Shifting device and shifting method for plate production and processing

A plate production and shifting device technology, applied in the field of plate processing, can solve the problems of cutting tool cuts, untimely retrieving materials, and low manual operation efficiency, so as to improve cutting precision, reduce the probability of damage, and improve the cutting effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

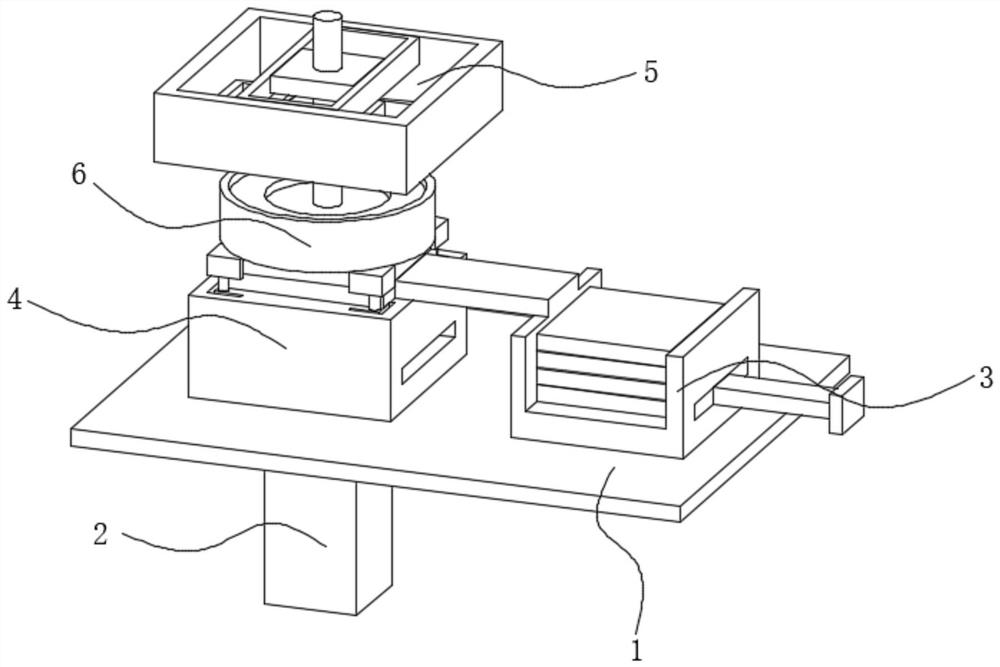

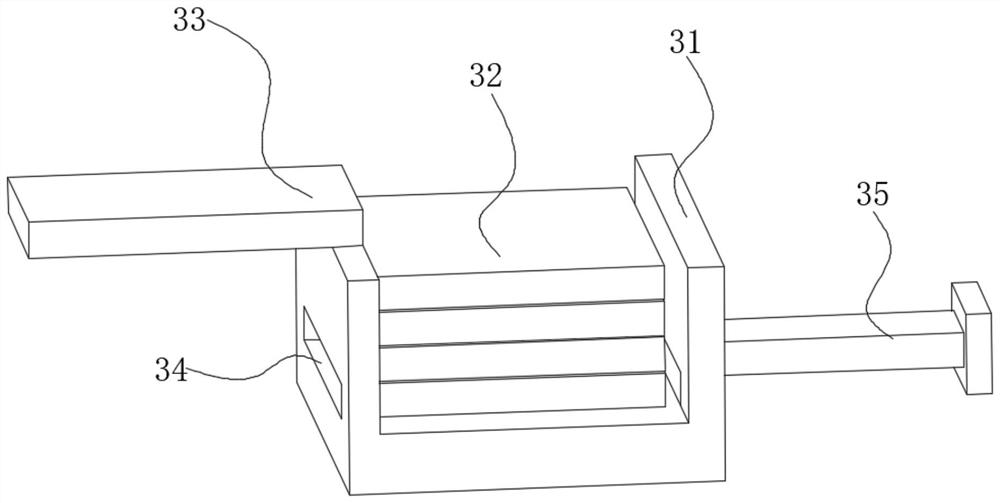

[0034] see Figure 1-Figure 4 , the present invention provides a technical solution: a displacement device for plate production and processing, comprising a fixed bottom plate 1, a propulsion device 2 is fixedly connected to the left side of the lower surface of the fixed bottom plate 1, and a right side of the upper surface of the fixed bottom plate 1 is fixedly connected with a In the loading device 3 , a plate processing table 4 is fixedly connected to the left side of the upper surface of the fixed base plate 1 , a control displacement device 5 is movably connected to the upper surface of the plate plate processing table 4 , and a calibration device 6 is arranged on the lower surface of the control displacement device 5 .

