Patents

Literature

90results about How to "Improve loading and unloading speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

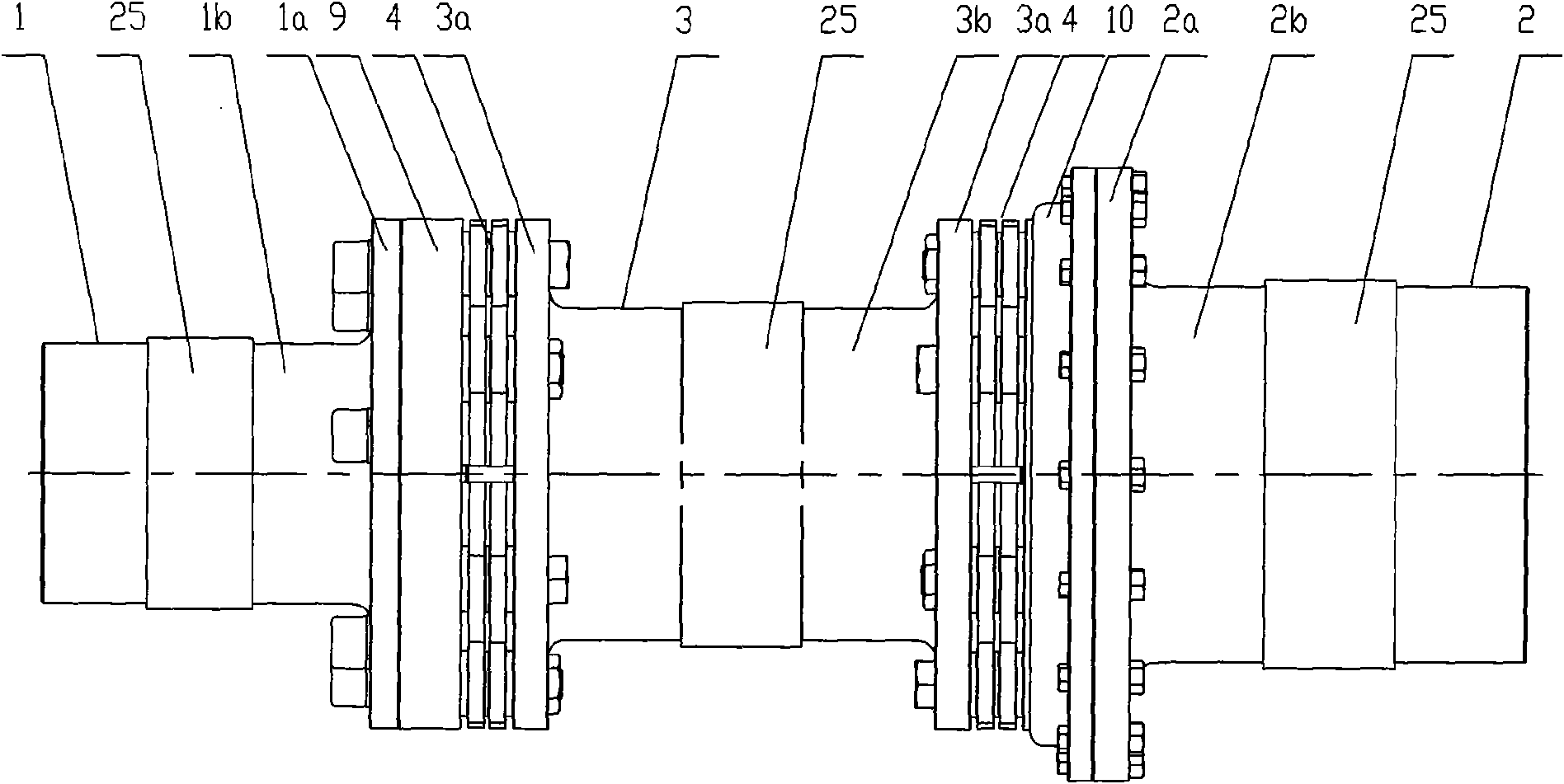

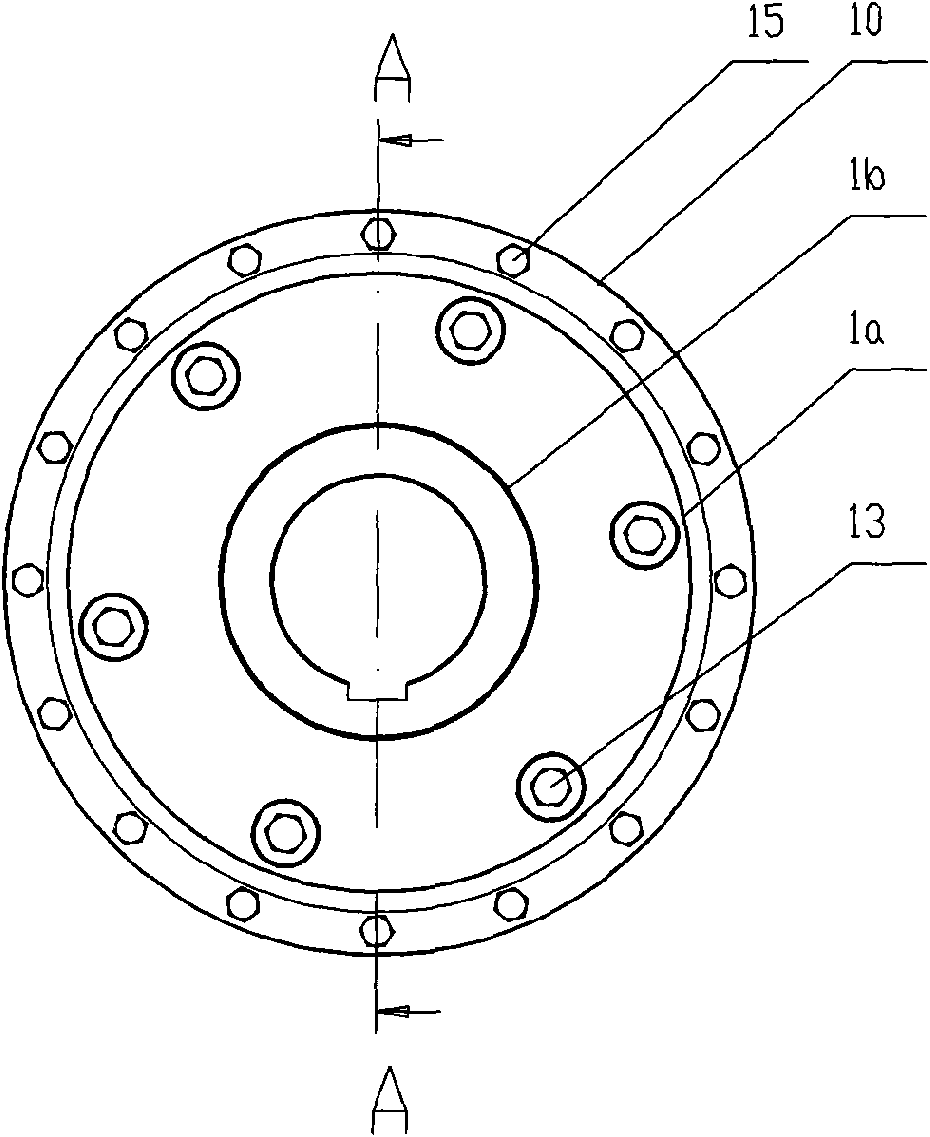

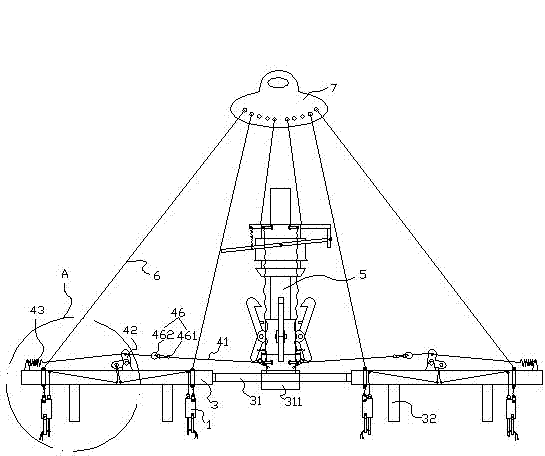

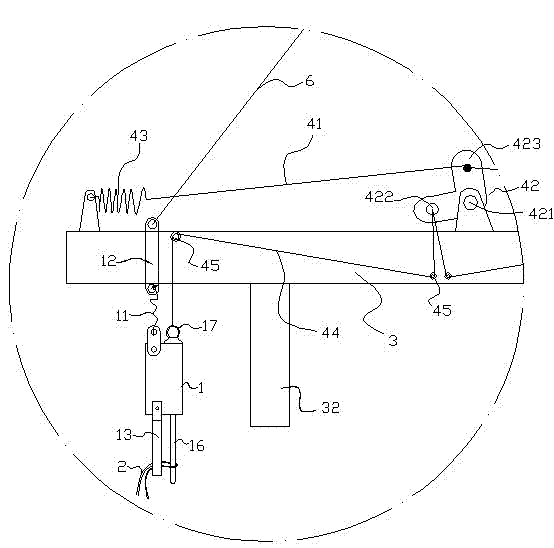

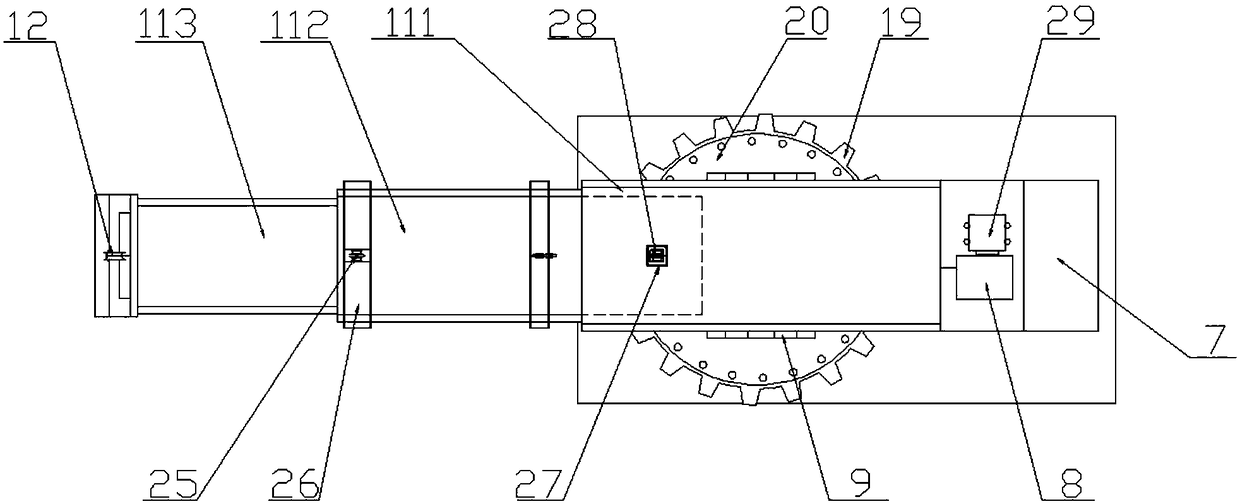

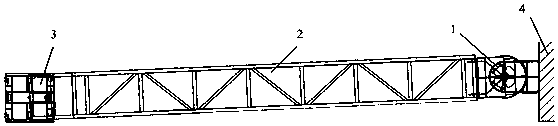

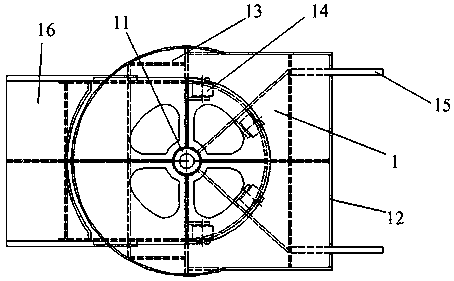

Variable-speed winch and foldable type onboard crane with same

ActiveCN102001596ASimple structureEasy loading and unloadingToothed gearingsWinding mechanismsLifting capacityDrive shaft

The invention relates to a variable-speed winch and a foldable type onboard crane comprising the same, relating to the field of winches. The variable-speed winch comprises a variable-speed mechanism, a driving shaft and a driven shaft, wherein the driven shaft is arranged on a stand of the variable-speed winch through a bearing and at the outer side of the driving shaft and is provided with a power output mechanism; the power output end of the driving shaft is provided with a gear locating slot, and the corresponding driven shaft is provided with a locating pin; the locating pin is arranged on the end part of the driving shaft or in the gear locating slot; the variable-speed mechanism comprises a center wheel and a planet wheel; the part of the driving shaft, which is close to the planet wheel, is provided with a radially outwards raised outer spline, and the inner surface of the corresponding variable-speed mechanism is provided with an inner spline; the inner wall of the driven shaft is provided with an inner spline in clearance fit with the outer spline of the driving shaft; and the outer spline of the driving shaft is respectively meshed with the inner spline of the variable-speed mechanism and the inner spline of the driven shaft to form multi-gear variable-speed transmission. The variable-speed winch can realize variable speed of at least two gears and has the advantages of simple structure, convenience for operation, good speed varying effect, small mass and high transmission ratio; and in addition, the foldable type onboard crane with the variable-speed winch has small size and high lifting capacity.

Owner:姜启胜

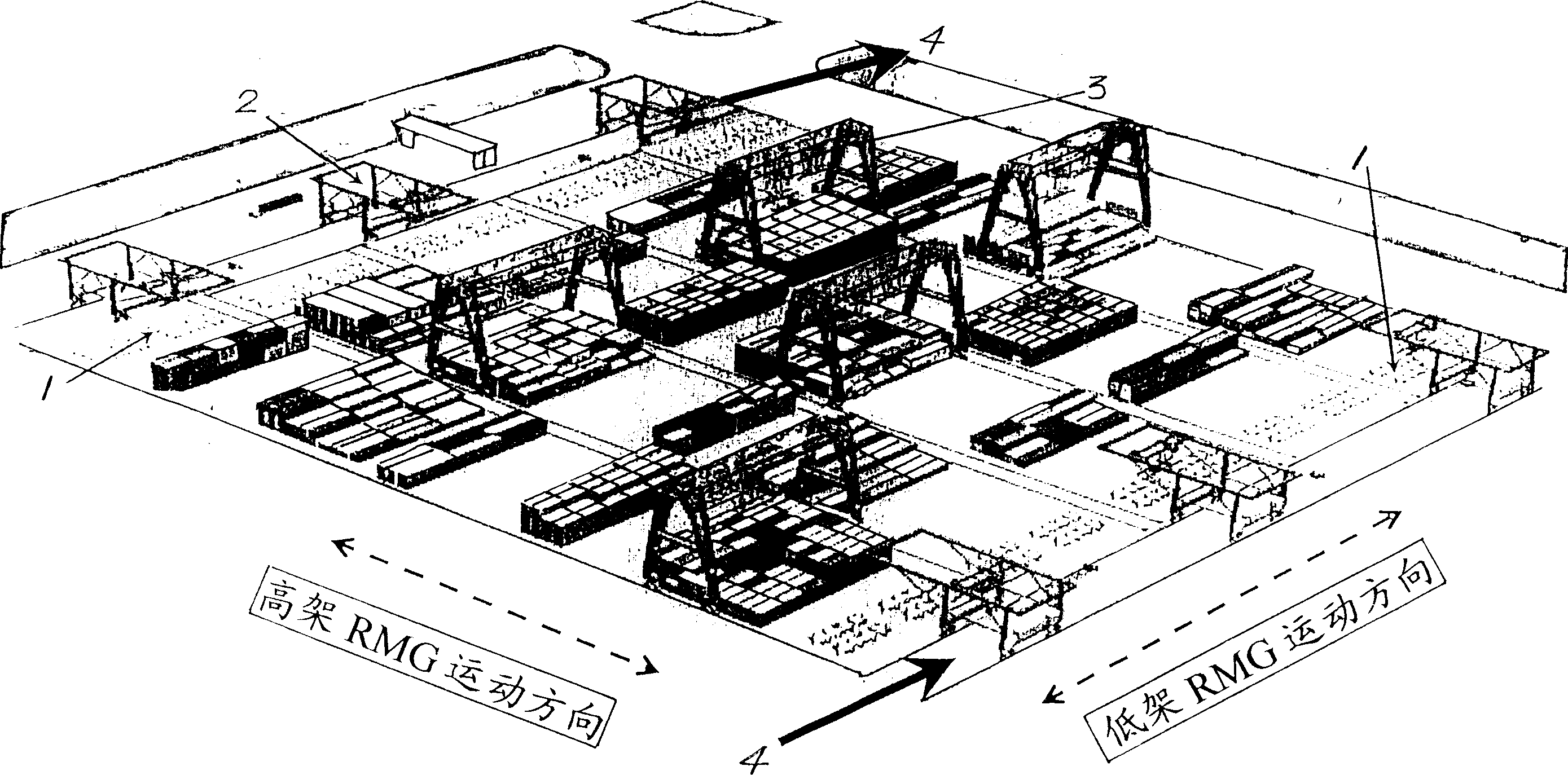

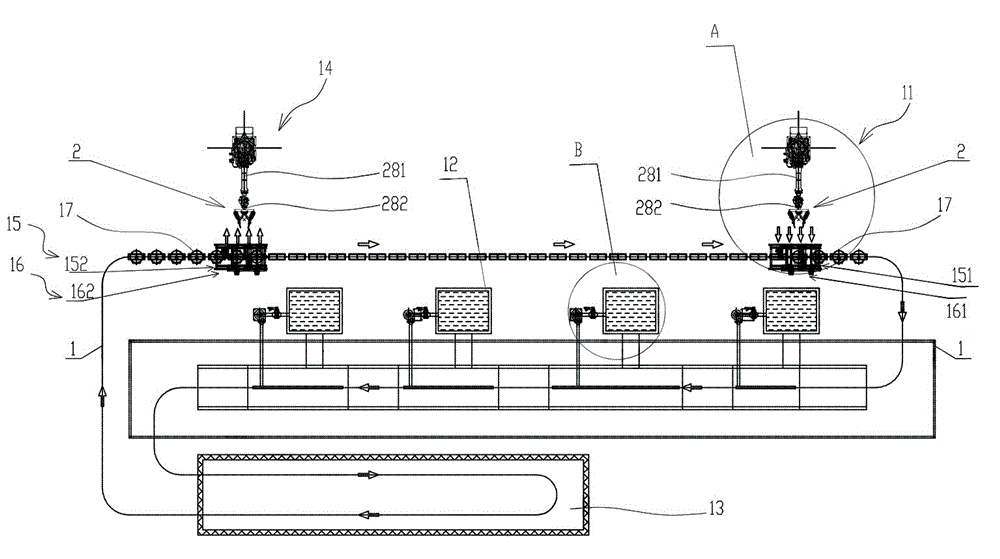

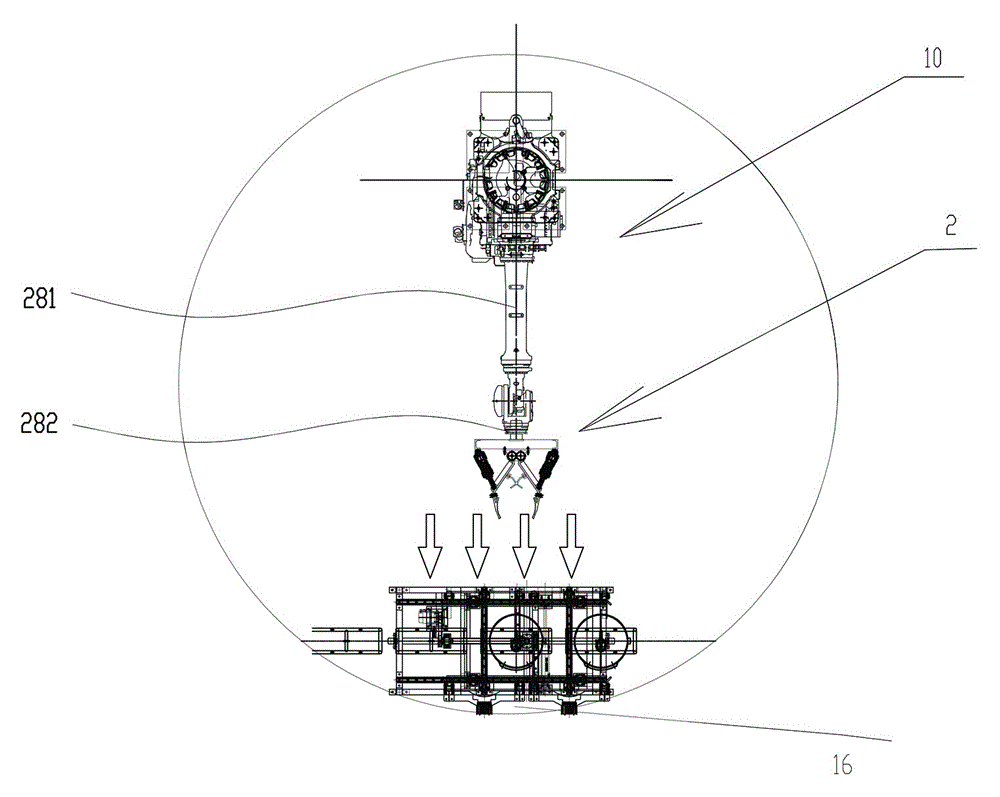

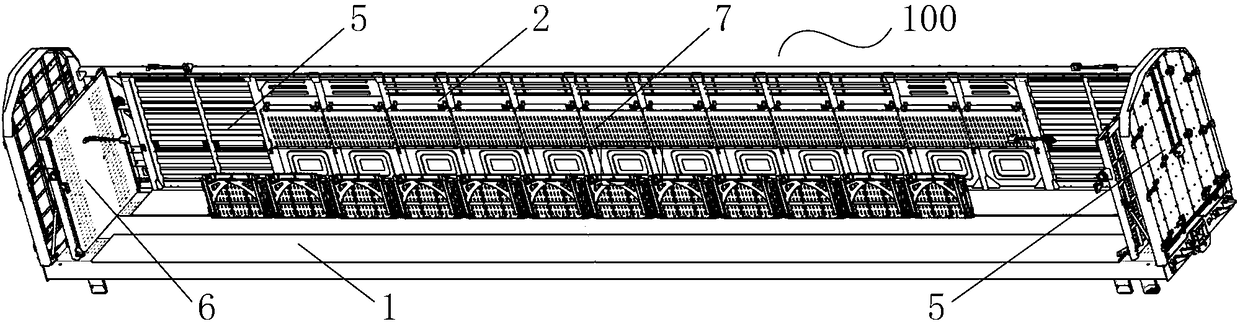

Automatization piling yard of containers and piling yard loading unloading process

InactiveCN1903684AIncrease productivity in yard operationsImprove loading and unloading speedStorage devicesLoading/unloadingYardLoading unloading

The present invention discloses a container automatic yard and yard loading and unloading process. It is characterized by that two ends of yard are respectively equipped with low-height container rail-mounted gantry crane, said low-height container rail-mounted gantry crane is positioned in the loading and unloading zone of yard end portion and is operated; on every stacking line of yard container zone a high-height container rail-mounted gantry crane is set. Said low-height rail-mounted gantry crane and high-height rail-mounted gantry crane are respectively connected with automatic yard management system. Said invention can greatly raise loading and unloading speed and raise production efficiency of yard work.

