Patents

Literature

60results about How to "Strong anti-friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for simultaneously and stably dispersing laminated nanosheets and spherical nanoparticles in oily medium and application thereof

ActiveCN104178249AEvenly dispersedStrong anti-frictionTransportation and packagingMixingEmulsionNanometre

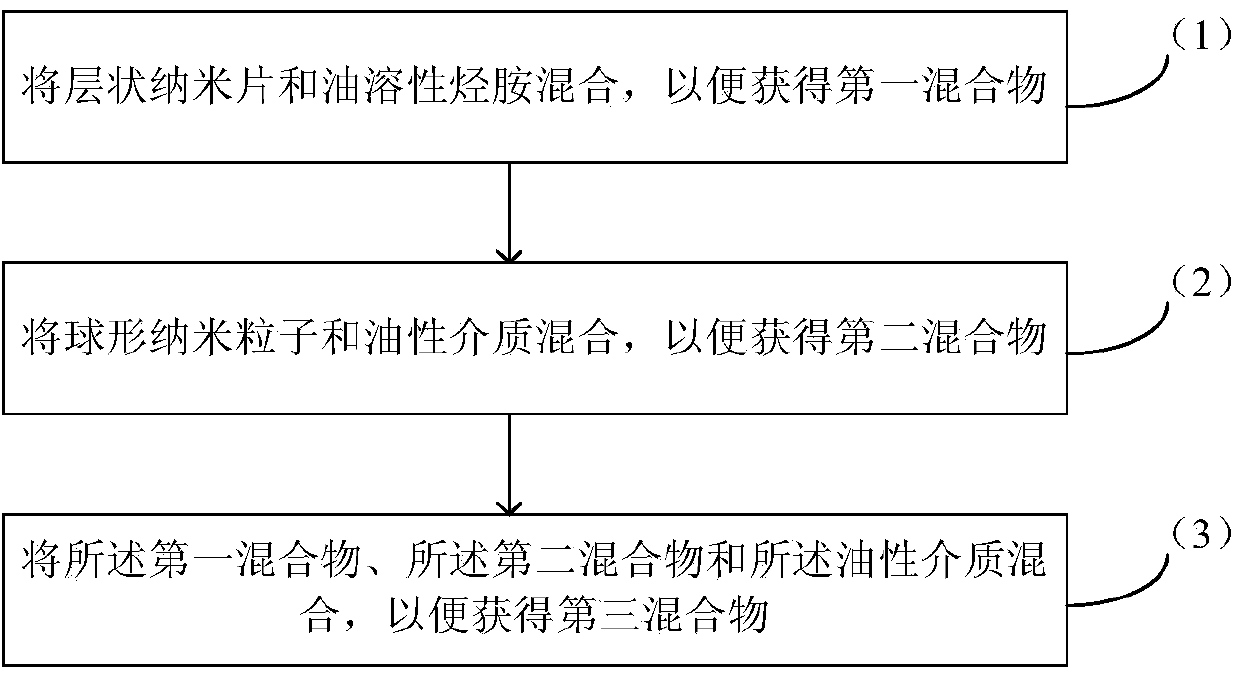

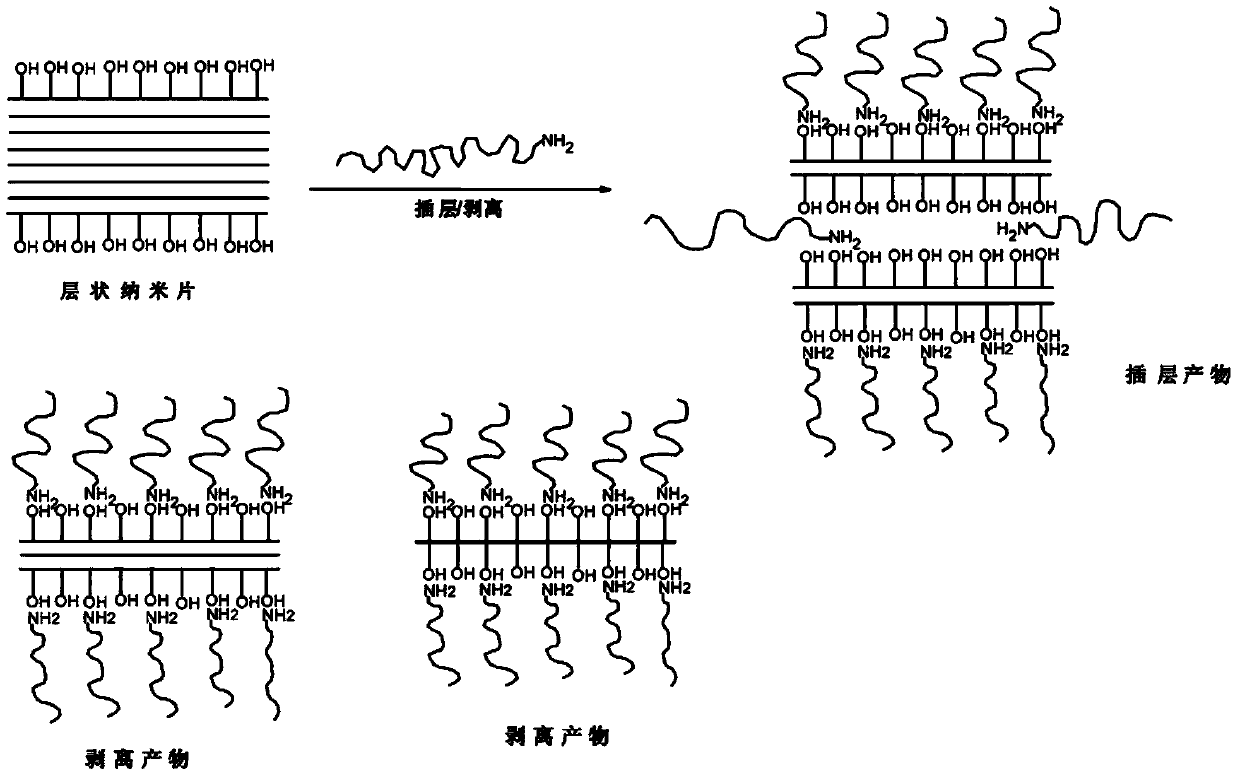

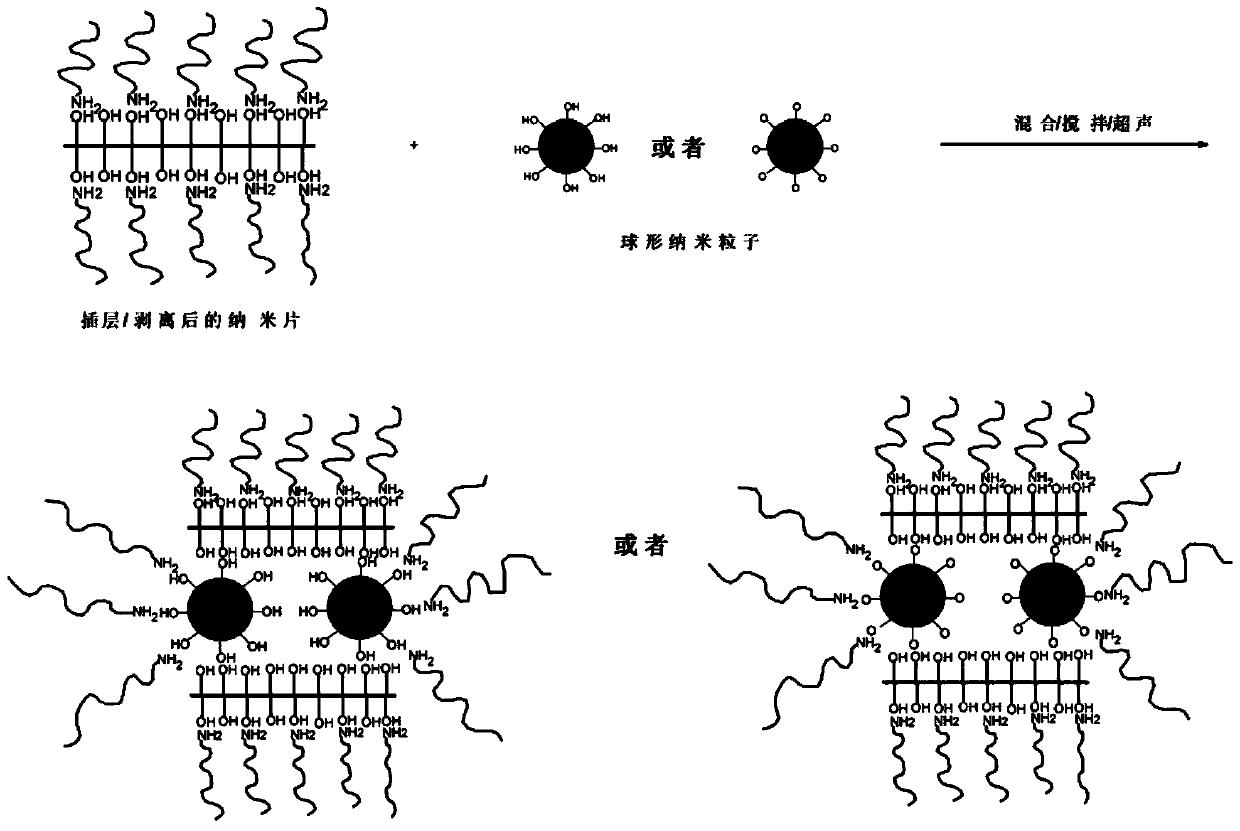

The invention discloses a method for simultaneously and stably dispersing laminated nanosheets and spherical nanoparticles in an oily medium and application thereof. The method comprises the following steps: (1) mixing the laminated nanosheets with oil-soluble alkylamine, so as to obtain a first mixture; (2) mixing the spherical nanoparticles with an oily medium, so as to obtain a second mixture; and (3) mixing the first mixture and the second mixture with the oily medium, so as to obtain a third mixture. By adopting the method, the spherical nanoparticles can be effectively stabilized by the nanosheets, the laminated nanosheets and the spherical nanoparticles can be simultaneously and stably dispersed in the oily medium, a solution or micro emulsion obtained through dispersion is good in stability and free of sedimentation or layering phenomenon, and the method can be implemented simply, conveniently and rapidly.

