Reverse clamping rotating workbench assembly for steering knuckle

A technology of rotary table and steering knuckle, which is used in metal processing mechanical parts, clamping, positioning devices, etc., can solve the problem that steering knuckle fixtures cannot meet the processing requirements of quick loading and unloading, the processing efficiency of steering knuckles is strict, and it is difficult to meet production requirements. and other problems to achieve the effect of optimizing the overall layout, optimizing the clamping components, and improving the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described below in conjunction with accompanying drawing.

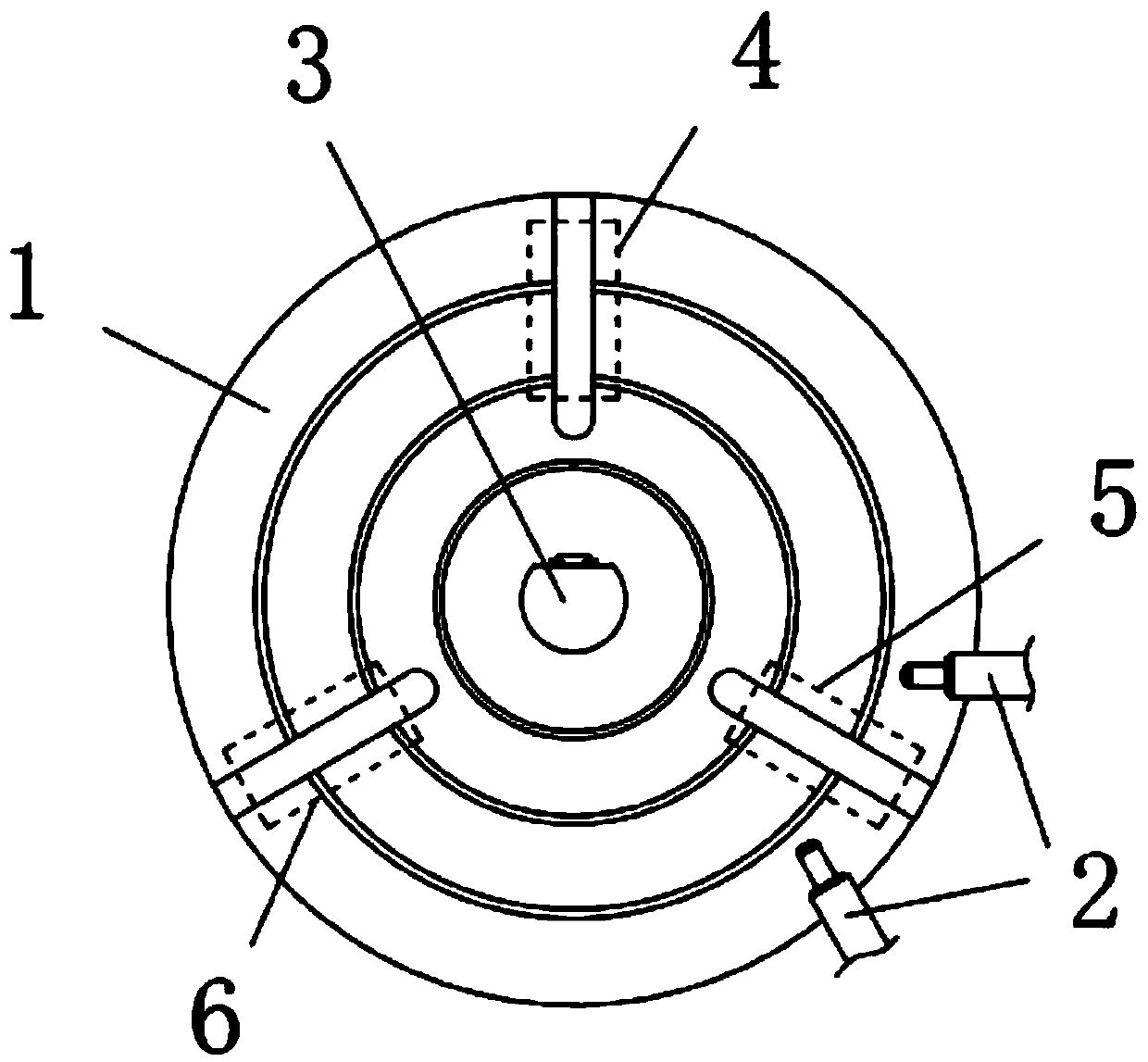

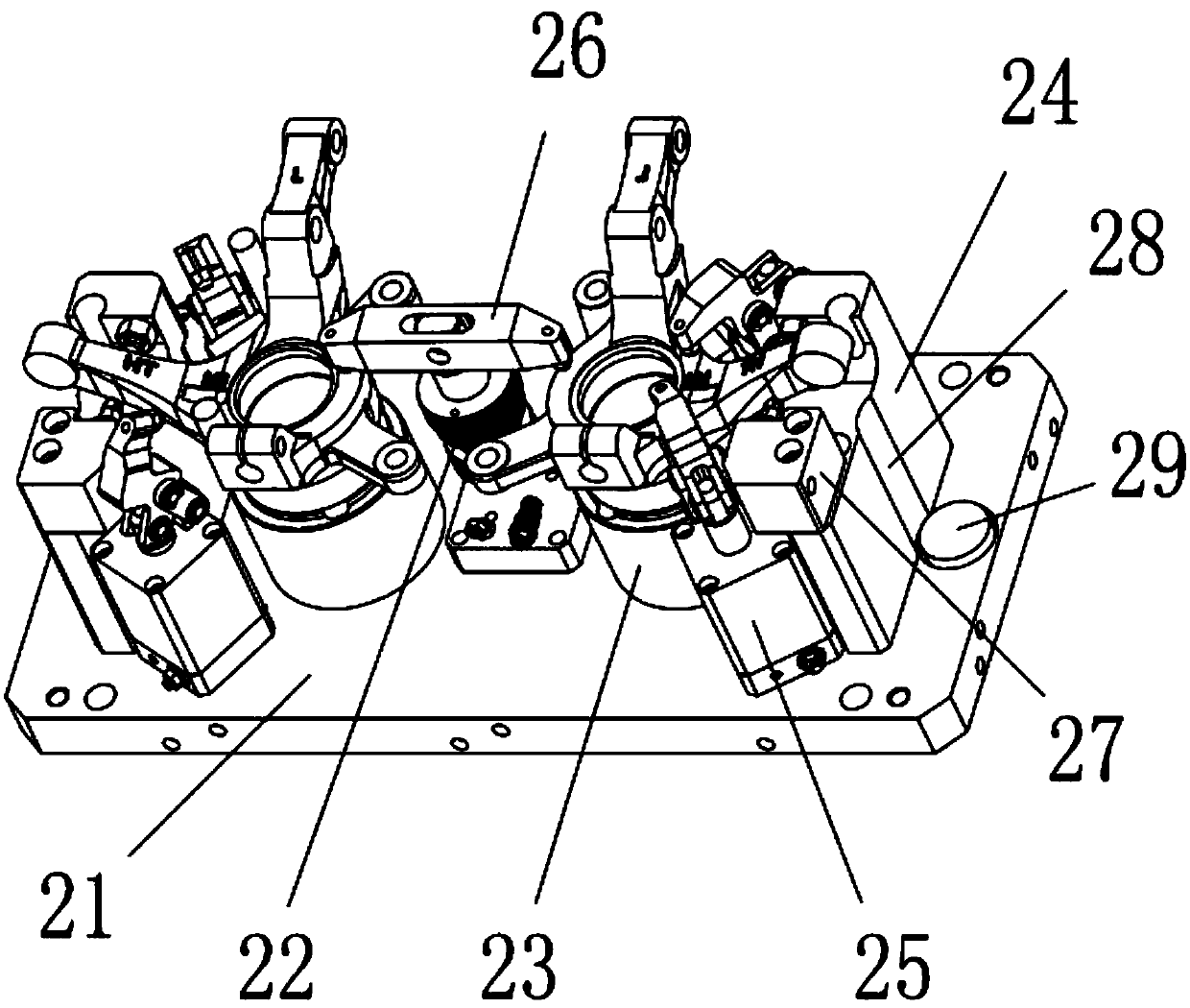

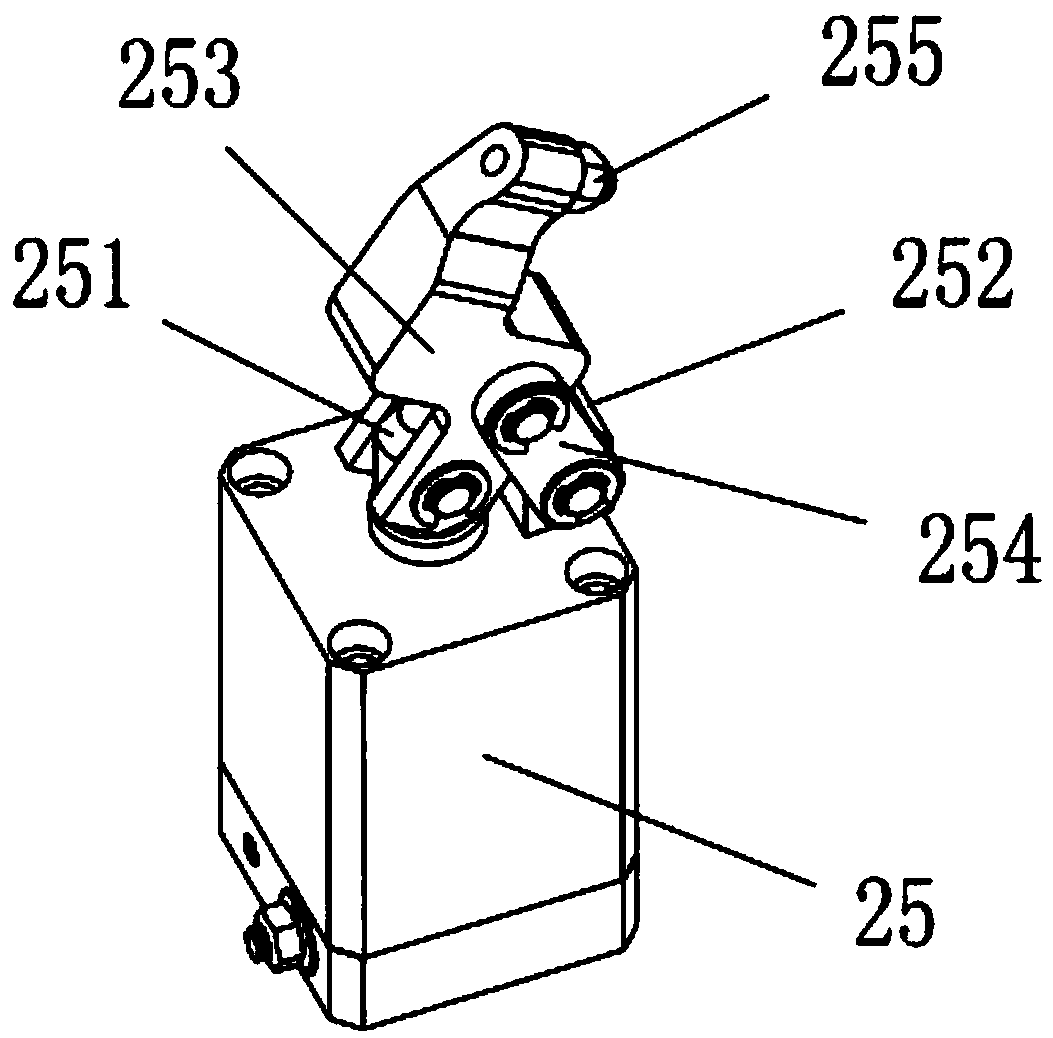

[0015] as attached Figure 1-3 As shown, a reverse clamping rotary table assembly of a steering knuckle according to the present invention includes a rotary table 1 and a flushing device 2; the rotary table 1 is a disc structure, and the center of the rotary table 1 is set There is a rotating shaft connection part 3, and the rotary table 1 is connected to the rotating drive mechanism through the rotating shaft connecting part 3; the rotary table 1 is provided with three fixture installation parts, and the three parts are respectively the processing part 4, the cleaning part 5 and the loading and unloading part 6. The working properties of the three positions are constantly changing with the rotation of the worktable, and each position is equipped with a reverse clamping fixture; the washing device 2 cooperates with the cleaning part 5, and the washing device 2 is generally connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com