Patents

Literature

51results about How to "Meet coating requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

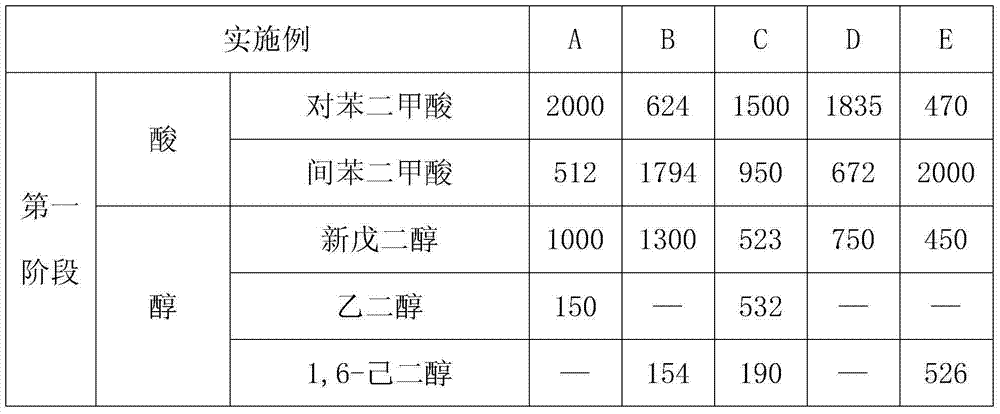

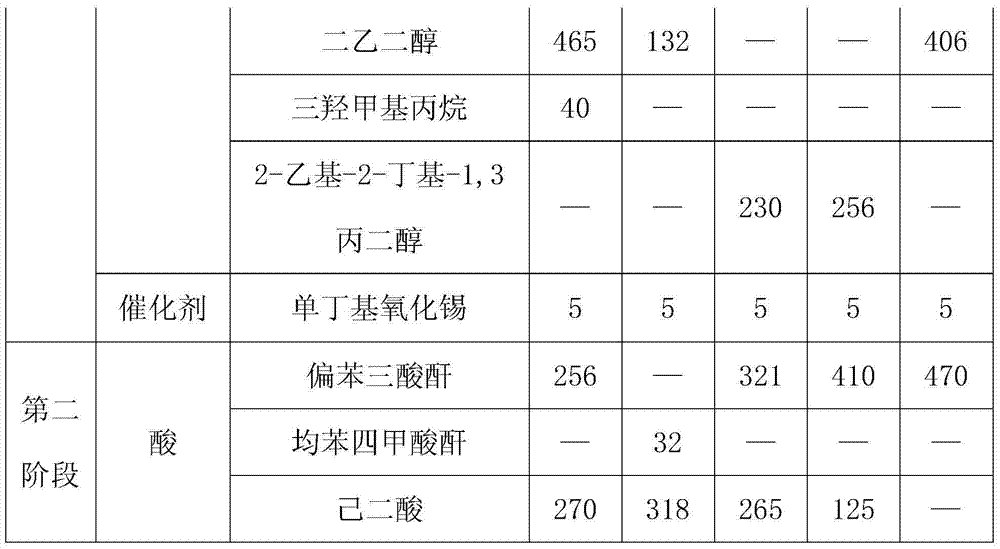

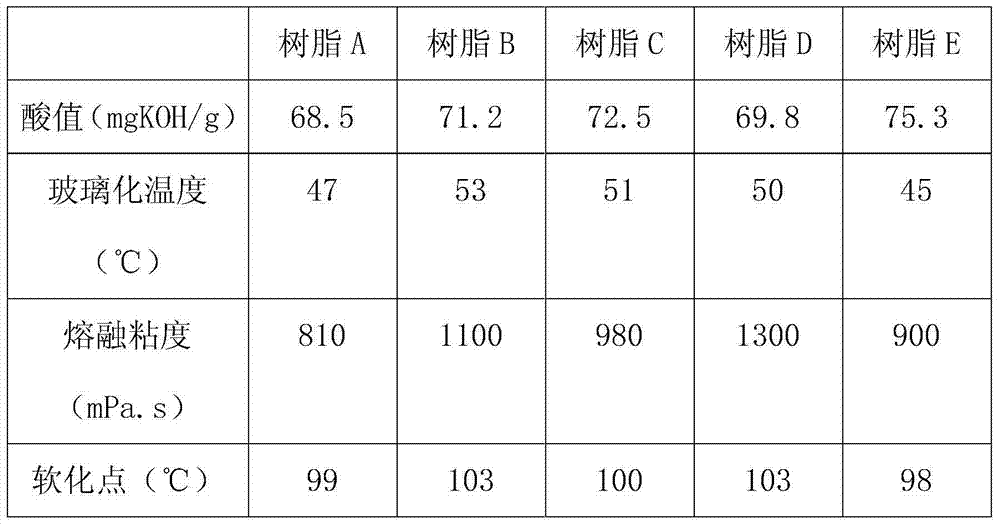

Preparation method and application of polyester resin applied to thermo-sensitive base material powder coating

ActiveCN103755940AMeet coating requirementsMeet flatness requirementsPowdery paintsPolyester coatingsAlcoholThree stage

The invention discloses a preparation method of polyester resin applied to a thermo-sensitive base material powder coating. The preparation method includes three stages, wherein the first stage comprises the steps of: putting a formula amount of alcohol into a reaction kettle, heating, stirring after the alcohol is completely melted, then adding the formula amount of an acid and an esterification catalyst, heating to 170-180 degrees centigrade, then heating to 245-250 degrees centigrade, and maintaining the reaction until reactants are clear; the second stage comprises the steps of: adding the acid, keeping the temperature at 210-220 degrees centigrade until the reactants are clear, sampling and measuring acid value; the third stage comprises the steps of vacuumizing at a vacuum degree from -0.095 to -0.097 MPa for 1.5-2 hours, and measuring the acid value. The invention further discloses application of the polyester resin to the thermo-sensitive base material powder coating. Polyester prepared by the method disclosed by the invention has a good hardness and a good adhesive force to a base material, simultaneously a coating has a good appearance and good chemical resistance, the coating requirement of the thermo-sensitive base material is satisfied, and the smoothness requirement of the thermo-sensitive base material is satisfied as well.

Owner:ANHUI SHENJIAN NEW MATERIALS

Colorful heat insulating and waterproof building paint

InactiveCN102675993AGood heat insulationReduce cooling energy consumptionNatural rubber coatingsGlass fiberSpray coating

The invention discloses colorful heat insulating and waterproof building paint, which comprises the components in parts by weight as follows: 20-30 parts of styrene-acrylic emulsion, 20-30 parts of natural rubber resin, 3-10 parts of paint dispersant, 10-15 parts of ethylene glycol, 0.5-1 parts of defoamer, 10-20 parts of pigment, 30-50 parts of low heat conductive coefficient filler, 4-8 parts of white carbon black and 10-15 parts of water. The colorful heat insulating and waterproof building paint is abundant in color, and can well meet the requirement of colorful outer wall paint of buildings with excellent heat insulating and waterproof effects which are same as those of white paint. The paint contains neither heavy metals nor formaldehyde and is relatively beneficial to health of human bodies. The paint is applicable for concrete pavements, asphalt pavements, plastic pavements, pavements of glass fiber reinforced plastics, and metal pavements, and is convenient to construct in ways of spray coating, brush coating and rolling coating.

Owner:开平市日固力涂料有限公司

Full-aqueous release coating for electrochemical aluminum hot stamping foil and preparation method of coating

ActiveCN110105861ASolve concentrationSolve quality problemsWax coatingsDuplicating/marking methodsHot stampingSolvent

The invention provides a full-aqueous release coating for an electrochemical aluminum hot stamping foil and a preparation method of the coating. When a release coating in an alcohol-water system is inuse, because the volatilization of ethyl alcohol and demulsification of a wax emulsion cause the quality defects such as concentration rising, which affects the release tightness of a product, and the utilization rate of the release coating in the alcohol-water system is low, a large amount of waste is caused. The full-aqueous release coating is prepared from, by weight, 80-98 parts of purified water, 1-5 parts of an aqueous polyurethane emulsion, 0.1-1 part of an aqueous acrylic emulsion, 0.1-1 part of a polyurethane crosslinking agent, 1-5 parts of an aqueous wax emulsion, 0.1-0.5 part of awetting agent and 0.1-1 part of a defoaming agent. The release coating improves the water resistance, solvent resistance, temperature resistance and mechanical properties of coating film; the recoating performance of the release coating is good, and coating requirements of subsequent colored layer coating can be met; the release effect is excellent, a hot stamping layer is transferred completely,and the release tightness is adjusted by adjusting the addition amount of a release agent.

Owner:云南玉溪东魅包装材料有限公司

Spray coating type low-absorption and low-emission thermal control coating, preparation method thereof and application thereof

ActiveCN106566408AMeet coating requirementsEasy constructionPolyester coatingsSpace environmentSpray coating

The invention relates to a spray coating type low-absorption and low-emission thermal control coating, a preparation method thereof and an application thereof, and belongs to the technical field of spacecraft thermal control coatings. The invention also provides a preparation method for preparing the spray coating type thermal control coating low in absorption and low in emission. Based on the method, the coating is directly sprayed and coated onto the outer surface of a spacecraft in the spray coating manner, so that the performances of low absorption and low emission are realized. On one hand, the influence of the solar irradiation on the temperature inside the spacecraft is reduced. On the other hand, the radiation and the heat leakage of the spacecraft to the space environment are reduced. Therefore, the coating has an important effect in maintaining the proper temperature of the spacecraft during the long-periodic detection activity.

Owner:BEIJING SATELLITE MFG FACTORY

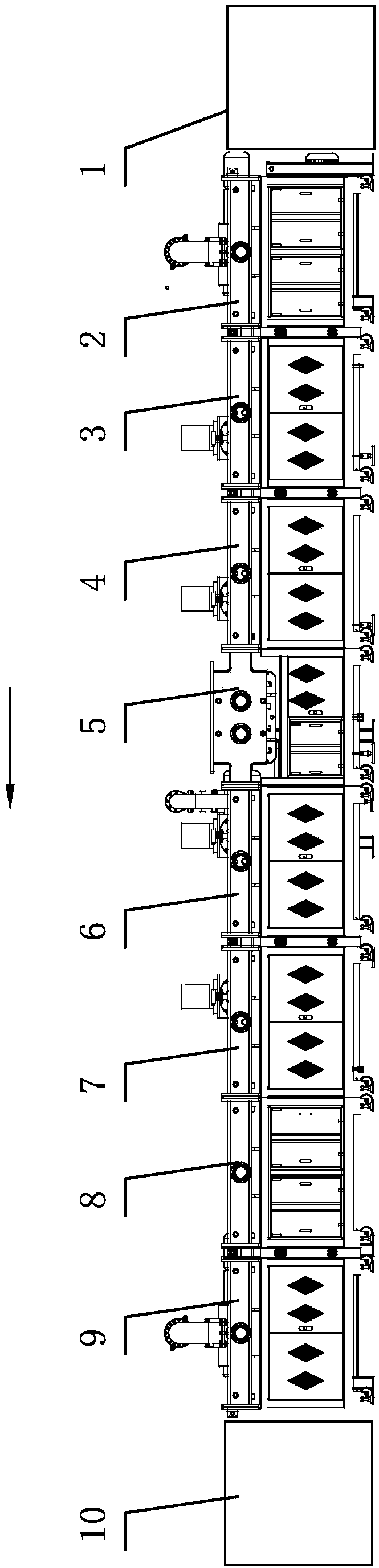

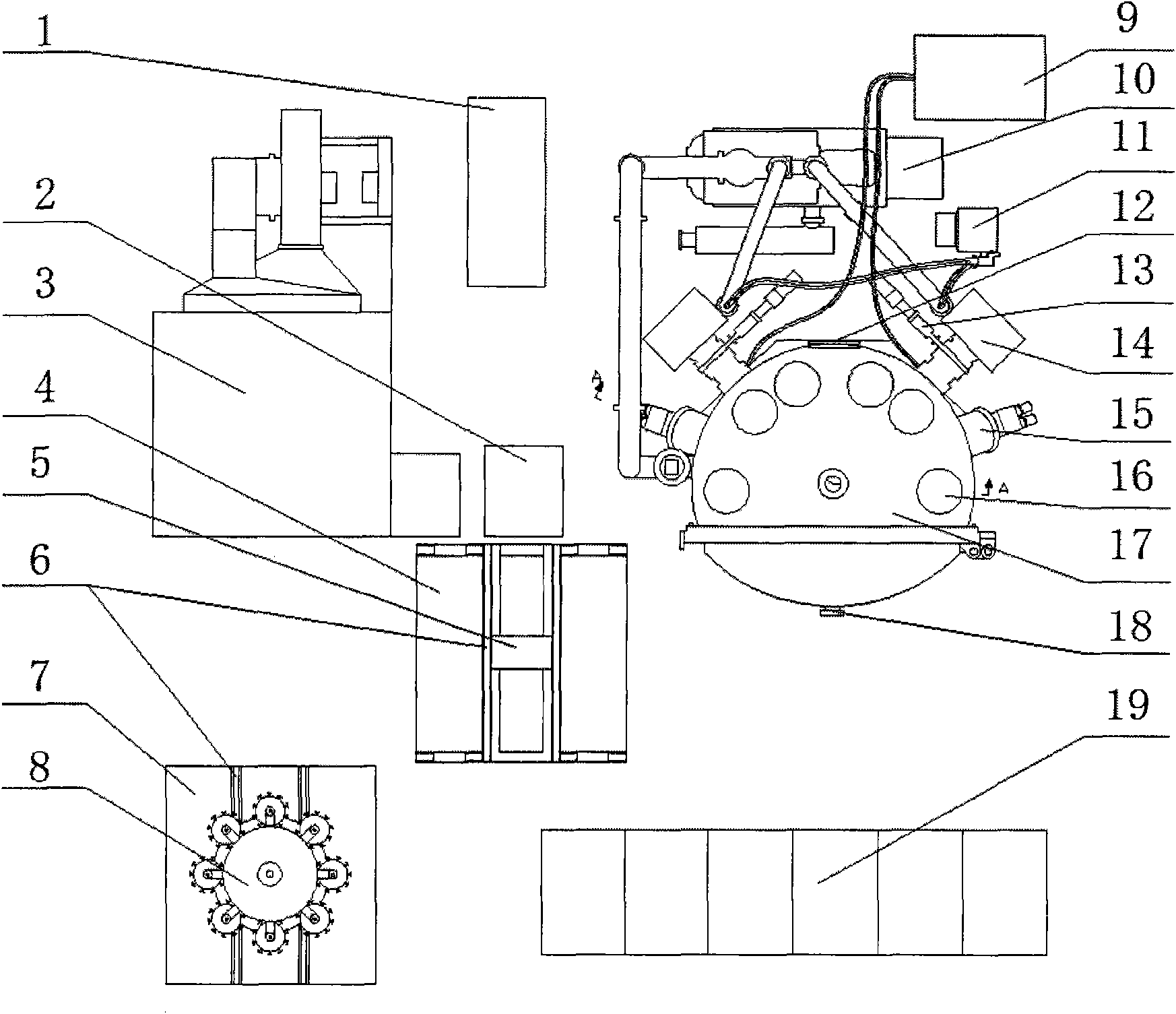

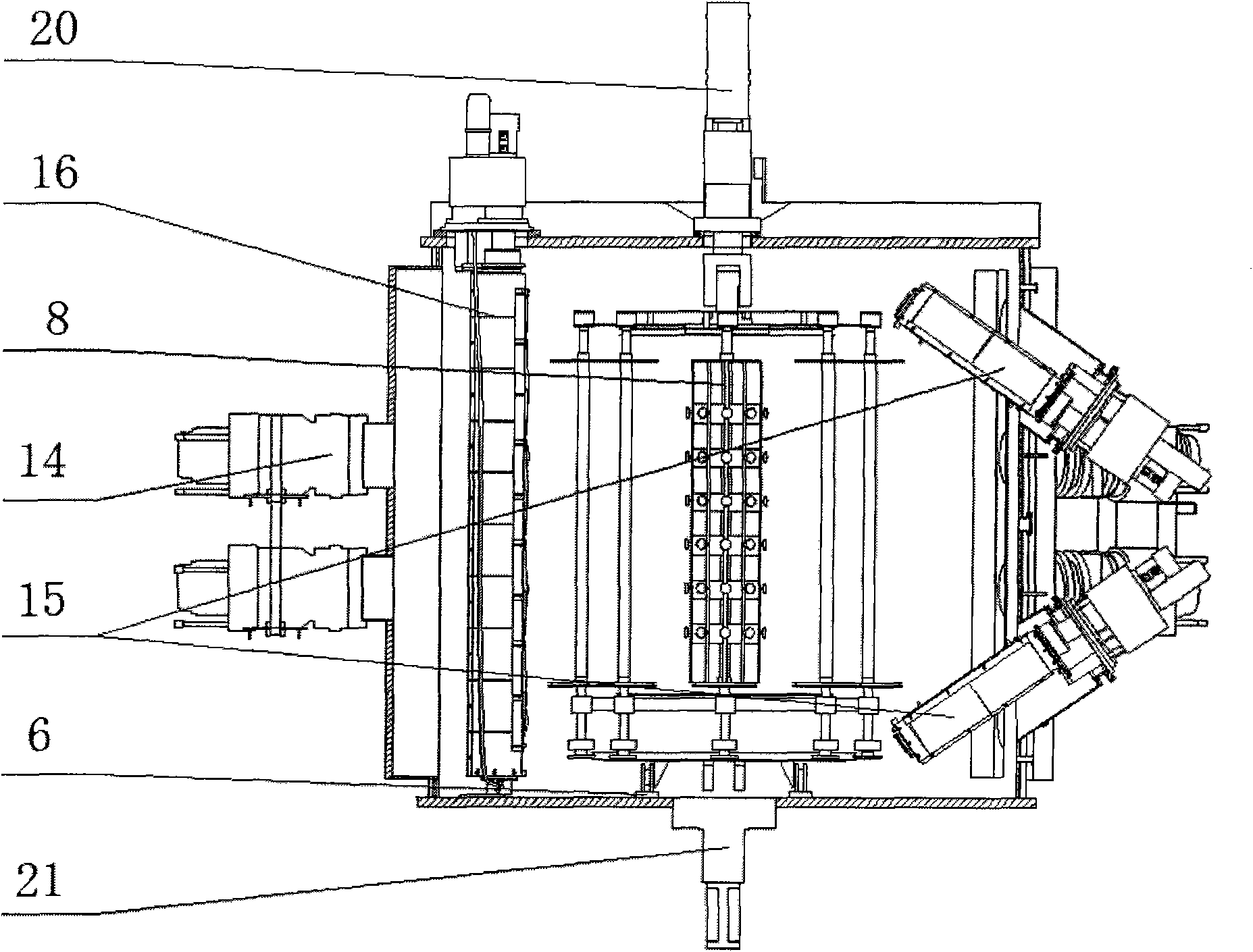

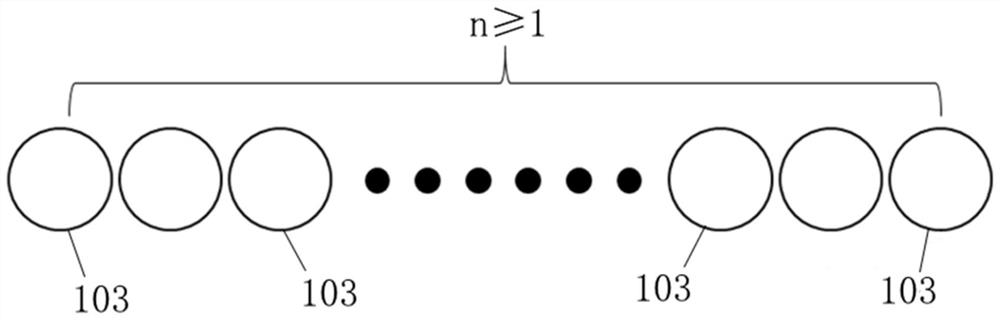

Multi-cavity horizontal magnetron sputtering film-coating production line and film-coating method thereof

InactiveCN108570651AAvoid pollutionMeet coating requirementsVacuum evaporation coatingSputtering coatingSputteringProduction line

The invention belongs to the technical field of film-coating devices, and particularly discloses a multi-cavity horizontal magnetron sputtering film-coating production line. The multi-cavity horizontal magnetron sputtering film-coating production line, in a forward direction of a substrate, successively comprises a feeding platform, a substrate feeding chamber, a heating chamber, a front bufferingchamber, at least two mutually independent magnetron sputtering vacuum film-coating chambers, a rear buffering chamber, a cooling chamber and a discharging platform, and further comprises a transmitting mechanism for transmitting the substrate. The magnetron sputtering film-coating production line is good in film forming effect of magnetron sputtering, high in production efficiency, and high in utilization ratio of a target material, and capable of satisfying the continuous film-coating requirements of a multi-layer functional film, and reducing the using cost of the target material.