Owner:SHENZHEN NANKE NEW MATERIALS TECH CO LTD

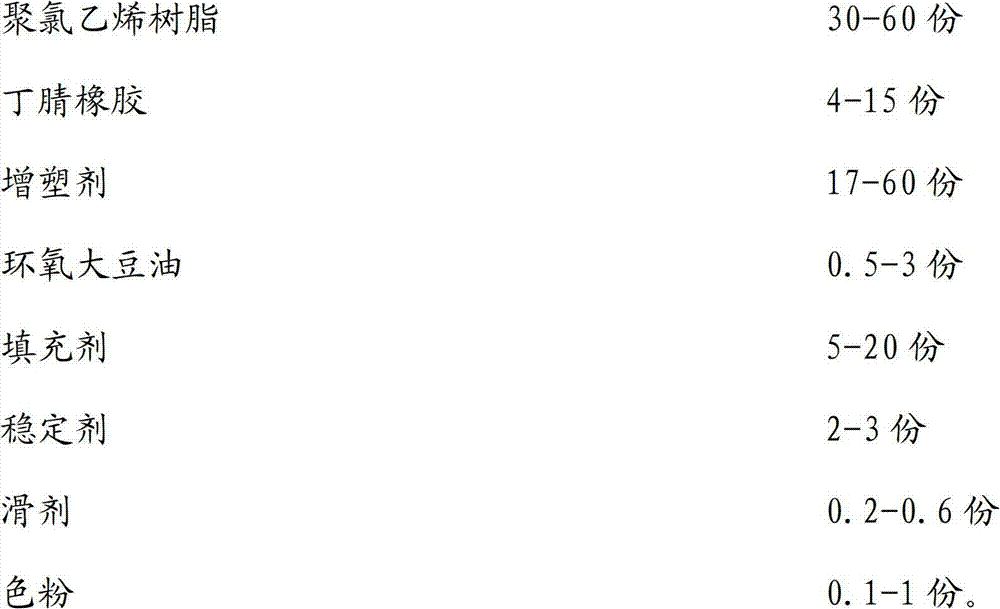

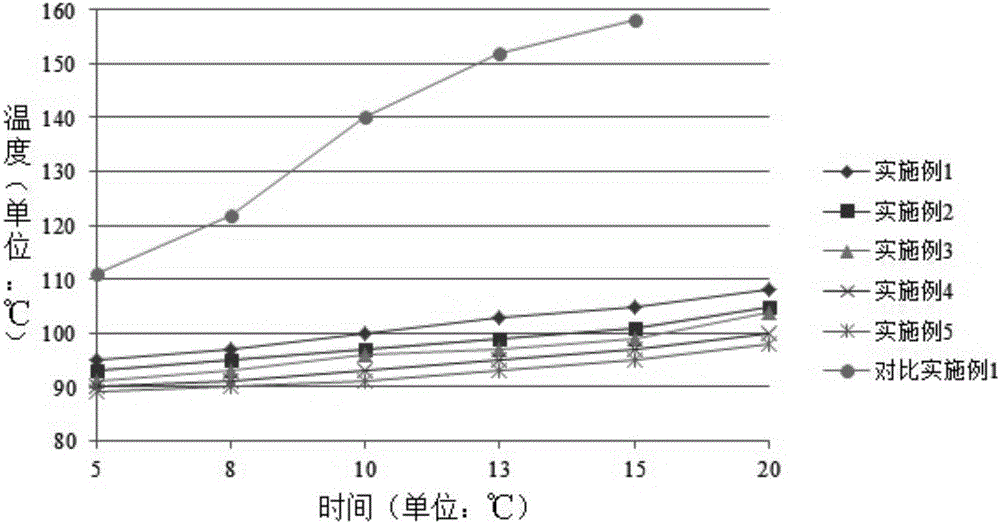

Polyvinyl chloride mixture for wires and cables and preparation method thereof

ActiveCN102775701ALow costSimple preparation processPlastic/resin/waxes insulatorsClimate change adaptationEpoxyPlasticizer

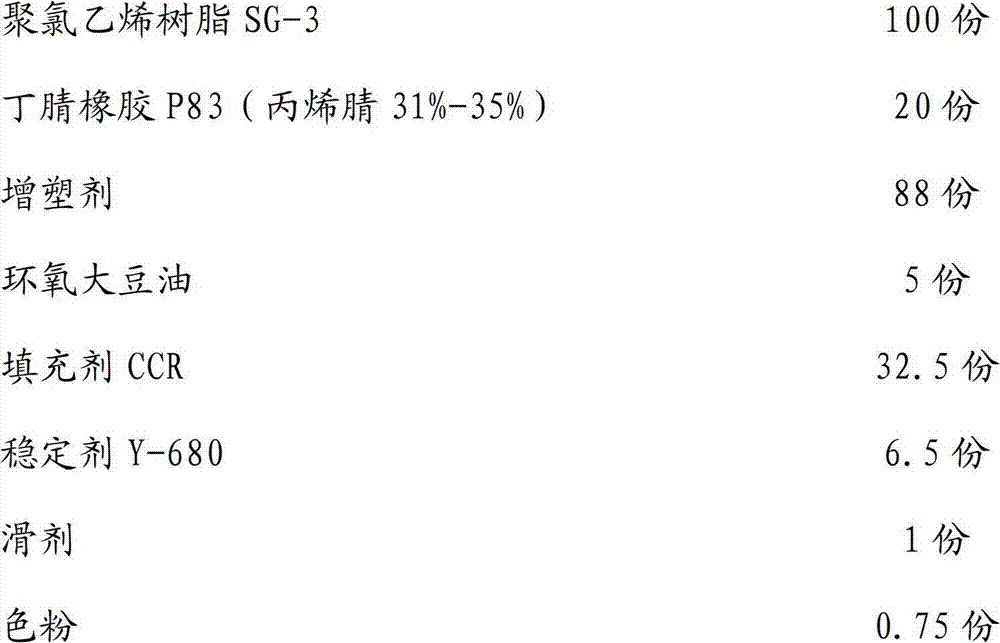

The invention discloses a polyvinyl chloride mixture for wires and cables and a preparation method thereof. The mixture comprises 30-60 parts of polyvinyl chloride resin, 4-15 parts of nitrile-butadiene rubber, 17-60 parts of plasticizer, 0.5-3 parts of epoxy soybean oil, 5-20 parts of filler, 2-3 parts of stabilizer, 0.2-0.6 part of lubricant and 0.1-1 part of toner. The preparation method comprises the following steps: adding polyvinyl chloride resin, plasticizer, stabilizer, filler, epoxy soybean oil, lubricant and toner together into a high-speed mixer, evenly mixing to a certain temperature, adding nitrile-butadiene rubber into the high-speed mixer to carry out secondary mixing, evenly mixing, mixing in a cold mixer while sending the mixture into a preheated granulator, and extruding and granulating to obtain the required polyvinyl chloride mixture for wires and cables. The polyvinyl chloride mixture disclosed by the invention still has the characteristics of torsion resistance, high elastic resilience, friction resistance, torsional deformation resistance and strong torsional fracture performance at -40 DEG C, and also has the advantages of low cost and simple preparation technique.

