Wire feeding mechanism, wire feeding device and additive manufacturing equipment based on additive manufacturing technology

A technology of wire feeding mechanism and wire feeding device, which is applied in the field of additive manufacturing, can solve problems such as prolonging working hours, contamination of workpieces, increasing the number of vacuum system degassing and pumping, and achieves the effect of improving processing efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

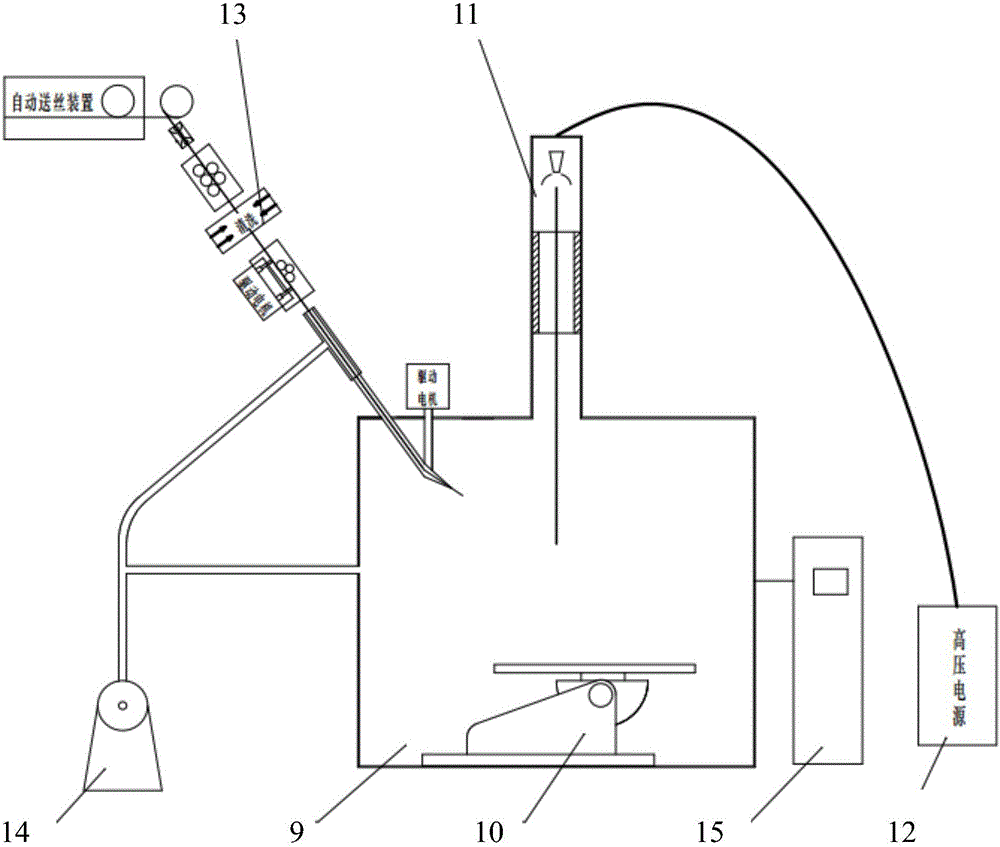

Examples

Embodiment 1

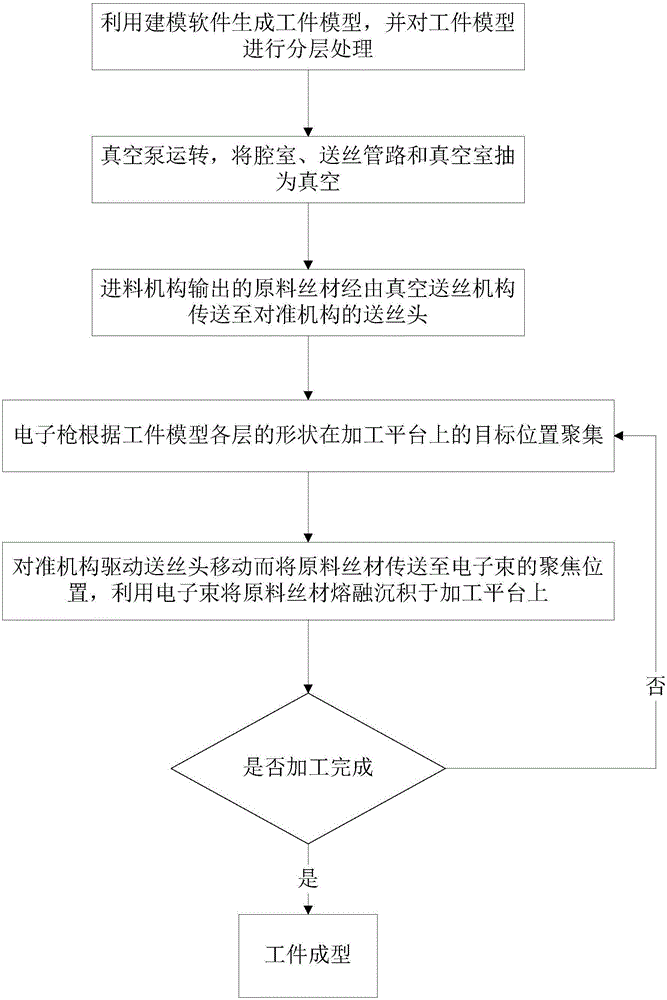

[0051] Embodiment 1: Use CAD to model the three-dimensional model of the pre-processed part, use data processing software to process the model layer by layer and convert it into a numerical control program, and then import it into the equipment control system. The fuse deposition process is expressed as follows:

[0052] Step a, the wire storage tray filled with wire material is pushed to the wire feeding station;

[0053] Step b. Place a metal substrate with the same or similar composition as the printed workpiece on the working platform in the vacuum chamber, as the base layer for the first layer of metal melting;

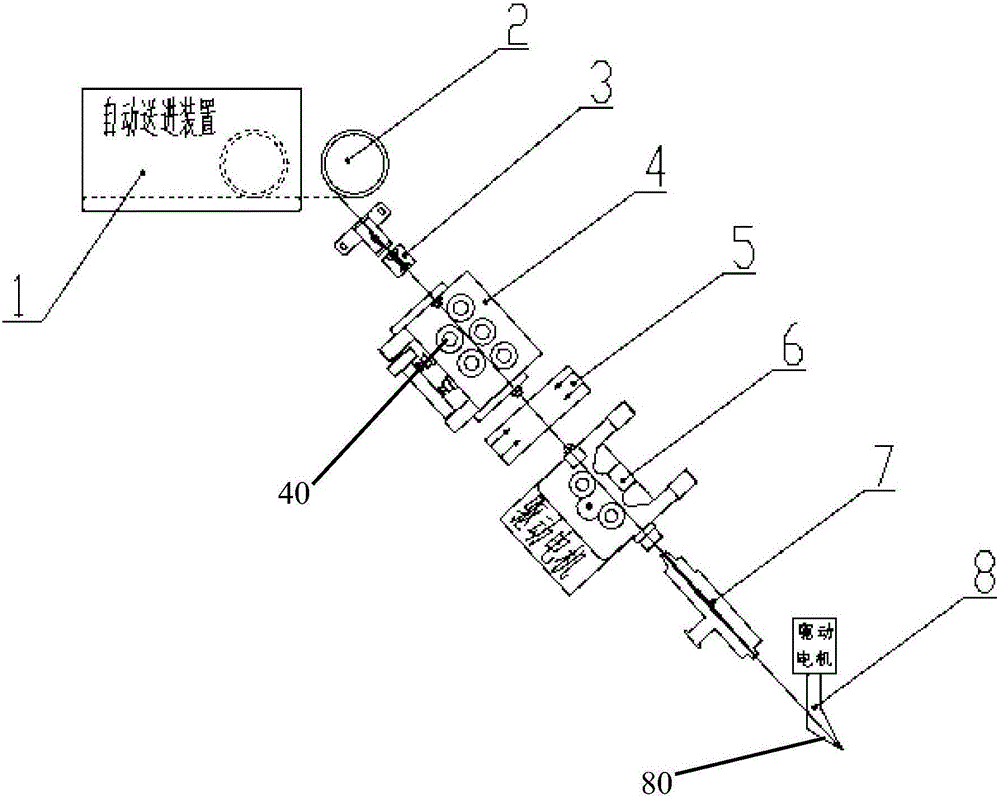

[0054] Step c. Pass the metal wire on the wire storage tray through the wire straightening mechanism, after cleaning and drying, enter the wire feeding mechanism, and then use the wire feeding motor to drive it through the metal inner tube with small holes and the wire feeding soft tube until the wire feeder comes out of the wire.

[0055] Step d, the motor of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com