Owner:包起帆 +1

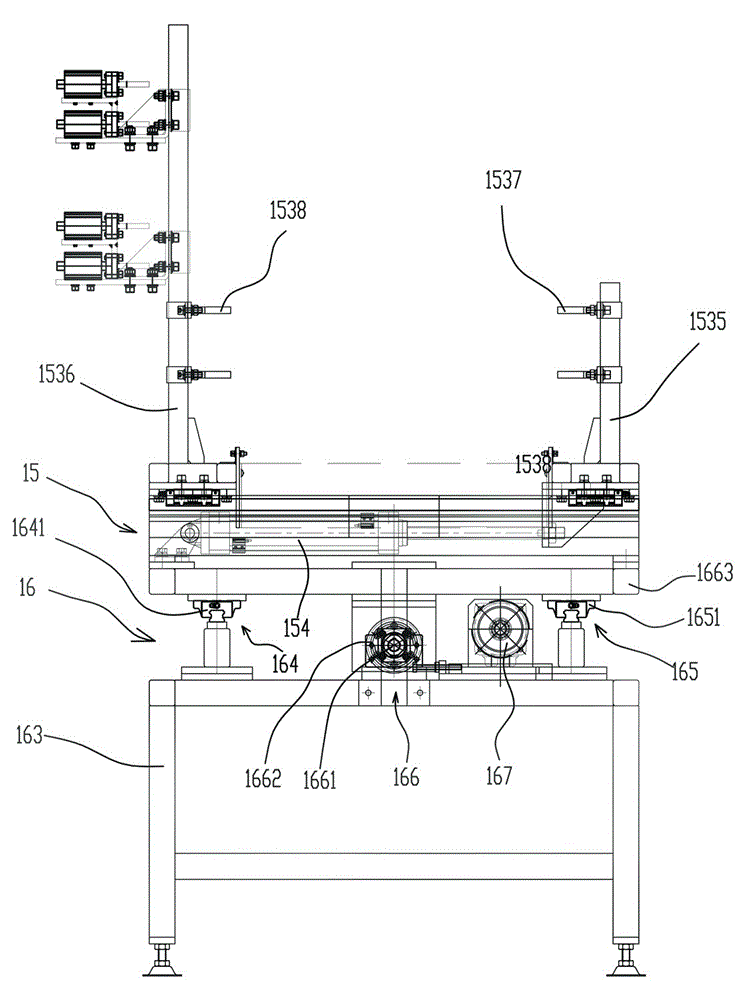

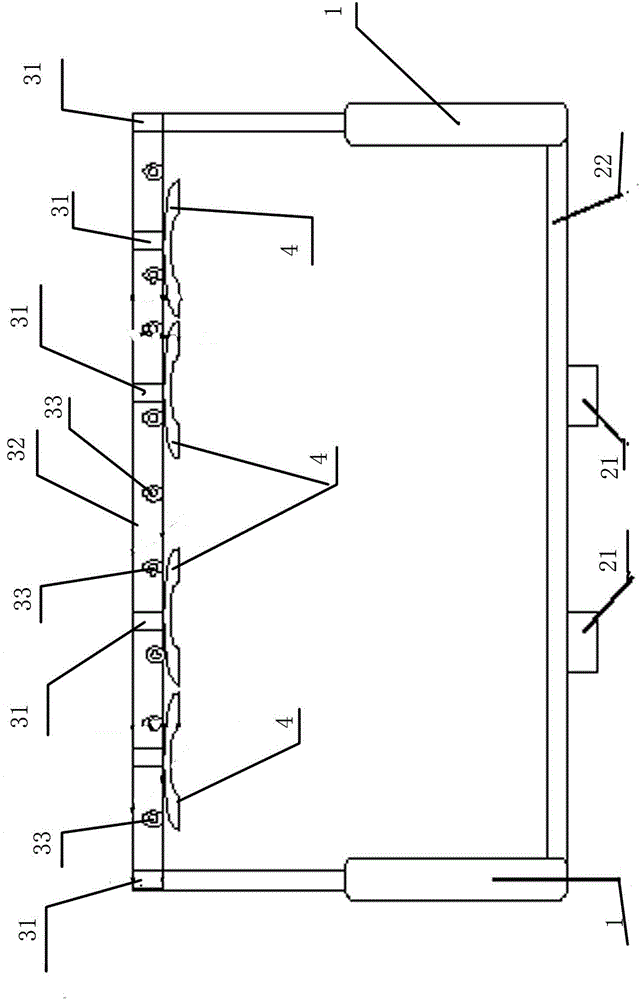

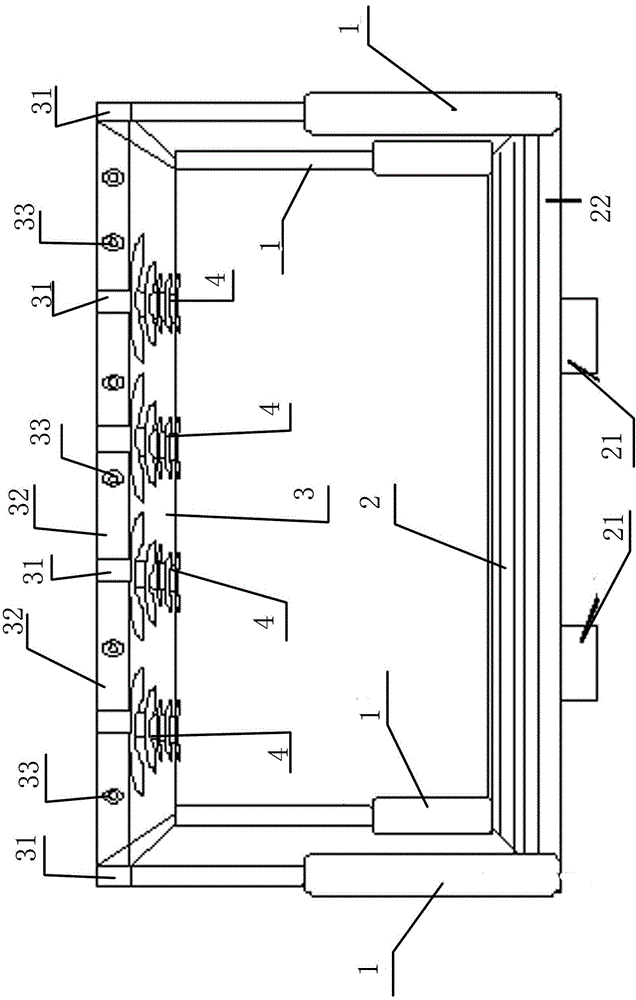

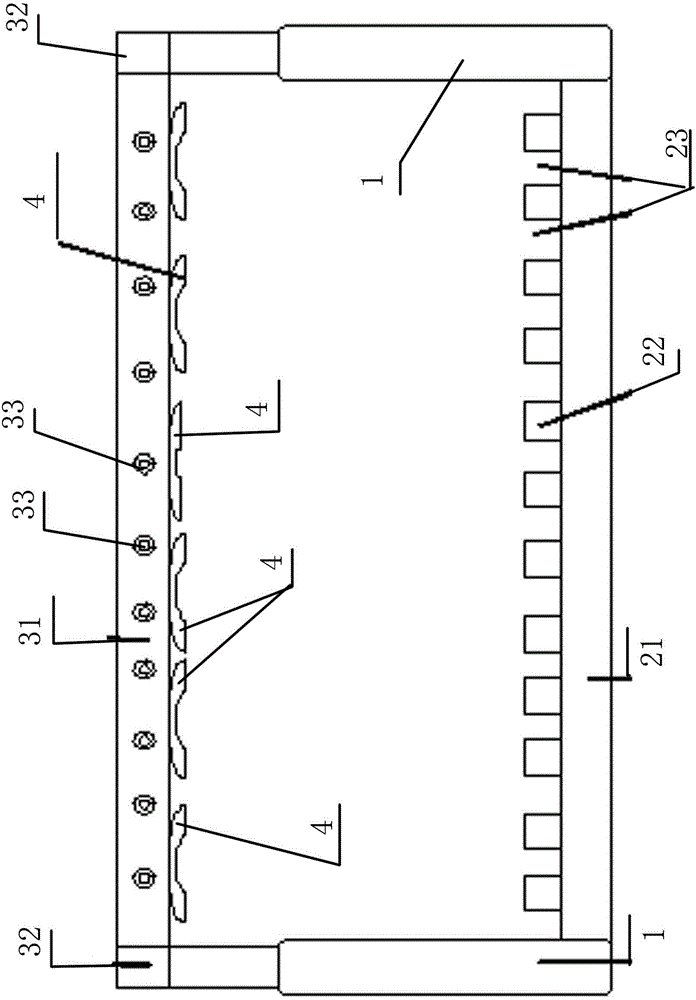

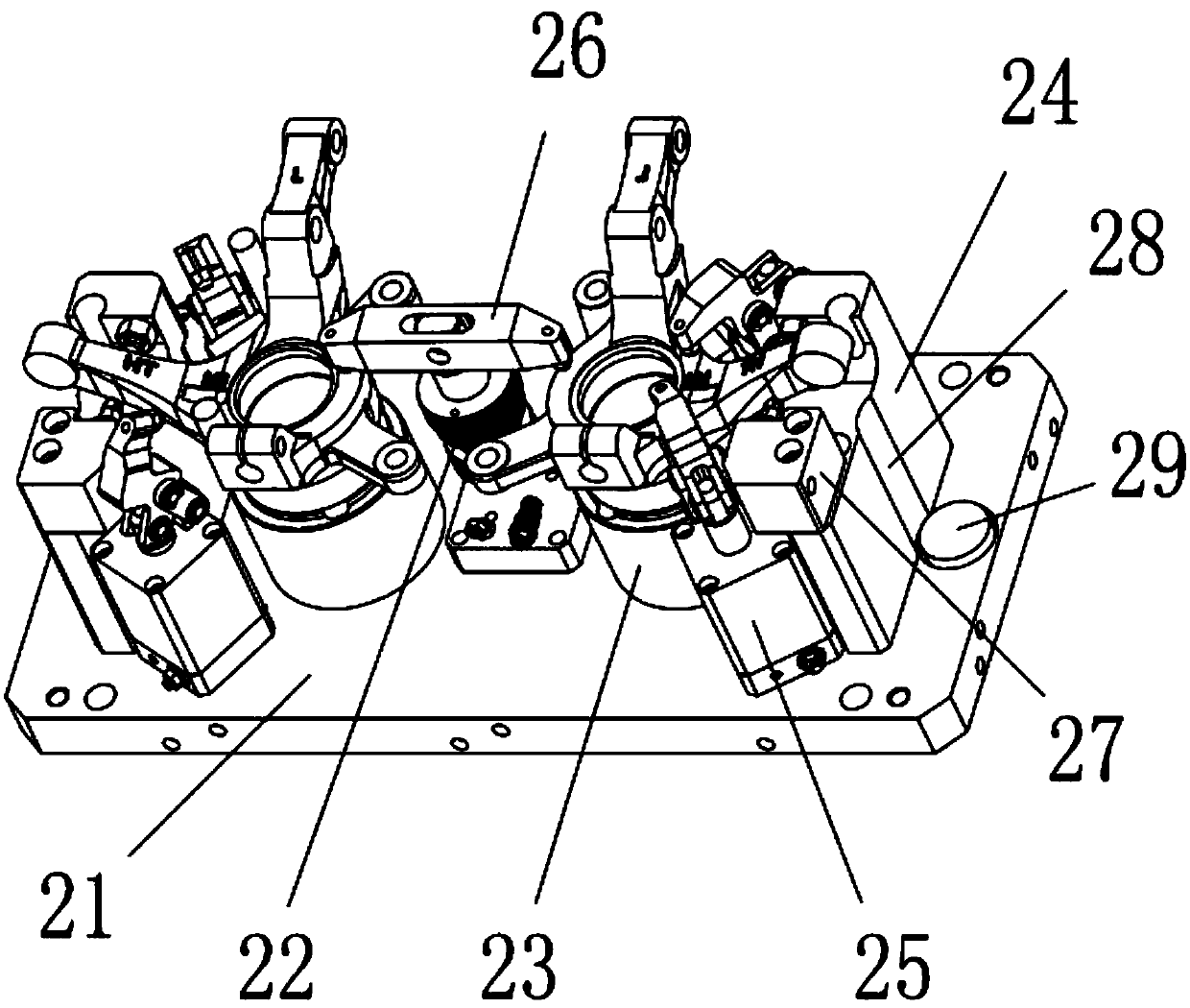

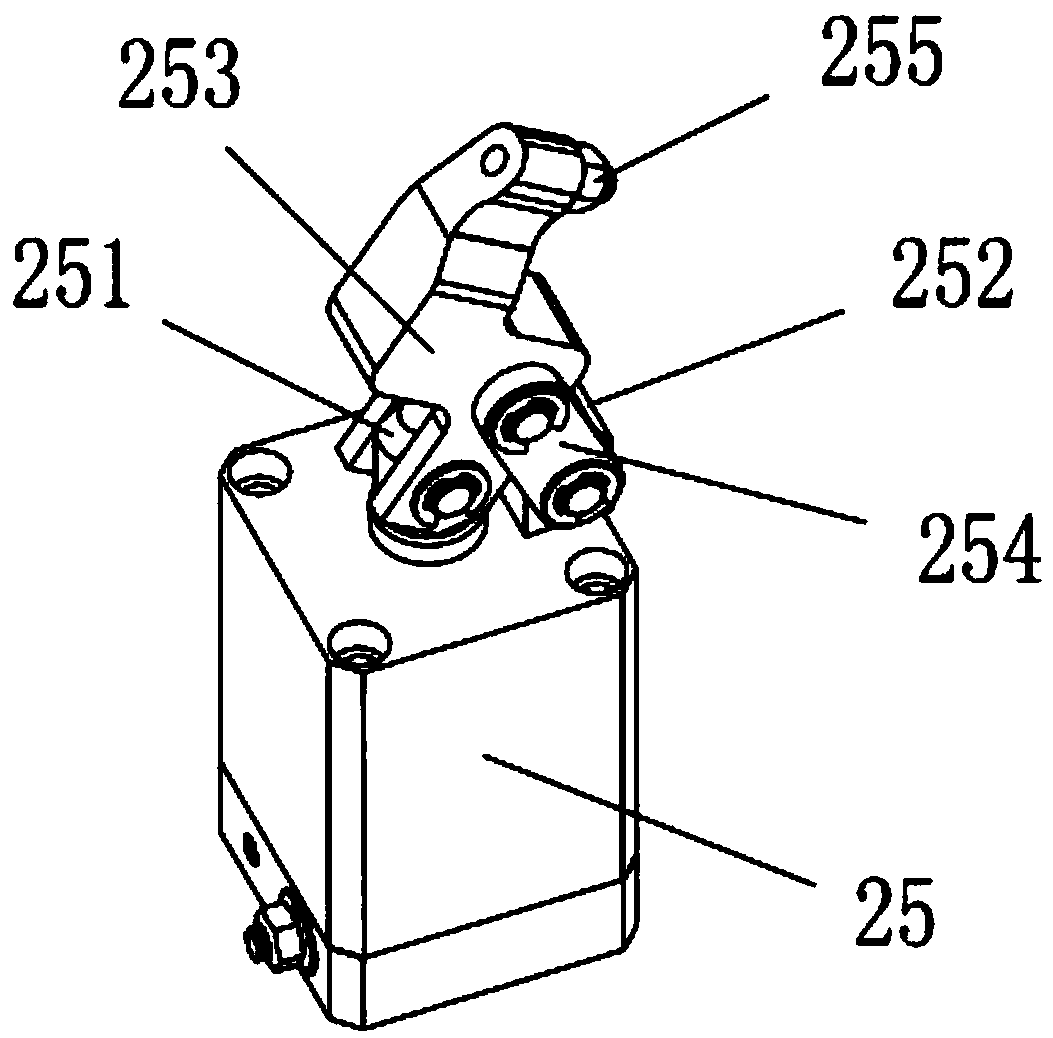

Workpiece feeding and discharging device of water heater inner container automatic spraying and acid pickling system and water heater inner container automatic spraying and acid pickling system

ActiveCN104984966AAccurate placementImprove loading and unloading speedHollow article cleaningHanging basketMechanical engineering

The invention discloses a workpiece feeding and discharging device of a water heater inner container automatic spraying and acid pickling system and the water heater inner container automatic spraying and acid pickling system. The workpiece feeding and discharging device of the water heater inner container automatic spraying and acid pickling system comprises a robot arranged on one side of a circulating conveying chain and used for automatically feeding and discharging a workpiece, and a strengthening device for clamping or releasing a hanging basket in a stretching and contracting mode. When the workpiece is fed or discharged, the strengthening device clamps the hanging basket, paws of the robot put a water heater inner container into the hanging basket or take the water heater inner container out of the hanging basket, and the strengthening device releases the hanging basket to complete feeding or discharging of the workpiece. The workpiece feeding and discharging device of the water heater inner container automatic spraying and acid pickling system and the water heater inner container automatic spraying and acid pickling system have the advantages of increasing the workpiece feeding and discharging speed and improving the production efficiency.

Owner:东莞市天美新自动化设备有限公司

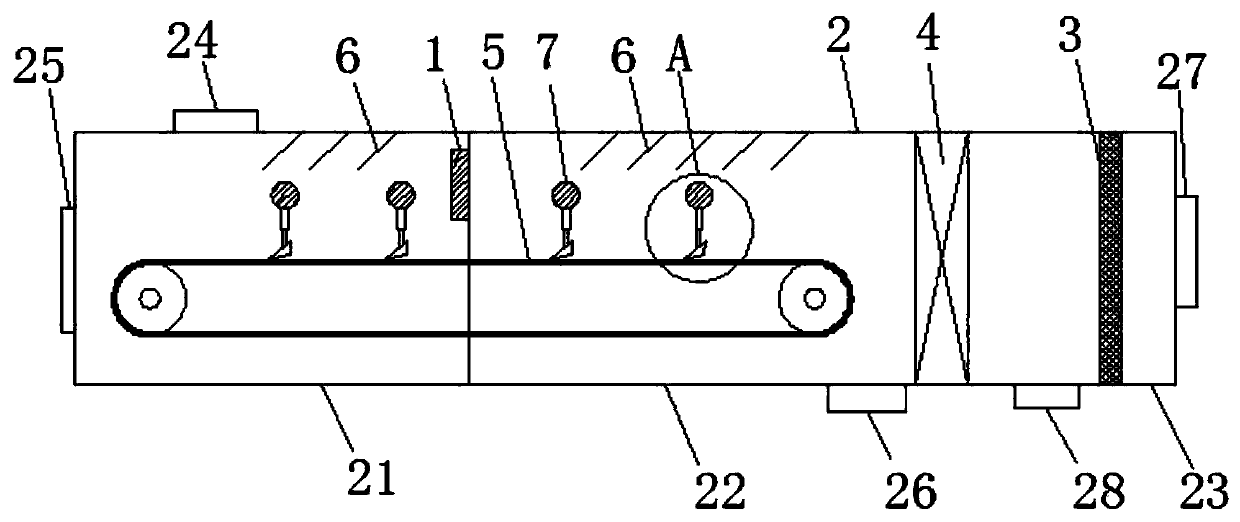

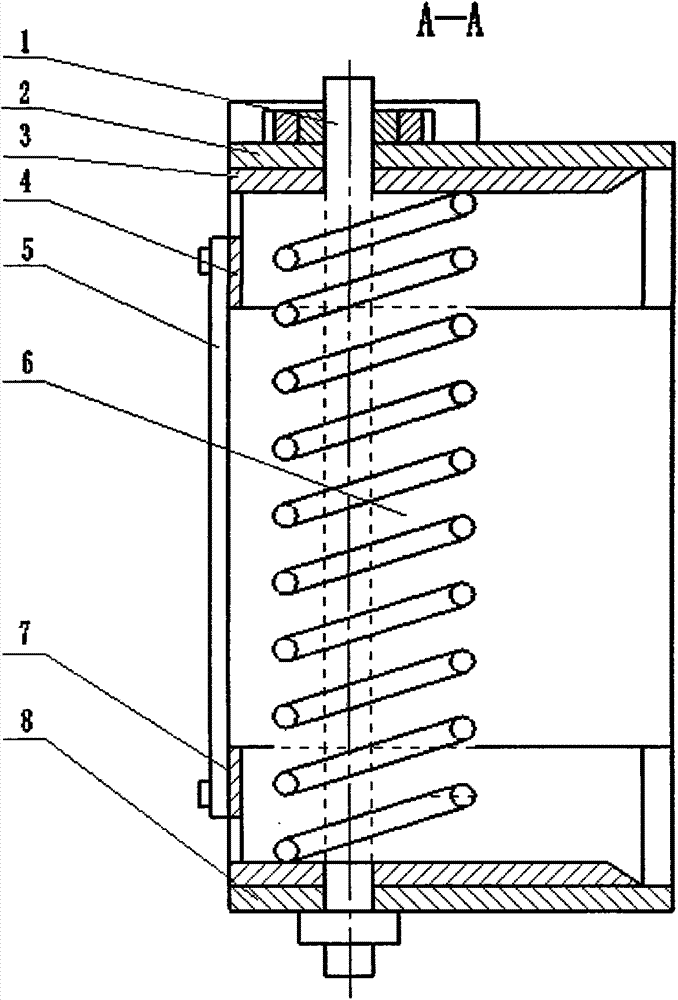

Processing device convenient to operate of bitter buckwheat products

InactiveCN109798756AReduce the temperatureImprove cooling effectDomestic cooling apparatusDrying gas arrangementsPolygonum fagopyrumEngineering

The invention discloses a processing device convenient to operate of bitter buckwheat products, and belongs to the field of bitter buckwheat product processing. The processing device convenient to operate of the bitter buckwheat products comprises a heating device, a refrigeration device, a material conveying device, and a conveying channel; the conveying channel comprises a drying section, a cooling section, and a dehumidification section connected successively; the refrigeration device comprises an evaporator, and the evaporator is located in the dehumidification section; an air supply fan is arranged between the dehumidification section and the cooling section; the heating device is located in the drying section; the material conveying device comprises a conveying belt, and the conveying belt is used for conveying materials from the drying section to the cooling section; air regulating plates are arranged on the inner wall of the cooling section and the inner wall of the drying section, the air regulating plates are arranged in an inclined mode, the free ends of the air regulating plates point to the surface of the conveying belt, and the inclined direction of the air regulatingplates is the same as the air supplying direction of the air supply fan; and the drying section is provided with a feeding port and an air outlet, the cooling section is provided with a discharging port, and the dehumidification section is provided with an air inlet and a water outlet. The processing device convenient to operate of the bitter buckwheat products can improve the drying effect, andeffectively reduce the harvesting temperature of the bitter buckwheat products.

Owner:安徽省钗源苦荞麦制品有限责任公司

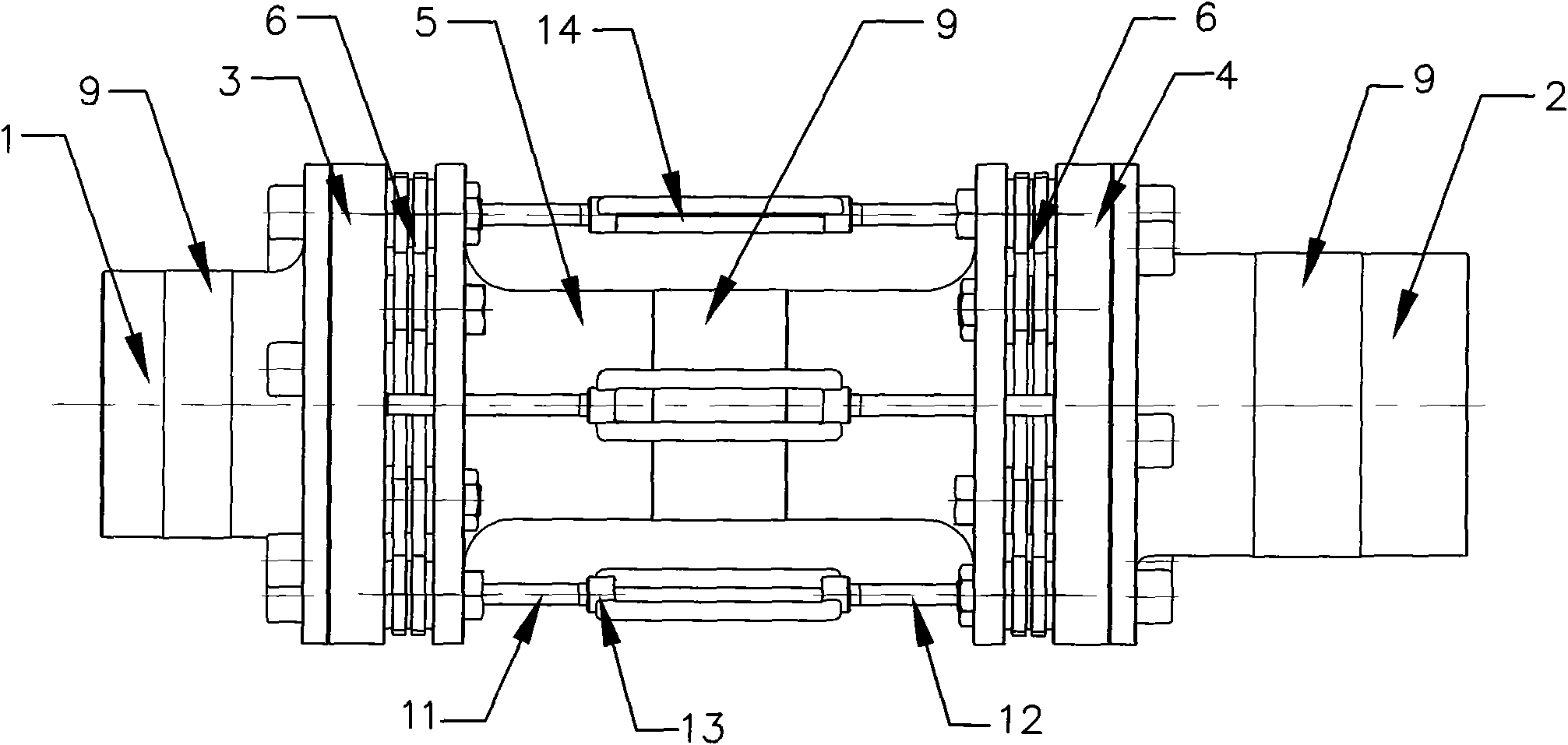

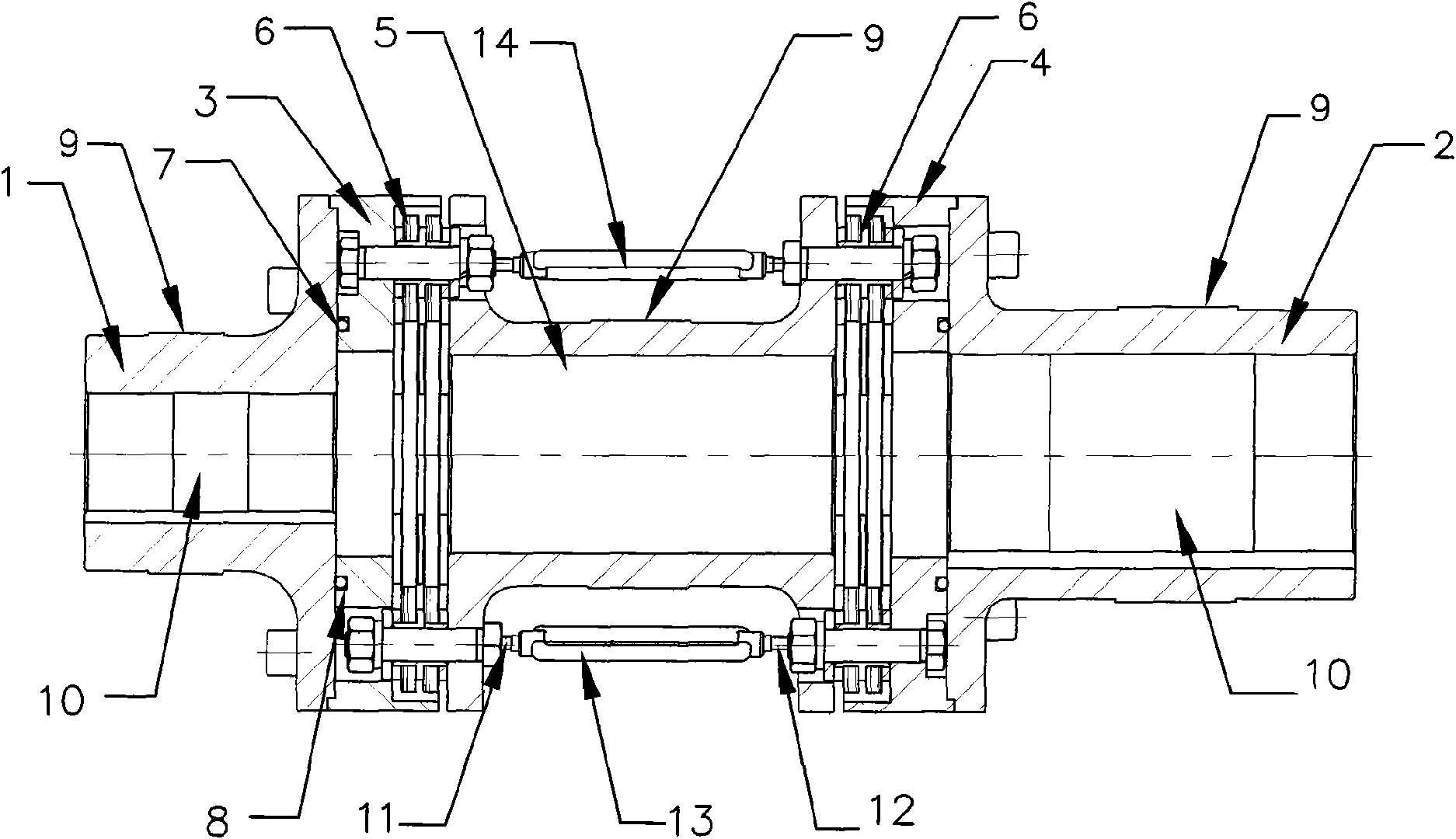

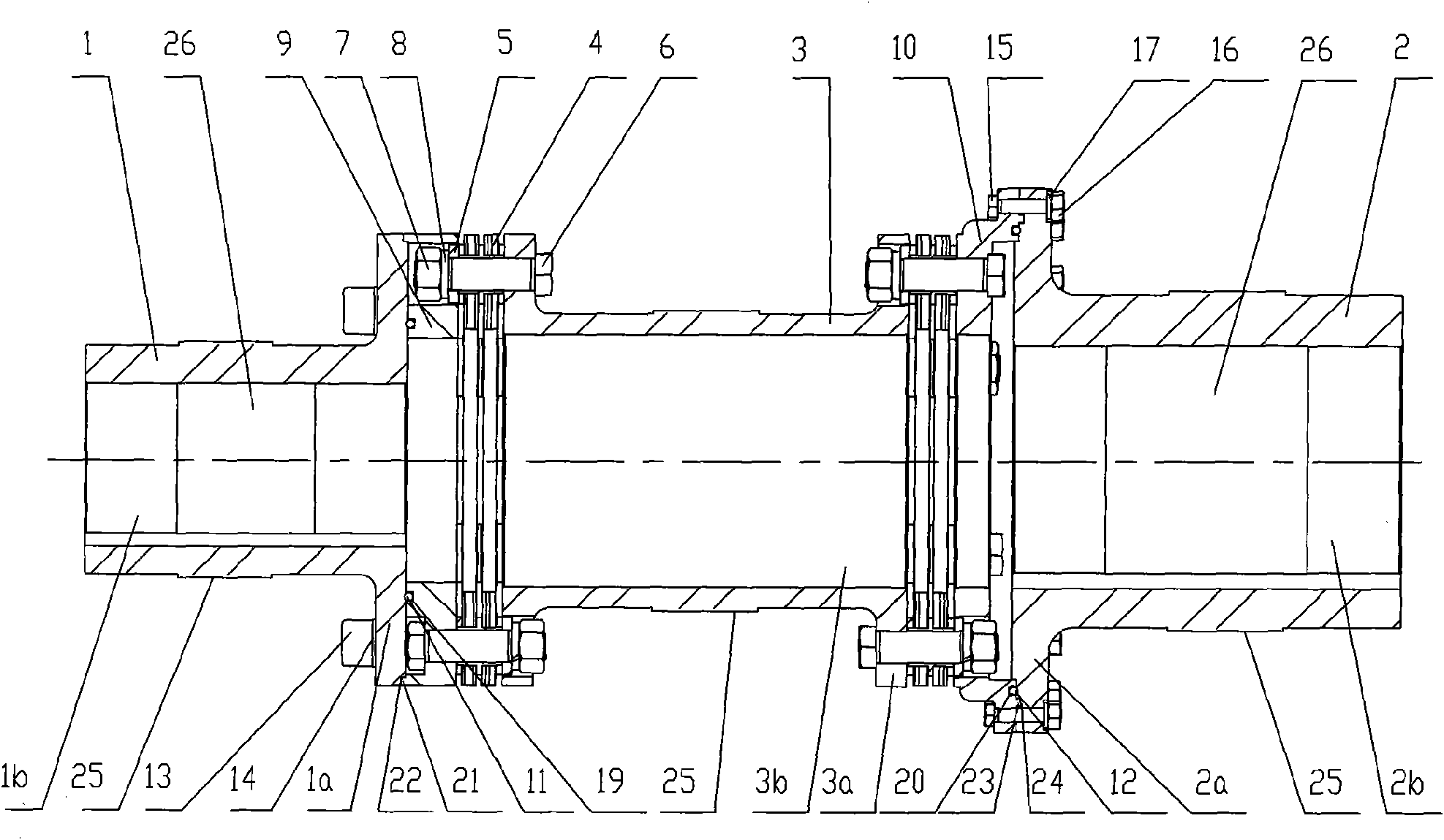

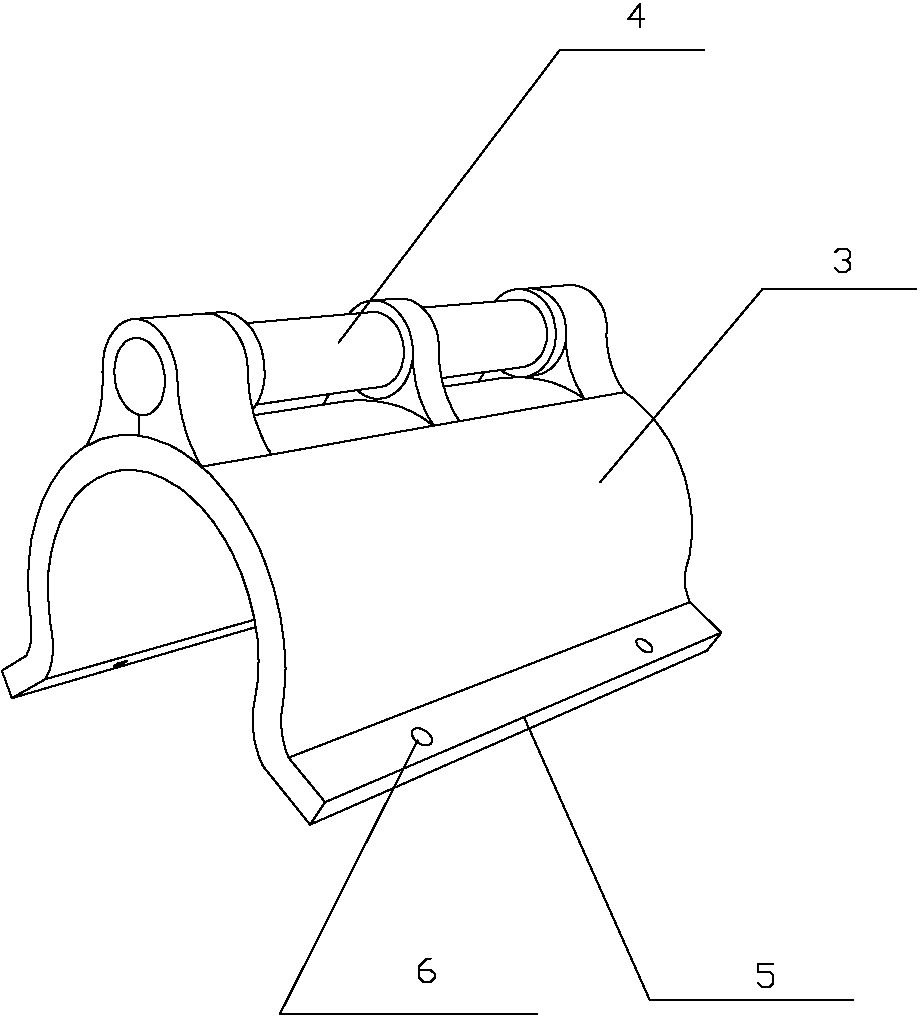

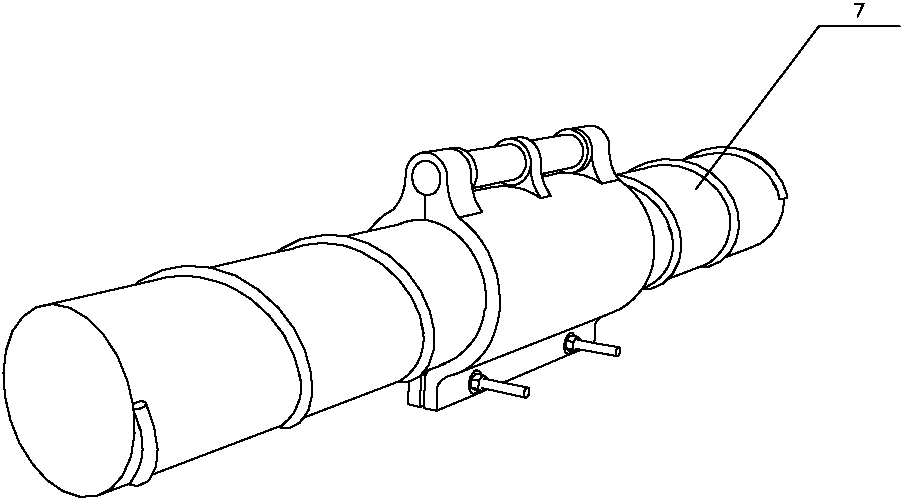

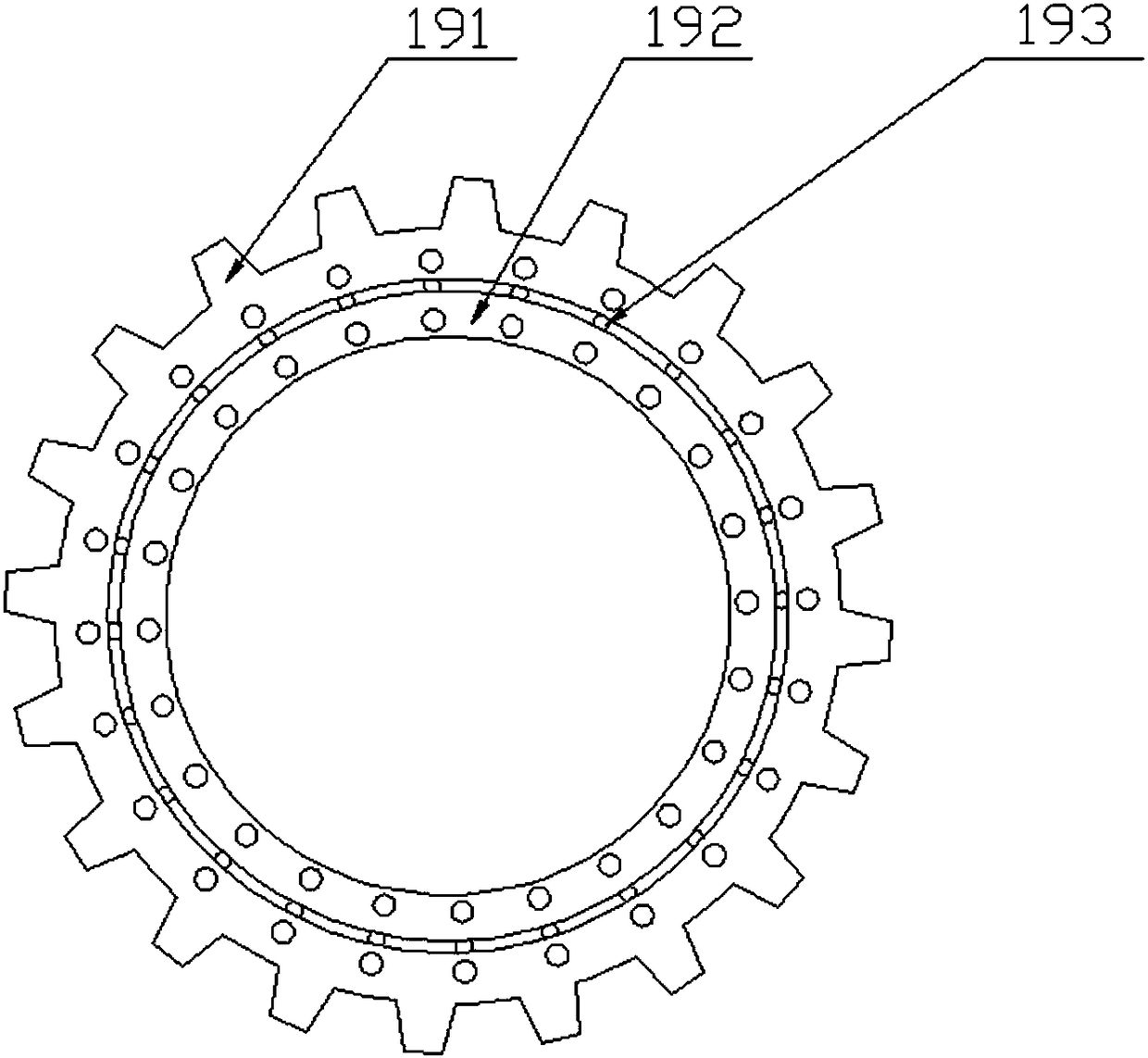

Actuation balance-free type large-torque flexible coupling

InactiveCN101629604AGuaranteed uptimeIncrease torqueYielding couplingCouplingArchitectural engineering

The invention relates to an actuation balance-free type super large torque flexible coupling with an intermediate section, which comprises two half-couplings, two butting discs and a diaphragm group and has improvements in also comprising the intermediate section, high-strength elastic rings and a tightening device, wherein the two butting discs and the two half-couplings are installed on both ends of the intermediate section through bolts and positioned by bayonets; the diaphragm group is laminated and installed among the butting discs and the intermediate section; the external side surfaces of the butting discs are provided with grooves in which the high-strength elastic rings are installed; the two half-couplings and the intermediate section are respectively provided with a circle of outward bulgy lug bosses; and the tightening device comprises two tightening bolts and a long nut, wherein one end of each tightening bolt is connected with each butting disc and the other end is screwed into the long nut. The actuation balance-free type super large torque flexible coupling with the intermediate section has the advantages of large power transfer torque, longer service life, wider configuration range and simple loading and unloading, thereby being suitable for fields of petroleum, chemical engineering, metallurgy, machinery, environmental protection, mining, shipping, aerospace, diversion engineering, nuclear power, military affairs, and the like.

