High-strength aluminum alloy plate

An aluminum alloy plate, high-strength technology, applied in the field of high-strength aluminum alloy plate, can solve the problems of inability to mix materials, fusion of raw materials, inability to accurately manufacture strength and formability aluminum alloy plates, etc., to achieve increased strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

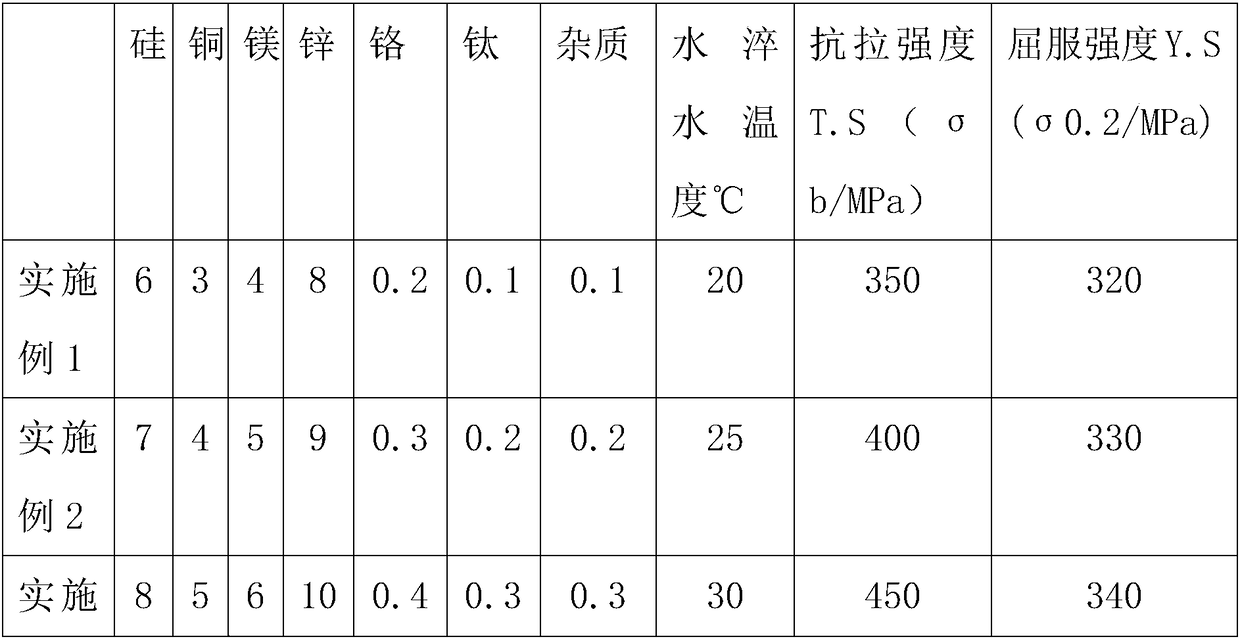

Embodiment 1

[0028] A high-strength aluminum alloy plate is prepared from the following raw materials according to the weight ratio: silicon accounts for 6%, copper accounts for 3%, magnesium accounts for 4%, zinc accounts for 8%, chromium accounts for 0.2%, titanium accounts for 0.1%, The others are aluminum and unavoidable impurities including steel and iron.

[0029] A method for preparing a high-strength aluminum alloy plate, the specific steps are as follows:

[0030] (1) Smelting: Put aluminum and silicon into a melting furnace for melting, smelting at 700°C for 5 hours, stir evenly after melting, add iron, copper, magnesium, zinc, chromium metal additives, stir well, take samples for analysis, take samples Spectral analysis is carried out by a spectrometer to check whether the components other than titanium meet the requirements, and the element content is adjusted to obtain an aluminum alloy melt whose composition meets the requirements;

[0031] (2) Refining and annealing: Refini...

Embodiment 2

[0038] A high-strength aluminum alloy plate is prepared from the following raw materials according to the weight ratio: aluminum accounts for 31%, silicon accounts for 7%, copper accounts for 4%, magnesium accounts for 5%, zinc accounts for 9%, chromium accounts for 0.3%, Titanium accounts for 0.2%, the rest is aluminum and unavoidable impurities including steel and iron.

[0039] A method for preparing a high-strength aluminum alloy plate, the specific steps are as follows:

[0040] (1) Melting: Put aluminum and silicon into a melting furnace for melting, melt at 730°C for 6 hours, stir evenly after melting, add iron, copper, magnesium, zinc, chromium metal additives, stir well, take samples for analysis, take samples Spectral analysis is carried out by a spectrometer to check whether the components other than titanium meet the requirements, and the element content is adjusted to obtain an aluminum alloy melt whose composition meets the requirements;

[0041] (2) Refining an...

Embodiment 3

[0048] A high-strength aluminum alloy plate is prepared from the following raw materials according to the weight ratio: aluminum accounts for 32%, silicon accounts for 8%, copper accounts for 5%, magnesium accounts for 6%, zinc accounts for 10%, chromium accounts for 0.4%, Titanium accounts for 0.3%, the rest is aluminum and unavoidable impurities including steel and iron.

[0049] A method for preparing a high-strength aluminum alloy plate, the specific steps are as follows:

[0050](1) Smelting: Put aluminum and silicon into a melting furnace for smelting, smelting at 750°C for 8 hours, stir evenly after melting, add iron, copper, magnesium, zinc, chromium metal additives, stir well, take samples for analysis, take samples Spectral analysis is carried out by a spectrometer to check whether the components other than titanium meet the requirements, and the element content is adjusted to obtain an aluminum alloy melt whose composition meets the requirements;

[0051] (2) Refin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com