Small truck lifting device

A lifting device and truck technology, applied to cranes and other directions, can solve problems such as high labor intensity, low work efficiency, and inability to disassemble, and achieve the effects of speeding up loading and unloading, reducing labor intensity, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

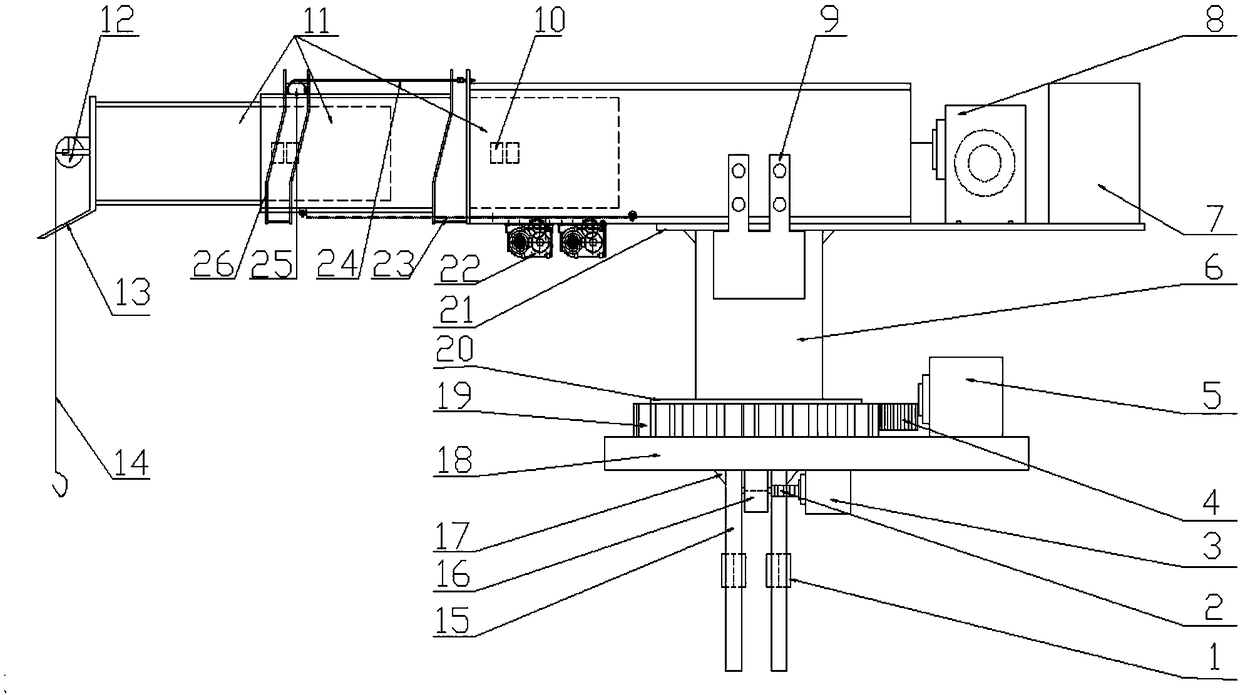

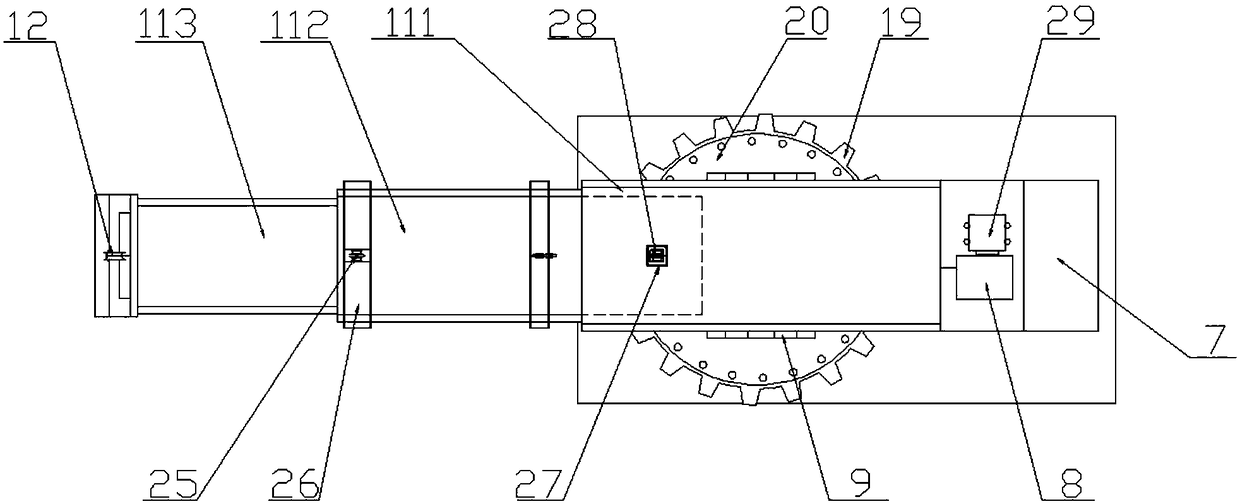

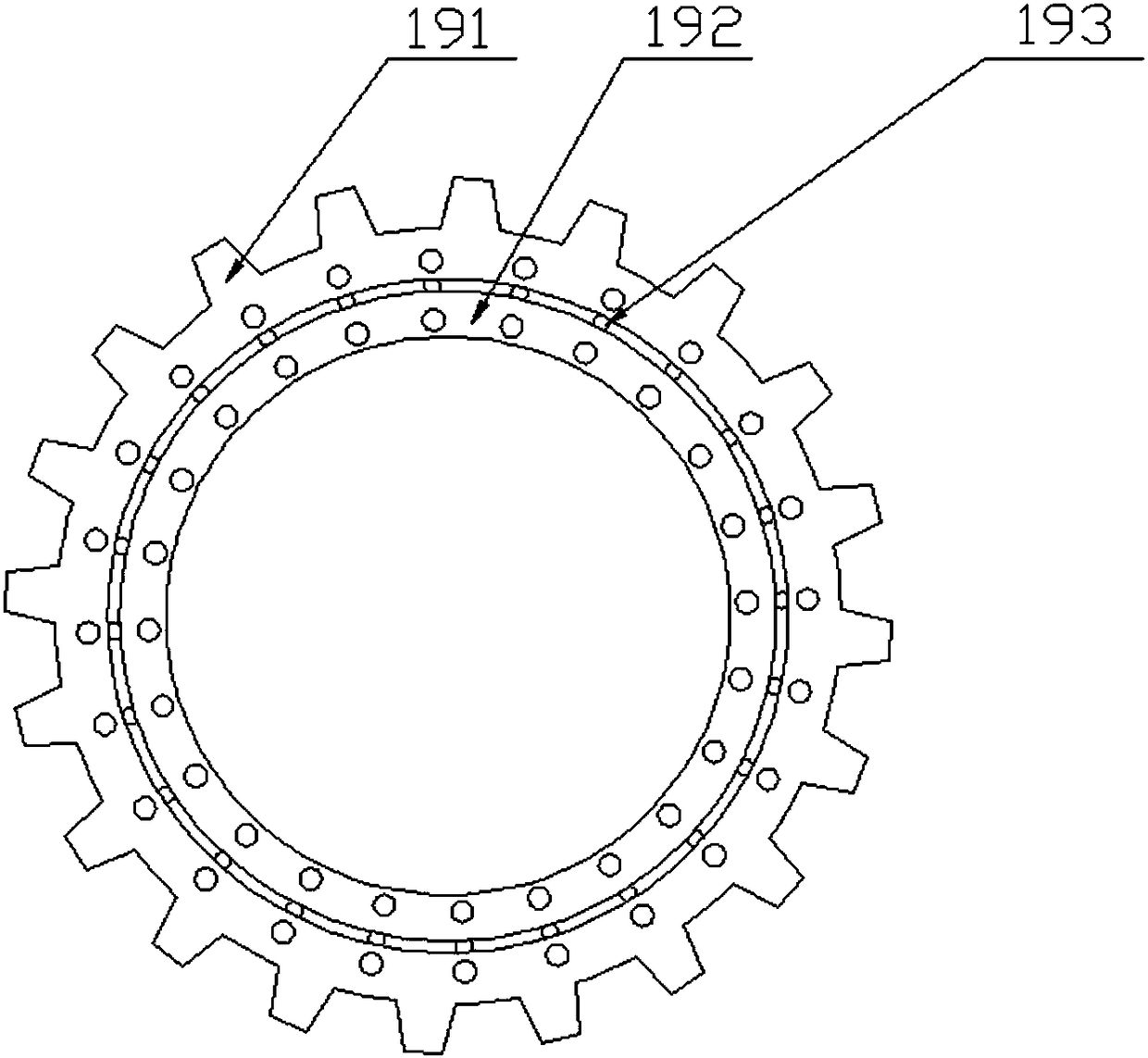

[0013] exist figure 1 and figure 2 In the schematic diagram of the small truck lifting device shown, the walking assembly has a moving walking wheel 16, the moving walking wheel axle is horizontal, and the two ends are respectively placed in the upper opposite shaft holes of the two parallel supporting plates 15, and the two parallel supporting plates The distance between the supporting plates is greater than the thickness of the compartment plate, and the height is less than or equal to the height of the compartment plate. Two opposite rectangular through holes are arranged on the two support plates, and an auxiliary walking wheel 1 is respectively arranged in each through hole. Wheel axle one end of wheel links to each other with motor-3 output shaft by speed reducer-2, and motor-be fixed on beam frame 18 below by fastener. The upper ends of the two support plates are welded under the beam frame and a reinforcing rib 17 is arranged at the junction. A support assembly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com