Patents

Literature

35results about How to "Improve cutting precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

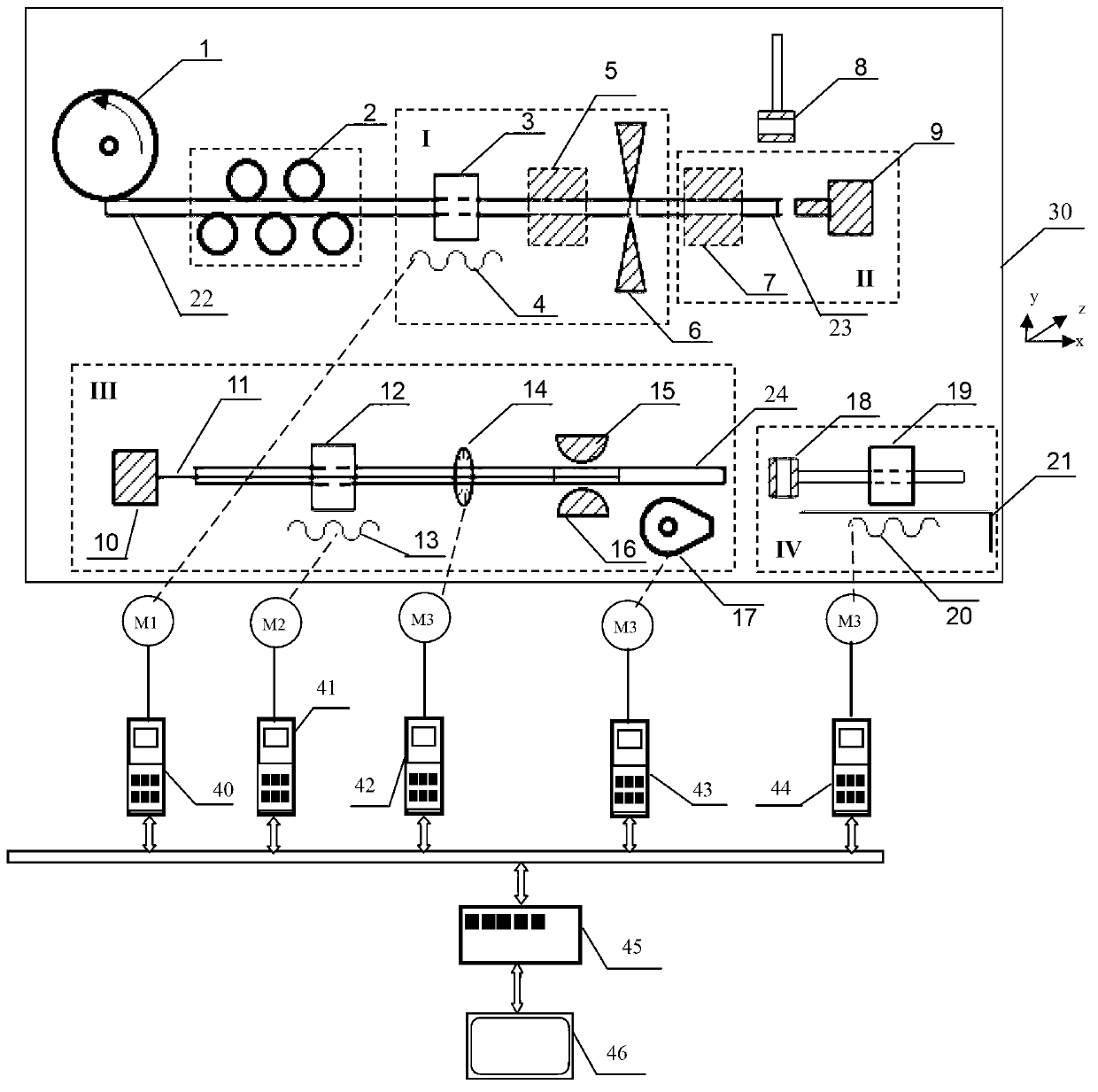

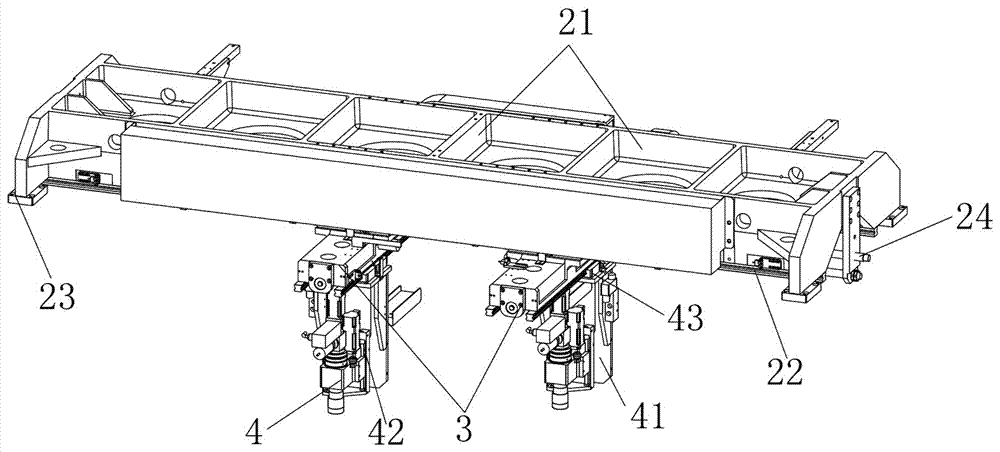

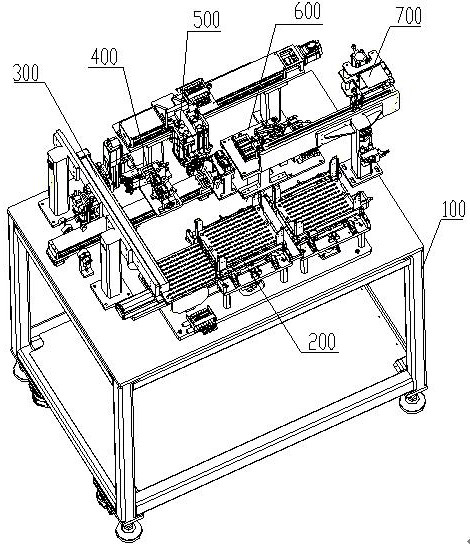

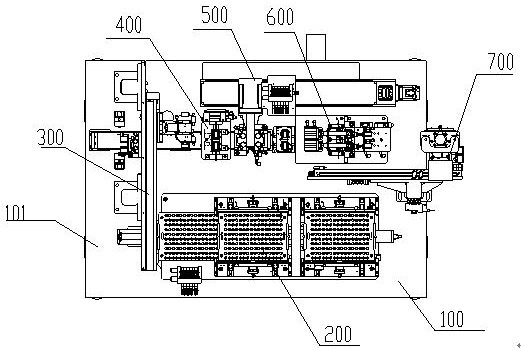

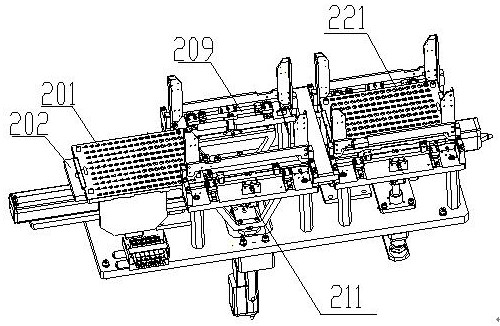

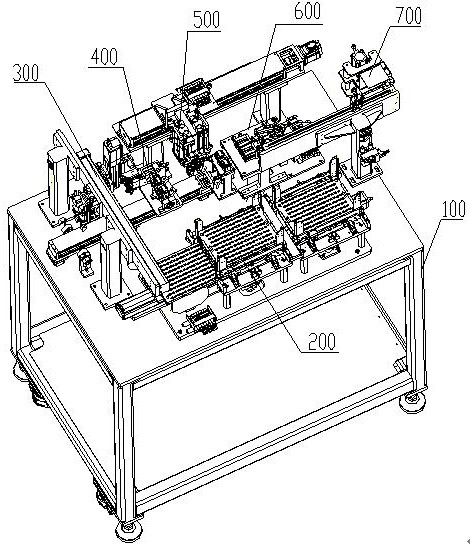

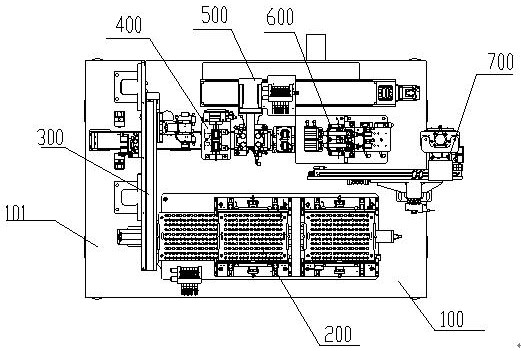

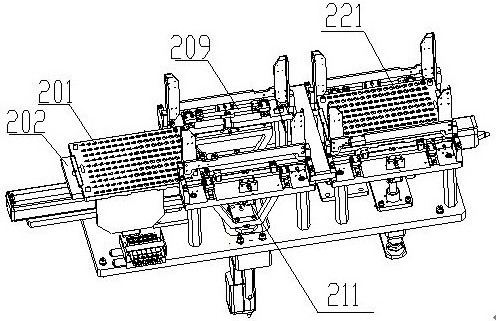

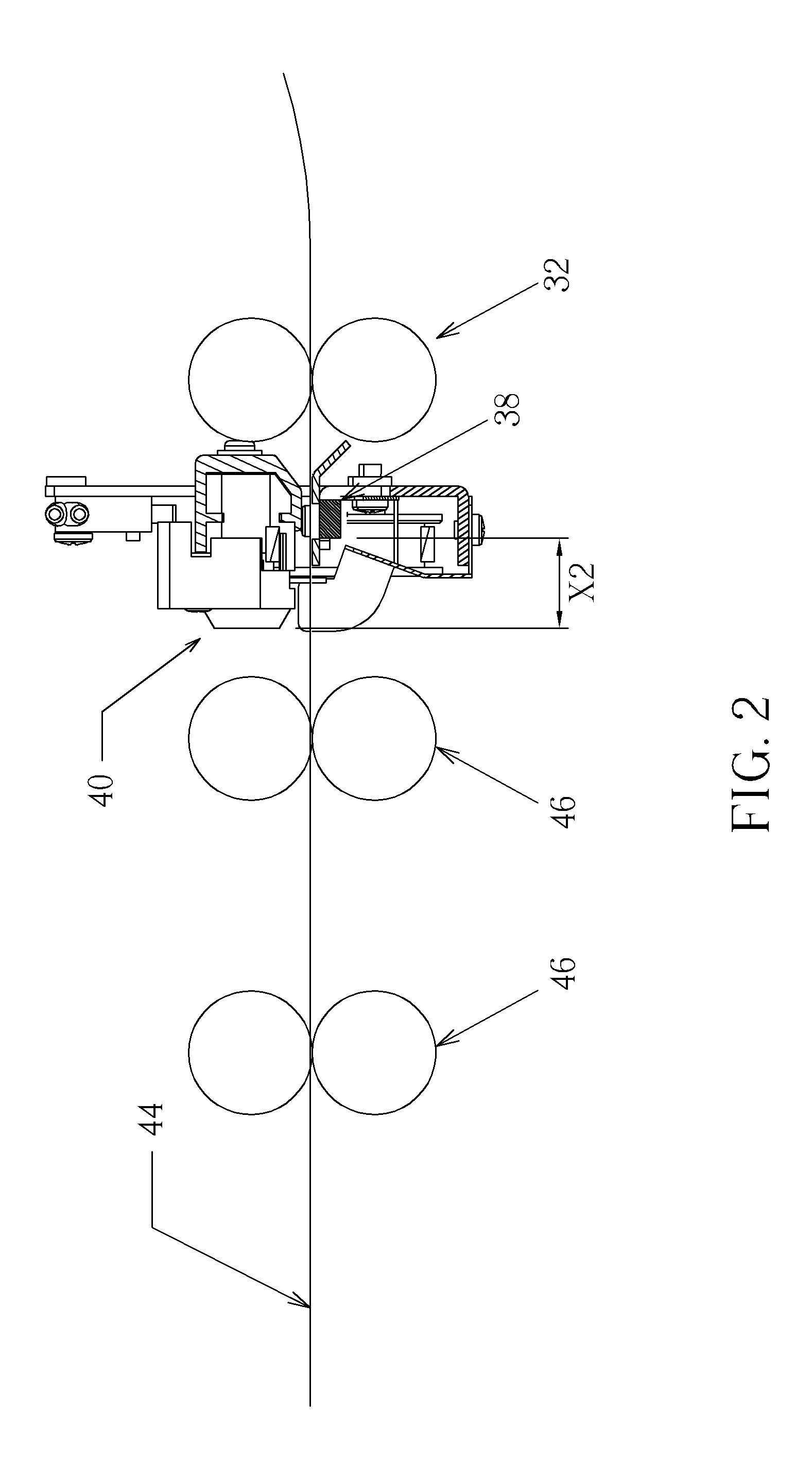

Method for optimization of pipe integrated numerical control machining process

InactiveCN103341521AImprove production efficiencyImprove processing qualityMetal-working feeding devicesStripping-off devicesNumerical controlMotor drive

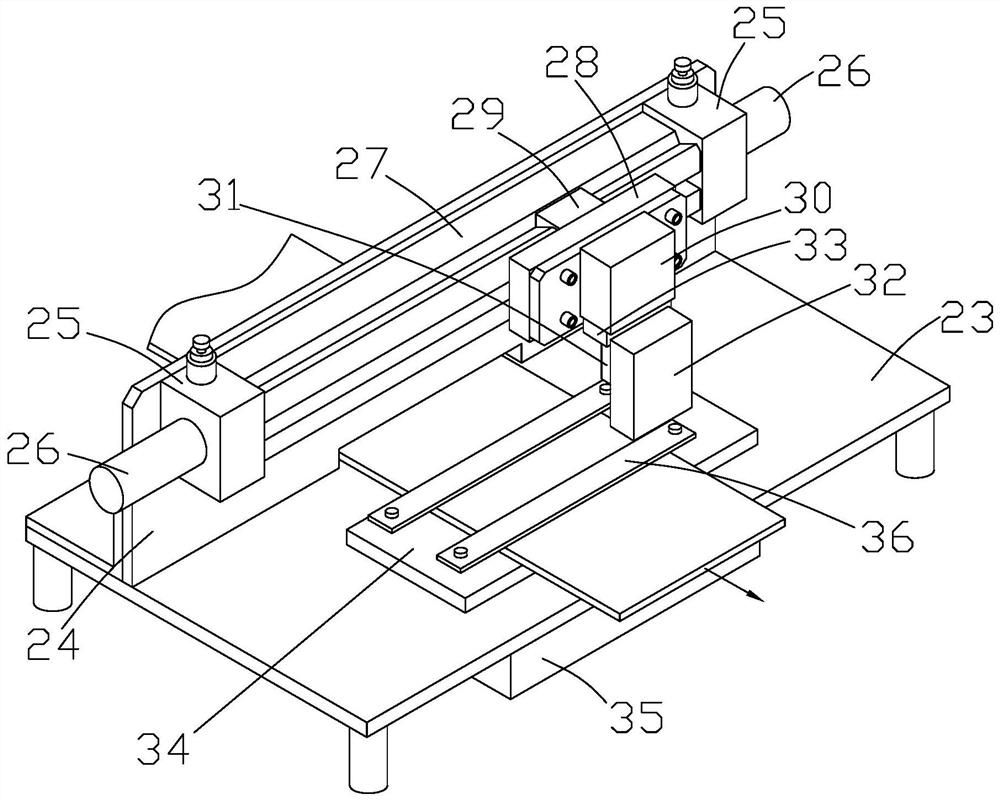

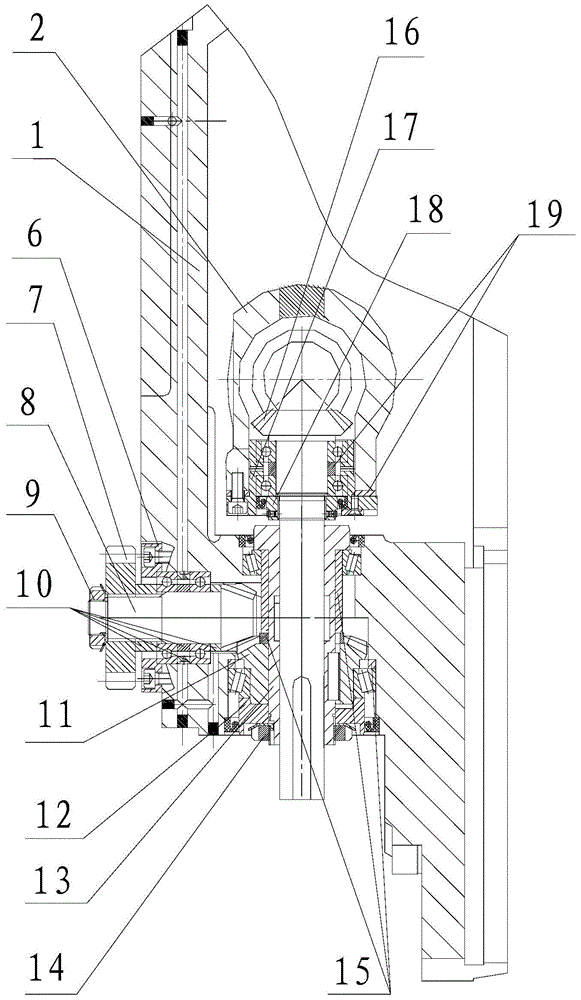

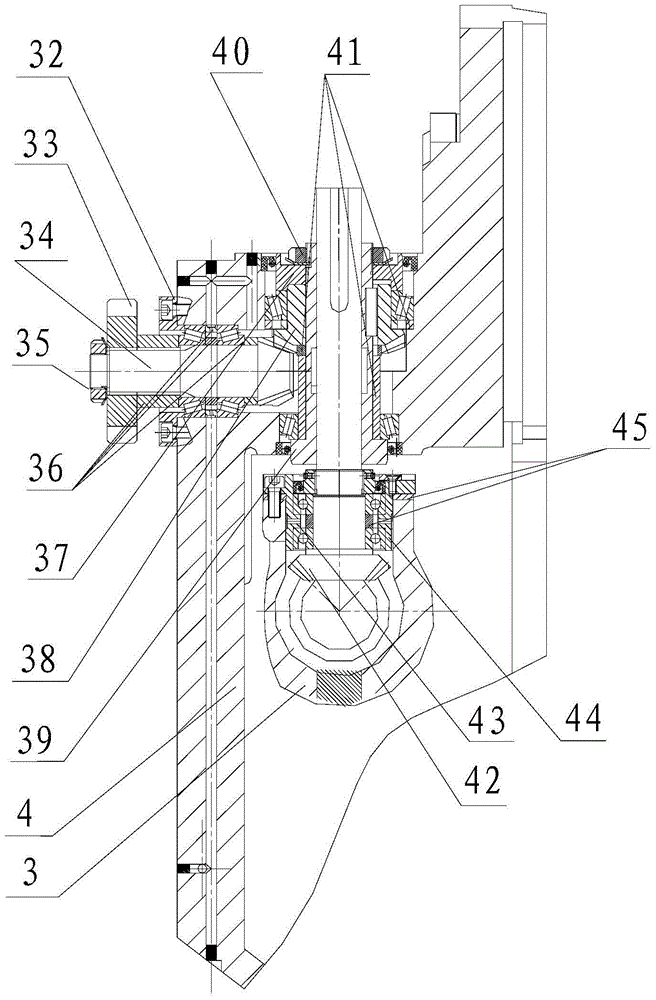

The invention provides a method for optimization of a pipe integrated numerical control machining process. The method comprises the following steps of rough shape cutting, pipe end molding, bend pipe molding, and split charging and discharging. A controller transmits control signals to servo drivers ((40)-(44)). The servo drivers drive motors (M1-M5) on processing devices and the motors drive the corresponding processing devices to work so that high-precision processing is finished. The method can automatically realize integrated numerical control machining or any combined machining such as pipe rough shape cutting and feeding, chipless rough shape cutting, spinning pipe end molding, bend pipe and manipulator automatic-feeding, three-dimensional bend pipe and manipulator automatic-discharging according to drawing information only by manual introduction of a pipe to a material picking opening of a machine tool, can avoid complex processing adopting multiple machine tools and multiple processing steps, can realize continuous automatic production, can improve production benefits and processing quality of pipe production, and can be used for bending molding processing of pipes used in the industries of air conditioners, water heaters, refrigerators or automobiles.

Owner:WUHAN UNIV OF TECH

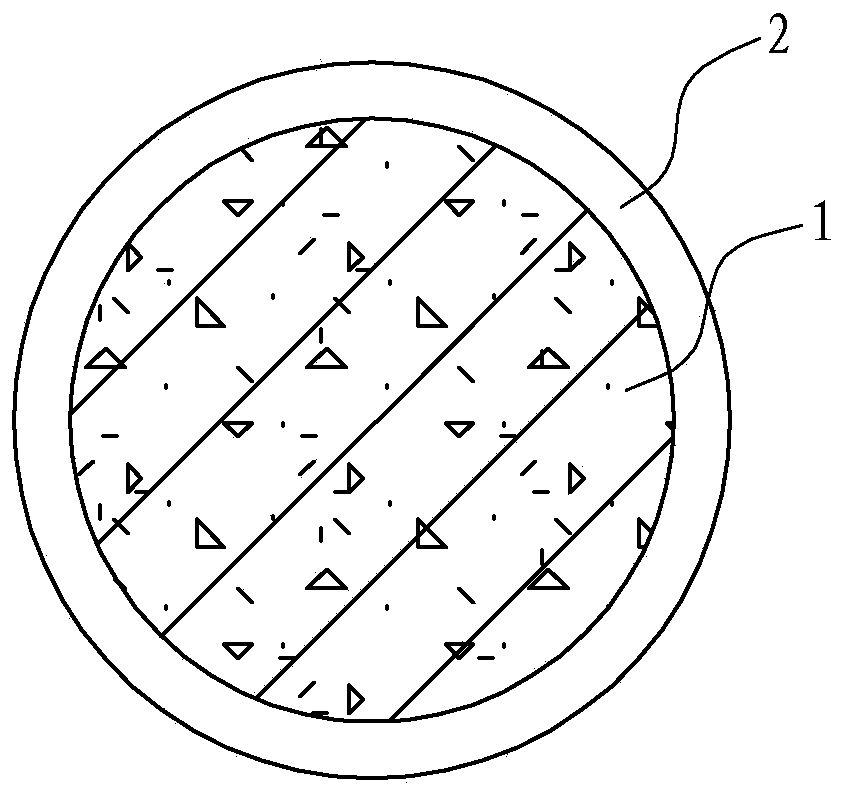

High-accuracy zinc base alloy electrode wire and preparing method thereof

ActiveCN104191056AGood for taking awayCutting discharge mitigationElectrical-based machining electrodesSurface finishImpurity

The invention relates to a high-accuracy zinc base alloy electrode wire. Components in a shell layer comprise, by weight, 70.5%-95% of Zn, 2.5%-27% of Cu, 0.02%-4.0% of X, 0.002%-0.4% of Y and inevitable impurities brought in by raw materials. X is any two kinds of metal from Ni, Ag, Cr, Si and Zr, the content ranges of the two kinds of metal are both 0.01%-2.0%, Y is any two kinds of elements of Ti, Al, Co, B and P, and the content range of the two elements are both 0.001%-0.2%. The epsilon phase content in the shell layer structure is over 80% by weight, the balance is a gamma phase or an eta phase, and epsilon phases are evenly distributed on the surface of core materials. Meanwhile, the invention relates to a preparing method of the electrode wire. Compared with the prior art, a metal workpiece subjected to cutting processing by the electrode wire is high in surface smoothness and good in surface quality, accordingly, cutting accuracy is high, meanwhile, the electrode wire preparing technology is simple, operability is high, the number of manufacturing steps is small, and large-scale and automatic production can be achieved easily.