Owner:深圳市金环宇电线电缆有限公司

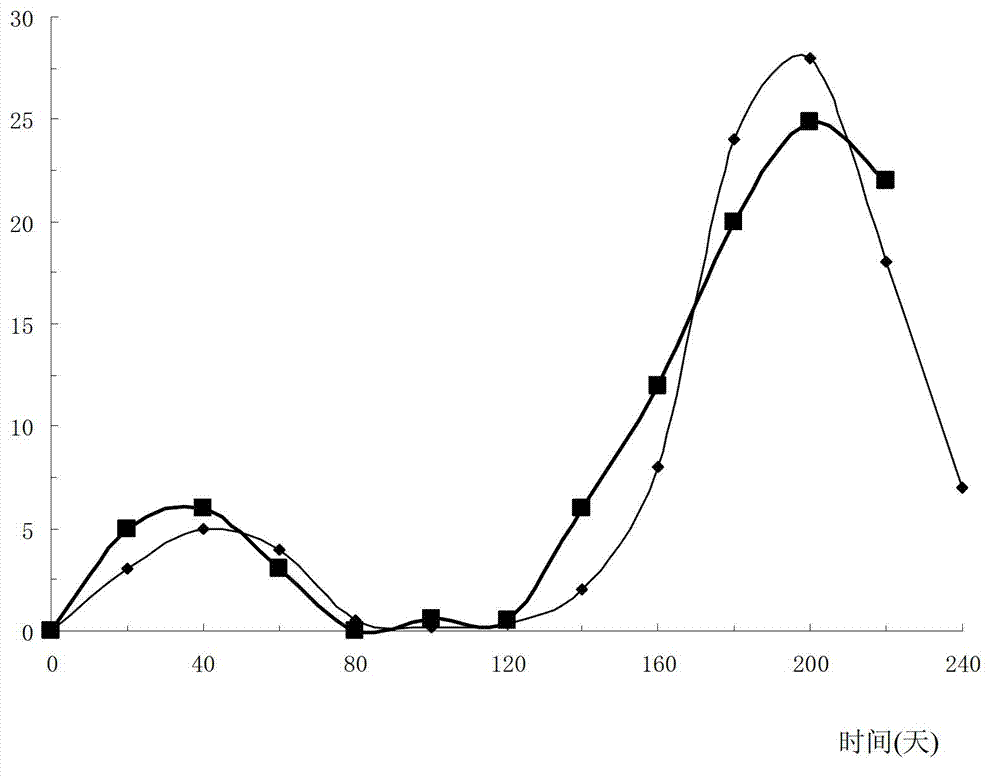

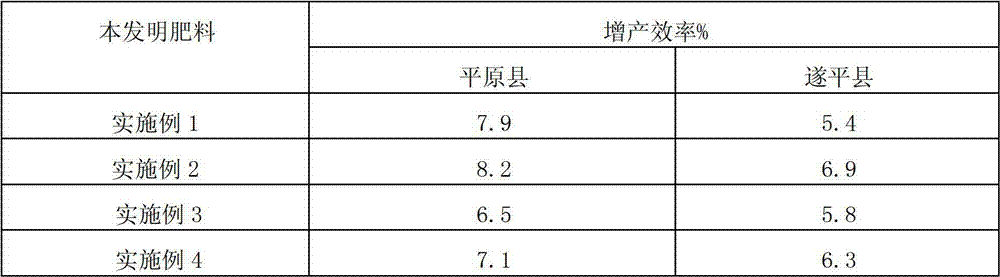

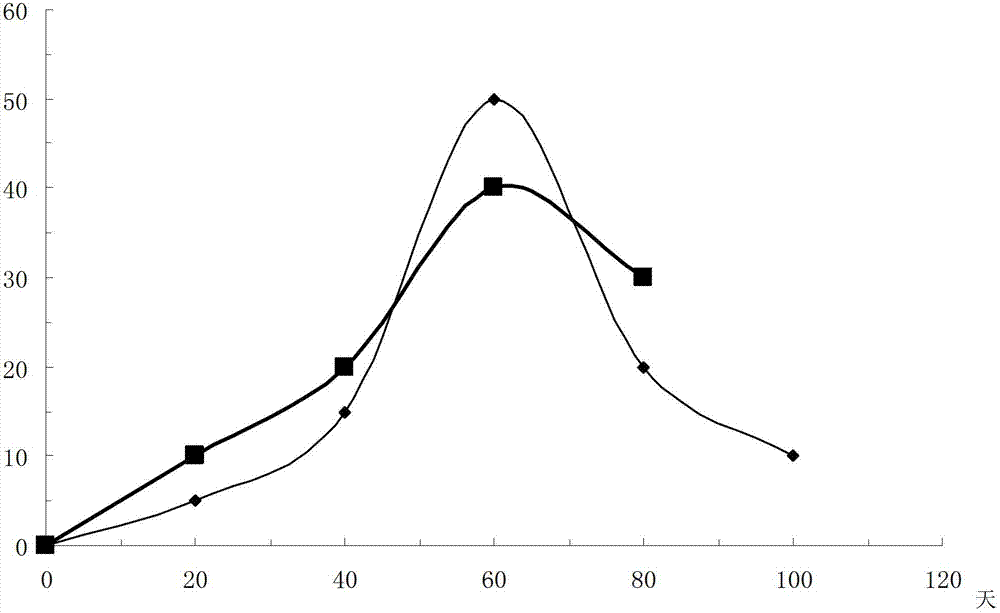

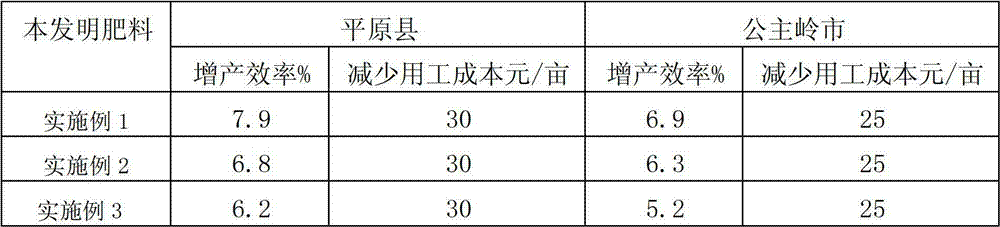

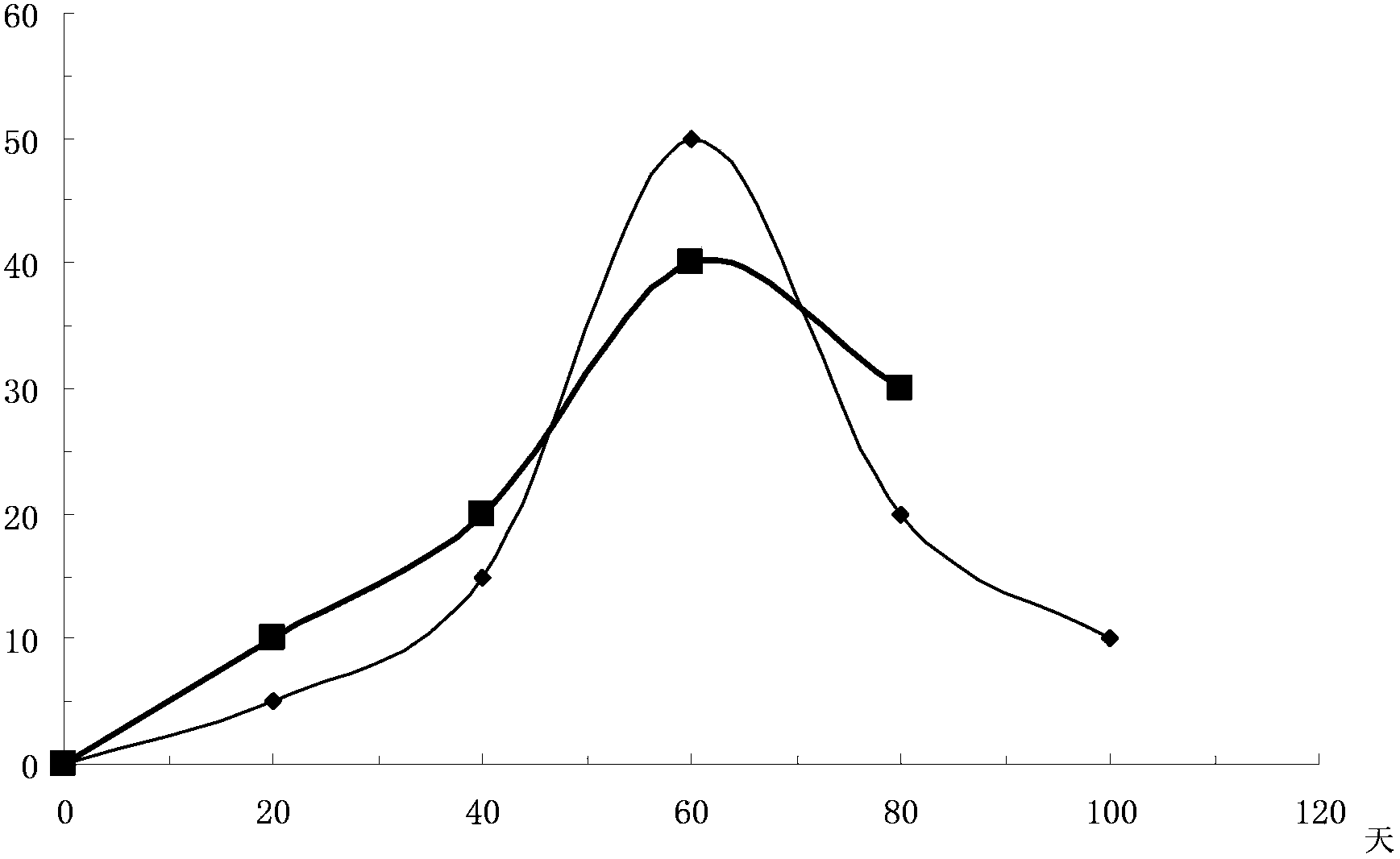

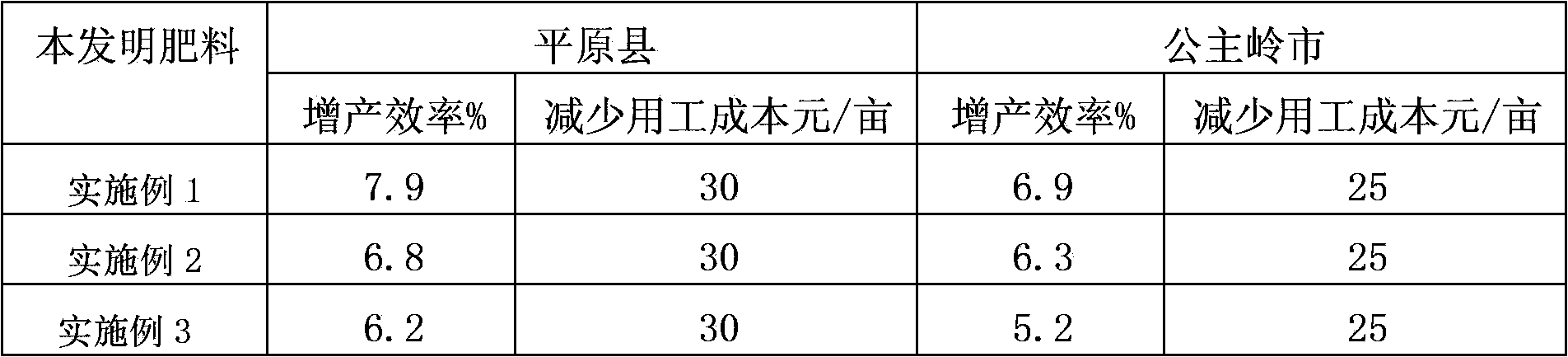

Preparation method of mechanically fertilized controlled-release fertilizer special for winter wheat

The invention relates to a preparation method of mechanically fertilized controlled-release fertilizer special for winter wheat. The preparation method comprises the following steps: taking urea, monoammonium phosphate, potassium chloride and zinc sulfate according to the proportion, granulating by a high tower to obtain granular core fertilizer; spraying urea solution onto the core fertilizer to form a urea film to obtain urea-coated fertilizer; taking epoxy resin and polyurethane, and adding curing agent T31, diluting agent benzyl glycidyl ether and talcum powder, mixing uniformly to obtain an outer film coating agent; spraying the outer film coating agent onto the urea-coated fertilizer to obtain three double-layer coated controlled-release fertilizer varieties I, II and III with the dosage of the outer film coating agent respectively occupying 3%, 5% and 7% of the urea-coated fertilizer; and further compounding according to the proportion to obtain the controlled-release fertilizer. The preparation method provided by the invention prepares the core fertilizer special for the wheat according to absorption requirements of the winter wheat on nutrition such as nitrogen, phosphorus, potassium and zinc; and then the double-layer coating is adopted, wherein an inner film improves surface characteristics of the fertilizer granules, and an outer film controls the nutrition release, so that controlled-release fertilizer is suitable for the nutrition absorption of the winter wheat and is suitable for mechanical fertilization.

Owner:菏泽金正大生态工程有限公司

Modified graphene lubricating oil with high dispersibility and high affinity, and preparation method thereof

The invention discloses a modified graphene lubricating oil with high dispersibility and high affinity, and a preparation method thereof. The modified graphene lubricating oil comprises, by weight, 0.3-1.5 parts of modified graphene, 0.3-1.5 parts of a dispersing agent, 0.1-2 parts of an affiliation agent, and 100 parts of base oil. According to the present invention, the formula is reasonable, and the preparation method is simple; the prepared lubricating oil has advantages of good stability, good affinity and improved lubricating performance, and can form ink on a mechanical member in mechanical movement so as to reduce the movement resistance of the mechanical member, reduce the friction coefficient, provide the super strong lubricating property and wear resistance, prolong the service life of mechanical member, and achieve energy saving; and the modified graphene lubricating oil can be widely used in a variety of mechanical members, and has great market potential and broad market prospects.

