Bottle blow-moulding machine die carrier/mold component

A blow molding machine and mold technology, which is applied to home appliances, other home appliances, applications, etc., can solve the problems of not being able to meet the needs of small-bottle beverages, and the speed cannot be increased, and achieve the effects of simple structure, improved production efficiency, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

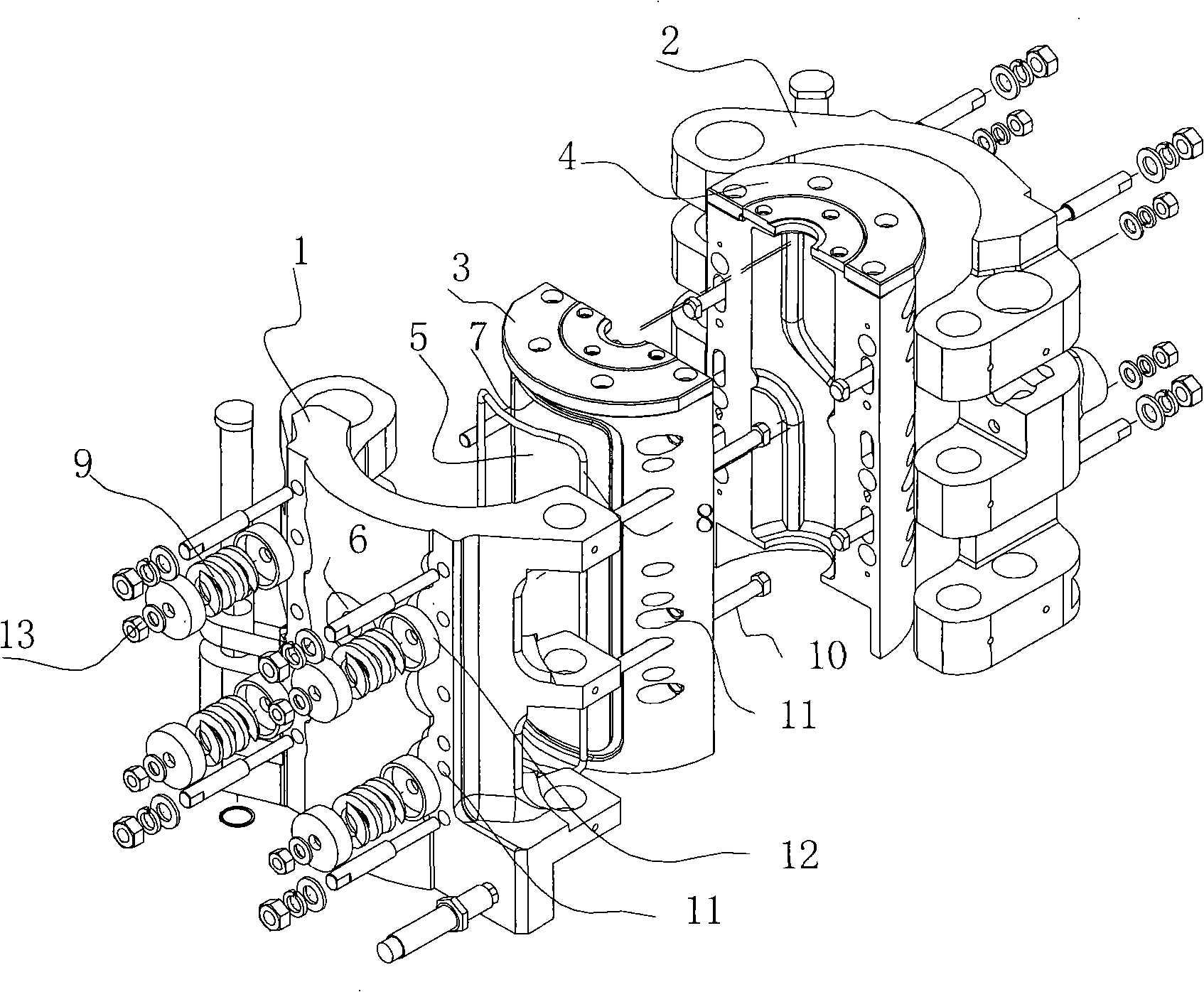

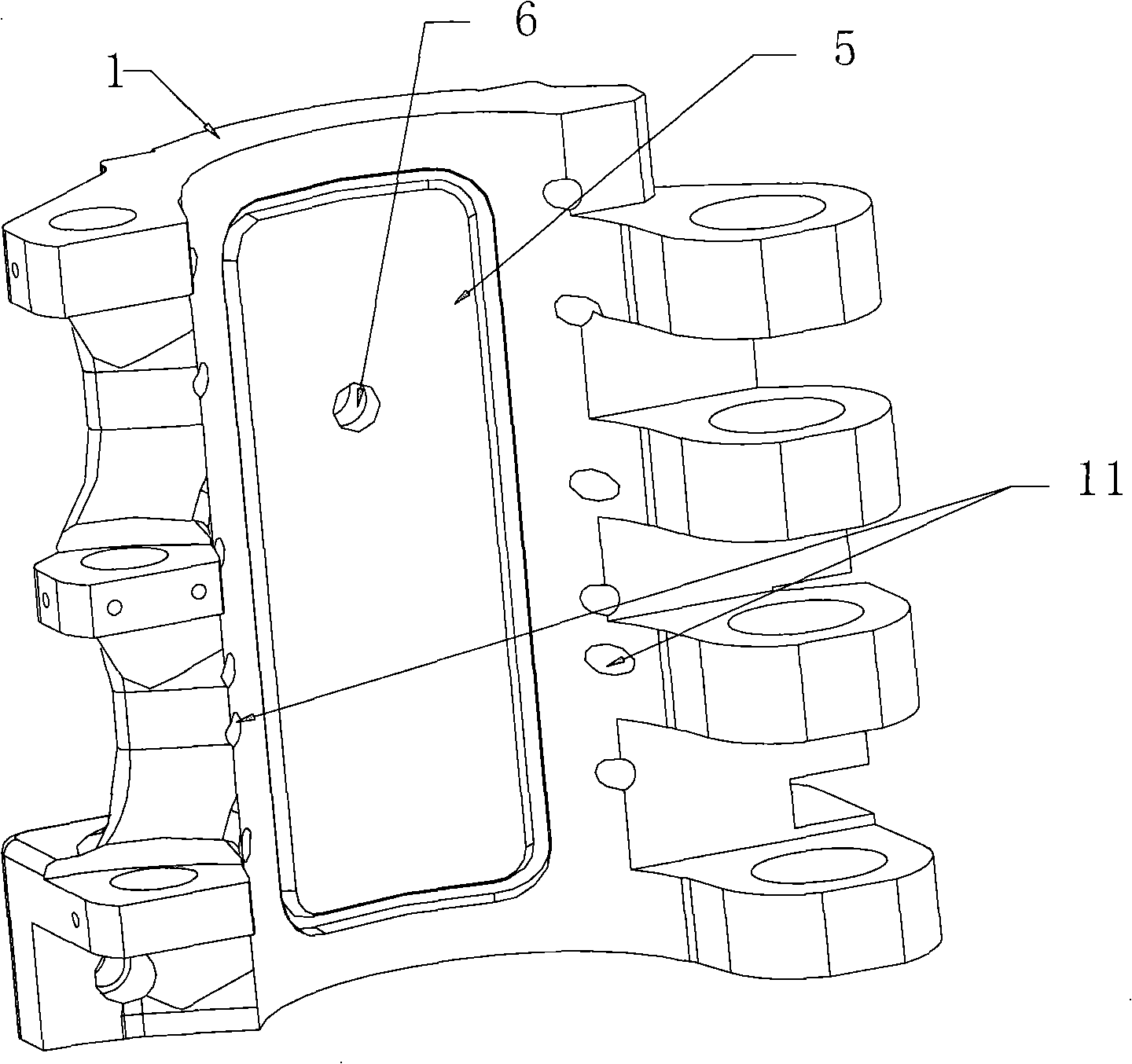

[0019] see figure 1 , figure 2 , the bottle blowing machine mold assembly of the present invention comprises left mold base 1, right mold base 2 and left mold 3, right mold 4, and described left and right molds 3,4 are installed in left and right mold bases 1,2, between mold and mold A sealing compensation device is provided between the frames, and the sealing compensation device includes an inner concave part 5 correspondingly provided on the outer wall of the mold or the inner wall of the mold frame. A sealing ring 8 is arranged around the inner concave part 5. The inner recess 5 forms a closed cavity, and an air hole 6 communicating with the closed cavity is also provided on the formwork. The inner recess 5 is along the left formwork (such as figure 2 ) or left mold (such as figure 1 ) for portrait settings.

[0020] exist figure 1 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com