Owner:NINGBO BODE HIGHTECH CO LTD

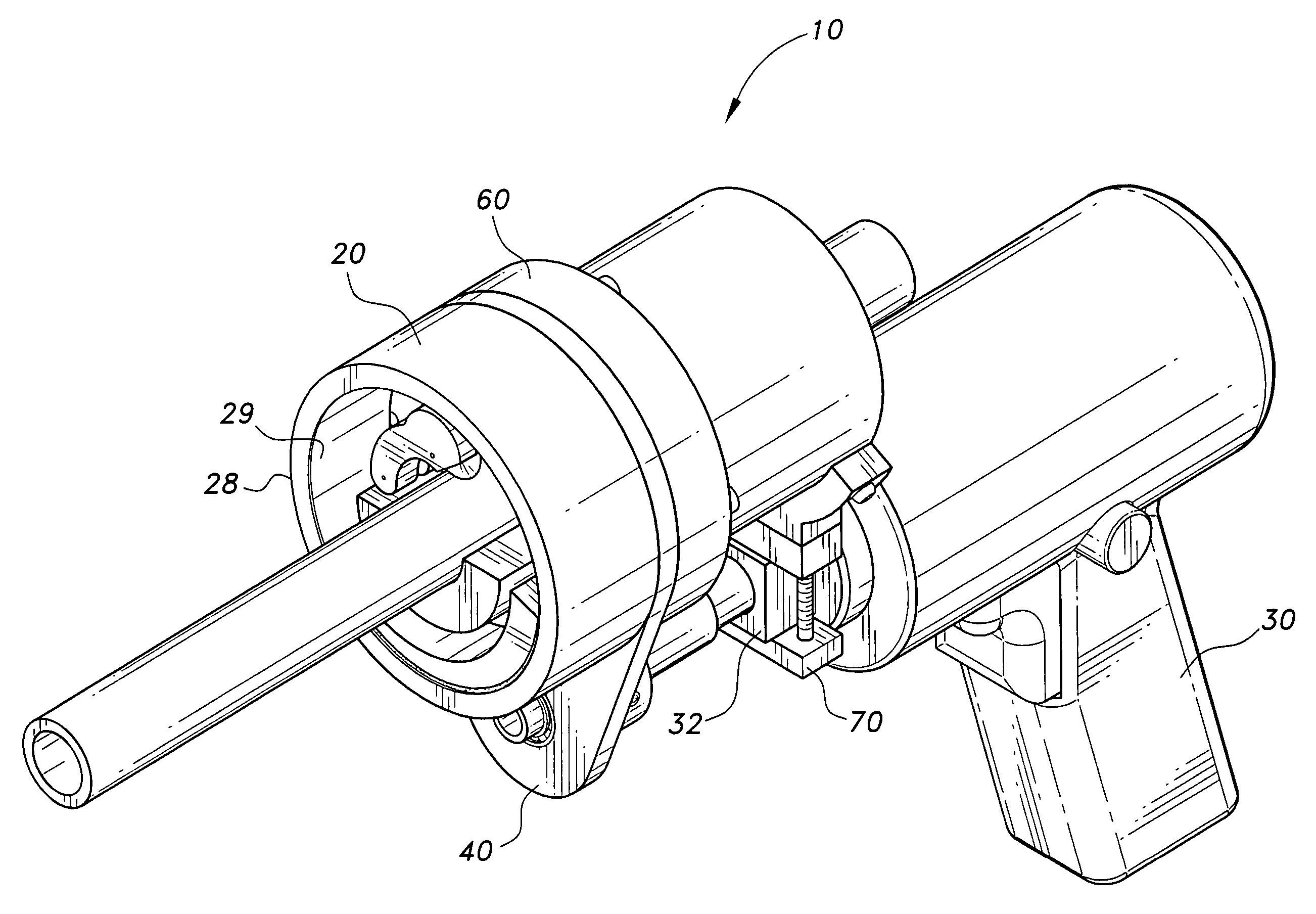

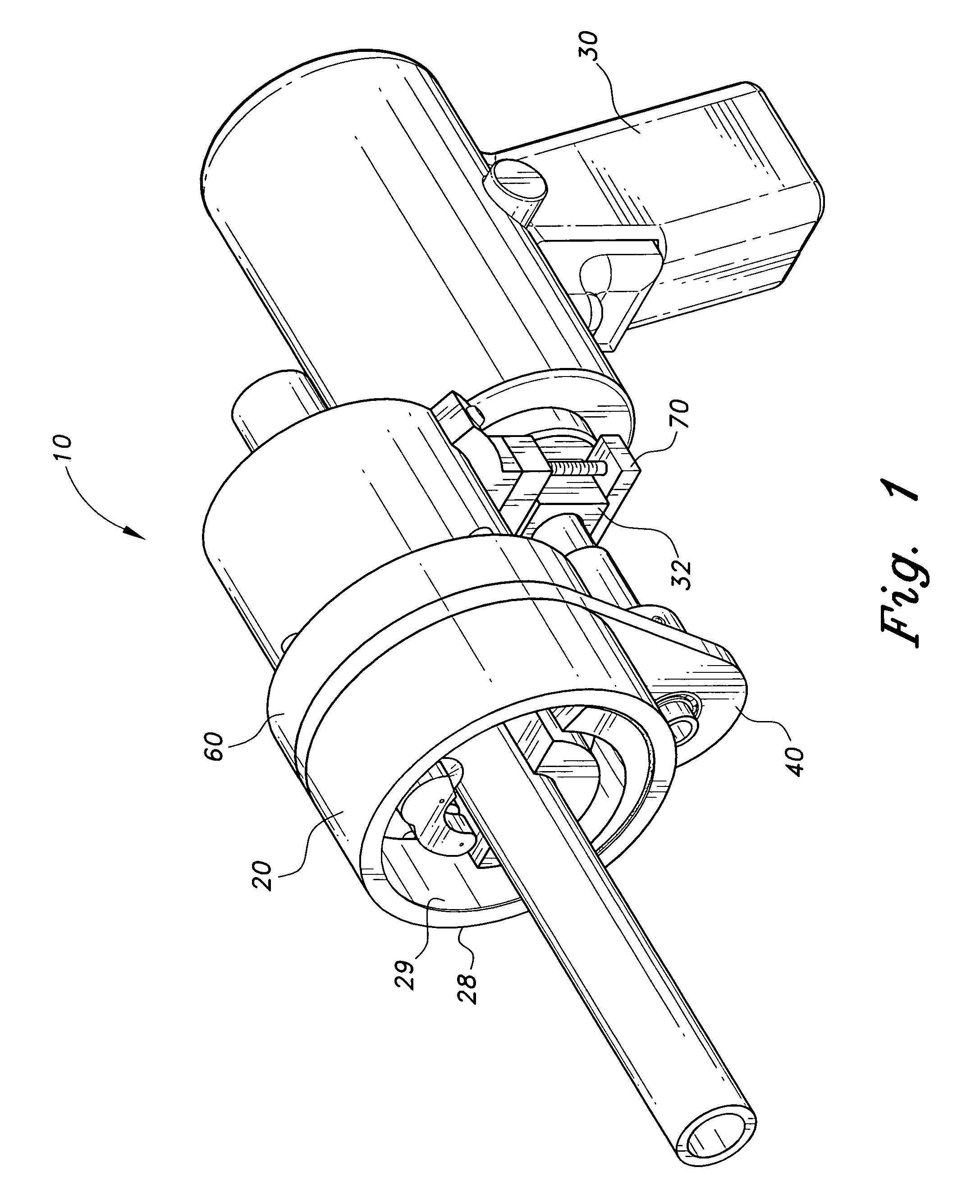

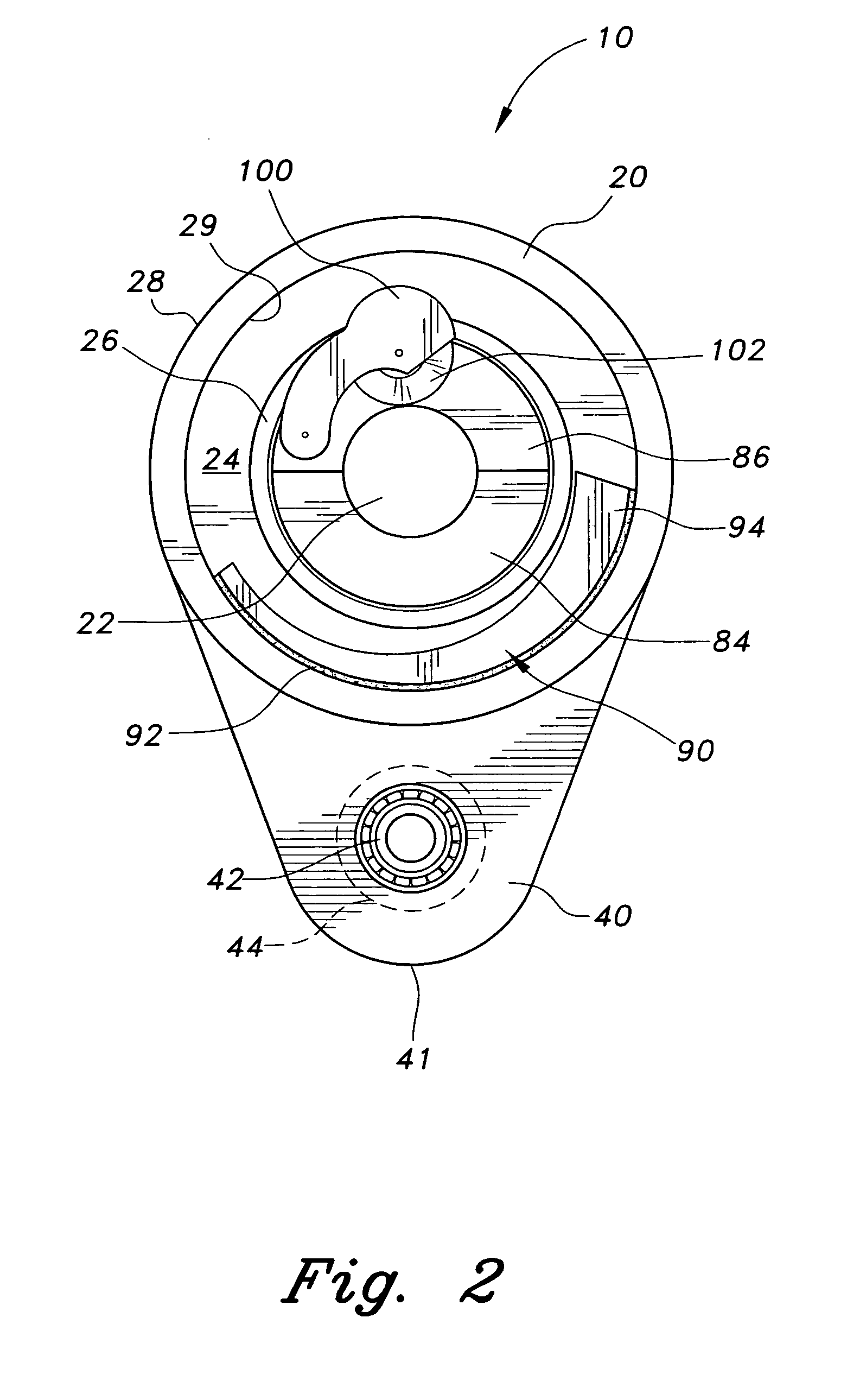

Powered tubing cutter

InactiveUS20050076508A1Improve cutting precisionIncrease production speedPortable power-driven toolsTube shearing machinesDrive shaftHand held

The powered tubing cutter is a hand held, mechanical device driven by a motor for cutting tubing / piping. The device comprises a housing, a drive plate, a main drive shaft, a cutting assembly having a cutting blade, a cam plate and a chain drive secured to a motor housing, having a handle, by a mounting bracket. The chain drive is powered by the motor, which causes the main drive shaft to rotate. The cutting assembly is pivotally secured to a pin on the main drive shaft. The pipe / tube to be cut is placed into the hole in the center of the housing and the main drive shaft. As the cutting assembly rotates with the main drive shaft the cam plate forces the cutting blade into cutting engagement with the tube / pipe.

Owner:GREEN CARROLL D +1

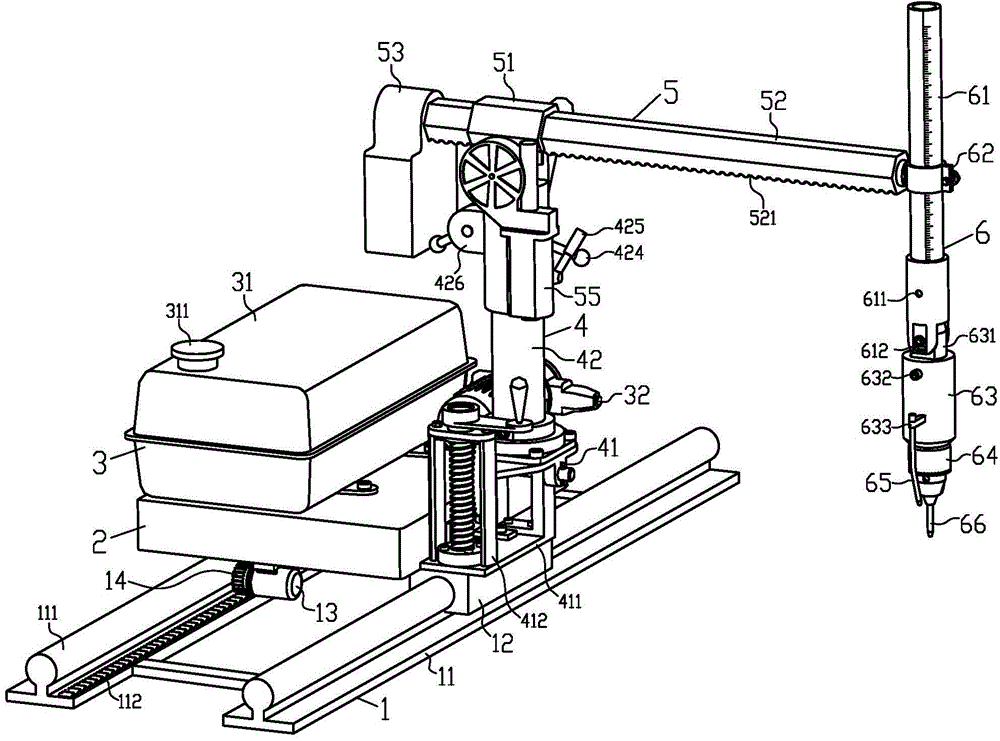

Cutting and processing device for acrylic products

InactiveCN104669334ARealize blanking and cutting functionAdjustable heightMetal working apparatusMotor driveEngineering

The invention discloses a cutting and processing device for acrylic products. The cutting and processing device comprises a self-sliding base, a machine body seat, a cooling system, a two-degree-freedom adjustable upright post, a translating device and a cutter, wherein a balancing weight is arranged inside the machine base seat; the cooling system is arranged on the machine body seat; the two-degree-freedom adjustable upright post is positioned on one side of the machine body seat. According to the cutting and processing device disclosed by the invention, the function of discharging and cutting acrylic materials can be realized, and processing operations of chamfering, routing, trimming and the like for the acrylic products can be finished. By using the cooling system, processed materials and tools can be cooled in real time, so the acrylic materials can be prevented from being bonded on the tools; longitudinal sliding and walking of the self-sliding base and translation of the cutter are respectively finished by motor drive, so the automatic degree is higher; for the cutter, corresponding tools can be changed according to the requirement, and the heights and inclined angles of the tools can be adjusted. The cutting and processing device disclosed by the invention has the advantages of compact and simple structure, stable and reliable work, convenience for operation and maintenance, low cost of an entire machine, high cutting and processing precision and the like.

Owner:华锻(安徽)机床制造有限公司

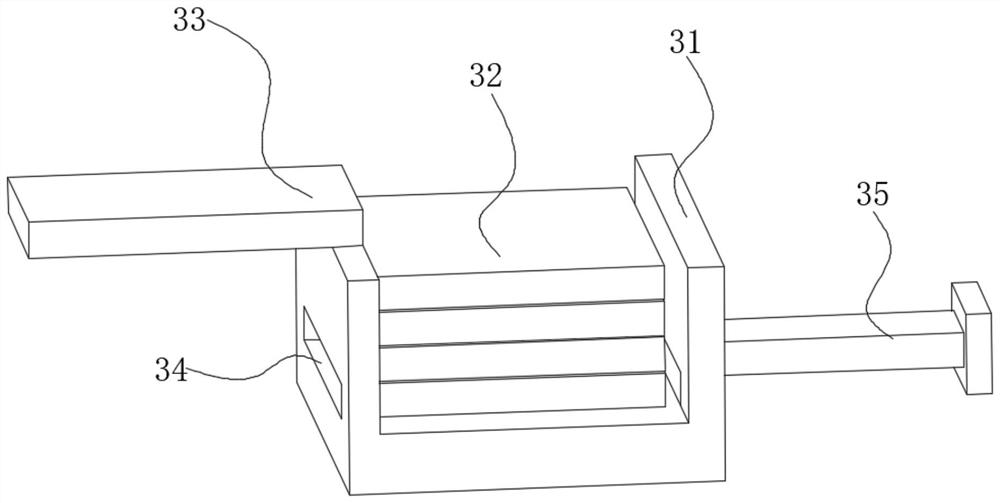

Cutting machine

InactiveCN106930092ANo misalignmentEnsure consistencySevering textilesThree-dimensional spaceEngineering

The invention discloses a cutting machine. The cutting machine comprises a frame and a feeding device which is arranged on the frame, wherein a feed inlet, a cutting station and a product collecting station are successively arranged on the frame along the feeding direction of the feeding device; a portal frame is arranged above the cutting station of the frame, the portal frame hoists at least one tool apron for mounting a tool, a mobile device which drives the tool apron to move in a three-dimensional space is arranged between the portal frame and the tool apron, and a traction material pressing device and a fixed pressing device are successively arranged along the feeding direction between the feed inlet and the cutting station. Cloth and a conveyor belt are clamped together and moved through the traction pressing device, so that the cloth in the transfer process is not staggered, and meanwhile, the cloth is tightly pressed to the conveyor belt through the fixed pressing device, so that the cloth cutting consistency and precision are guaranteed, and the problem that the cloth which is cut is easy to be staggered is solved.

Owner:GBOS LASER INC

Electromagnetic coreless fixture with locating ring capable of axially floating

ActiveCN102658509AReduce axial playReduce the adverse effects of the vertical difference in the outer diameter of the workpieceRevolution surface grinding machinesGrinding work supportsMarine engineeringMagnetic poles

The invention discloses an electromagnetic coreless fixture with a locating ring capable of axially floating. Above a main shaft are arranged an inner magnetic pole, a magnetic shield ring, an inner floating ring and an outer floating ring, and on the inner floating ring is arranged a conical surface pocket provided with a ceramic ball. The inventive electromagnetic coreless fixture can avoid direct fixation of the locating ring on the main shaft to form rigid connection, which leads to direct influence of main shaft vibration and side swing on stability of the locating ring and a workpiece mounted on the locating ring; and effectively reduce the adverse effects of axial movement of the main shaft and workpiece outer diameter vertical deviation through floating connection formed between the inner and the outer floating ring by pocket connection, improve workpiece machining precision, effectively improve product quality and yield and production efficiency and effectively lower production costs.