Owner:CHONGQING DELING TECH

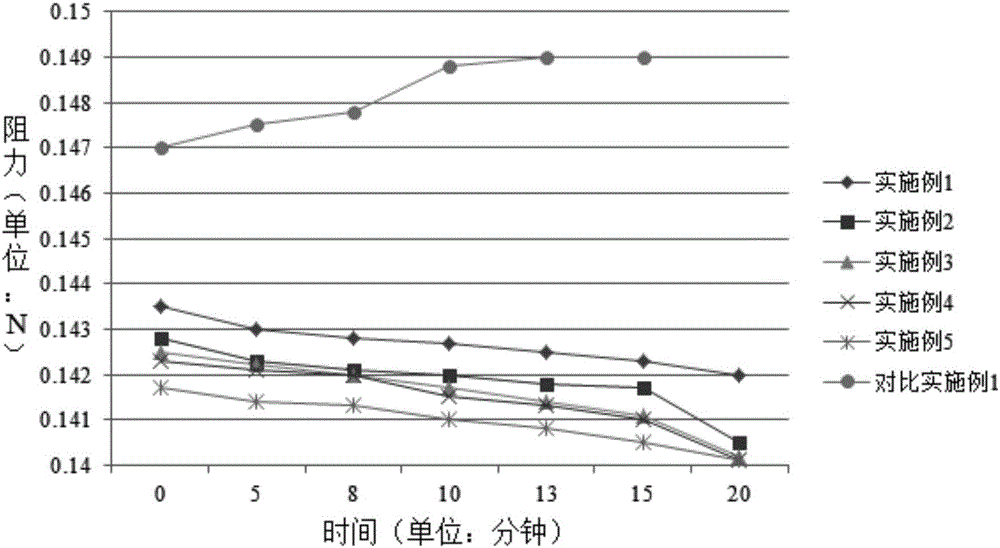

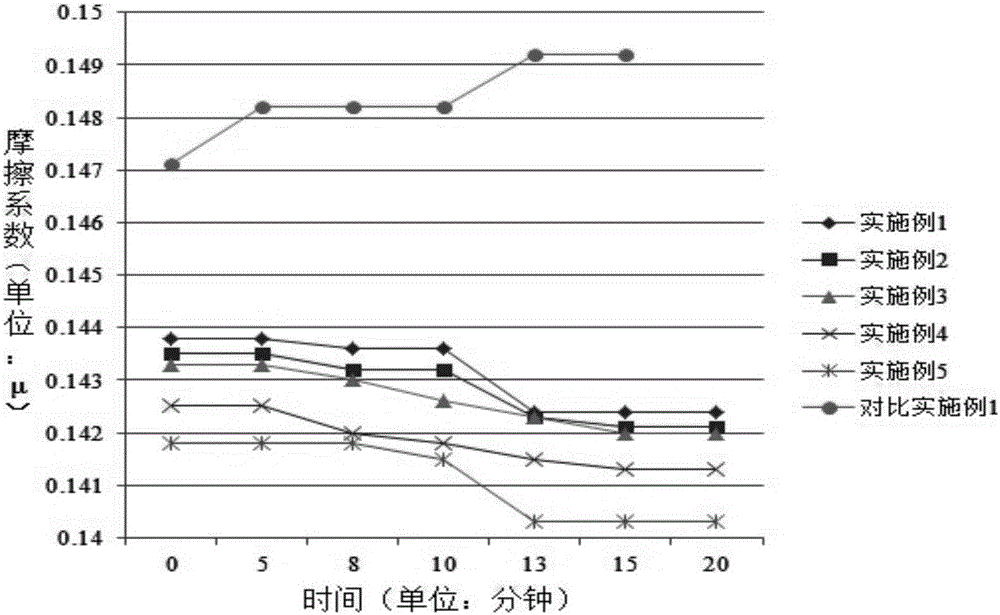

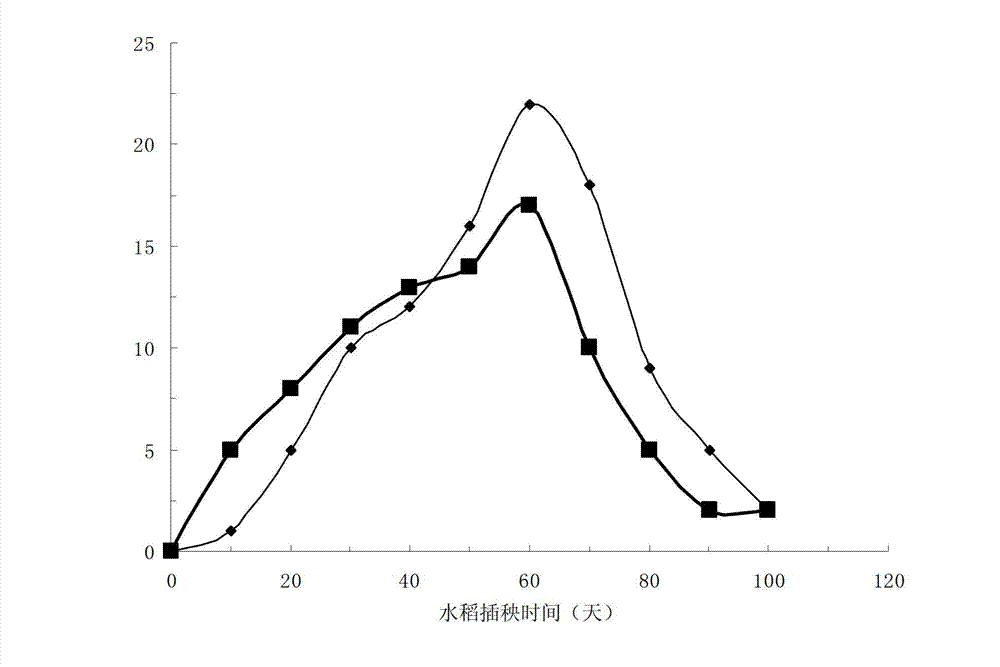

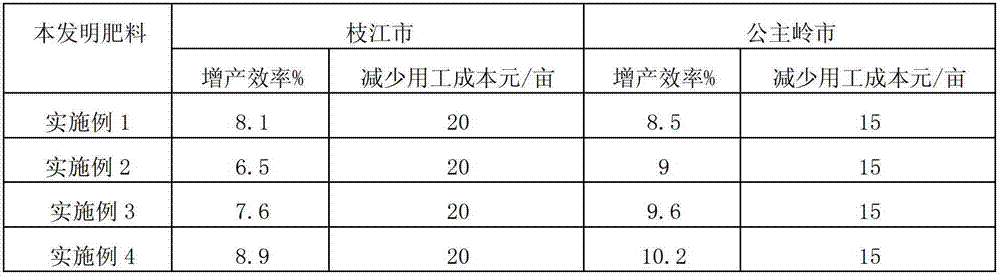

Preparation method for controlled-release fertilizer special for mechanically applied rice

The invention relates to a preparation method for controlled-release fertilizer special for mechanically applied rice. The preparation method comprises the following steps: performing double-layer coating by using high tower pelleting compound fertilizer as core fertilizer to obtain the corresponding double-layer coating controlled-release fertilizer I, double-layer coating controlled-release fertilizer II and double-layer coating controlled-release fertilizer III, wherein the bottom layer urea coating accounts for 4 to 6 weight percent of the core fertilizer, and the outer layer film coating agent accounts for 2 weight percent, 4 weight percent and 6 weight percent of the urea coated fertilizer respectively based on the total weight of the reclaimed polyethylene film resin and the reclaimed polystyrene foam resin; and mixing the double-layer coating controlled-release fertilizer I, the double-layer coating controlled-release fertilizer II and the double-layer coating controlled-release fertilizer III according to the mass ratio of 1:(1-3):(1-2) to obtain the controlled-release fertilizer special for mechanically applied rice. The controlled-release fertilizer special for mechanically applied rice meets the absorption requirements of the rice on nitrogen, phosphorus and potassium nutrients in the growth stage, is difficult to crush and is suitable for mechanical fertilizer application.

Owner:菏泽金正大生态工程有限公司

Lubricating oil with modified graphene and good dispersibility and method for preparing lubricating oil

The invention discloses lubricating oil with modified graphene and good dispersibility and a method for preparing the lubricating oil. The lubricating oil with the modified graphene comprises, by weight, 0.3-1.5 parts of modified graphene oxide, 0.3-1.5 parts of dispersing agents and 100 parts of base oil. The lubricating oil and the method have the advantages that formulas are reasonable, the method is simple, the prepared lubricating oil is good in stability and ultra-strong in lubricity and anti-attrition property, the lubricating properties can be enhanced, movement resistance can be reduced when the lubricating oil is used in mechanical movement, friction coefficients can be lowered, the service lives of mechanical components can be prolonged, and energy can be saved; the lubricating oil can be widely applied to various mechanical components, and accordingly the lubricating oil and the method have huge market potential and broad market prospects.

Owner:CHONGQING DELING TECH

Iron-chromium-boron-silicon/FeS composite solid lubrication thin film and method for making same

ActiveCN101398122ANovel structureImprove bindingMolten spray coatingEngine lubricationSurface layerSulfur

