Truck carriage with tilt-up door

A technology for trucks and carriages, which is applied in the field of automotive devices, which can solve the problems of inability to load and unload a large number of goods at the same time, rigid loading and unloading angles, small loading and unloading doors, etc., and achieve the effects of increased loading and unloading speed, no loading and unloading dead angle, and fast loading and unloading speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

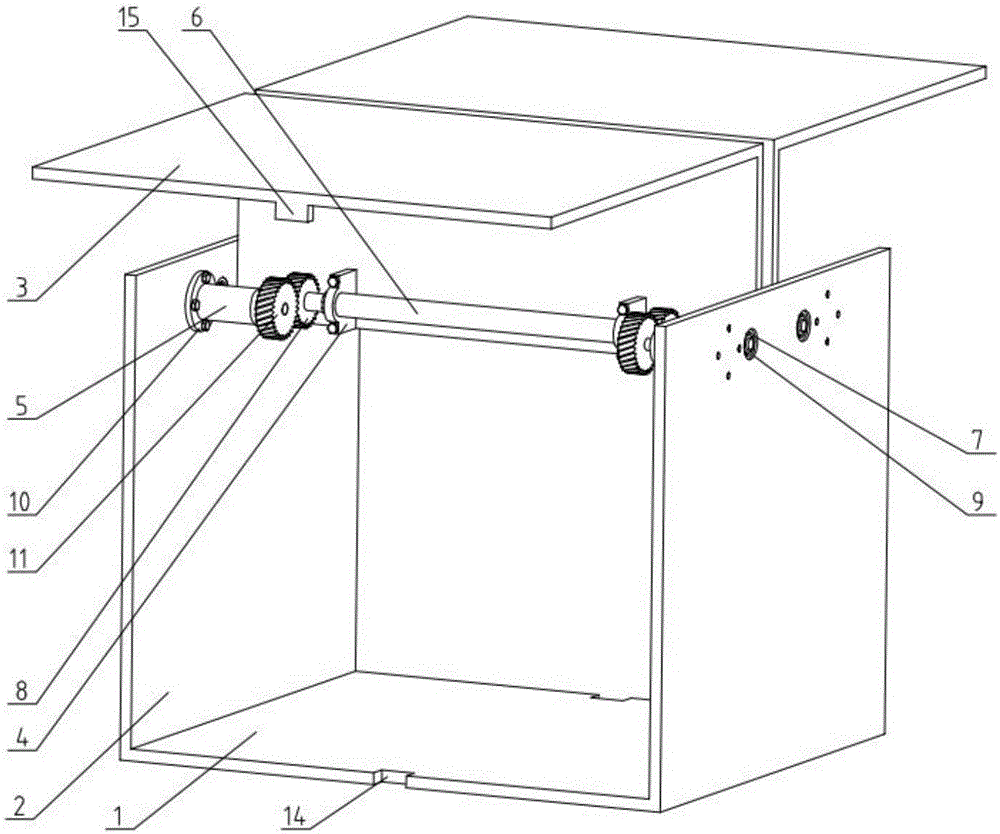

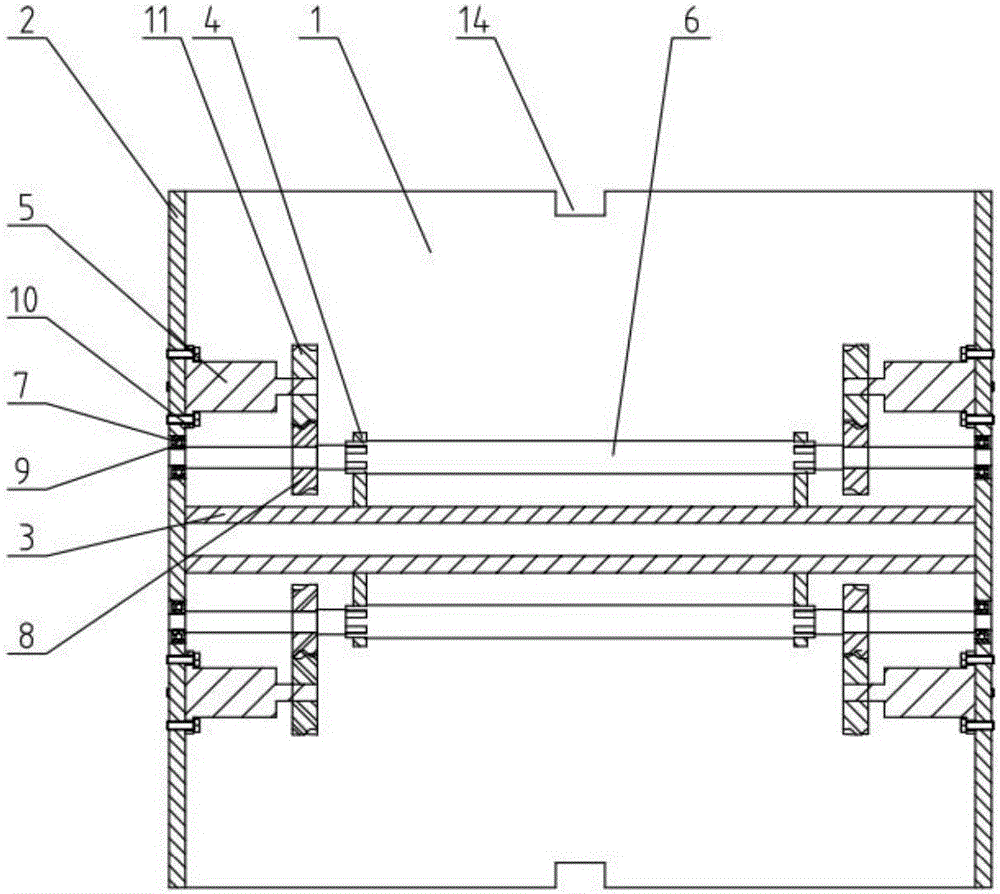

[0028] Such as Figure 1 to Figure 3 Shown: it is a truck box with an upturning door according to the present invention, which includes a U-shaped box body composed of a bottom plate 1 and a vertical plate 2 located at the front and rear ends of the bottom plate 1 according to the traveling direction of the car, wherein the top of the vertical plate 2 A reversible upturning door 3 is provided in the left and right symmetrical mirror images at the middle position. The upturning door 3 is composed of two flat plates perpendicular to each other. A sleeve 4, the splined sleeve 4 runs through a rotating shaft 6 that can be connected in transmission, and the rotating shaft 6 is in transmission connection with the motor 5 arranged on the inside of the vertical plate 2; the motor 5 is connected with a control switch through a wiring harness.

[0029] The transmission connection mode in which the motor 5 is arranged on the inside of the vertical plate 2 is a gear transmission connectio...

Embodiment 2

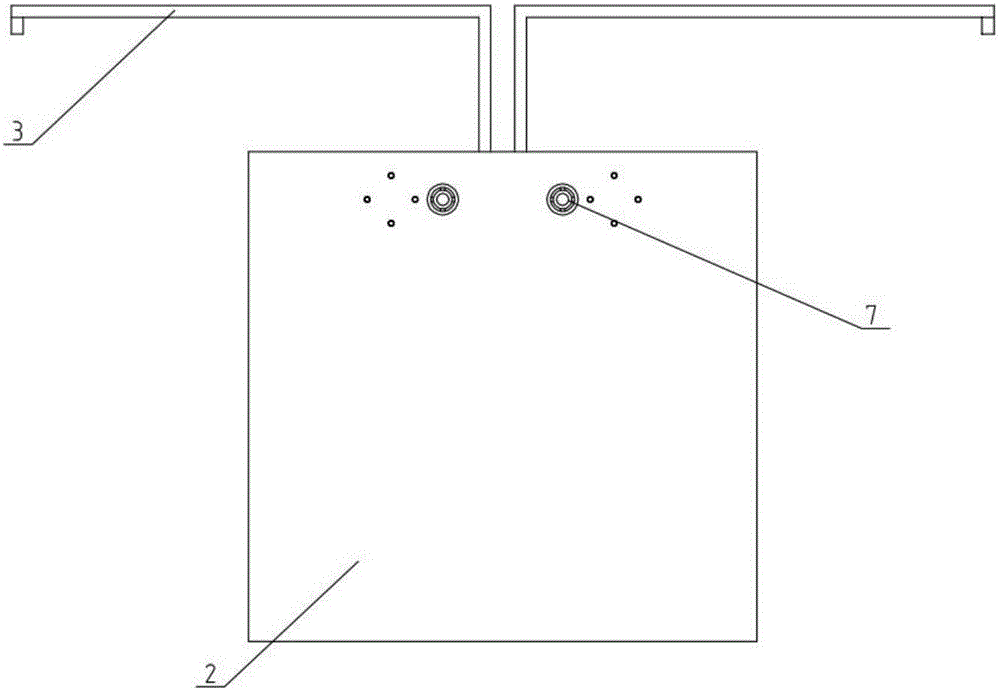

