A barrel for coating and a coating machine using the barrel

A coating and barrel technology, which is applied in the direction of application, making medicines into special physical or taking forms of devices, coatings, etc., can solve the problems of single length and poor applicability, and achieves improved applicability, reasonable arrangement, Guaranteed to work properly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

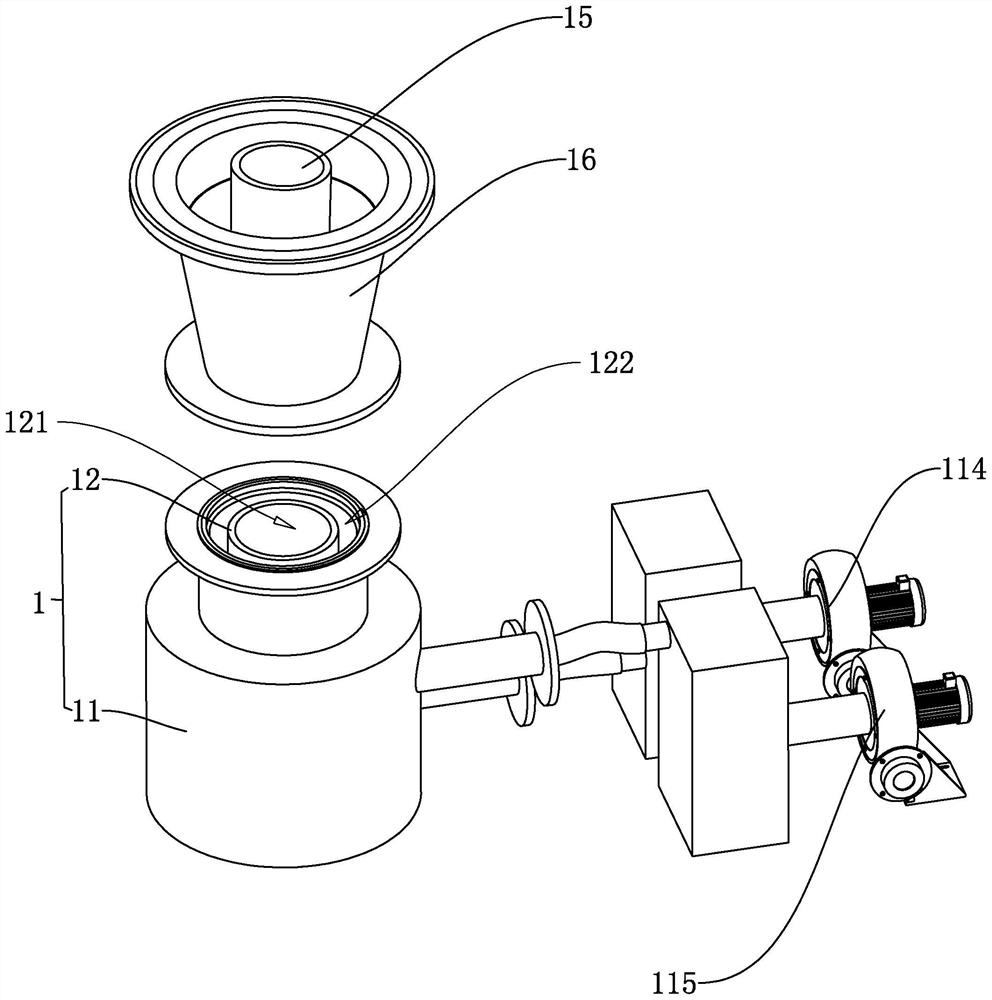

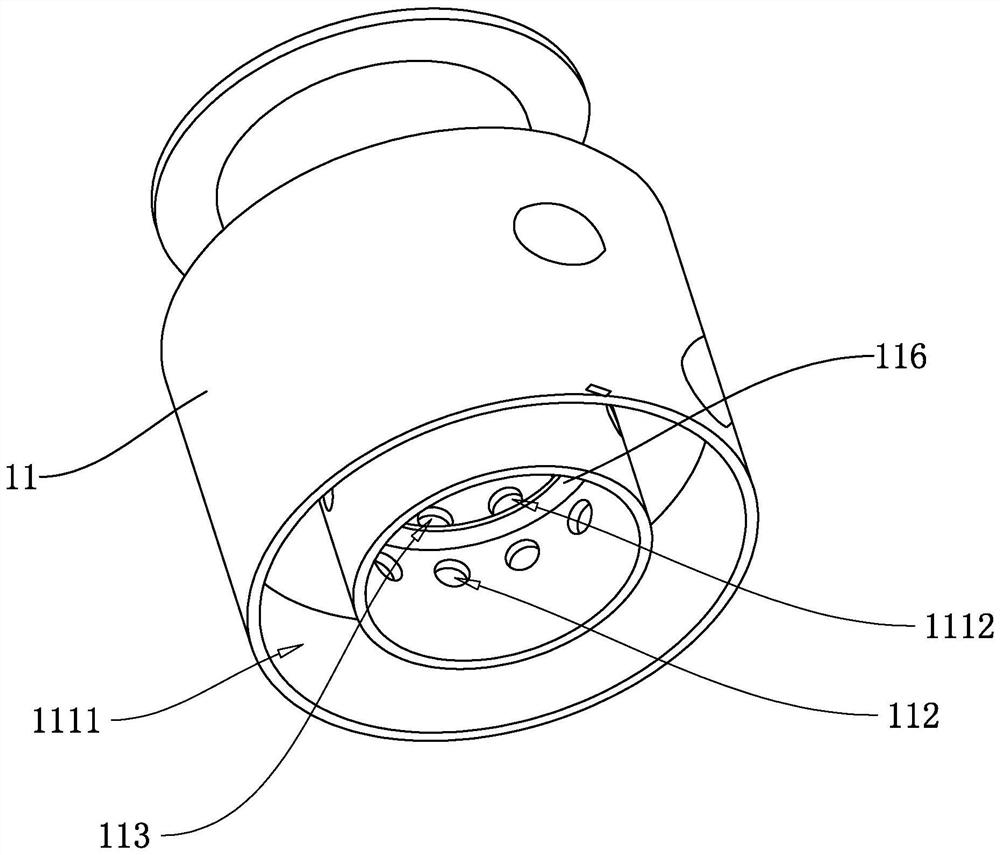

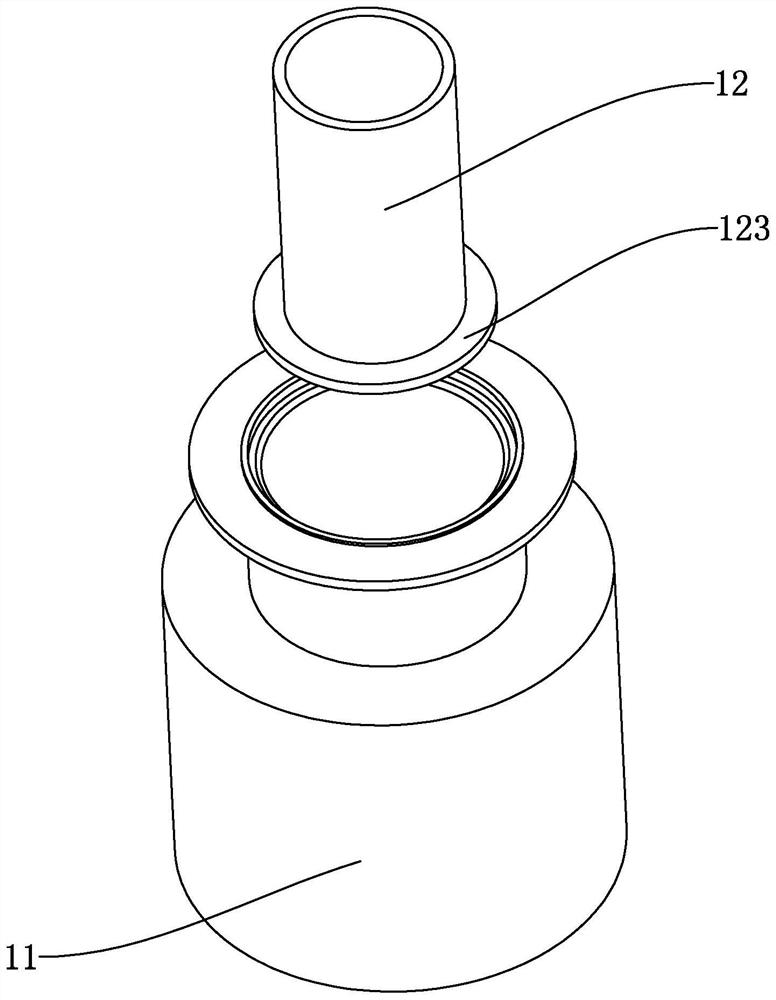

[0047] refer to figure 1 and figure 2 , a barrel body for coating, which is installed on the lower side of the feeding tray 31 of the coating machine, and is used to blow the material in the feeding tray 31 upward into the coating barrel 3, so that the material and the coating barrel 3 are blown upward. The suspended coating medium is sticky and forms a coating layer. refer to Figure 15 , including the air inlet barrel 1, the air inlet barrel 1 includes an outer cylinder 11 that communicates with the feeding tray 31, and an inner cylinder 12 embedded in the outer cylinder; A second variable frequency fan 115 is connected to the air inlet of the outer cylinder 11; at the same time, according to the difference between the ascending path and the falling path of different materials, an extension pipe 15 is communicated between the inner cylinder 12 and the feeding tray 31, and the outer A tapered tube 16 is communicated between the cylinder 11 and the material holding tray 31...

Embodiment 2

[0058] refer to Figure 7 , a coating machine, comprising the barrel in embodiment 1, the coating machine also includes a control cabinet 2, and a coating barrel 3 hinged on one side of the control cabinet 2 in the horizontal direction, the coating barrel 3 is installed on the side wall There is a feeding device 32 for spraying the coating medium; the air inlet barrel 1 is detachably fixed on the lower side of the coating barrel 3, and the air inlet barrel 1 and the coating barrel 3 are arranged in communication; the first variable frequency fan 114, the second variable frequency fan The fans 115 are installed in the control cabinet 2, and the air outlets of the first variable frequency fan 114 and the second variable frequency fan 115 are connected with ventilation pipes 17, and any ventilation pipes 17 extend out of the control cabinet 2 and are respectively connected to the corresponding first fan. Cavity 1111 and second air cavity 1112. At the same time, a heater 18 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com