Owner:李文聪

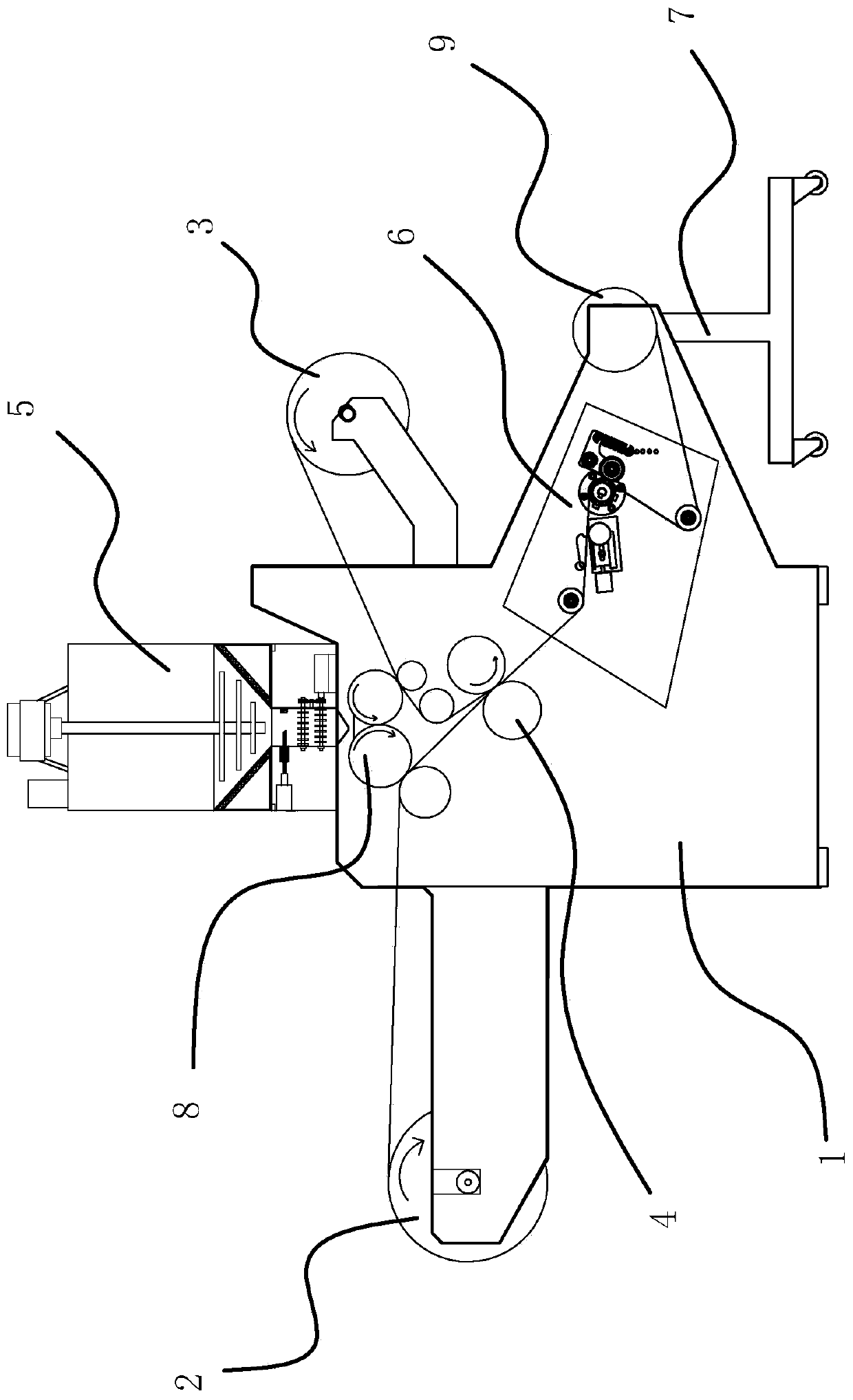

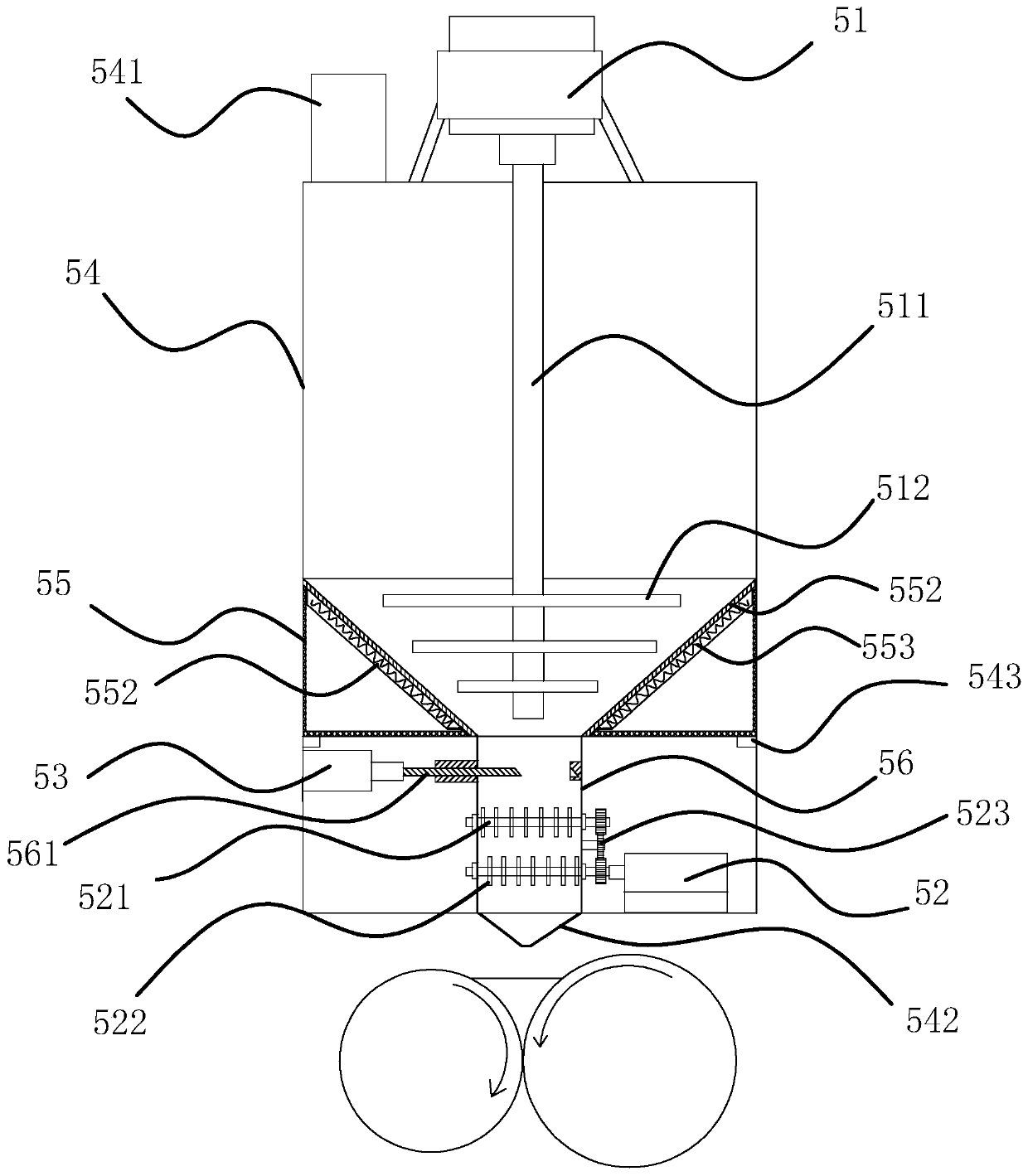

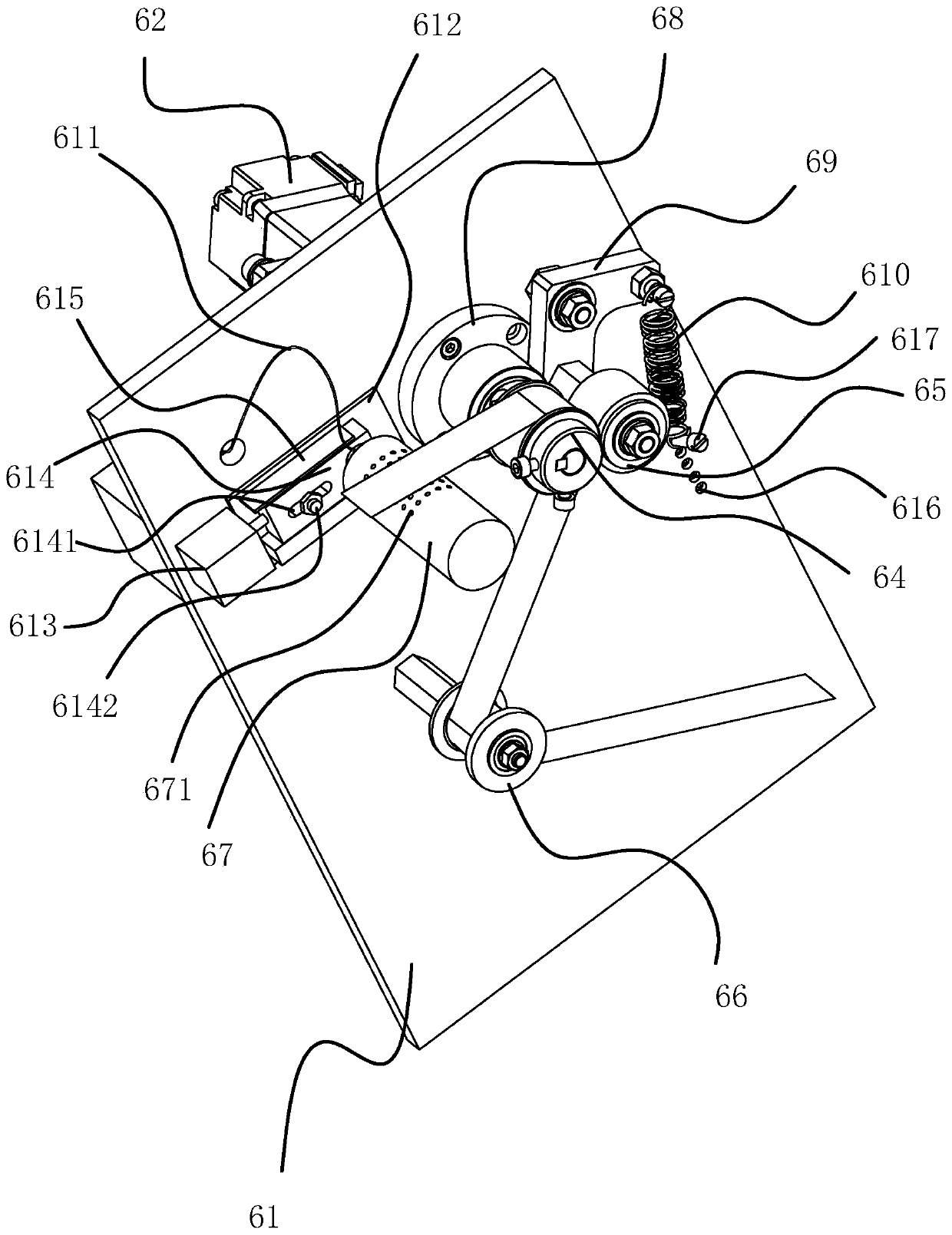

Plastic thin film laminating machine

The invention provides a plastic thin film laminating machine. The plastic thin film laminating machine comprises a rack, a first unwinding roller, a second unwinding roller, a pair of laminating rollers, a gluing mechanism, a traction mechanism and a winding mechanism. The first unwinding roller and the second unwinding roller are rotatably connected to the rack, the laminating rollers are rotatably arranged at the position, between the gluing mechanism and the traction mechanism, of the rack, the winding mechanism comprises a transfer base and a winding roller, the two ends of the winding roller are provided with winding rotating shafts, one end of the rack is provided with a C groove allowing the winding rotating shafts to transversely slide in, the transfer base is provided with a supporting structure for supporting the winding rotating shaft to rotatably adjust the height of the winding roller, and a driving motor, a driven shaft, a winding shaft sleeve and a gear assembly are arranged on one side of the rack. The supporting structure in the winding mechanism can adjust the height of the U supporting part, the winding rotating shaft can be aligned with a shaft hole of a driven shaft, and the driven shaft drives the winding roller to rotate more stably.

Owner:浙江天畅塑胶有限公司

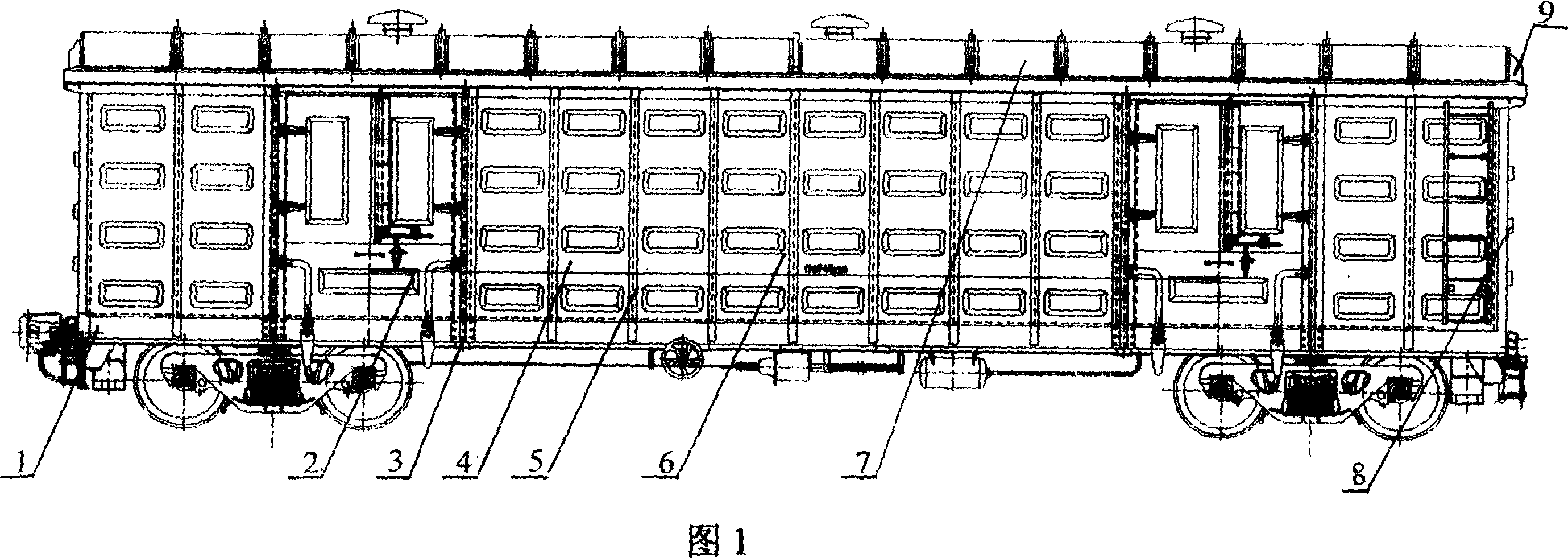

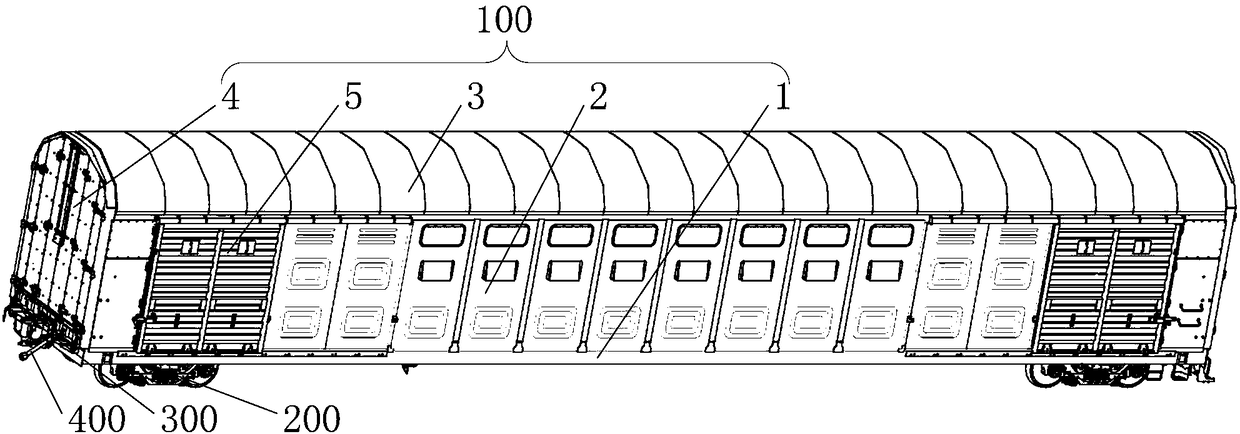

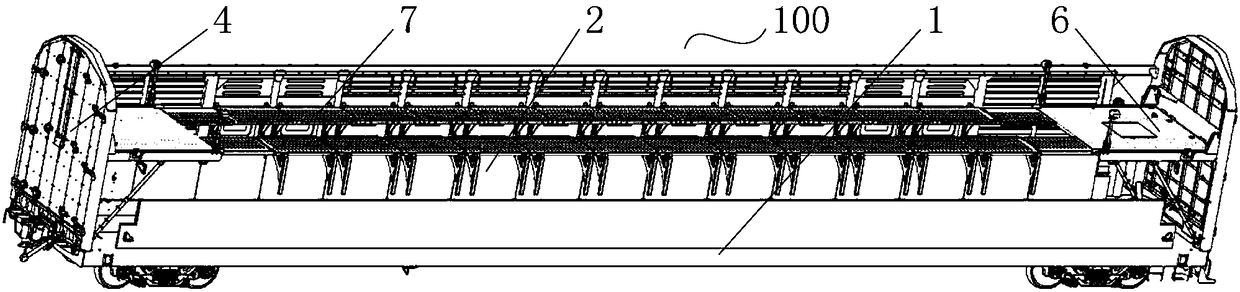

All-purpose house car

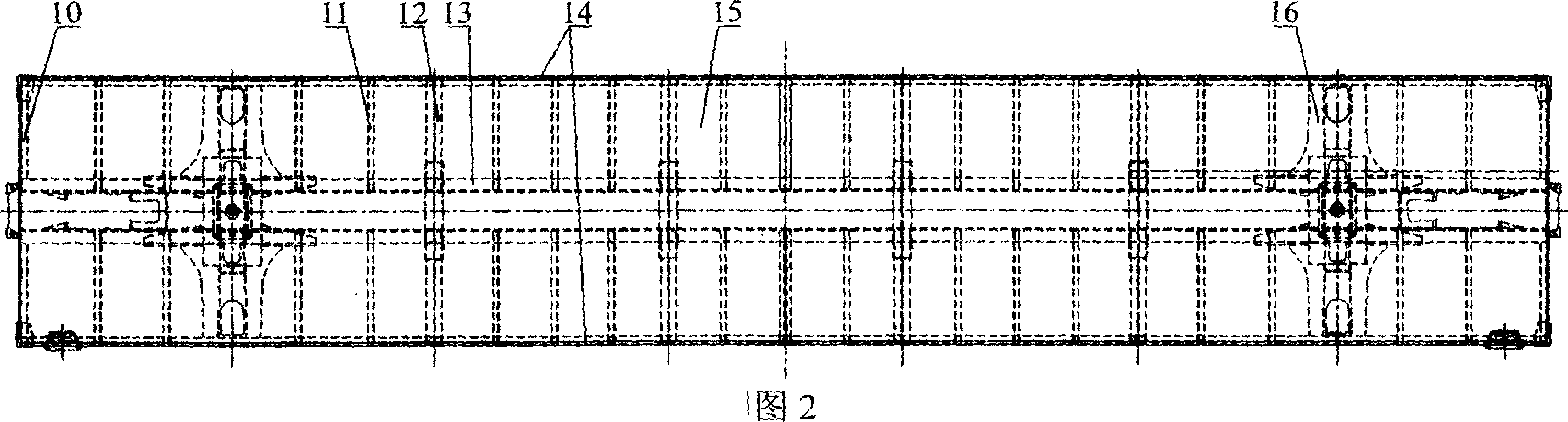

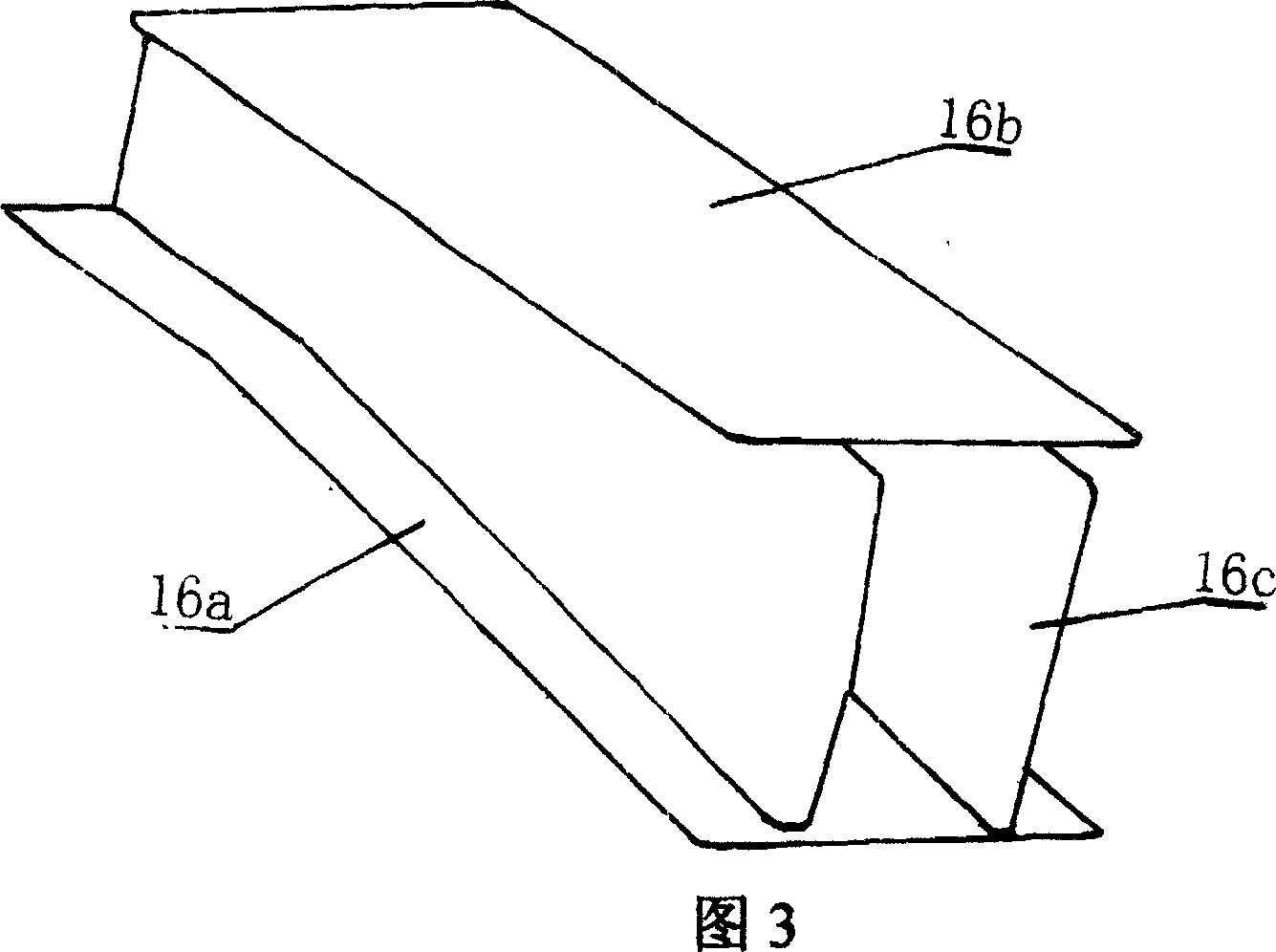

ActiveCN1923588AEasy to useReduce stress gradientRailway transportAxle-box lubricationBogieSteel frame

A commonly used cote truck belongs to railway transportation vehicle, or specifically, a railway truck. It comprises of a body, braking mechanism, clasp bumper mechanism and a steering rack. The key know-how rests on the body, which includes the bottom frame, a plate cylindrical side wall made up of side plate and side cylinder, end wall, roof that has venting system at both ends, and also a door on the side wall and supported by the doorpost. This cote truck substantially adopts the case and enclosed section structure by forming a reasonable overall force frame to achieve the ideal carrying effect and the extension of the car's life span. And the feature of reducing the dead load of the steel frame without degrading the level of rigidity has made this structure having bigger bearing ability.

Owner:CRRC MEISHAN

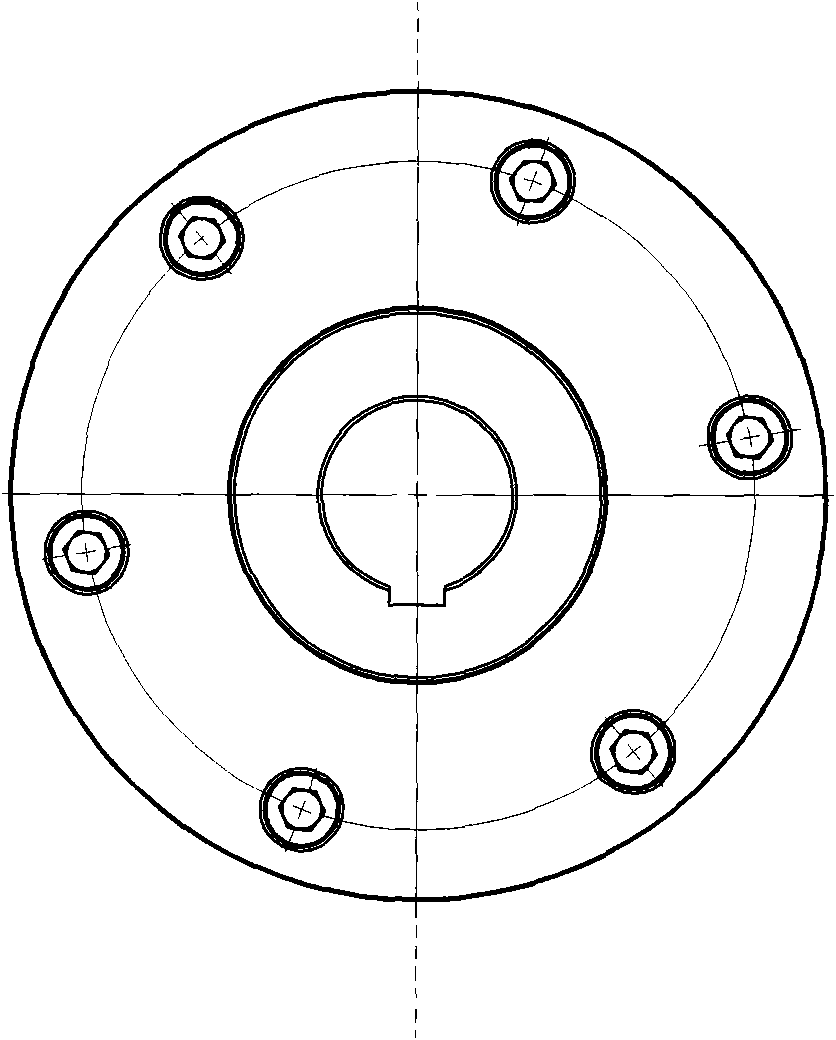

Actuation balance-free type single-reducing coupling

The invention relates to an actuation balance-free type single-reducing coupling which comprises two half-couplings, an intermediate section and a diaphragm group, wherein each of the two half-couplings is an axis connecting sleeve provided with a flange at one end; the intermediate section is an axis connecting sleeve provided with flanges at both ends; the external side of the flange at one end of the intermediate section is sequentially connected with the diaphragm group and a butting disc; the external side of the flange at the other end of the intermediate section is sequentially connected with the diaphragm group and a reducing disc; the two half-couplings are respectively connected with the butting disc and the reducing disc in a bayonet positioning mode; the axis connecting sleeves of the two half-couplings and the intermediate section are respectively provided with an outer lug boss; and the diaphragm group is laminated and produced in such a way that all elastic flakes are threaded and connected by double-faced rivets and hydraulically punched. The actuation balance-free type single-reducing coupling can meet precision requirements of 2.5 level dynamic balance without actuation balance at the rotating speed of 10000r / min or below, thereby omitting the working procedure of actuation balance and overcoming the defect of unprepossessing appearance caused by the drilling of the coupling.