Owner:GUANGDONG ZHENHUA TECH CO LTD

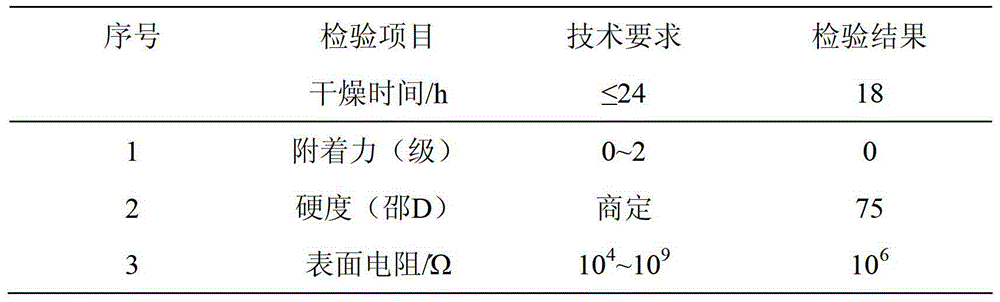

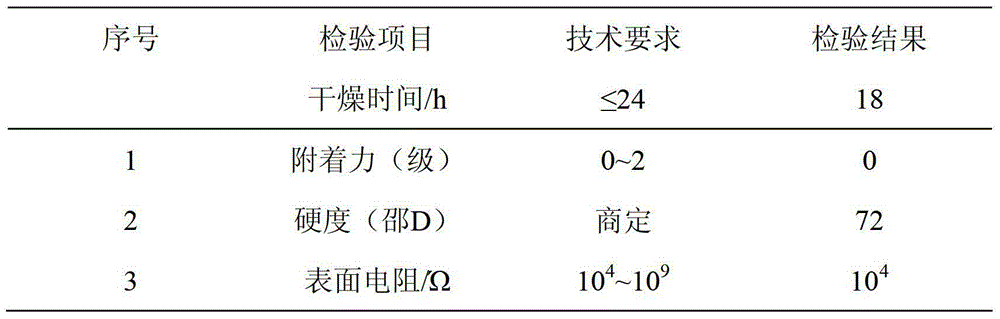

Water-based epoxy antistatic floor primer and surface paint and preparation method thereof

InactiveCN104449246AImprove adhesionNot easy to fall offEpoxy resin coatingsElectrically-conductive paintsWater basedGraphite

The invention discloses water-based epoxy antistatic floor primer and surface paint and a preparation method thereof. The paint is composed of a component A and a component B, wherein the component A is composed of generation II water-based epoxy resin curing agent, water, conductive graphite and dispersing agent; and the component B is composed of bisphenol A epoxy resin and diluter. The preparation method comprises the following steps: dispersing the conductive graphite in a water solution of the generation II water-based epoxy resin curing agent through the dispersing agent, and grinding to obtain the component A; and adding the corresponding component B to obtain the paint. The paint is environment-friendly, favorable in safety and good in antistatic property; and the preparation method is simple, quick and low in cost, and can realize industrial production.

Owner:CHINA PETROLEUM & CHEM CORP

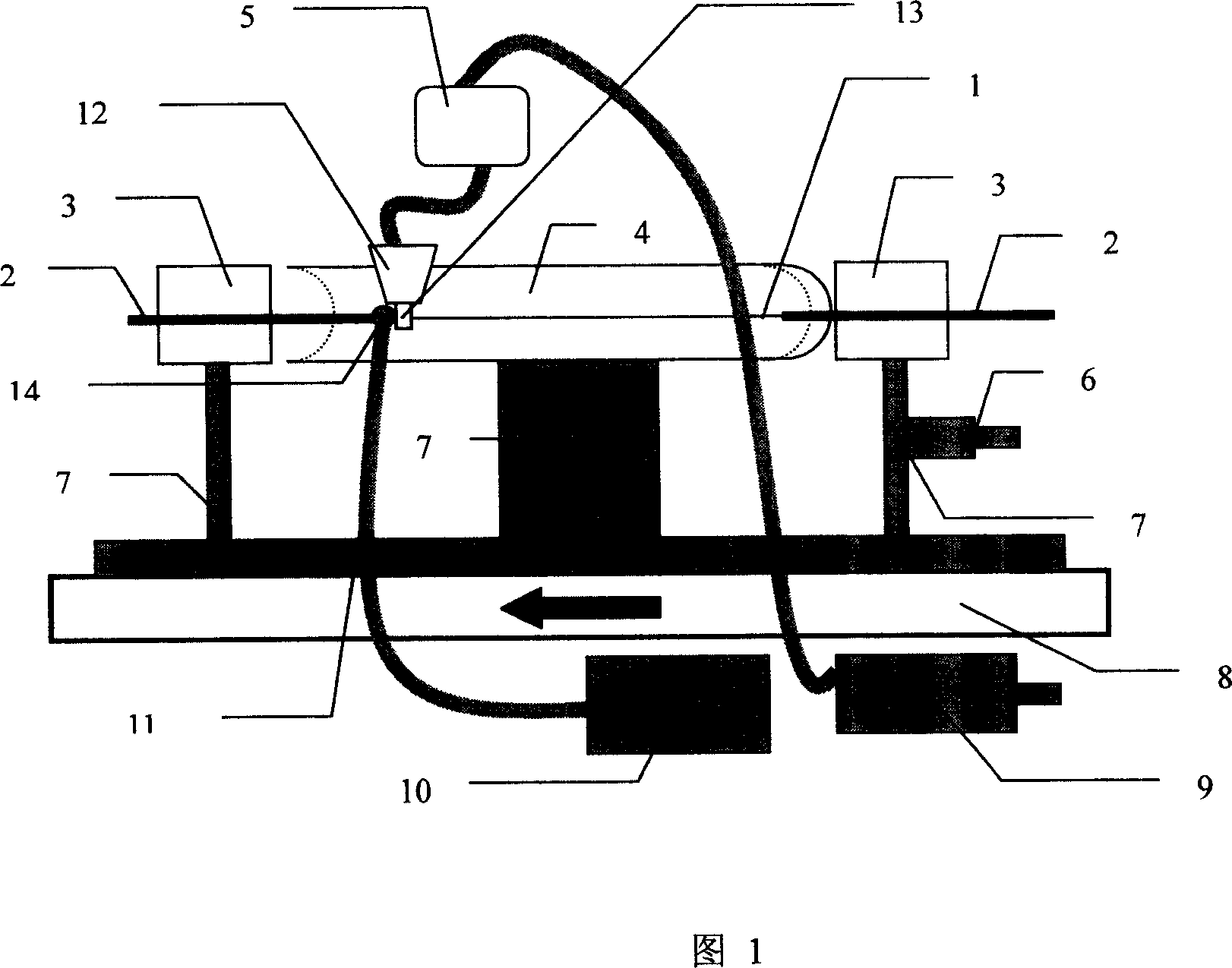

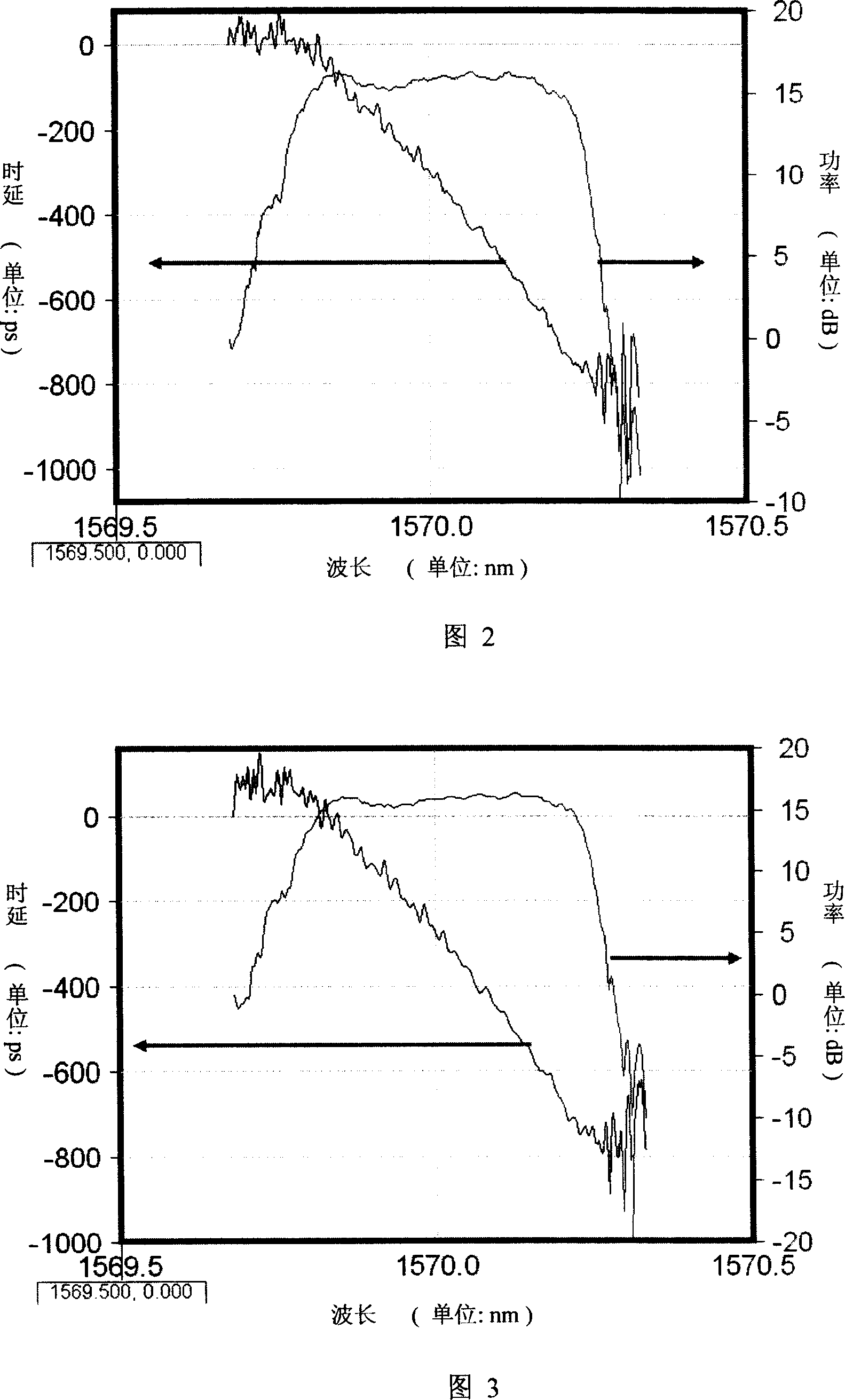

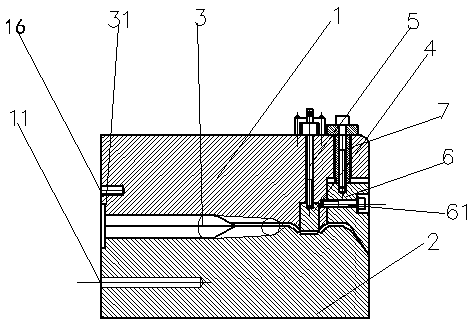

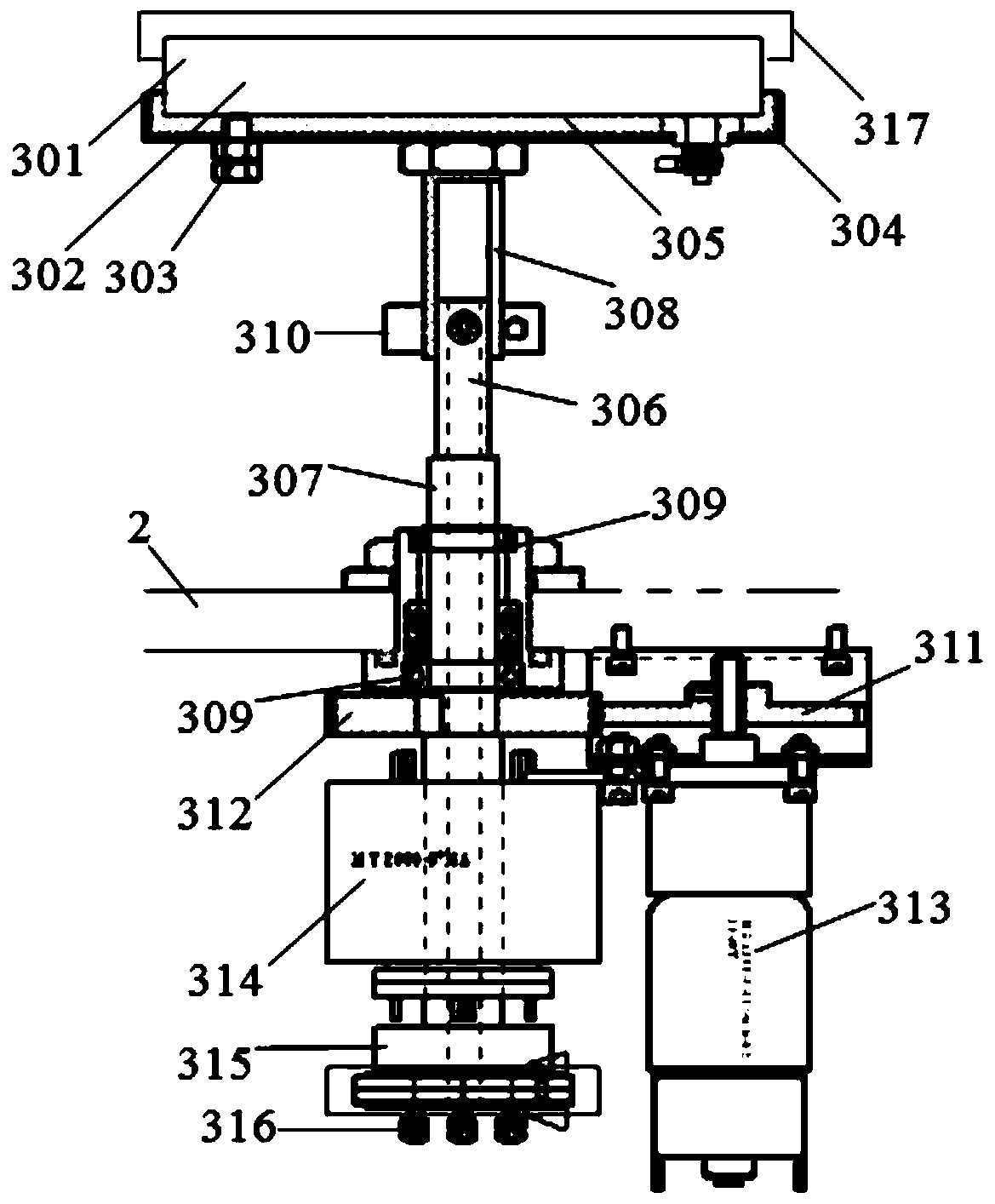

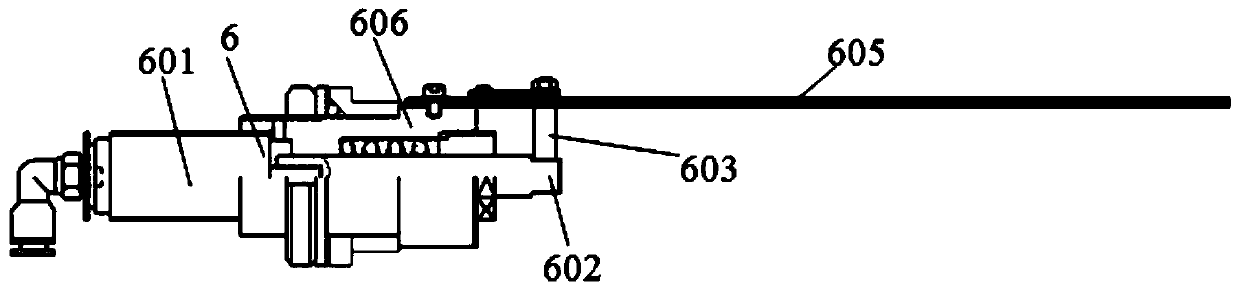

Coating apparatus and process for longoptic fiber grating

InactiveCN1986081AMeet coating requirementsCoating length adjustablePretreated surfacesCoatingsGratingFiber gratings

The present invention discloses coating apparatus and process for long fiber grating. The coating apparatus consists of high precision mobile platform, stress adjustable optical regulator, controllable coating material container, coating pliers, ultrasonic light source, reflector, etc. and has relatively low cost. The coating process includes shifting the high precision mobile platform, regulating the optical regulator, regulating the stress, controlled coating the fiber grating, and curing the coated layer with the precisely controlled ultrasonic light source. The present invention has adjustable coating length up to 200 mm, unchanged characteristic of the coated fiber grating and raised mechanical stress performance.