Owner:NINGBO ZHENHAI SILVER BALL BEARING CO LTD

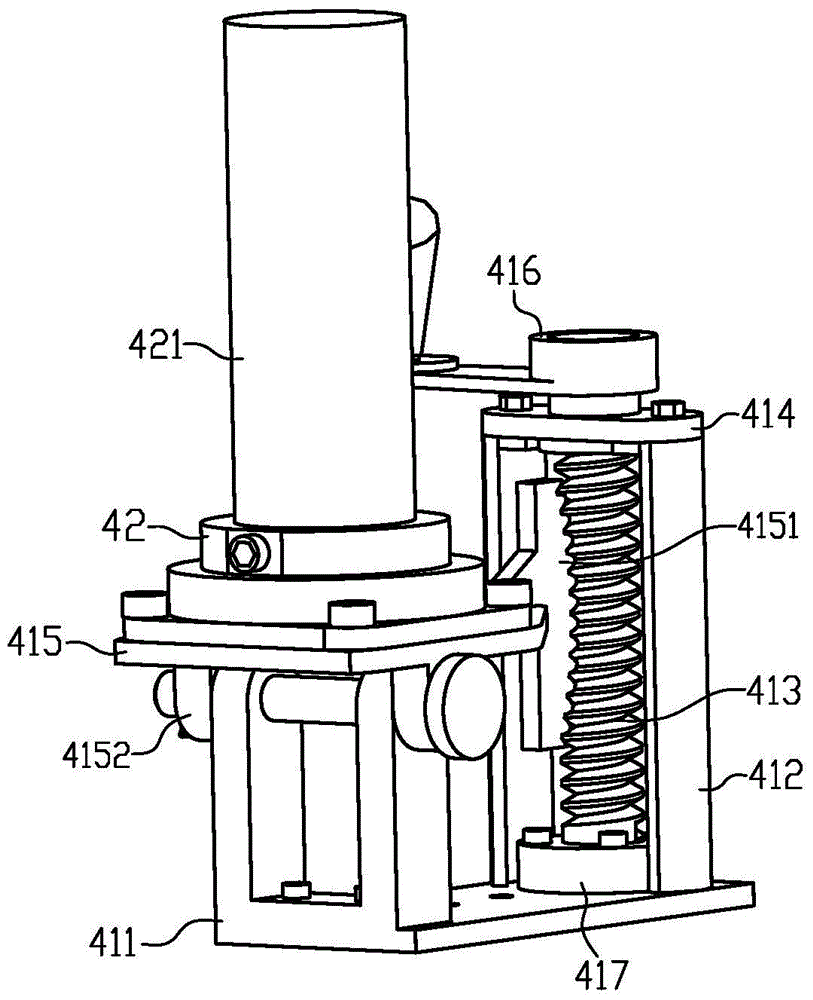

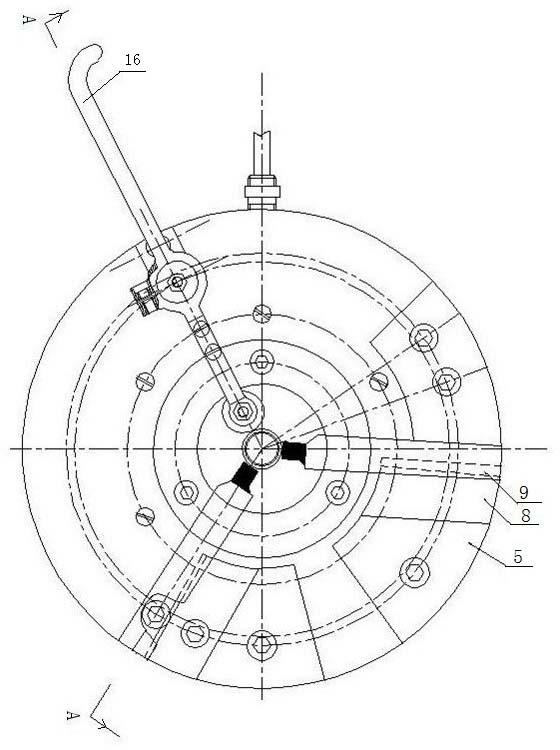

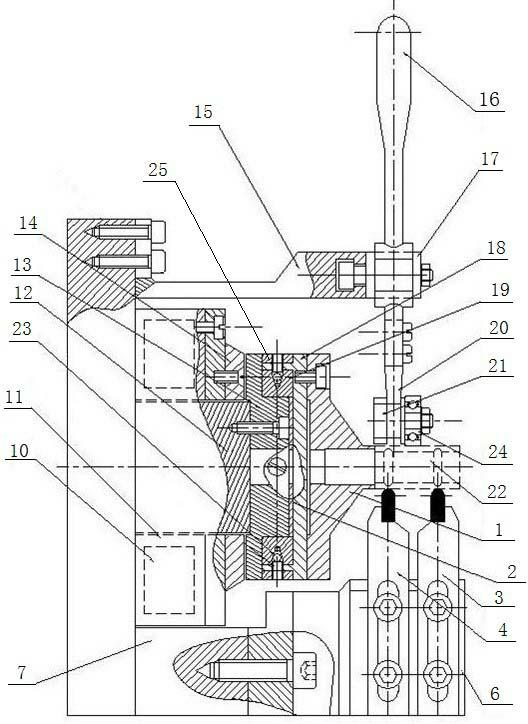

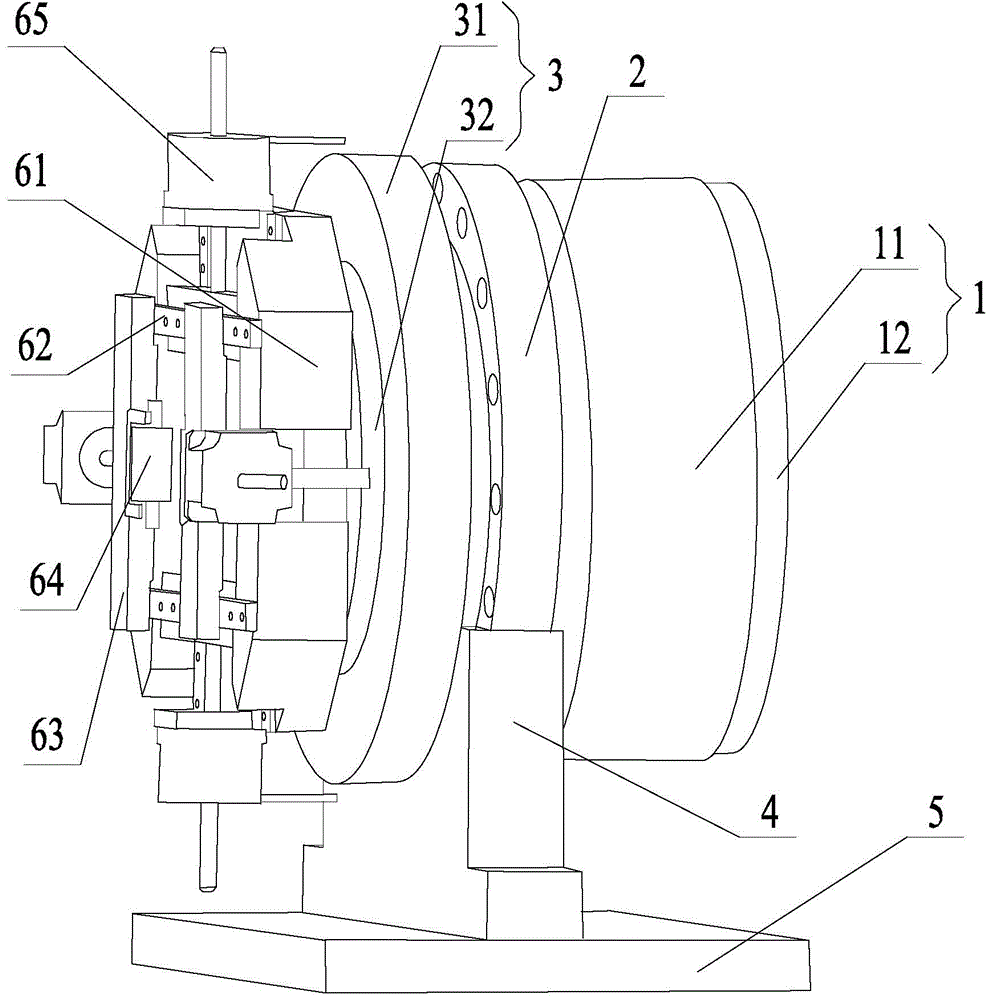

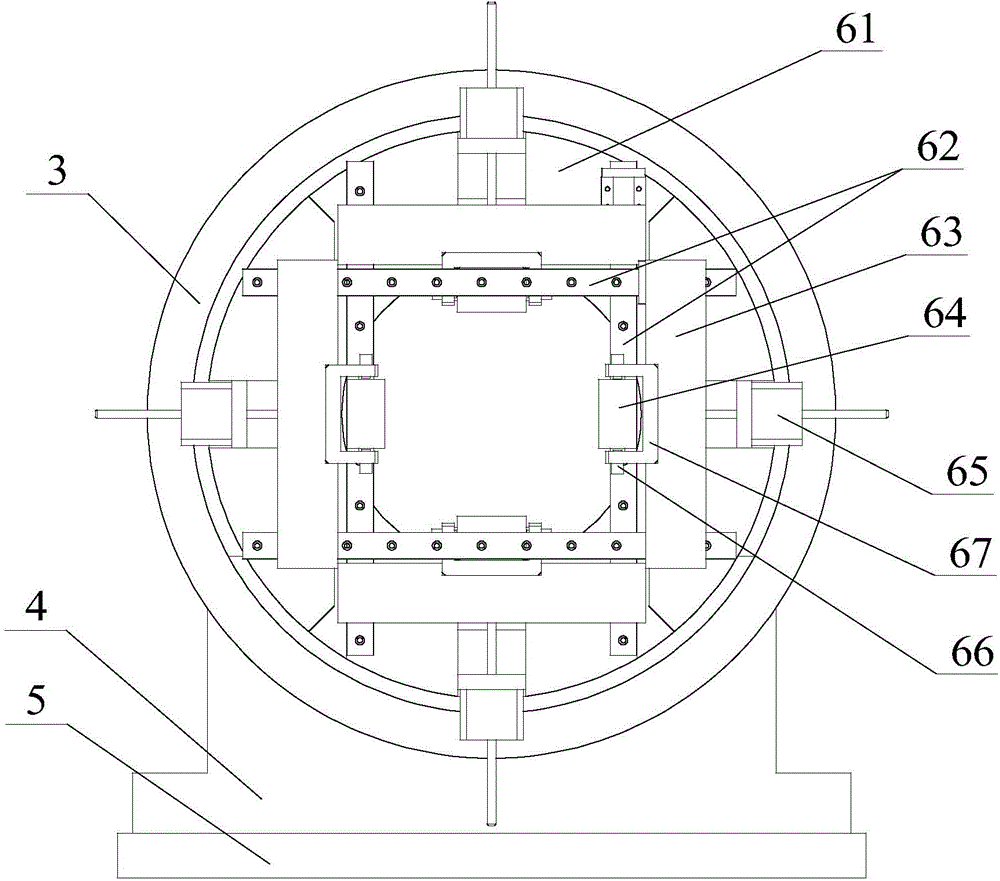

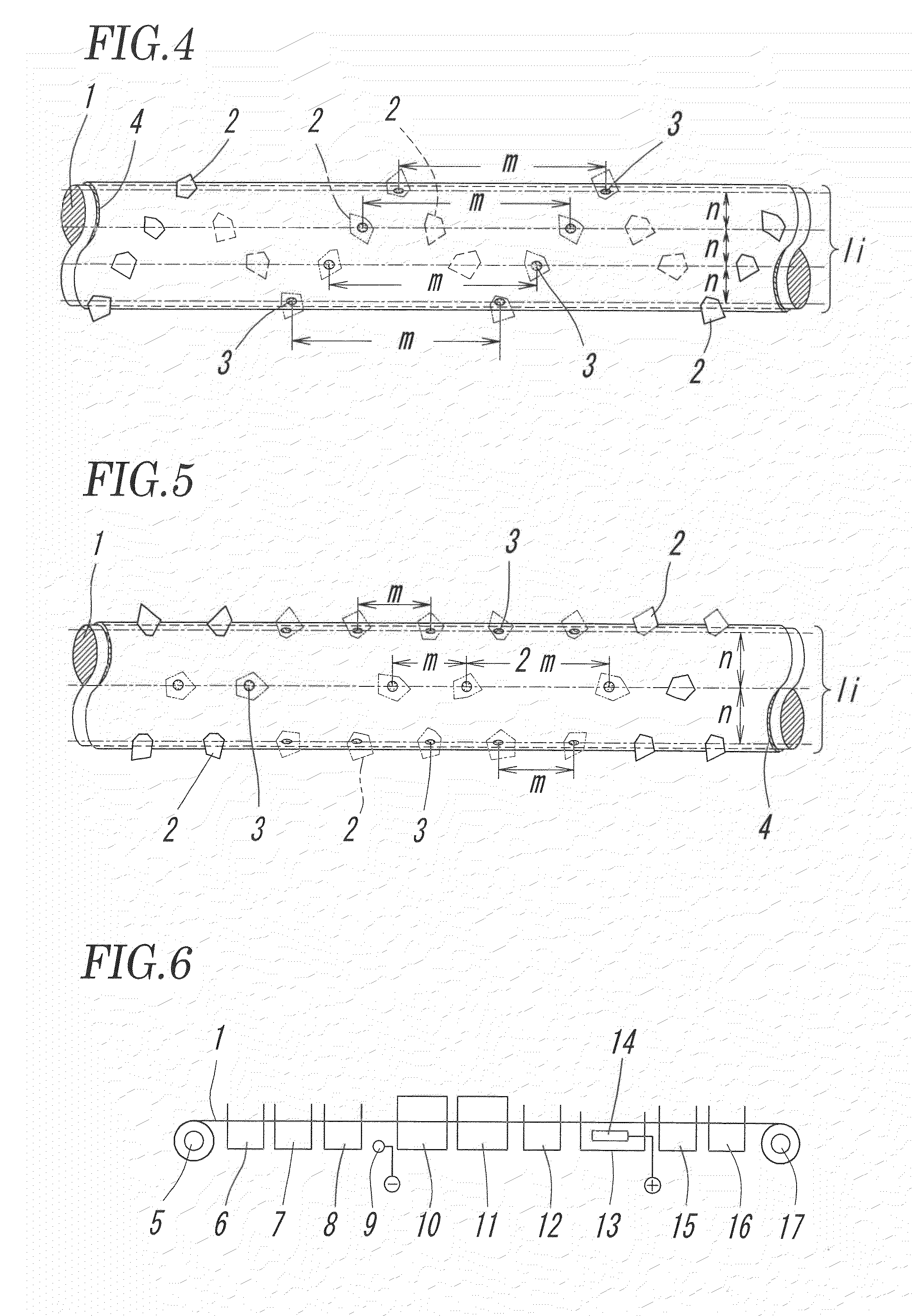

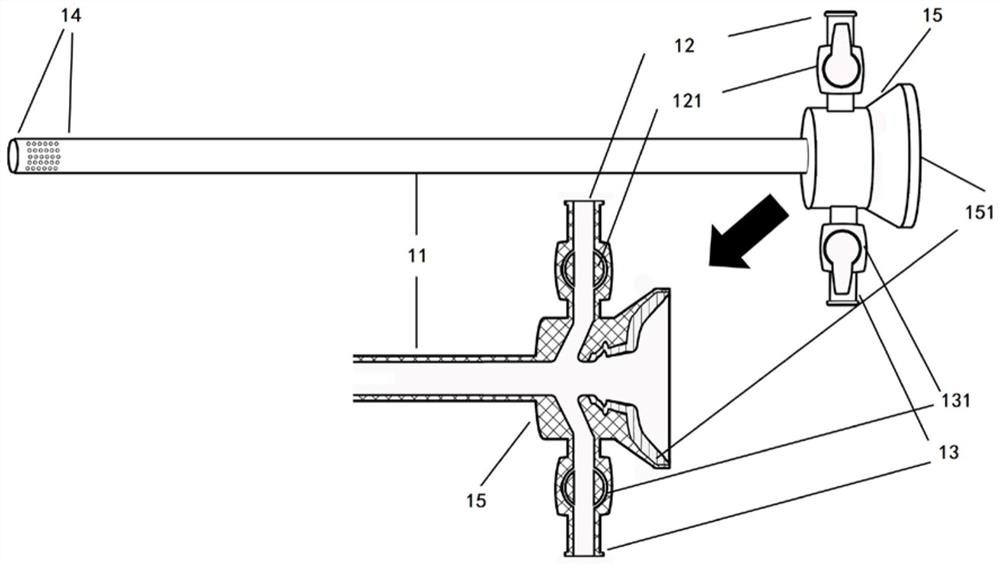

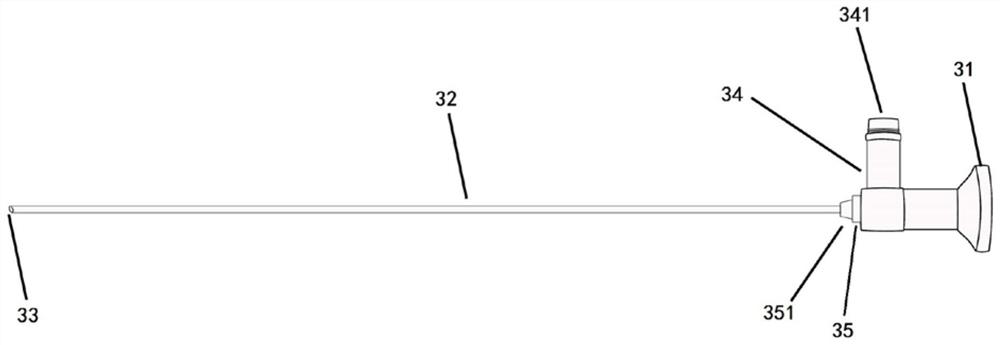

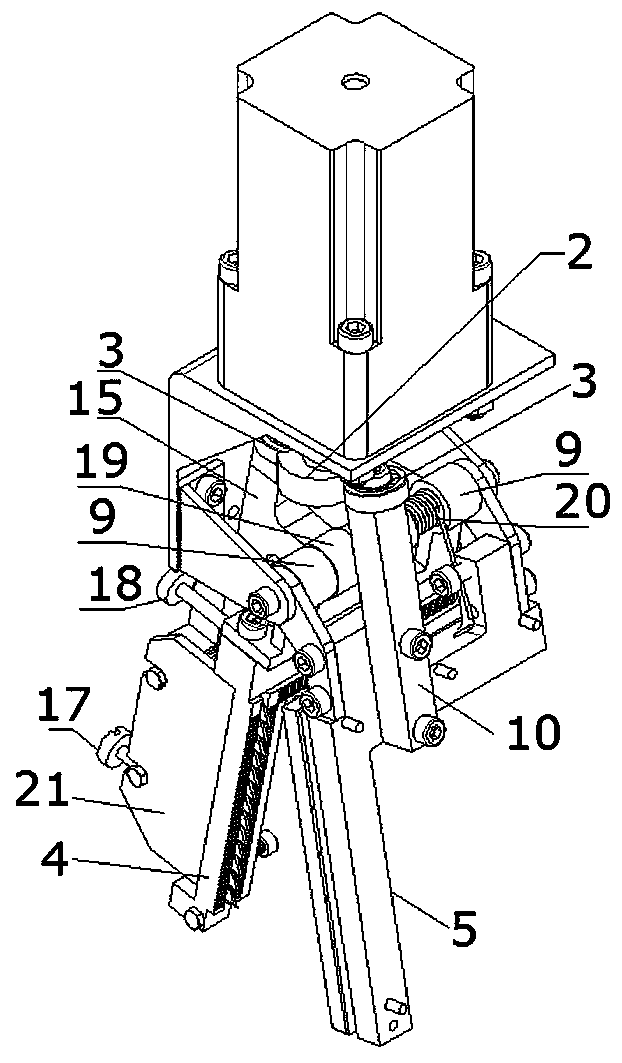

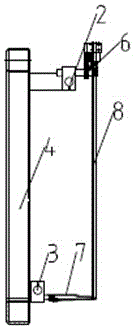

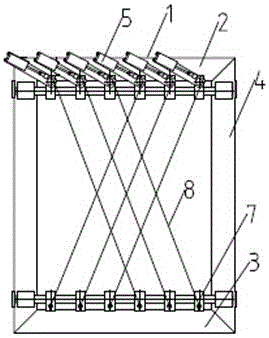

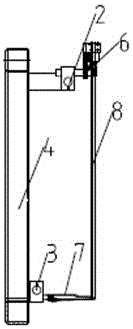

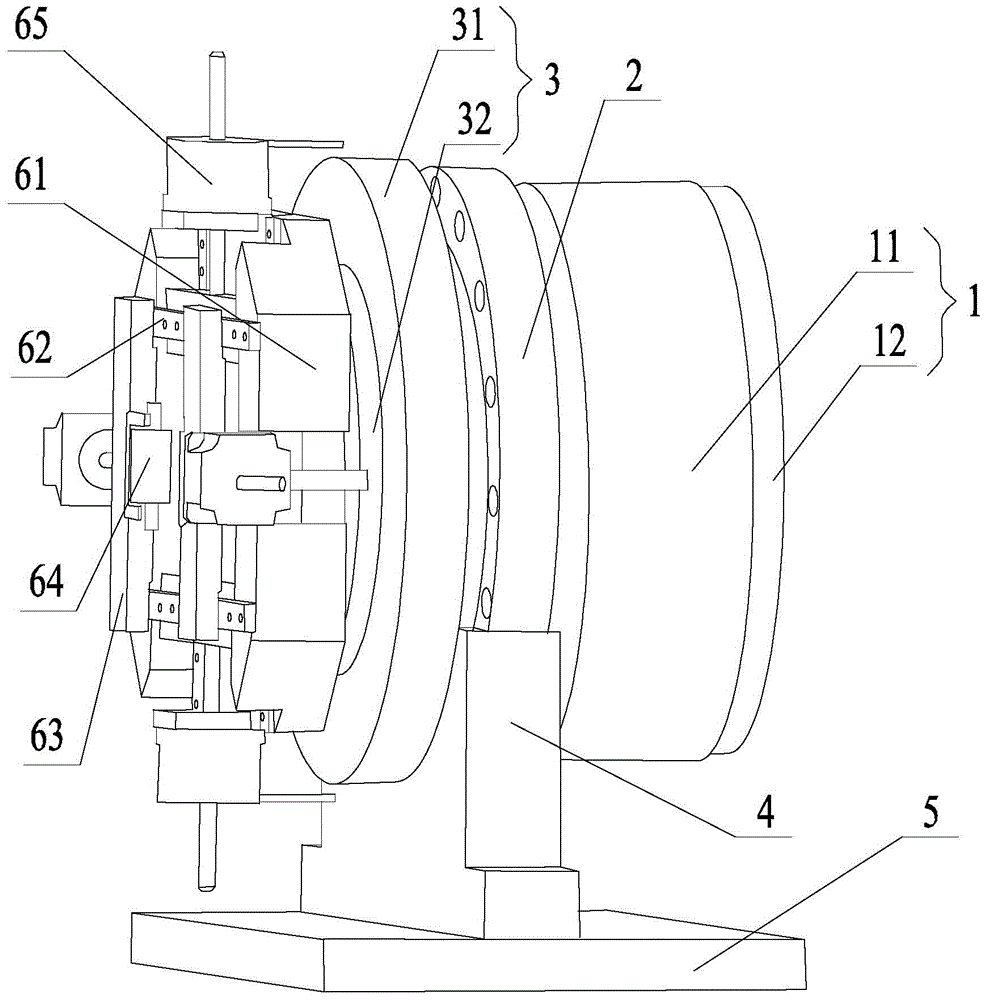

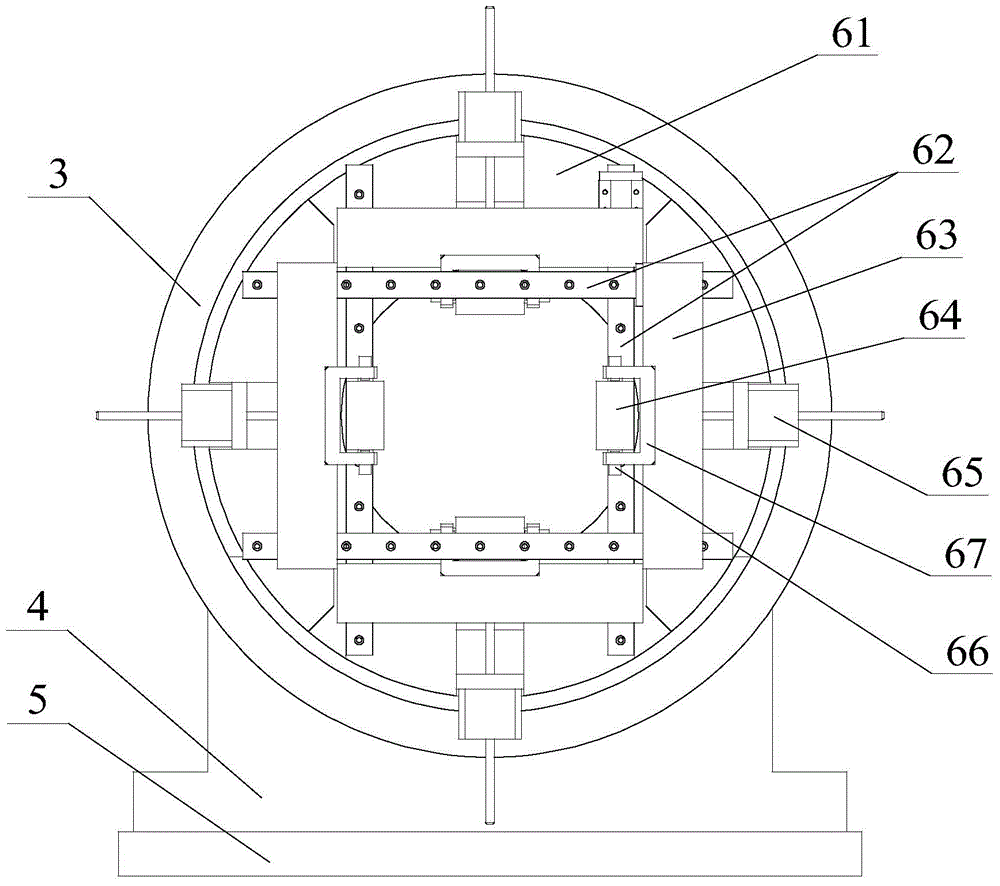

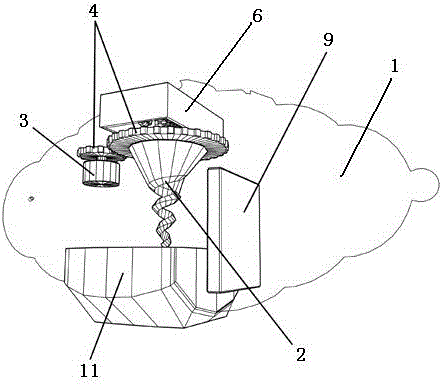

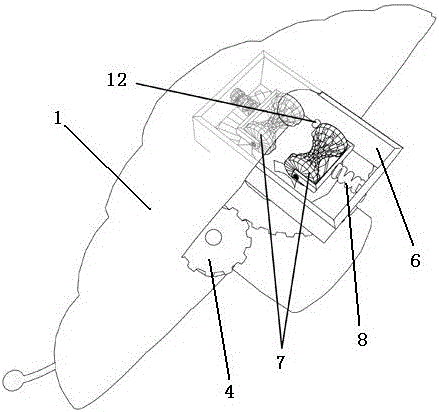

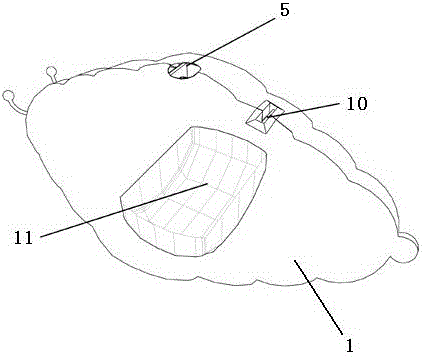

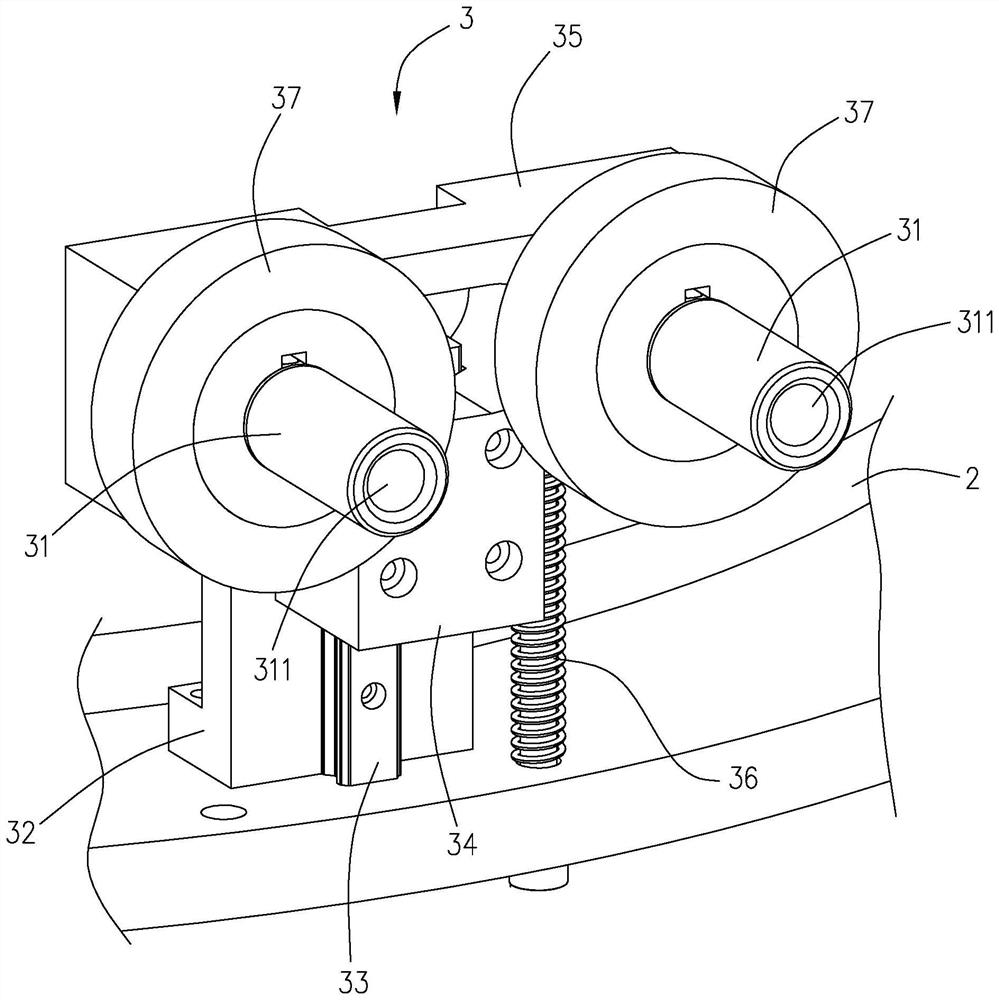

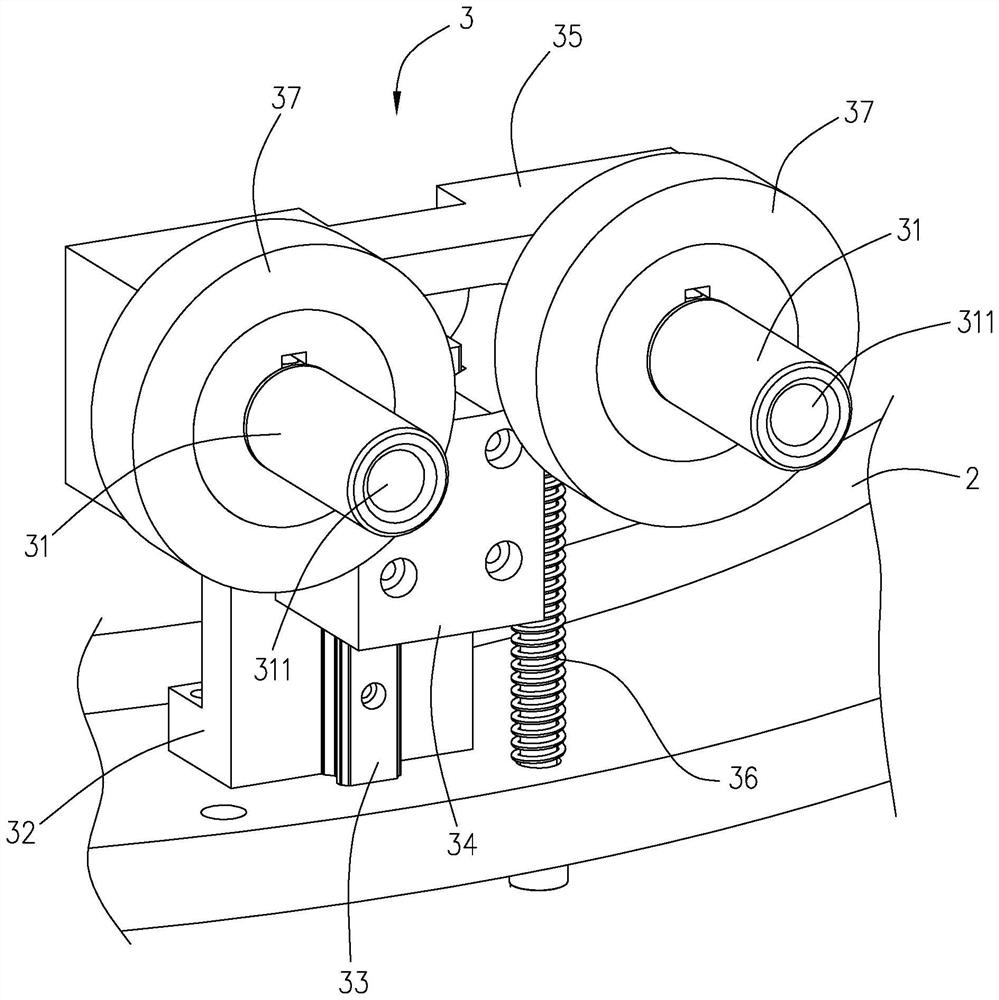

Central support for laser pipe cutting

ActiveCN104014941ASmooth rotationAvoid moment imbalanceWelding/cutting auxillary devicesAuxillary welding devicesLaser cuttingEngineering

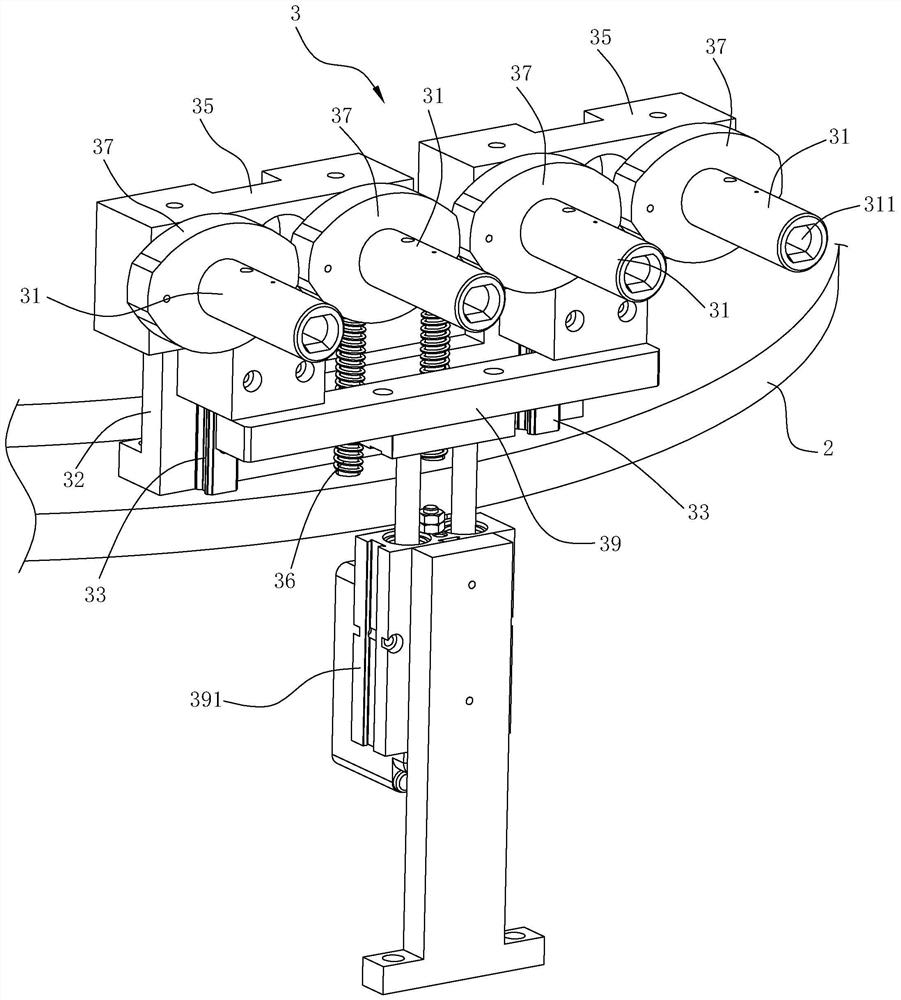

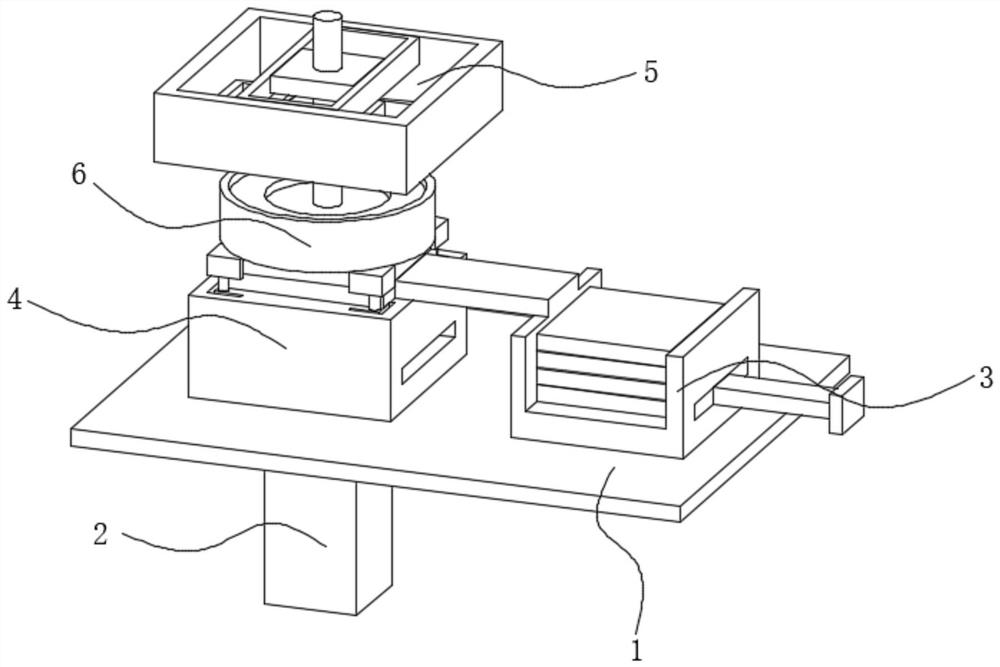

The invention relates to the field of laser cutting devices, in particular to a central support for laser pipe cutting. The outer ring of a large-through-hole bearing is fixed to a fixing base. A frameless motor is arranged on one side of the large-through-hole bearing. A slip ring is arranged on the other side of the large-through-hole bearing. A rotor of the frameless motor, the inner ring of the large-through-hole bearing and a rotary slip ring body of the slip ring are connected in sequence and have the same rotation axis. An idler wheel connecting disk is fixed to the rotating slip ring body, and the rotation axes of the idler wheel connecting disk and the rotating slip ring body are identical. Two pairs of parallel guide rails are arranged on the other side of the idler wheel connecting disk, wherein the two pairs of parallel guide rails are perpendicular to each other. Each pair of parallel guide rails is movably provided with two sliding plates. Each sliding plate is provided with an idler wheel. The four idler wheels face the rotation axis of the idler wheel connecting disk. Each idler wheel is connected with a stepping motor. The frameless motor and the stepping motors are connected with an externally arranged controller. By the adoption of the central support for laser pipe cutting, stable and synchronous rotation of the pipes can be achieved; the central support is suitable for supporting various pipes, and the cutting precision is high.

