Organic silicon coating adhesive and preparation method thereof

A coating technology and silicone technology, which is applied in the field of silicone coating and its preparation, can solve the problems of low hardness and general anti-friction performance of the silicone coating, and is suitable for large-scale production, easy to scale up, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] The present invention also provides a method for preparing the silicone coating glue described in the above technical solution, comprising the following steps:

[0074] Mix the modified silicone resin, cross-linking agent, catalyst, ultraviolet indicator and tackifier evenly to obtain the silicone coating glue.

[0075] The invention uniformly mixes the modified silicone resin, the crosslinking agent, the catalyst, the ultraviolet indicator and the tackifier to obtain the organosilicon coating glue. In the present invention, the modified silicone resin, cross-linking agent, catalyst, ultraviolet indicator and tackifier are the same as those described in the above technical solution, and will not be repeated here.

[0076] The preparation method provided by the invention has simple process, is easy to scale up, and is suitable for large-scale production.

[0077] The invention provides a silicone coating glue, comprising the following components: 100 parts by weight of ...

Embodiment 1

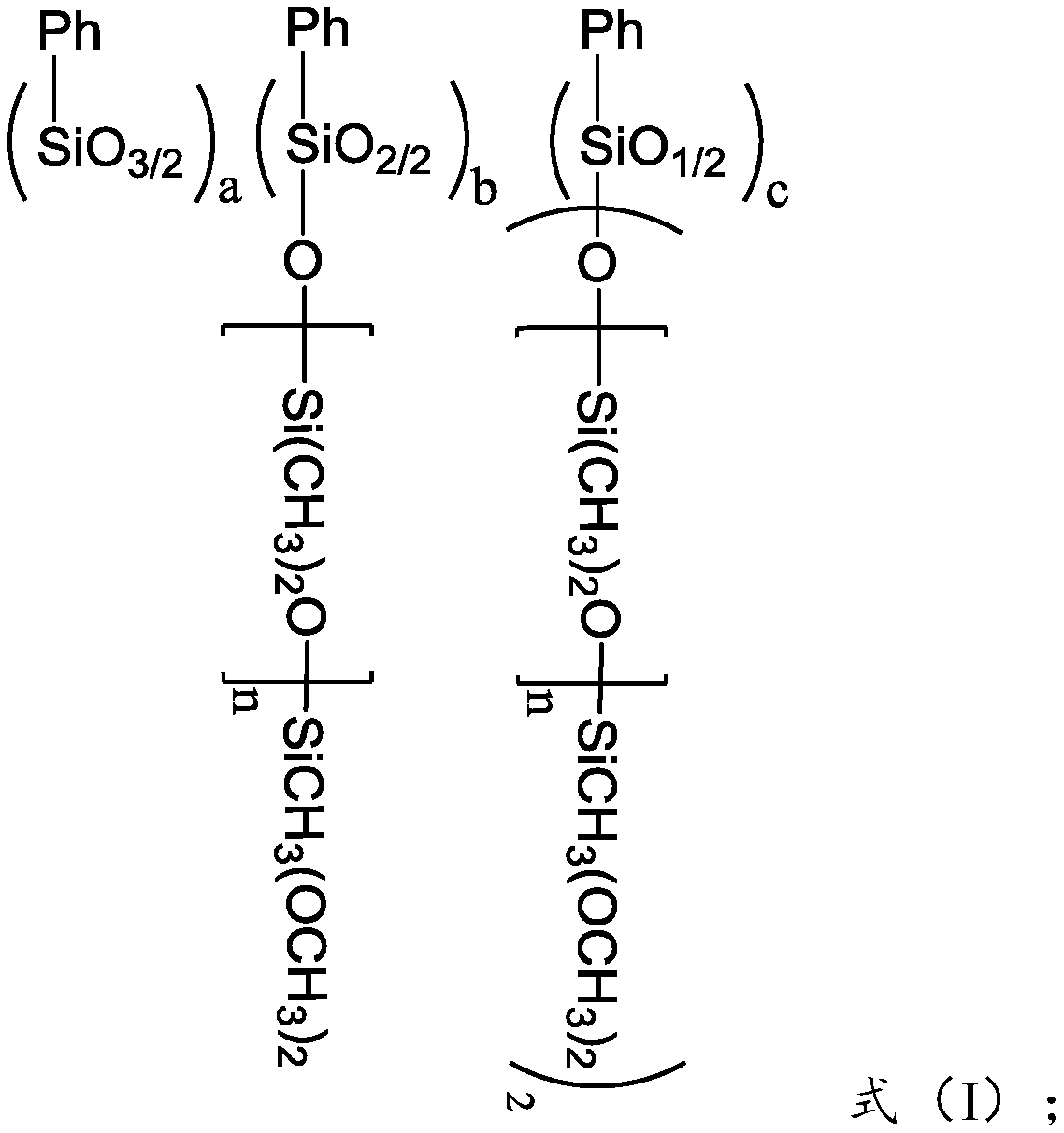

[0081](1) Take 5kg of phenyltrimethoxysilane and 7kg of toluene and add them to the reactor, then add 5g of hydrochloric acid, and then gradually add 1.363kg of water into the reactor within 0.5h under the protection of nitrogen. Raise the temperature to 40°C for 10 hours; after the reaction, let stand to separate layers, remove the upper water layer, then add 4 kg of hydroxyl-terminated polydimethylsiloxane at 50 mPa·s, then add 0.05 g of ferric chloride, and heat up to React at 90°C for 8 hours; after the reaction, cool down to 80°C, add 2.5kg of methyltrimethoxysilane and 2g of tetrabutyl titanate, and react at 80°C for 5h; after the reaction, remove excess methyltrimethoxysilane And part toluene, obtain the product of solid content 80%; The expression of this product is:

[0082]

[0083] In formula (I), a+b+c=1, a=0.71, b=0.14, c=0.15; n is an integer ≥1.

[0084] (2) Add 3wt% methyltrimethoxysilane, 2wt% tetrabutyl titanate, 0.01wt% 2-(2-hydroxyl-5-methylphenyl) to t...

Embodiment 2

[0086] (1) Get 5kg of phenyltrimethoxysilane and 10kg of toluene and join in the reactor, then add 7g of trifluoromethanesulfonic acid, then gradually drop 1.636kg of water into the reactor within 1h under the protection of nitrogen, After the addition of water drops, raise the temperature to 70°C and react for 6.5 hours; after the reaction, let stand to separate and separate the upper water layer, then add 4.5 kg of hydroxyl-terminated polydimethylsiloxane at 1000 mPa·s, and then add iron octoate 0.1g, heat up to 100°C for 6 hours; after the reaction, cool down to 90°C, add 1.5kg of methyltrimethoxysilane and 2.6g of isopropyl titanate, and react at 90°C for 3h; evaporate the excess Methyltrimethoxysilane and part toluene, obtain the product of solid content 75%; The expression of this product is:

[0087]

[0088] In formula (I), a+b+c=1, a=0.85, b=0.11, c=0.04; n is an integer ≥1.

[0089] (2) Add 2wt% tetraethoxysilane, 1.5wt% tetrabutyl titanate, 0.012wt% 2,4-dihydrox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com