Owner:李文聪

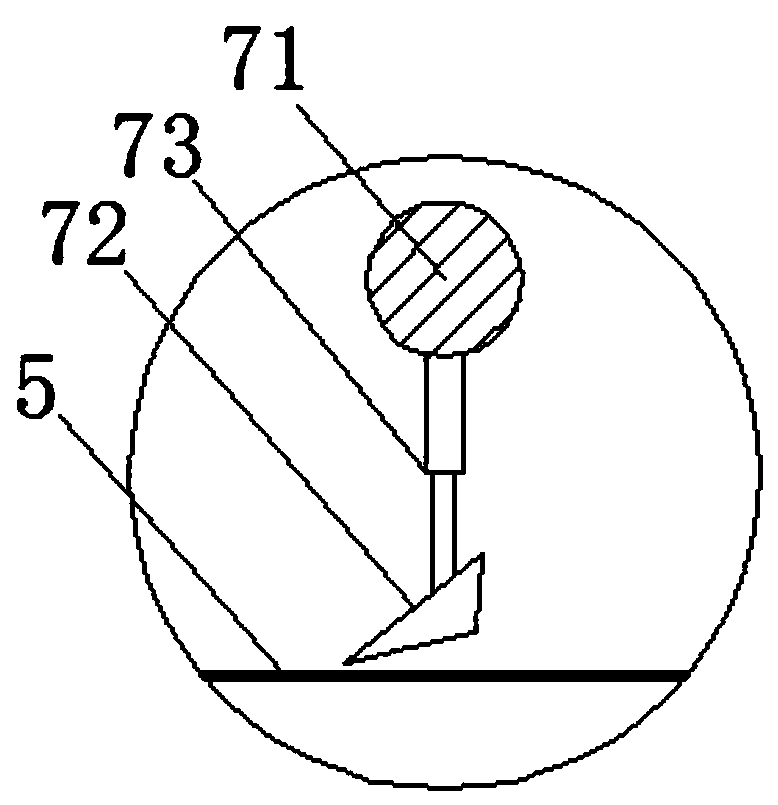

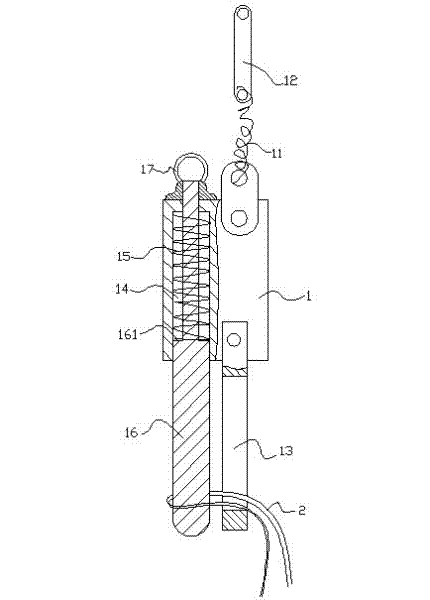

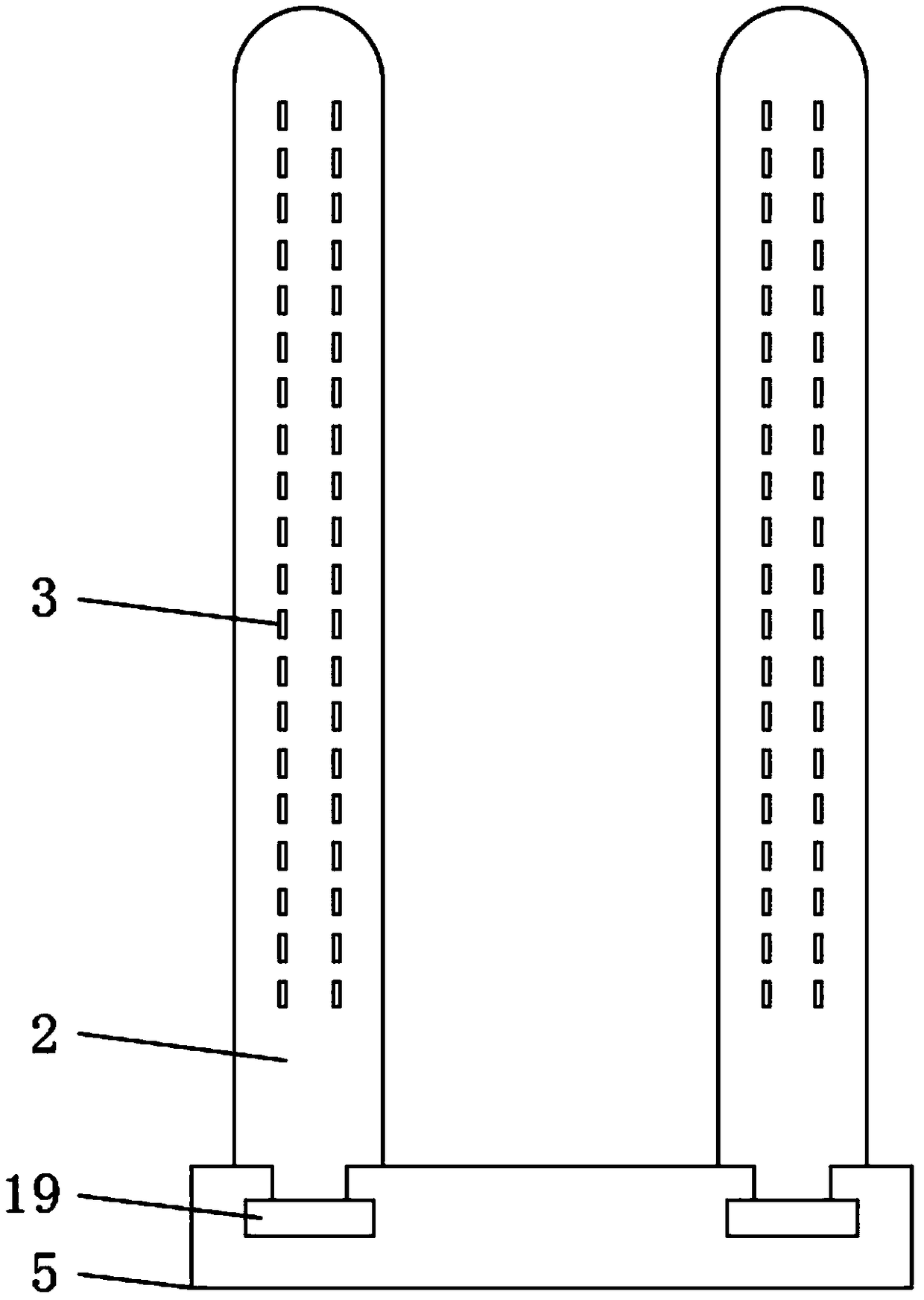

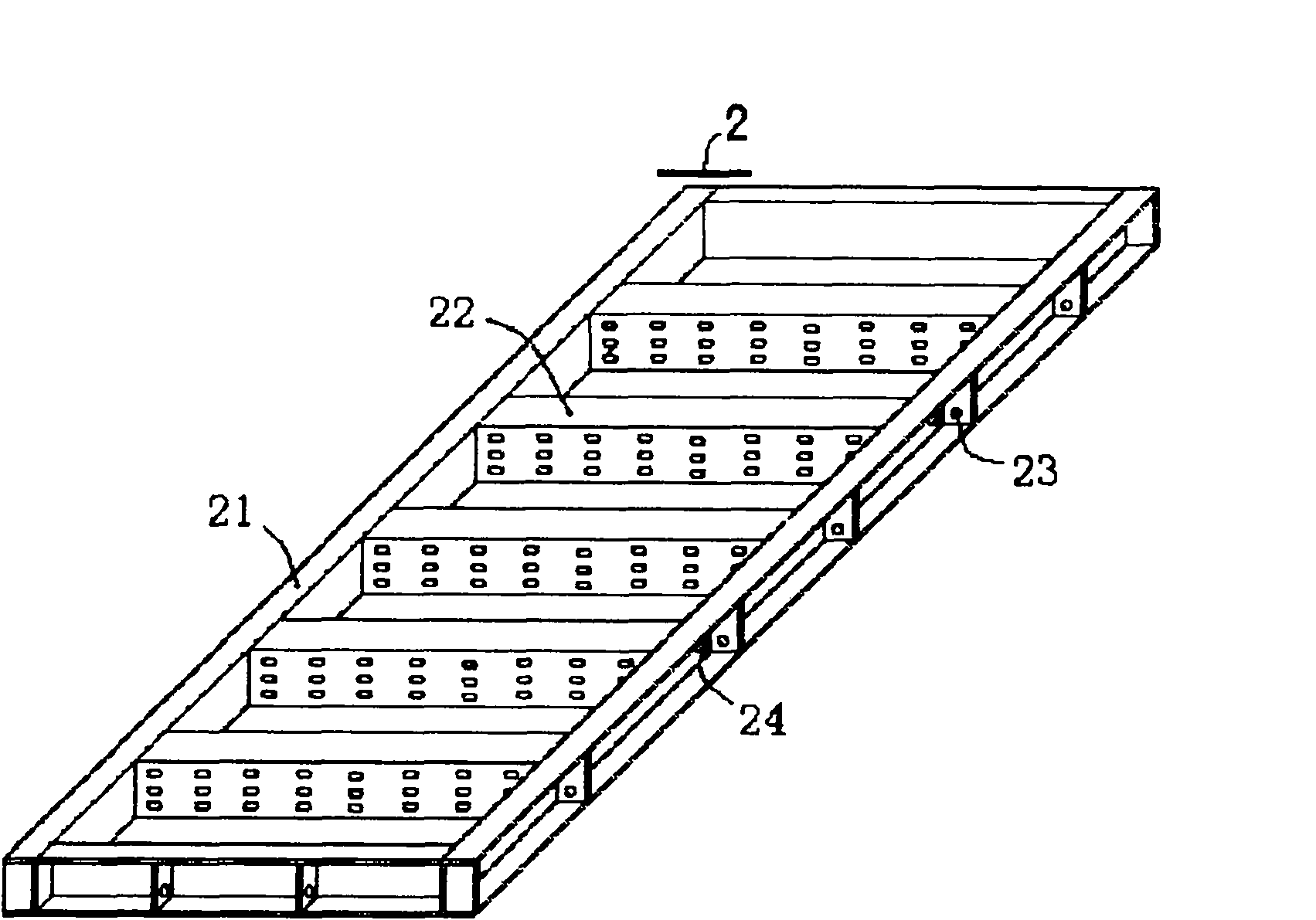

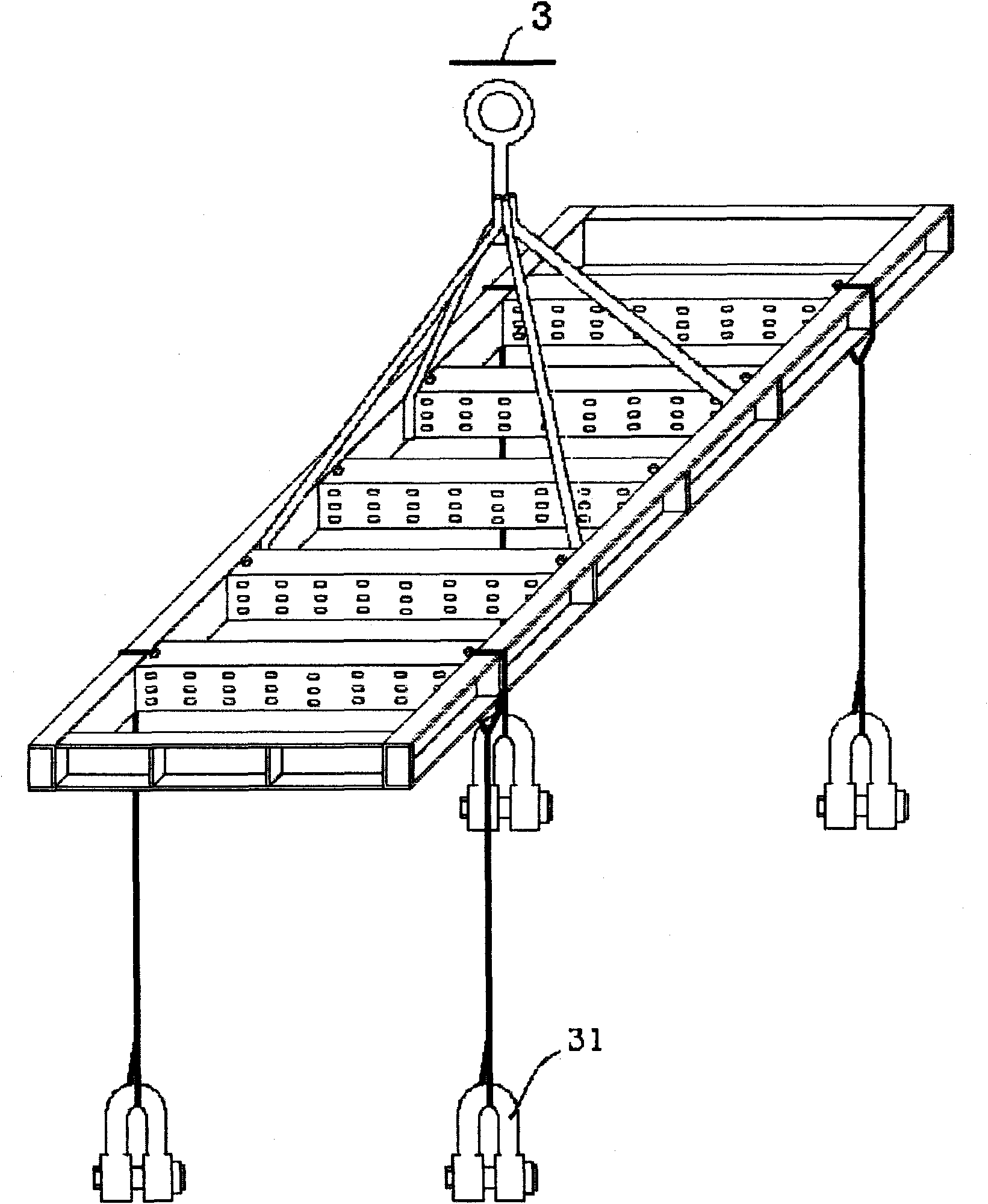

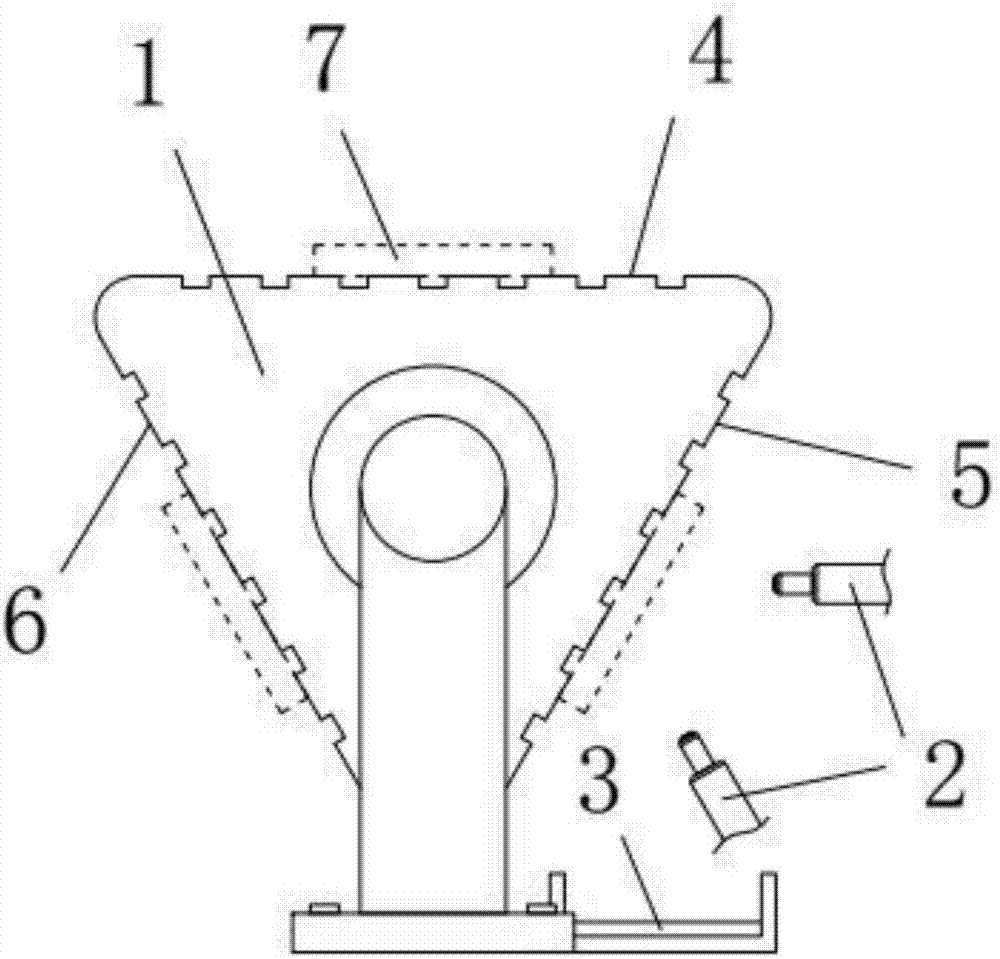

Automatically-released hoist ring and combined loading and unloading frame with same

ActiveCN102476777ARealize automatic unhookLabor savingLoad-engaging elementsWorking environmentEngineering

The invention discloses an automatically- released hoist ring and a combined loading and unloading frame with the same. The automatically-released hoist ring comprises a body, the upper end of the body is hinged to a connecting chain and a connecting ring, the lower end of the body is hinged to a snap ring, a two-stepped mounting hole is arranged in the body, an elastic device is arranged in the mounting hole and comprises a spring and a pull rod, the upper end of the pull rod penetrates through the spring and extends out of the body from the upper end of the mounting hole, and a nut lifting ring is arranged at a position, extending out of the body, of the upper end of the pull rod. By the aid of the automatically-released hoist ring, a flexible container and a lifting device are manually operated only at a lifting end, and unloading is automatically performed at an unloading end without manual operation. Compared with the prior art, the automatically- released hoist ring greatly improves transfer efficiency, saves labor by half, and avoids the influence of a severe working environment at the unloading end on physical and mental health of workers. In addition, the combined loading and unloading frame overcomes the defect that shipment cannot be realized once as a large freighter with a wide deck has dead angles.

Owner:WENLING SHENGKAI LOGISTICS EQUIP TECH CO LTD

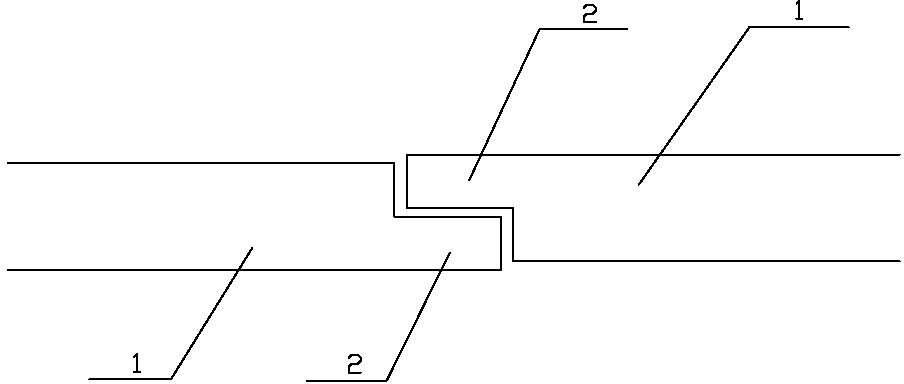

Steel bar connection method and matched fastener thereof

InactiveCN103276906AEasy to operateSimple structureBuilding reinforcementsBuilding material handlingEngineeringConstruction management

The invention relates to a steel bar connection method which mainly includes the following process steps: straightening steel bars; cutting tenons at the ends of the steel bars; joggling the steel bars: a matched fastener is sleeved at the joggled position of the steel bars and bolts are screwed. The invention further provides the fastener used in the method in a matched mode. The fastener is formed by two symmetrical semicircular-cylinder bodies made of steel. One sides of the bodies are connected together through a hinge, and flanges are arranged on the other sides of the bodies respectively. The steel bar connection method is simple to operate and few in processing procedures, reduces labor intensity of workers, improves production efficiency and saves production cost. Meanwhile, the fastener used in the method in a matched mode is simple in structure and convenient to use, can improve mounting and demounting speed and connection reliability, improves the construction quality and facilitates construction management.

Owner:JINLING INST OF TECH

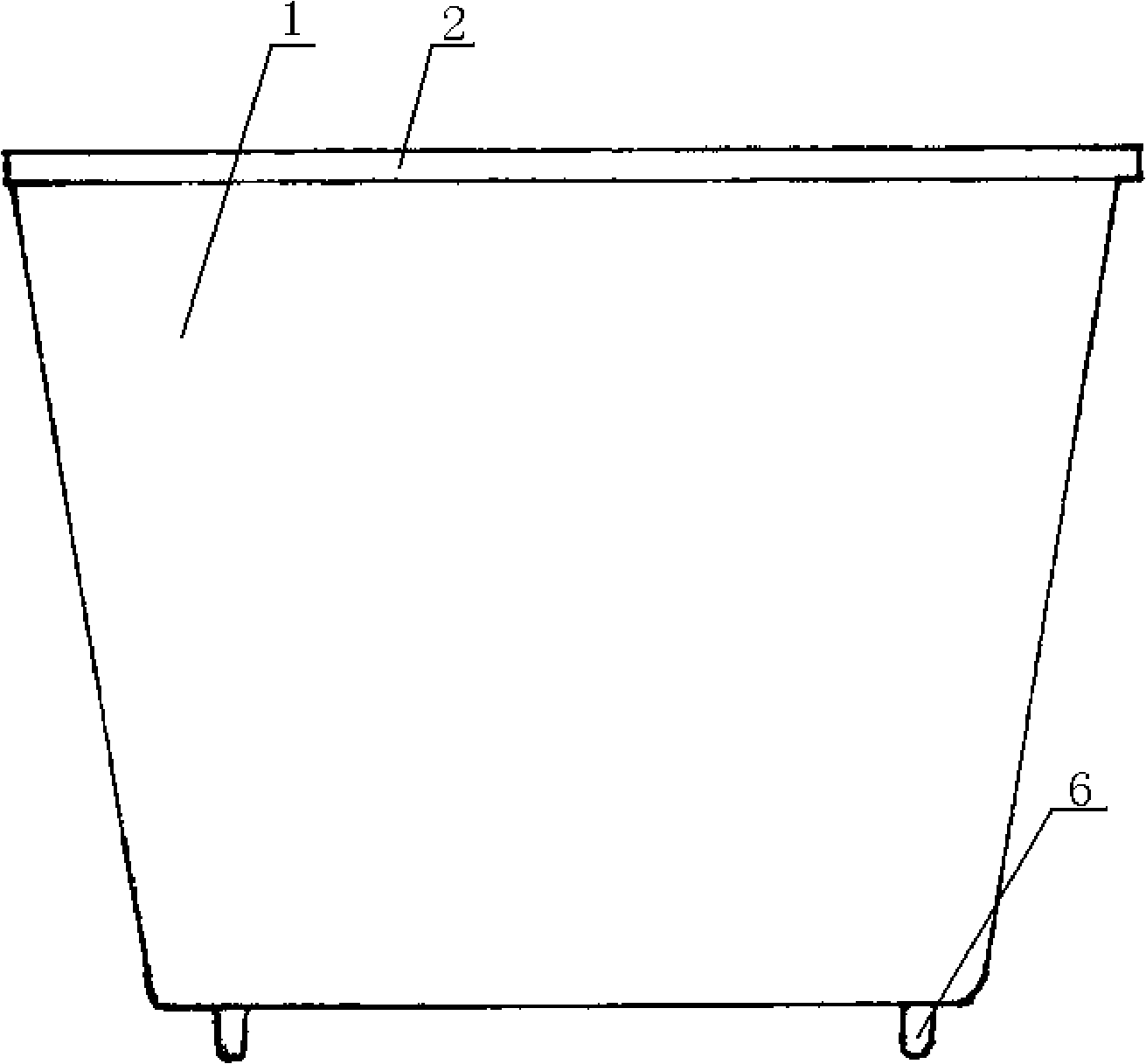

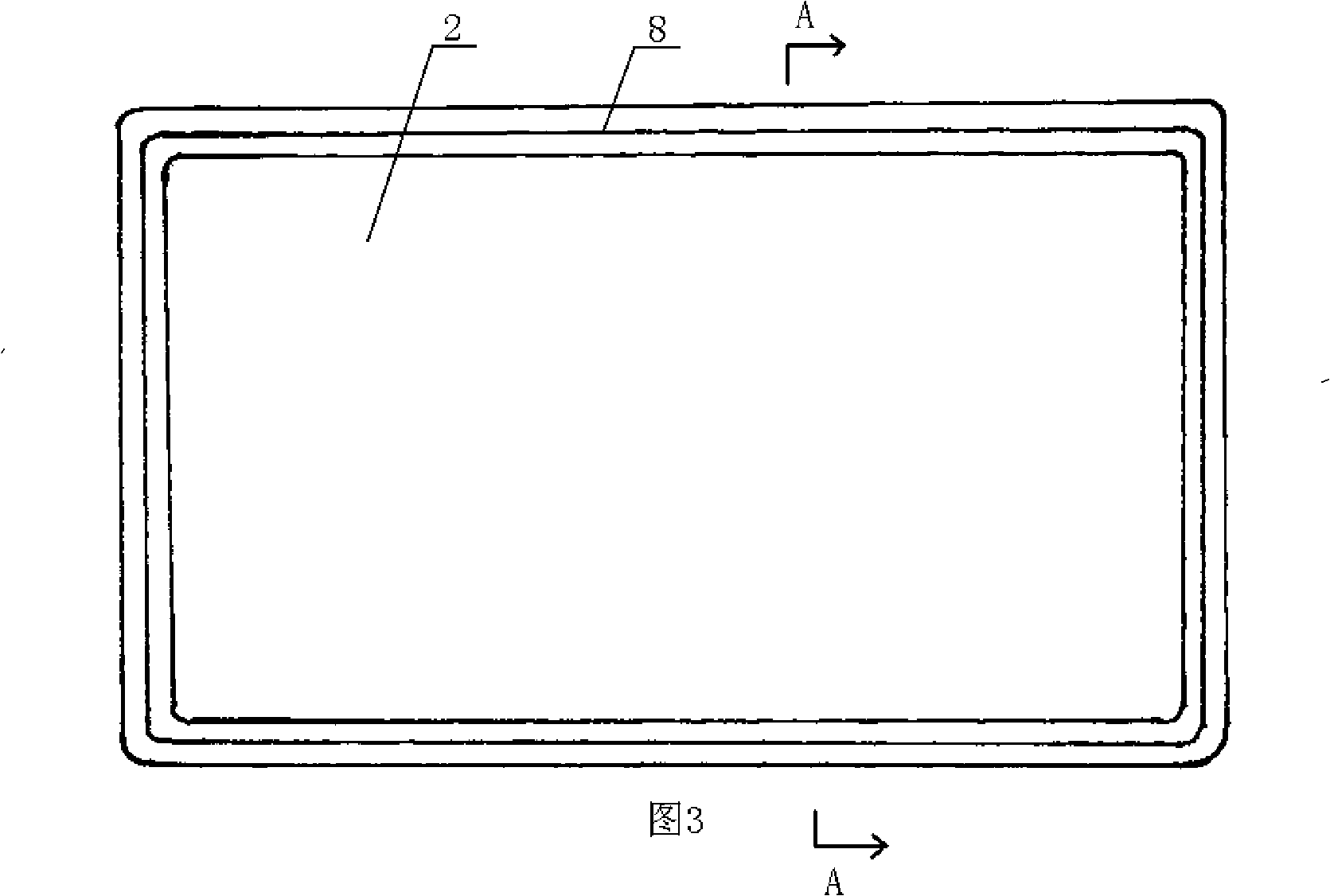

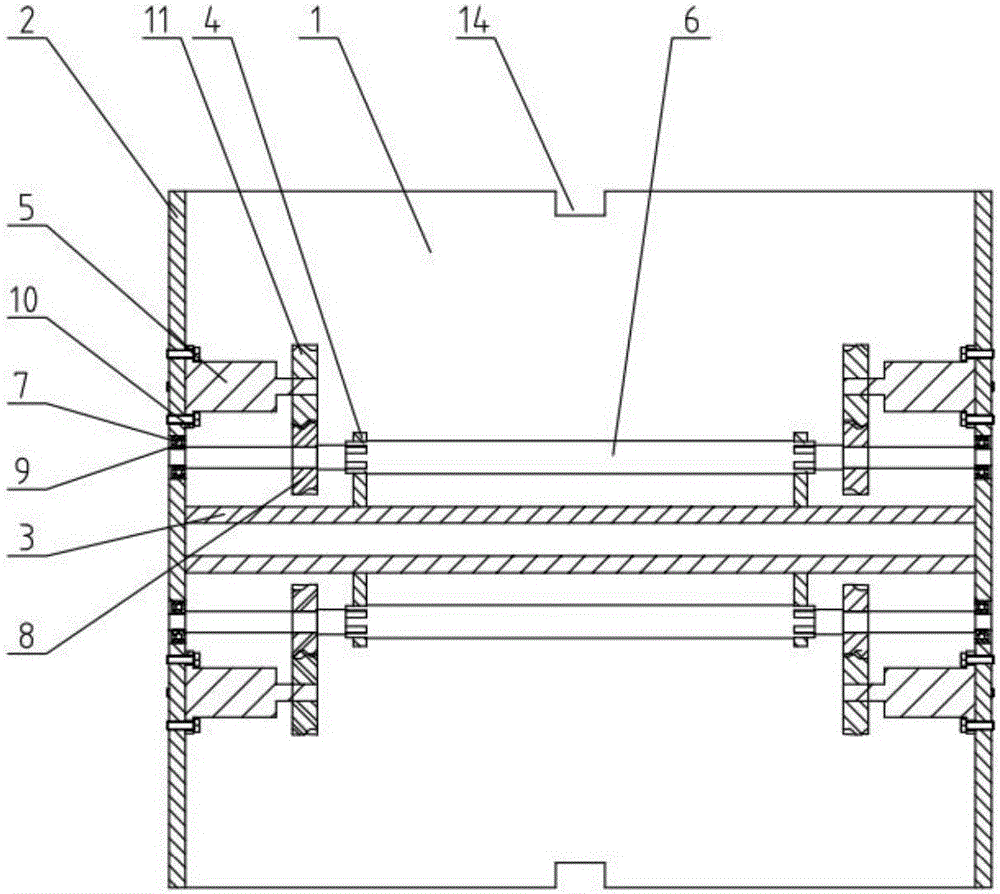

Vacuum no-oxygen bulk grain warehouse

InactiveCN101356878AFree from pollutionProtect your healthAgriculture tools and machinesLarge containersLogistics managementFree state

A vacuum oxygen-free bulk barn is characterized in that a barn body and a barn cover used for sealing the barn body are surrounded into the barn; a seal ring is arranged at the connection part between the barn body and the barn cover, a suction opening is arranged on the barn, the barn cover is sealed and airtight during grain storage, and the suction opening is connected with an exhaust fan after the grain is stored and the barn cover is covered, the inner part of the barn body is vacuumized to cause the barn to be in an oxygen-free state. The vacuum oxygen-free bulk barn has the advantages that the aging speed of the grain can be delayed in the process of grain storage, thus ensuring the grain quality and realizing pollution-free grain storage; loading and unloading of the grain for in-and-out warehouse are convenient in the process of grain transport; and the vacuum oxygen-free bulk barn also has the advantages of reducing the packaging link, low requirements for the storehouse, being capable of realizing flow and simplification of grain transport, and realizing rapid, simple and low cost transport of grain logistics.

