Spray coating type low-absorption and low-emission thermal control coating, preparation method thereof and application thereof

A heat-control coating and low-emissivity technology, applied in coatings, polyester coatings, etc., can solve problems such as unfavorable return cabin surface application, high-emissivity coating radiation heat leakage, and complex construction of multi-layer structures. , achieve excellent space environment stability, ensure resistance to space environment stability, and ensure the effect of space environment stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A method for preparing a spray-coated low-absorption and low-emission thermal control coating, the steps of the method comprising:

[0035] (1) Add the filler and anti-sedimentation modifier into the solvent, and disperse evenly. When dispersing, use mechanical stirring, the stirring speed is 200-1200 rpm, and the dispersion time is 0.5-3h;

[0036] (2) Add binder to the system obtained in step (1), and stir evenly, the stirring speed is 200-1200 rpm, and the stirring time is 0.5-1h;

[0037] (3) Add catalyst and curing agent to the system obtained in step (2), and stir evenly, the stirring speed is 200-1200 rpm, and the stirring time is 5-30min, to obtain the paint material;

[0038] (4) Filter the paint material obtained in step (3) with a 120-200 mesh copper mesh to obtain a sprayable low-absorption and low-emission thermal control coating paint material.

[0039] An application of a spray-on low-absorption and low-emission thermal control coating. The sprayable low...

Embodiment 1

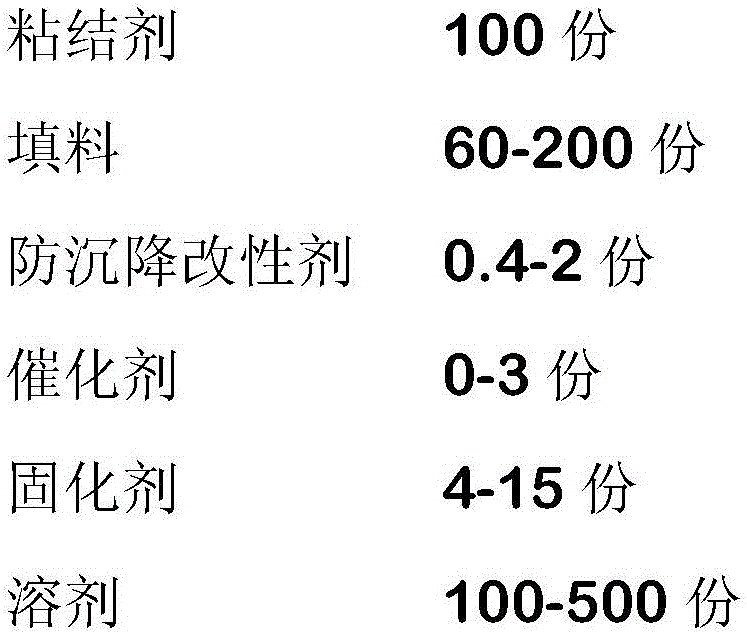

[0042] A spray-on low-absorption and low-emission thermal control coating, calculated as 100 parts of the binder in the thermal control coating, other compositions and mass parts in the thermal control coating are as follows:

[0043]

[0044] The binder is dihydroxy silicone resin;

[0045] The filler is flake aluminum powder;

[0046] Described anti-sedimentation modifier is KH550 silane modified coupling agent;

[0047] Described catalyst is dibutyltin dilaurate;

[0048] Described curing agent is ethyl orthosilicate;

[0049] Described solvent is butyl acetate mixture.

[0050] A method for preparing a spray-coated low-absorption and low-emission thermal control coating, the steps of the method comprising:

[0051] (1) Add aluminum powder and KH550 to the solvent, and disperse evenly. When dispersing, use mechanical stirring, the stirring speed is 500 rpm, and the dispersion time is 1.5h;

[0052] (2) Add dihydroxy silicone resin to the system obtained in step (1),...