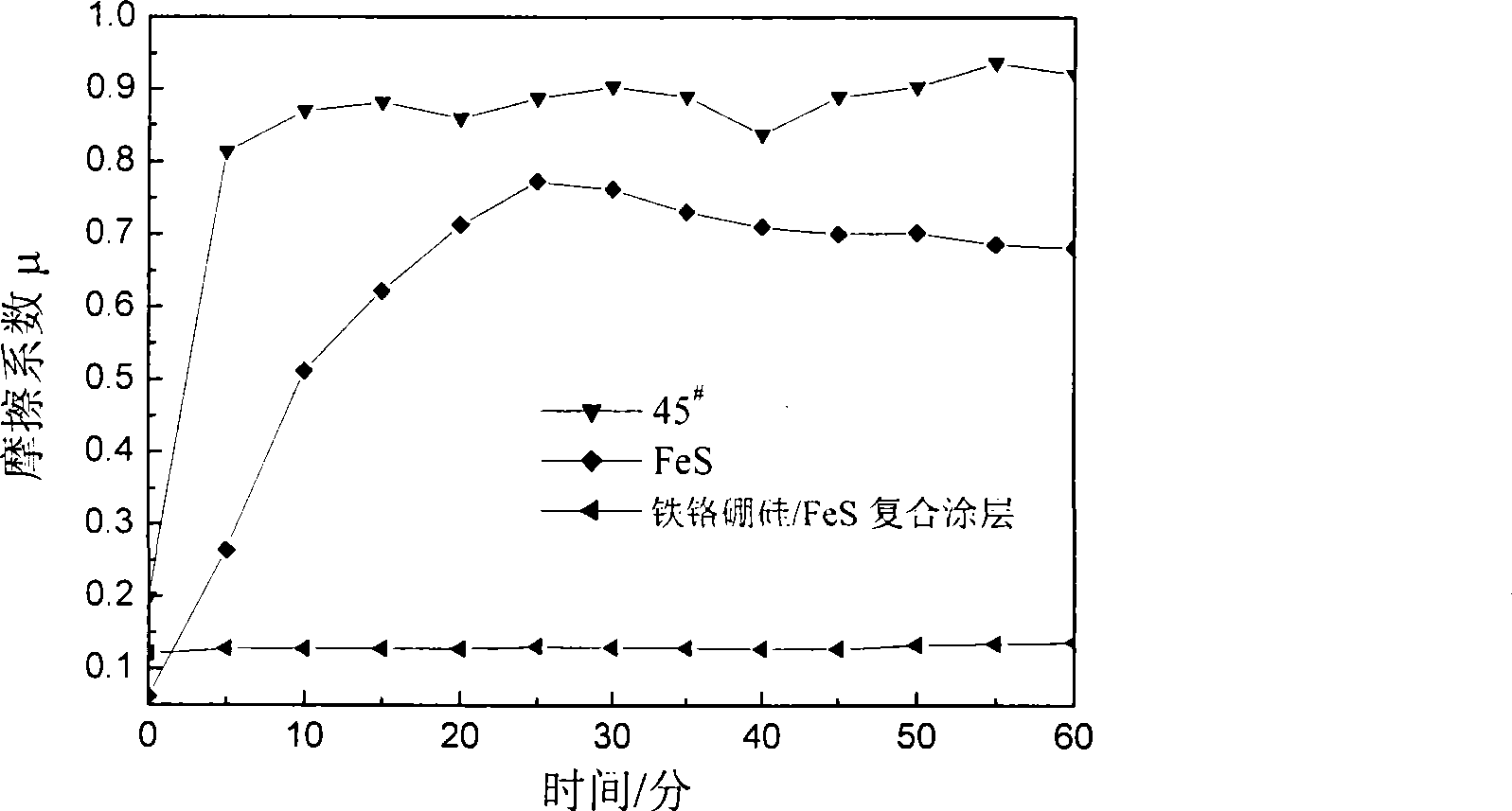

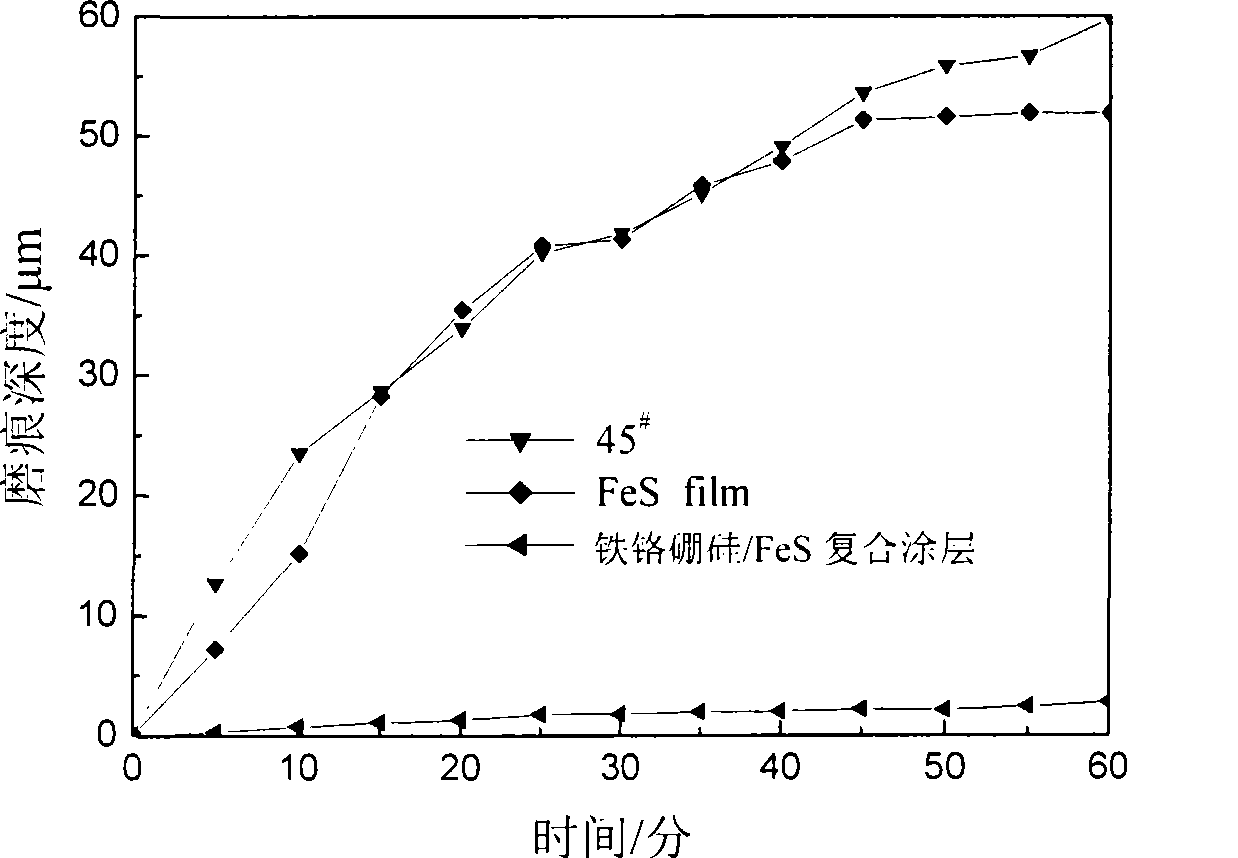

The invention discloses an Fe-Cr-B-Si / FeS composite solid lubricating film and a preparation method thereof, which firstly uses ultrasonic plasma for spray painting an Fe-Cr-B-Si coating on a substrate and then low temperature ion sulfurizing treatment is carried out to the Fe-Cr-B-Si coating and the Fe-Cr-B-Si / FeS composite solid lubricating film is prepared. The Fe-Cr-B-Si / FeS composite solid lubricating film is characterized in that: the Fe-Cr-B-Si coating is firstly painted and then the sulfurizing treatment is carried out to the coating so that the surface layer of the coating reacts with sulfurous steam to form an FeS layer, and finally, the upper part of the Fe-Cr-B-Si coating turns out to be an FeS solid lubricating layer. The invention has a novel structure and no obvious boundary exists on the FeS layer of the Fe-Cr-B-Si coating and the FeS layer has good binding capacity with the substrate. Compared with the prior art, the invention has good nano mechanical properties with an anti-friction capacity better than the prior art by more than 20 times. As the invention is the FeS layer obtained from sulfurizing on the surface of the Fe-Cr-B-Si coating, thus having a compact structure; besides, the friction property of the Fe-Cr-B-Si / FeS composite solid lubricating film is stable and the anti-friction property thereof is much better under the conditions of either dry friction or oiling.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

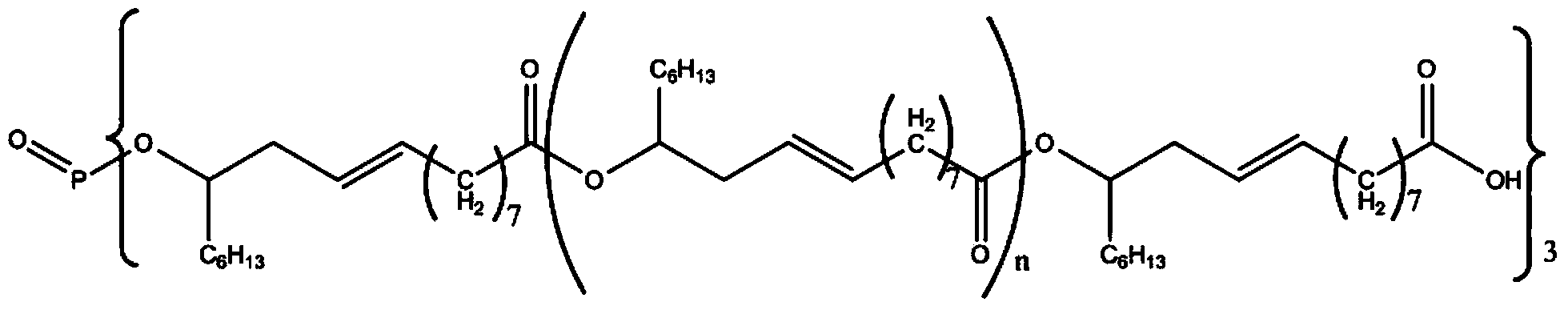

Polyricinoleate phosphate and preparation method thereof, and application of polyricinoleate phosphate in preparing biodegradable trace cutting oil

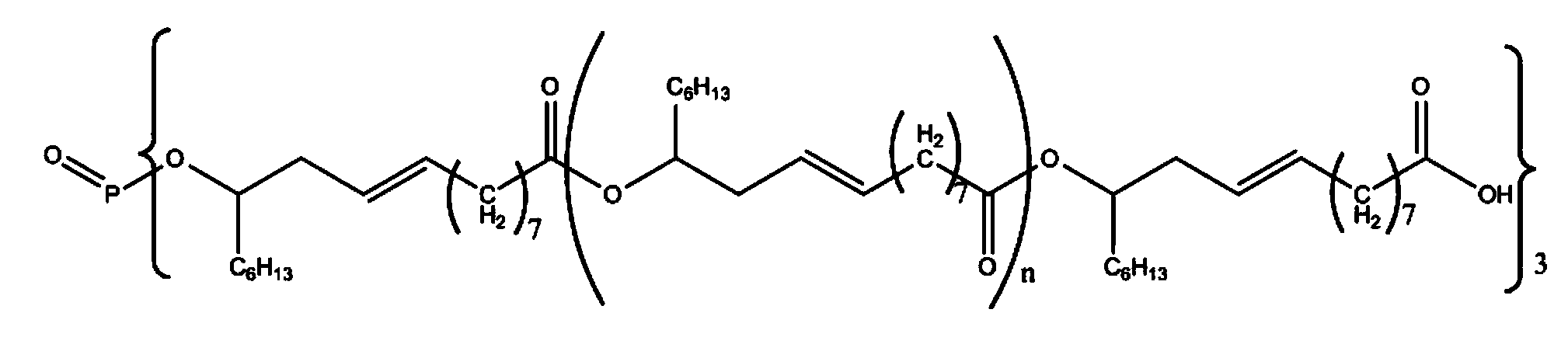

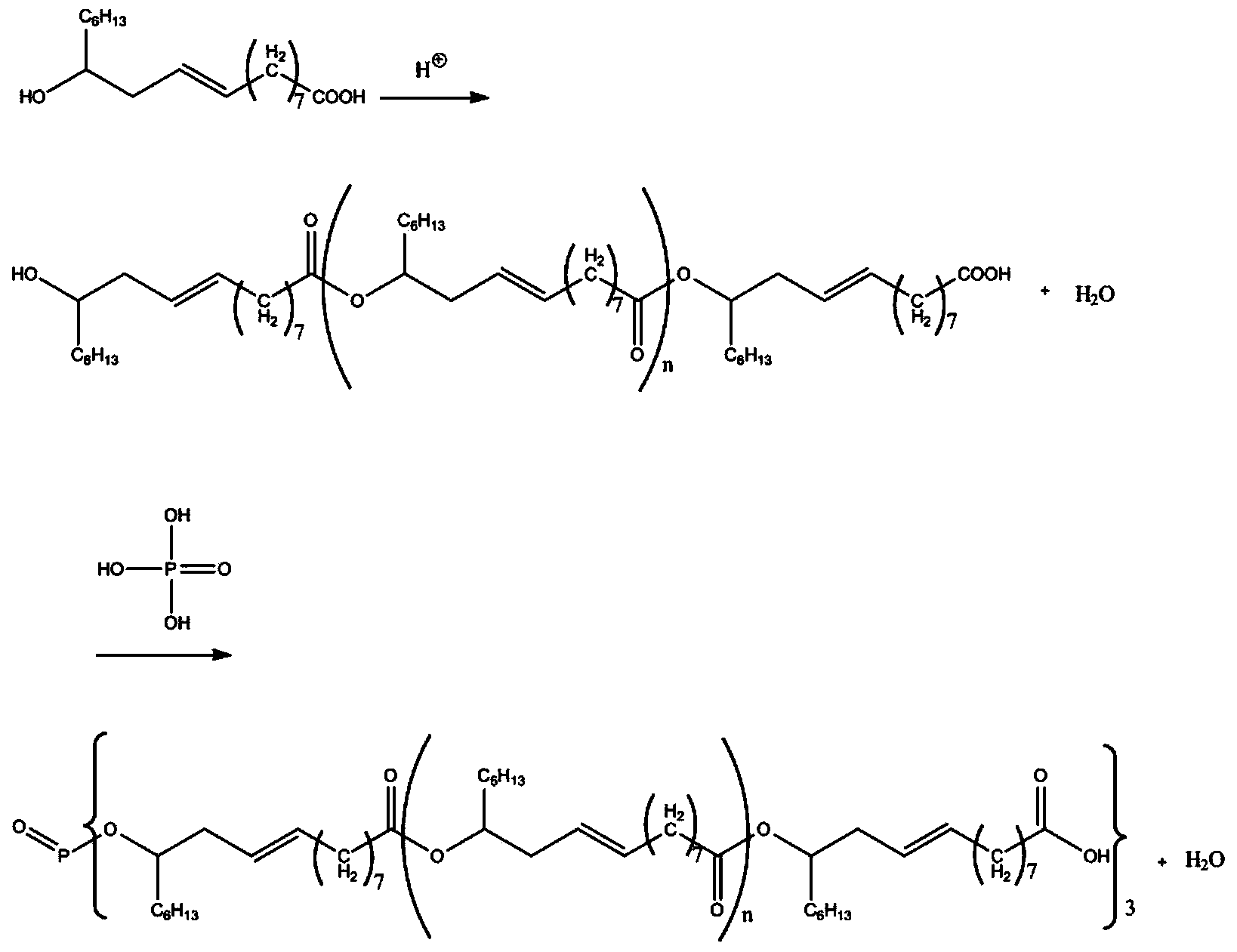

ActiveCN103450255ALow viscosityEasy to useGroup 5/15 element organic compoundsBase-materialsPhosphateStructural formula

The invention relates to a polyricinoleate phosphate and a preparation method thereof, and application of the polyricinoleate phosphate in preparing biodegradable trace cutting oil. The invention is characterized in that the molecular structural formula of the polyricinoleate phosphate is disclosed in the specification. The polyricinoleate phosphate can be mixed with low-viscosity ester to prepare trace cutting oil. The trace cutting oil has favorable lubricating property extreme pressure antiwear property; a slight amount of trace cutting oil can satisfy the high-end requirement for metal working, thereby reducing the harm to the environment and workers; and the trace cutting oil is biodegradable, thereby minimizing the environmental pollution.