Owner:陈宏 +1

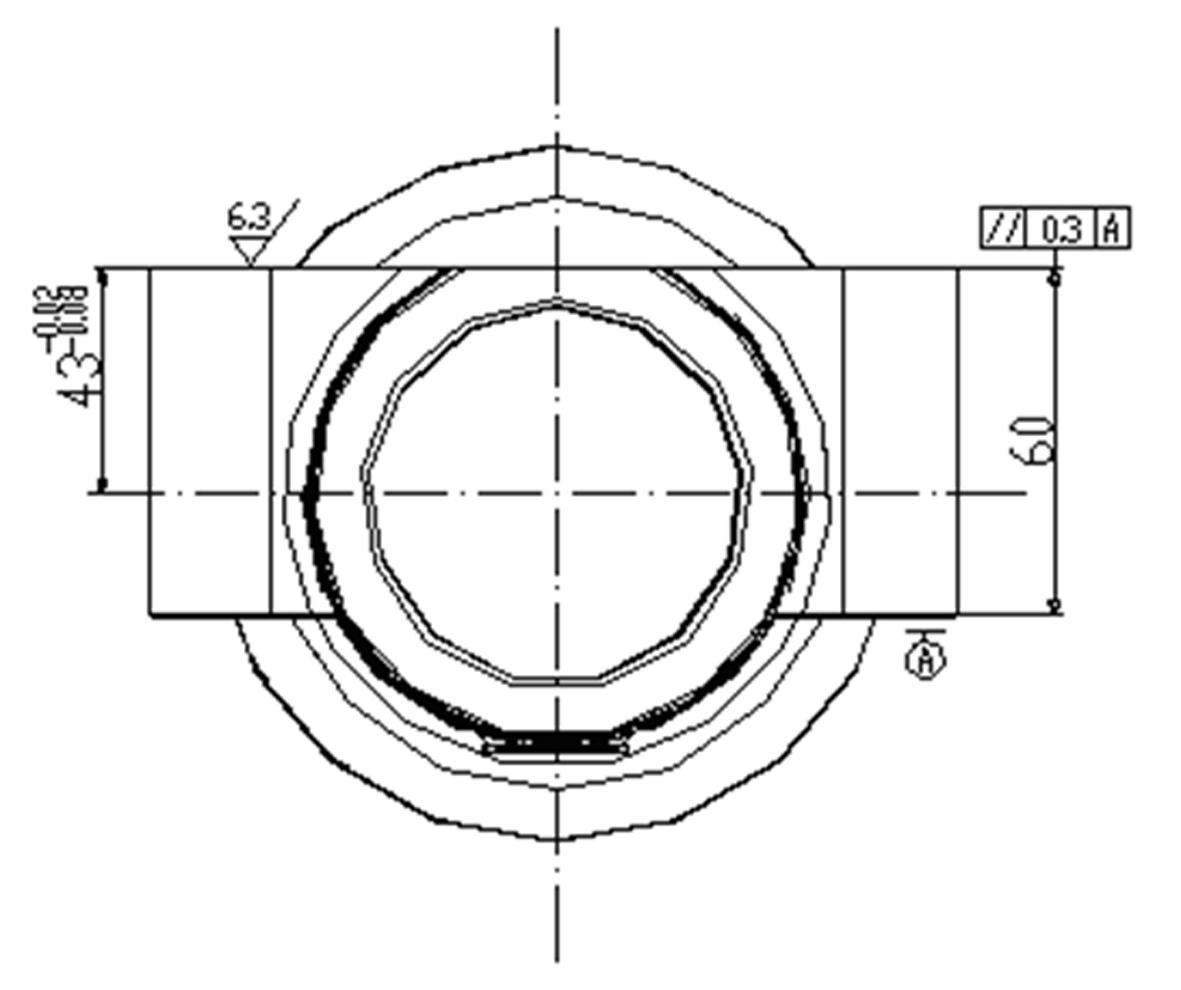

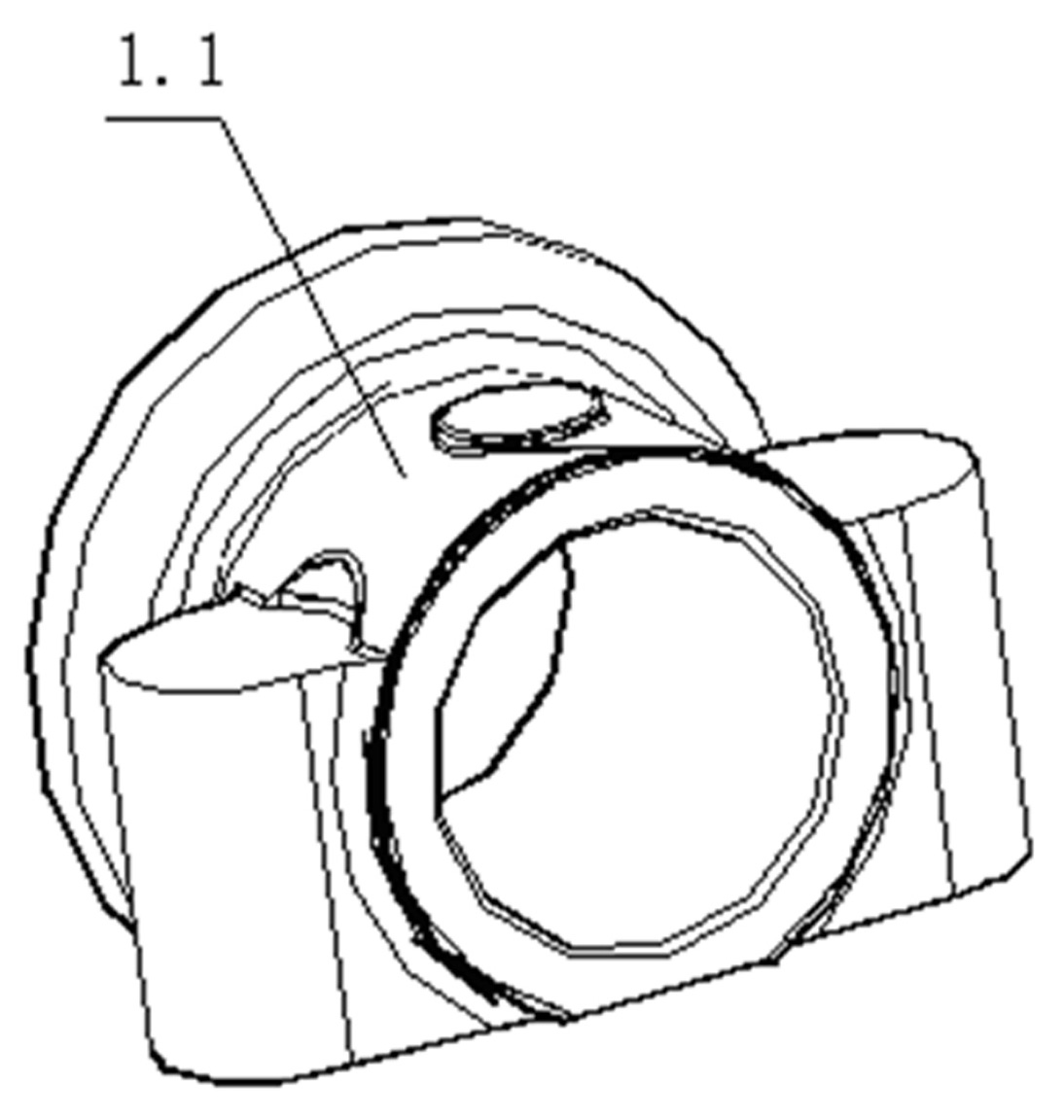

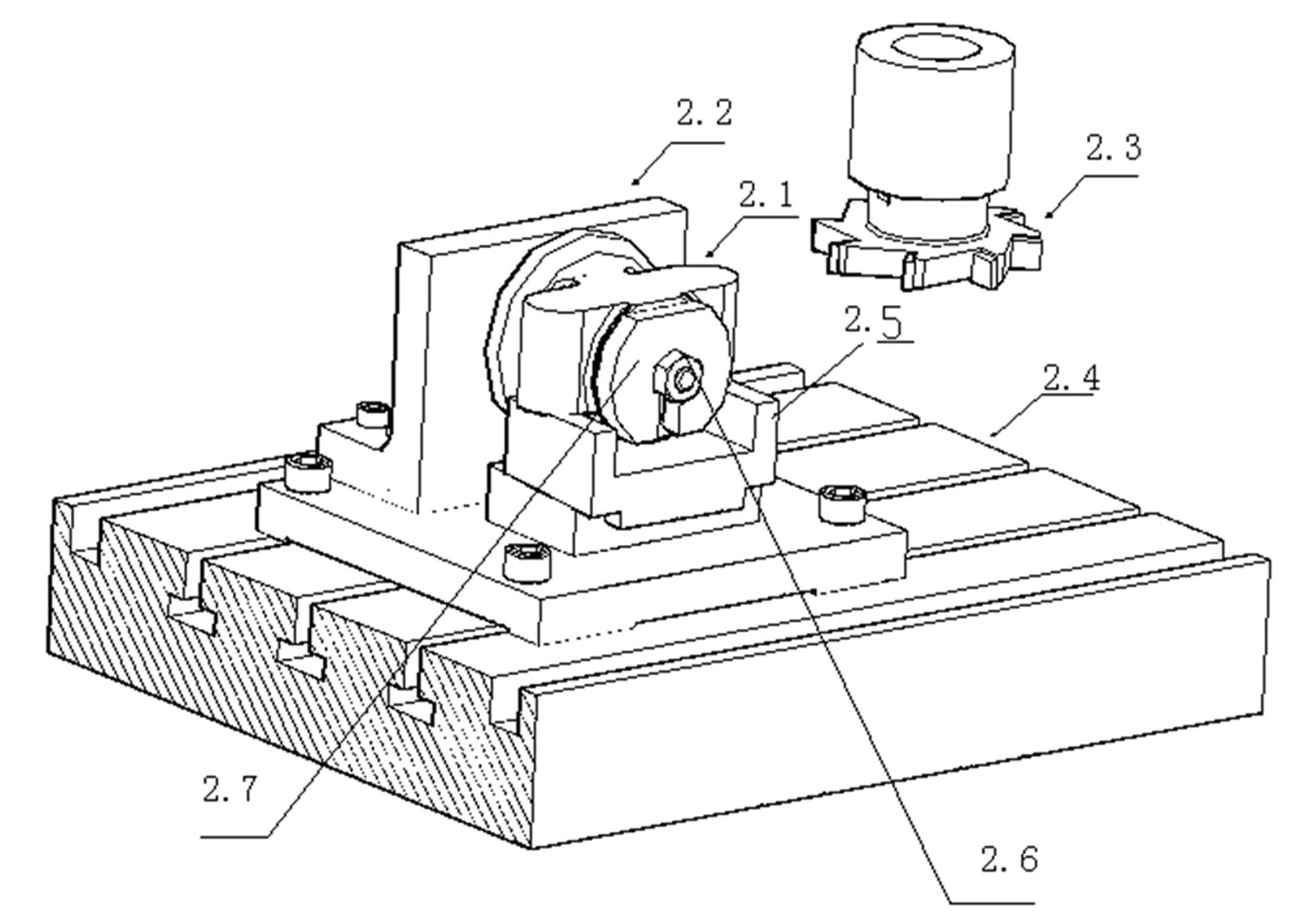

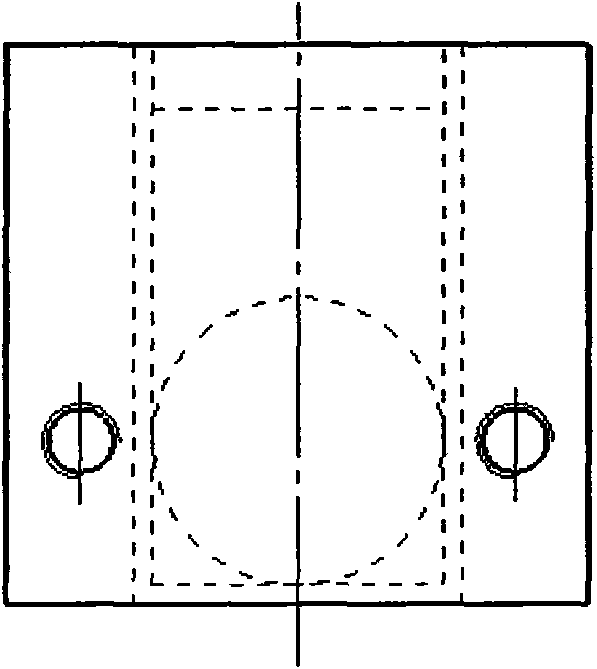

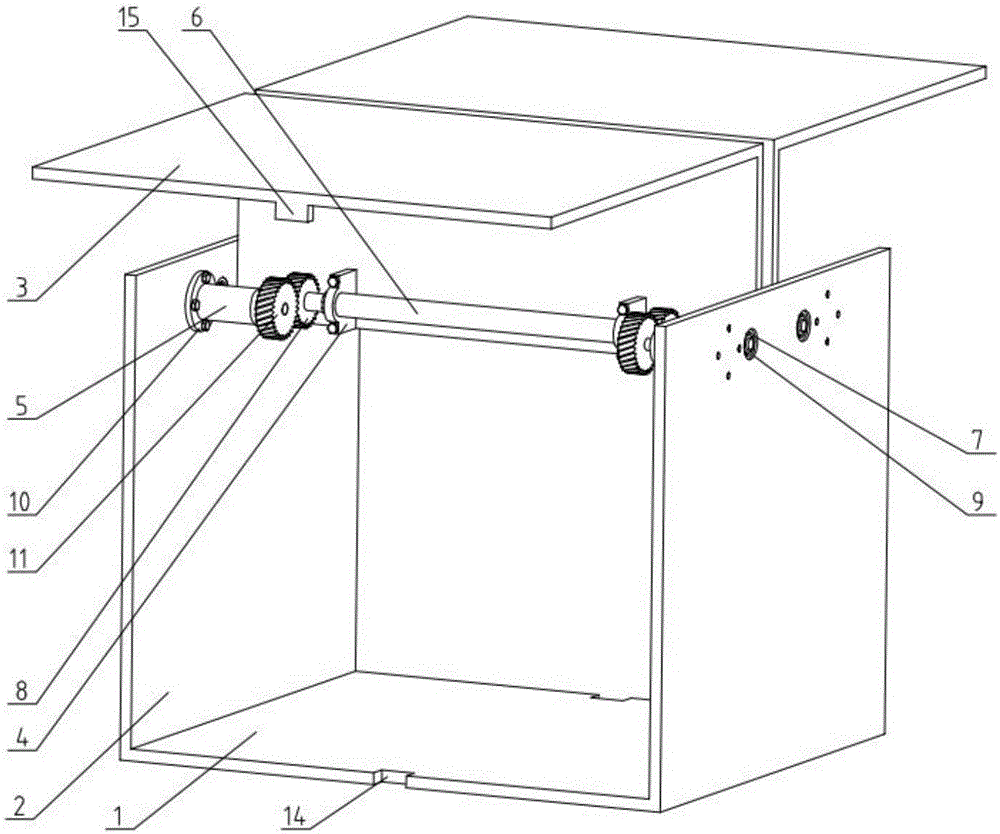

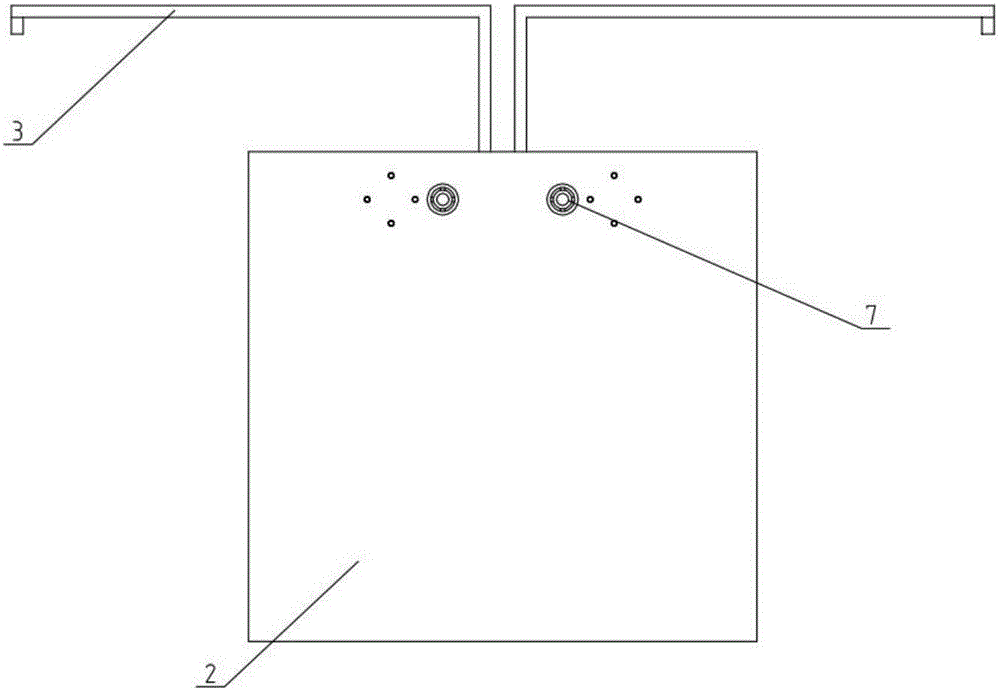

Milling positioning tool for shaft sleeve

InactiveCN101927436AImprove machining accuracyImprove loading and unloading speedPositioning apparatusMetal-working holdersEngineeringProcessing accuracy

The invention discloses a milling positioning tool for a shaft sleeve. The tool comprises an angle iron core rod positioning seat and an oblique filling iron, wherein the oblique filling iron comprises an upper part and a lower part; the bottom surface of the lower part is horizontal, while the top surface is provided with an oblique groove; the top surface of the upper part is provided with a horizontal groove, of which the width is not less than the width of a cambered part outside the machined shaft sleeve; the depth of the horizontal groove is not less than the height of the cambered part outside the machined shaft sleeve; the upper edge of the horizontal groove is horizontal; the bottom surface of the upper part is provided with an oblique bump corresponding to the oblique groove; and the oblique bump slides in the oblique groove and is closely attached to the oblique groove. After the tool is used, the machining accuracy is greatly improved, and the assembling and disassembling speed is also greatly increased.

Owner:溧阳市虹翔机械制造有限公司

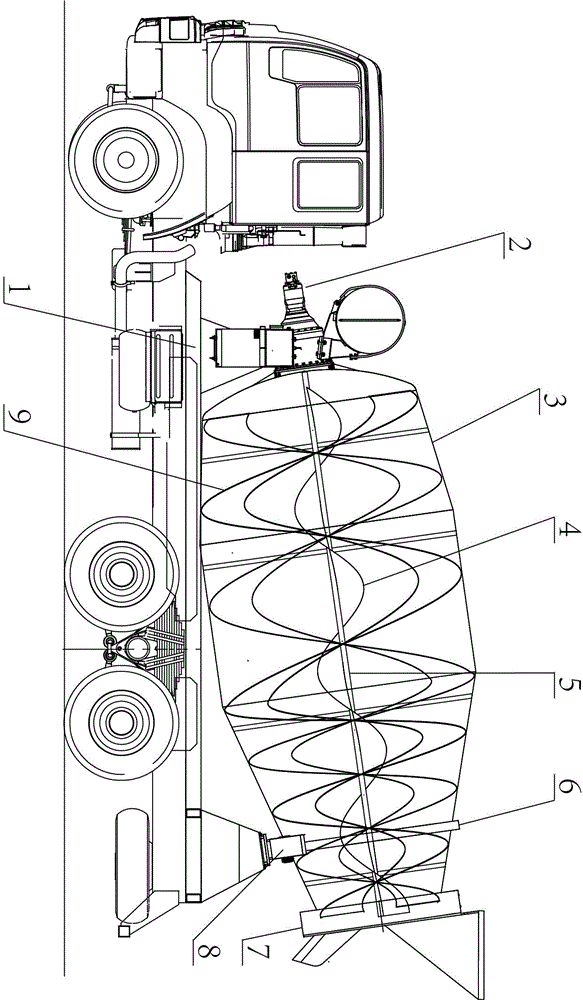

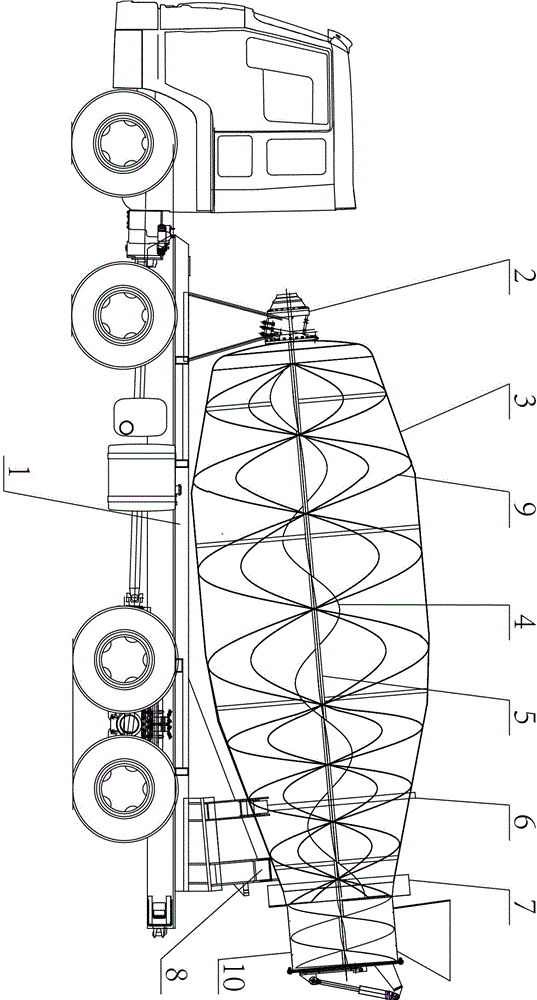

Composite screw transporting vehicle

ActiveCN104385462AStir wellImprove mixing uniformityDischarging apparatusCement mixing apparatusSludgeEngineering

The invention discloses a composite screw transporting vehicle. The rear end of a rotary material cylinder is connected with a rotary sealing mechanism, wherein a main screw blade is spirally mounted on the inner wall of the rotary material cylinder; a center shaft is arranged inside the rotary material cylinder; a secondary screw blade is mounted on the center shaft. The secondary blade and the main blade have synergistic effects. When the composite screw transporting vehicle is used as a high-viscosity concrete transporting vehicle or a sludge transporting vehicle, the loading and unloading rate is relatively high, and the utilization rate of the material cylinder is relatively high; when the composite screw transporting vehicle is used as a concrete transporting vehicle, the concrete is relatively uniformly stirred; the delamination is alleviated; the quality of the high-quality concrete is not influenced.

Owner:YANTAI SHENGLIDA ENG TECH

Lateral clamping turnover machining mechanism for steering knuckles

InactiveCN107900749AGuaranteed stabilityImprove processing efficiencyPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses a lateral clamping and turning processing mechanism of a steering knuckle, which comprises a turning table, a flushing device and a chip removal mechanism; the turning table is provided with a processing table, a cleaning table and a clamping table. There is a lateral clamping fixture; the lateral clamping fixture includes a bottom plate, and at least one side plate frame is arranged on the bottom plate, and a lateral oil cylinder, a brake arm positioning pin and a plurality of stop pins are arranged on the side plate frame; There is a side clamping assembly that cooperates with the steering knuckle workpiece, and the positioning pin of the brake arm cooperates with the brake arm; in the present invention, three tables are set on the workbench, one table is processed, and the other two tables can be cleaned, loaded and unloaded at the same time , improve the processing efficiency; and optimize the clamping parts of the fixture, improve the loading and unloading speed of the steering knuckle workpiece, and improve the efficiency; the side clamping components are closely matched to fix the main structure of the steering knuckle workpiece, ensuring the clamping accuracy stability.

Owner:SUZHOU ZHENJIACHEN PRECISION MACHINERY CO LTD

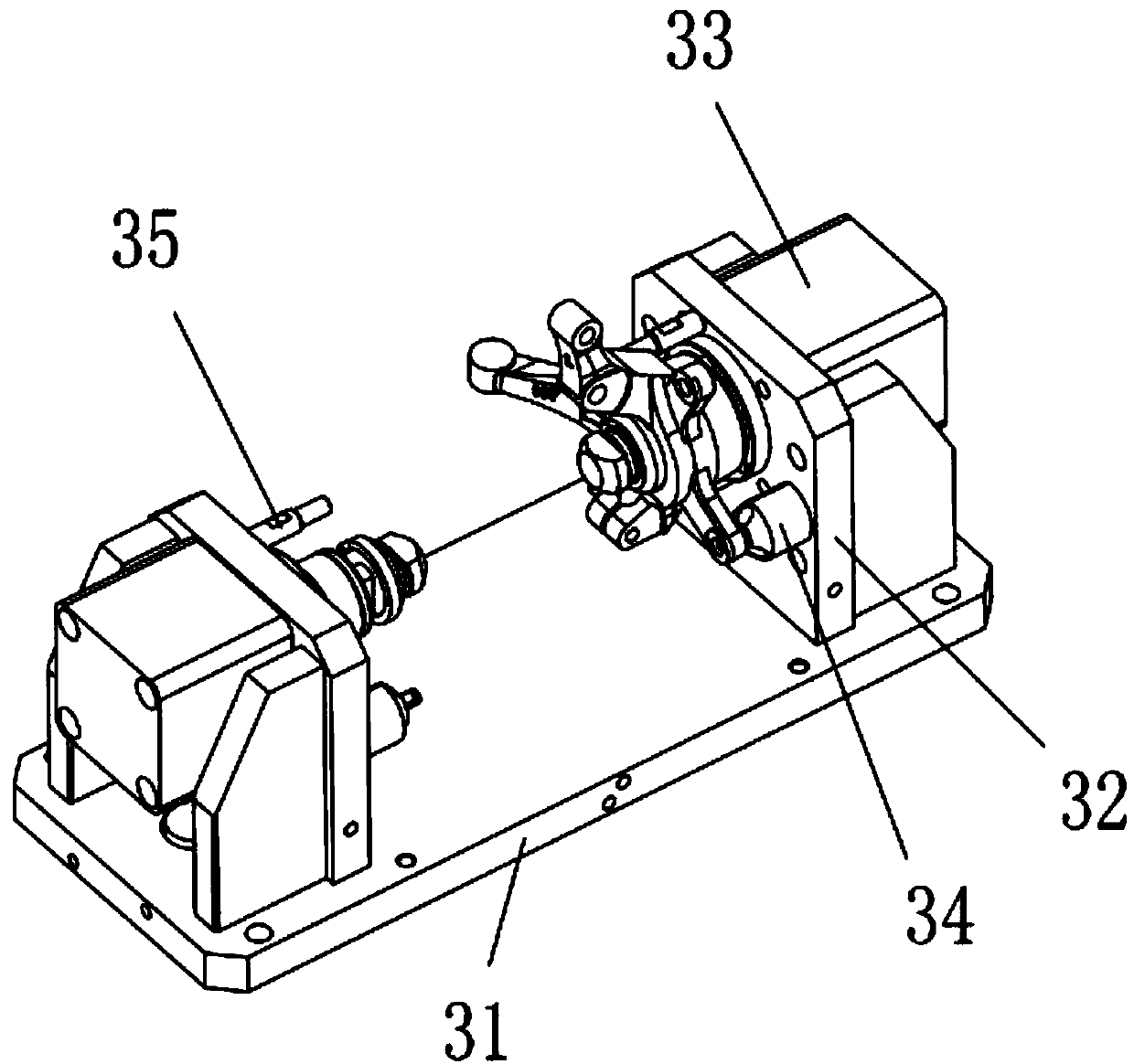

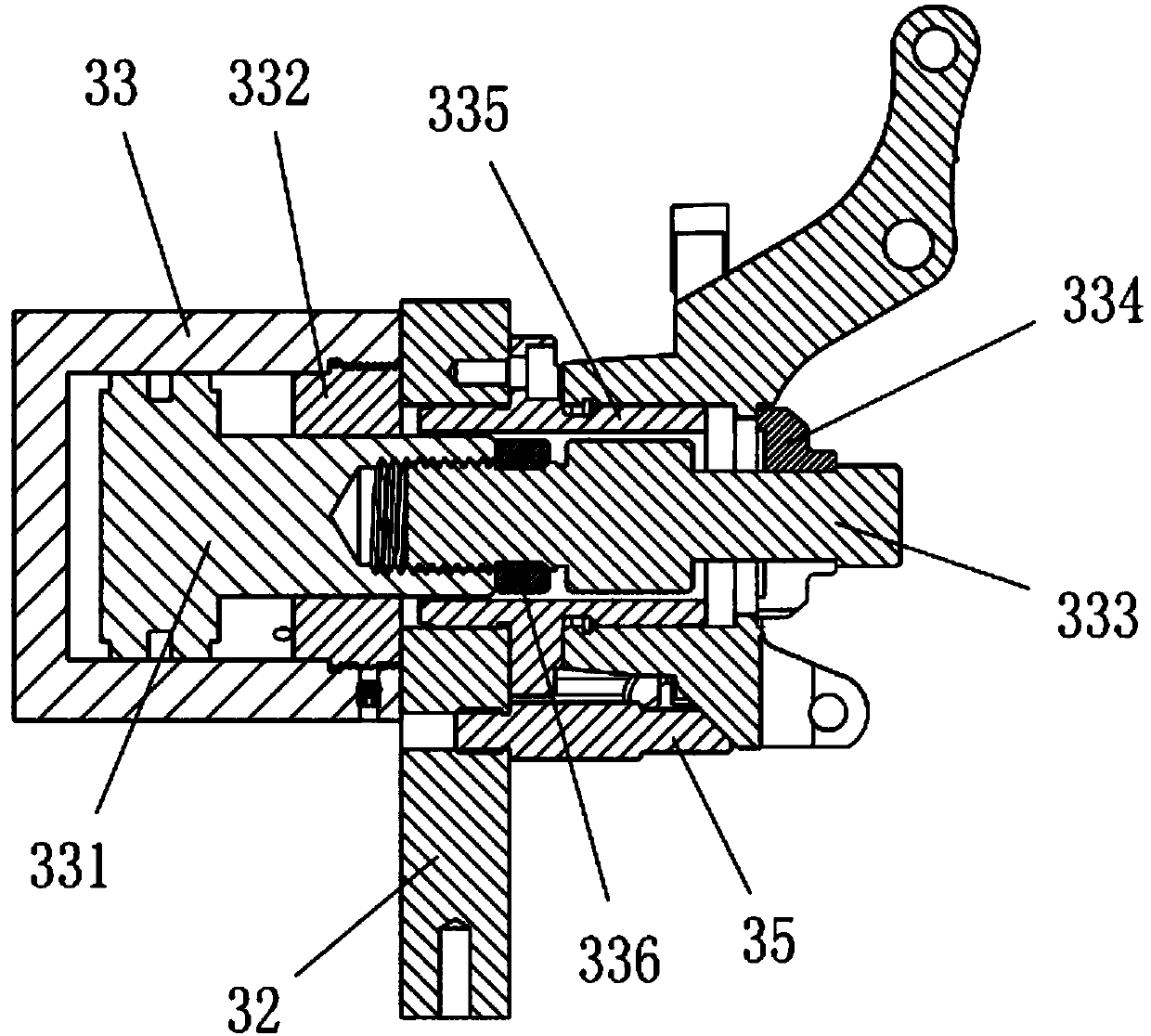

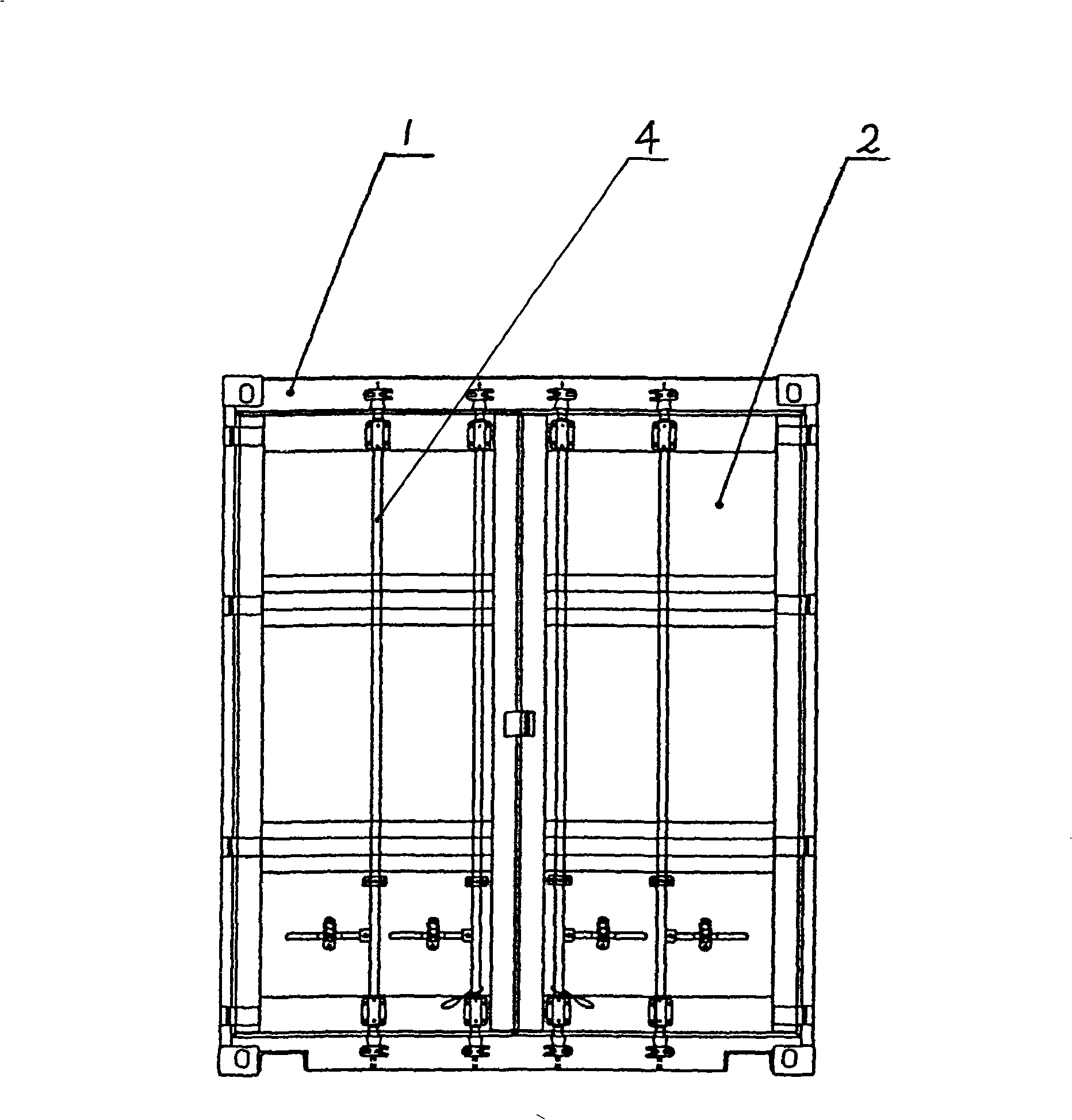

Dual-purpose transport body for railway transport vehicles and general cargoes

ActiveCN108128314AEasy to load and unload by yourselfEasy loadingUnderframesAxle-box lubricationDual purposeEngineering

The invention relates to a dual-purpose transport vehicle body for railway transport vehicles and general cargoes. The vehicle body comprises a bottom frame,two side walls vertically fixedly connectedwith the both sides of the bottom frame, a vehicle top of which the two sides of the bottom are fixedly connected to the tops of the two side walls, two end doors respectively located at the two endsof the vehicle body,side doors disposed on the side walls,two upper end brackets respectively installed on both ends of the vehicle body and a plurality of groups of upper middle brackets installed in the vehicle body; each group of the upper middle brackets comprise two upper middle brackets symmetrically disposed on the two side walls; the upper end brackets and the upper middle bracketsall adopt overturn structures and can be rotated to horizontal positions and vertical positions. The upper end brackets and the upper middle brackets are used asupper vehicle loading platforms when rotated to the horizontal positions; the upper end bracketsare used asend walls to bear the longitudinal force of the general cargoes during transportation when rotated to the vertical positions; when rotatedto the vertical positions, the upper middle brackets are close to the side walls to set aside the space inside a vehicle for loading of the general cargoes.