Owner:BEIJING JIAOTONG UNIV

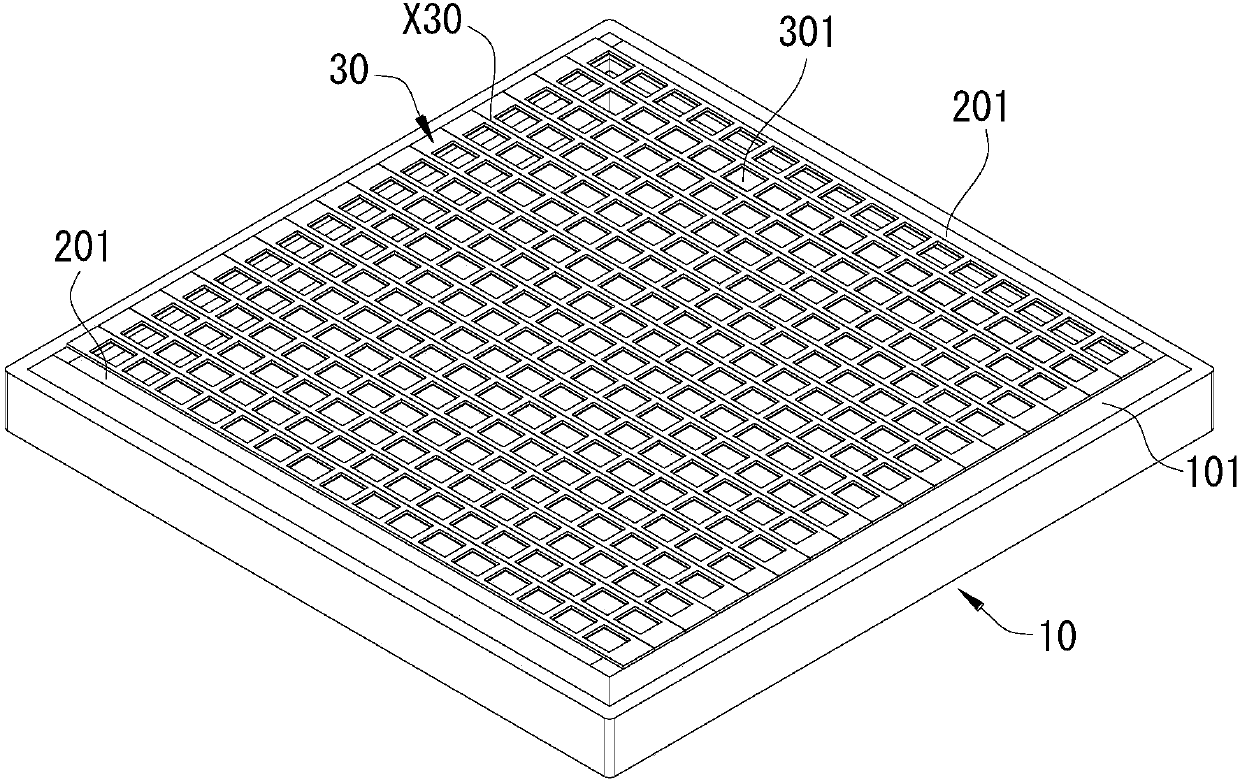

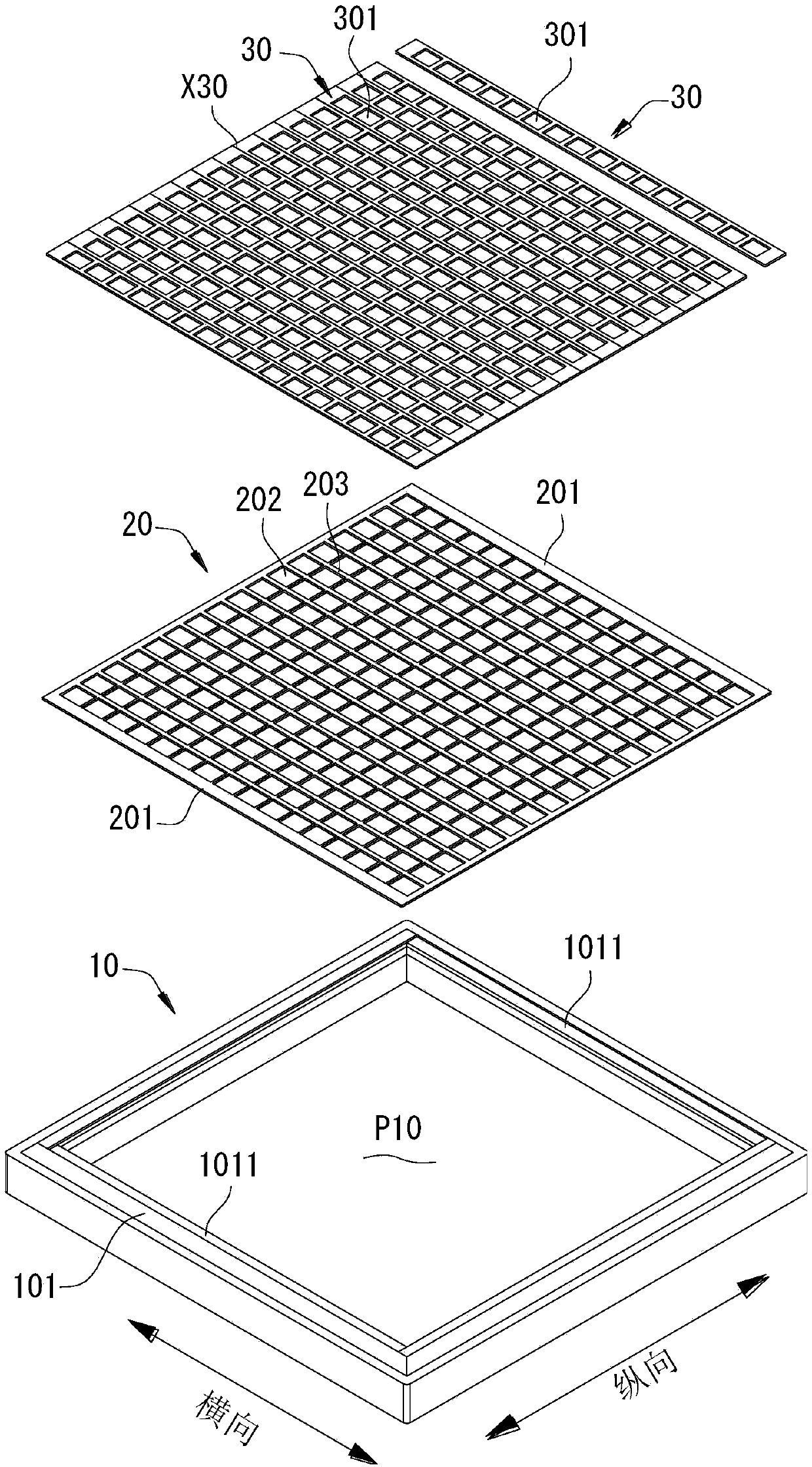

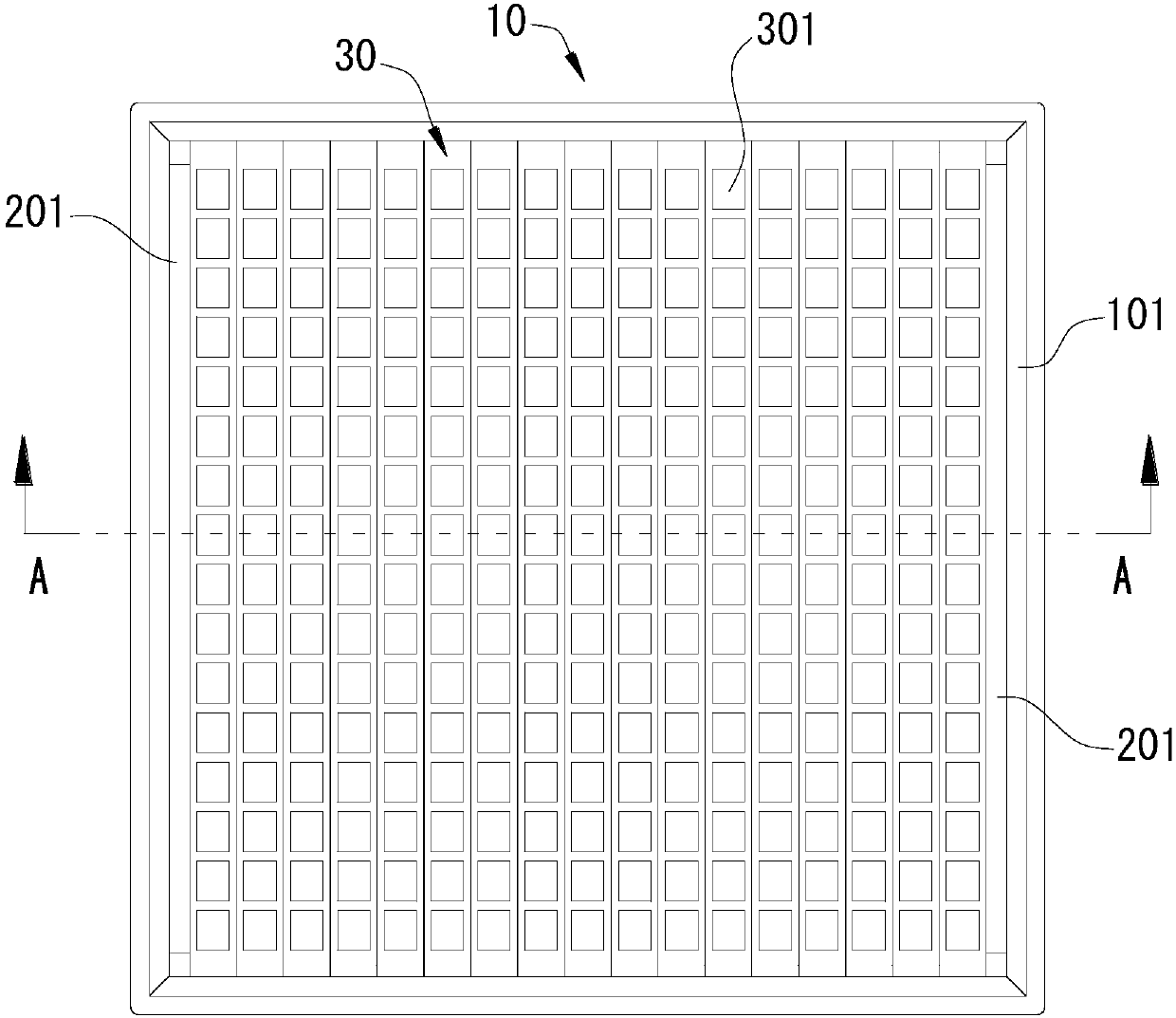

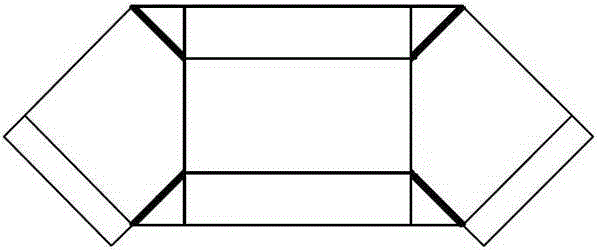

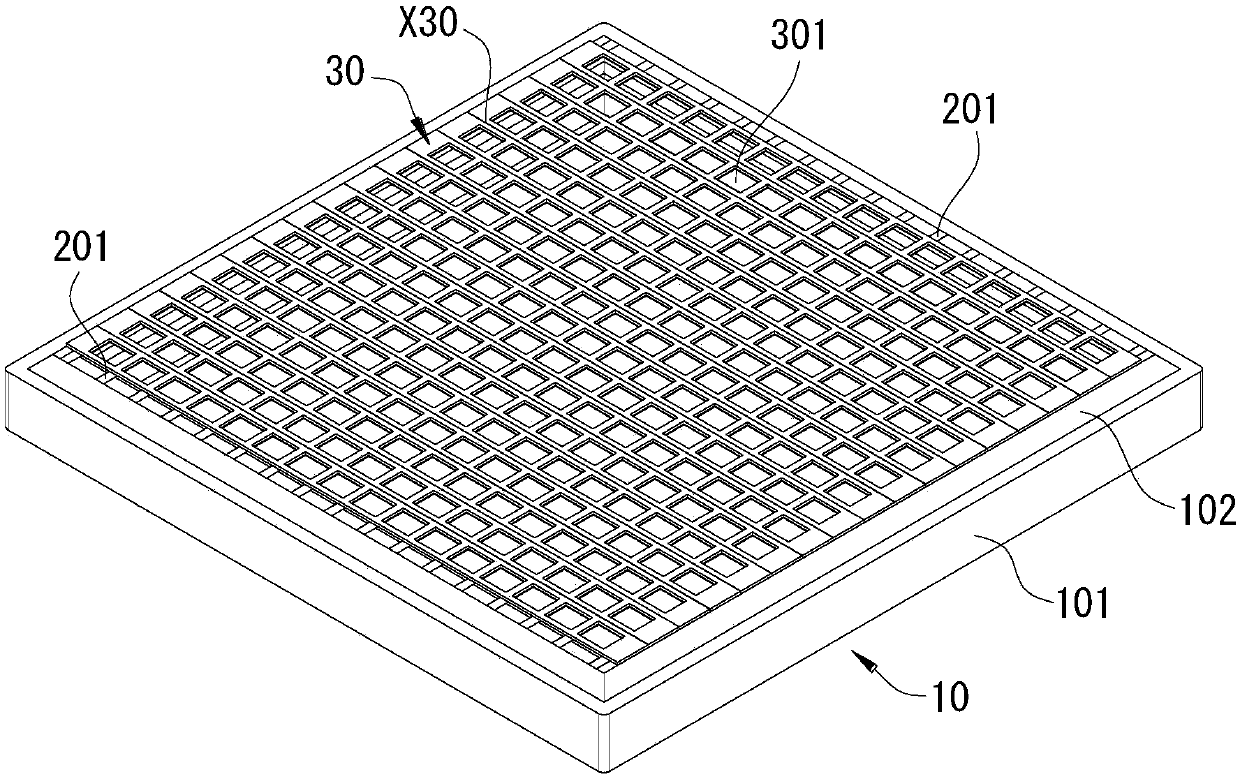

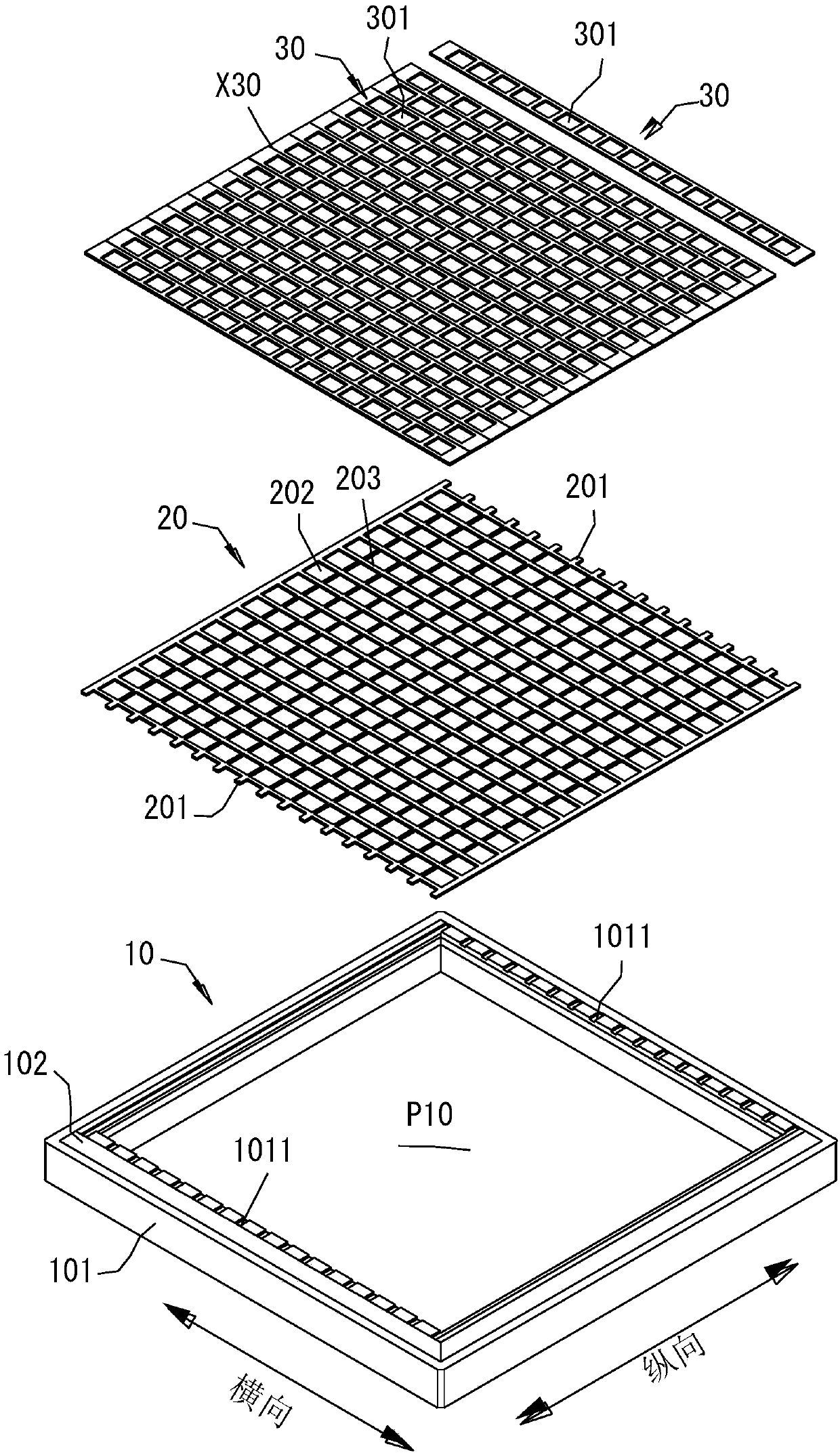

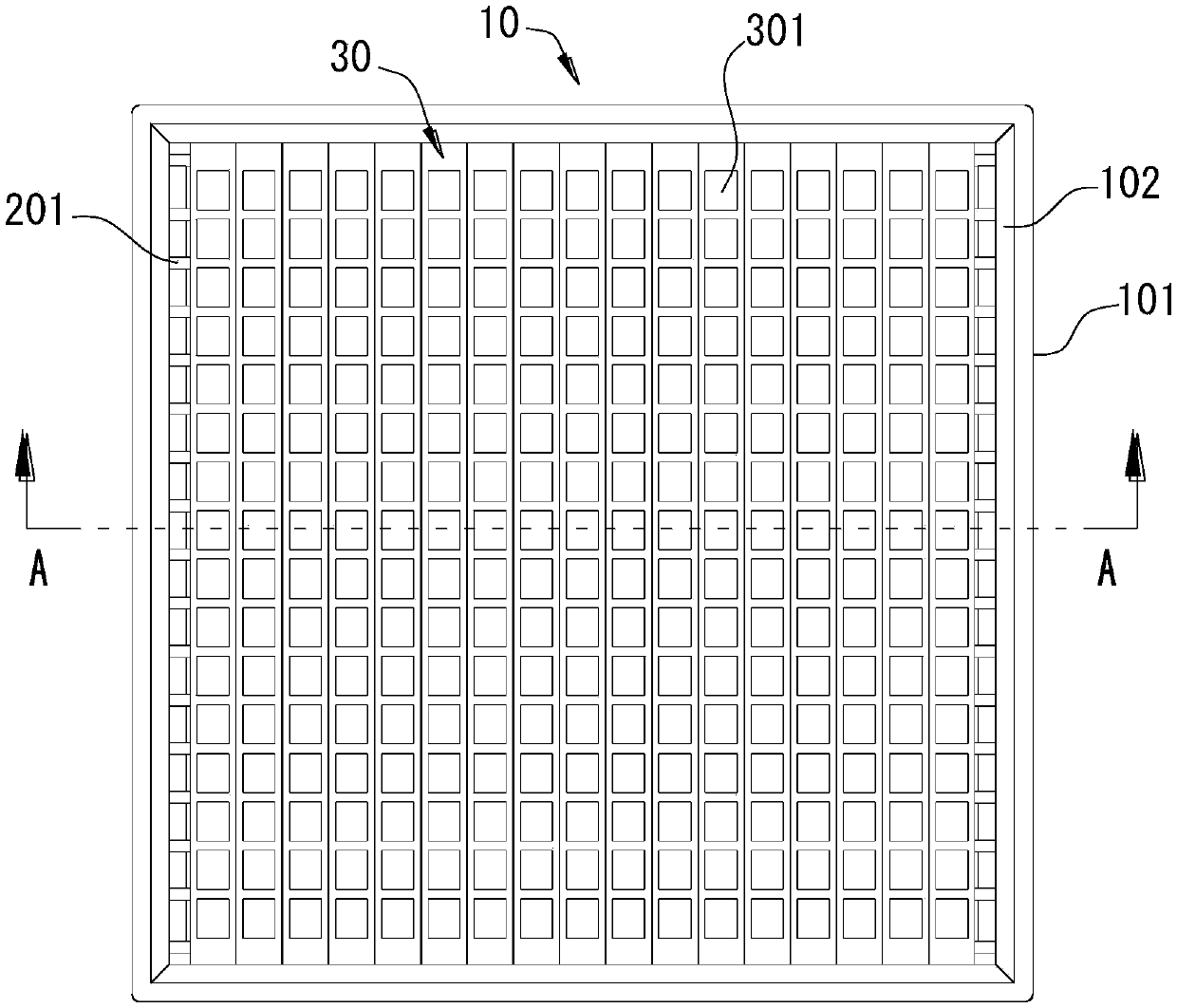

High-precision mask plate

PendingCN107815642AStable structureImprove yieldVacuum evaporation coatingSputtering coatingDisplay deviceStructural engineering

The invention discloses a high-precision mask plate which comprises a plate frame, multiple strip-shaped mask sheets and a supporting mask net. A hollow-out area is formed in the center of the plate frame. The periphery of the hollow-out area forms a frame edge. The top faces of two opposite edges on the plate edge are provided with strip-shaped grooves correspondingly. A spliced gap is formed between every two adjacent strip-shaped mask sheets. The two ends of each strip-shaped mask sheet are welded to the top faces of the other two opposite edges on the plate edge. Each strip-shaped mask sheet is provided with a mask pattern. The supporting mask net is located below the multiple strip-shaped mask sheets. The two opposite side edges on the supporting mask net extend to form welding edgescorrespondingly. The two welding edges are welded into two strip-shaped grooves correspondingly. The supporting mask net supports the multiple strip-shaped mask sheets and covers all the spliced gapswithout shielding all the mask patterns. According to the high-precision mask plate, the film coating requirement of a glass substrate with the large size can be met, batch production is achieved, theproduction efficiency is improved, and the requirements of a displayer for the yield and precision in the batch production process can also be met.

