Flying device and method of comb and flying dyeing all-in-one machine

An all-in-one machine and comb technology, which is applied in the field of flying hair device of comb flying and dyeing all-in-one machine, can solve the problems of comb needle grinding trouble, poor effect of comb needle grinding and unevenness, etc., so as to avoid accidental injury, improve grinding and cutting precision, The effect of improving quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

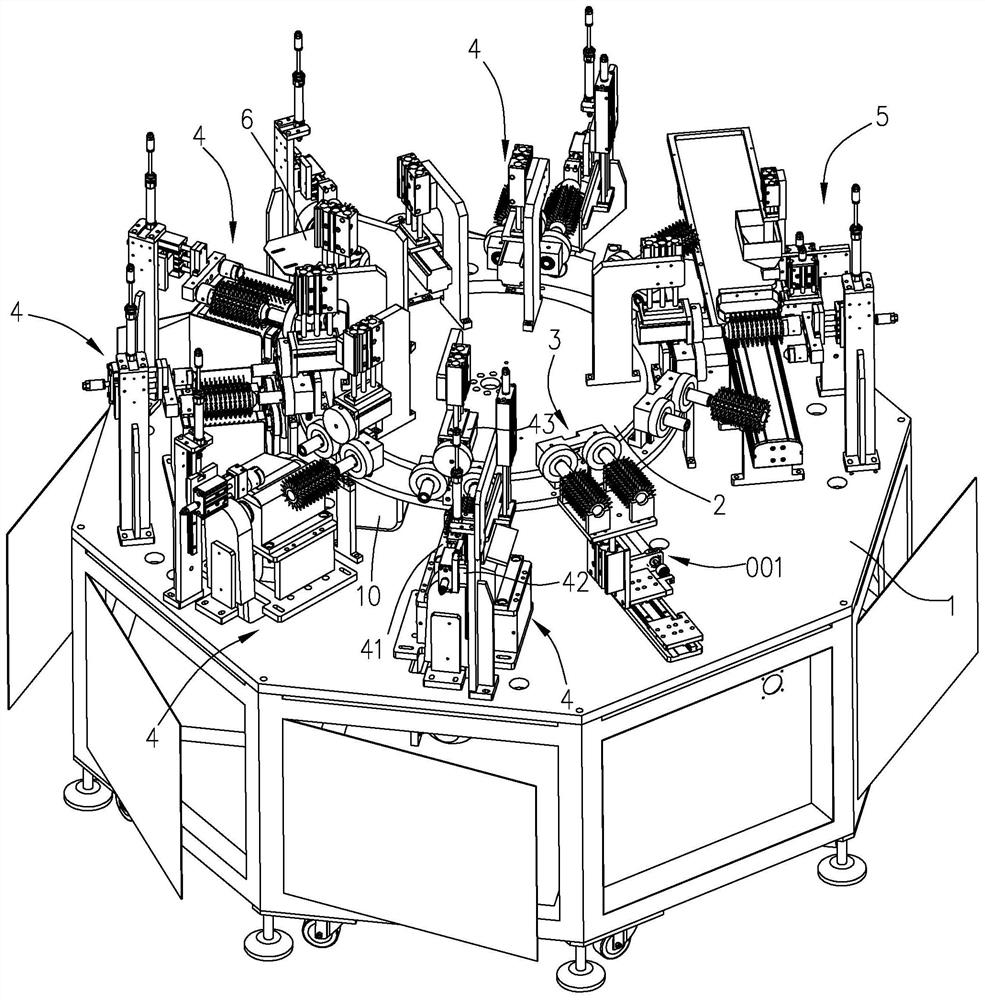

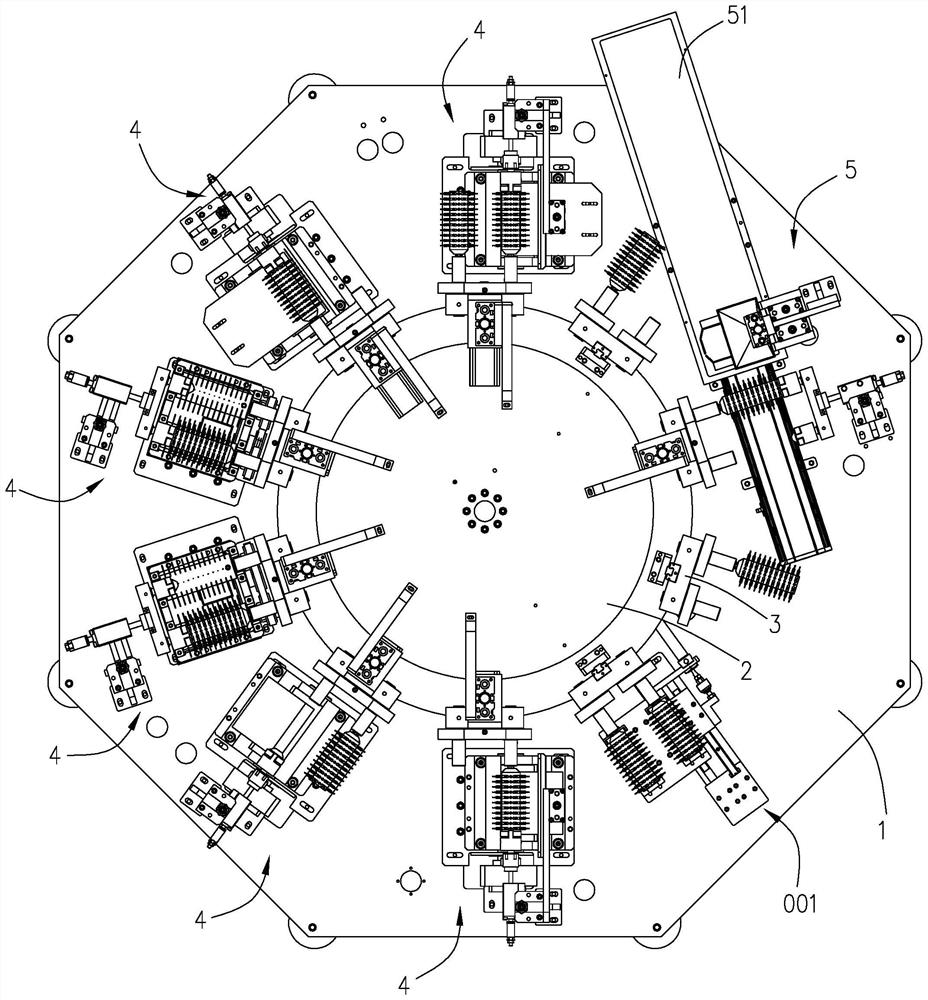

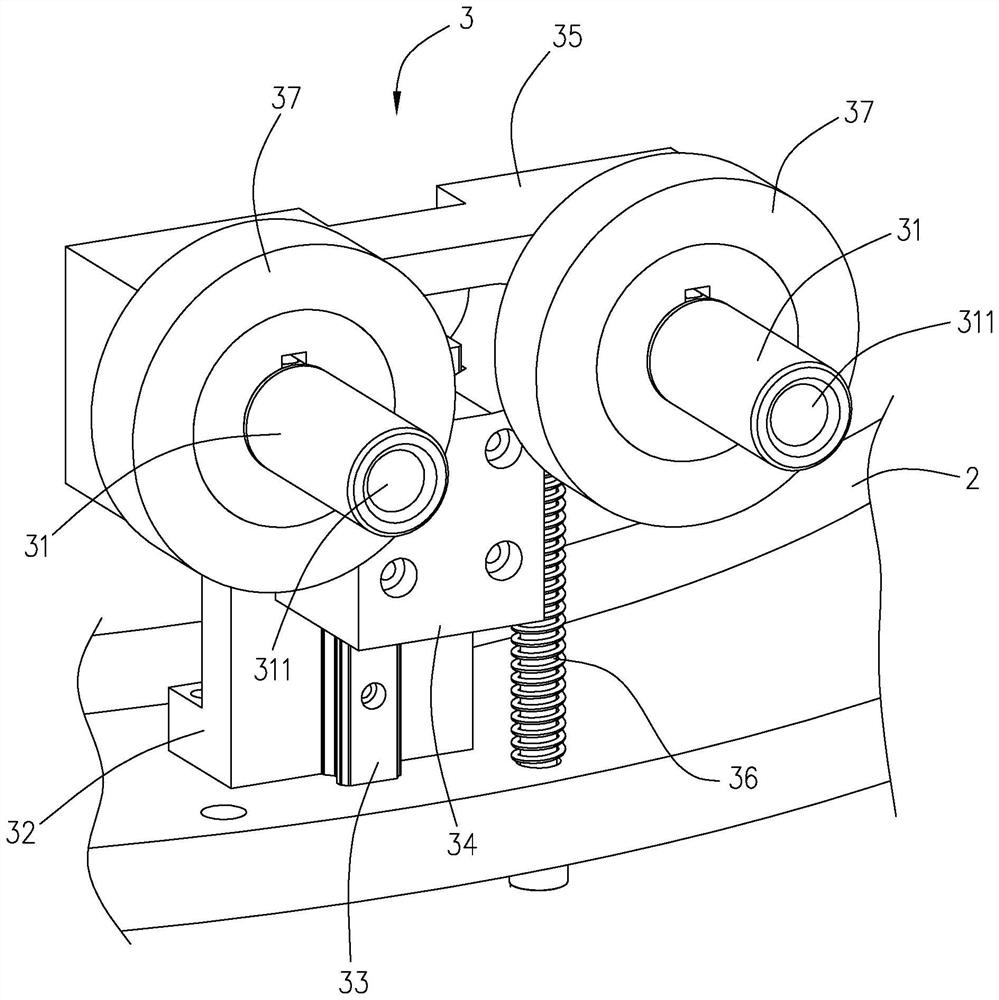

[0044] like Figures 1 to 10 As shown, the comb flying and dyeing integrated machine in this embodiment includes an assembly platform 1, a turntable 2, a first driving mechanism 10, a positioning assembly 3, a flying hair device, and a dyeing head mechanism 5, which is used for fully automatic completion of comb needle grinding. and dyeing process. This embodiment can process one or more combs at the same time. In this embodiment, four combs are processed at a time. Correspondingly, the outer circumference of the turntable 2 is provided with a feeding and unloading station and four grinding workers from front to back according to the processing sequence. position, a dye head station.

[0045] Specifically, the turntable 2 is in the shape of a disk and is rotatably provided on the assembly platform 1 , and the edge of the turntable 2 has a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com