Owner:CRRC QIQIHAR ROLLING CO LTD

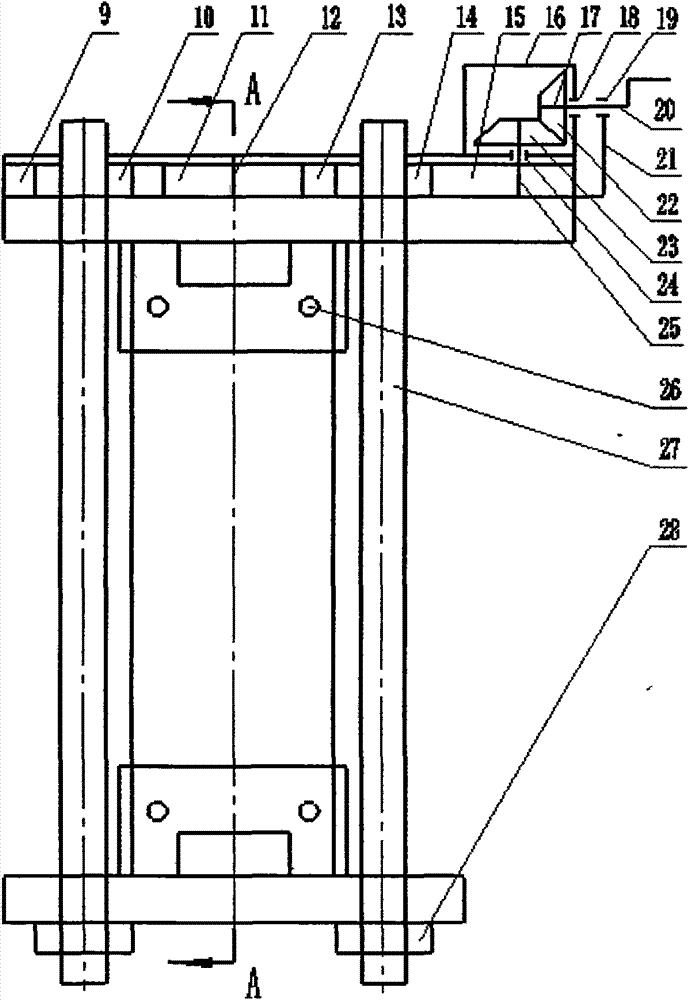

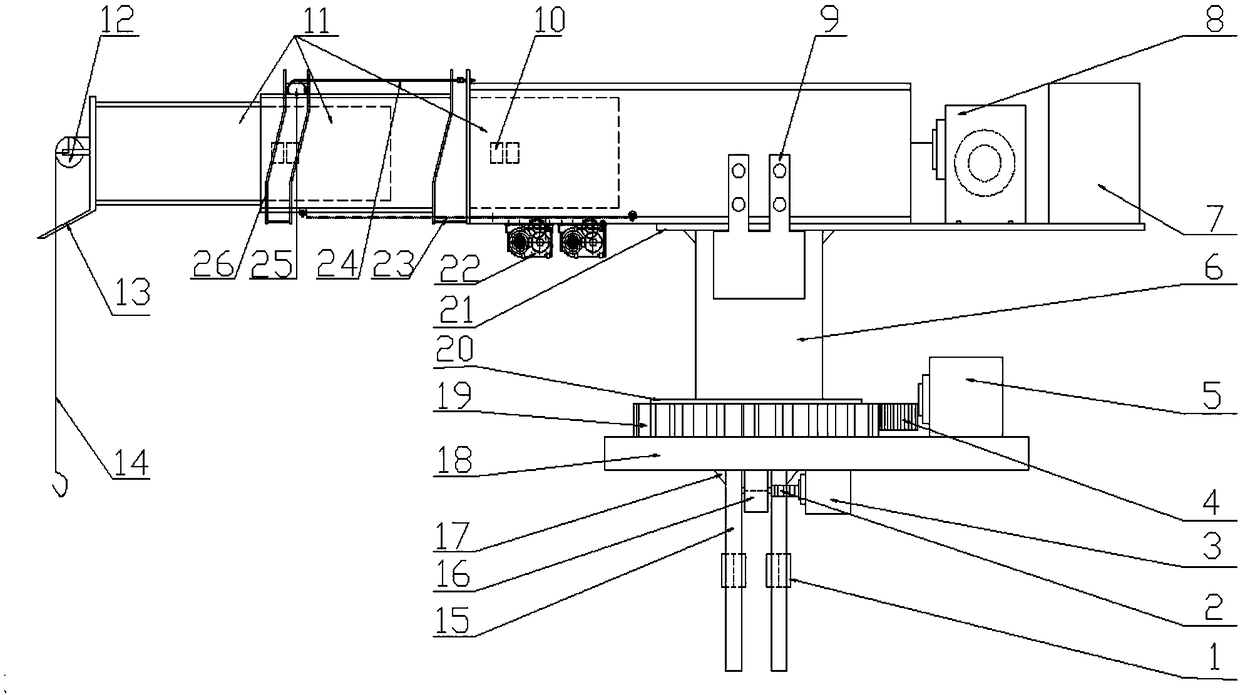

Large-sized pressure spring loading and unloading machine

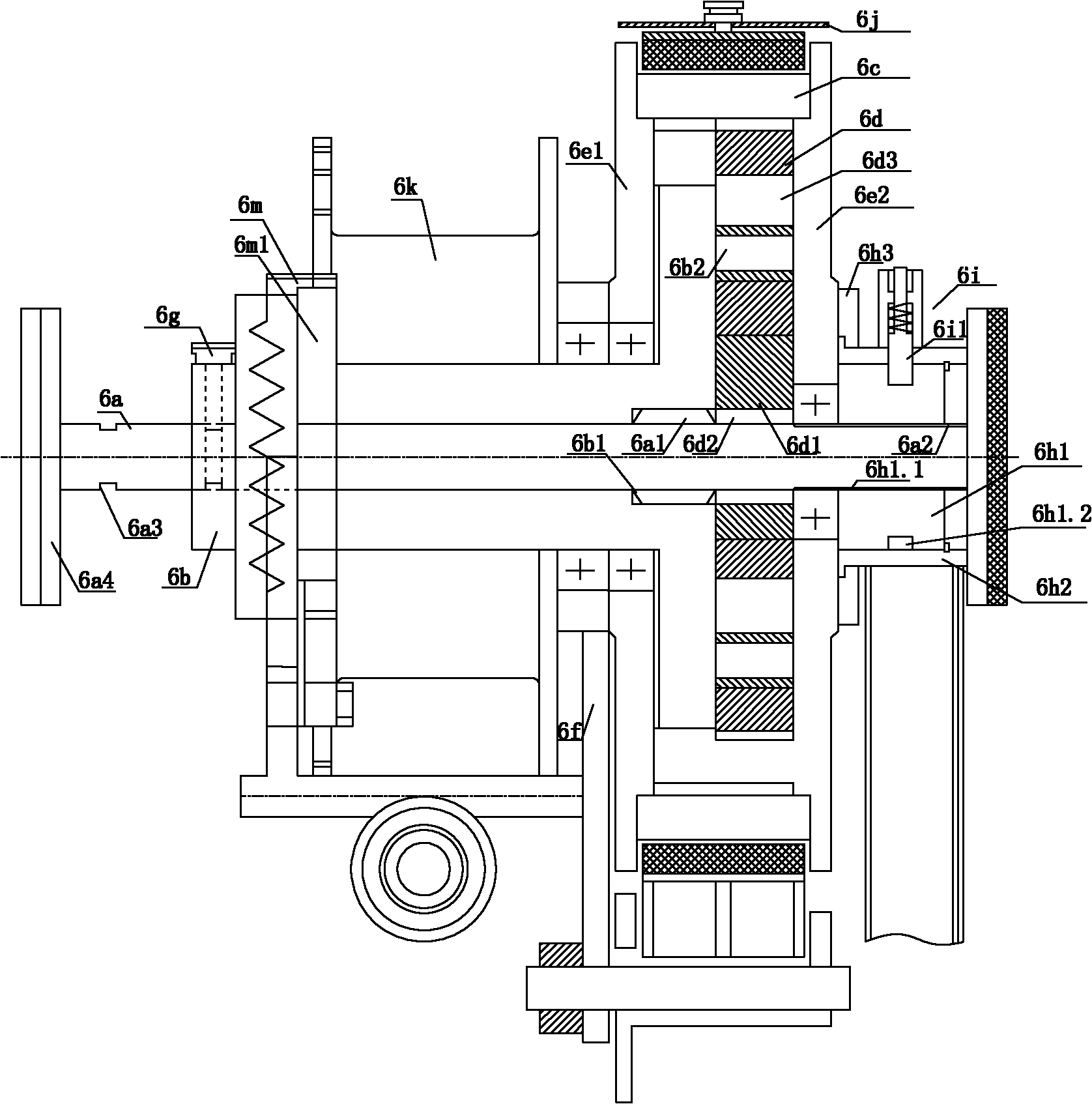

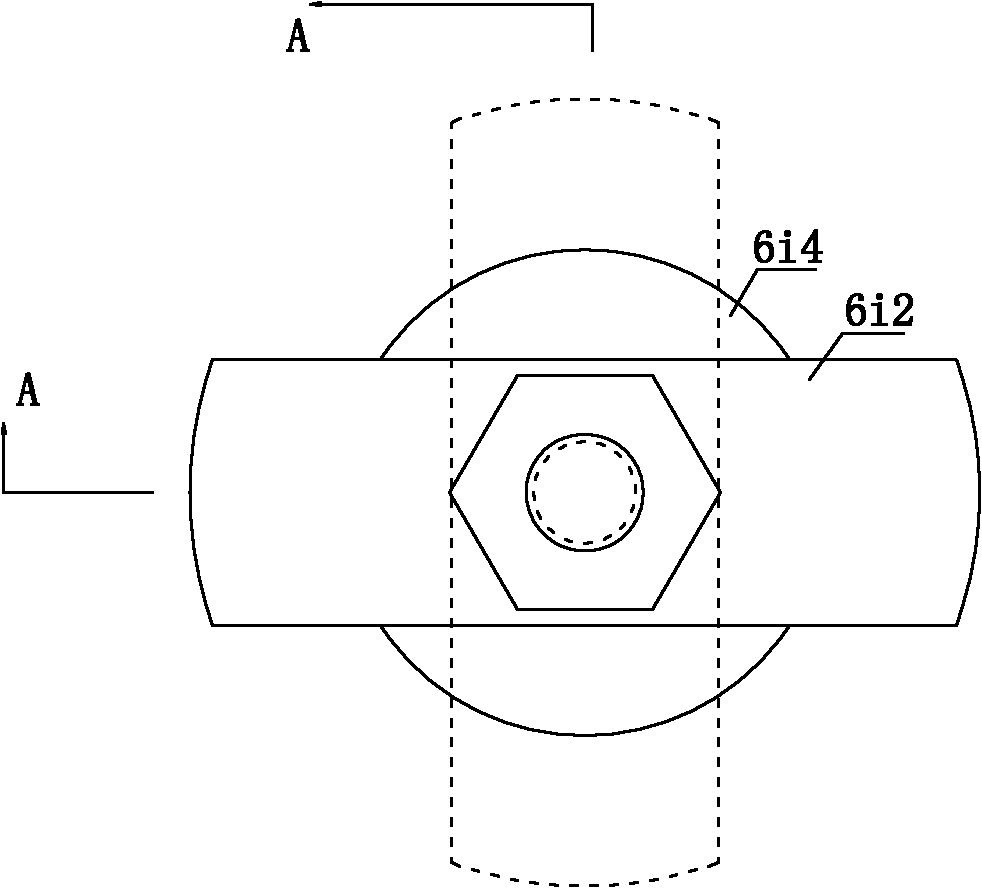

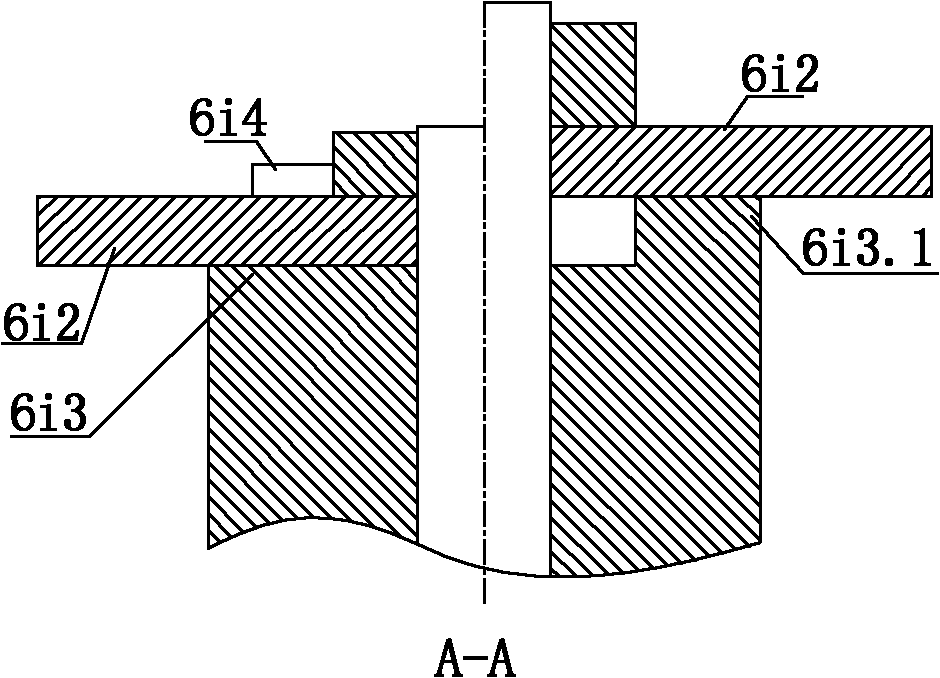

InactiveCN104511742AAxial positioning is accurateImprove wear resistanceMetal working apparatusGear wheelWear resistant

The invention discloses a large-sized pressure spring loading and unloading machine. A left lead screw cylinder shaft is connected with an upper spring fixing seat, a lower spring fixing seat, a left lead screw nut and a nut; a right lead screw cylinder shaft is connected with the upper spring fixing seat, the lower spring fixing seat, a right lead screw nut and a nut; the upper spring fixing seat and the lower spring fixing seat are provided with a wear-resistant lining; an upper spring pushing support plate is connected with the wear-resistant lining and the upper spring fixing seat; a lower spring pushing support plate is connected with the wear-resistant lining and the lower spring fixing seat; a left lead screw gear is connected with the upper spring fixing seat and the left lead screw nut and is engaged with a middle gear; a right lead screw gear is connected with the right lead screw nut and is engaged with a driving gear. The driving bevel gear is engaged with a driven bevel gear. A spring pulling plate is connected with the upper spring pushing support plate and the lower spring pushing support plate; a gearbox casing is connected with the upper spring fixing seat.

Owner:王荣

Multifunctional lifting cargo container for motor vehicle

The invention discloses a multifunctional lifting cargo container for a motor vehicle, and particularly relates to a technology through which goods in a motor vehicle cargo container can be mechanically separated from the motor vehicle cargo container, goods can be conveniently and mechanically loaded and unloaded, and goods in the cargo container can be conveniently and mechanically bound, reinforced and clamped. The cargo container is characterized by comprising at least one elevator, a cargo container bottom with a plurality of groove planes, and a cargo container top, wherein one end of the elevator is fixedly connected with the cargo container bottom with the groove planes, the other end of the elevator is fixedly connected to the cargo container top, and the whole cargo container top vertically ascends or descends under the action of the elevator. By means of the multifunctional lifting cargo container for the motor vehicle, the goods can be conveniently and mechanically loaded and unloaded and can be conveniently and mechanically bound, reinforced, stabilized and clamped after being loaded. Meanwhile, the height of the cargo container is reduced to the largest extent in the transport process, wind resistance is reduced, energy is saved, transport safety is improved, time for waiting loading and unloading of the goods of the motor vehicle is fully saved, transport efficiency and benefits of the motor vehicle are given full play of, and a reliable mechanical work guarantee is provided for all links of work of an automatic mechanical logistics chain.

Owner:钟华

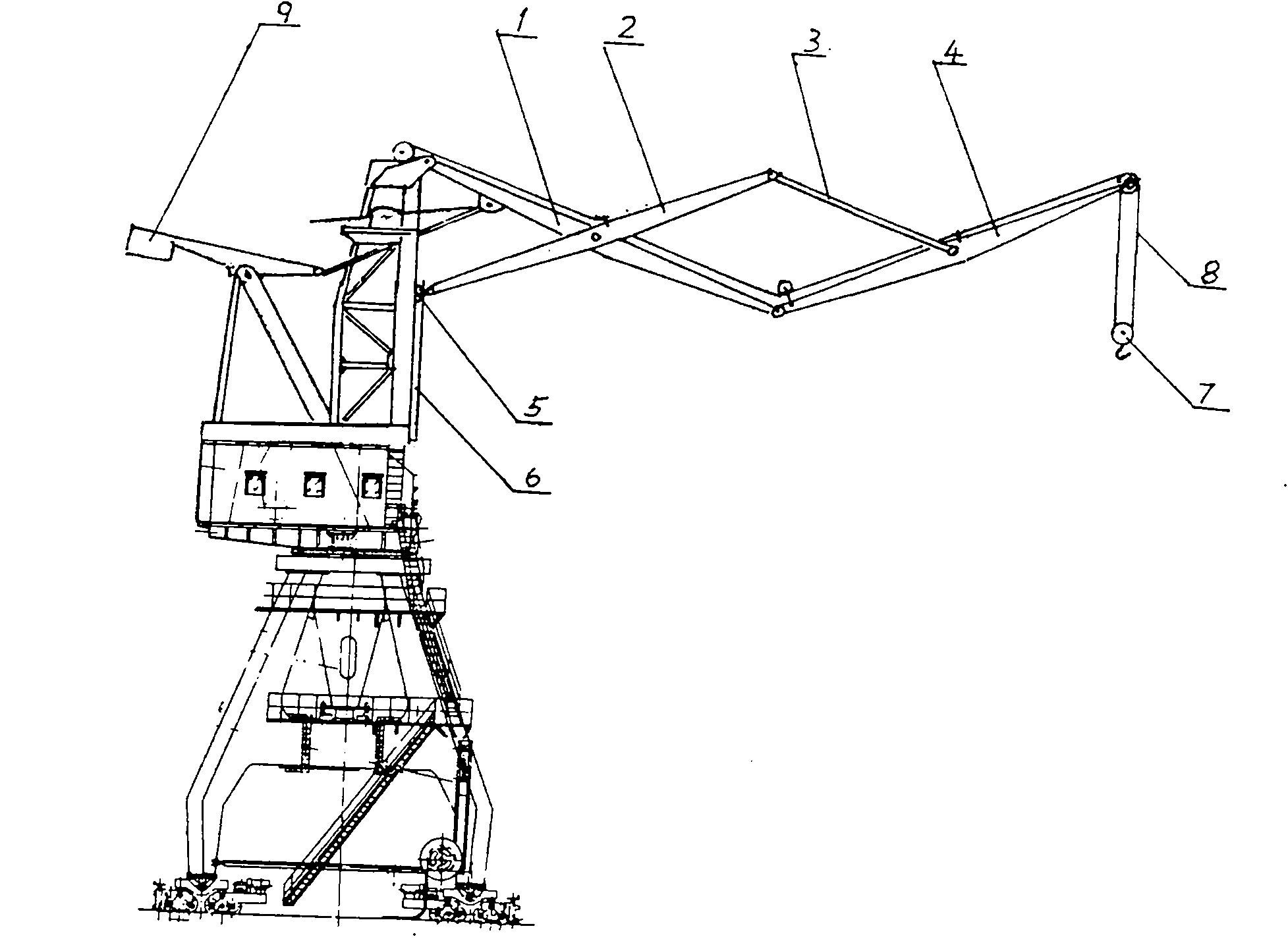

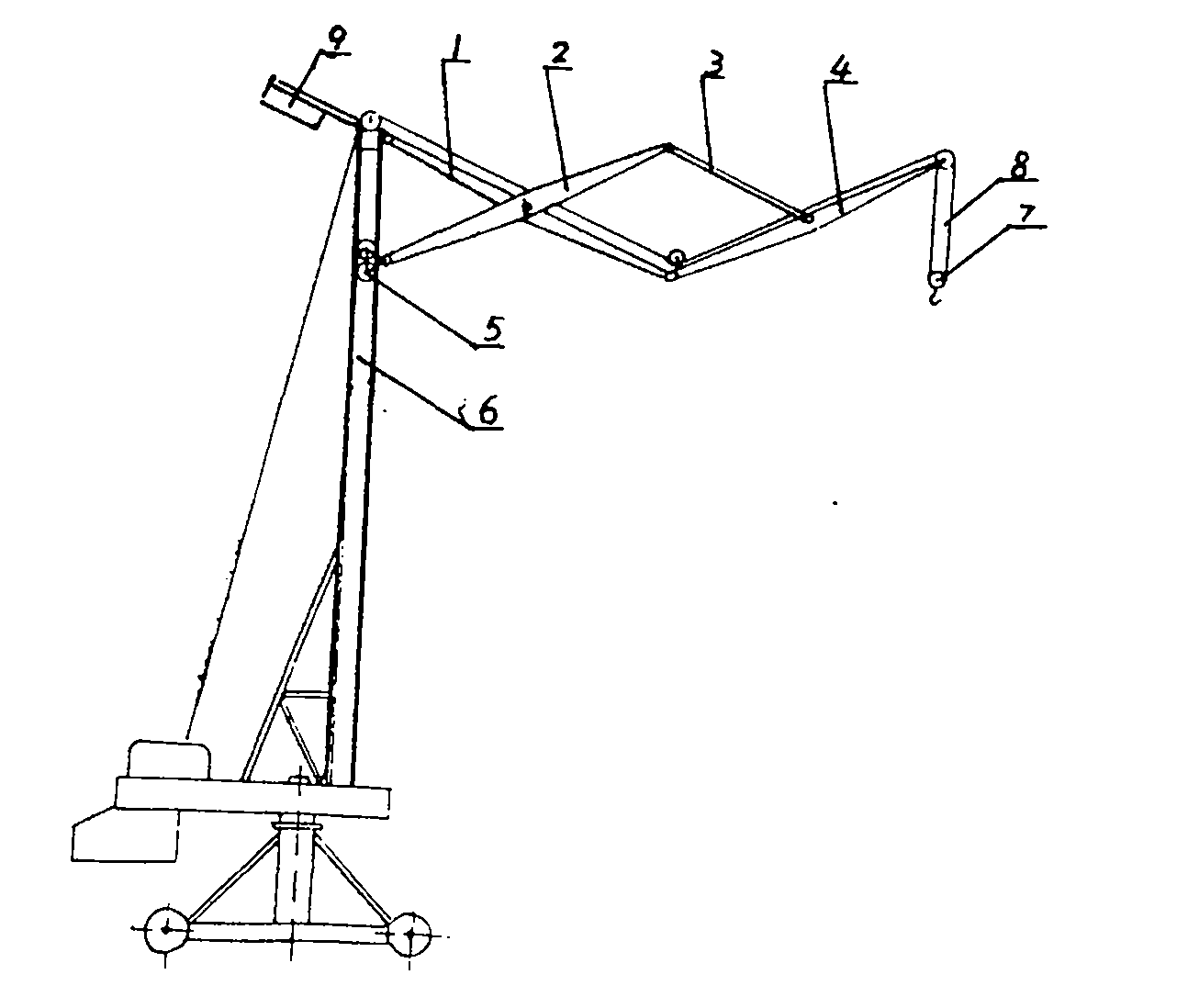

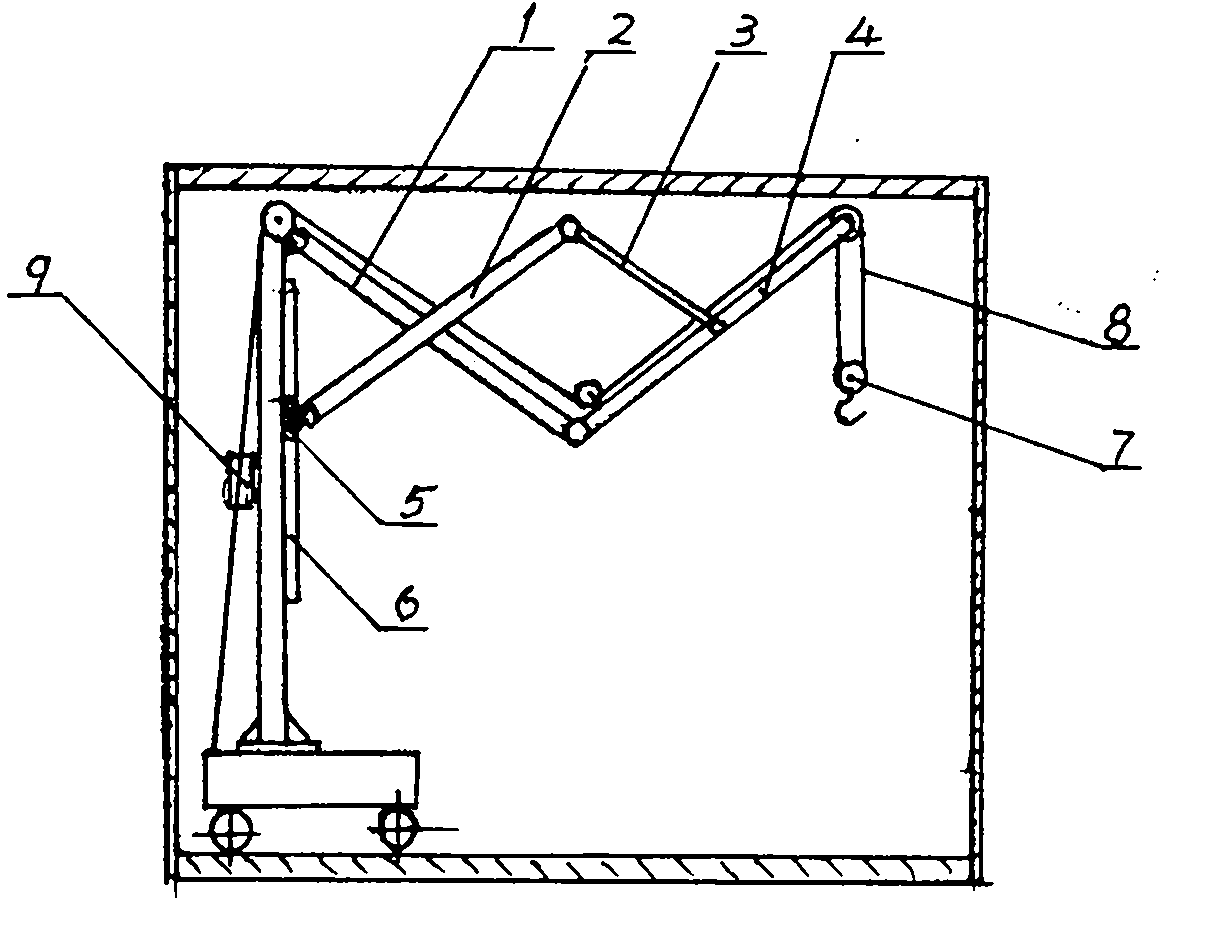

Four-rod-crossing amplitude compensation device

The invention discloses a four-rod-crossing amplitude compensation device, which can realize amplitude variation in horizontal direction, and is composed of a cross arm, a rear arm, a short arm, a front arm, a guide wheel, a vertical guide rail, a hanger steel wire rope winding system and a counter weight. The four-rod-crossing amplitude compensation device is characterized in that the upper end of the rear arm is hinged with an upper part of a crane, the middle point of the rear arm is hinged with the middle point of the cross arm, and the lower end of the rear arm is hinged with the lower end of the front arm; the lower end of the cross arm is provided with the guide wheel which can move up and down along the vertical guide rail, and the upper end of the cross arm is hinged with the upper end of the short arm; the lower end of the short arm is hinged with the middle point of the front arm; and the cross arm, the rear arm and the front arm are same in length, and the short arm is 1 / 2 of the front arm in length. The steel wire rope of the winding system extends along the rear arm to reach a pulley at the lower end of the rear arm after passing through a pulley at the top end of the rear arm, and then hangs downwards after reaching the pulley at the top end of the front arm by extending along the front arm. When the amplitude varies, the guide wheel at the lower end of the cross arm moves up and down along the vertical guide rail, the peal of the front arm moves horizontally, thus the amplitude variation in the horizontal direction of hangers is realized. The four-rod-crossing amplitude compensation device has the advantages of simple structure, low center of gravity, small appearance size, good stability, short guide rail length, easiness in overall arrangement, implementation of ideal horizontal amplitude variation, and saved energy consumption, and can be widely applied to various cantilever cranes.

