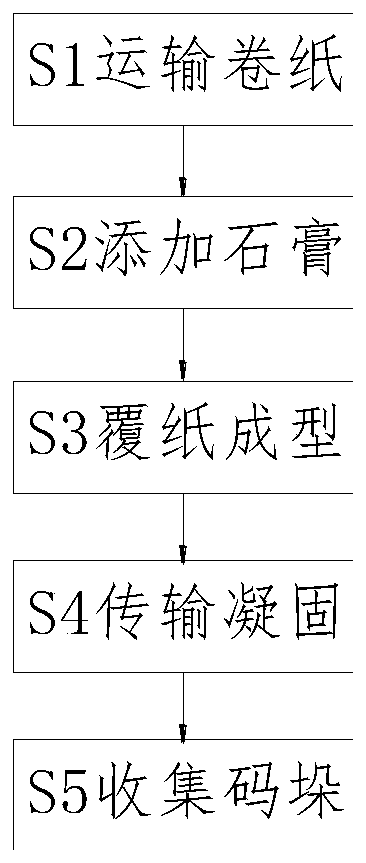

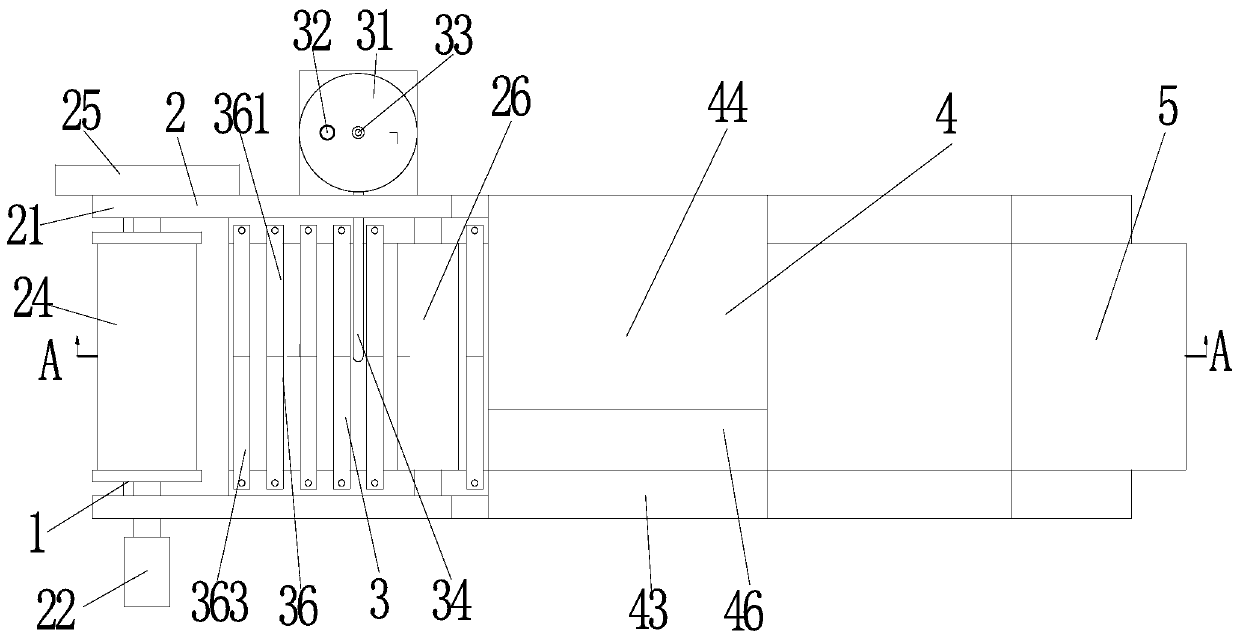

Gypsum plaster board manufacturing and forming method

InactiveCN111360975AQuality assuranceQuality impactAuxillary shaping apparatusRolling paperEngineering