Owner:南京新展新材料有限公司

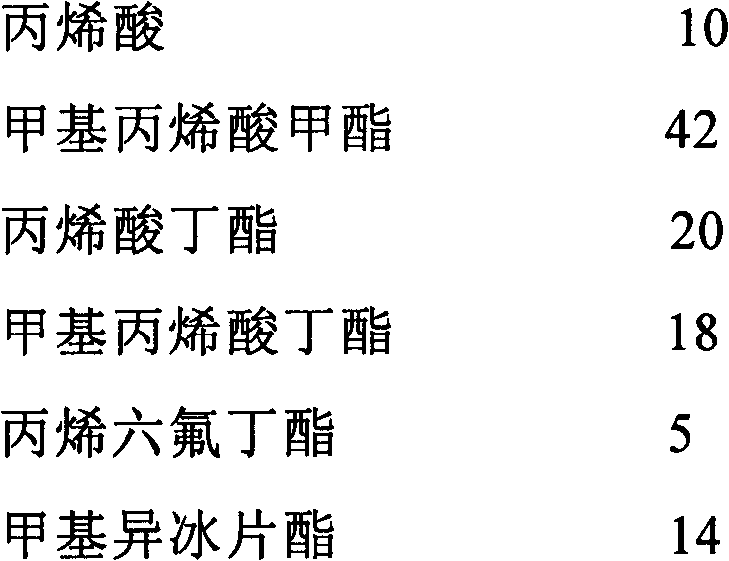

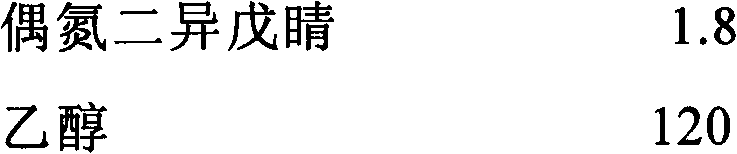

Acrylic ester powdered resin having self-cleaning property and synthesizing method thereof

InactiveCN102363640AStrong anti-frictionWide range of high and low temperature performancePowdery paintsSolubilityAcrylic resin

The invention relates to an acrylic ester powdered resin having a self-cleaning property and a synthesizing method thereof. The acrylic ester powdered resin comprises the following components in part by weight: 8-15 parts of polymeric carboxylic acids, 40-60 parts of methyl methacrylates, 10-25 parts of butyl acrylates, 10-30 parts of butyl methacrylates, 5-20 parts of fluorinated monomers, 10-20 parts of methyl isobornyl thiocyanoacetates and 1.5-3.5 parts of initiating agents. Several conventional acrylate monomers, isobornyl acrylate monomers and fluorinated acrylate monomers are copolymerized, degassed, crushed and like, thereby acquiring the powdered acrylic resin having an excellent property. Compared with the prior art, the resin synthesized according to the synthesizing method has excellent ageing resistance and scraping resistance as well as self-cleaning property, contains no VOC (Volatile Organic Compounds) and has water solubility.

Owner:SHANGHAI CHENGYING NEW MATERIALS +1

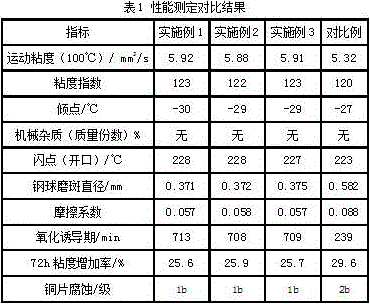

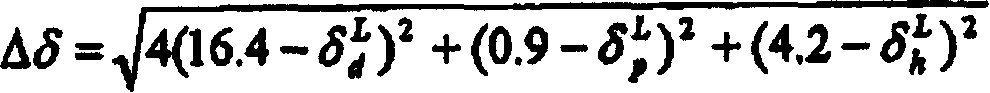

Lubricating oil for vehicles and preparation method thereof

InactiveCN105482884AGood synergyGood anti-wear and anti-friction synergistic performanceLubricant compositionLAUROYL SARCOSINEBismuth

The invention relates to a lubricating oil for vehicles, which is prepared from the following components in parts by weight: 92-100 parts of base oil, 6-8 parts of ricinoleic acid, 3-4 parts of ethylenediamine oleate, 2-3 parts of vinyl ethyl ether, 3-4 parts of sodium lauroyl sarcosine, 1.5-2 parts of perfluorooctyl ethylene, 12-15 parts of 2-ethyl decanol, 2-3 parts of ethylene bis oleamide, 4-5 parts of sodium ethylenediamine diorthophenylacetate and 1.2-1.8 parts of nano bismuth oxide. The lubricating oil for vehicles is prepared from the nano active components and multiple additives by a special technique; the components have outstanding synergistic effects; and the lubricating oil for vehicles has favorable antiwear anti-friction synergistic performance, effectively prolongs the oxidation induction time of the oil product, effectively inhibits the increase of the viscosity of the oil product, and has favorable antioxidation synergistic performance. Besides, the added additives enhance the corrosion inhibition property.

Owner:王丹

Cosmetic composition comprising a sebum-absorbing powder and a powder with a low critical surface energy

InactiveCN1569033AGood cosmetic propertiesStrong anti-frictionCosmetic preparationsHair cosmeticsMaterials scienceCritical surface

Disclosed herein is a cosmetic composition comprising at least one sebum-absorbing powder having a sebum uptake, at least one second powder having a critical surface energy of less than or equal to 24 mN / m, and a liquid binder phase comprising at least one non-volatile oil. The composition may make it possible to obtain a skin makeup with good cosmetic properties over time, such as a good rub resistance, transfer-free properties, good uniformity, maintenance of the initial color of the makeup, and the absence of sheen (i.e., resistance of the matte effect).

Owner:LOREAL SA

Special fertilizer for water plants for shrimp and crab culture pond

InactiveCN106116803AGood controlled release effectMeet absorption requirementsCalcareous fertilisersAnimal corpse fertilisersSodium BentoniteManganese

The invention discloses special fertilizer for water plants for a shrimp and crab culture pond. The fertilizer is prepared from raw materials in parts by weight as follows: 5-15 parts of monoammonium phosphate, 10-30 parts of urea, 5-20 parts of poly potassium phosphate, 5-15 parts of bentonite, 2-10 parts of pottery clay, 2-8 parts of zeolite powder, 2-10 parts of borax, 5-12 parts of weathered coal, 1-4 parts of nano calcium carbonate, 10-20 parts of molasses powder, 2-12 parts of fish meal, 5-15 parts of fermented cassava, 2-10 parts of chicken manure, 5-15 parts of honey, 0.5-1.5 parts of EDTA (ethylene diamine tetraacetic acid) chelated manganese, 0.5-1.5 parts of diaminoferric xanthohumate and 1-6 parts of an outer-layer coating agent. The fertilizer is environment-friendly, contains very rich nutritional substances, has the good slow-release effect and can meet requirements of the water plants in the whole growth period through one-time fertilizer application.

Owner:ANQING FUJIANG FISHERIES BREEDING CO LTD

Preparation method of special disposable mechanically-applied fertilizer for corn

The invention relates to a preparation method of a special disposable mechanically-applied fertilizer for corn. According to the invention, urea, monoammonium phosphate, potassium chloride and zinc sulfate are compounded, a high-tower granulated compound fertilizer is used as the core fertilizer, and double film layers are coated, wherein the inner layer film is a urea film and used for improving the surface characteristic of the fertilizer granules, and the outer layer film is a thermoplastic resin coating and a thermosetting coating and is used for controlling the release of the nutrients. The special mechanically-applied fertilizer for corn has more smooth and harder surface, and is suitable for mechanical application. The fertilizer satisfies the requirements of corn for absorbing nitrogen, phosphorus, potassium, zinc and other nutrients; and the large-scale field test proves that the fertilizer has favorable yield increase effect.

Owner:菏泽金正大生态工程有限公司

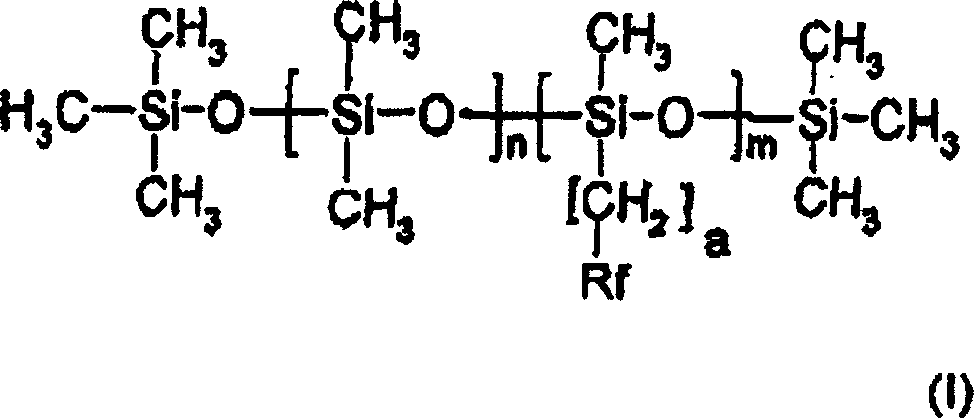

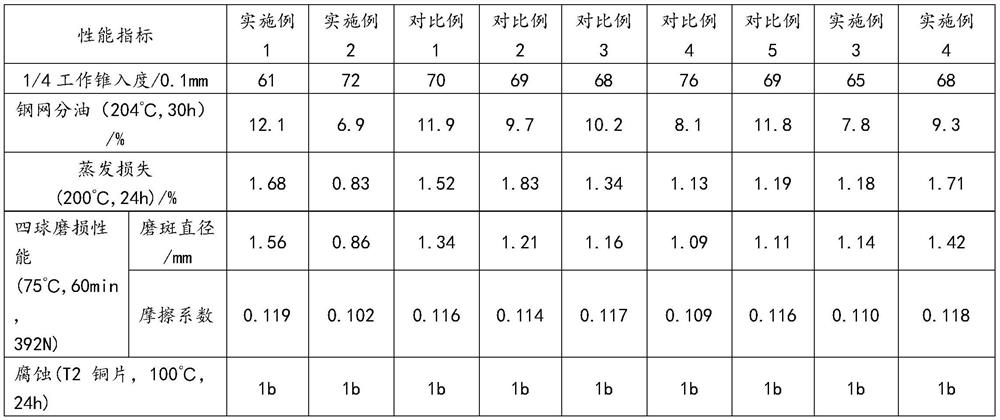

Perfluoropolyether type lubricating grease of composite thickening agent and preparation method of perfluoropolyether type lubricating grease

ActiveCN113956911AGood stabilityGood anti-friction performanceLubricant compositionPolytetrafluoroethylenePerfluoropolyether

The invention belongs to the field of lubricating materials, and particularly relates to perfluoropolyether type lubricating grease of a composite thickening agent and a preparation method of the perfluoropolyether type lubricating grease. The perfluoropolyether type lubricating grease comprises the following components in percentage by weight based on the total weight of the components: 55 to 85 weight% of perfluoropolyether oil, 12 to 42 weight% of a composite thickening agent and 0.1 to 3 weight% of an additive, and the composite thickening agent is selected from two or more of polytetrafluoroethylene, chlorotrifluoroethylene-polyethylene copolymer and tetrafluoroethylene-hexafluoropropylene copolymer. The perfluoropolyether type lubricating grease prepared by blending the perfluoropolyether oil serving as the base oil, the composite thickening agent and the additive has relatively good colloid stability, high temperature resistance and wear resistance, and the components and the preparation process are simple and easy to implement.

Owner:CHINA PETROLEUM & CHEM CORP

Code-jet printing ink modifier

The invention relates to a code spraying ink modifying agent which comprises the components with weight percentage: 20-60wt% of solvent, 10-40wt% of latent solvent, 1-10wt% of anticoagulant, 1-10wt% of electrical conduction control agent, 0.1-6wt% of pH conditioning agent, 5-15wt% of adhesive force promoting agent, 0.1-4wt% of osmotic agent, 0.5-9wt% of stabilizing agent and 0.1-5wt% of coloring agent. The anticoagulant and the latent solvent contained in the code spraying ink modifying agent can effectively improve the phenomenon that a nozzle is easy to plug by code spraying ink, and ensures the code spraying ink to be dried rapidly and print more clearly and smoothly; the contained adhesive force promoting agent can be used for strengthening the adhesiveness of the code spraying ink for base material, especially metal base material, so as to lead the image to be firmer and hard wearing. Various auxiliary agents in the invention are matched for use, so that the performance of the code spraying ink can be effectively enhanced, the image resolution ratio is improved, the separation of ink dots is clear, the problem of trickling and deforming of the ink can be solved, and the corrosion resistance is improved.