Embodiment 2

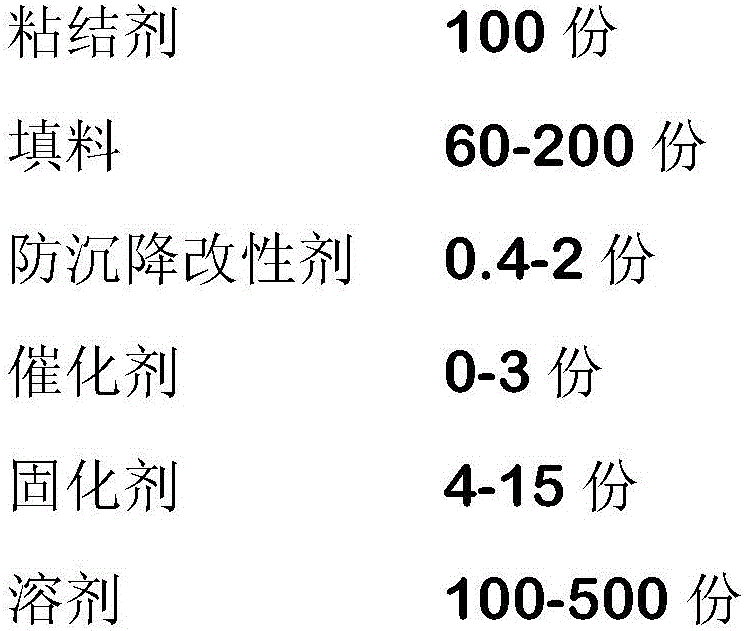

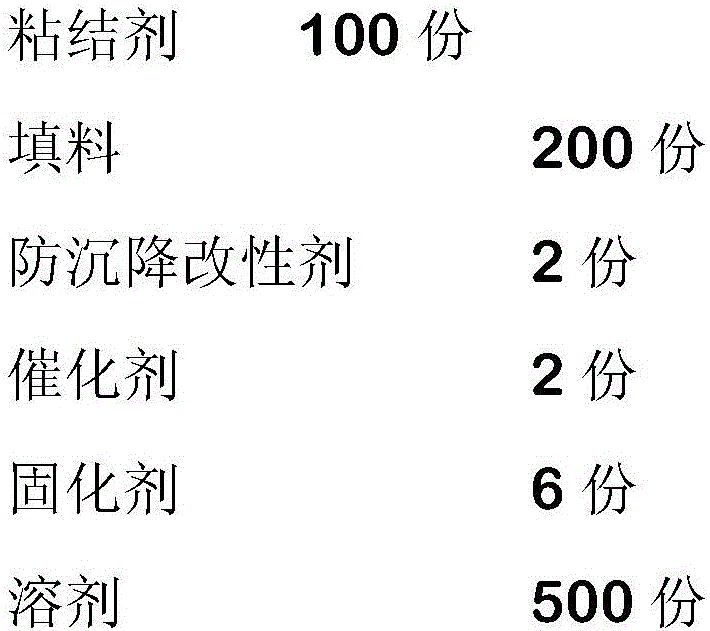

[0057] A spray-on low-absorption and low-emission thermal control coating, calculated as 100 parts of the binder in the thermal control coating, other compositions and mass parts in the thermal control coating are as follows:

[0058]

[0059] Described binding agent is polyester resin;

[0060] The filler is flake aluminum powder;

[0061] Described anti-sedimentation modifier is KH560 silane modified coupling agent;

[0062] Described curing agent is isocyanate;

[0063] Described solvent is xylene mixture.

[0064] A method for preparing a spray-coated low-absorption and low-emission thermal control coating, the steps of the method comprising:

[0065] (1) Add the filler and KH560 to the solvent and disperse evenly. When dispersing, use mechanical stirring, the stirring speed is 800 rpm, and the dispersion time is 2 hours;

[0066] (2) Add polyester resin to the system obtained in step (1), and stir evenly, the stirring speed is 400 rpm, and the stirring time is 1h; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com