The invention relates to a gypsum plaster board manufacturing and forming method. Gypsum plaster board manufacturing and forming equipment comprises a workbench, a paper coating device, a conveying device, a forming device and a belt conveyor, wherein the paper coating device is arranged at the upper end of the left side of the workbench, the conveying device is arranged at the right end of the paper coating device, the forming device is arranged at the right end of the conveying device, and the belt conveyor is arranged at the right end of the forming device. According to the gypsum plaster board manufacturing and forming method, roll paper on the upper side and roll paper on the lower side are conveyed through the paper coating device, so that the roll paper is prevented from inclining and falling off; gypsum slurry is stirred and filtered through the conveying device, so that the quality of gypsum boards is guaranteed; the flowing track of the gypsum slurry is controlled, so that the gypsum slurry is prevented from being splashed; roll paper on the upper side is squeezed through the forming device, so that the purpose that the gypsum slurry makes full contact with the roll paperis achieved, and meanwhile, the situation that the quality of the gypsum boards is affected due to the fact that the roll paper on the upper side and the roll paper on the lower side are attached tothe forming device is avoided.

Owner:盛亚明

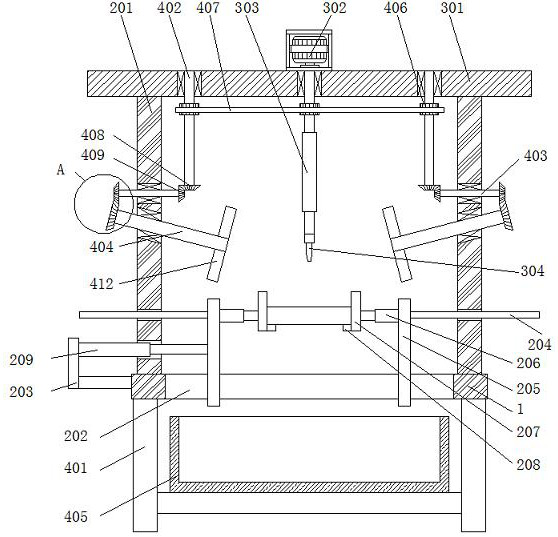

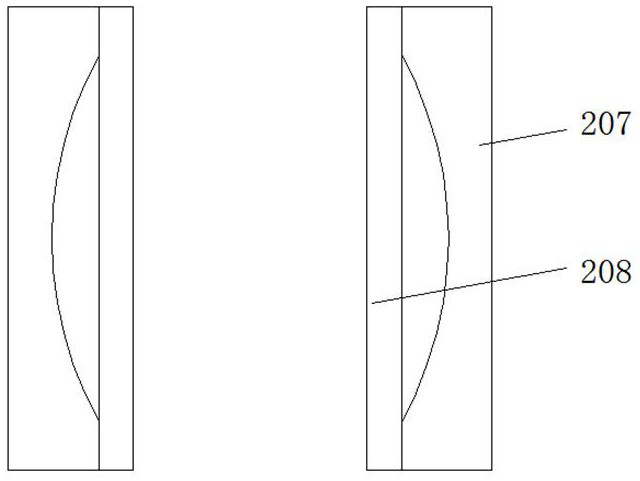

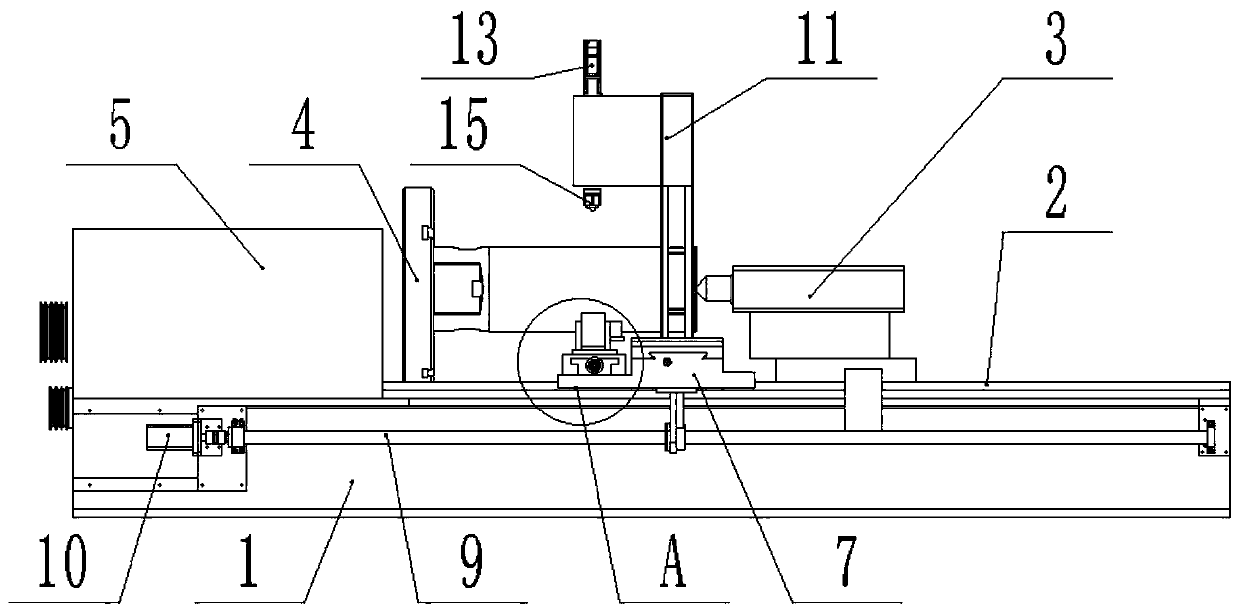

High-speed laser cladding processing machine tool and processing method

InactiveCN111451845AStable supportRelieve stress concentrationGrinding carriagesGrinding drivesEngineeringMachine tool

The invention discloses a high-speed laser cladding processing machine tool, and belongs to the technical field of machine tool processing. The high-speed laser cladding processing machine tool comprises a base, wherein a slide rail is arranged on the base; a rotary ejector pin is arranged on the slide rail in a sliding mode; one end of the slide rail is equipped with a chuck; the chuck is connected to a reduction box; the reduction box is connected to a first servo motor; a first slide table is mounted on the slide rail; one end of the first slide table is connected to a second servo motor, and the other end of the first slide table is connected to a