Owner:WUHAN TIANQI LASER EQUIP MFG

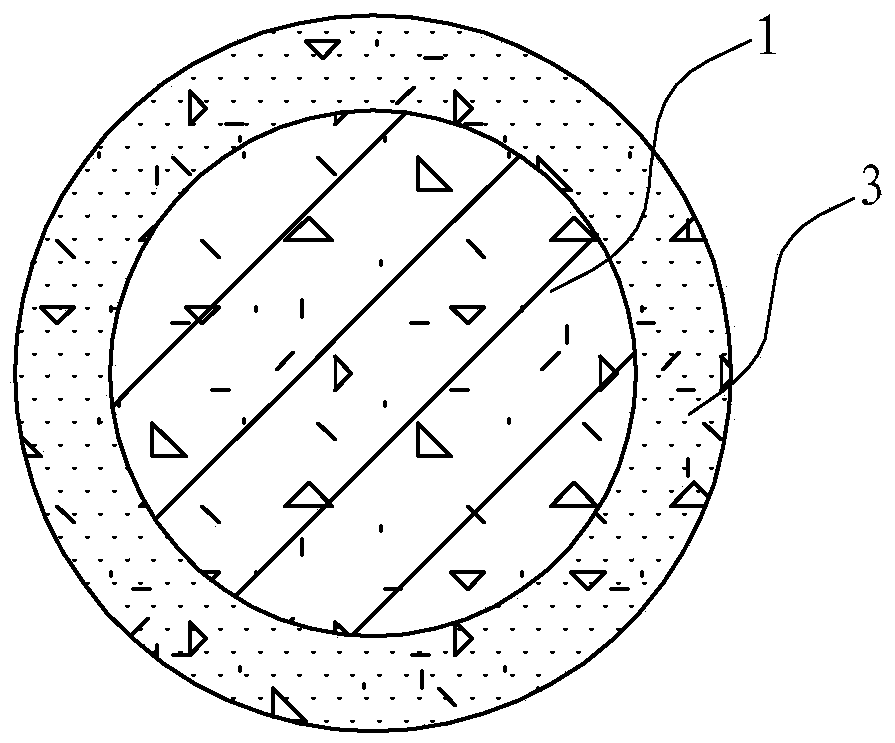

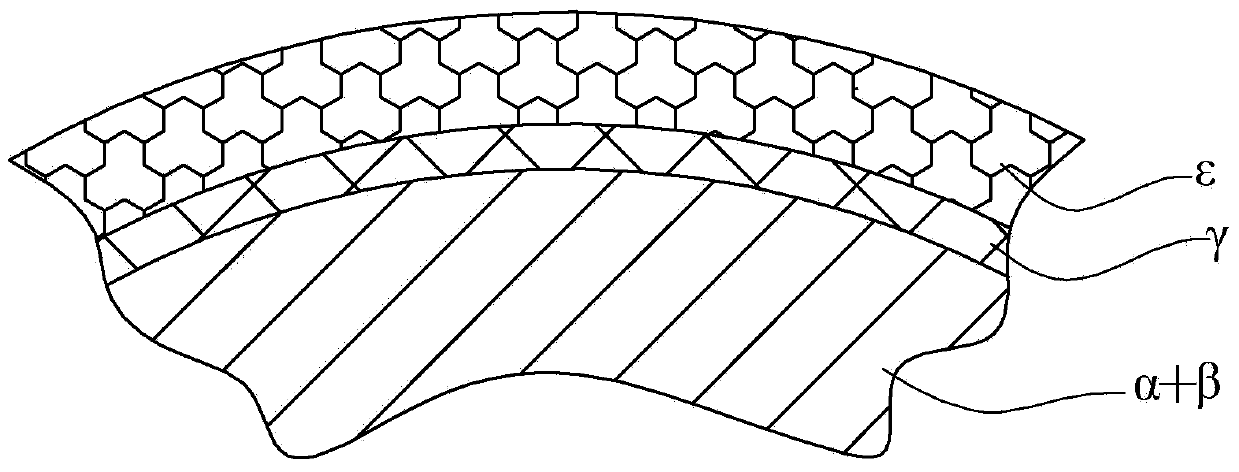

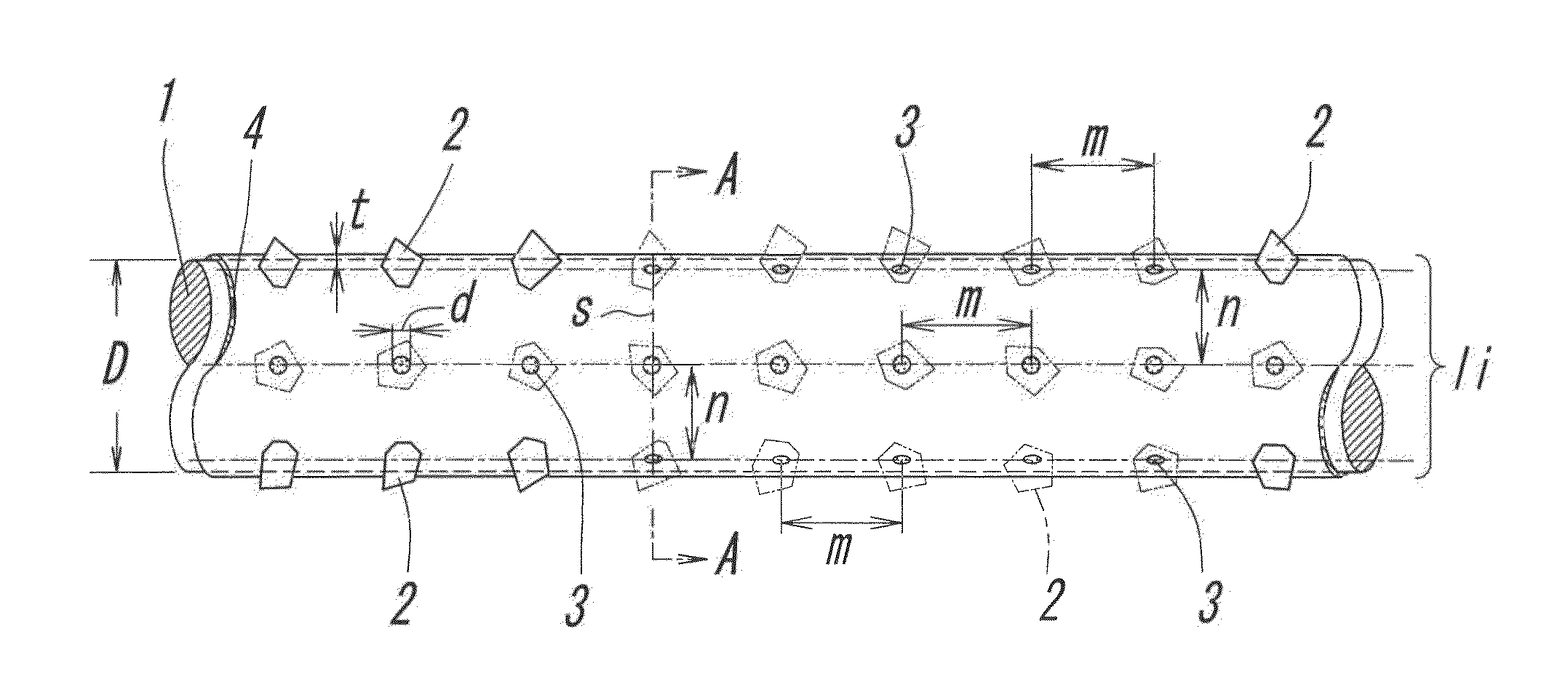

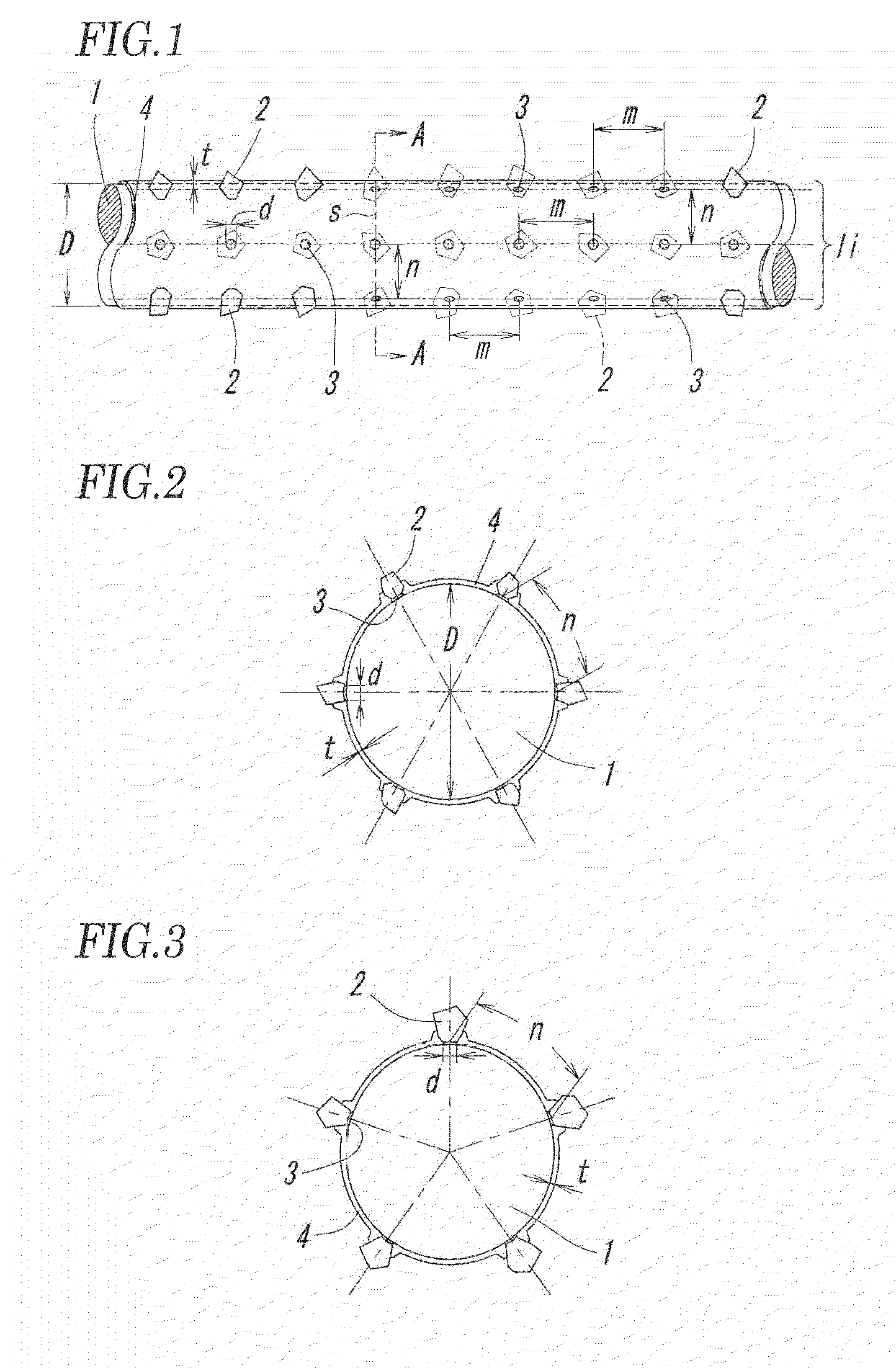

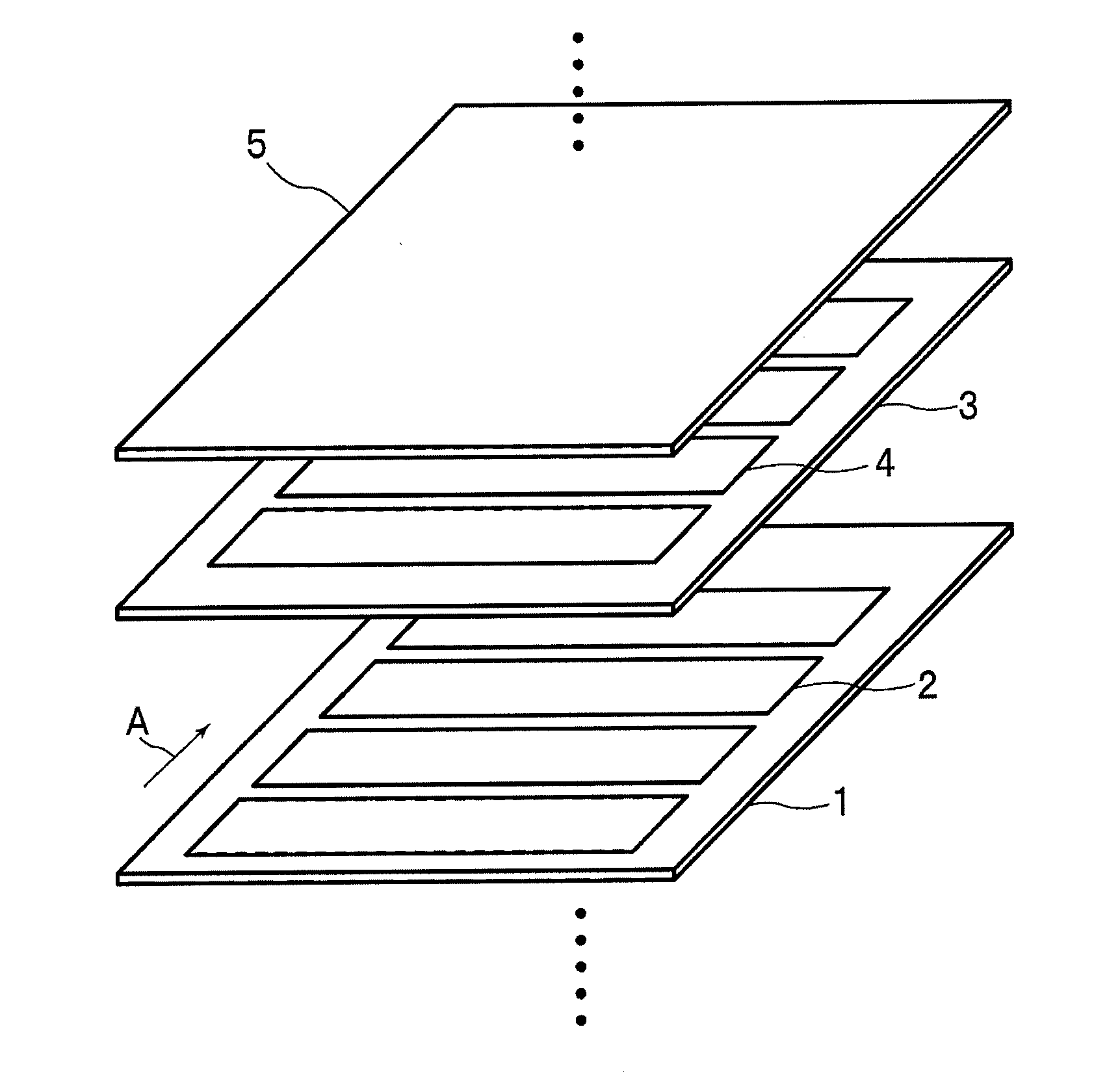

Fixed abrasive grain wire saw, its manufacturing method, and method of cutting workpiece by using it

InactiveUS20150040884A1Suppress formingImprove grinding efficiencyAbrasion apparatusMetal sawing toolsAdhesiveWire saw

A fixed abrasive grain wire saw that can improve precision of a cut plane of a workpiece and grinding efficiency and can prolong product life, a method of manufacturing the fixed abrasive grain wire saw, and a method of machining a workpiece by the fixed abrasive grain wire-saw. To fasten abrasive grains to an outer circumferential surface of a metal core wire, a plurality of transfer rollers, in each of which many tiny holes filled with an adhesive are formed, are used to transfer the adhesive to the outer circumferential surface of the core wire to form, on the outer circumferential surface, a plurality of rows of punctiform adhesive layers that are linearly arrayed in the axial direction at regular intervals. The abrasive grains are tentatively fastened to the adhesive layers, after which the abrasive grains are permanently fastened with a metal plated layer formed by electrolytic deposition.

Owner:RIIDO

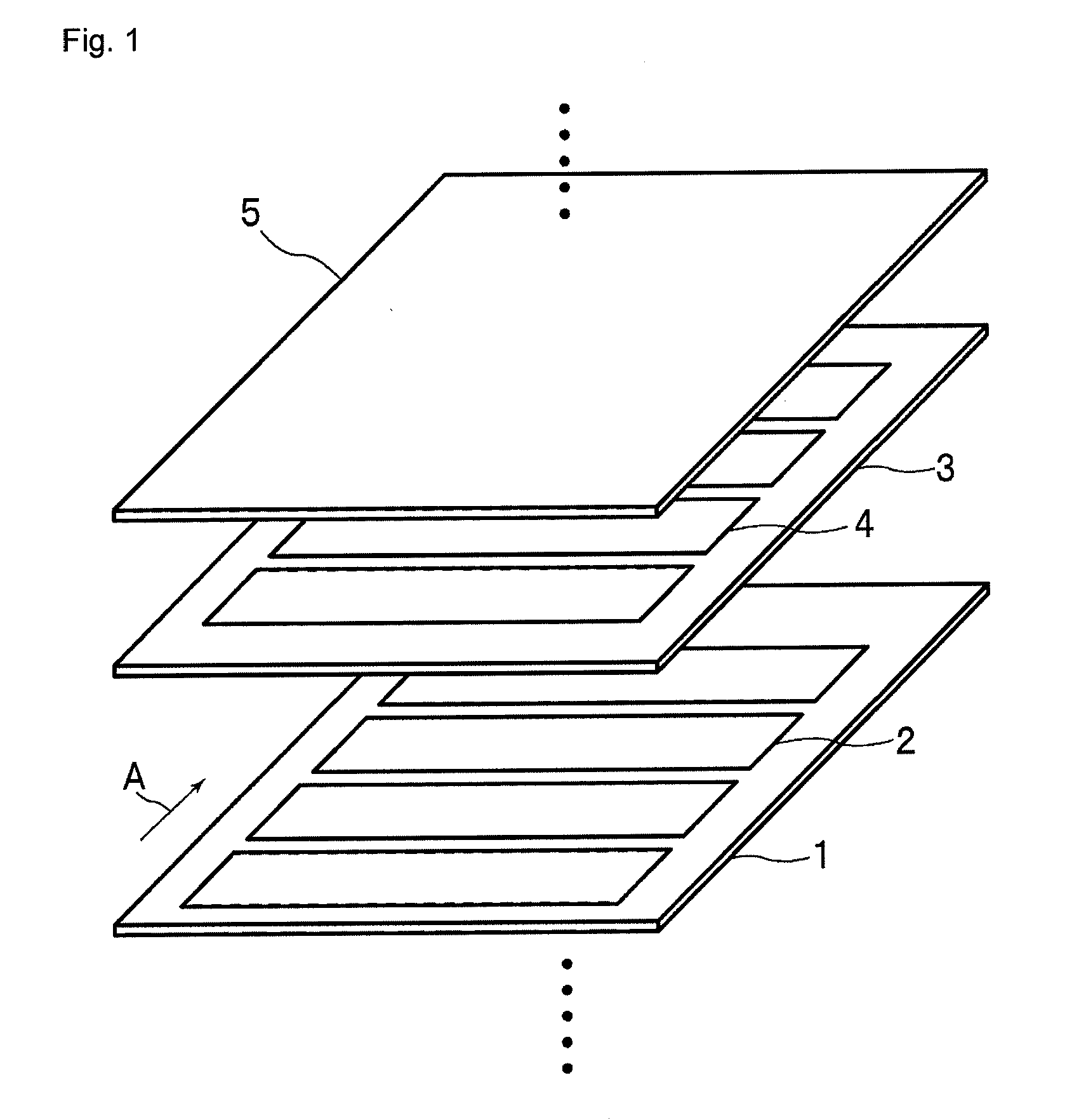

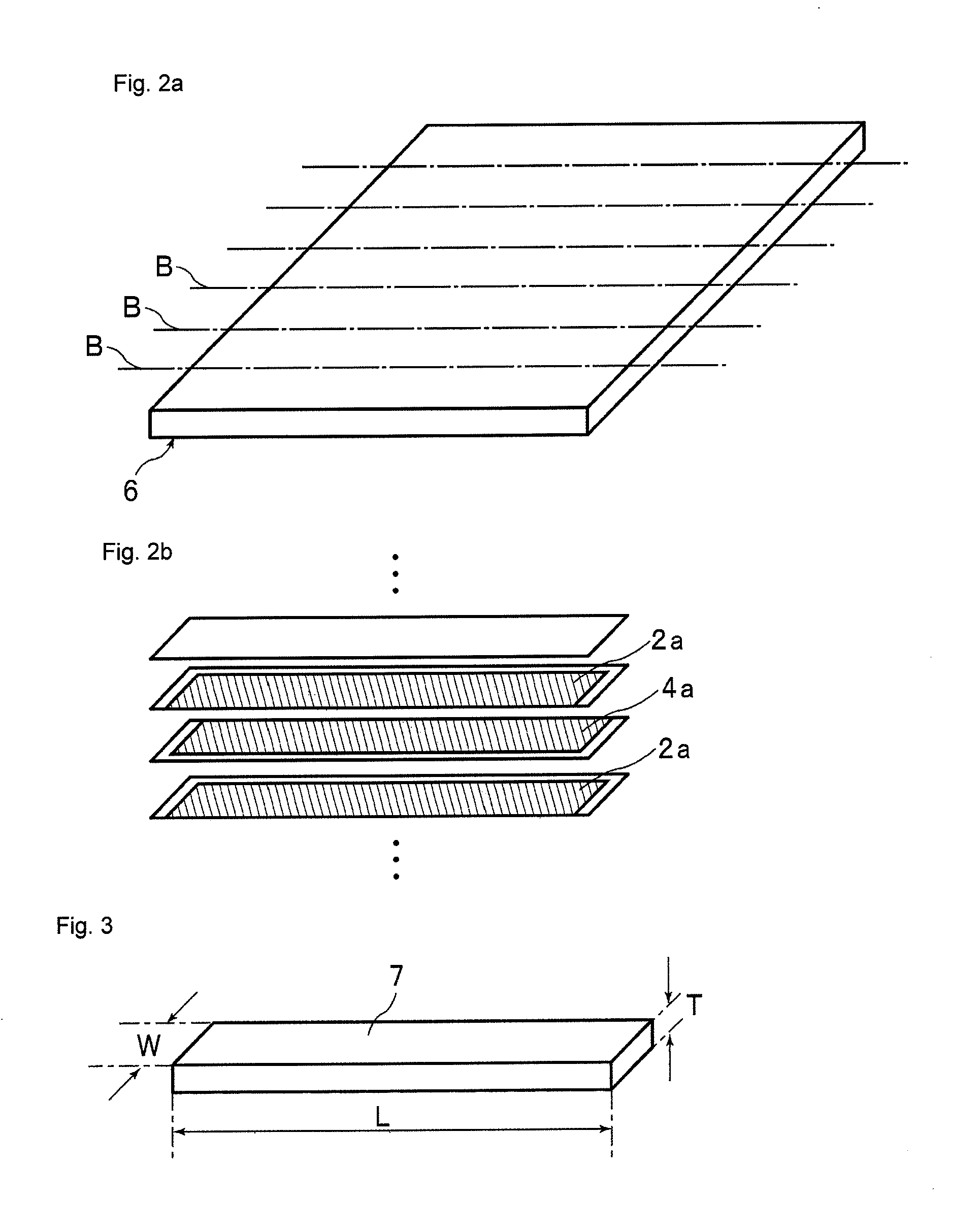

Laminated Pieozelectric Ceramic Element Manufacturing Method

ActiveUS20110024033A1Simplify lamination step stepSimplified cutting stepsPiezoelectric/electrostrictive device manufacture/assemblyLamination ancillary operationsMetallurgySecondary layer

There is provided a laminated piezoelectric ceramic element manufacturing method, wherein, even when the number of internal electrode laminations is increased, the lamination and cutting steps can be simplified, to enhance cutting precision and make cutting cost low. A first laminated body having stripe-like internal electrodes is cut into a plurality of second laminated bodies so as to have a width-direction dimension W corresponding to a width dimension of a laminated piezoelectric ceramic element chip to be ultimately obtained. Two or more second laminated bodies are laminated in the laminating direction to obtain a third laminated body, and the third laminated body is cut in the laminating direction and parallel to the width direction W to obtain a laminated piezoelectric body.