Owner:BEIJING KEYIN MODERN PRINTING TECH

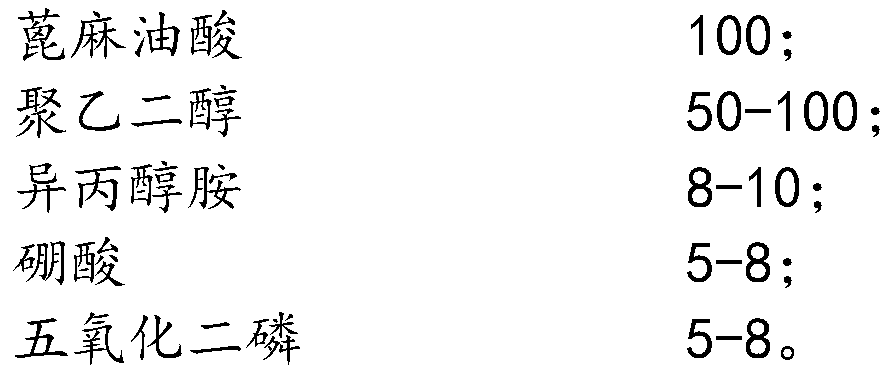

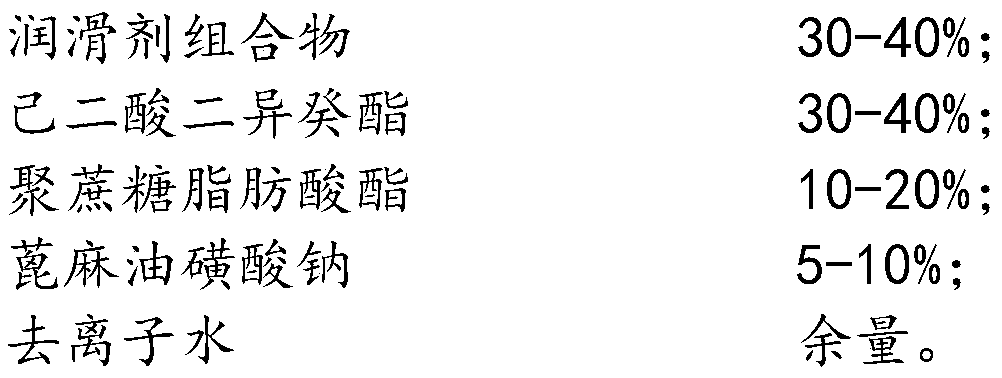

Phosphorus-boron-nitrogen-containing lubricating composition minimal quantity lubricant and preparation method thereof

PendingCN111040828AImprove the lubrication effectPromote degradationAdditivesActive agentPolyethylene glycol

The invention provides a lubricant composition. The lubricant composition is prepared from, by weight, 100 parts of ricinoleic acid, 50-100 parts of polyethylene glycol, 8-10 parts of isopropanolamine, 5-8 parts of boric acid and 5-8 parts of phosphorus pentoxide. The lubricant composition prepared in the invention is a B-P-N type friction modifier and an antirust agent, and is also a good surfactant. The invention also provides a minimal quantity lubricant prepared from the lubricant composition. The minimal quantity lubricant is characterized by also containing diisodecyl adipate, polysucrose fatty acid ester, castor oil sodium sulfonate, deionized water and other components. The minimal quantity lubricant prepared in the invention can meet the requirements of lubrication cooling, extreme pressure wear resistance and rust prevention in metal processing; and the usage amount of the lubricant can be saved by 90% or more when the lubricant is matched with a minimal quantity lubricationdevice.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

Heat insulation asphalt anticorrosive paint

InactiveCN101423730ALow costTime-saving and labor-savingFireproof paintsAnti-corrosive paintsEpoxyPhosphorous acid

The invention discloses a thermal insulation asphalt anticorrosion paint, which consists of isocyanate, polyether, an epoxy resin, phosphorous acid, coal tar pitch, methylbenzene, a thermal insulation material and a solvent, wherein the isocyanate is polymethylene polyphenyl isocyanate No.400, the solvent is dimethylbenzene, and the thermal insulation material consists of 50 to 80 portions of hollow glass fine powder and 80 to 100 portions of expanded perlite powder. The anticorrosion paint has the characteristics of thin coatings, low cost, time-saving and labor-saving coating, good thermal insulation performance, firm adhesion force, strong friction force resistance, resistance to chemical corrosion of acid, alkali and salt and so on.