first lead screw; the first lead screw is connected to a third servo motor; a bracket is fixedly mounted on the first slide table; a secondslide table is mounted on the bracket; one end of the second slide table is equipped with a fourth servo motor; a laser cladding head bracket for mounting a laser cladding head is fixedly arranged onthe second slide table; a small slide rail is arranged on the first slide table at one side of the laser cladding head bracket; two movable bases are mounted on the small slide rail in the sliding mode; the movable bases are connected to a two-way lead screw; the two-way lead screw is connected to a fifth servo motor; a grinding mechanism is mounted on the movable bases; and a damping mechanism ismounted between the movable bases and the grinding mechanism.

Owner:山东高锻机械有限公司

Double-shaft blending device used for selenium-rich rice processing

PendingCN108371898AAvoid cakingAdequate responseRotary stirring mixersTransportation and packagingEngineeringProcessing cost

The invention discloses a double-shaft blending device used for selenium-rich rice processing, comprising a bottom plate, wherein an expansion link is fixedly connected to the right side of the top ofthe bottom plate, a case is rotationally connected to the top end of the expansion link by a first rotating block, a protection box is fixedly connected to the left side of the case, a blending box is fixedly connected to the left side of the protection box, and a first motor is fixedly connected to the bottom of the inner wall of the case. According to the double-shaft blending device used for selenium-rich rice processing, due to the arrangement of two blending rods, blending effect and blending efficiency are improved, so that selenium-rich rice sufficiently reacts with additives; and thecaking of the selenium-rich rice is avoided; the selenium-rich rice can also be mixed with other materials, so that the practicability of the device is improved, material can be conveniently discharged from the discharge hole, operation is simple, the material is prevented from being left in the blending box, processing cost is lowered, and workers can conveniently observe the amount of the additives in the storage box and the amount of the additives added into the blending box, so as to prevent excessive use amount of the additives to avoid affecting the processing quality of the selenium-rich rice.