Owner:MURATA MFG CO LTD

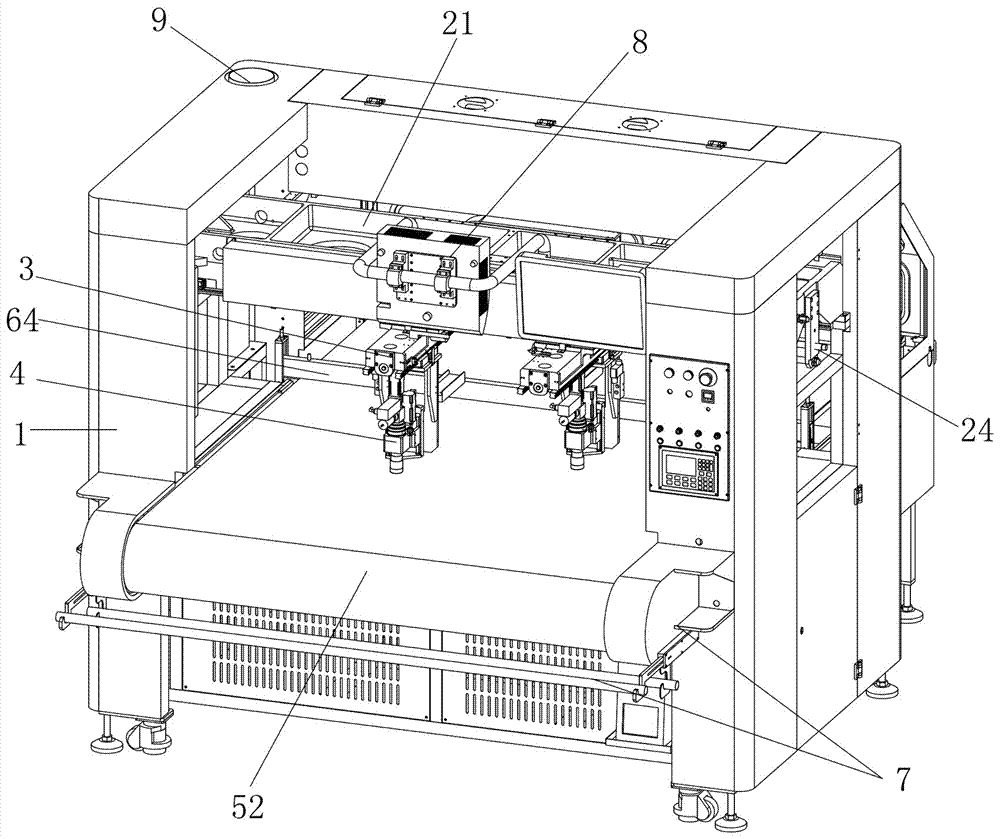

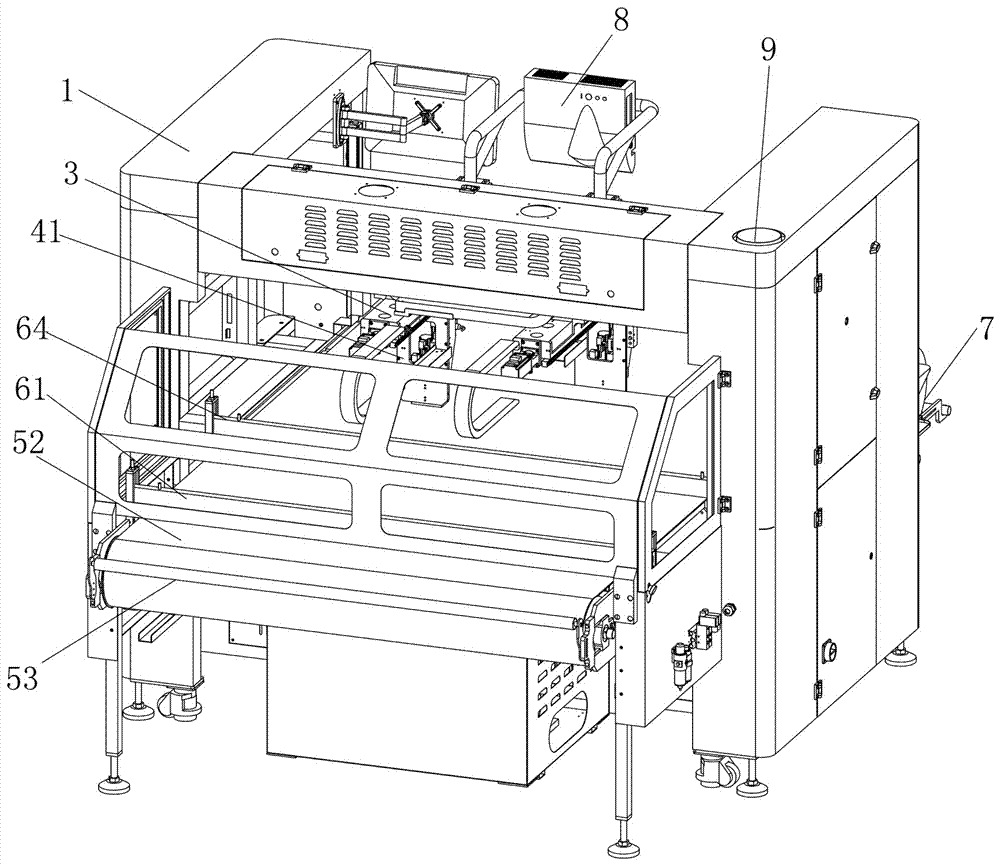

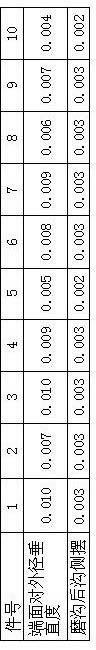

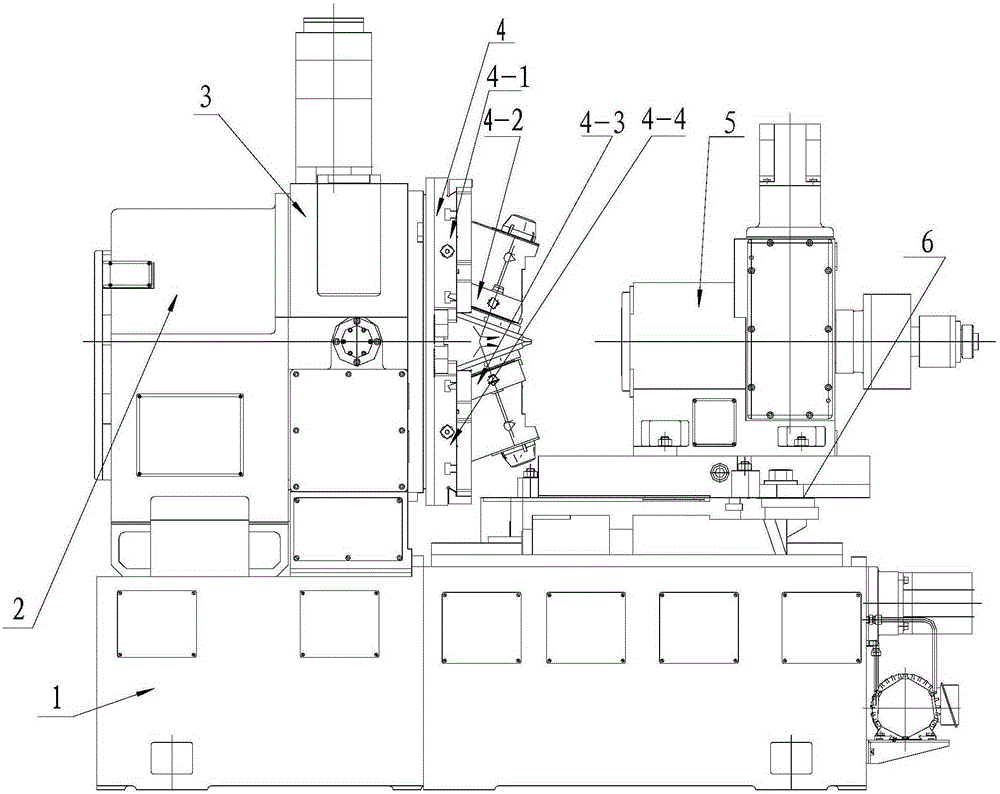

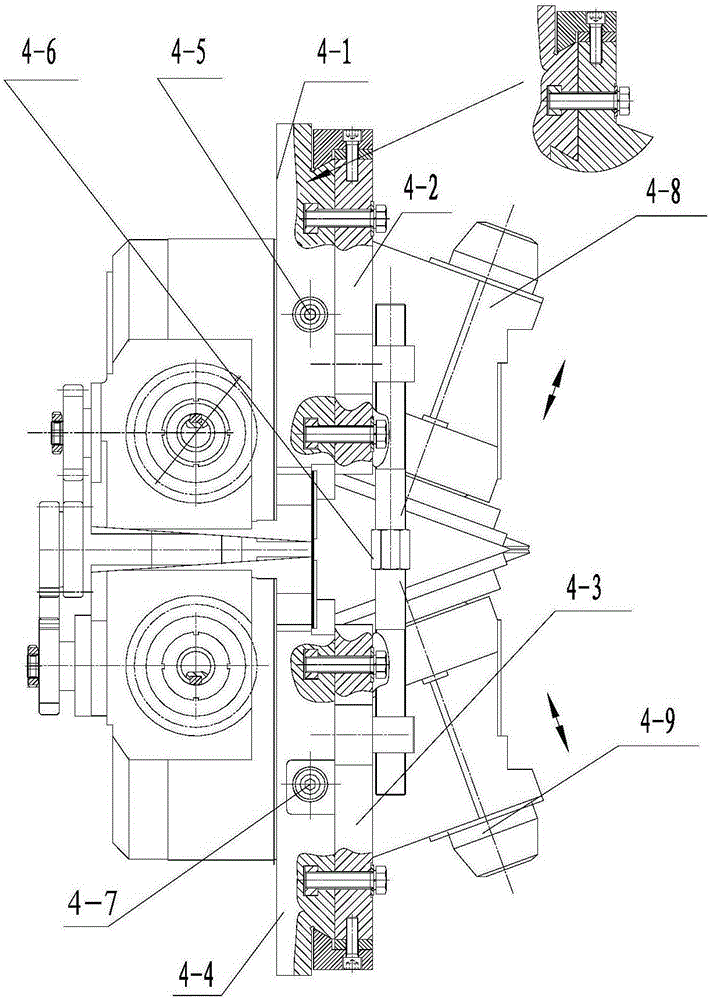

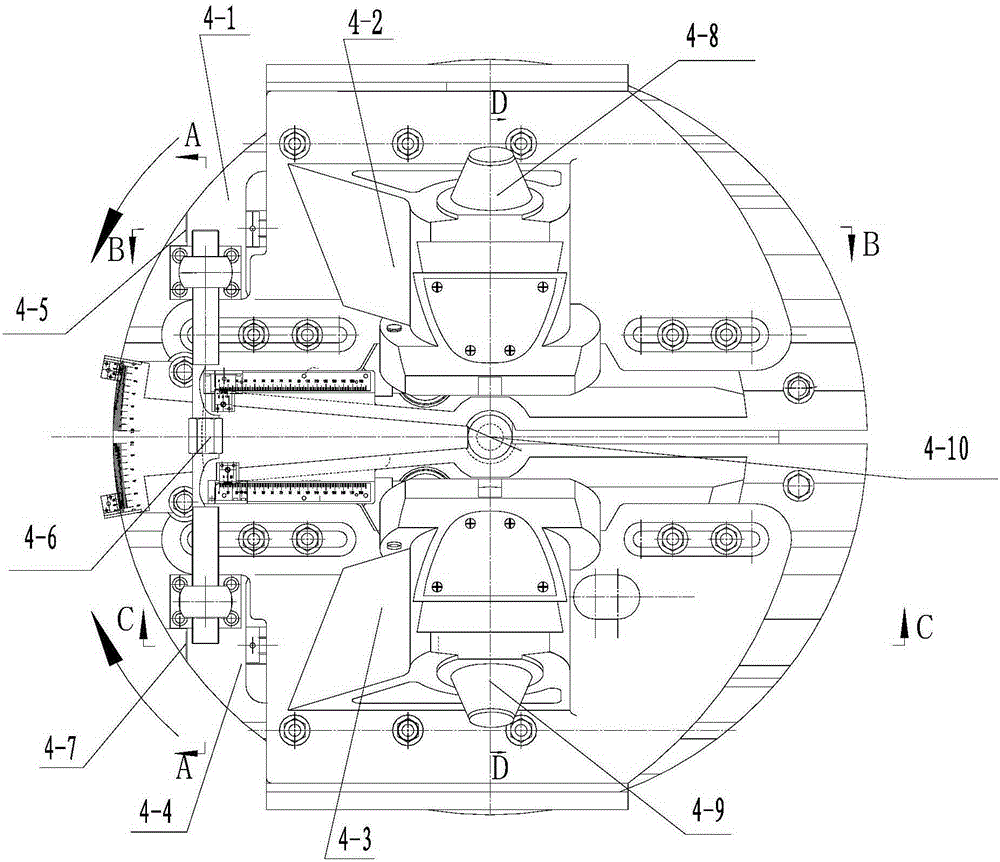

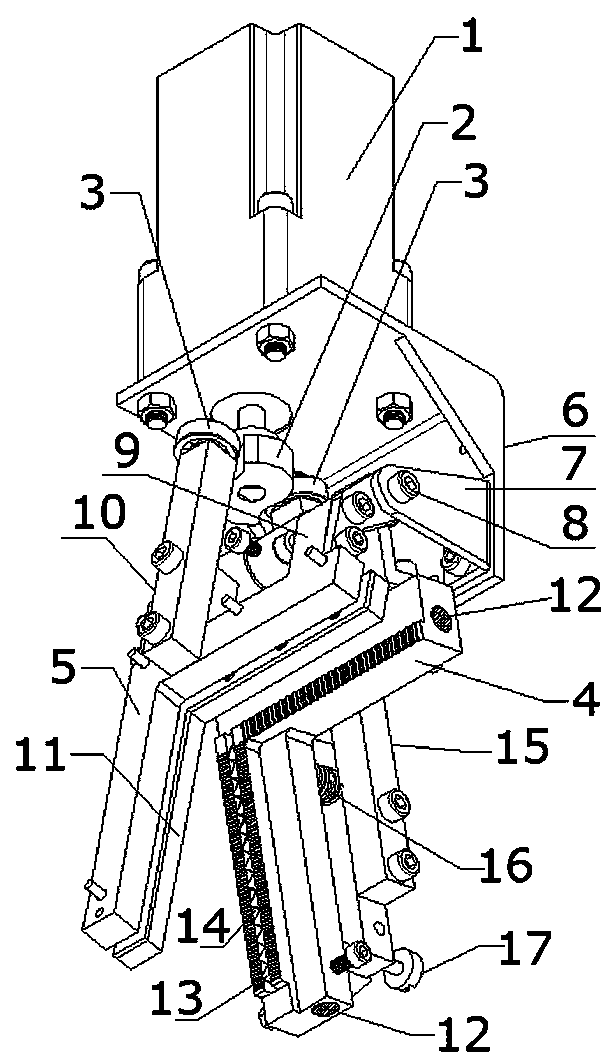

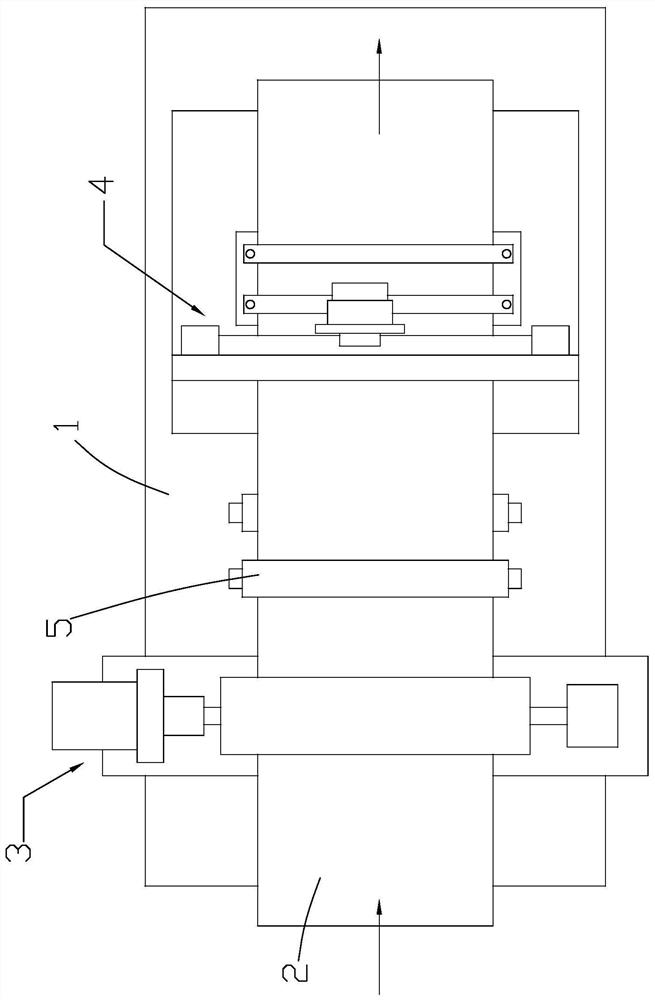

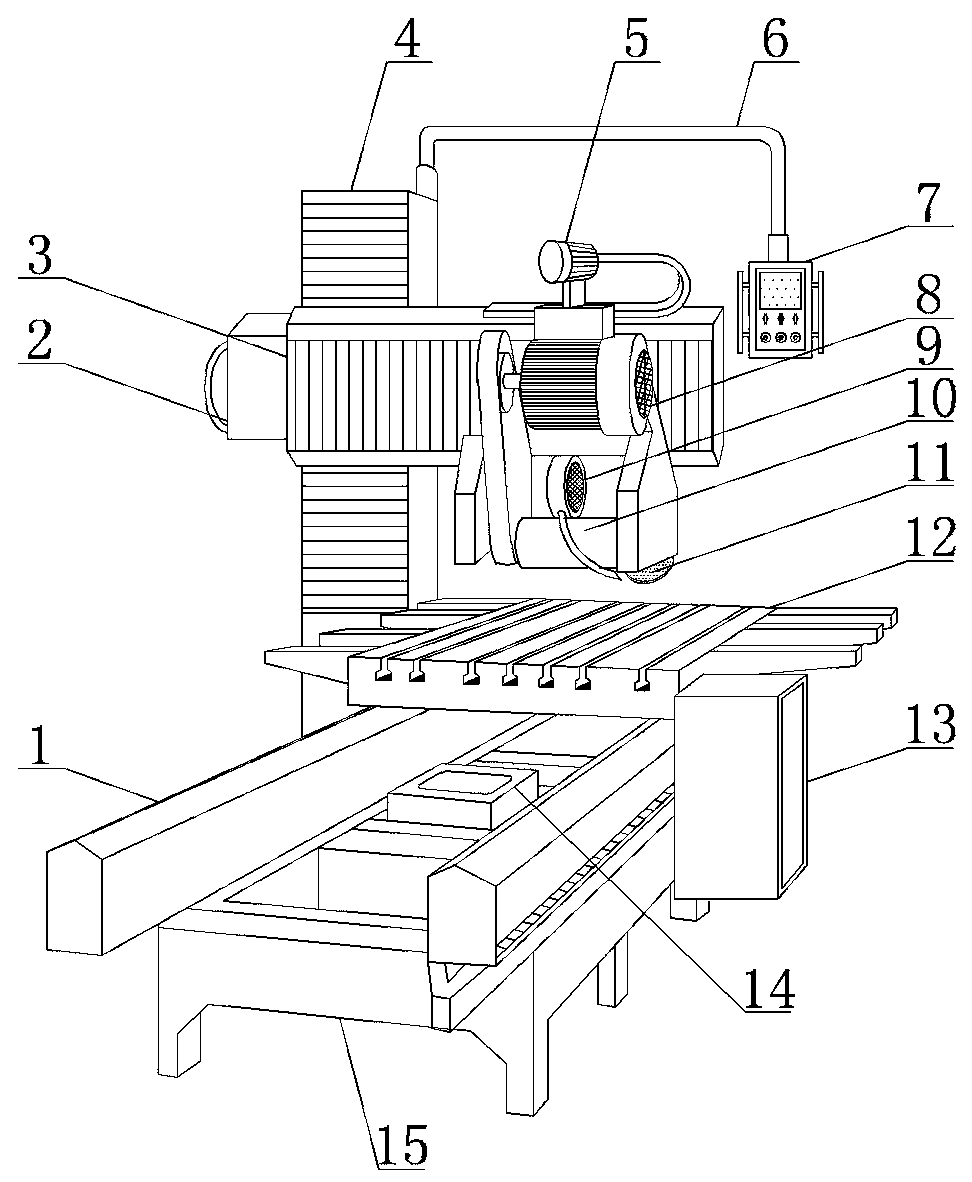

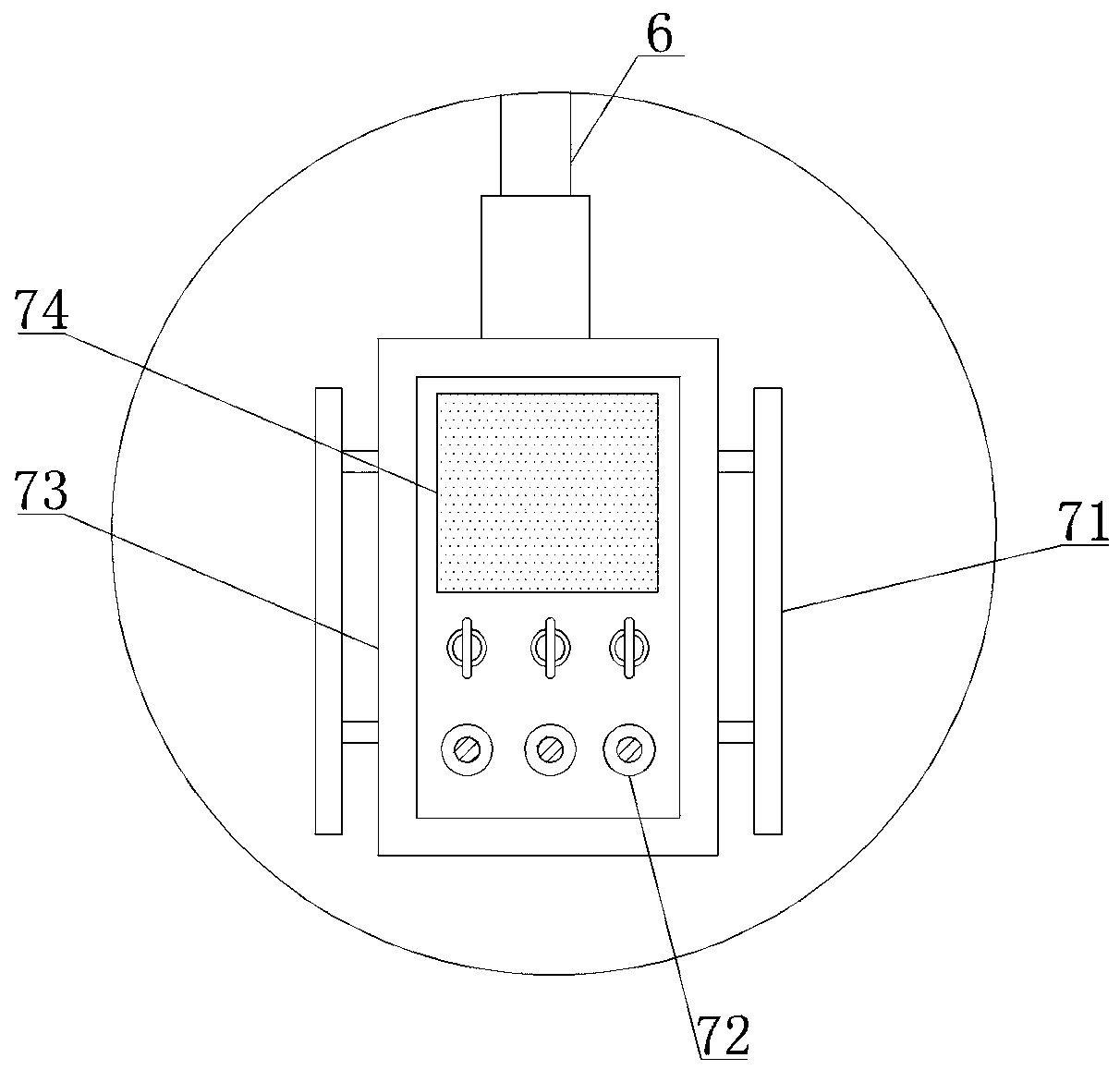

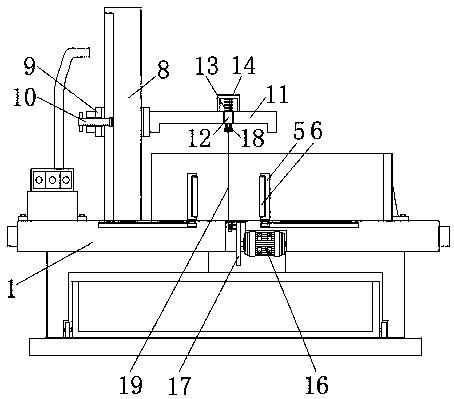

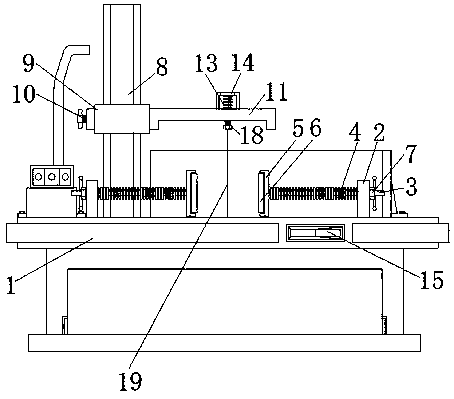

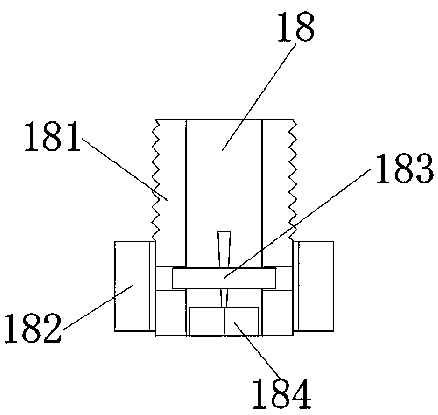

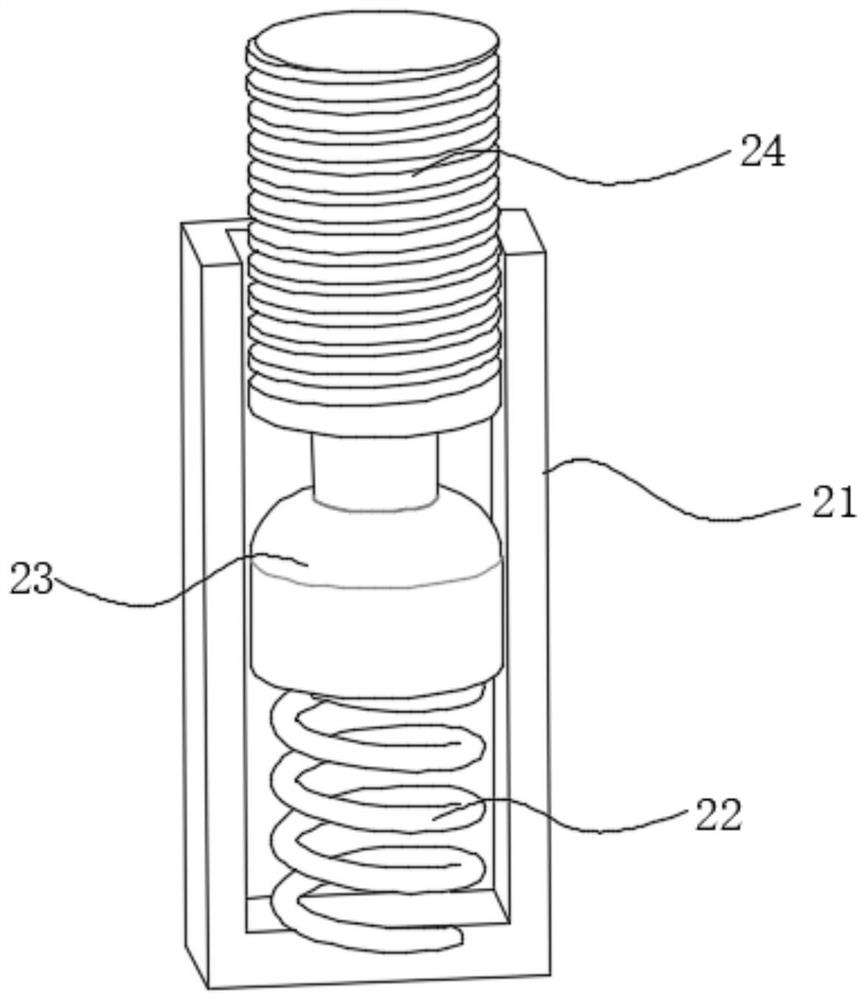

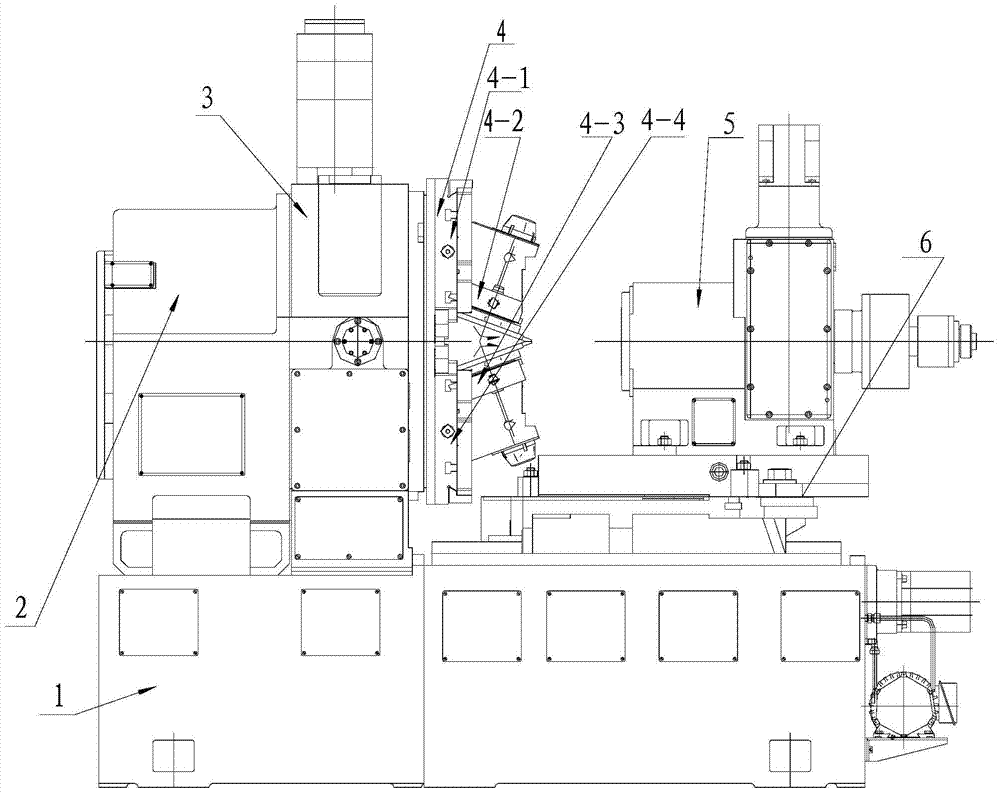

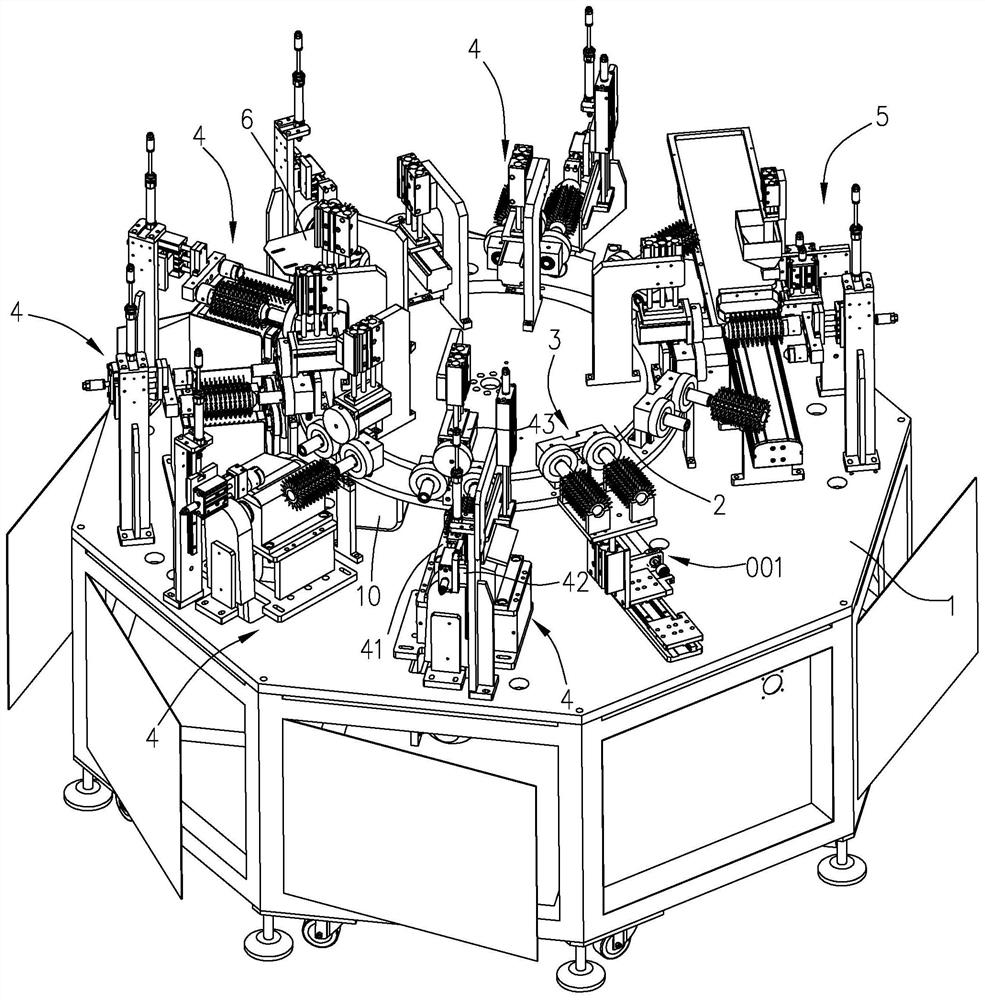

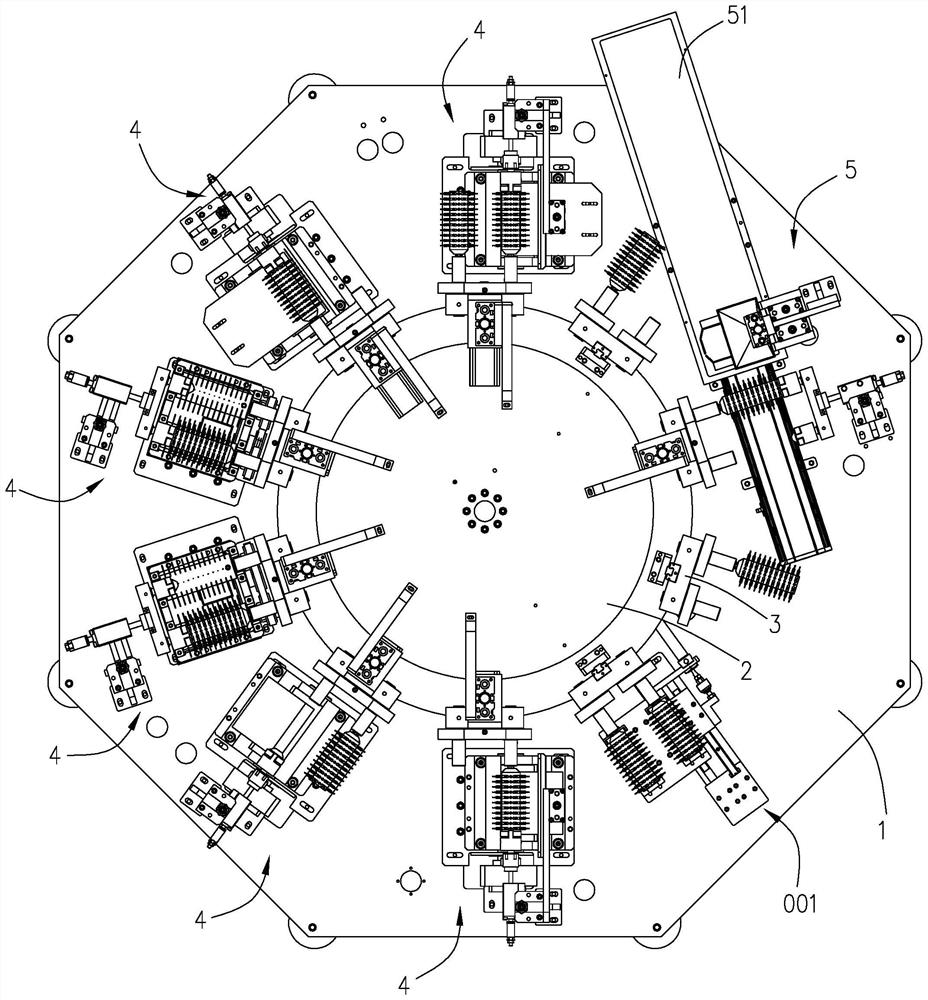

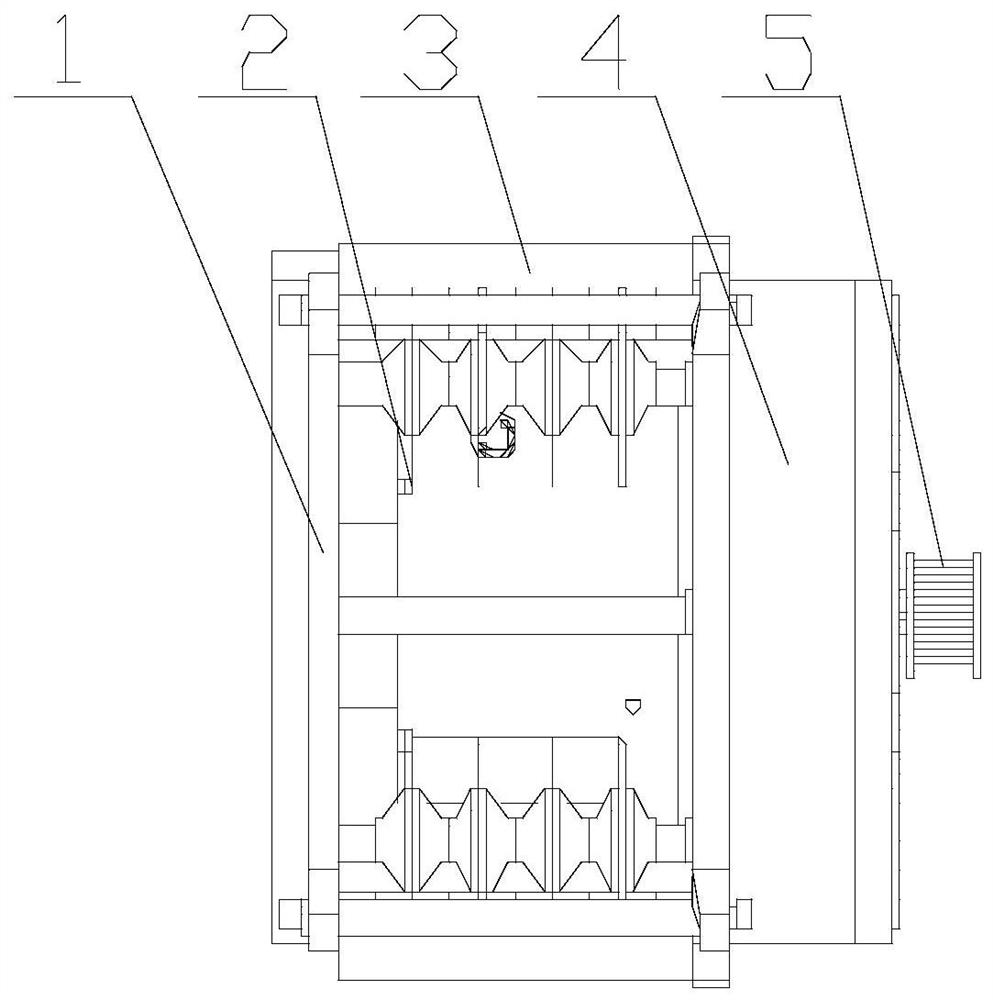

Numerical-control double-cutter-head gear milling machine for straight bevel gears

ActiveCN105215475AImprove cutting precisionAccurate graduationMetal working apparatusGear-cutting machinesNumerical controlManufacturing cost reduction

The invention relates to a numerical-control double-cutter-head gear milling machine for straight bevel gears. The numerical-control double-cutter-head gear milling machine comprises a tool body assembly, a main driving box assembly, a cradle assembly, a cutting tool box assembly, a workpiece box assembly, a saddle turnplate assembly and the like. The numerical-control double-cutter-head gear milling machine is characterized in that the cutting tool box assembly comprises an upper tool holder component, a lower tool holder component, an upper tool box component, a lower tool box component, an upper-lower tool holder angle adjusting mechanism, an upper tool box transverse movement adjusting device and a lower tool box transverse movement adjusting device, and the upper tool holder component, the lower tool holder component, the upper tool box component, the lower tool box component, the upper-lower tool holder angle adjusting mechanism, the upper tool box transverse movement adjusting device and the lower tool box transverse movement adjusting device are installed on drum wheels of the cradle assembly. A spring damping device used for eliminating movement gaps during scale division actions is arranged in the workpiece box assembly. The numerical-control double-cutter-head gear milling machine has the advantages that the overall rigidity of a gear machine tool can be improved, the structure of the machine tool, various movement axis transmission chains and adjustment calculation programs are sufficiently simplified, the manufacturing cost is reduced, and the gear cutting machining accuracy is substantially improved; large-scale gear machining can be achieved, and requirements for machining a single gear or a small batch of various gears can be met.

Owner:天津第一机床有限公司

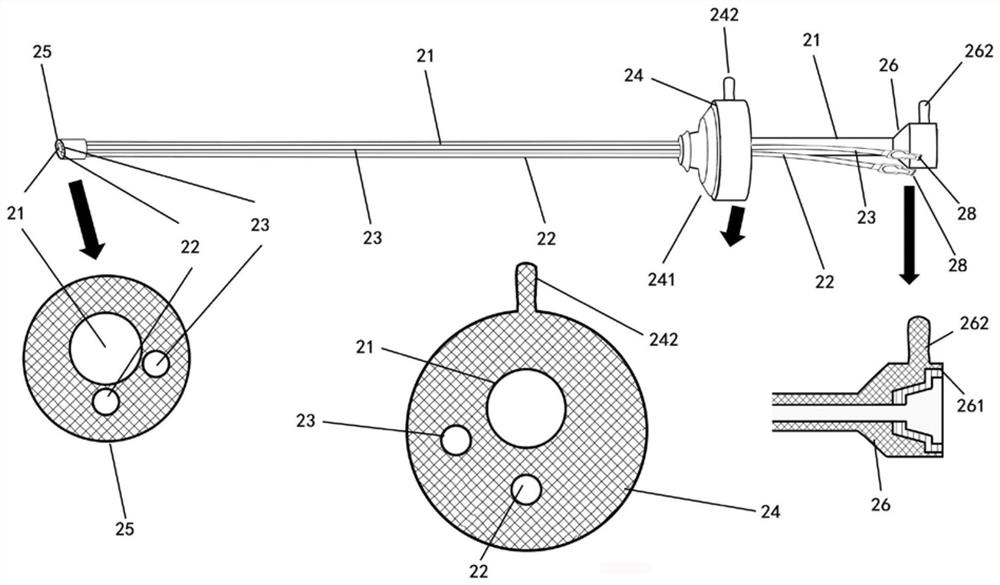

Transurethral double-operation-channel bladder tumor laser monoblock excision equipment

The invention discloses transurethral double-operation-channel bladder tumor laser monoblock excision equipment, which comprises an outer sheath, an operation sheath, a cystoscope endoscope, a laser optical fiber, traction pliers and pushing pliers, wherein the outer sheath comprises an outer sheath body, a water feeding connector and a water discharging connector; the inner end side wall of the outer sheath body is provided with a plurality of perfusion holes; the operation sheath comprises a bladder endoscope operation pipe, a laser operation pipe and an auxiliary pliers operation pipe, wherein the bladder endoscope operation pipe, the laser operation pipe and the auxiliary pliers operation pipe are arranged in parallel, and the operation sheath can be put in the outer sheath body; the bladder endoscope comprises an eyepiece, an endoscope