Cross topping and cutting device on basis of vapor-pressure aerating building block

A cutting device and autoclaved aeration technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems affecting the appearance quality of the finished blank, affecting the cutting dimensional accuracy of the blank, affecting the flatness of the cutting surface, etc. Corner collapse, reasonable and simple structure, and the effect of improving cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

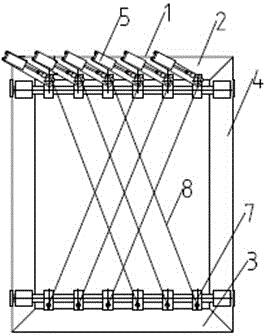

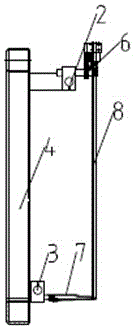

[0013] Such as figure 1 , 2 As shown, the cross-top cutting device includes a movable pre-cut frame 1, a steel wire side extension support rod 7, a clamping wire cylinder 5, and a cutting wire 8. The mobile pre-cut frame 1 includes an upper beam 2 and a lower beam 3 And the two longitudinal beams 4 connecting the upper beam 2 and the lower beam 3, the upper beam 2 is provided with six clamping wire cylinders 5 equidistantly arranged, and the clamping wire cylinders 5 are fixedly connected with the upper beam 2 through the cylinder fixing frame 6 , the lower crossbeam 3 is provided with equidistant, stepped arrangement of six steel wire side extension support rods 7, the steel wire side extension support rods 7 are fixedly connected with the lower crossbeam 3 through bolts, and the upper end of the cutting steel wire 8 is connected with the clamping wire cylinder 5 , the lower end of the cutting steel wire 8 is connected with the steel wire side extension support rod 7, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com