Owner:SHITAI COUNTY XINTIAN OILS CO LTD

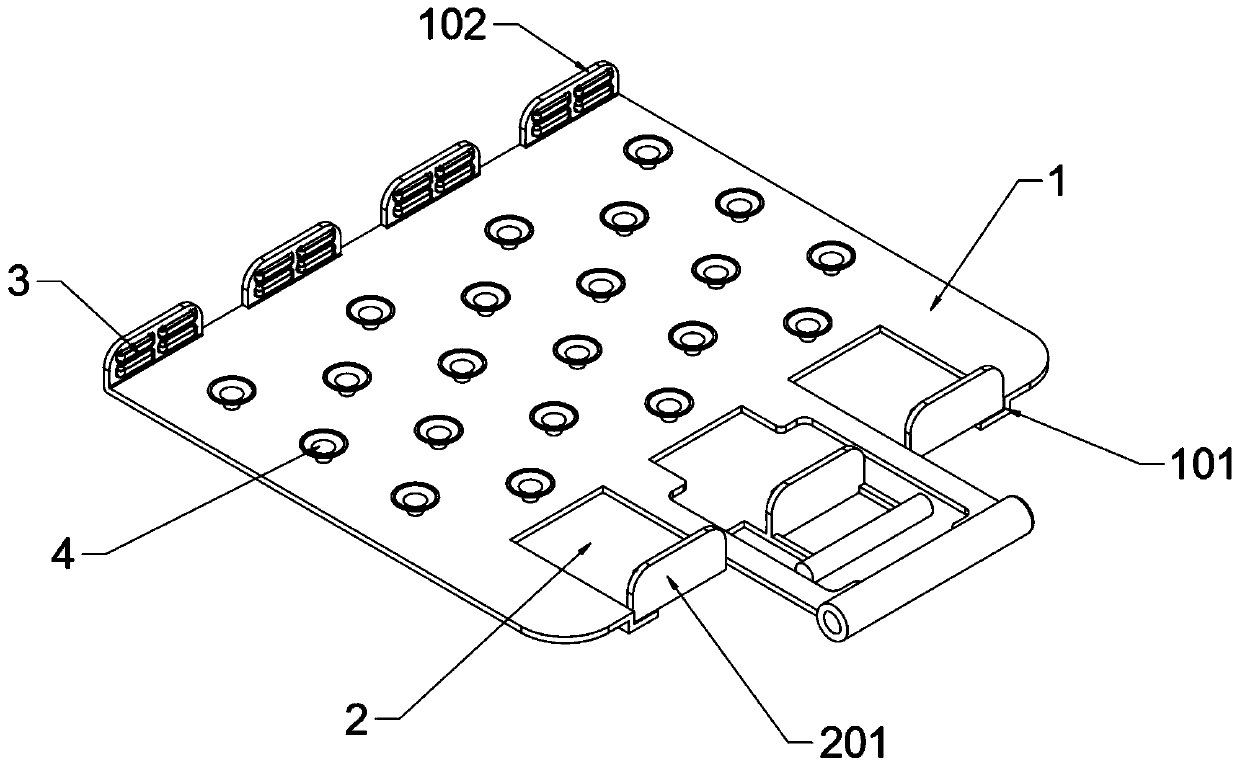

Clamping device for machining PCB and equipped with flexible clamping body structure

ActiveCN110035616AEasy to detectGuarantee product qualityCircuit board tools positioningEngineeringProduction quality

The invention provides a clamping device for machining a PCB and equipped with a flexible clamping body structure. The clamping device comprises a transmission motor and a control electric box; the clamping plate is of a rectangular plate-shaped structure, and the right end of the clamping plate is of a handle-shaped structure; a movable clamping plate is located at the bottom of the clamping plate, the right end of the movable clamping plate is of a handle-shaped structure, and both the clamping plate and the movable clamping plate are made of transparent plastic; latex blocks are arranged atfourteen positions, and the latex blocks are arranged on the outer side end surfaces of a main clamping block and an auxiliary clamping block, so that the main clamping block and the auxiliary clamping block are attached to the left end and the right end of the PCB respectively, the PCB is fixed inside the clamping plate, the PCB is conveniently detected by workers, and the production quality ofthe PCB is guaranteed; and the use of a tension spring is matched, so that the movable clamping plate can be driven to slide in a sliding groove at the bottom of the clamping plate, so that the main clamping block at the left end of the clamping plate 1 and the auxiliary clamping block at the right end of the movable clamping plate can be more tightly attached to the left end and the right end ofthe PCB under the influence of tension of tension spring, thereby ensuring the clamping stability of the PCB.