Owner:深圳浚漪科技有限公司

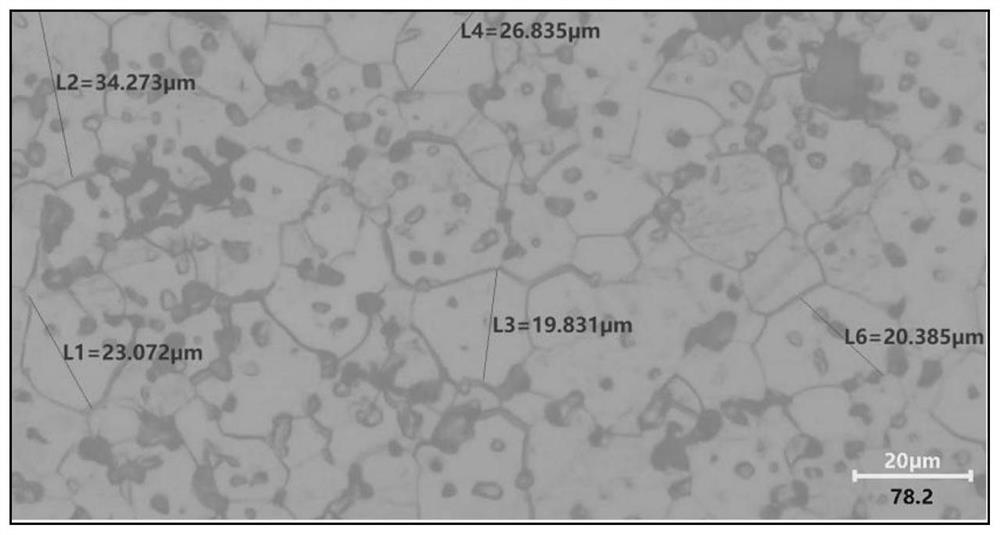

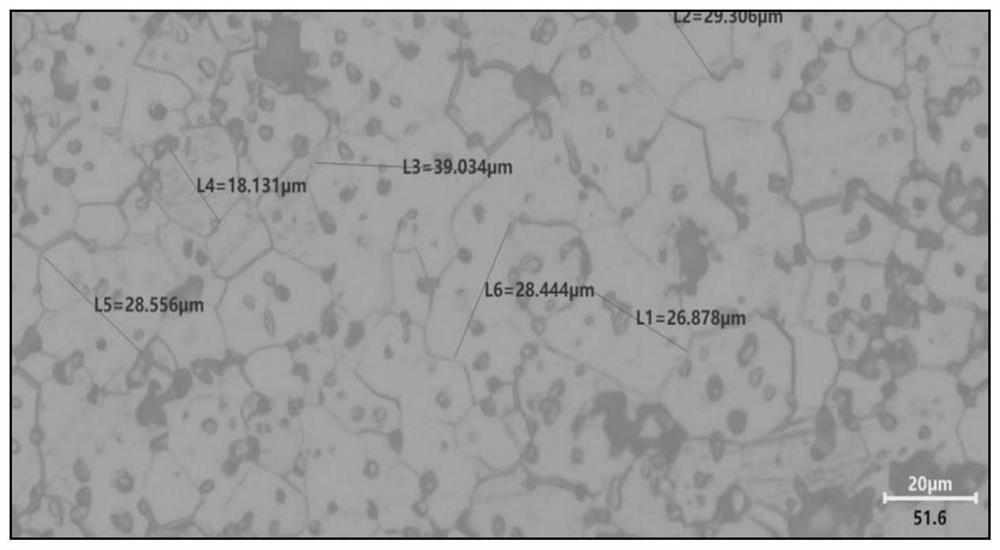

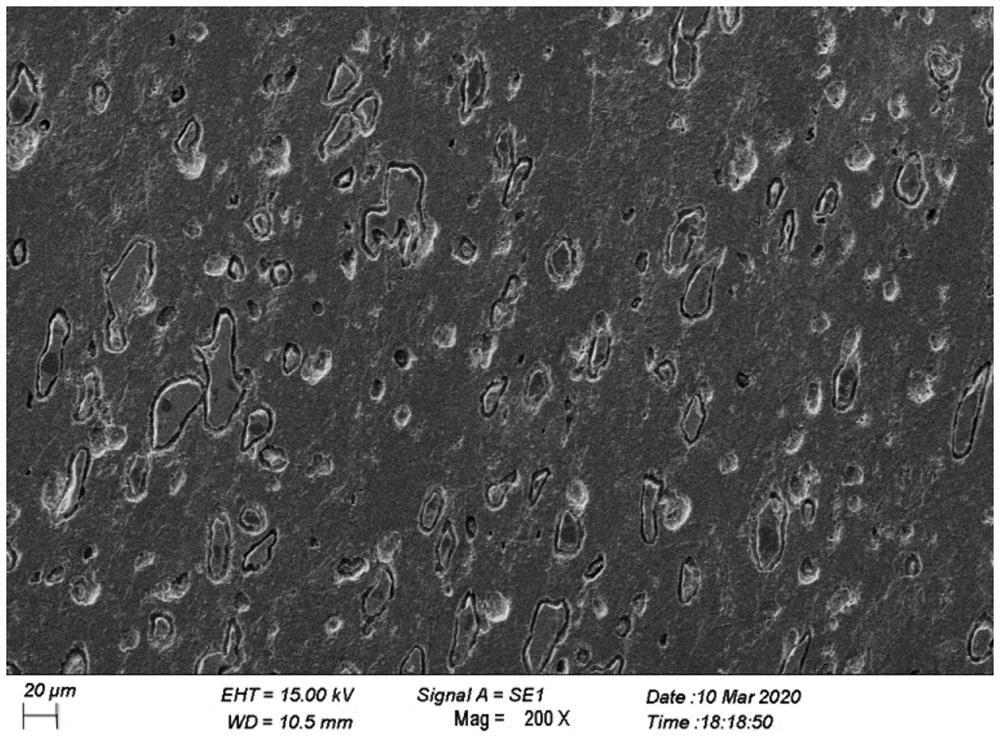

Molybdenum-nickel-based multi-element alloy rotary target material and preparation method thereof

ActiveCN113463053AImprove adhesionImprove antioxidant capacityNuclear energy generationVacuum evaporation coatingIngotTitanium

The invention discloses a molybdenum-nickel-based multi-element alloy rotary target material and a preparation method thereof. The atomic composition of the rotary target material is Mo100-x-y-zNixTiyAlz, X, Y and Z represent the atomic composition percentage, X is larger than or equal to 10 and smaller than or equal to 40, Y is larger than or equal to 1 and smaller than or equal to 20, and Z is larger than or equal to 1 and smaller than or equal to 18. The preparation method comprises the steps of mixing molybdenum powder, electrolytic nickel powder and titanium-aluminum pre-alloy powder in proportion, then carrying out deoxidation and purification treatment, ball milling and mixing, powder filling and compaction treatment, cold isostatic pressing forming, demolding, vacuum horizontal sintering, rotary swaging treatment and annealing treatment to obtain a molybdenum-nickel-titanium-aluminum alloy pipe ingot, and finally slicing the molybdenum-nickel-titanium-aluminum alloy pipe ingot through machining to prepare the molybdenum-nickel-titanium-aluminum alloy target material. According to the preparation method, introduction of impurity elements can be reduced in the preparation process, the produced target material is uniform in component, free of segregation and fine in grain, the density can reach a theoretical value of 99% or above, and the coating requirement of a current large-size sputtering target material can be completely met.

Owner:NANJING DAMAI SCI&TECH IND CO LTD

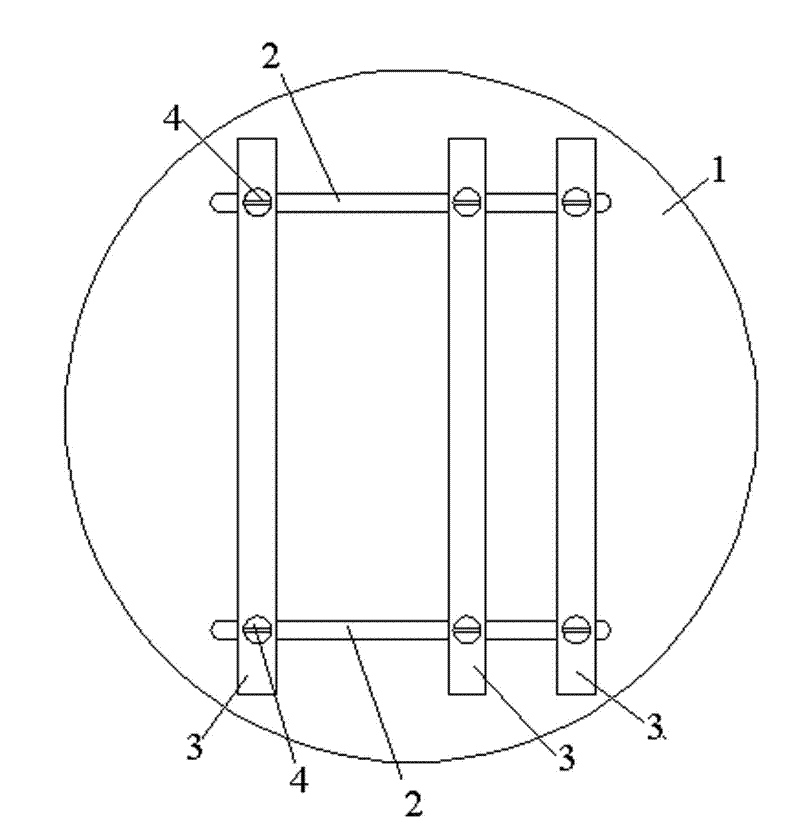

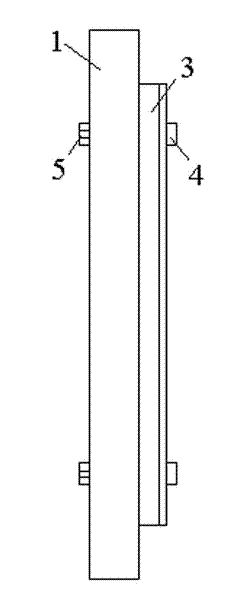

Multifunctional substrate frame for vacuum coating equipment

InactiveCN102330065AMeet coating requirementsEasy to installVacuum evaporation coatingSputtering coatingOptical thin filmEngineering

The invention discloses a multifunctional substrate frame for vacuum coating equipment, which comprises a mounting disk and at least two mounting bars, wherein two long strip sliding chutes are arranged on the mounting disk in parallel; the mounting bars are provided with two mounting holes; and the central distance between the two mounting holes is the same as that between the two sliding chutes. According to the substrate frame disclosed by the invention, the mounting requirements on coating an optical thin film in the vacuum coating and coating substrates with different sizes and shapes in other vacuum coating equipment can be met. The invention has the beneficial effects that the waste of designing and processing the substrate frame in the vacuum coating can be greatly reduced, the research periods of different products are shortened, and the like, and batch coating can be realized.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

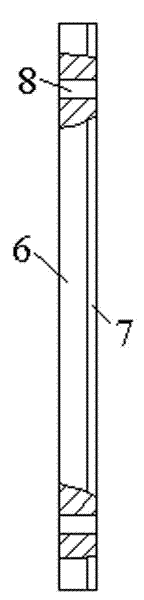

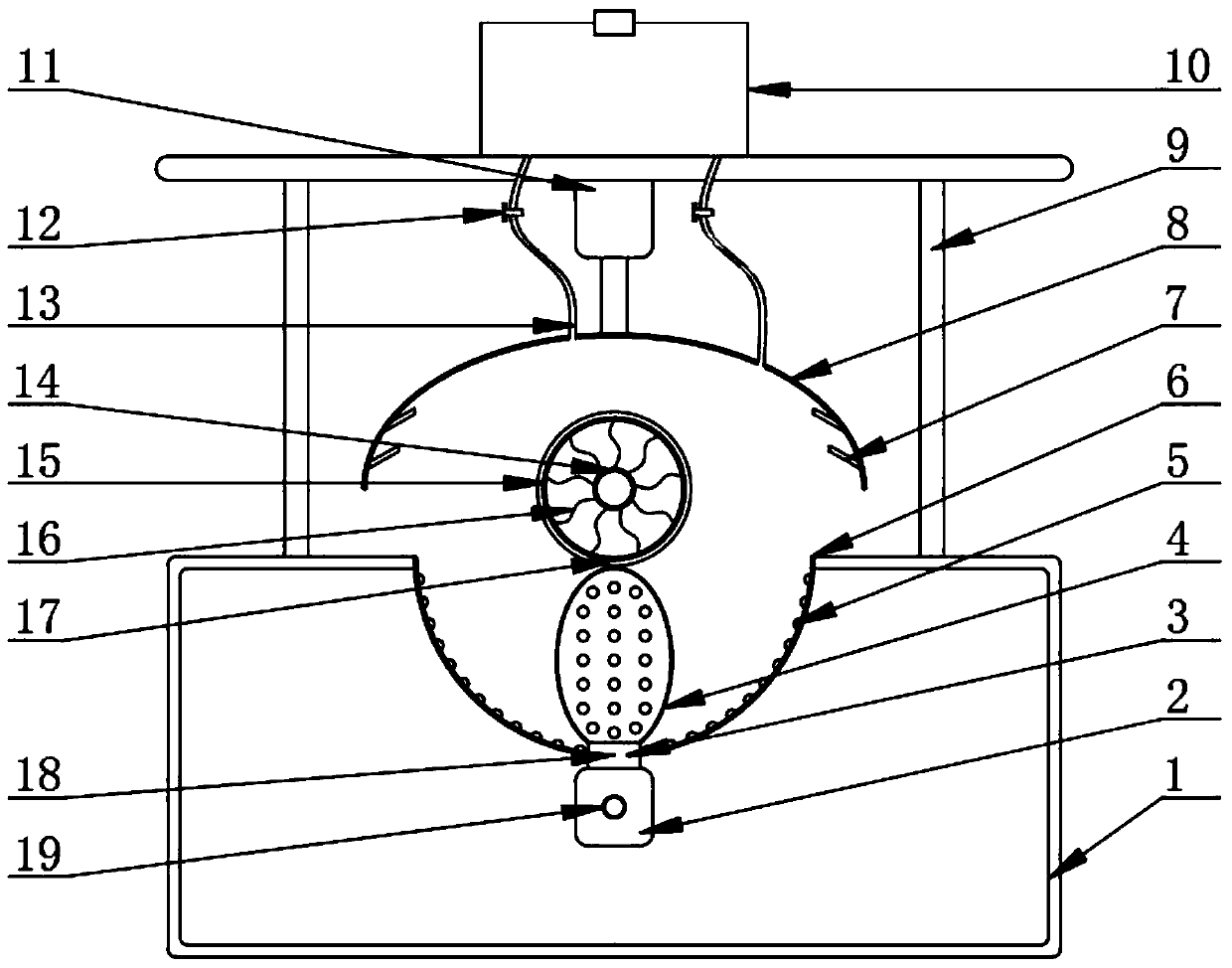

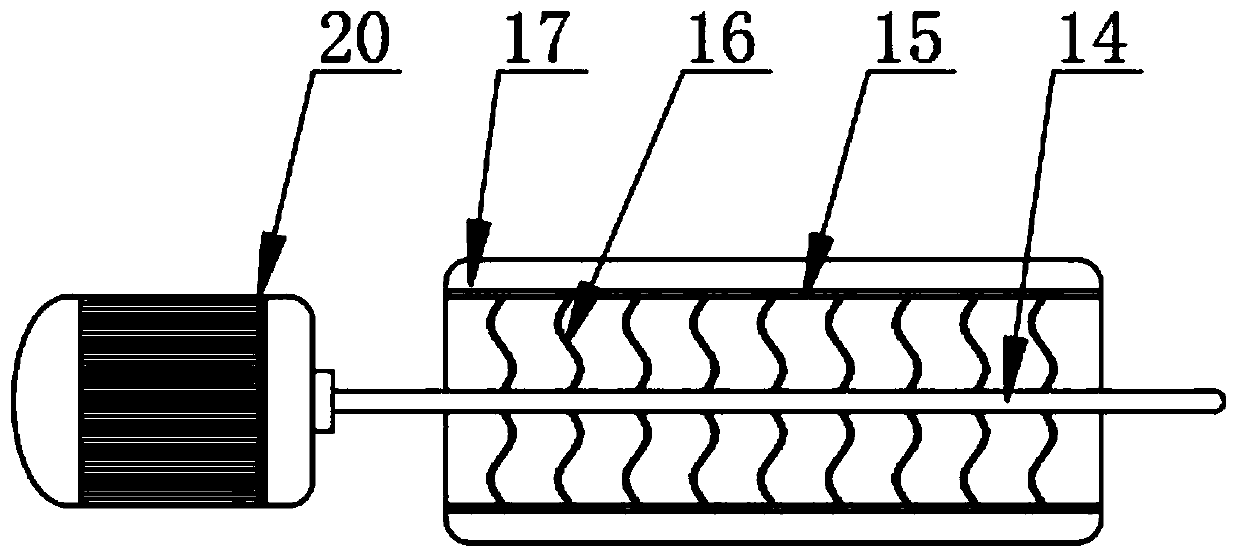

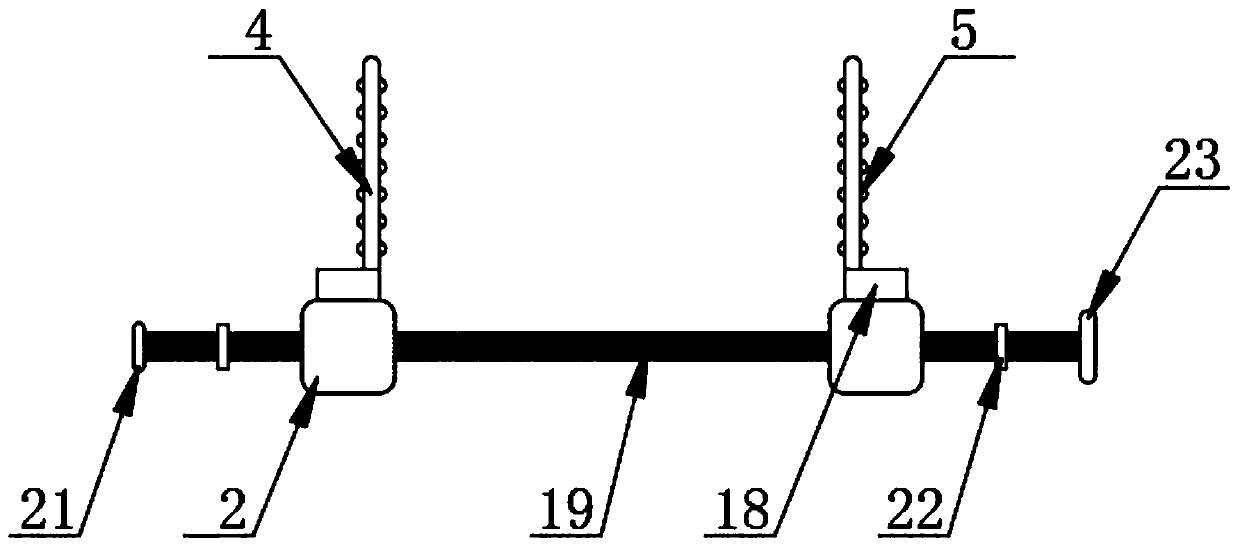

Anti-frost-crack hard downpipe and processing technology thereof

InactiveCN111592723AImprove low temperature resistanceGood anti agingLiquid surface applicatorsChloropene polymer coatingsPhosphorous acidNanoparticle

The invention discloses an anti-frost-cracking hard downpipe and a processing technology thereof. The anti-frost-cracking hard downpipe comprises an inner pipeline layer and an outer composite coating; the inner pipeline layer is prepared from, by weight, 90 parts of PVC resin, 25 parts of PVDF resin, 5 parts of triphenyl phosphite, 5 parts of vinyl tert-butyl triperoxide silane, 2 parts of zinc oxide nanoparticles, 2 parts of aluminum nitride nanoparticles and 2 parts of silver nanowires. The outer composite coating is uniformly attached to the inner pipeline layer, and the anti-frost-crack hard downpipe is manufactured according to different functions of the outer composite coating and the inner pipeline layer, so that the anti-frost-crack hard downpipe has the characteristics of excellent low temperature resistance, ageing resistance and high strength; and the inner pipeline layer is evenly coated with the outer coating, and the clamping distance can be adjusted at will according tothe inner pipeline layers different in size, length and size to meet the coating requirement, so the situation that the inner pipeline layers deviate and incline obliquely is avoided, and the coatinguniformity and the machining quality of the whole pipeline are improved.

Owner:安徽英标新材料科技有限公司

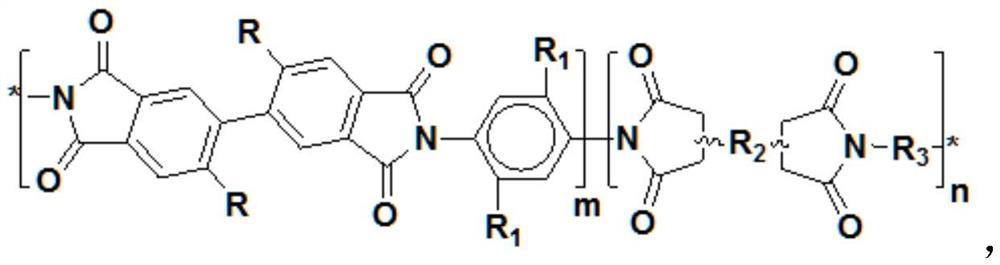

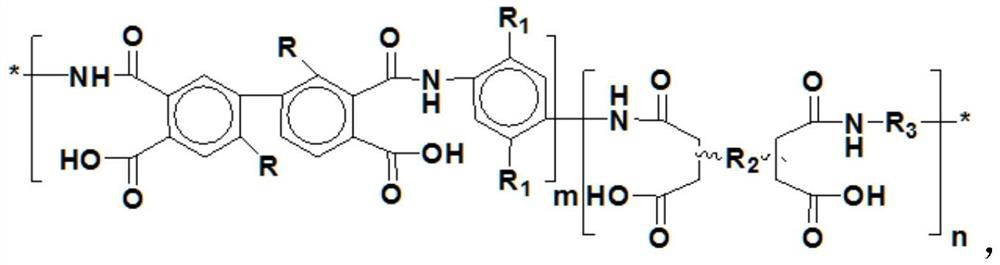

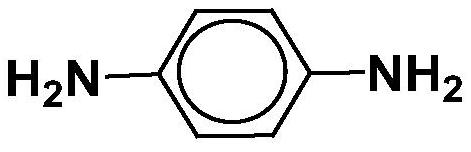

Modified polyamide acid resin slurry and preparation method thereof, and adhesive-free copper-clad plate

PendingCN111961202AModerate viscosityMeet coating requirementsSynthetic resin layered productsElectrical equipmentPolymer sciencePolyamide

The invention discloses a modified polyamic acid resin slurry, which has the characteristics of proper viscosity, good leveling coating performance, strong adhesion and the like, and is wide in raw material source range, low in cost and suitable for large-scale production. According to the invention, the adhesive-free copper-clad plate prepared from the modified polyamic acid resin slurry and a copper foil has excellent dielectric properties, low hygroscopicity and dimensional stability, can meet the specification requirements of a high-frequency flexible printed circuit board on a copper-cladplate, and improves the quality of the circuit board; and more importantly, an adhesive-free copper-clad plate prepared from the modified polyamide acid resin slurry and a copper foil has a great cost advantage. The invention also discloses a preparation method of the modified polyamide acid resin slurry.