Owner:吴文发

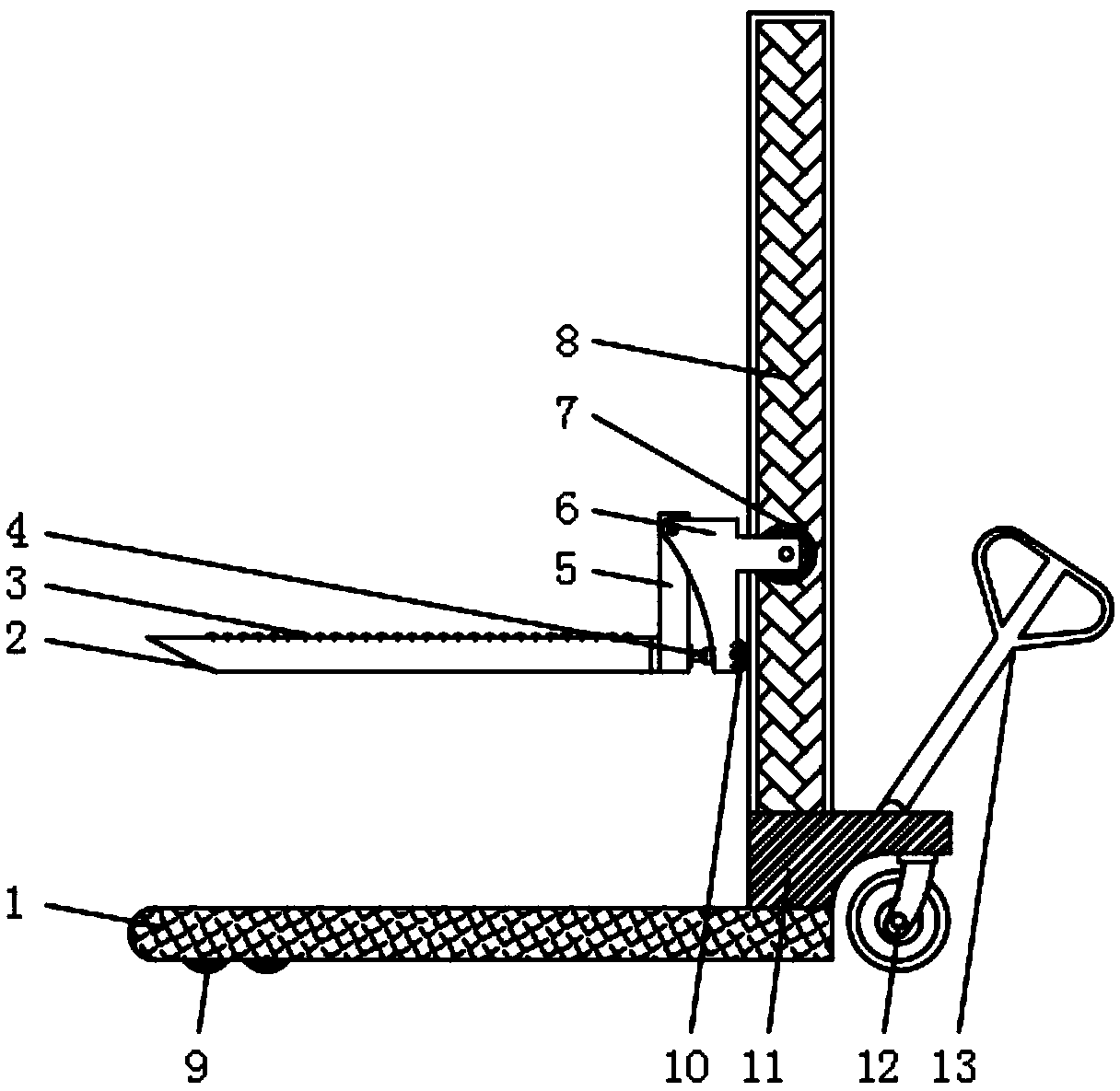

Novel multifunctional goods trolley

InactiveCN109095399AAvoid random slidingImprove loading and unloading speedLifting devicesTransport engineeringPallet fork

Owner:扬州达安运输有限公司

Warehouse arranging method capable of achieving rapid cargo unloading

InactiveCN107985889AShorten the timeImprove loading and unloading speedStorage devicesElectric controlUtilization rate

The invention discloses a warehouse arranging method capable of achieving rapid cargo unloading. Through wheels arranged on storage racks, the storage racks are controlled by an electric control device to move and arranged for rapid centralized cargo loading and unloading, the mode is much rapider than traditional loading and unloading modes, in the traditional loading and unloading modes, cargosneed to be transferred to the storage racks from a warehouse door one by one, through centralized loading and unloading, the carrying time is reduced, and the loading and unloading speeds are greatlyincreased; through tracks, the storage racks run in the preset tracks orderly, the tracks of the storage racks are arranged longitudinally and transversely, the storage racks can be independently allocated, management is more convenient, due to the fact that the storage racks can move, loading and unloading channels do not need to be reserved between the storage racks, and the space utilization rate of the mode is higher; control is achieved through a wireless operation panel, an operator responsible for allocation can conduct field operation, and allocation is more convenient; and after numbering or classification, the required storage racks are clearly assigned to move to a loading and unloading zone through a control center, operation is detailed, and the efficiency is improved.

Owner:CHENGDU LIXIN SCI & TECH

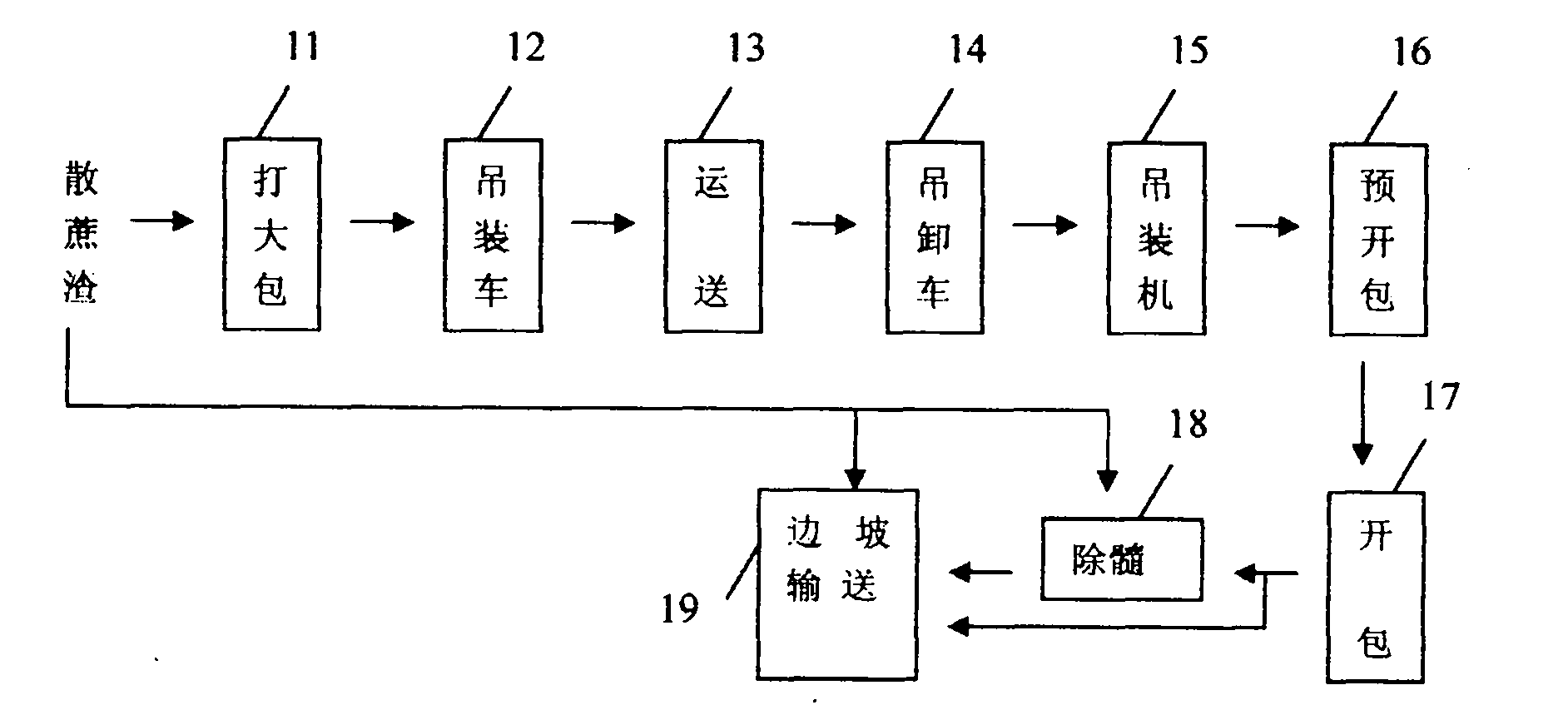

Bagasse transportation operation flow and equipment

InactiveCN101844664APlace stableNot so easy to collapseConveyorsArticle unpackingEngineeringMechanical engineering

The invention discloses a bagasse transportation operation flow, and discloses a bagasse pre-opener and a conveyor used with the operation flow. The operation flow can lighten the labor intensity of bagasse loading and unloading workers, improve the speed and quality of the bagasse loading and unloading operation, improve the safety factor of bagasse transportation and improve the space utilization rate of a bagasse storage yard.

Owner:陈运

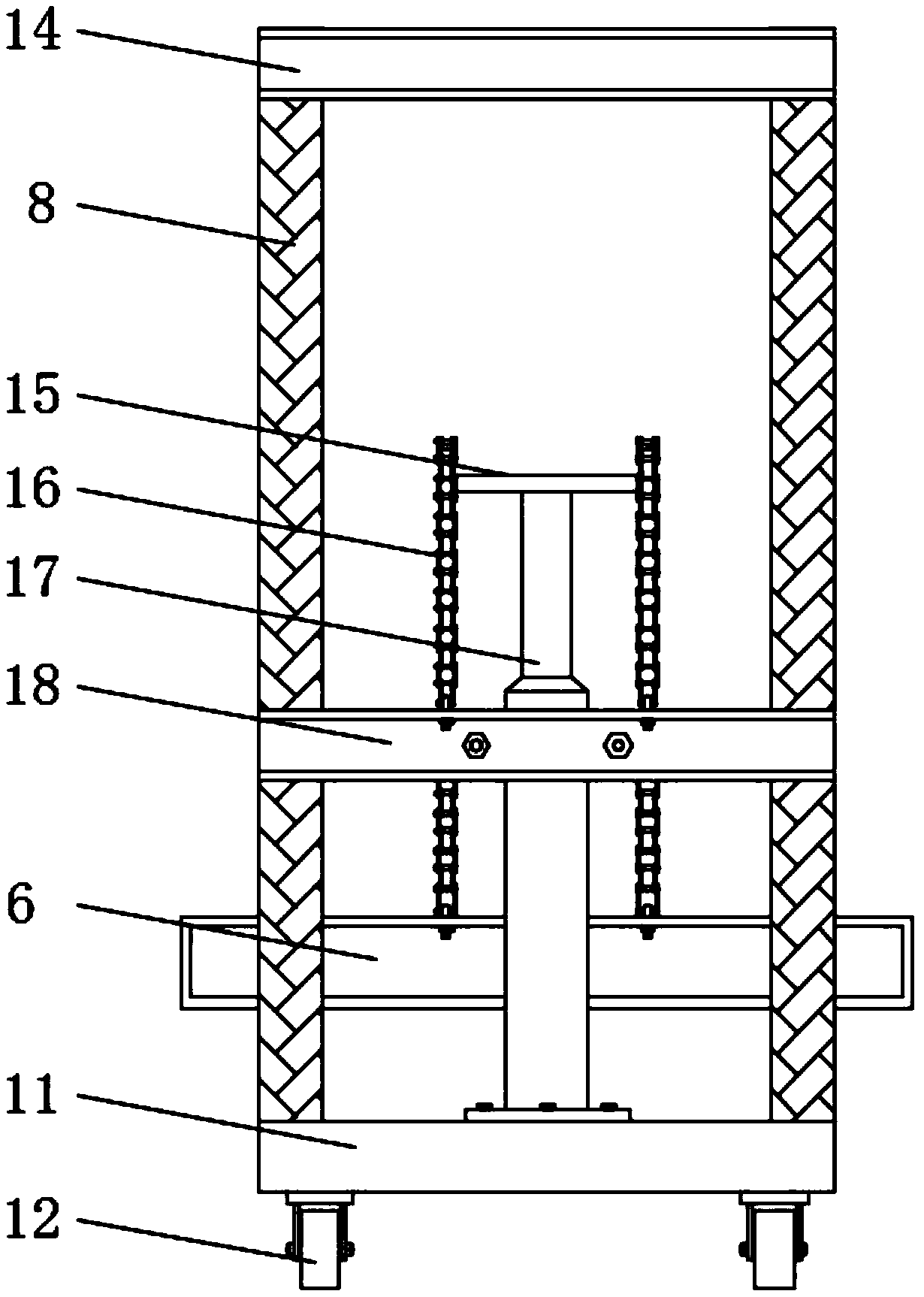

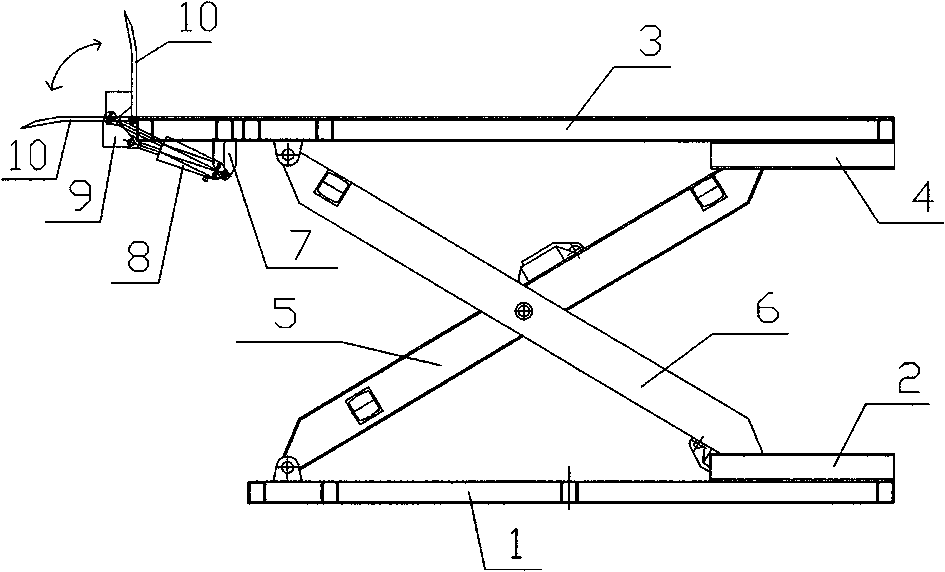

Hydraulic lifting platform

InactiveCN109399501AReduce the difficulty of reversingLoading and unloadingLifting framesControl engineeringTruck

The invention discloses a hydraulic lifting platform with a lapping plate. The hydraulic lifting platform comprises a lifting platform base, a lifting platform face is arranged over the lifting platform base, a hydraulic driving lifting bracket is arranged between the lifting platform base and the lifting platform face, the hydraulic lapping plate is arranged on the unloading side of the lifting platform face, the upper end of the connecting end of the hydraulic lapping plate is connected with the lifting platform face through a pin shaft, the lower end supporting point of the connecting end of the hydraulic lapping plate is connected with one end of a hydraulic oil cylinder through a pin shaft, and the other end of the hydraulic oil cylinder is connected with a hydraulic oil cylinder basefixed to the lower surface of the lifting platform face through a pin shaft. According to the hydraulic lifting platform, the truck backing difficulty is reduced; high-weight cargoes can be conveniently and quickly loaded and unloaded by means of a low-cost manual hydraulic carrying cart, and a forklift is not used; and the loading and unloading speed can be increased.

Owner:江苏博创升降机械有限公司

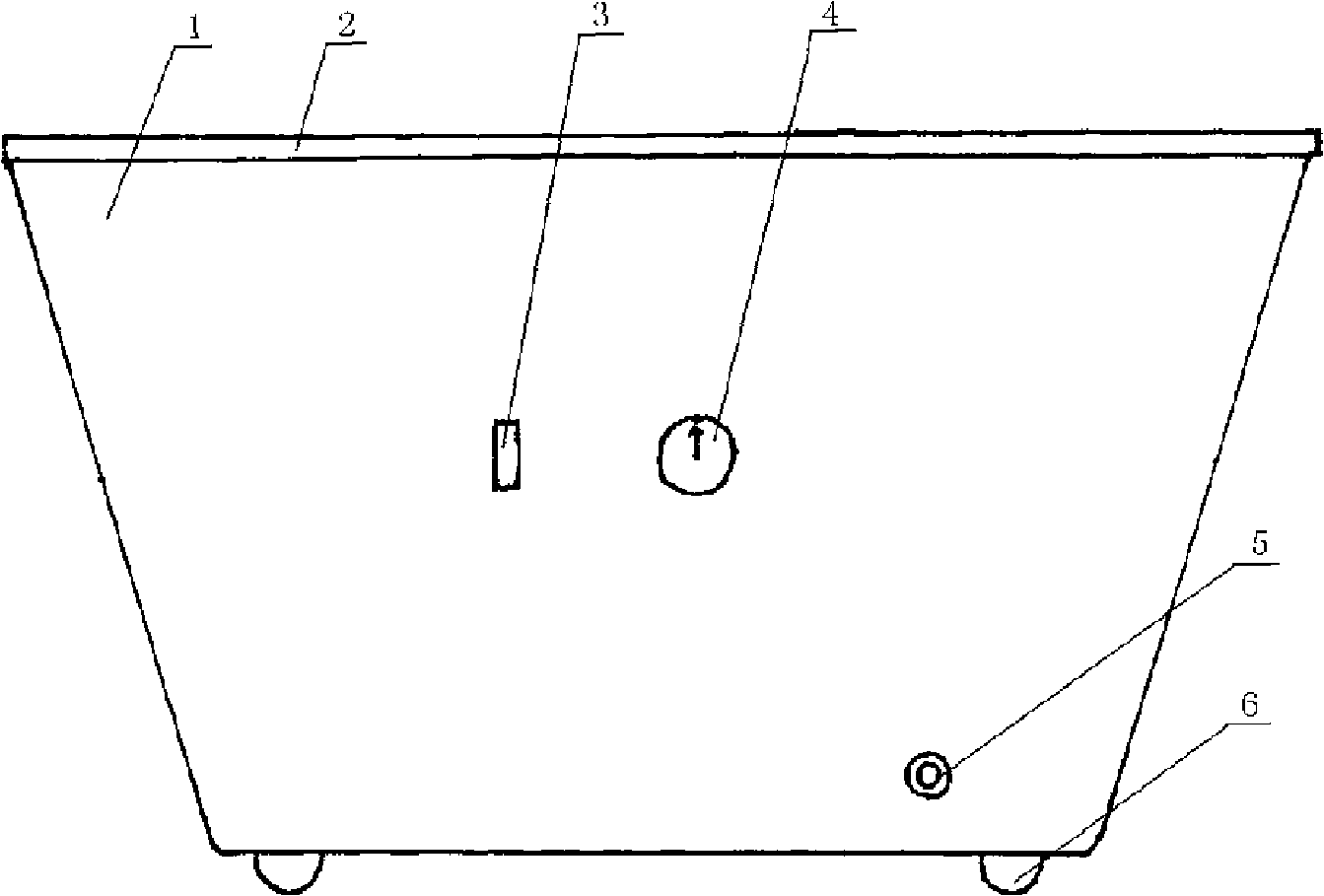

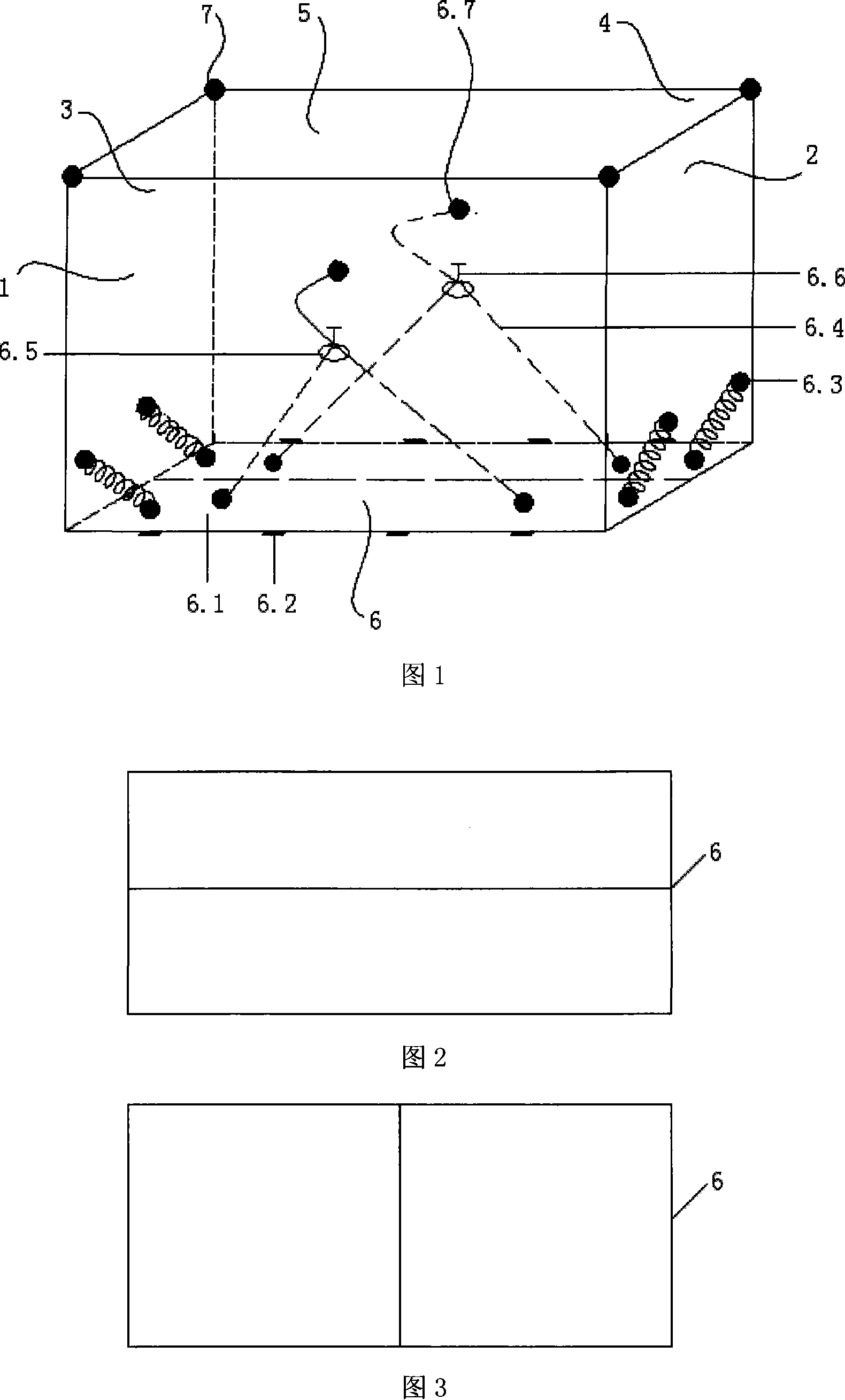

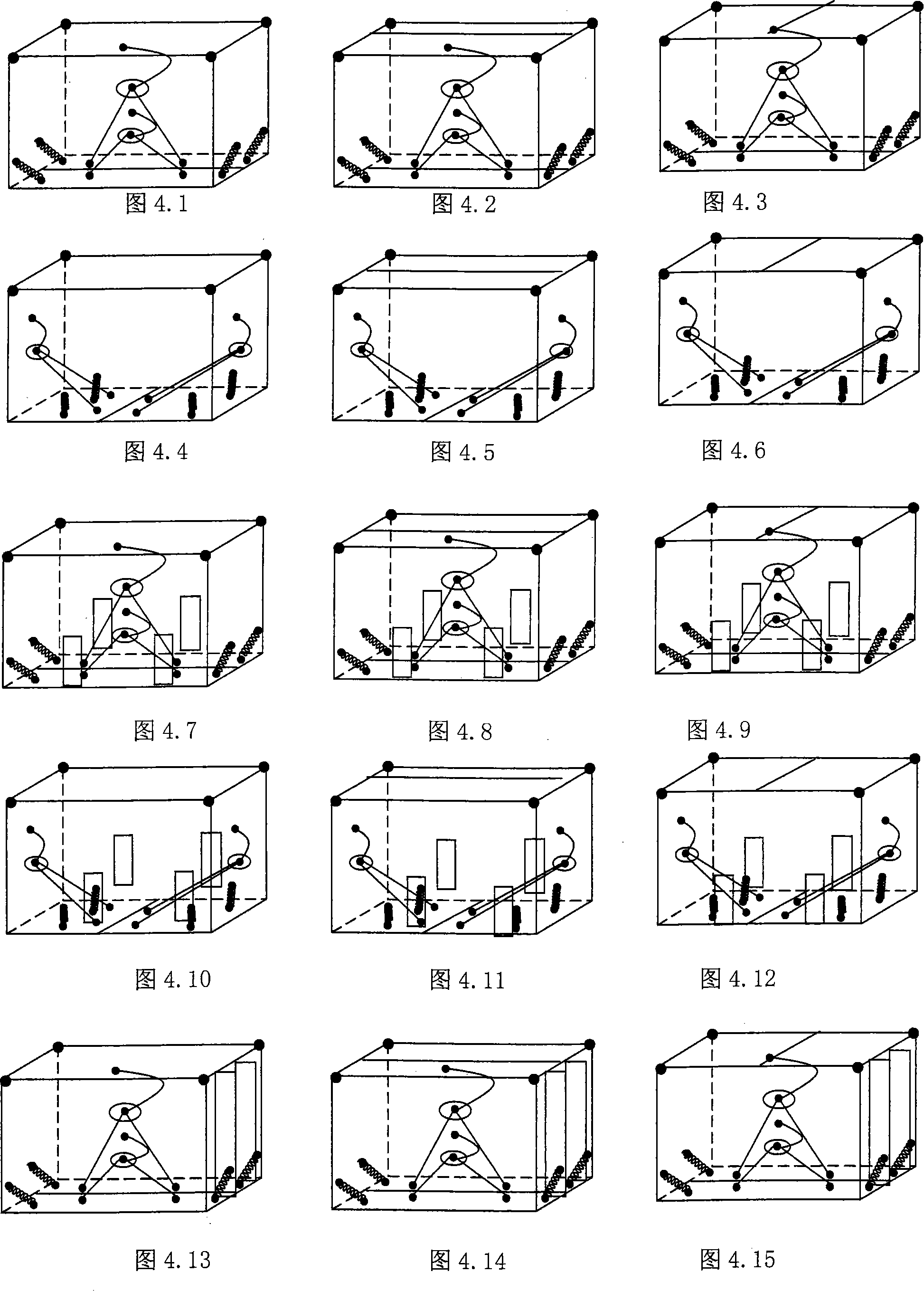

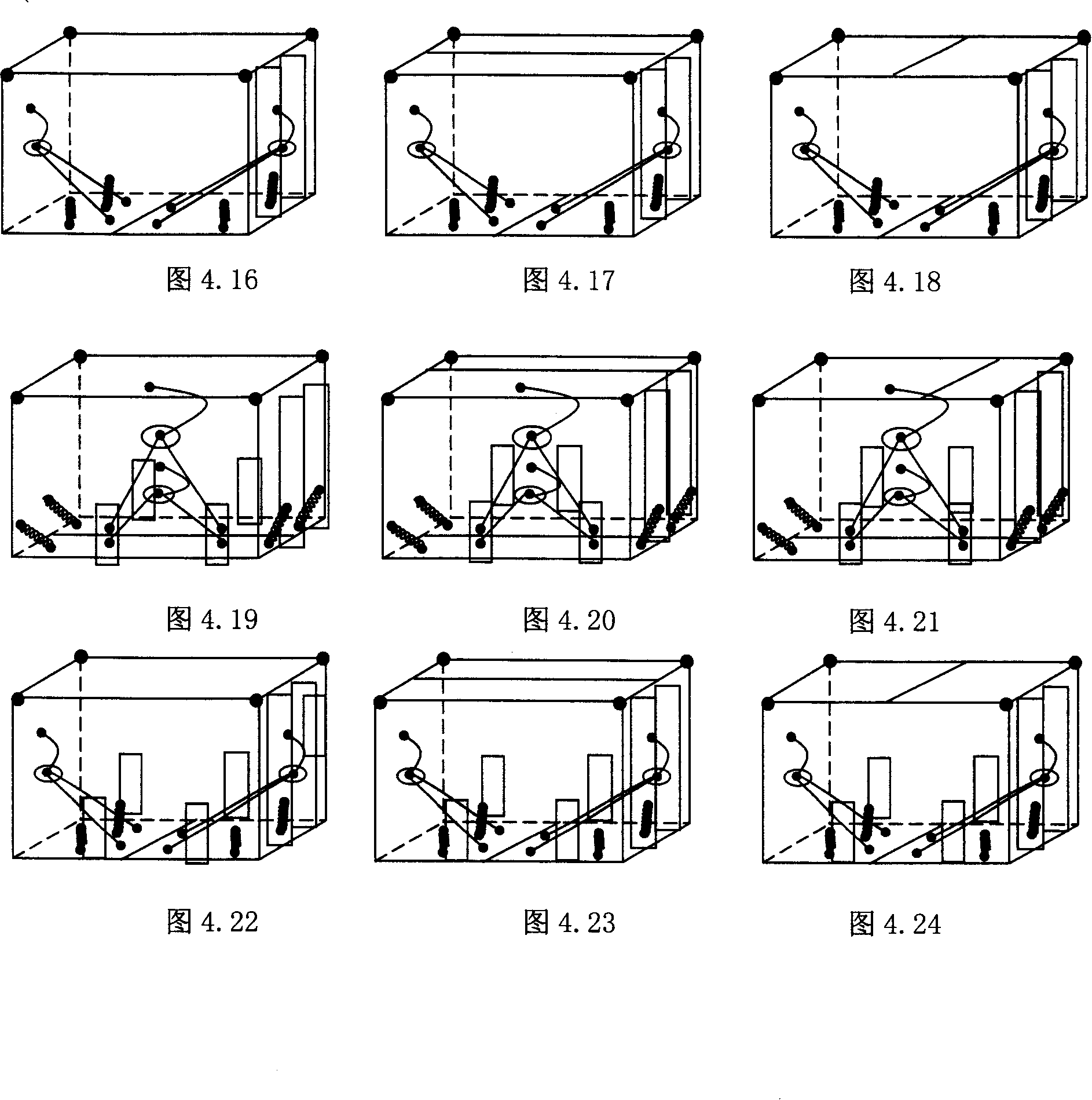

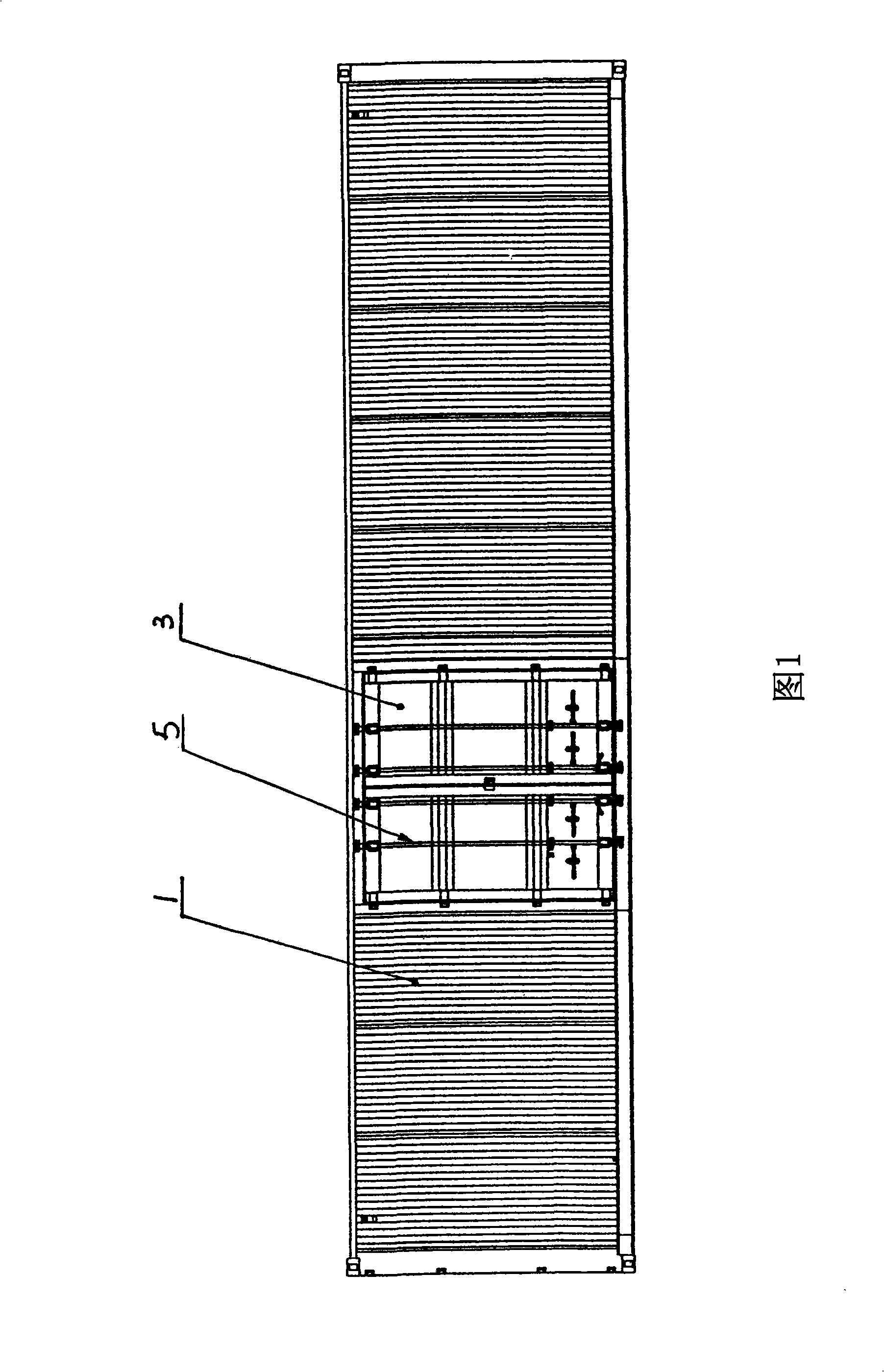

Multi-door container based on underside door

InactiveCN101121458AEasy to coordinate loading and unloadingRealize mechanized operationLarge containersEngineeringMechanical engineering