Owner:苏州有容电子有限公司

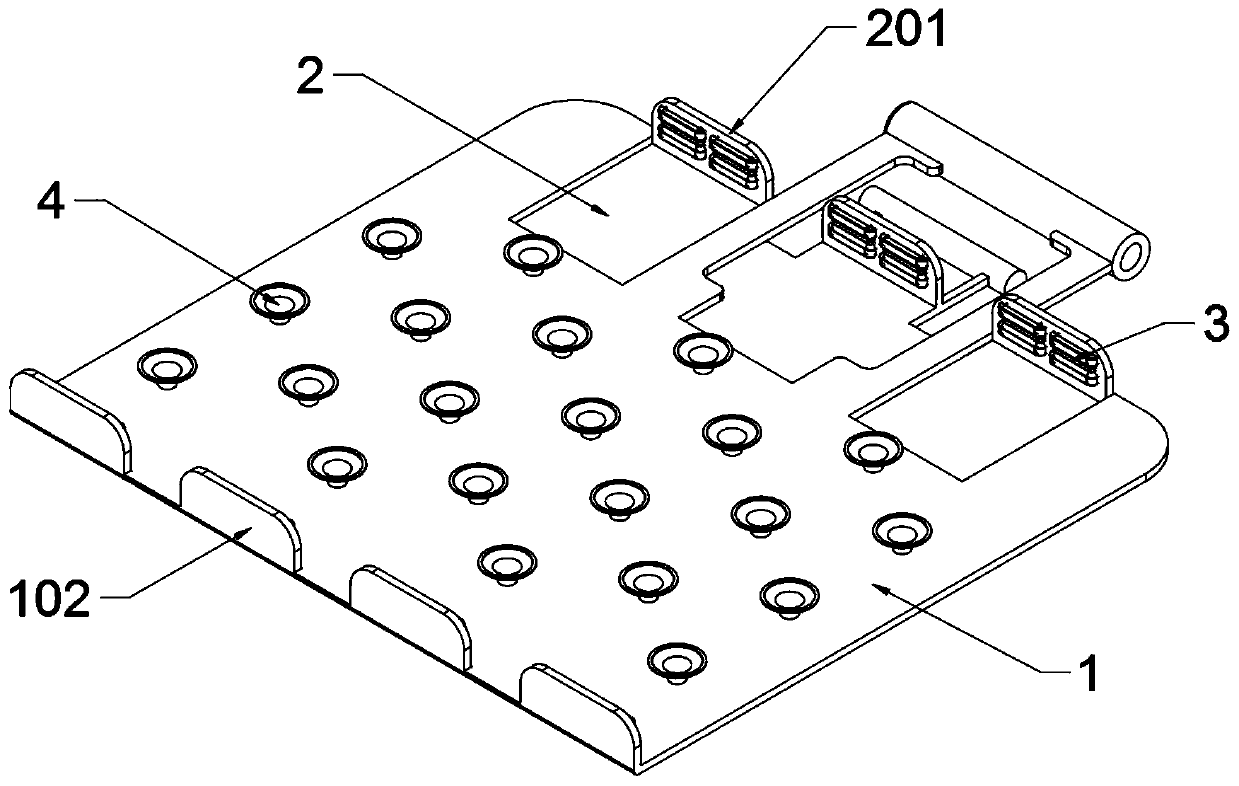

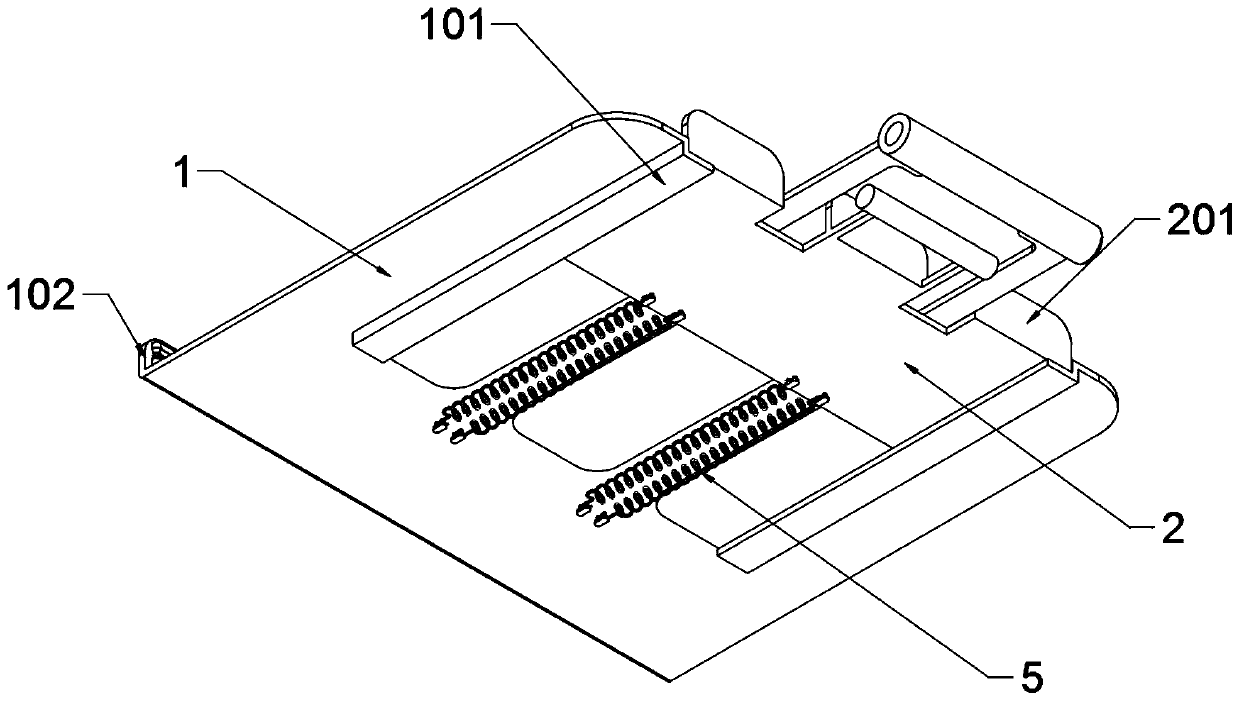

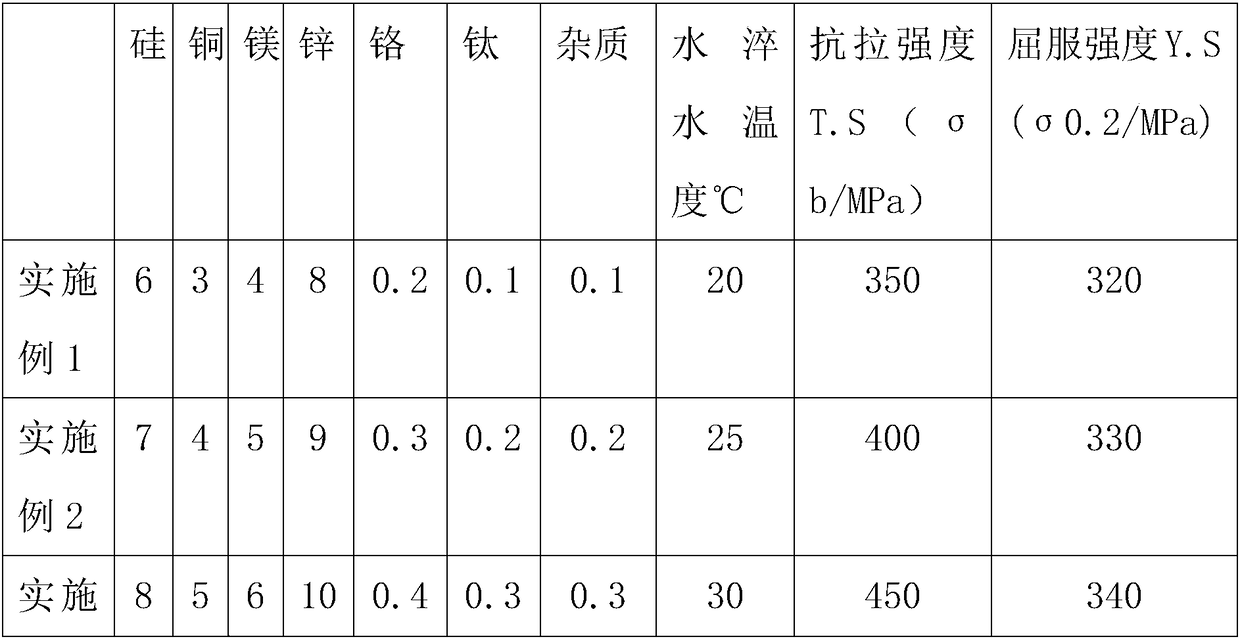

High-strength aluminum alloy plate

The invention discloses a high-strength aluminum alloy plate. The high-strength aluminum alloy plate is prepared from, by weight, 5.8%-8.2% of silicon, 2.6%-5.4% of copper, 2.8%-6.3% of magnesium, 7.8%-10.7% of zinc, 0.1%-0.5% of chromium, 0.1%-0.4% of titanium, aluminum and unavoidable impurities. According to the high-strength aluminum alloy plate, the strength and the good molding property of the aluminum alloy plate can be improved by adding zinc, iron and titanium metal additives; it can be guaranteed that the contents of the components are accurate through spectrum analysis of a spectrumanalyzer; the water temperature is controlled at 20 DEG C or above in the water quenching process, and therefore the condition that the aluminum alloy plate machining quality is influenced due to thefact that the water temperature is too low can be avoided; and a hot rolling method is adopted as a machining method, through a series of machining including smelting, refining, annealing, casting, hot rolling, water quenching, cold rolling, finishing and artificial aging treatment, fusion machining can be well conducted on raw materials, the materials are fully mixed, a finished product meets any needed roughness machining after being subjected to finishing, and a better using prospect is brought.