Owner:ZHONGSHAN POLYTECHNIC

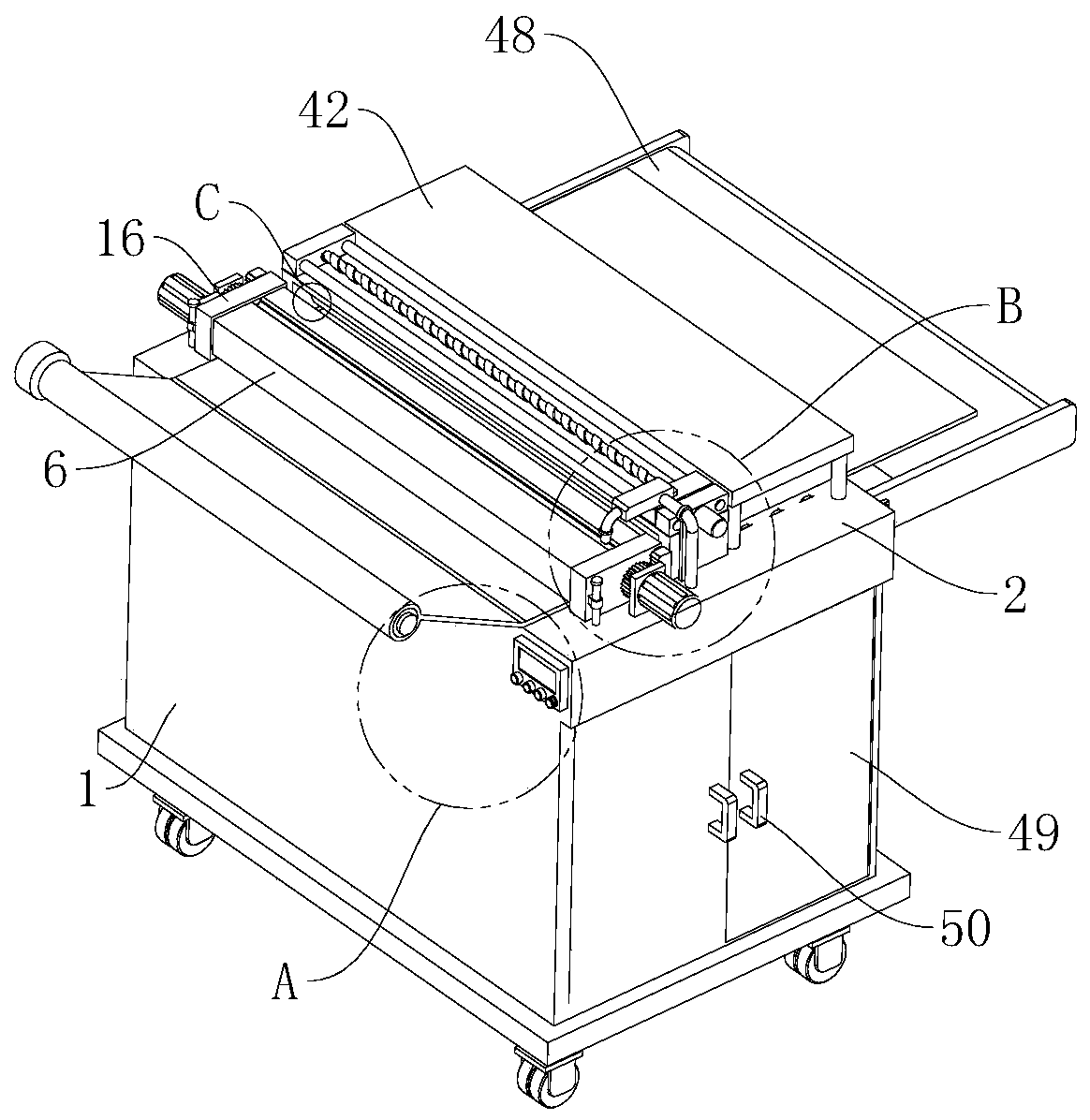

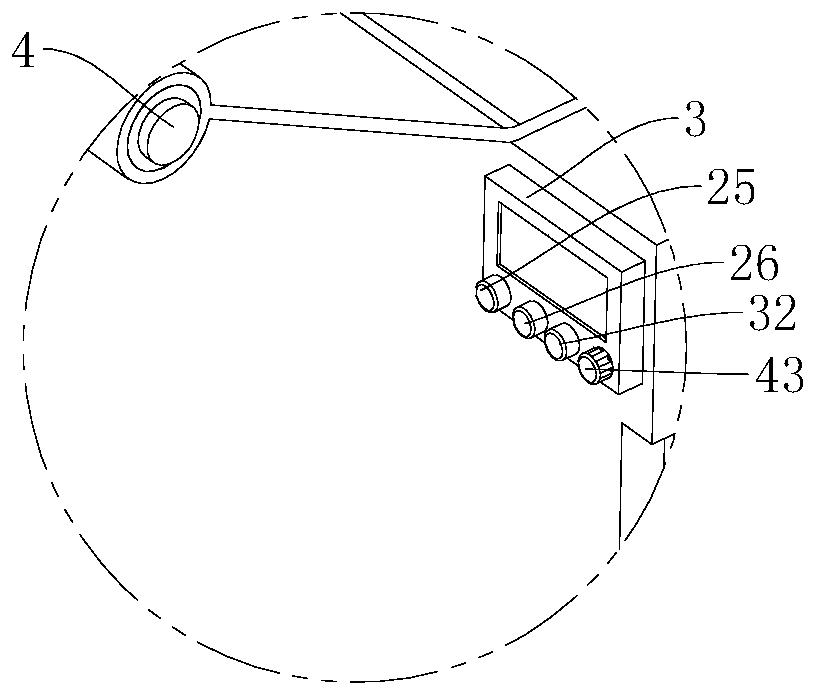

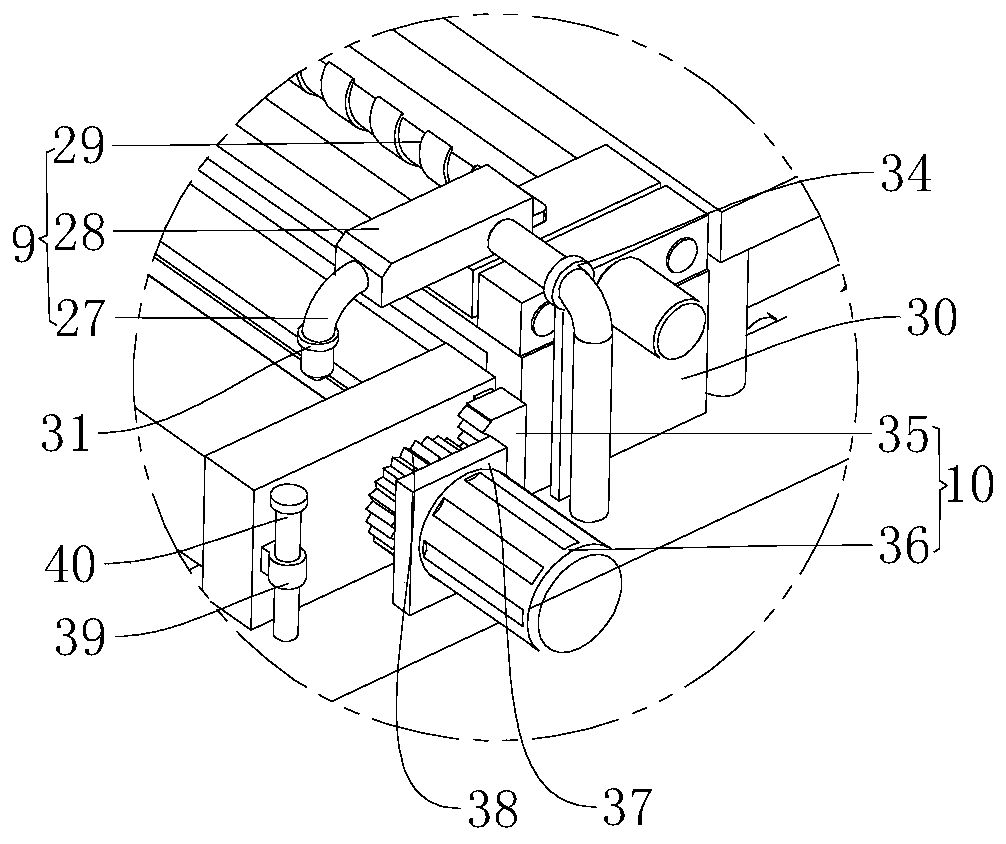

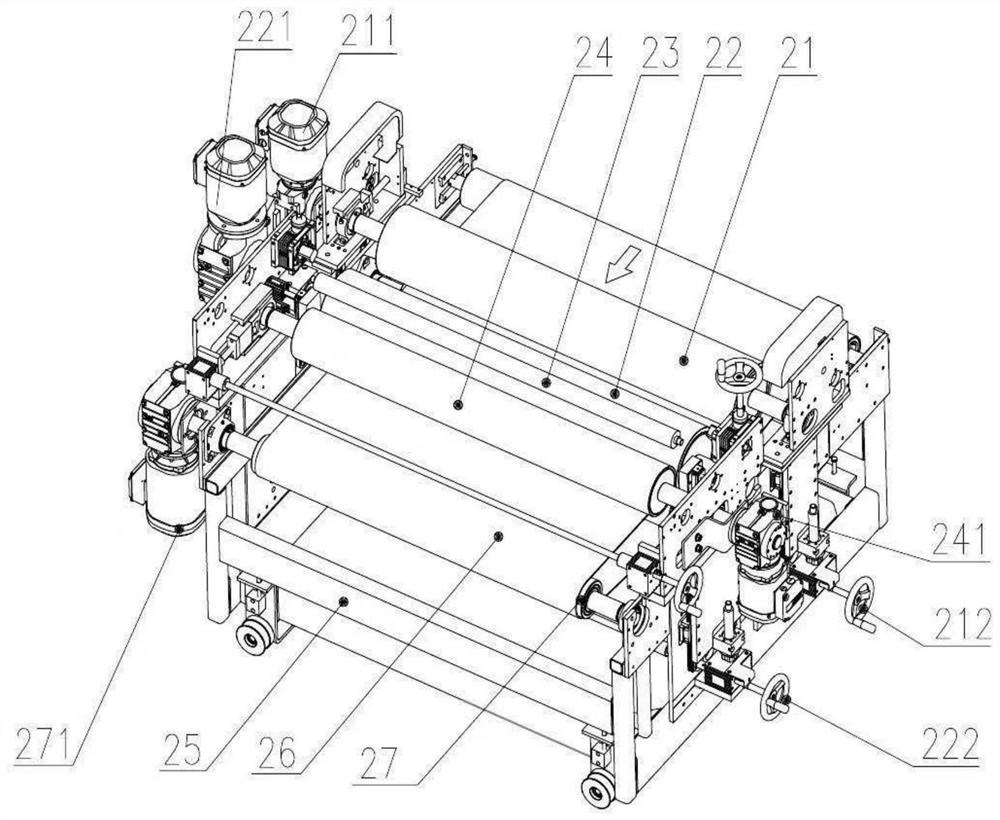

Coiled material type base material laminating production equipment

The invention relates to the technical field of laminating, in particular to coiled material base material laminating production equipment. The equipment comprises a case body and universal wheels, wherein the case body is vertically arranged; the equipment further comprises a controller, a feeding mechanism, a laminating mechanism and a drying mechanism. The feeding mechanism comprises a sleeve rod and a feeding assembly. The laminating mechanism comprises a gluing roller, a supply assembly, a spraying assembly and two height adjusting assemblies. The drying mechanism comprises a drying assembly and three conveying assemblies. The supply assembly, the spraying assembly and the drying assembly are all electrically connected with the controller According to the invention, the production equipment is simple in structure, convenient to use, small in occupied space and high in laminating speed, the height adjusting assemblies are designed, the laminating requirements of coiled material type base materials with different thicknesses can be met, the designed knob switch and the electric heating plate are used in cooperation, the laminating effect is remarkably improved, and meanwhile thebase materials cannot be scalded.

Owner:丽水俊翔信息技术有限公司

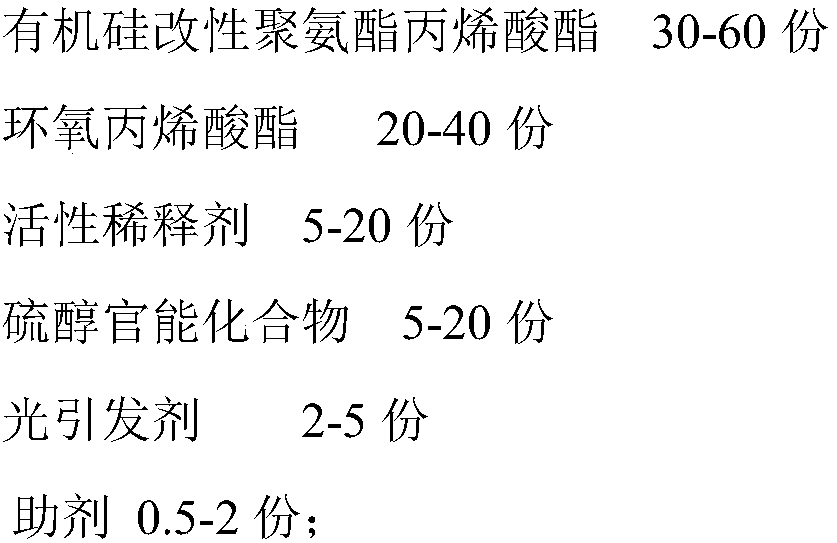

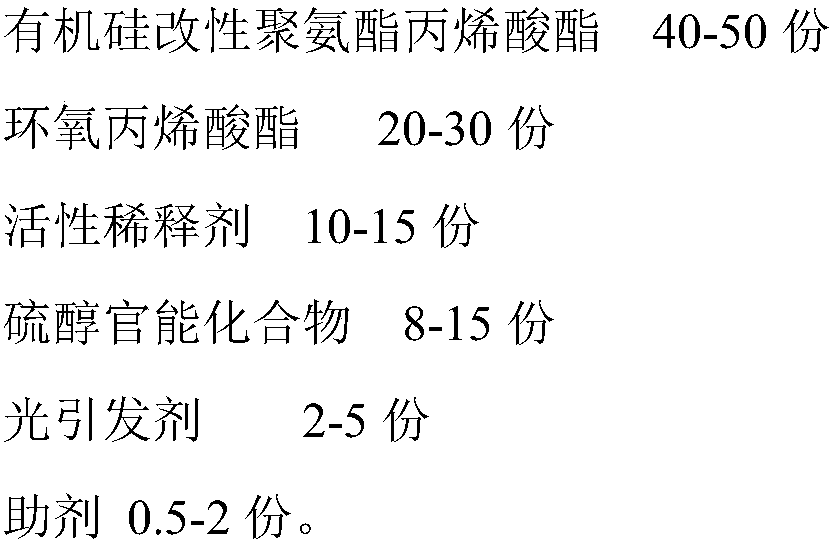

Coating system applied to surface of plastic substrate and plastic product prepared by coating system

ActiveCN108441110AIncreased durabilityMeet coating requirementsPolyurea/polyurethane coatingsEpoxy resin coatingsWear resistantCoating system

The invention discloses a coating system applied to the surface of a plastic substrate. The coating system comprises a UV curing primer and a wear-resistant protective PVD coating, wherein the UV curing primer comprises: 30-60 parts of organosilicone-modified urethane acrylate, 20-40 parts of epoxy acrylate, 5-20 parts of a reactive diluent, 5-20 parts of a thiol functional compound, 2-5 parts ofa photoinitiator, and 0.5-2 parts of an addition agent; the wear-resistant protective PVD coating is a TiaX(1-a)CrNsOt coating, wherein X represents Si or / and Al; a is greater than or equal to 0.5 andsmaller than 1; the sum of r, s and t is 1; and the thickness of the coating is between 0.5 microns to 5 microns. The surface of a plastic product prepared by the coating system has metallic luster,and the coating is good in adhesive force, excellent in durability, excellent in wear resistance and scratch resistance, and suitable for packaging products, craft decorations, electronics, home appliances and automobile industries and the like.

Owner:深圳市正和忠信股份有限公司

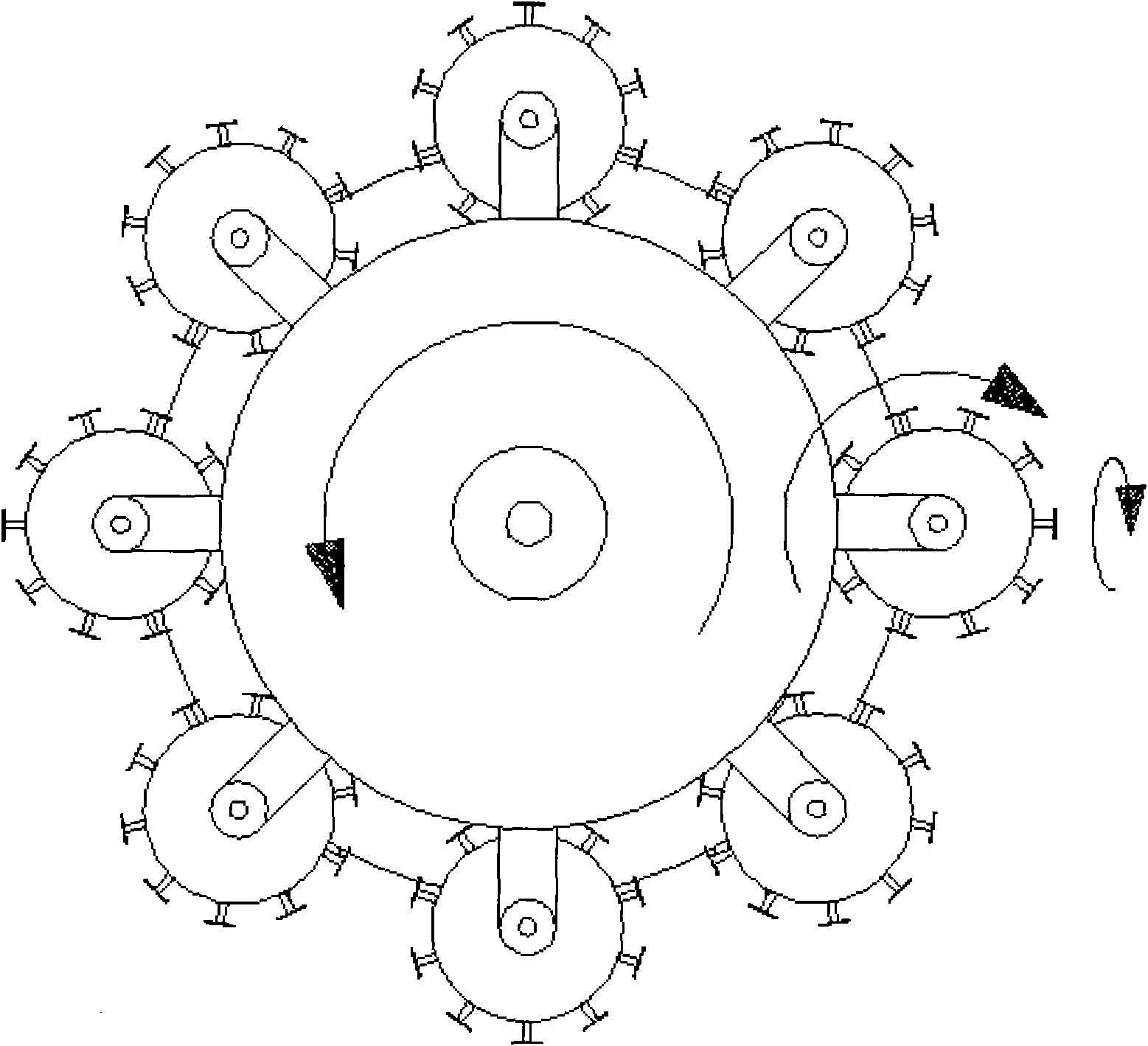

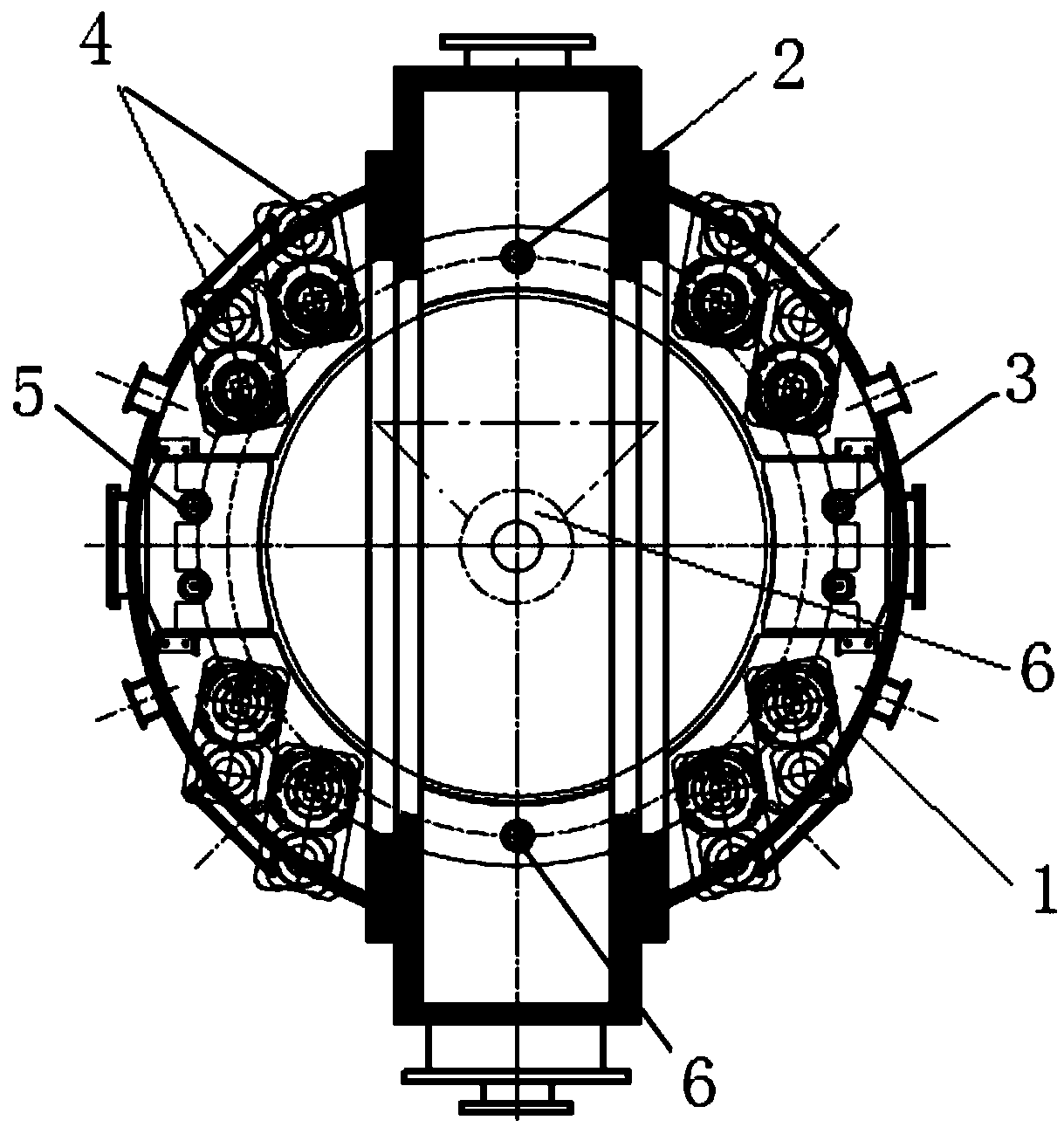

Vacuum magnetron sputtering color plating equipment

ActiveCN101988187AImprove technical levelAdvanced technologyVacuum evaporation coatingSputtering coatingSputteringEngineering