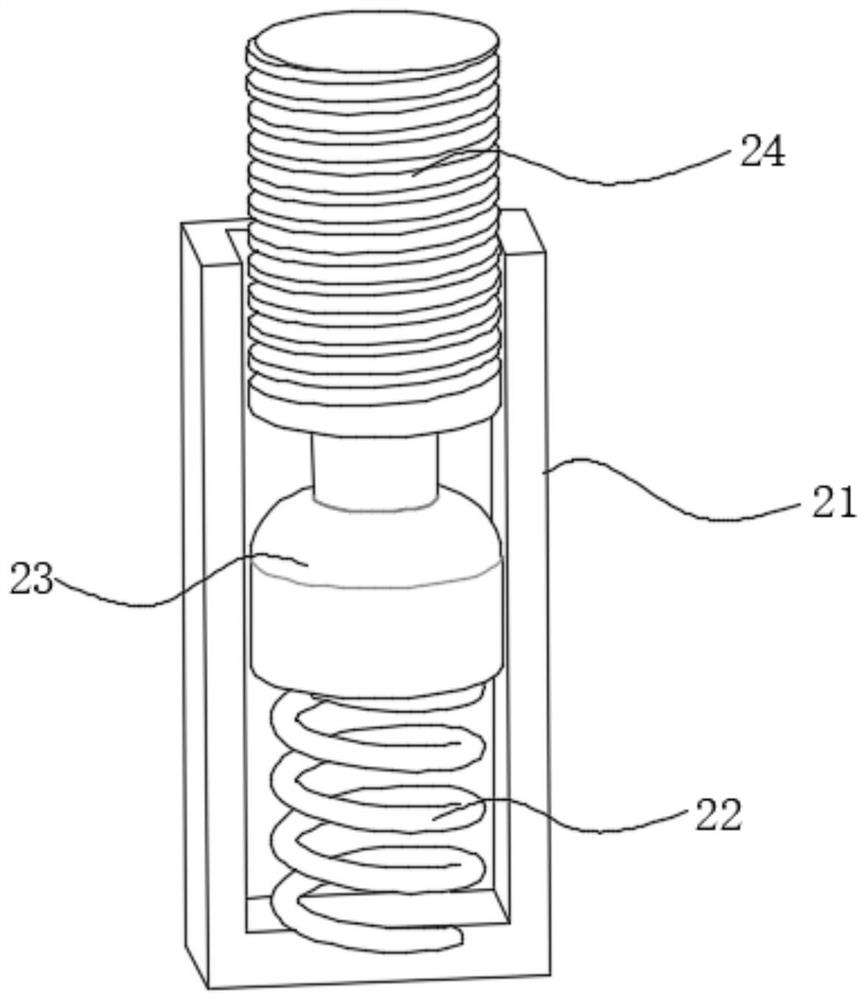

[0035] The propulsion device 2 includes a sliding motor housing 21, a vertical spring 22 is fixedly connected to the lower part of the inner wall of the sliding motor housing 21, a propulsion motor 23 is fixedly connected to the top of the vertical sprin...

Embodiment 2

[0045] see Figure 1-Figure 5 , the present invention provides a technical solution: on the basis of the first embodiment, a displacement device for plate production and processing includes a fixed bottom plate 1, a propulsion device 2 is fixedly connected to the left side of the lower surface of the fixed bottom plate 1, and the fixed bottom plate 1 The right side of the upper surface is fixedly connected with a feeding device 3, the left side of the upper surface of the fixed base plate 1 is fixedly connected with a plate processing table 4, and the upper surface of the plate processing table 4 is movably connected with a control displacement 5, and the lower part of the control displacement 5 is connected. The surface is provided with a proofing device 6 .

[0046] The propulsion device 2 includes a sliding motor housing 21, a vertical spring 22 is fixedly connected to the lower part of the inner wall of the sliding motor housing 21, a propulsion motor 23 is fixedly connect...

Embodiment 3

[0056] see Figure 1-Figure 6 , the present invention provides a technical solution: on the basis of the first embodiment, a displacement device for plate production and processing includes a fixed bottom plate 1, a propulsion device 2 is fixedly connected to the left side of the lower surface of the fixed bottom plate 1, and the fixed bottom plate 1 The right side of the upper surface is fixedly connected with a feeding device 3, the left side of the upper surface of the fixed base plate 1 is fixedly connected with a plate processing table 4, and the upper surface of the plate processing table 4 is movably connected with a control displacement 5, and the lower part of the control displacement 5 is connected. The surface is provided with a proofing device 6 .

[0057] The propulsion device 2 includes a sliding motor housing 21, a vertical spring 22 is fixedly connected to the lower part of the inner wall of the sliding motor housing 21, a propulsion motor 23 is fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com