Owner:ANHUI AOYA ALLOY

An edge sealing machine for toy production

The invention discloses an edge sealing machine for toy production. The machine comprises a toy edge sealing machine bottom conveying stand control case, a toy edge sealing machine edge sealing hot seal transmission machine body and a toy edge sealing machine internal control transmission box. The toy edge sealing machine bottom conveying stand control case is provided with toy edge sealing machine bottom conveying stand side baffle plates, a toy edge sealing machine bottom conveying stand work piece hot seal conveying stand and a work piece hot seal conveying stand edge sealing welding groove. When the device is in use, edge-sealing operation can be carried out continuously by starting that convey station, and automatically triggers the internal drive mechanism during the transfer of theconveyor station, the invention can improve the production efficiency of the toy processing, reduce the error, avoid product damage and waste, and increase the enterprise benefit.

Owner:浙江云上实业有限公司

Stirring equipment for paint mixing

InactiveCN113559734APromote environmental protectionImprove reliabilityRotary stirring mixersMixer accessoriesProcess engineeringMechanical engineering

The invention relates to stirring equipment for paint mixing. The stirring equipment comprises a main body, a stirring device and two supporting legs, and also comprises a paint scraping mechanism and an impurity removing mechanism, wherein the paint scraping mechanism comprises a paint scraping ring, two lifting blocks, two lifting assemblies and two auxiliary assemblies; and the impurity removal mechanism comprises a first filter screen, a second filter screen, a crushing box, a crushing assembly, a driving assembly and a limiting assembly. According to the stirring equipment for paint mixing, through the paint scraping mechanism, paint adhering to the interior of the main body is scraped off, so paint waste caused by the fact that the paint adheres to the inner wall of the main body is prevented, the environmental protection property of the equipment is improved, the work of cleaning the inner wall of the main body is achieved, the situation that the paint is left on the inner wall of the main body and influences subsequent paint mixing work is avoided, and the reliability of the equipment is improved; and the function of removing impurities of the paint is achieved through the impurity removing mechanism, and therefore, the quality of the discharged paint can be improved, and subsequent paint processing quality is not influenced.

Owner:美嘉(广州)装饰材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com