body, an objective lens and a light guiding barrel, wherein the endoscope body of the bladder endoscope can be put in the bladder endoscope operation pipe; the laser optical fiber can be put in the laser operation pipe; the traction pliers and the pushing pliers independently comprise a handle, a pliers rod and a pliers head and can be put in the auxiliary pliers operation pipe; the pliers clamping surface of the pliers head of the traction pliers has a fine grained structure, and the outer end of the pliers head of the traction pliers has a mouse tooth structure; the handle has a buckling and locking structure; and the pliers clamping surface of the pliers head of the pushing pliers has a sawtooth structure. The transurethral double-operation-channel bladder tumor laser monoblock excision equipment has the advantages that a surgeon can conveniently operate the transurethral double-operation-channel bladder tumor laser monoblock excision equipment, operation is more accurate, an applicable range is wide and the like.

Owner:THE SECOND HOSPITAL AFFILIATED TO SUZHOU UNIV

Medicine bag hot sealing and easily-torn line pressing cutting integral forming device

The invention relates to the technical field of plastic bag sealing, in particular to a medicine bag hot sealing and easily-torn line pressing cutting integral forming device. A speed reduction stepping motor is adopted for driving the whole device, two bearings are attached to a bidirectional cam under the effect of a torsion spring, the bidirectional cam is used for strutting a first pressing rod and a second pressing rod, closing of an L-shaped hot sealing metal plate and an L-shaped silica gel plate is achieved, and therefore hot sealing is conducted on a medicine bag; meanwhile, when thedistance of the two bearings is the largest, a blade is pushed from a blade channel under the condition that the medicine bag does not need to be moved, and the blade cuts a hot sealing bar accurately. A traditional hot sealing device and a traditional cutting pressing device are integrated, one driving part is omitted, in addition, hot sealing and cutting pressing are synchronously completed, thecost is saved, the efficiency is improved, and the cutting pressing accuracy is further greatly improved.

Owner:苏州慧思腾科技有限公司

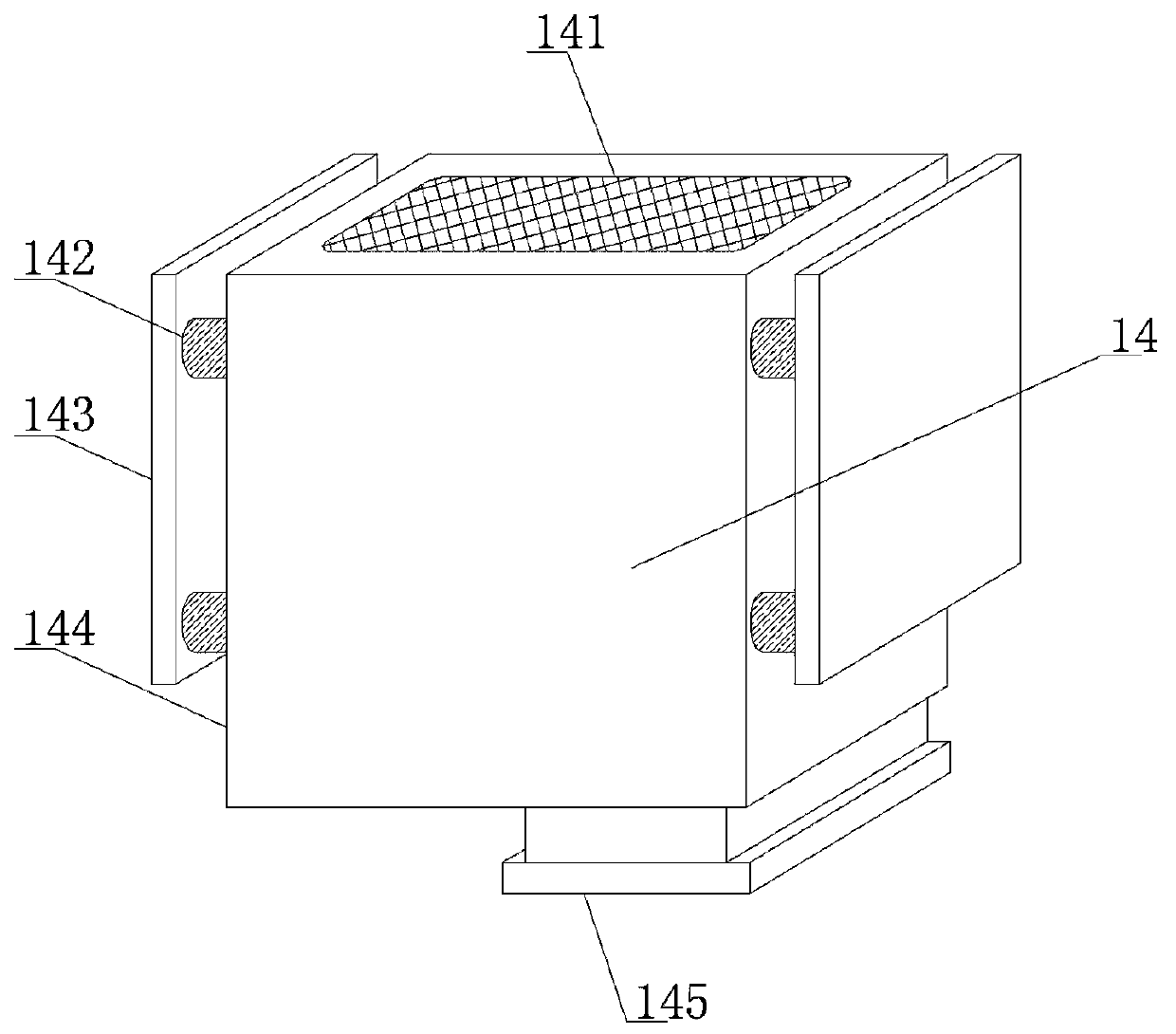

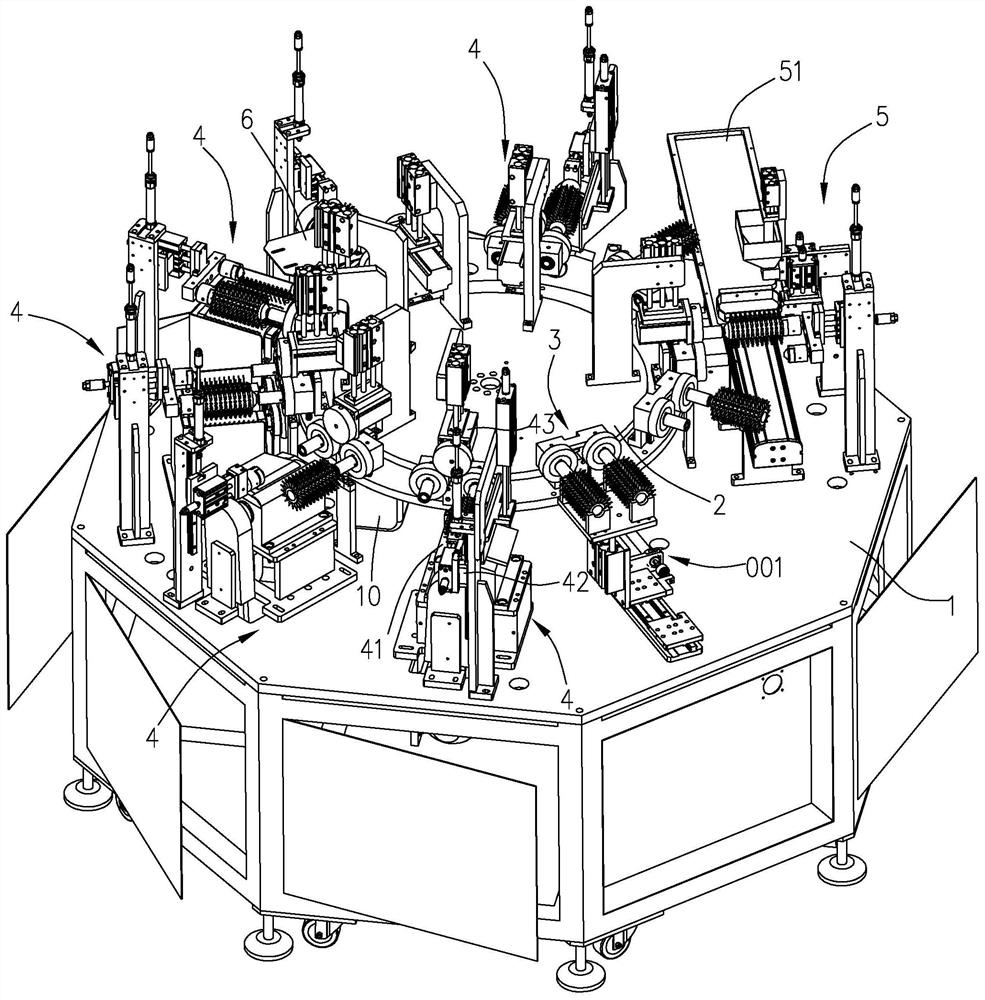

Insert and insert core disassembling and assembling device

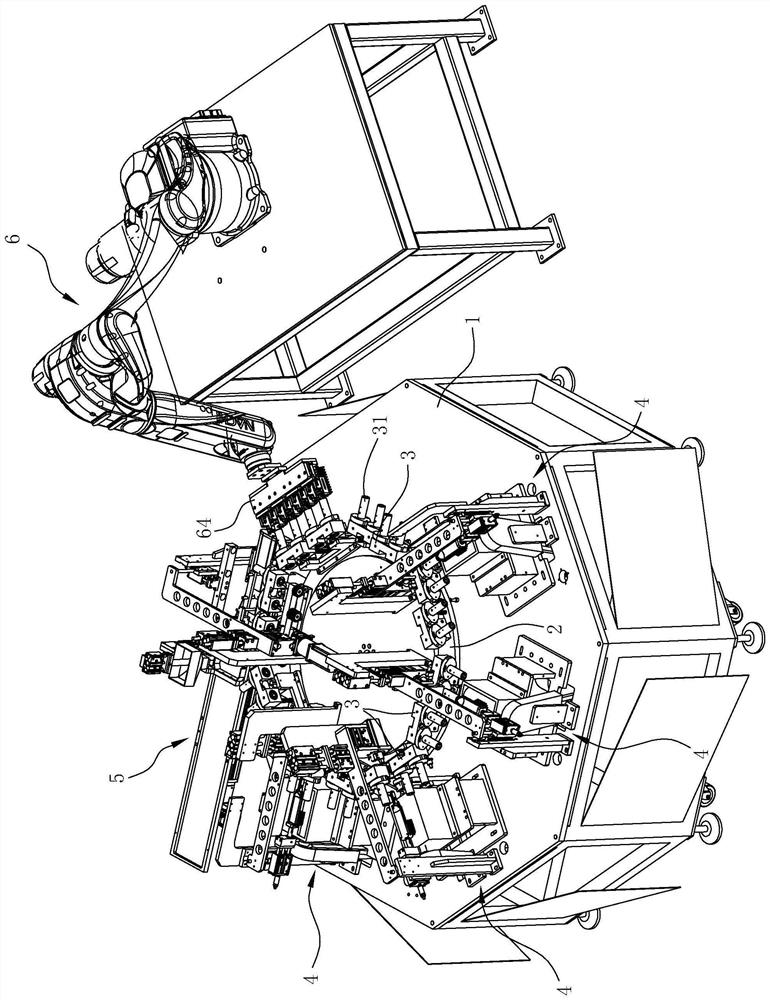

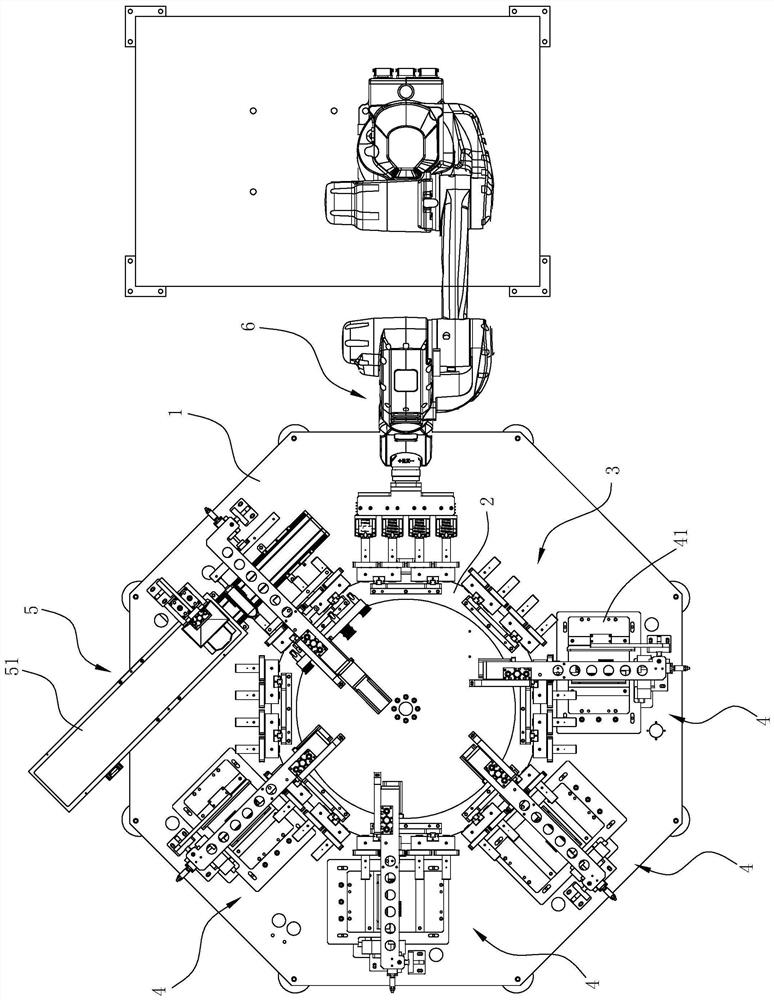

ActiveCN111890632ARealize the function of automatic croppingAchieve consistencyCoatingsManual handlingIndustrial engineering

The invention provides an insert and insert core disassembling and assembling device. The device comprises a sprue cutting and separating mechanism used for cutting a sprue of a formed product and separating an insert core in the formed product from the product; an insert core transferring and carrying mechanism which is used for carrying the insert cores separated by the sprue cutting and separating mechanism to the insert core assembling mechanism; an insert feeding and carrying mechanism which is used for carrying a to-be-assembled insert to an insert core assembling mechanism; and the insert core assembling mechanism is used for assembling the insert core and the insert together. By means of the insert and insert core disassembling and assembling device provided by the invention, the problems that the labor intensity of workers is high, the insert assembling size is poor in consistency, the efficiency is low, and the sprue shearing quality is uneven due to the fact that the manualoperation is adopted in the exiting insert feeding, disassembling of an injection support product and the shearing production process are solved.