The invention discloses vacuum magnetron sputtering color plating equipment. In order to remove a shadow region of a complex-shaped product during film formation and improve the surface film forming uniformity of the product, on one hand, the revolution and rotation of a workpiece are finished by a suspension rod with a planetary gear structure; and on the other hand, symmetrical compensating inclined targets are arranged between columnar magnetron targets on upper and lower sides of a sample suspending rack (8). Because the sample rack loads bias pressure, a magnetron target filming material can be deposited on a product substrate in multiple directions. By combining the multifunctional sample suspending rack and the compensating inclined targets, a film-coating dead angle can be effectively removed, the film forming quality is improved, and the complex-shaped product substrate can be plated.

Owner:沈阳科友真空技术有限公司

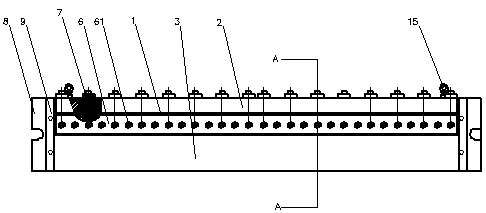

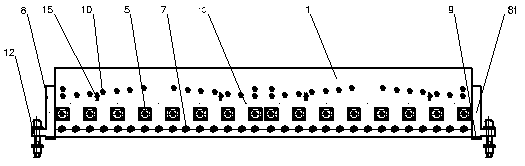

Wide-width whole-core fire-retardant conveyor belt rubber double-sided double-coat-hanger runner coating mould

InactiveCN108544731AMeet coating requirementsMeet the requirements of the required amountTemperature controlConveyor belt

The invention discloses a wide-width whole-core fire-retardant conveyor belt rubber double-sided double-coat-hanger runner coating mould. The mould is composed of two sets of symmetrically-arranged extruder mould units. Each mould unit comprises an upper mould block, a lower mould block, side fenders, thickness mould strips and the like. The coating mould is characterized in that the upper mould blocks and the lower mould blocks are connected through mould block bolts, the side fenders are mounted on the two sides, double-coat-hanger molding cavities are formed in the middles, and two feed inlets are formed; flow choking bars, flow choking bar regulating mechanisms, lips and lip regulating mechanisms are arranged on the upper mould blocks correspondingly; the upper mould block, the lower mould block and the side fenders are provided with hot oil circulation temperature control runners correspondingly; the thickness mould strips are mounted on the two sides of the lips of the mould; andthe two sets of mould units are connected through mould connecting bolts. According to the coating mould, by means of the technical means including the double feed inlets, the double-coat-hanger runners, the adjustable flow choking bars, the adjustable lips and the like, the sufficient rubber extruding amount and the excellent uniform pressure condition are guaranteed, wide-width whole-core fire-retardant conveyor belt rubber with the width being 2000-3600mm can be fast extruded, diluted, pressed uniformly and coated, and the variety range and application range of PVC / PVG whole-core fire-retardant conveyor belts are expanded.

Owner:马润秋

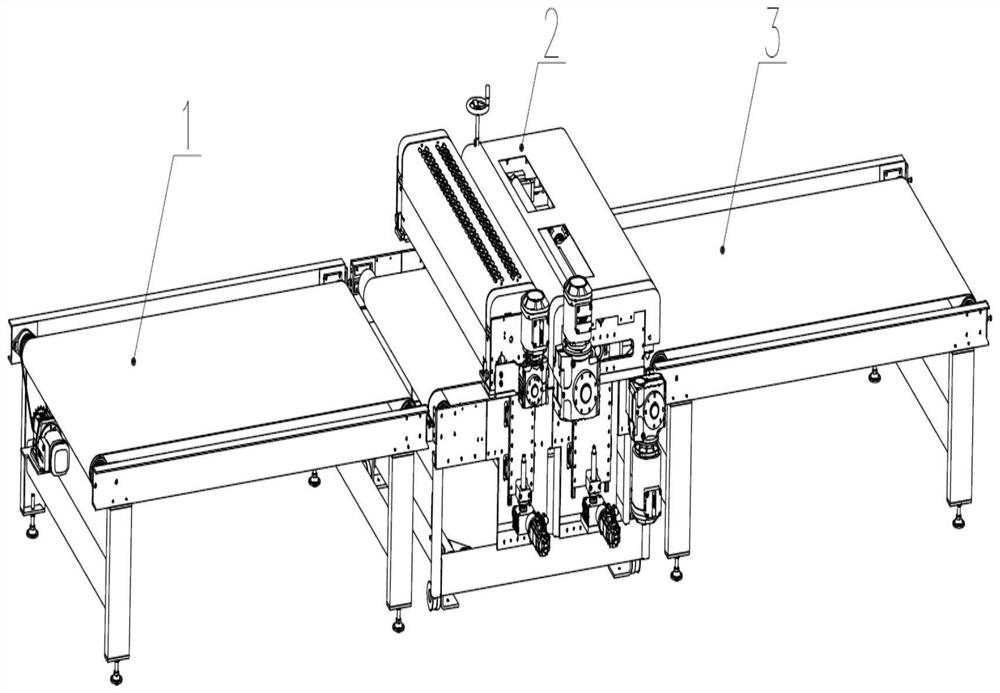

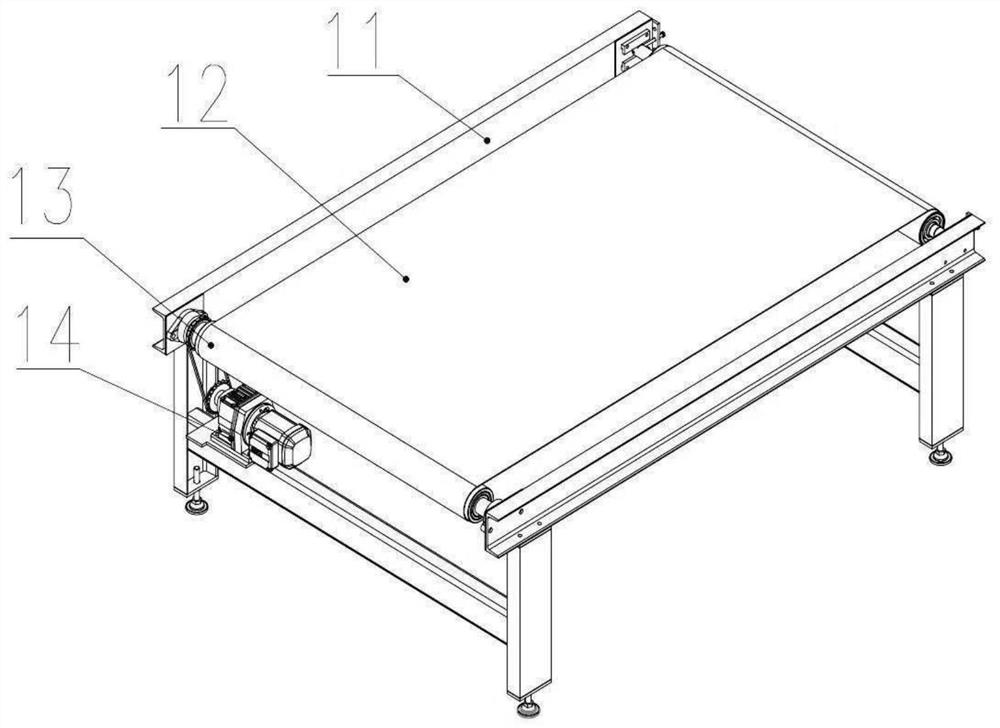

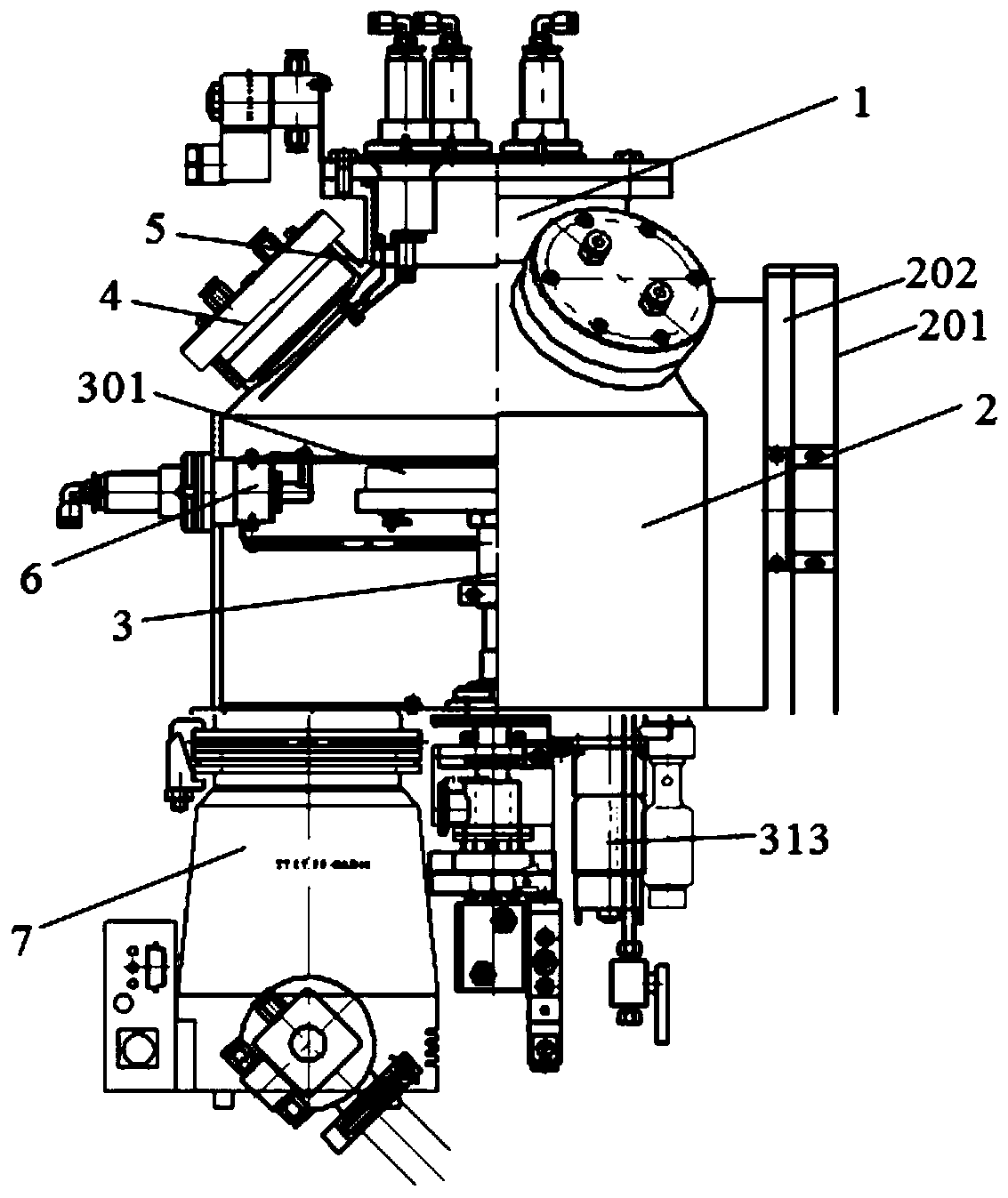

Coating machine for anti-reflection film of photovoltaic glass

The invention discloses a coating machine for an anti-reflection film of photovoltaic glass, belonging to the technical field of deep processing of glass. The coating machine comprises: a front belt conveying device; a rear belt conveying device; and a coating machine host, which is arranged between the front belt conveying device and the rear belt conveying device, wherein the coating machine host comprises a material pressing roller, a coating roller, a grain removing roller, a quantifying roller, a rack, a first belt and a middle belt conveying device, a first driven roller and a first driving roller are rotatably arranged on the rack, the first belt is wound on the first driven roller and the first driving roller, the two ends of the first belt are in transmission connection with the first driven roller and the first driving roller respectively, a first motor is installed on the rack, and the first motor is in transmission connection with the first driving roller. When the coating machine is in use, the coating machine has the advantages of optimized structure, high stability, high control precision, high production efficiency, high uniformity, low equipment cost, easy process control and capability of realizing continuous production.

Owner:CHINA TRIUMPH INT ENG

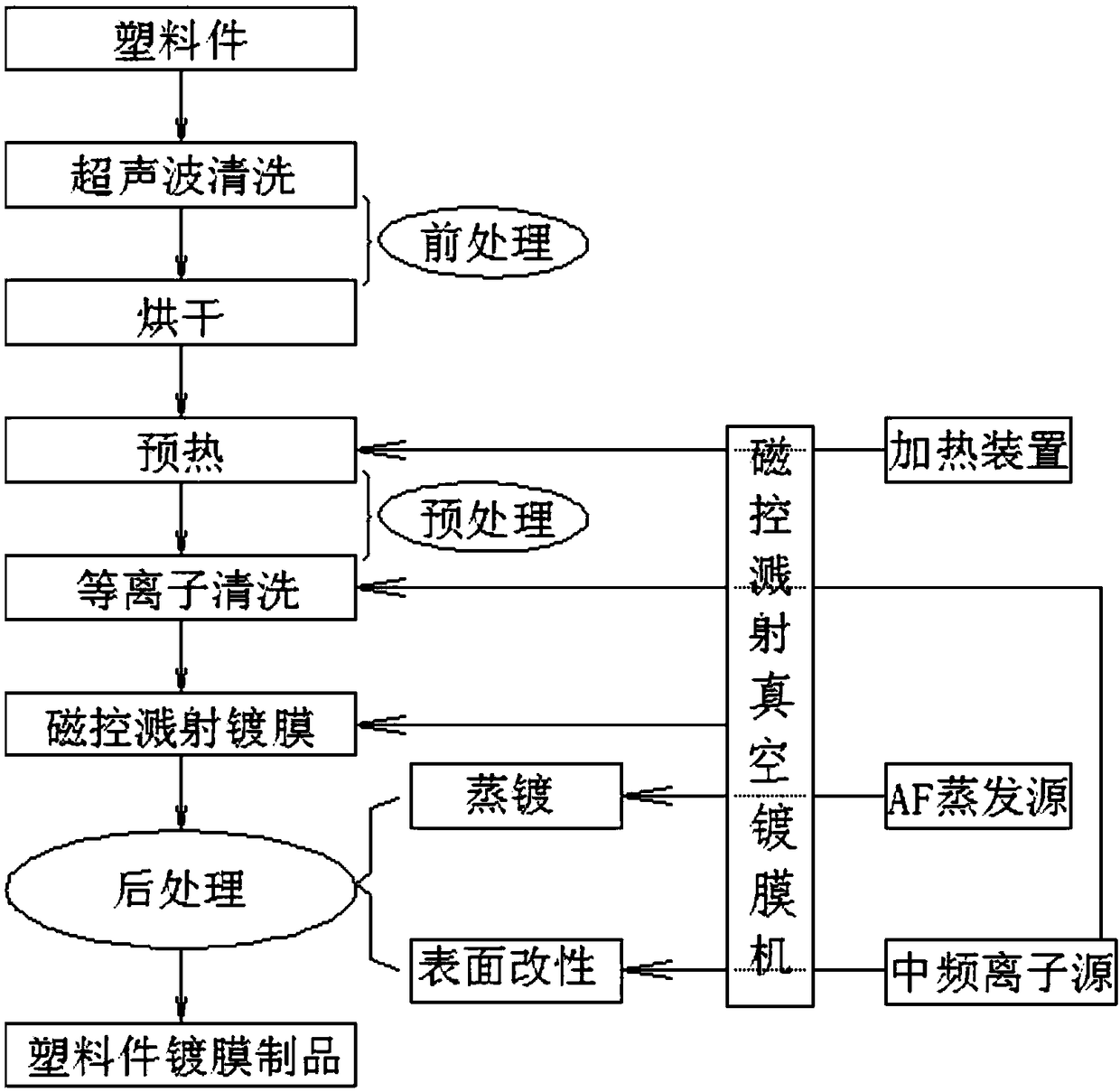

Process for magnetron sputtering film plating on surfaces of plastic parts

ActiveCN109338320ACompact structureIncrease productivityVacuum evaporation coatingSputtering coatingSputteringMedium frequency

The invention relates to the technical field of plastic film plating, and discloses a process for magnetron sputtering film plating on the surfaces of plastic parts. The process comprises the steps of(1) pretreatment of the plastic parts, (2) magnetron sputtering film plating of the plastic parts and (3) aftertreatment of the plastic parts, wherein the steps of pretreatment of the plastic parts,magnetron sputtering film plating of the plastic parts and aftertreatment of the plastic parts are all performed on the same magnetron sputtering vacuum film plating machine; the magnetron sputteringvacuum film plating machine comprises a vacuum cavity; and the vacuum cavity is provided with a heating device for preheating the plastic parts, a medium-frequency ion source module for vacuum plasmacleaning or surface modification of the surfaces of the plastic parts, a twin rotating magnetron target for magnetron sputtering film plating of the plastic parts, and an evaporation module for evaporation. The process overcomes the defects in a traditional plastic part surface spraying process, increases the adhesion of film layers of the plastic parts after film plating, and improves the film plating quality.

Owner:JIANGYIN GUANGKE PHOTOELECTRIC PRECISION EQUIP CO LTD

Production technology for dynode shell

InactiveCN105206486AMeet coating requirementsImprove performanceVessels or leading-in conductors manufactureEngineeringSecondary electrons

The invention discloses a production technology for a dynode shell. The technology includes the steps of 1, machining a lining piece, wherein the lining piece is machined according to a plane drawing of the dynode shell of an electron multiplier, folding lines are marked on the lining piece, and it is guaranteed that the lining piece corresponds to the structure of the dynode shell after being folded; 2, cleaning the lining piece; 3, plating the surface of the lining piece with a film with a secondary electron emission function so as to form a dynode shell piece structure; 4, forming the dynode shell of the electron multiplier, wherein the dynode shell piece structure is folded along the folding lines designed in advance to form the dynode shell. The technology can meet the film plating requirement of a dynode of the electron multiplier and effectively solve the problems of poor film formation uniformity and stability in dynode film plating.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Nano sericite and preparation method thereof

InactiveCN109777156AStop yellowingAdjustable viscosityMaterial nanotechnologyPigment treatment with macromolecular organic compoundsAcid washingSilicon dioxide

The invention relates to a nano sericite and a preparation method thereof. The nano sericite is prepared from, 43-50 parts of silica, 28-38 parts of aluminum hydroxide, 3-5 parts of potassium oxide, 6-9 parts of sodium oxide, 8-10 parts of a dispersant, 1-5 parts of a bleaching agent, 1-3 parts of a strong oxidant and 0-1 part of water. The preparation methods of nano sericite includes the following steps that coarse crushing of schist sericite ore, dual-roll crushing to form crude sericite powder, quartz ore separation, acid washing and bleaching, striping and untrafining, viscosity modification, and screening qualified products by airflow classification of superfine grinding powder. The produced sericite has the advantages of high whiteness and brightness and low viscosity.