[0034] Such as Figure 4 and Figure 5 Shown: it is a truck box with an upturning door according to the present invention, which includes a U-shaped box body composed of a bottom plate 1 and a vertical plate 2 located at the front and rear ends of the bottom plate 1 according to the traveling direction of the car, wherein the top of the vertical plate 2 A reversible upturning door 3 is provided in the left and right symmetrical mirror images at the middle position. The upturning door 3 is composed of two flat plates perpendicular to each other. A sleeve 4, the splined sleeve 4 runs through a rotating shaft 6 that can be connected in transmission, and the rotating shaft 6 is in transmission connection with the motor 5 arranged on the outside of the vertical plate 2; the motor 5 is connected with a control switch through a wiring harness.

[0035] The transmission connection mode in which the motor 5 is arranged on the outside of the vertical plate 2 is a gear transmission conn...

Embodiment 3

[0040] Such as Figure 6Shown: it is a truck box with an upturning door according to the present invention, which includes a U-shaped box body composed of a bottom plate 1 and a vertical plate 2 located at the front and rear ends of the bottom plate 1 according to the traveling direction of the car, wherein the top of the vertical plate 2 A reversible upturning door 3 is provided in the left and right symmetrical mirror images at the middle position. The upturning door 3 is composed of two flat plates perpendicular to each other. sleeve 4, the spline sleeve 4 runs through a rotating shaft 6 that can be connected by transmission, and the rotating shaft 6 is directly connected to the motor 5 arranged outside the vertical plate 2. The specific solution is: the motor 5 passes through the The end flange 13 is installed on the outside of the vertical plate 2, and the output shaft of the motor 5 passes through the bearing installation hole 9 provided on the vertical plate 2 from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com