Owner:GEER TECH CO LTD

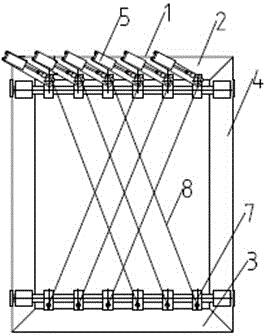

Cross topping and cutting device on basis of vapor-pressure aerating building block

The invention discloses a cross topping and cutting device on the basis of a vapor-pressure aerating building block. The cross topping and cutting device comprises a movable pre-cutting frame, steel wire side-stretching support rods, wire clamping and staying air cylinders and cutting steel wires. Flatness of the cut surface is ensured while elastic deformation force of the cutting steel wires is concentrated in the middle of a blank, elastic stress is offset by the cross structure, and edge breakage caused by diagonally pulling the steel wires to separate from the single side is avoided; cutting accuracy is ensured by the cross cutting steel wires, lateral cross grains are eliminated, and similar cutting effect of scissors during cutting is generated. The cross topping and cutting device is novel in design, reasonable and simple in structure.

Owner:DONGYUE MACHINERY GRP

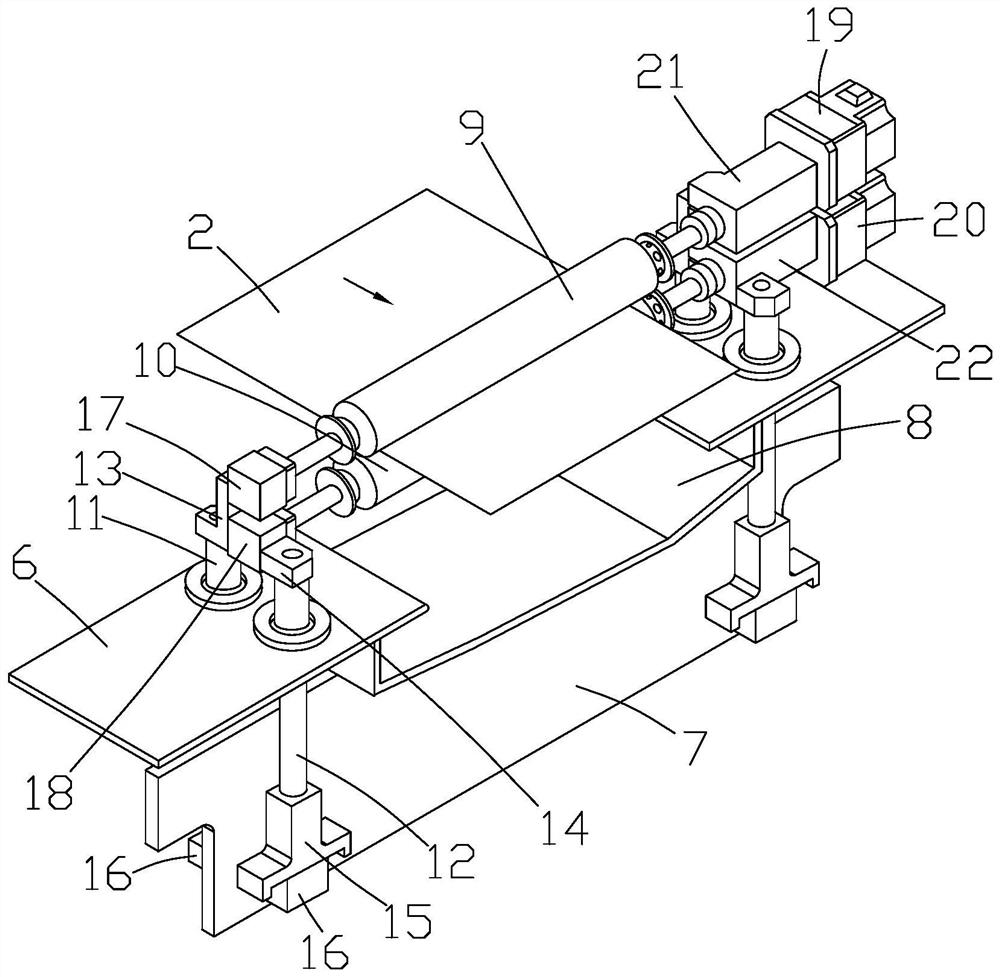

An intelligent platform rear projection film processing device and method

ActiveCN109080100BImprove machining accuracyHigh transparencyMetal working apparatusEngineeringAssembly line

The invention discloses an intelligent podium rear projection film processing device and method, comprising a base plate, an extrusion forming device and a cutting device, the extrusion forming device and the cutting device are located on the top surface of the base plate, between the extrusion forming device and the cutting device An auxiliary roller is provided, and the rear projection film passes through the extrusion forming device, the auxiliary roller and the cutting device in sequence. The processing method includes: raw material mixing, rear projection film extrusion molding, rear projection film cutting and rear projection film post-processing. The rear projection film processing method of the present invention has simple steps, not only improves the extrusion molding efficiency of the rear projection film, but also improves the cutting processing precision of the rear projection film, meets the needs of assembly line production, and improves the production efficiency of the rear projection film.

Owner:ZHEJIANG COLLEGE OF CONSTR

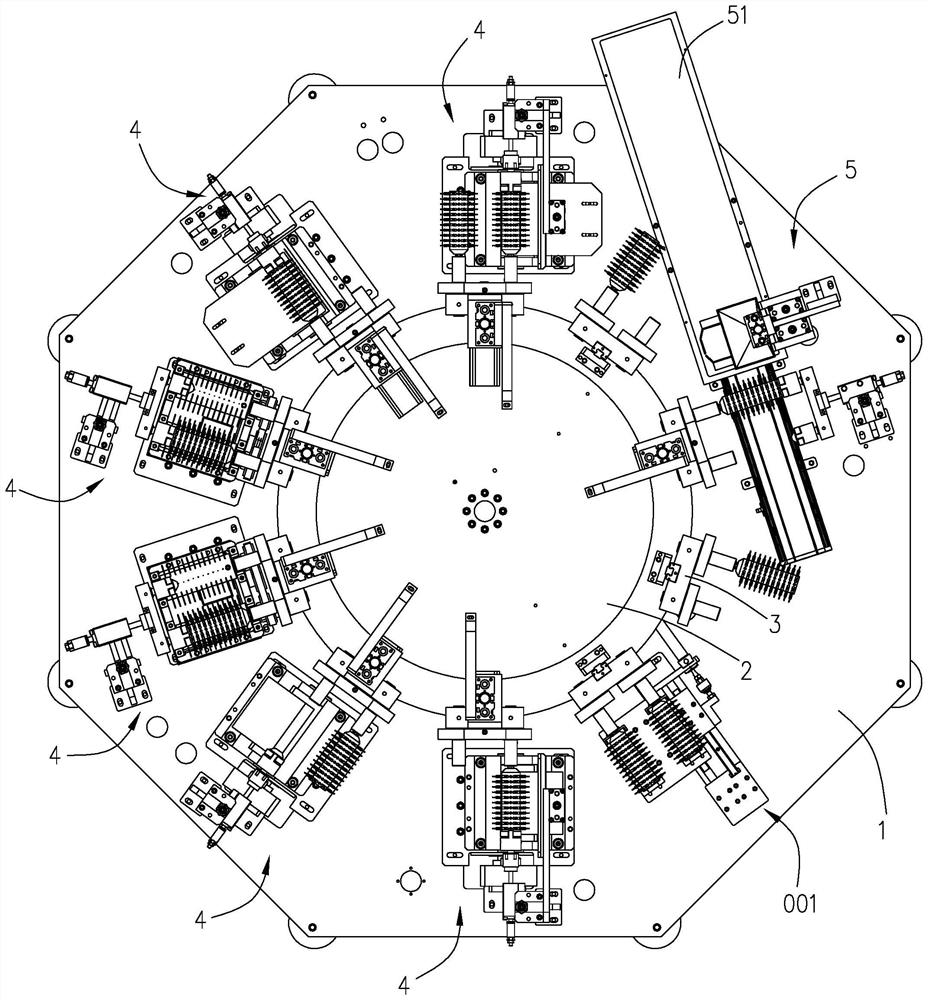

Fan-shaped combing, flying and dyeing all-in-one machine

The invention relates to a fan-shaped combing, flying and dyeing all-in-one machine which comprises an assembling platform, a rotating disc, a first driving mechanism, a positioning assembly, a flying mechanism, a dyeing head mechanism and a feeding and discharging mechanism. The invention provides the special automatic equipment for performing flying and head dyeing treatment on the comb needles on the fan-shaped comb, the processes of feeding, comb needle grinding and cutting, head dyeing and discharging are performed in a reciprocating manner, and structures matched with the fan-shaped structure of the comb are arranged on the positioning assembly during the comb needle grinding and cutting and head dyeing treatment, so that the comb needle grinding and cutting efficiency is improved, and the comb needle grinding and cutting efficiency is improved. The grinding and cutting amount of the card wires is always kept consistent along with the rotation of the fan-shaped structure, so that the grinding and cutting precision is effectively improved; meanwhile, the whole process does not need manual participation, so that the influence of human factors is reduced, the quality stability of combs produced in the same batch is improved, and the production cost of the combs is reduced.

Owner:宁波宇鸿正信智能科技有限公司

A cross-top cutting device based on autoclaved aerated blocks

The invention discloses a cross topping and cutting device on the basis of a vapor-pressure aerating building block. The cross topping and cutting device comprises a movable pre-cutting frame, steel wire side-stretching support rods, wire clamping and staying air cylinders and cutting steel wires. Flatness of the cut surface is ensured while elastic deformation force of the cutting steel wires is concentrated in the middle of a blank, elastic stress is offset by the cross structure, and edge breakage caused by diagonally pulling the steel wires to separate from the single side is avoided; cutting accuracy is ensured by the cross cutting steel wires, lateral cross grains are eliminated, and similar cutting effect of scissors during cutting is generated. The cross topping and cutting device is novel in design, reasonable and simple in structure.

Owner:DONGYUE MACHINERY GRP

A ceramic profiling processing workbench

ActiveCN108582526BEasy to useEasy to fixWorking accessoriesCleaning using gasesBraced frameEngineering

Owner:PINGDINGSHAN UNIVERSITY

Insert and insert disassembly and assembly device

ActiveCN111890632BRealize the function of automatic croppingAchieve consistencyCoatingsManual handlingIndustrial engineering

The invention provides a device for disassembling and assembling inserts and inserts, including a cutting and pouring separation mechanism, which is used to cut the gate of a molded product and separate the insert from the product in the molded product; the insert transfer and handling mechanism is used to It is used to transport the inserts separated by the cutting and pouring separation mechanism to the insert assembly mechanism; the insert feeding and handling mechanism is used to transport the inserts to be assembled to the insert assembly mechanism; the insert assembly mechanism is used to place the insert Assembled with insert. Utilizing the present invention can solve the problems of high labor intensity, poor consistency of insert assembly size, low efficiency, and cutting and pouring due to the use of manual operations in the existing production process of insert feeding, injection molded bracket product removal and shearing. The quality of the mouth is uneven and so on.

Owner:GEER TECH CO LTD

A laser cutting tube center bracket

ActiveCN104014941BSmooth rotationAvoid moment imbalanceWelding/cutting auxillary devicesAuxillary welding devicesLaser cuttingEngineering

The invention relates to the field of laser cutting devices, in particular to a central support for laser pipe cutting. The outer ring of a large-through-hole bearing is fixed to a fixing base. A frameless motor is arranged on one side of the large-through-hole bearing. A slip ring is arranged on the other side of the large-through-hole bearing. A rotor of the frameless motor, the inner ring of the large-through-hole bearing and a rotary slip ring body of the slip ring are connected in sequence and have the same rotation axis. An idler wheel connecting disk is fixed to the rotating slip ring body, and the rotation axes of the idler wheel connecting disk and the rotating slip ring body are identical. Two pairs of parallel guide rails are arranged on the other side of the idler wheel connecting disk, wherein the two pairs of parallel guide rails are perpendicular to each other. Each pair of parallel guide rails is movably provided with two sliding plates. Each sliding plate is provided with an idler wheel. The four idler wheels face the rotation axis of the idler wheel connecting disk. Each idler wheel is connected with a stepping motor. The frameless motor and the stepping motors are connected with an externally arranged controller. By the adoption of the central support for laser pipe cutting, stable and synchronous rotation of the pipes can be achieved; the central support is suitable for supporting various pipes, and the cutting precision is high.

Owner:WUHAN TIANQI LASER EQUIP MFG

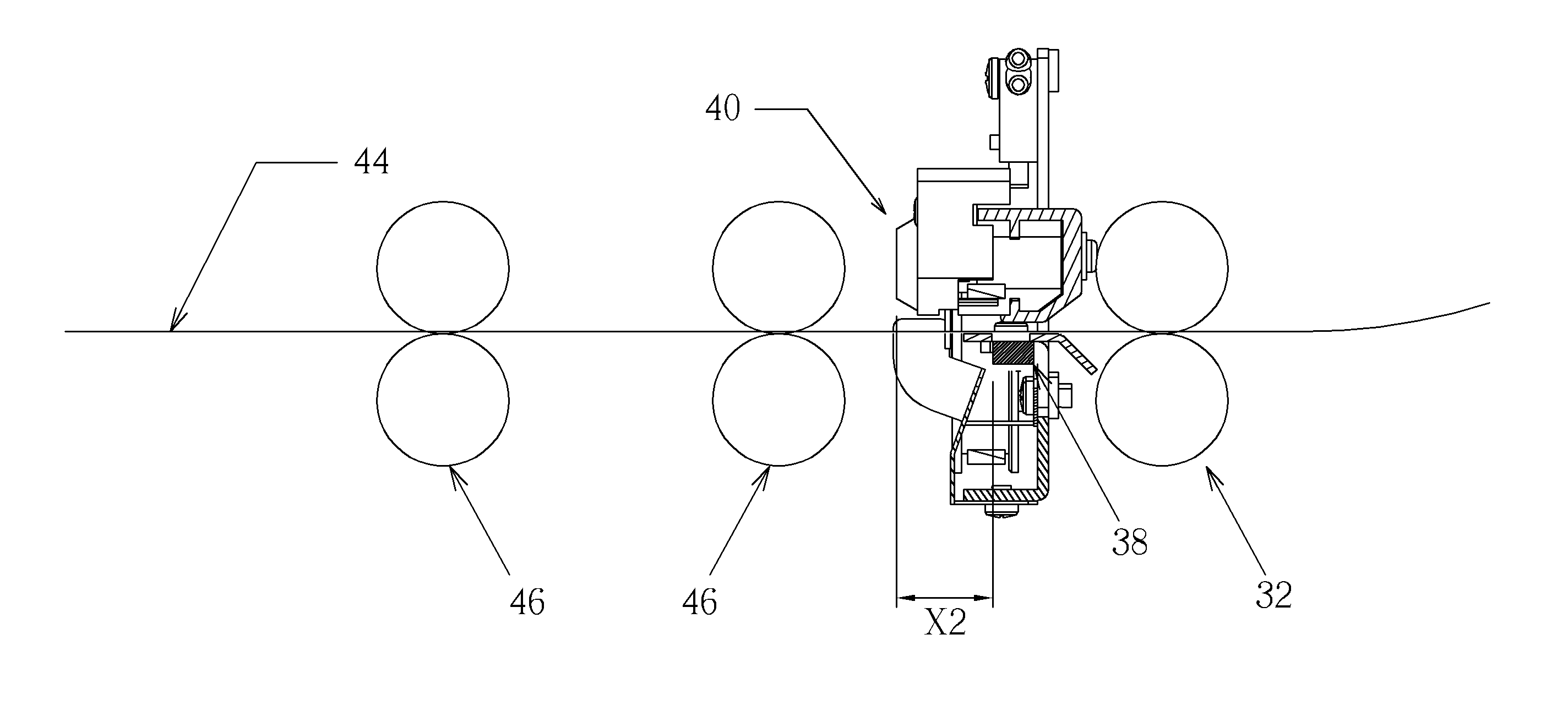

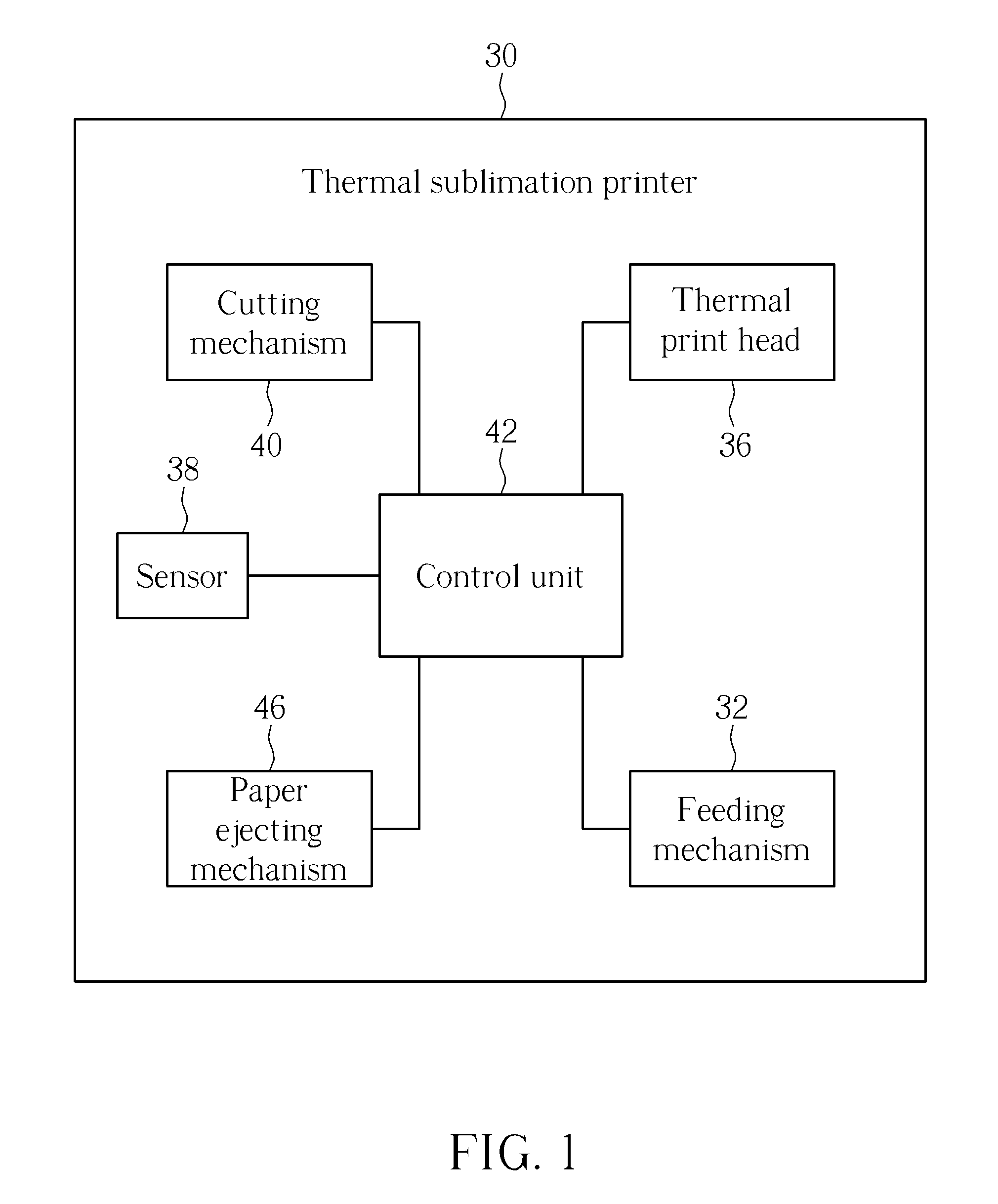

Ribbon capable of enhancing cutting precision

InactiveUS20120268545A1Avoid fracturesImprove cutting precisionRecording apparatusInk ribbonsEngineeringHeat sensitive

A ribbon includes at least one dye region, at least one separating region and at least one recognition dye region. Each of the dye regions includes a plurality of dye zones. The separating region is formed on a side of the dye region for separating different dye regions. The recognition dye region is formed on the separating region or formed within a range covered by the corresponding dye region. A thermal print head of a thermal sublimation printer transfers the dye region and the recognition dye region of the ribbon onto a print medium, so as to form an image area and a recognition mark on the print medium, correspondingly. A cutting mechanism of the thermal sublimation printer is used for cutting the print medium when a sensor of the thermal sublimation printer senses the recognition mark.

Owner:HI TOUCH IMAGING TECH CO LTD

Automatic-control electric pencil sharpener

InactiveCN105904892AAvoid safety accidentsImprove cutting precisionSharpenersAutomatic controlElectric machinery

The invention provides an automatic-control electric pencil sharpener. The automatic-control electric pencil sharpener comprises a machine body. A rotary pencil sharpener body is arranged in the machine body. A motor is arranged beside the rotary pencil sharpener body. The motor is in transmission with the rotary pencil sharpener body through a linkage gear. A clamping device is arranged above the rotary pencil sharpener body. A pencil above the rotary pencil sharpener body is clamped through the clamping device. A pencil inlet is formed in the portion, over the rotary pencil sharpener body, of the machine body. The pencil is inserted into the machine body through the sharpener inlet in the machine body, the rotary pencil sharpener body is driven by the motor to sharpen the pencil, and the pencil is fixed through the clamping device; the sharpening precision is improved, the structure is compact, the design is reasonable, and pencil sharpening is completed fully automatically without intervention; and since the rotary pencil sharpener body is arranged in the machine body, children cannot make contact with the rotary pencil sharpener body, and thus the children are protected against possible safety accidents while high efficiency is achieved.

Owner:ANHUI NORMAL UNIV

Low-power-consumption spark wire automatic cutting device

InactiveCN110695473AStable cutting processImprove cutting precisionElectrical-based machining electrodesElectrical-based auxillary apparatusElectric machineryStructural engineering

The invention discloses a low-power-consumption spark wire automatic cutting device. The device comprises an operation platform, a switch button and a motor. Supporting blocks are welded to the left side and right side of the upper portion of the operation platform correspondingly, and supporting screw rods are inserted into the supporting blocks. The outer sides of the supporting screw rods are sleeved with first springs. Clamping plates are fixedly welded to one ends of the supporting screw rods, and pin rollers are evenly hinged to the interiors of clamping plates. The other ends of the supporting screw rods are sleeved with fastening nuts. A supporting column is fixedly welded to the rear portion of the left side of the top of the operation platform. According to the low-power-consumption spark wire automatic cutting device, the two sets of clamping plates are arranged and elastically supported by the first springs correspondingly, the positions of the two sets of clamping plates can be freely adjusted through cooperation of the supporting screw rods, workpieces of different specifications can be clamped during cutting machining of the device, and the workpieces are stable during cutting machining. The pin rollers are arranged and can freely rotate in the clamping plates, the workpieces can smoothly move, and the cutting machining accuracy of the device is greatly improved.