Owner:安徽格锐新材料科技有限公司

High-precision supporting mask plate

PendingCN107841710AStable structureImprove yieldVacuum evaporation coatingSputtering coatingDisplay deviceStructural engineering

The invention discloses a high-precision supporting mask plate. The high-precision supporting mask plate comprises a plate frame, a plurality of strip-shaped mask sheets and a supporting membrane net.The plurality of strip-shaped mask sheets are closely arranged in sequence in the longitudinal direction. A splicing gap is formed between every two adjacent strip-shaped mask sheets. Each strip-shaped mask sheet extends in the transverse direction, and the two ends of each strip-shaped mask sheet are welded to the top faces of the plate frame. Each strip-shaped mask sheet is provided with at least one mask pattern. The supporting membrane net is located below the plurality of strip-shaped mask sheets and is fixed to the plate frame. The supporting membrane net is used for supporting the plurality of strip-shaped mask sheets and covering all the splicing gaps without blocking the mask patterns. The high-precision supporting mask plate provided by the embodiment of the invention can meet the requirements for film coating of large-size glass substrates, achieve mass production and improve the production efficiency and can also meet the requirements for the yield and precision of displayers in the mass production process. Besides, the service life of the high-precision supporting mask plate is long, and the cost of a user side is low.

Owner:深圳浚漪科技有限公司

High-wear-resistant and high-gloss UV coating for PC base material of automobile interior trim optical components and preparation method thereof

ActiveCN109535992AMeet coating requirementsImprove wear resistanceFireproof paintsPolyurea/polyurethane coatingsAcrylic resinWear resistant

The invention discloses a high-wear-resistant and high-gloss UV coating for a PC base material of automobile interior trim optical components. The coating comprises the following raw materials in parts by weight: 35-55 parts of polyurethane acrylic resin A, 10-20 parts of polyurethane acrylic resin B, 5-15 parts of 1,6-hexanediol diacrylate, 5-10 parts of a wear-resistant auxiliary agent, 1-3 parts of a leveling agent, 1-2 parts of an ultraviolet absorbent, 2-5 parts of a photoinitiator, 10-20 parts of a solvent and 40-60 parts of a diluent. The functional degrees of polyurethane acrylic resinA and polyurethane acrylic resin B are 6-8 and 3.5-4 respectively. The coating can directly coat a PC surface, not only meets the requirements of chemical resistance, weatherability and other conventional paint properties for automobile interior trims, but also meets light transmission required by optical components, and has the greatest advantage meeting the requirements of high wear resistance.The wear resistance passes through GMW 1444-2014 (ASTM D-1044) tests.

Owner:PETER LACKE SHANGHAI

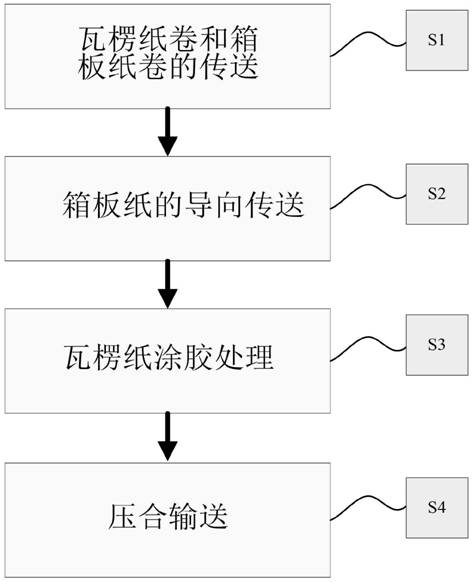

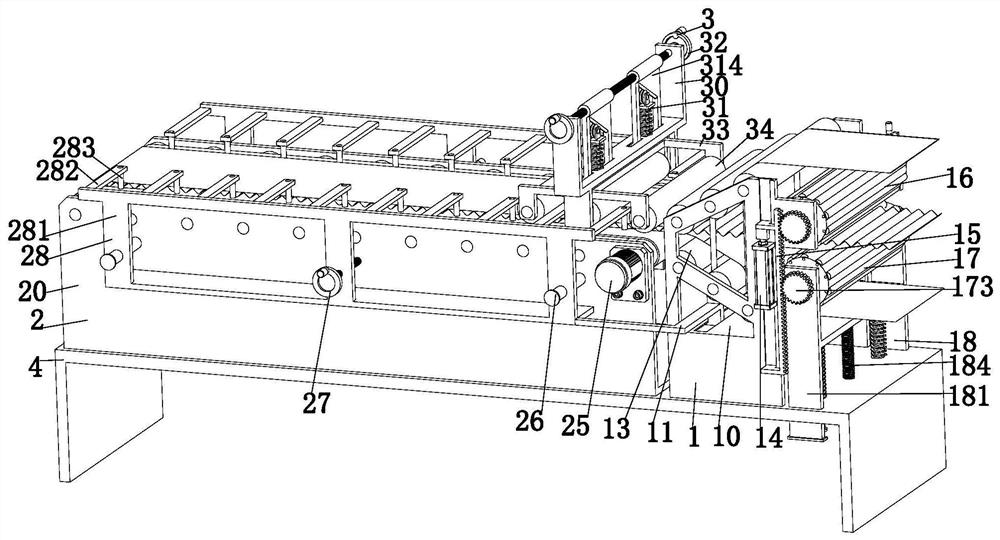

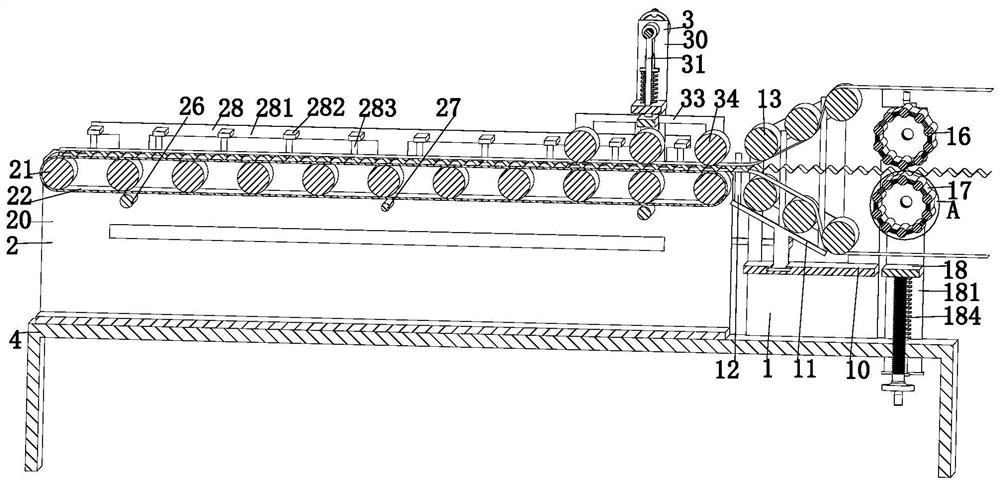

Logistics packaging box corrugated board processing method

ActiveCN113478941ARealize spacing distance adjustmentMeet coating spacing requirementsBox making operationsPaper-makingCardboardLogistics management

The invention provides a logistics packaging box corrugated board processing method, which comprises a roll coating mechanism, a transmission mechanism, a rolling mechanism and a main beam cross frame. The problems as follows are solved: an existing device for coating corrugated paper with glue has limitation, only the corrugated paper with one height size can be coated during glue coating, and corresponding equipment needs to be replaced for coating treatment when the corrugated paper with different height sizes is replaced; the glue is prone to deposition and solidification in the coating process, the viscosity of glue is reduced, and the gluing quality of cardboard paper and corrugated paper is influenced; the coating flow rate of glue is difficult to control, the edges of corrugated paper and cardboard paper cannot be aligned, applied and glued easily due to the fact that the corrugated paper and the cardboard paper do not have a guide movement track in the conveying process, deviation can occur, and the forming quality of the corrugated paper board is affected; and the height cannot be adjusted in the rolling, applying and gluing process of the corrugated paper board, and the pressing requirements of corrugated boards with different thicknesses cannot be met.

Owner:佛山市傲彩包装制品有限公司

Integrated preparation device of high-flux magnetron sputtering nano film device

ActiveCN110777344AReduce volumeImprove consistencyVacuum evaporation coatingSputtering coatingSputteringControl system

The invention relates to an integrated preparation device of a high-flux magnetron sputtering nano film device. The integrated preparation device of the high-flux magnetron sputtering nano film devicecomprises a main machine, a vacuum air extractor, a power supply and control system and a machine cabinet; the main machine comprises a working chamber, a sample rack, five magnetic control targets and a sample baffle plate; the five magnetic control targets obliquely surround the top of the working chamber to realize co-sputtering or sequential sputtering; each magnetic control target is provided with a target baffle; the target baffle temporarily shields the corresponding magnetic control target through contraction opening and closing; the sample rack is arranged below the magnetic controltargets; the top of the sample rack is provided with a sample cover; the sample cover is provided with a plurality of sample through holes and is used for high-flux preparation of multi-component mixed nano films and nano multilayer functional film devices; and the sample baffle is arranged above the sample cover. According to the design of the magnetic control targets of a coating preparation device, the space inside the working chamber is fully utilized, and the co-sputtering or the sequential sputtering coating can be realized. The sample cover is provided with not less than 100 sample through holes, hundreds of identical samples can be prepared simultaneously in a single time, and the possibility is provided for high-flux coating of a material genome.

Owner:纳能镀膜丹阳有限公司

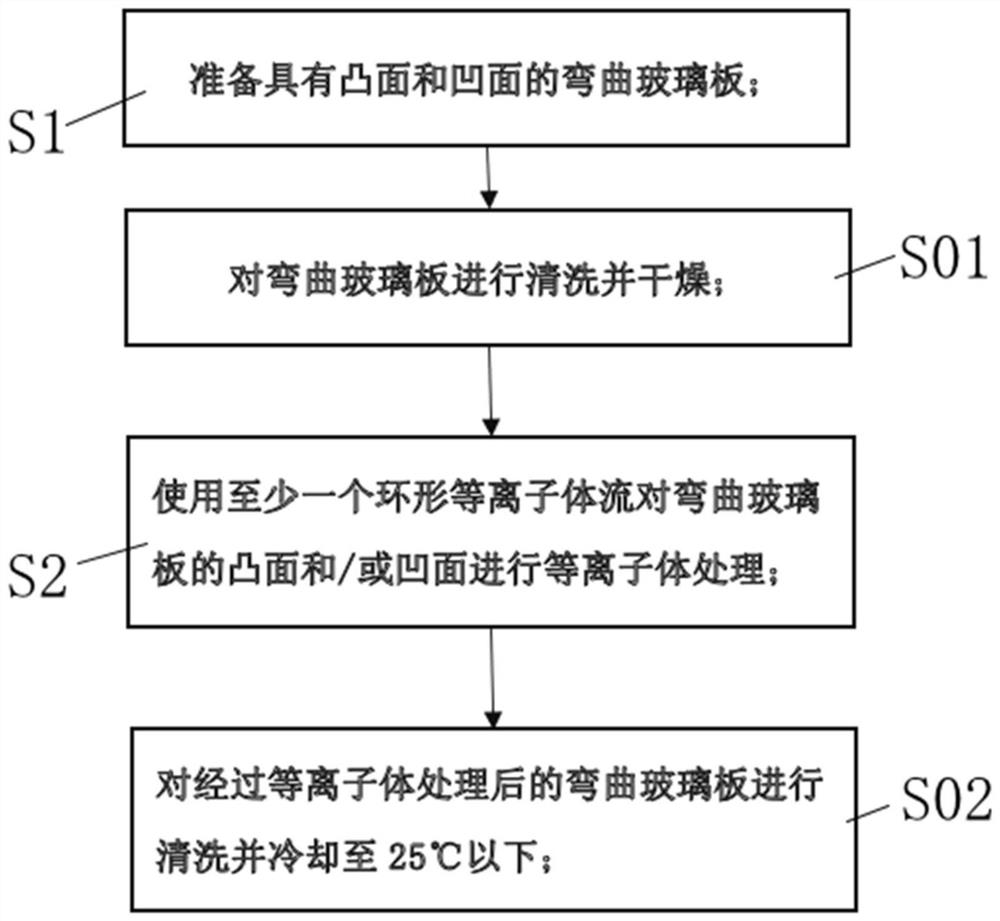

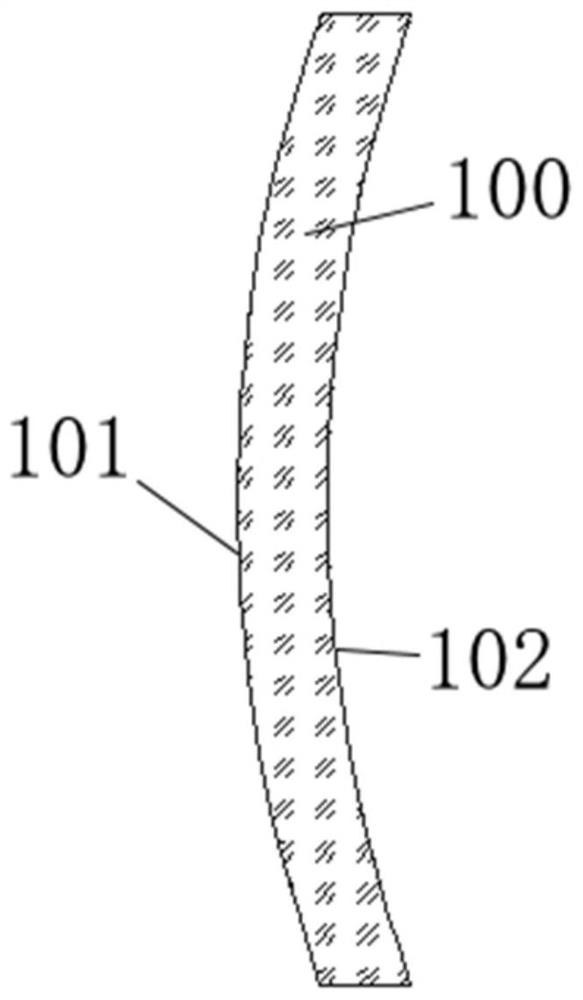

Surface treatment method of bent glass plate

ActiveCN111842389AMeet the processing capacityImprove wettabilityFlexible article cleaningSurface cleaningAqueous droplet

The invention relates to the technical field of glass surface treatment, in particular to a surface cleaning method of automotive glass, and particularly provides a surface treatment method of a bentglass plate suitable for being coated with a sol-gel coating. The surface treatment method comprises the following steps of S1, preparing the bent glass plate with a convex surface and a concave surface; and S2, performing plasma treatment on the convex surface and / or the concave surface of the bent glass plate by using at least one annular plasma flow, wherein the surface water drop contact angleof the convex surface or the concave surface subjected to the plasma treatment is less than 10 degrees. According to the surface treatment method, oil stains or organic pollutants attached to the glass surface can be removed, the wettability of the glass surface is improved, the surface tension of the bent glass plate is rapidly treated to 70 mN / m or above, and therefore the coating requirement of a subsequent functional coating is met; and the treatment speed can be increased while the plasma treatment effect is met, and the surface treatment method can adapt to bent glass plates with different shapes, different sizes and different molded surfaces.

Owner:FUYAO GLASS IND GROUP CO LTD

Film forming agent for rice seed coating and preparation method thereof

The invention provides a film forming agent for rice seed coating and a preparation method thereof and relates to the technical field of suspension seed coating agents. The preparation method comprises the following steps: physically blending 1 percent to 8 percent of polyvinyl alcohol and 1 percent to 3 percent of sodium alginate and styrene to obtain a film-forming material for the rice seed coating; adding 1 percent to 8 percent of the polyvinyl alcohol and 1 percent to 3 percent of the sodium alginate and styrene into a dispersant at the ratio of (1 to 3) to (1 to 3) to (2 to 4); shearing on a high-speed tissue dispersing machine for 20min to 40min under revolutions of 10000rmp to 15000rpm, so as to obtain binary film-forming blending emulsion. The film forming agent has good air permeability and water permeability, has certain elasticity and meets the requirements of the rice seed coating; the film forming agent has a good film forming property and low releasing rate, the germination rate of rice seeds is high and the requirements of a rice suspension seed coating agent are met.

