High-speed laser cladding processing machine tool and processing method

A technology of laser cladding and machining machine tools, applied in metal processing equipment, grinding machine parts, grinding machines, etc., can solve the problems of increasing the axial constraint of the workpiece due to thermal expansion, reducing the strength of the workpiece, increasing the amount of deformation, etc. The effect of avoiding processing quality, reducing cracking and alleviating stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

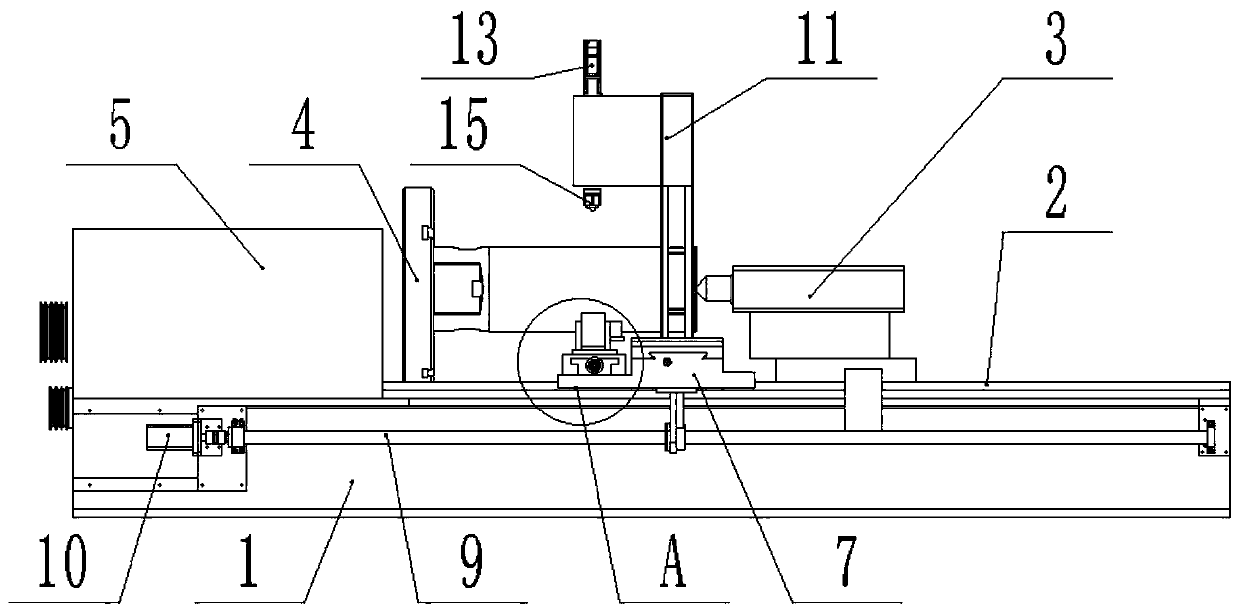

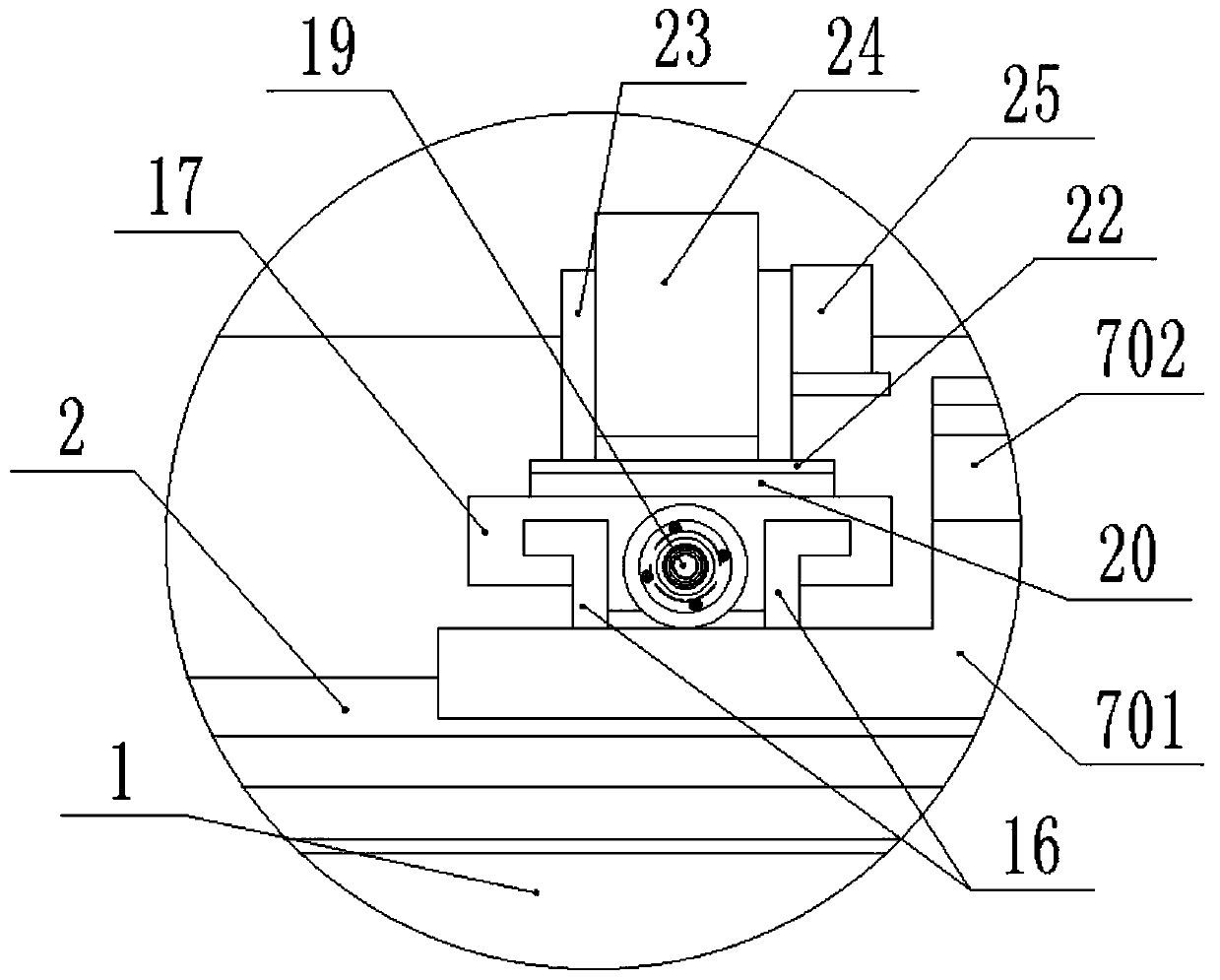

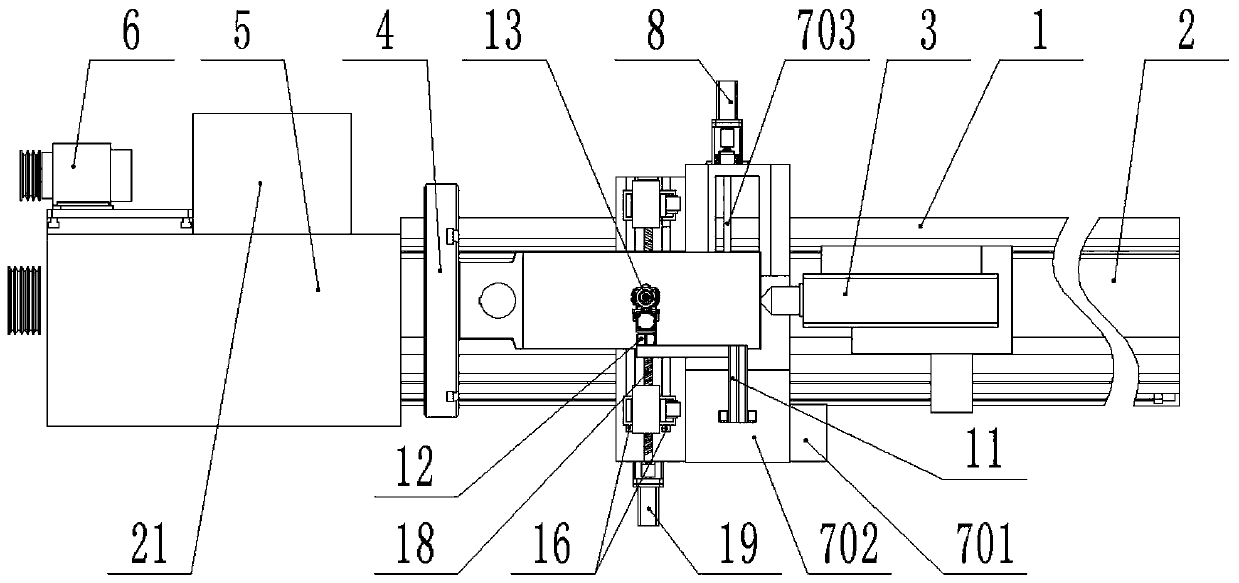

[0034] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

[0035] like Figure 1-4A high-speed laser cladding machine tool shown includes a base 1, a control box 21 is provided on one side of the base 1, and the control box 21 is electrically connected to a first servo motor 6, a second servo motor 8, a third servo motor The servo motor 10, the fourth servo motor 13, the fifth servo motor 19, the grinding mechanism and the laser cladding head 15, the base 1 is provided with a slide rail 2, and the slide rail 2 is slidably provided with a rotary thimble 3, The precise control of the rotary thimble 3 is realized through the electric telescopic rod, and the chuck 4 matched with the rotary thimble 3 is installed on one end of the slide rail 2, and the workpiece is fixed through the cooperation of the chuck 4 and the rotary thimble 3, A reduction box 5 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com