Owner:保时杰数控机床江苏有限公司

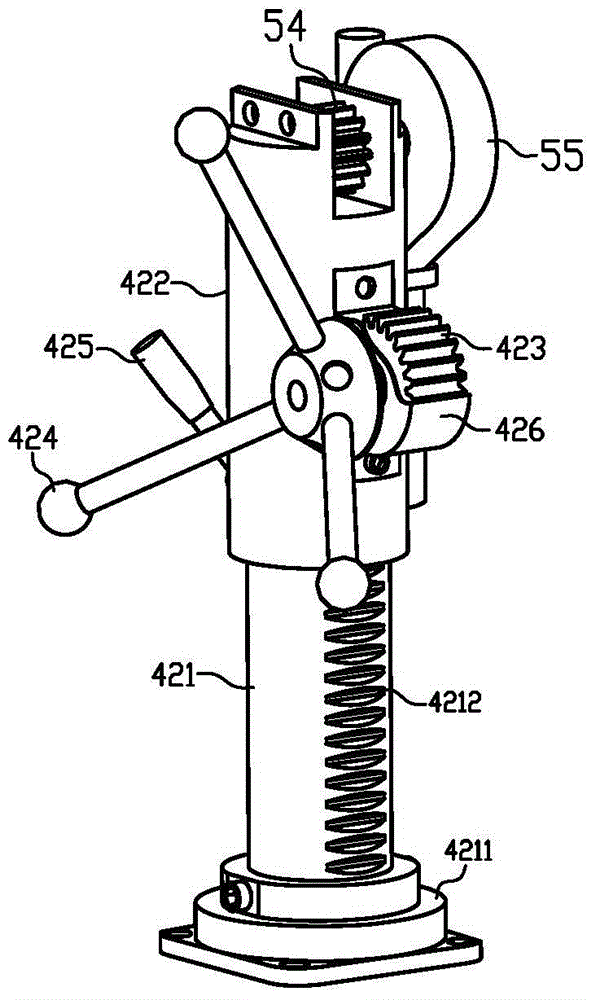

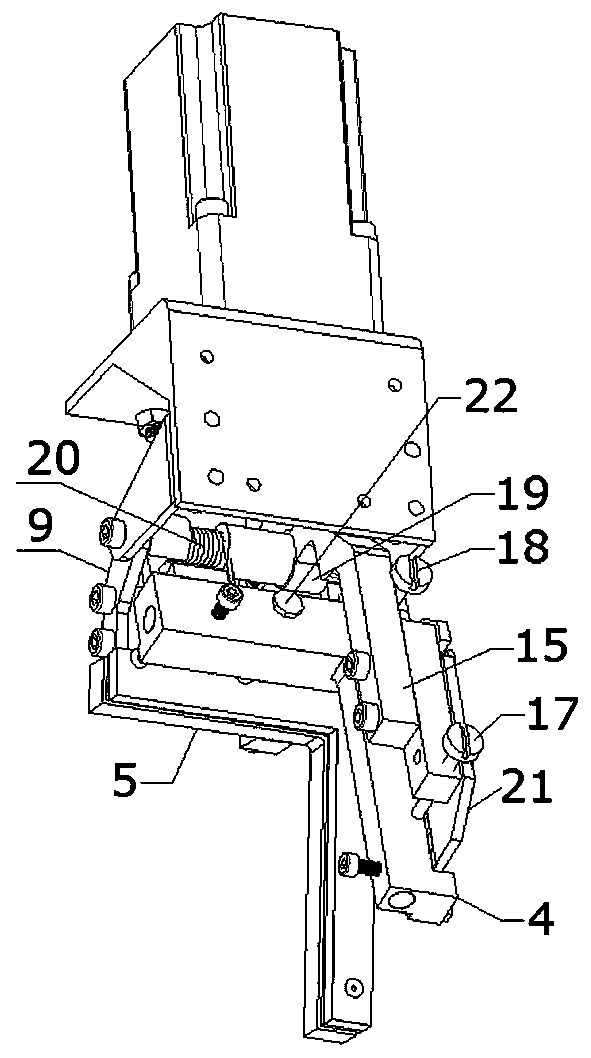

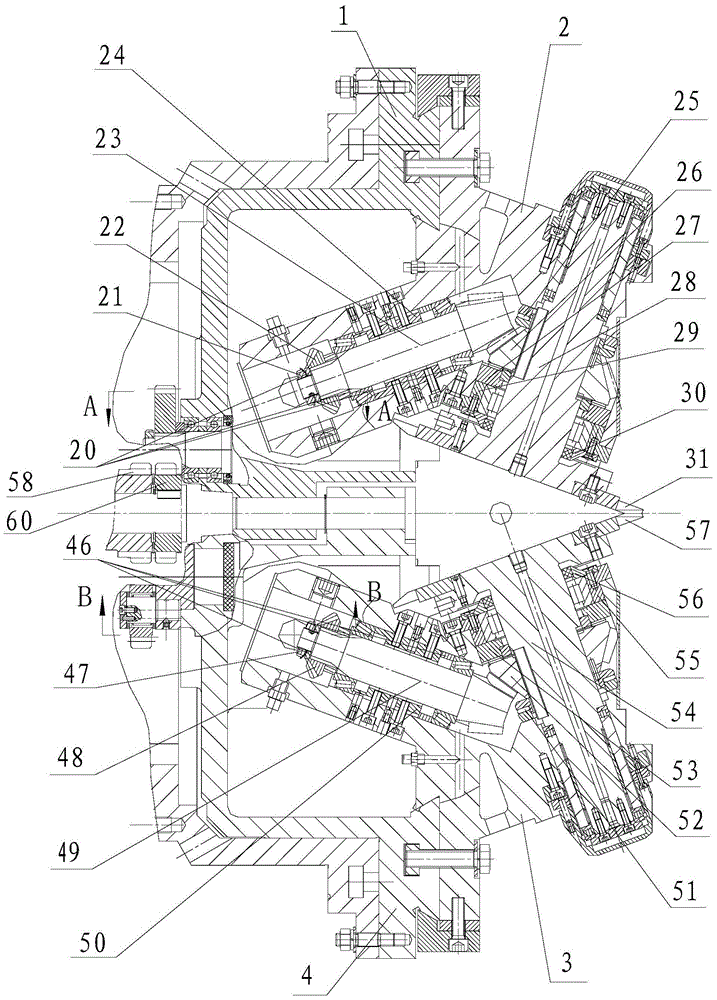

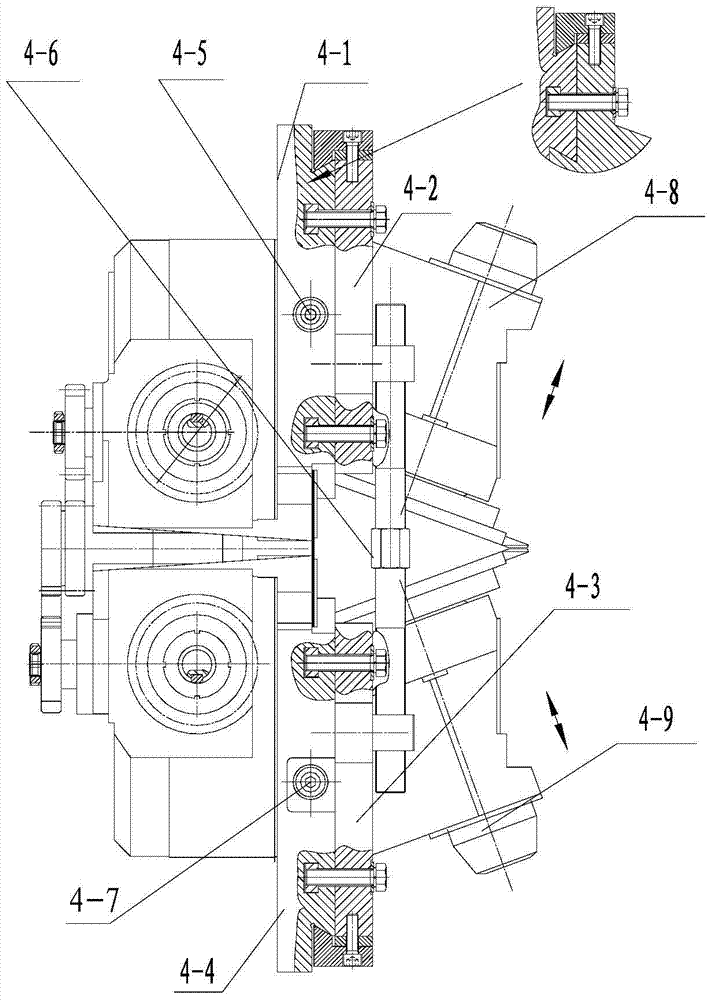

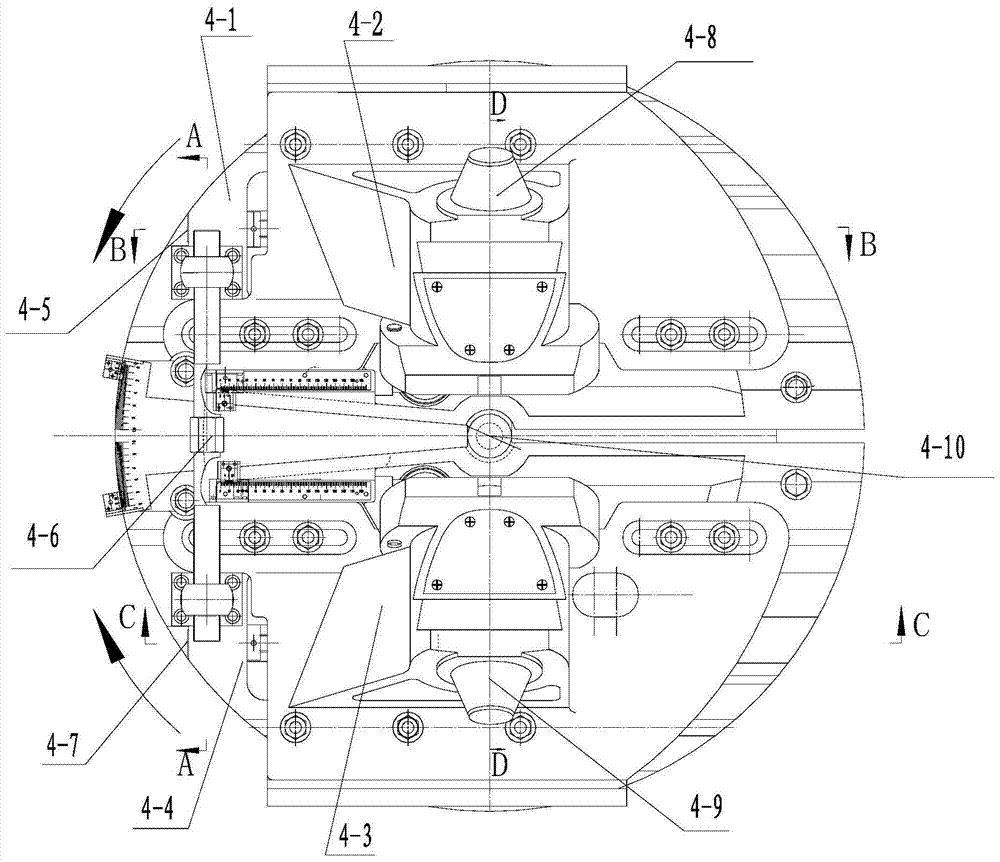

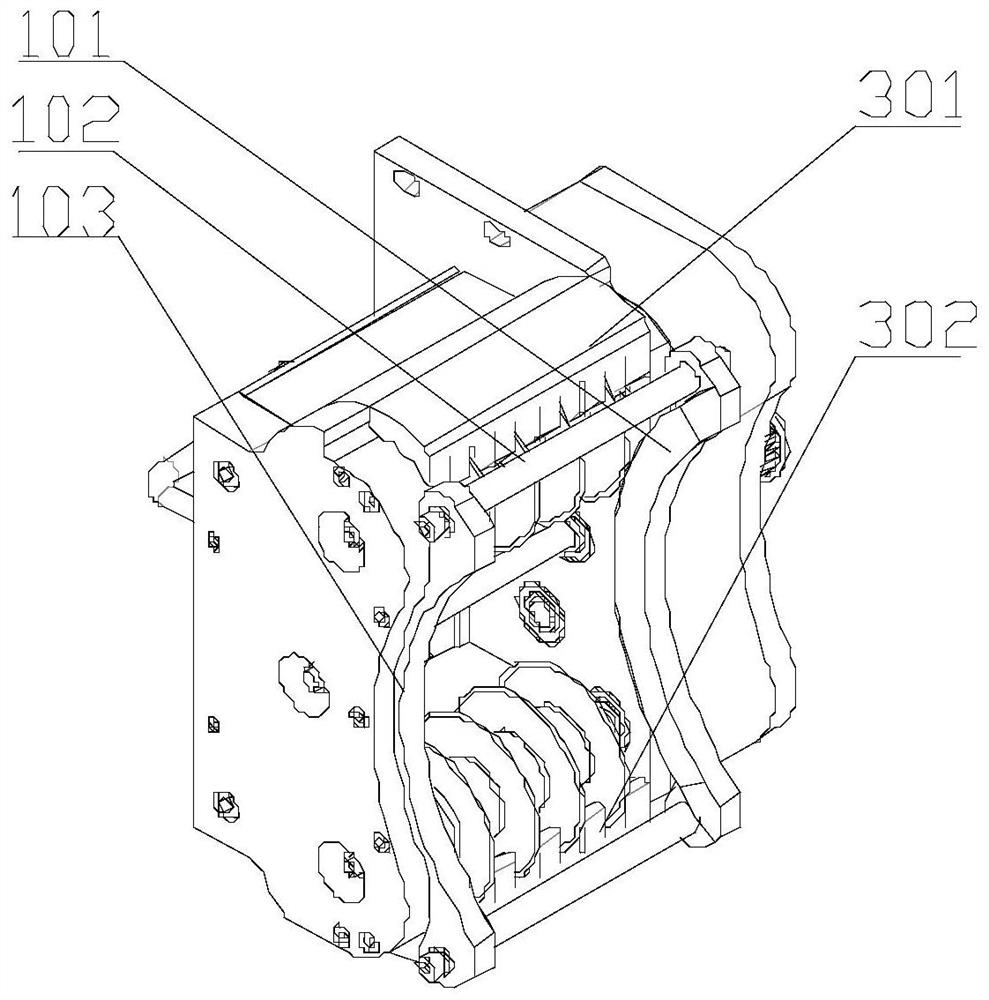

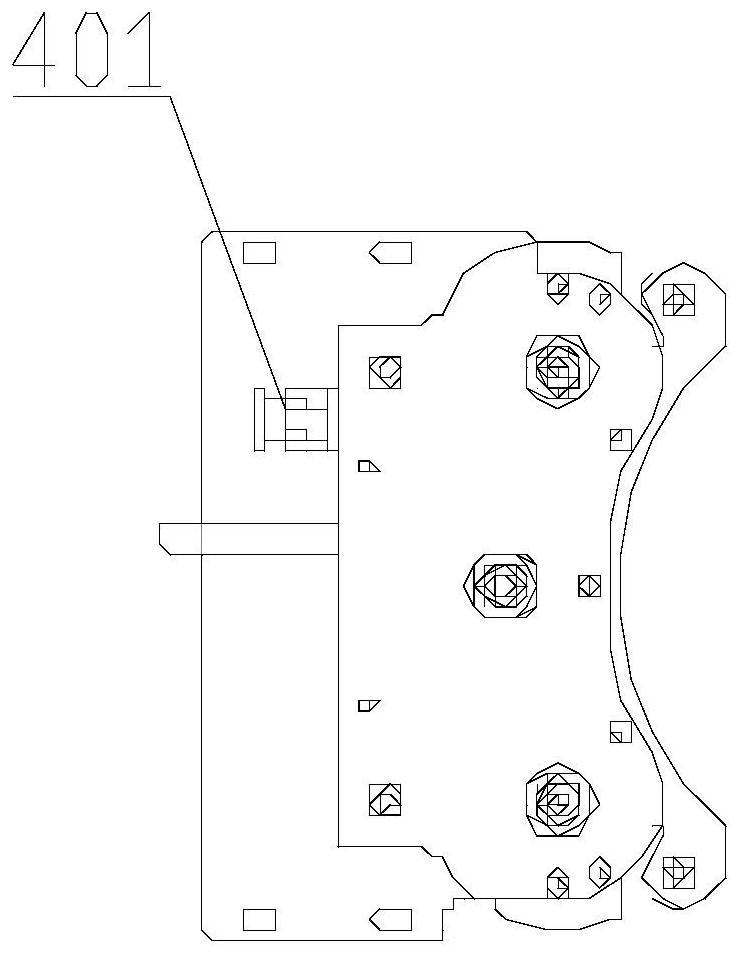

Cutter box transmission device of numerical control double-cutter-head straight bevel gear milling machine

InactiveCN105033722AImprove cutting precisionGuaranteed transmission rigidityDriving apparatusGear teethNumerical controlManufacturing cost reduction

The invention relates to a cutter box transmission device of a numerical control double-cutter-head straight bevel gear milling machine. The cutter box transmission device is characterized in that the cutter box transmission device comprises an upper cutter rest seat transmission mechanism, a lower cutter rest seat transmission mechanism, an upper cutter rest transmission mechanism and a lower cutter rest transmission mechanism; the upper cutter rest seat transmission mechanism and a cradle assembly inner transmission wheel A form a transmission chain through a first straight gear and an upper transmission intermediate wheel; the lower cutter rest seat transmission mechanism and a cradle assembly inner transmission wheel B form a transmission chain through a second straight gear and a pair of lower transmission intermediate wheels; the upper cutter rest transmission mechanism forms a transmission chain through a second bevel gear shaft, a second bevel gear, a third bevel gear shaft and a third bevel gear; and the lower cutter rest transmission mechanism forms a transmission chain through a fifth bevel gear shaft, a fourth bevel gear, a sixth bevel gear shaft and a sixth bevel gear. The cutter box transmission device has the beneficial effects that the machine tool structure and all the movement shaft transmission chains can be sufficiently simplified, the manufacturing cost can be reduced, and the gear cutting precision can be greatly improved; and batch gear machining can be achieved, and the production requirements for small and medium batches and multiple varieties can be met.

Owner:TIANJIN NO 1 MACHINE TOOL WORKS

Shifting device and shifting method for plate production and processing

PendingCN114559285AAvoid risk of injuryImprove loading and unloading speedMetal working apparatusConveyor partsEngineeringManual handling

The invention belongs to the technical field of plate processing, and particularly relates to a plate production and processing shifting device and method, the plate production and processing shifting device comprises a fixed bottom plate, the left side of the lower surface of the fixed bottom plate is fixedly connected with a propelling device, and the right side of the upper surface of the fixed bottom plate is fixedly connected with a feeding device; a plate machining table is fixedly connected to the left side of the upper surface of the fixed bottom plate, a control displacement device is movably connected to the upper surface of the plate machining table, and a correcting device is arranged on the lower surface of the control displacement device. In the process of using the device to replace plates, an operator can always keep an absolute safe distance from related machining devices such as a plate machining table, the risk that the operator is hurt by internal sharp objects such as a cutting tool during plate replacement is avoided, manual operation or mechanical operation can be carried out, and the plate replacement efficiency is improved. And good conditions are created for automatic production, so that the feeding and discharging speed is increased, and the production efficiency is improved.

Owner:泗阳晨茂木业有限公司

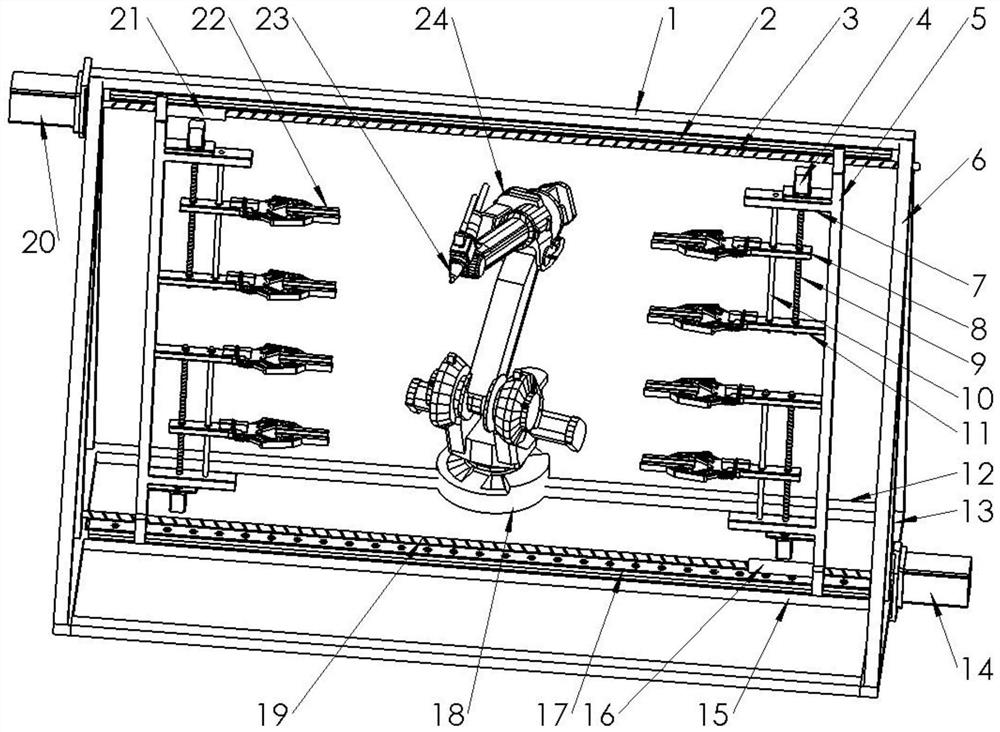

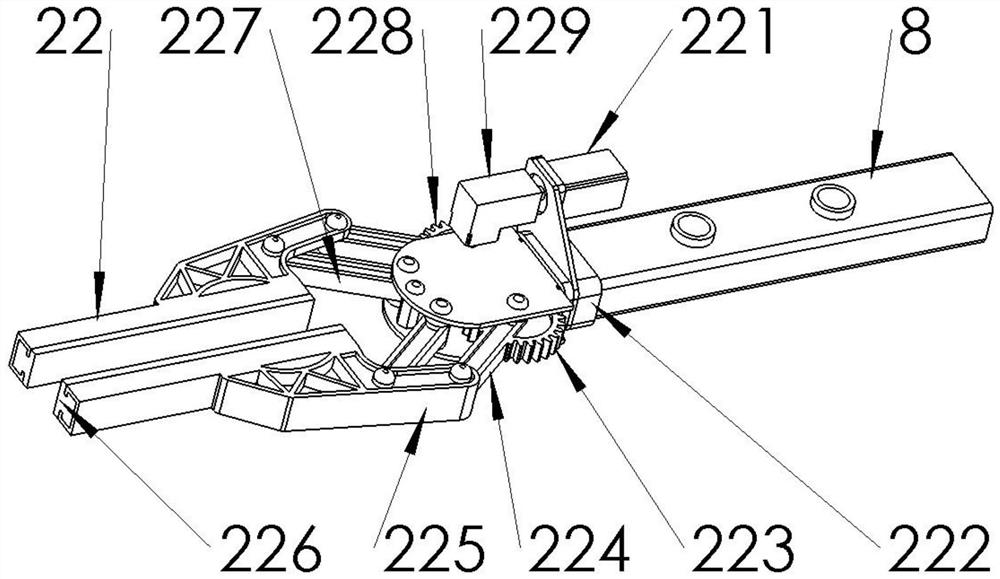

A three-dimensional laser cutting robot for plates

ActiveCN110202280BImplement loadingRealize vertical clampingWelding/cutting auxillary devicesAuxillary welding devicesVertical planeLaser cutting

The invention discloses a three-dimensional laser cutting robot for plates. On the basis of the existing mechanical arm with a laser cutting head, a frame with a triangular prism frame structure is arranged directly in front of the base of the mechanical arm. There are two sets of dynamic and static clamping bodies on the opposite sides of the left and right expansion bodies. The dynamic and static clamping bodies are equipped with fixed automatic plate clamping hands and movable plate automatic clamping hands. The fixed plate automatic clamping The hand and the movable sheet automatic gripper can be automatically clamped on the side of the vertically placed sheet respectively, and the movable sheet automatic gripper moves up and down relative to the fixed rod sheet automatic gripper, which can form a movable clamping action on the sheet . The present invention uses a mechanical arm with a laser cutting head to realize three-dimensional laser cutting, and in order to facilitate cutting of the plate, the plate is three-dimensionally clamped, so that the laser cutting head performs a relatively small laser cutting action on the vertical surface, which can effectively improve Cutting precision.

Owner:JINAN G WEIKE SCI & TECH

Comb flying and dyeing all-in-one machine

PendingCN114474536AAvoid accidental injuryImprove cutting precisionCoatingsDyeingManufacturing engineering

The invention relates to a comb flying and dyeing all-in-one machine which comprises a rotary table, a plurality of positioning assemblies, a flying mechanism, a flexible blocking piece and a dyeing head mechanism, and the positioning assemblies are arranged on operation stations respectively and used for conveying to-be-processed combs in the circumferential direction of the rotary table. The invention provides automatic equipment special for integrated treatment of flying hair and head dyeing of DP combs, the process of feeding, card wire grinding and cutting, head dyeing and discharging is carried out in a reciprocating mode, only the ends of card wires can be ground and cut through a flexible blocking piece when the card wires are ground and cut, accidental damage to the ends of plastic sleeves is avoided, and the grinding and cutting precision can be effectively improved; meanwhile, the whole process does not need manual participation, so that the influence of human factors is reduced, the quality stability of combs produced in the same batch is improved, and the production cost of the combs is reduced.

Owner:宁波宇鸿正信智能科技有限公司

CNC Double Cutter Straight Bevel Gear Milling Machine

ActiveCN105215475BImprove cutting precisionAccurate graduationMetal working apparatusGear-cutting machinesNumerical controlManufacturing cost reduction

The invention relates to a numerically controlled double-cutter bevel gear milling machine, comprising a bed assembly, a main drive box assembly, a cradle assembly, a tool box assembly, a workpiece box assembly and a bed saddle rotary plate assembly etc., characterized in that: the tool box assembly includes an upper tool holder seat assembly and a lower tool holder seat assembly installed on the drum of the cradle assembly, an upper tool box assembly, a lower tool box assembly, an upper and lower tool holder seat angle adjustment mechanism, The upper tool box lateral movement adjustment device and the lower tool box lateral movement adjustment device, and the workpiece box assembly is equipped with a spring damping device for eliminating the movement gap in the indexing action. The advantages are: it can enhance the overall rigidity of the gear machine tool, fully simplify the structure of the machine tool, the transmission chain of each motion axis and adjust the calculation program, reduce the manufacturing cost, and greatly improve the machining accuracy of the gear; it can not only realize the processing of large quantities of gears, but also It is suitable for single-piece or multi-variety small-batch gear processing requirements.

Owner:通用技术集团天津第一机床有限公司

Flying device and method of comb and flying dyeing all-in-one machine

InactiveCN114505992AAvoid accidental injuryImprove cutting precisionCoatingsEngineeringElectrical and Electronics engineering

The invention relates to a flying device and method for a comb flying and dyeing all-in-one machine, and the device comprises a positioning assembly which comprises a clamping sleeve used for fixing a to-be-processed comb; the flying mechanism is close to the edge of the turntable, is arranged on the assembly platform and is provided with a flying cutter group which can be in contact with comb needles of the comb to grind and cut the comb in a state that the jacket moves downwards; and the flexible blocking piece is integrated with the flying mechanism and is used for allowing card wires of a comb to penetrate through to be matched with the flying knife group for sanding so as to prevent plastic sleeves on the peripheries of the card wires from being in contact with the flying knife group. When the card wires are abraded and cut, the card wires penetrate through the flexible blocking piece and make contact with the fly hair cutter set located below the flexible blocking piece for abrading and cutting, and the plastic sleeve is blocked on the flexible blocking piece and does not participate in abrading and cutting, so that only the ends of the card wires are abraded and cut, the ends of the plastic sleeve are prevented from being accidentally damaged, the abrading and cutting precision can be effectively improved, and the service life of the card wires is prolonged. Therefore, the quality stability of combs produced in the same batch is improved.

Owner:宁波宇鸿正信智能科技有限公司

Cigarette filter stick cutter box, system and method

PendingCN112743616ASolve the problem of segmentation machining accuracyGood for automatic grindingCleaning using gasesMetal working apparatusStructural engineeringKnife blades

The invention provides a cigarette filter stick cutter box, system and method. The cigarette filter stick cutter box comprises a cutter box body, a cutter sharpening mechanism and a cutter assembly connected to the cutter box body, wherein the cutter assembly comprises a plurality of blades, the cutter sharpening mechanism is provided with cutter sharpening slots in one-to-one correspondence to the blades, the motion track of the blades passes through the cutter sharpening slots in the working state, and a set gap is formed between the side surface of each blade and the grinding surface of the corresponding cutter sharpening slot. The cigarette filter stick cutter box solves the problems that some easy-to-stick sweeps are attached to the cutting edge of the cutter and are not easy to clean, and the cutting machining precision of filter sticks, paper tubes, firmware and the like is seriously affected by too much attached sweeps. The cutter sharpening mechanism is integrated on the cutter box, so that sweeps adhered to the cutting edge of the cutter can be automatically polished, and thus, the machining stability and the segmented cutting precision of cigarette filter sticks, paper tubes and the like are improved.

Owner:ETABONG QINGDAO TOBACCO MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com