Piston ring clamp set for rapid clamping and thread locking prevention

A piston ring and jig assembly technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve unrealistic problems, achieve the effects of improving production efficiency, convenient loading and unloading, and ensuring normal loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

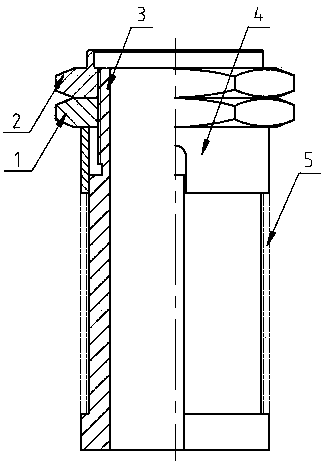

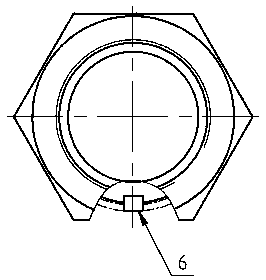

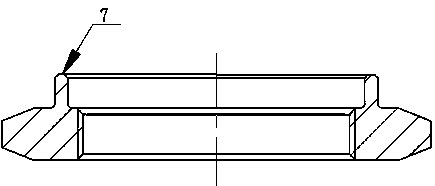

[0015] The structure of the piston ring fixture set for fast clamping and anti-locking of the thread of the present invention is as follows: figure 1 and figure 2 As shown, it includes a compression sleeve 4, a key 6, a compression nut 1, a lock nut 2, and a clamp sleeve 3. The outer circle of the clamp sleeve 3 is provided with a long strip key 6, and the width of the key 6 is the same as the diameter of the clamp sleeve 3. The sum of the sum is greater than the diameter of the ring mouth of the piston ring 5, the piston ring 5 is set on the clamp sleeve 3, the ring mouth of the piston ring 5 is positioned by the key 6, the clamp sleeve 3 is located on the upper part of the piston ring 5, and the compression sleeve 4 is set, and the clamp The upper part of the tool cover 3 is provided with an external thread, and the clamp cover 3 is located on the upper part of the compression sleeve 4 to install the compression nut 1 and the lock nut 2 in sequence, and the upper part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com