The present invention discloses an underside door-based multi-door container, concerning the container. The present invention contains a front side (1), a back side (2), a left side (3), a right side (4), an upper side (5) and a bottom side (6). The structure is as followings (1). The upper side (5) is on top with a cover or without a cover. When the upper side (5) is provided with the cover, the door is opened longitudinally or transversely. (2). The bottom side (6) is opened longitudinally or transversely. (3). The left side (3) and the right side (4) can be opened or can not be opened. (4). The back side (2) can be opened or can not be opened. The present invention can pick up the speed of loading and discharge of the goods and improve the work efficiency. The present invention can work together with a chain block and a crane conveniently, realizing the mechanized operation, automatic opening and closing of the doors and safe work. The present invention is applicable to various containers, in particular to the solid bulk container.

Owner:李锦

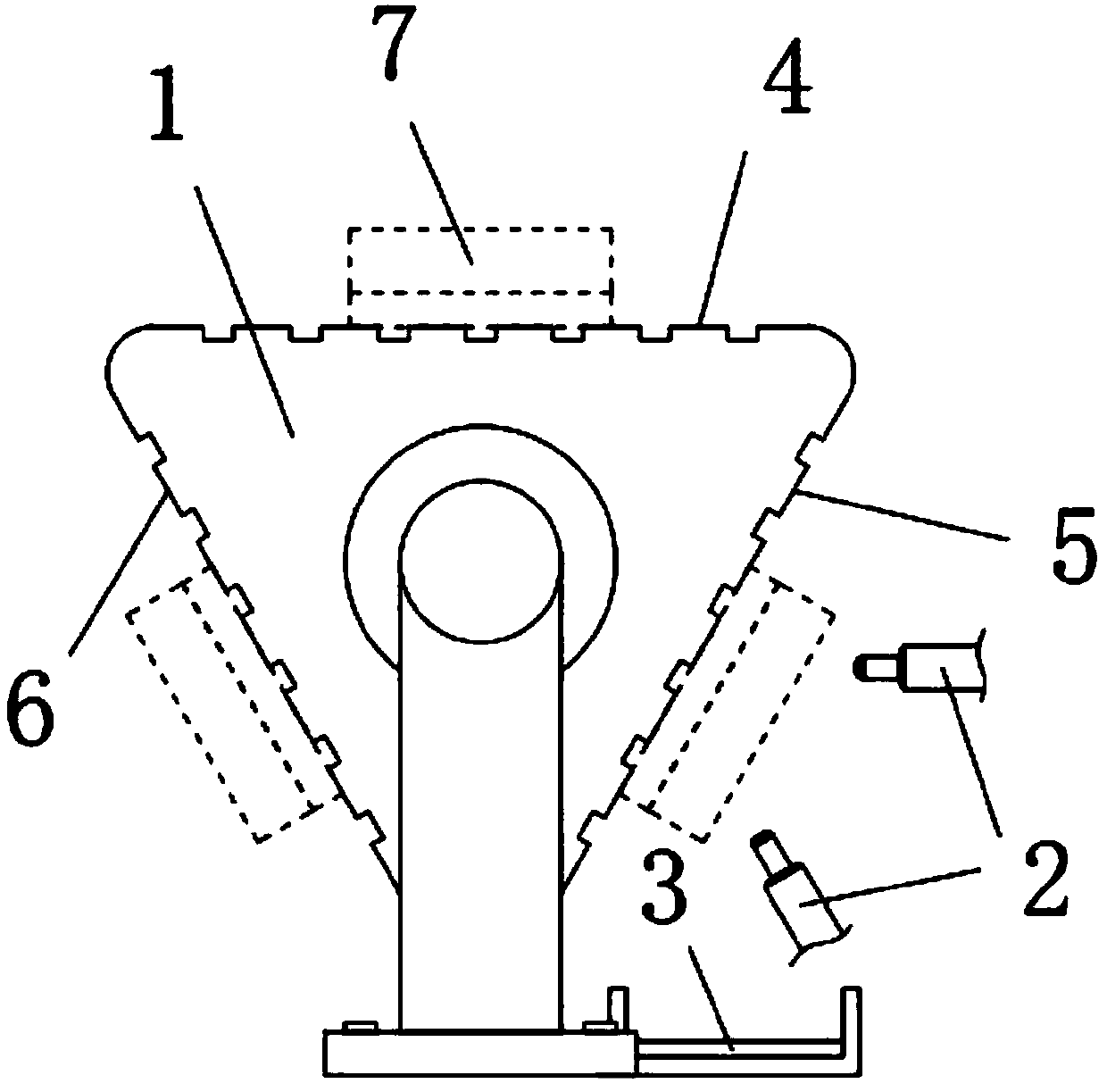

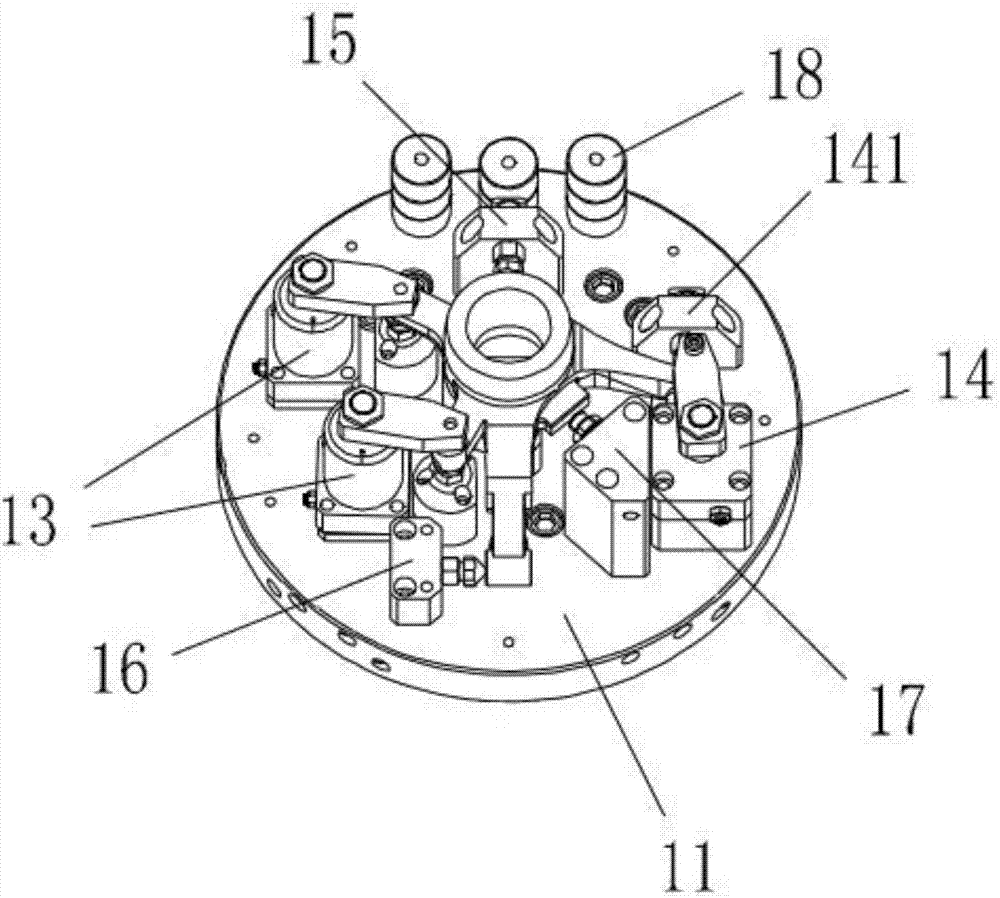

Overturning machining mechanism for central hole of steering knuckle

InactiveCN107877188AImprove loading and unloading speedOptimize layoutLarge fixed membersPositioning apparatusControl armEngineering

The invention discloses an overturning processing mechanism for the center hole of a steering knuckle, which comprises an overturning worktable, a flushing device and a chip removal mechanism; the overturning workbench is at least provided with a processing tabletop, a cleaning tabletop and a clamping tabletop, and each tabletop is Equipped with a center hole processing fixture; the center hole processing fixture includes a disc seat, and the disc seat is equipped with a brake arm pressing seat, a steering arm pressing seat, a steering arm top block, a control arm top block, and a shock absorber arm top block and side top blocks; the present invention sets three tables on the workbench, one table is processed, and the other two tables can be cleaned and loaded and unloaded at the same time, which improves the processing efficiency; and optimizes the clamping parts of the fixture to improve the steering knuckle workpiece. The loading and unloading speed improves the efficiency; each main structure of the steering knuckle workpiece has clamping parts to ensure the stability of the clamping; and the overall layout of the clamping parts is optimized so that the disc seat basically maintains the weight balance in all directions , to ensure the machining accuracy.

Owner:SUZHOU ZHENJIACHEN PRECISION MACHINERY CO LTD

Truck carriage with tilt-up door

InactiveCN106697078AChange the basic structureSolve the slow loading and unloading of goodsLoading-carrying vehicle superstructuresEngineeringControl switch

The invention provides a truck carriage with a tilt-up door; the truck carriage comprises a carriage box consisting of a bottom plate and vertical plates; the middle of the top parts of front and back vertical plates are crossly and symmetrically provided with a turnover tilt-up door; the tilt-up door consists of two flat panels which are perpendicular to each other, and the cross section thereof is in the shape of L, wherein two ends of inside of the flat panel are respectively and fixedly connected with spline sleeves, and the spline sleeves are in transmission connection with a motor at inside or outside of each vertical plate; the motor is connected with a control switch. The truck carriage changes the basic structure of the traditional automobile carriage, thus the automobile truck carriage is more practicable and convenient; the truck carriage fundamentally solves the problems that the traditional carriage is slow to load and unload goods and cannot load and unload large goods, and the carriage has a dead corner for loading and unloading, and cannot be loaded by the fork, and the goods shall be moved twice. For two sides of the carriage can be opened at the same time, the loading and unloading speeds are largely improved, and the labor intensity is reduced. The truck carriage needs not to open and close by labor force, thus the efficiency is improved.

Owner:ZHENJIANG COLLEGE

Small truck lifting device

A small truck lifting device mainly comprises a walking component, a supporting component, a telescopic arm component and a lifting component, wherein the walking component has a moving wheel with a horizontal axis, and the two ends of the axle are respectively fixed in axle holes on the upper portion of two parallel support plates under a beam frame and one end is connected to an output shaft ofthe motor through a reducer. The supporting component is arranged on the beam frame, the inner ring of which is fixed on the beam frame and the outer ring of which is a gear ring that meshes with theoutput gears of a second motor and a second reducer and is connected with a supporting connecting plate. The supporting connecting plate is fixedly connected with the lower end of a column, the upperend of which is provided with a supporting plate. The front part of the supporting plate is provided with the telescopic arm component, and the rear part of the supporting plate is provided with the lifting component. The small truck lifting device is convenient to use, and can walk on the boxcar board. thus, loading and unloading of goods in a wider range are guaranteed, labor intensity is effectively reduced, labor is saved, loading and unloading speed is accelerated, work efficiency is raised, and the problem that it is not convenient to use professional lifting devices is solved.

Owner:YANSHAN UNIV

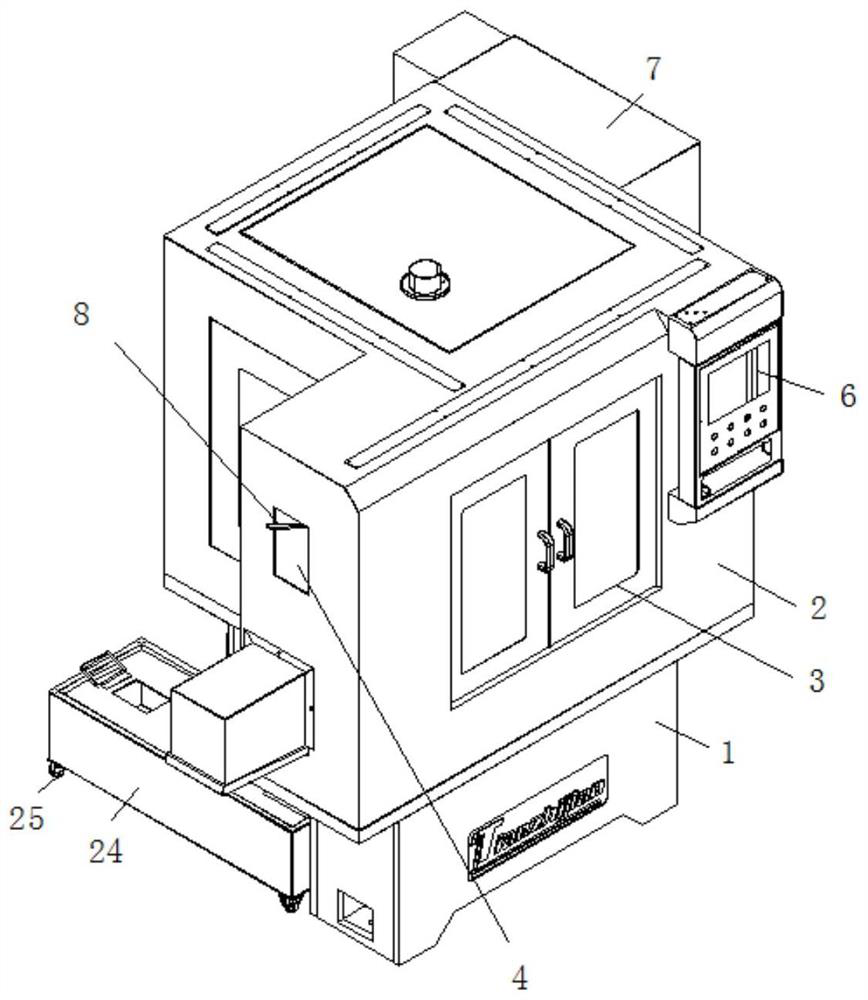

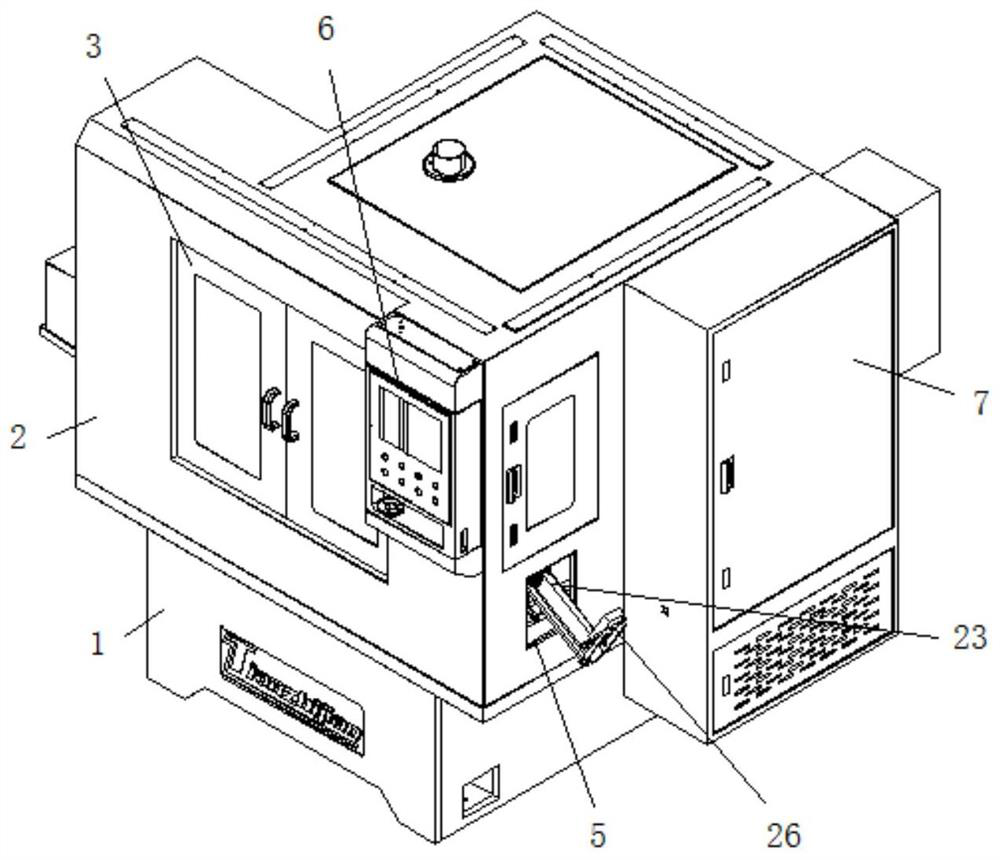

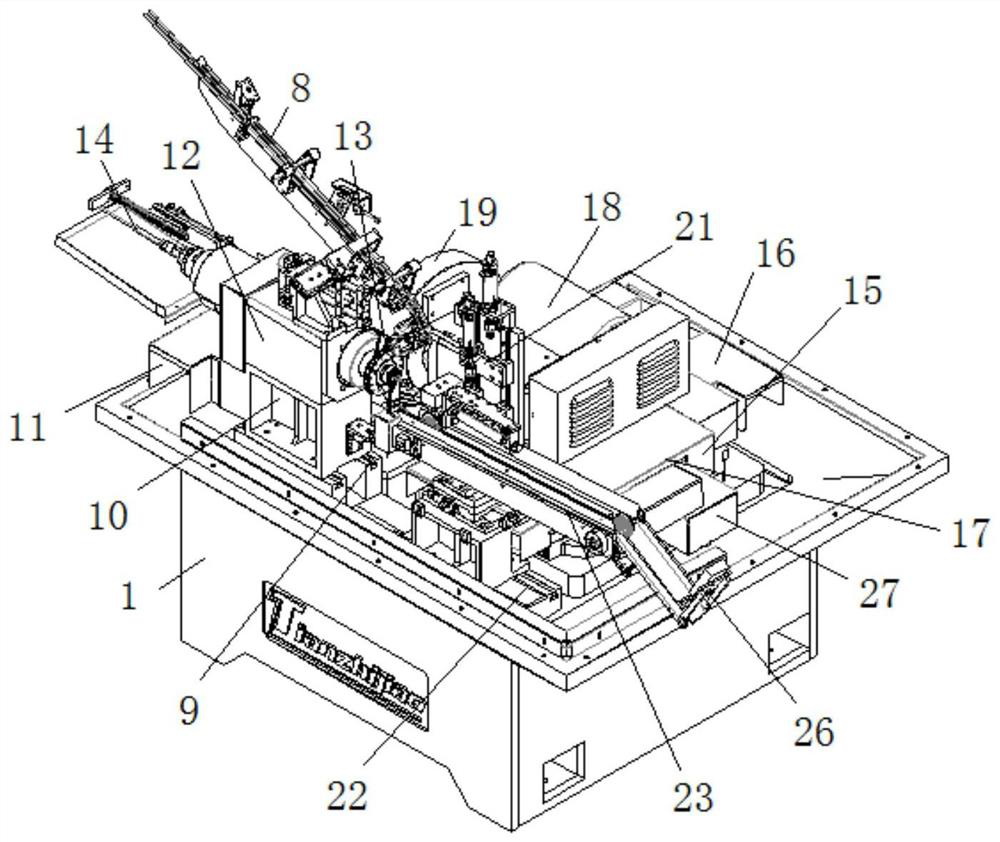

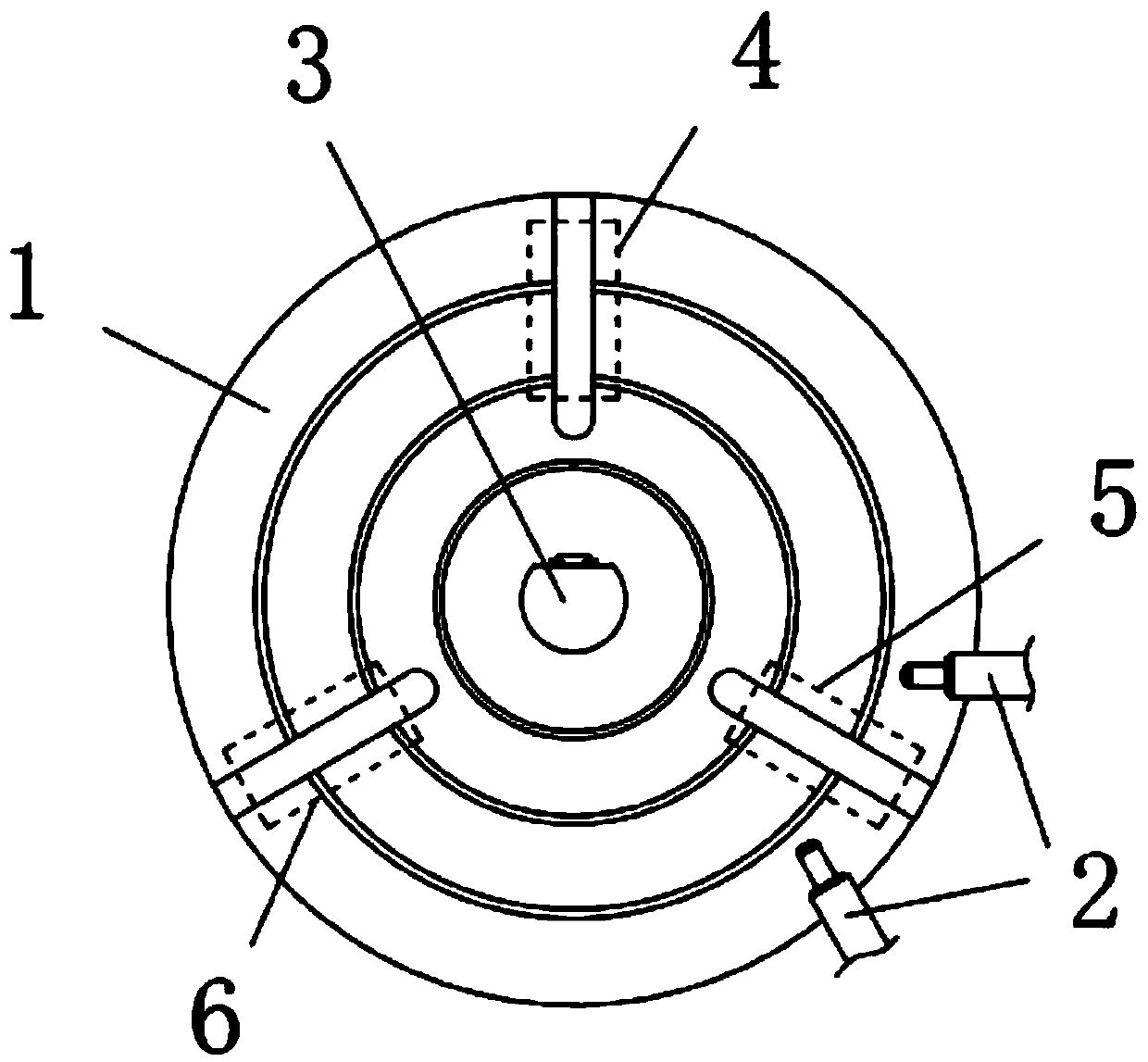

CBN valve accurate grinding conical surface grinding machine

PendingCN112658834AEasy to processFast processingRevolution surface grinding machinesAbrasive surface conditioning devicesElectrical controlEngineering

The invention discloses a CBN valve fine grinding conical surface grinding machine, which comprises a machine tool body; a machine tool protective cover is fixedly connected to the upper end of the machine tool body; a left-right moving door is movably connected to the front end of the machine tool protective cover; a feeding port is formed in the left end of the machine tool protective cover, and a discharging port is formed in the right end of the machine tool protective cover; the front end of the machine tool protective cover is fixedly connected with an operation control box, and the operation control box is located on the outer side of the left-right sliding door; the right end of the machine tool protective cover is fixedly connected with an electric control cabinet, and the electric control cabinet is electrically connected with the machine tool body and the operation control box; the outer side of the machine tool body is detachably connected with a cooling grinding fluid water tank; and universal trundles are fixedly installed at the lower end of the cooling grinding fluid water tank. According to the CBN valve accurate grinding conical surface grinding machine provided by the invention, overall rapid and stable clamping is guaranteed, the overall clamping stability is improved, overall trimming is facilitated, and therefore the overall good using effect is guaranteed.

Owner:SUZHOU TIANZHIJIAO PRECISION MACHINERY CO LTD

Reverse clamping rotating workbench assembly for steering knuckle

InactiveCN107855785AImprove loading and unloading speedImprove processing efficiencyLarge fixed membersPositioning apparatusMachine partsEngineering

The invention discloses a rotating workbench assembly for a steering knuckle. The rotating workbench assembly comprises a rotating workbench and a washing device; the rotating workbench is of a disc structure and is provided with a rotating shaft connection part, a machining part, a cleaning part and an assembling and disassembling part, and each part is provided with a reverse clamping fixture; each reverse clamping fixture comprises a base, a main pressing seat and a horizontal clamping assembly is arranged on the base, the horizontal clamping assembly comprises a positioning seat, a clamping seat and two auxiliary pressing seats; and each main pressing seat is provided with a main press arm, each clamping seat is provided with a steering arm clamping block and a fixed jacking head, andeach steering arm clamping block is provided with a hydraulic jacking head. According to the reverse clamping rotating workbench assembly for the steering knuckle, the three fixture installing parts are arranged on the workbench, one fixture installing part is used for machining, the other two fixture installing parts are used for washing as well as assembling and disassembling, and the machiningefficiency is improved; in addition, clamping parts of the fixtures are optimized, the assembling and disassembling speed of the steering knuckle workpiece are increased, and the efficiency is improved; and the main body structure of the steering knuckle workpiece is fixed through all the clamping parts, and the clamping stability is ensured.

Owner:SUZHOU ZHENJIACHEN PRECISION MACHINERY CO LTD

Boarding device

InactiveCN109606574AImprove stabilityImprove securityCargo handling apparatusPassenger handling apparatusSheet steelEngineering

The invention discloses a boarding device, which comprises a turntable mechanism, a boarding ladder and a trolley. The boarding ladder includes a turntable frame, a turntable shaft, and a turntable having a first buckle; and the turntable is arranged on the turntable frame and rotates around the turntable shaft at the turntable frame. The boarding ladder includes a first connecting buckle that connects the first buckle of the turntable and a second connecting buckle that connects a second buckle of a connection slide. The trolley includes a trolley body, a rotation beam, a trolley rotating shaft, a plurality of trolley roller mechanisms, and a second buckle; the plurality of trolley roller mechanisms are respectively fixed on steel plates at the end portion of the rotation beam; and the trolley roller mechanisms are arranged on the upper surface of the trolley body. According to the invention, on the basis of the flexible cooperation of the trolley body with the turntable, the boardingladder can rotate at a proper position freely with the ship body, so that the safety of the boarding personnel is improved and the e loading and unloading speeds of the shipboard are increased and thus the shipbuilding construction efficiency is improved.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

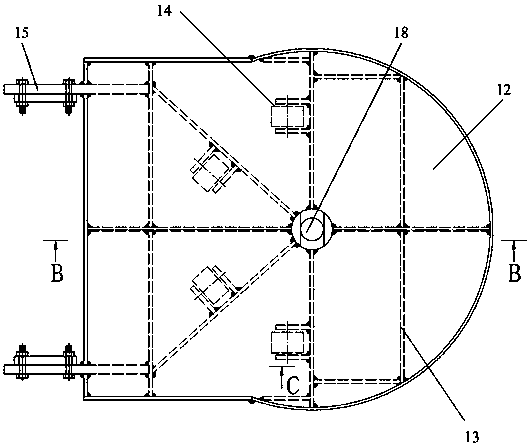

Container

InactiveCN101306751AImprove loading and unloading speedImprove work efficiencyLarge containersEngineeringMechanical engineering

Owner:ZHANGJIAGANG HAIGUO HEAVY FORGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com