Owner:贵州省植物保护研究所

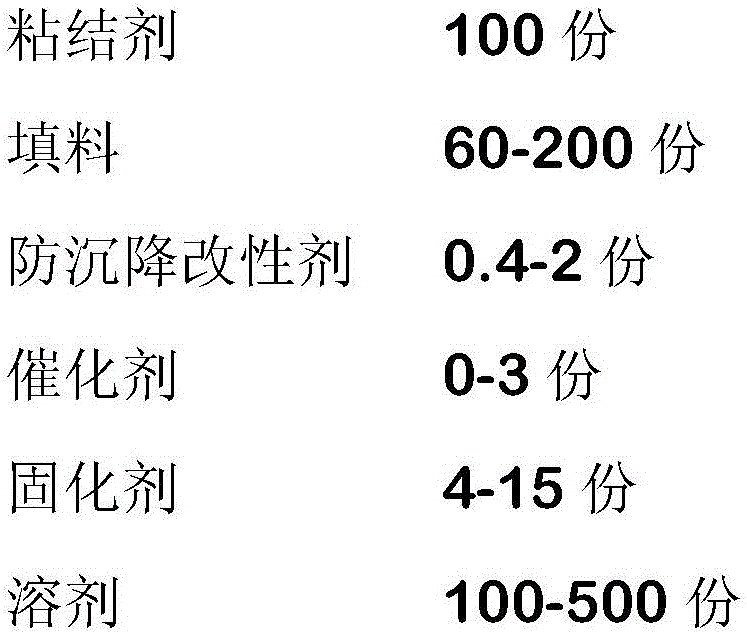

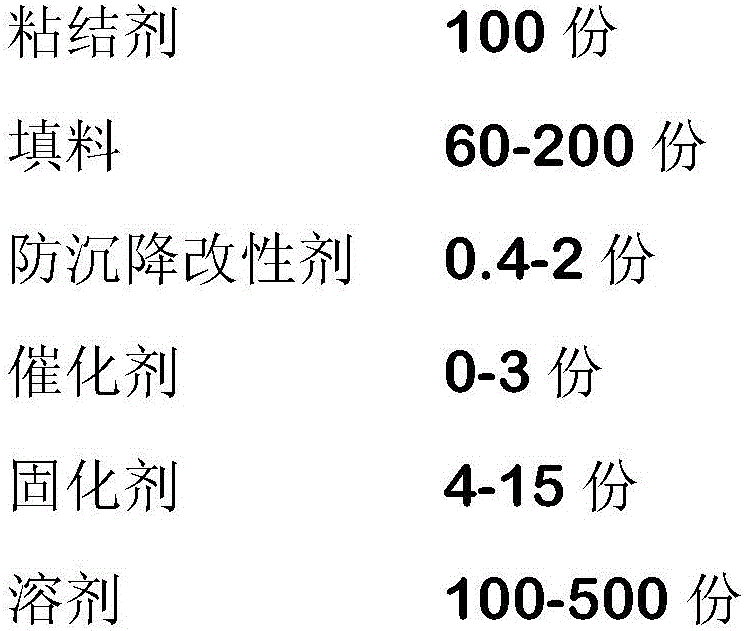

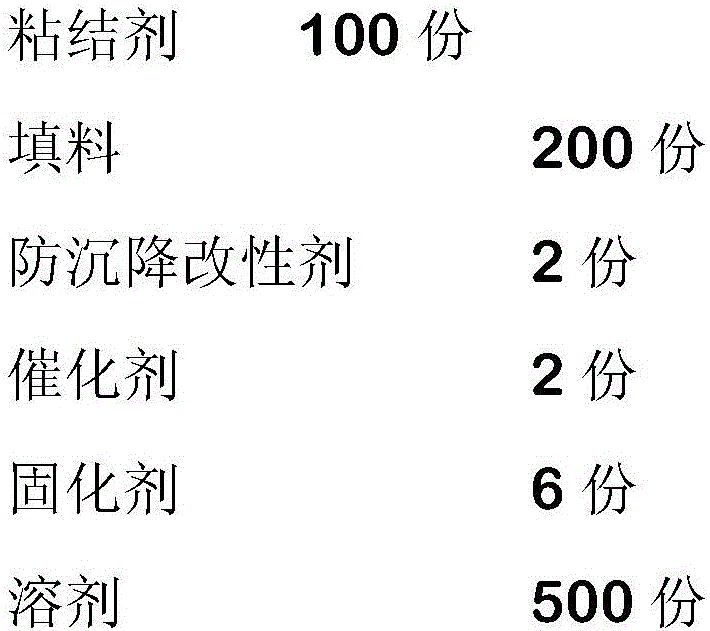

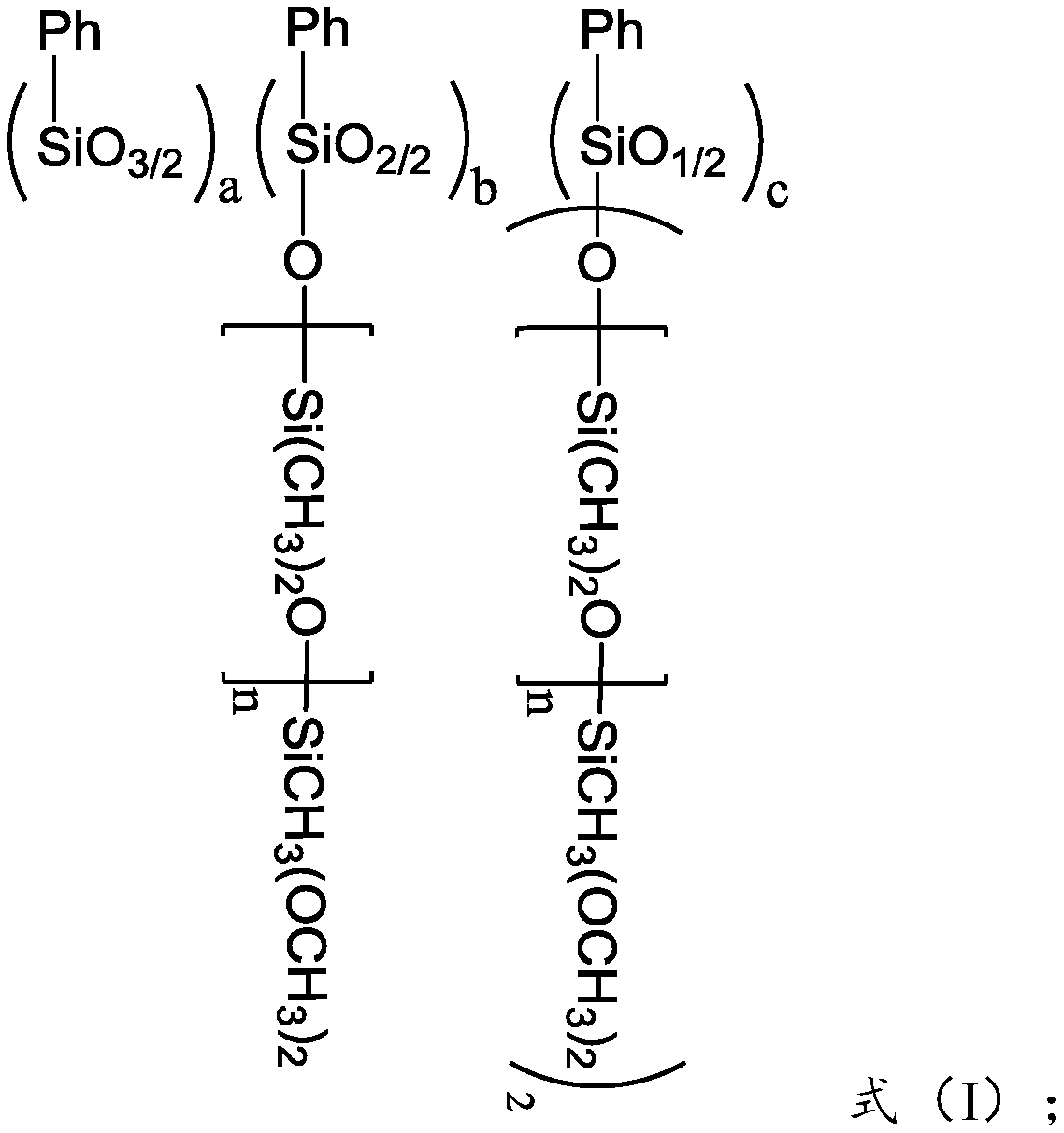

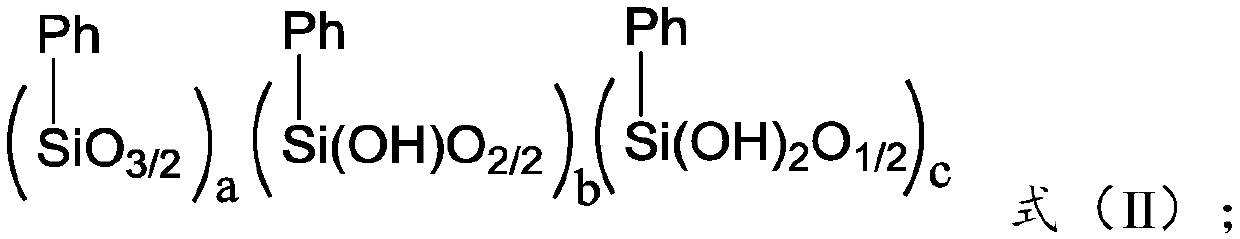

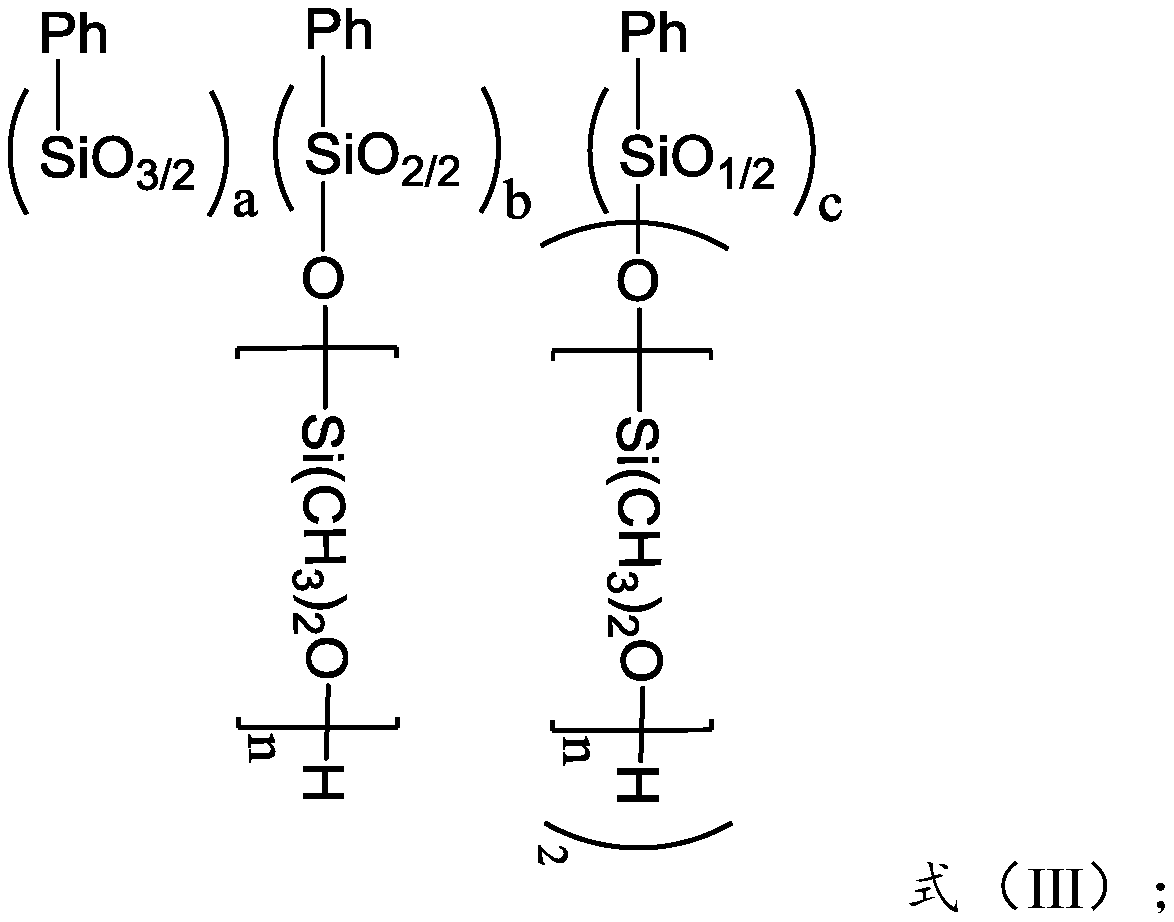

Organic silicon coating adhesive and preparation method thereof

The invention provides an organic silicon coating adhesive, which comprises, by weight, 100 parts of a modified silicon resin, 1-5 parts of a cross-linking agent, 0.5-3 parts of a catalyst, 0-0.2 partof an ultraviolet indicator, and 0-1 part of a tackifier, wherein the modified silicon resin has a general formula represented by a formula (I), a+b+c is 1, a is greater than 0 and less than 1, b isgreater than 0 and less than 1, c is greater than or equal to 0 and less than 1, and n is an integer of greater than or equal to 1. Compared with the organic silicon coating adhesive in the prior art,the organic silicon coating adhesive of the invention has the following characteristics that the modified silicon resin with the specific general formula is used as the main component, and is matchedwith other components with specific contents to achieve good interaction, such that the organic silicon coating adhesive has high hardness while various properties of the organic silicon coating adhesive meet the coating requirements of circuit boards, the cured adhesive surface is smooth and has excellent friction resistance, and the good protection effect can be achieved by coating the surfaceof a circuit board with a thin layer of the organic silicon coating adhesive.

Owner:HANGZHOU ZHIJIANG NEW MATERIAL CO LTD +1

A kind of high wear-resisting high-gloss UV coating for PC base material of automotive interior optical parts and preparation method thereof

ActiveCN109535992BMeet coating requirementsImprove wear resistanceFireproof paintsPolyurea/polyurethane coatingsAcrylic resinHexanediol diacrylate

The invention discloses a high wear-resistant and high-gloss UV coating for PC substrates of automotive interior optical parts, comprising the following raw materials in parts by weight: 35-55 parts of polyurethane acrylic resin A, 10-20 parts of polyurethane acrylic resin B, 1 , 5-15 parts of 6-hexanediol diacrylate, 5-10 parts of wear-resistant additive, 1-3 parts of leveling agent, 1-2 parts of ultraviolet absorber, 2-5 parts of photoinitiator, 10-part of solvent 20 parts and 40-60 parts of diluent, wherein the functionalities of polyurethane acrylic resin A and polyurethane acrylic resin B are 6-8 and 3.5-4 respectively. The coating can be directly coated on the surface of PC. In addition to meeting the conventional paint properties such as chemical resistance and weather resistance required for automotive interiors, it also meets the light transmission required for optical components. The biggest advantage is that it meets the requirements of Requirements for high wear resistance, the wear resistance has passed the test of GMW14444‑2014 (ASTM D‑1044).

Owner:PETER LACKE SHANGHAI

A method for preparing a large-size molybdenum-niobium planar target

ActiveCN111534800BReduce oxygen contentHigh purityVacuum evaporation coatingSputtering coatingNiobiumThermal deformation

The invention discloses a method for preparing a large-size molybdenum-niobium planar target, which comprises 1) a powder granulation step, 2) a hot isostatic pressing step, 3) a thermal deformation step and a cleaning processing step. Through the preparation method of the present invention, a large-size target material with uniform structure composition, small average grain size, low oxygen content, high purity and high density is produced. The large-size target material prepared by the preparation method of the present invention meets the requirements of the sputtering target Material coating requirements.

Owner:东莞市欧莱溅射靶材有限公司 +1

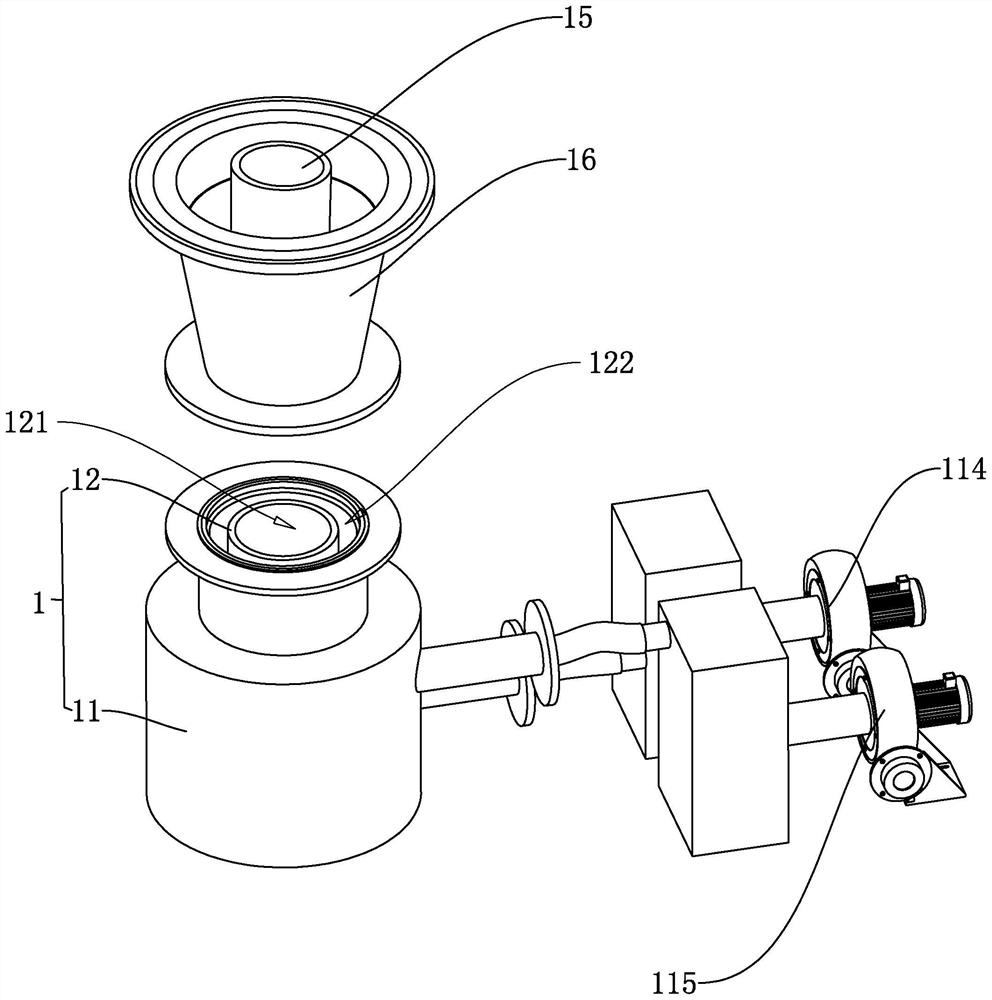

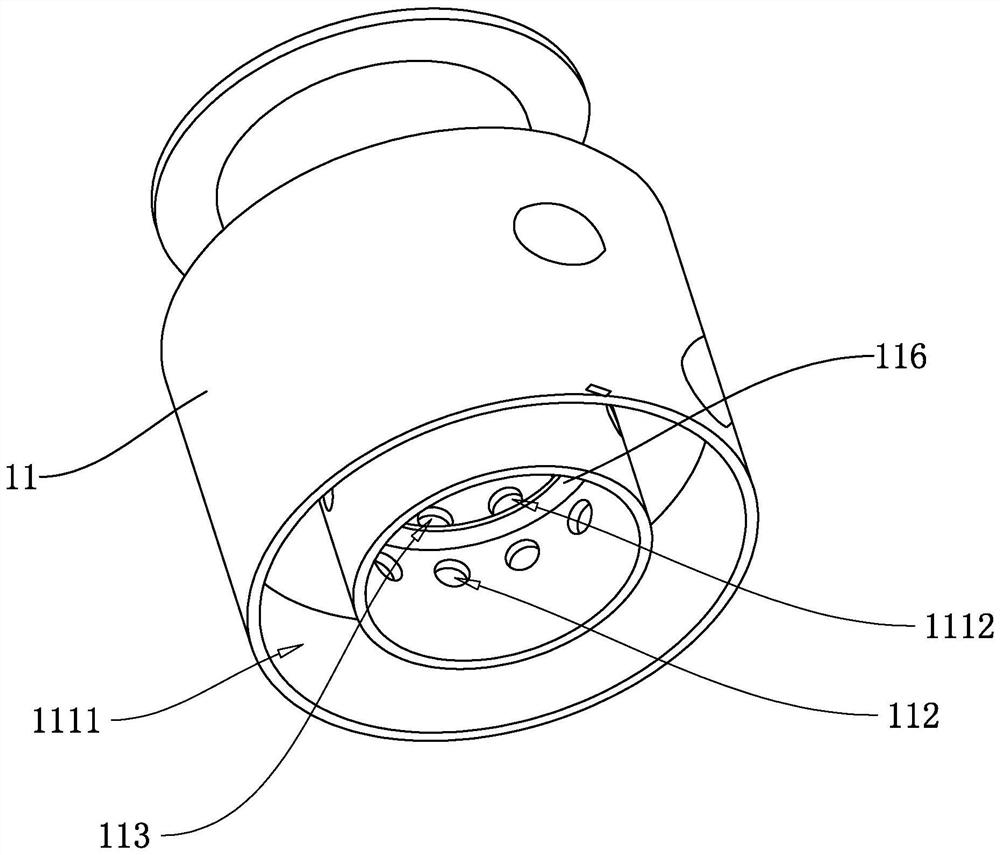

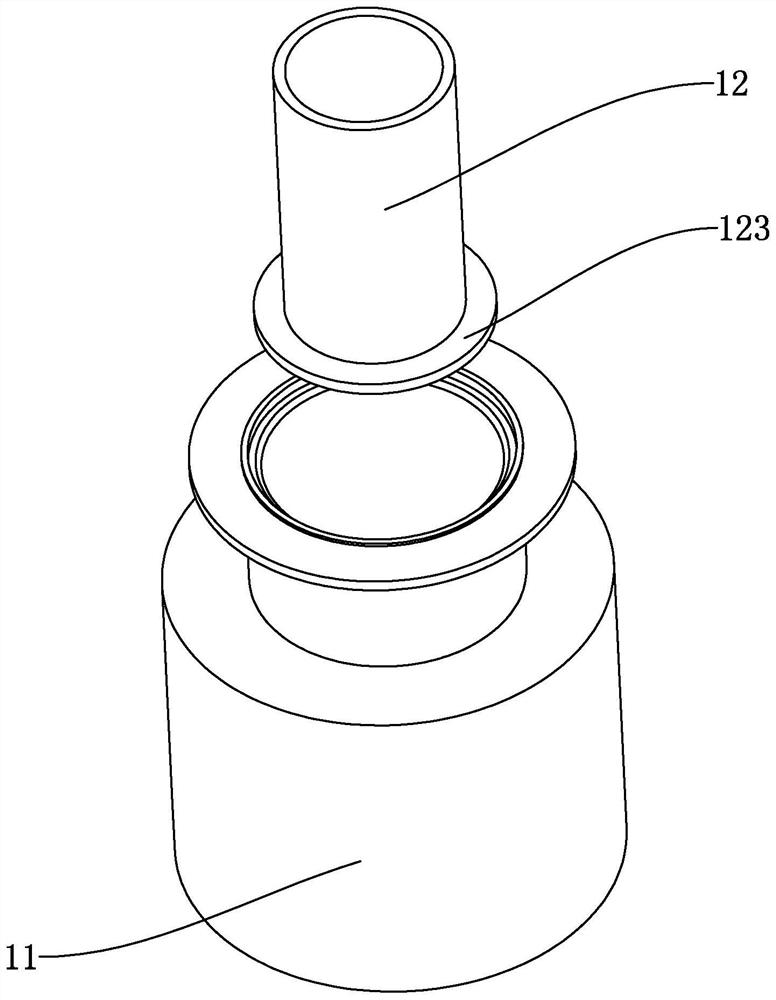

A barrel for coating and a coating machine using the barrel

ActiveCN113081834BMeet coating requirementsImprove applicabilityConfectionerySpraying apparatusEngineeringMechanical engineering

The application discloses a barrel body for coating, which relates to the technical field of coating equipment, which includes an air inlet barrel, a first air duct and a second air duct are arranged in the air intake barrel, and the first air duct and the The second air ducts are all in communication with the material holding tray, and the air inlets of the first air duct and the second air duct are respectively connected with a first frequency conversion fan and a second frequency conversion fan. This application uses the first air channel and the first frequency conversion fan to blow the material upwards, so that the material first rises and then falls along the parabolic trajectory in the coating barrel, and uses the second air channel and the second frequency conversion fan to provide upward flow for the falling materials. Thrust, by adjusting the air output rate of the first variable frequency fan and the second variable frequency fan, the effect of adjusting the suspension time of the material in the coating barrel is achieved, which effectively improves the scope of application of the coating machine and increases its practicability.

Owner:SHANGHAI PILOTECH INSTR & EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com