Owner:徐东

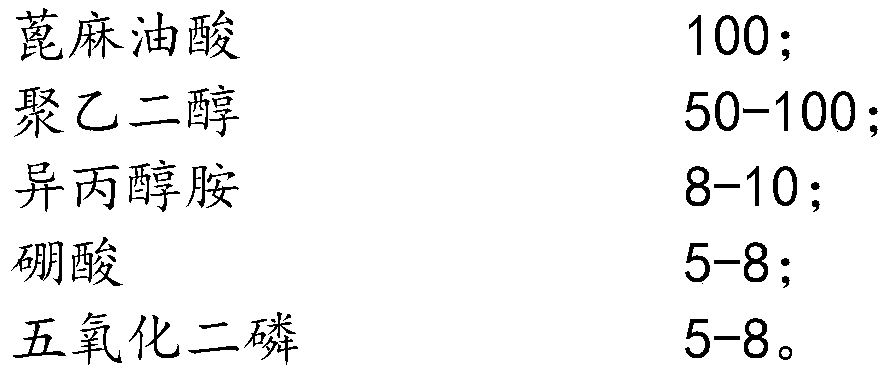

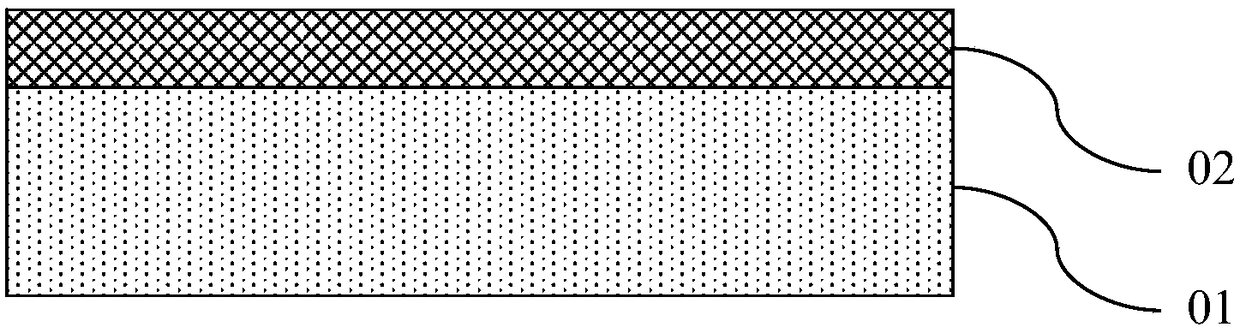

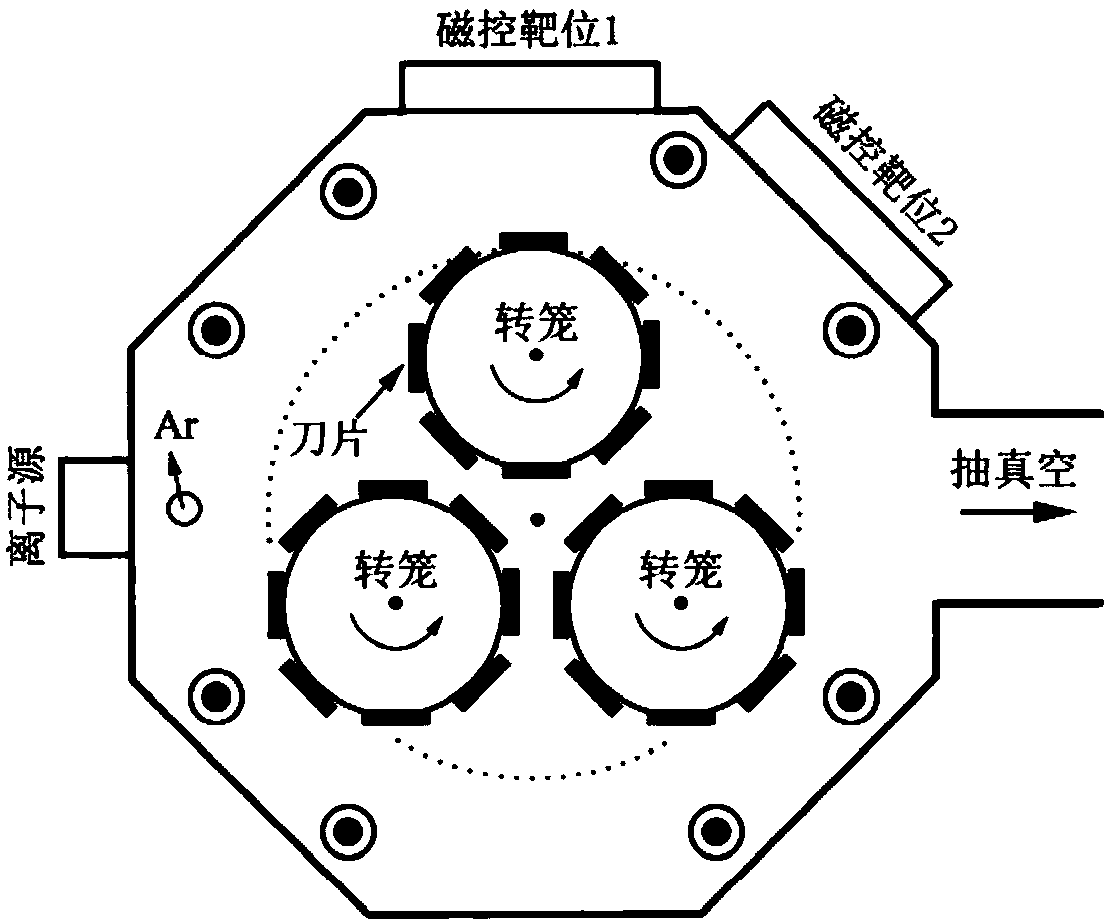

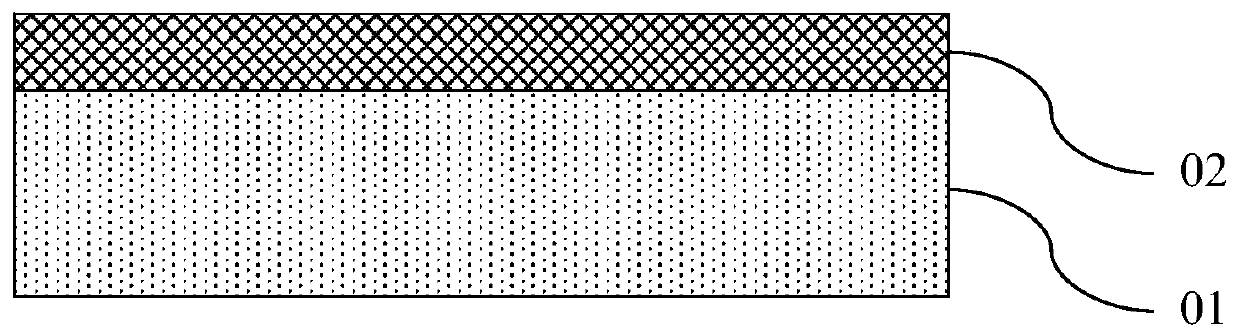

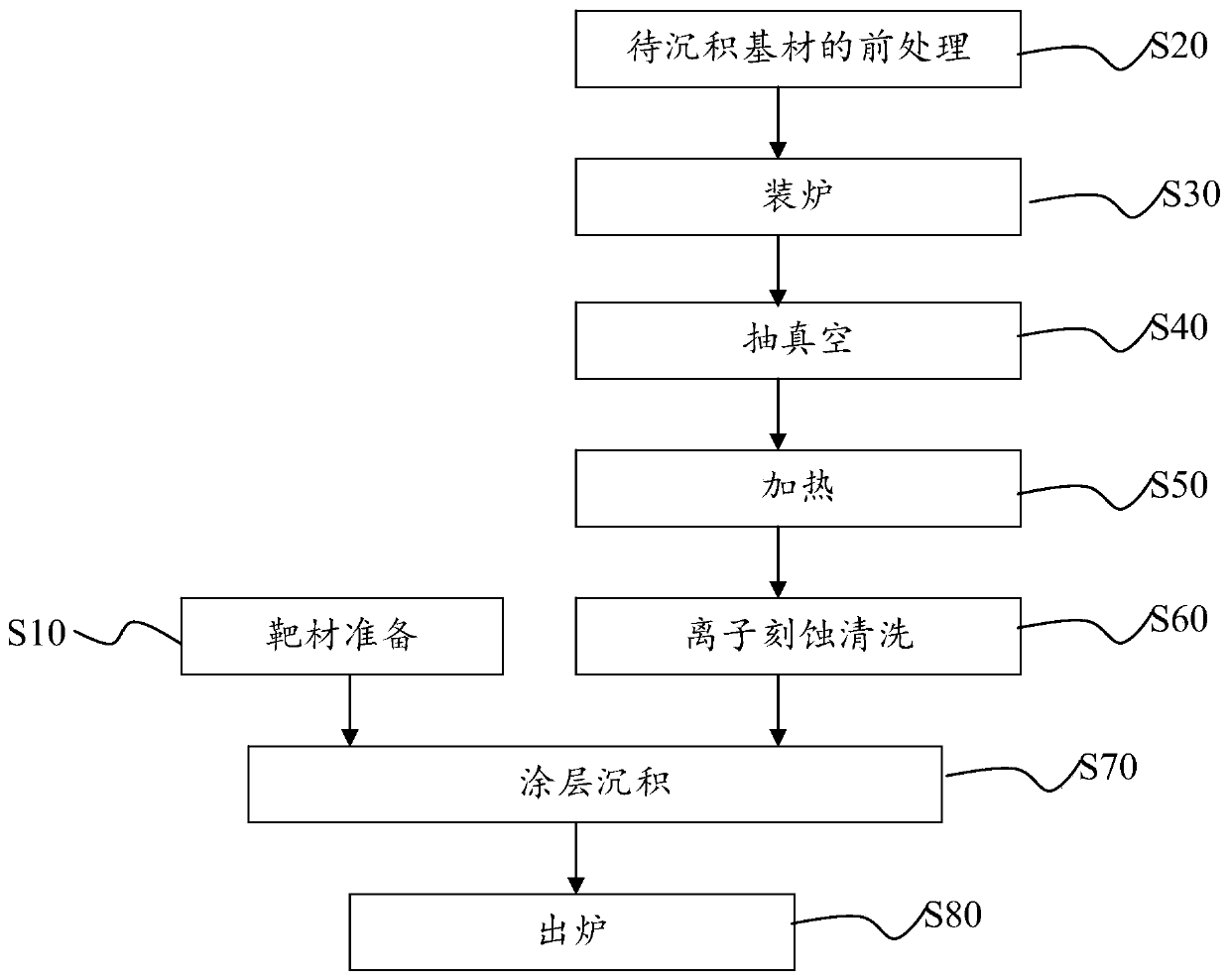

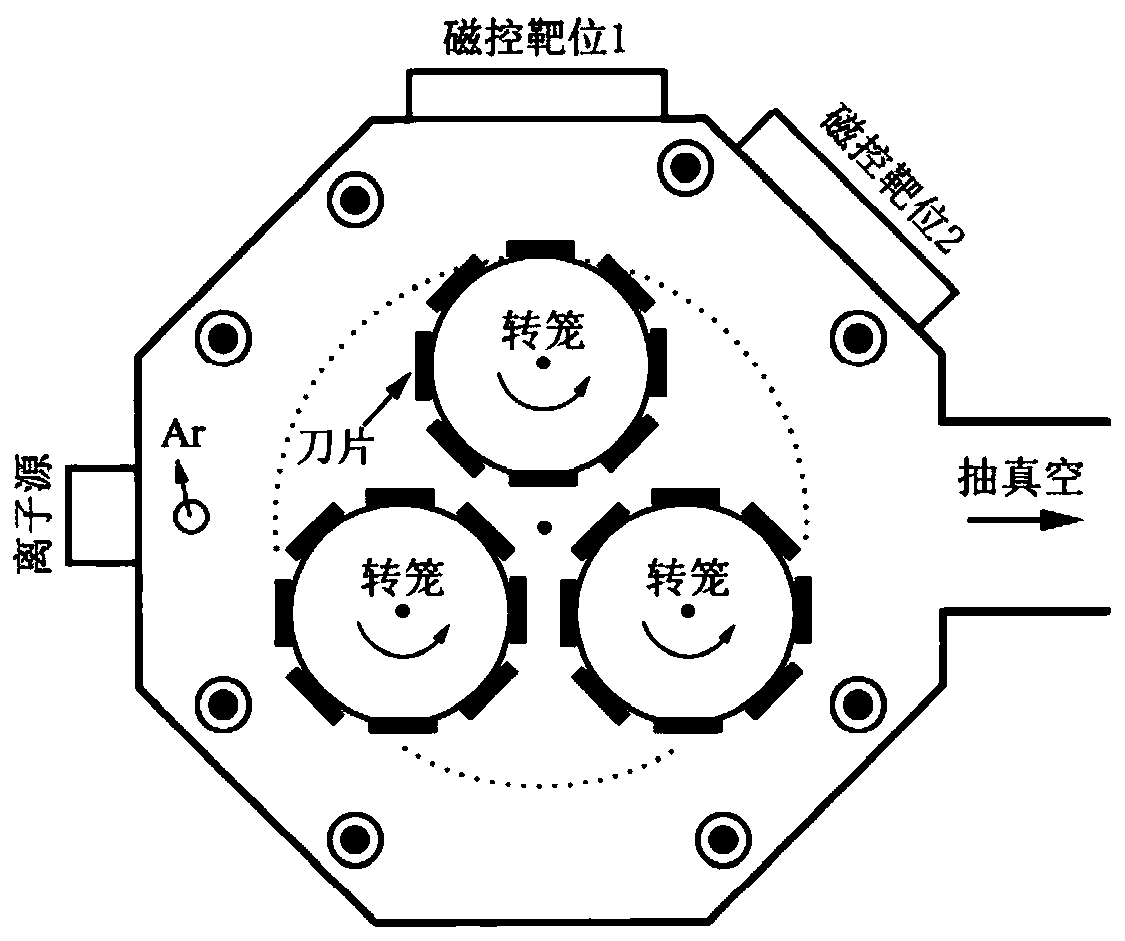

TiB2 self-lubricating coating, preparation method thereof and abrasion-resistant component

ActiveCN108251803AHigh hardnessImprove wear resistanceVacuum evaporation coatingSputtering coatingFriction reductionCutting force

The invention discloses a TiB2 self-lubricating coating, a preparation method thereof and an abrasion-resistant component. The TiB2 self-lubricating coating comprises a hard phase TiB2 and a vanadiumelement doped in the TiB2. The TiB2 self-lubricating coating has a low friction coefficient and achieves a friction reduction effect, the usage temperature range is wide, and the friction coefficientstability of the coating is good; and as for the preparation method of the coating, target conductivity is high, the deposition efficiency is high, the technical conditions are easily controlled, maneuverability is high, controllability is good, industrial production is easily achieved, and the prepared TiB2 self-lubricating coating has stable performance. The surface of the abrasion-resistant component is provided with the TiB2 self-lubricating coating, and thus the abrasion-resistant component is low in cutting force and cutting temperature, high in processing precision and long in service life.

Owner:SHENZHEN INST OF ADVANCED TECH

tib 2 Self-lubricating coating and its preparation method and wear-resistant component

ActiveCN108251803BHigh hardnessImprove wear resistanceVacuum evaporation coatingSputtering coatingCutting forceCoating

Owner:SHENZHEN INST OF ADVANCED TECH

Magnesium alloy cutting fluid containing colloidal particles and preparation method thereof

InactiveCN108192715AStrong resistance to hard waterGood workpiece protectionLubricant compositionColloidal particleElectronics

The invention provides magnesium alloy cutting fluid containing colloidal particles and a preparation method thereof. The magnesium alloy cutting fluid containing colloidal particles is prepared fromthe colloidal particles, lubricant, rust-proof sustained-releasing preparation, complex salt, surfactant, and pH buffer agent. The magnesium alloy cutting fluid provided by the invention has the advantages of being good in working liquid stability, good in rust-proof performance, strong in cutting capacity, good in tool anti-attrition, environment-friendly and the like. The magnesium alloy cuttingfluid can be applied to the functional electronics industry, can be applied to the auto spare parts industry, and has important significance.

Owner:SHENZHEN RUN SUN CHEM TECH

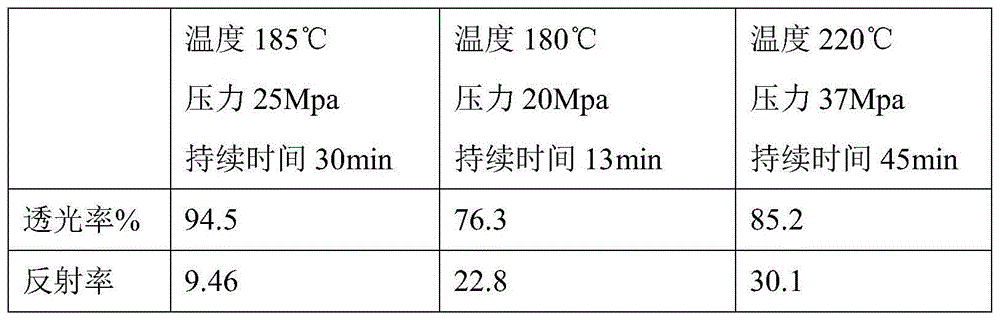

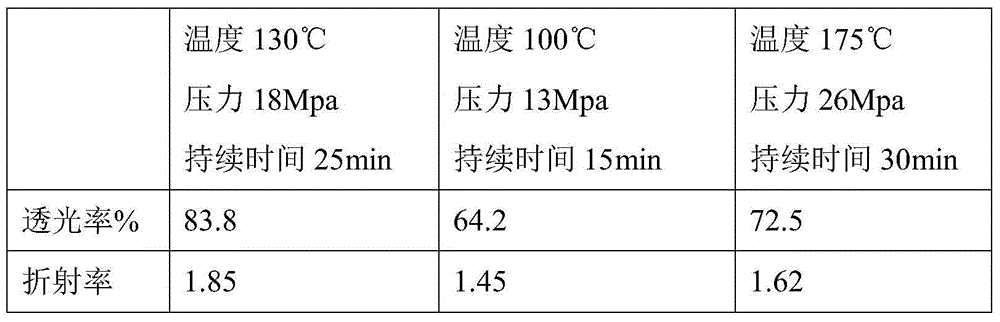

Method for making plastic transparent and semitransparent business cards

InactiveCN104527195AReduce reflective effectHigh transparencyLamination ancillary operationsSynthetic resin layered productsBusiness cardPunching

The invention discloses a method for making plastic transparent and semitransparent business cards, which relates to a method for making business cards. The invention aims to solve the problem that transparent plastic business cards in the prior art are not high in transparency, but too high in reflective rate, so that information on the business cards only can be seen in ideal light, but semitransparent plastic business cards are low in light transmittance and refractive index, so that the transparency of the semitransparent plastic business cards is low. The method comprises the steps of printing, laminating and punching; a plastic transparent business card, from top to bottom, sequentially comprises an upper nano-material layer, an upper PET layer, an ARM base, a lower PET layer and a lower nano-material layer; the laminating step is implemented by, from top to bottom, sequentially superimposing and arranging an upper nano-material layer, upper PET layer, printed ARM base, lower PET layer and lower nano-material layer of a plastic transparent business card, and laminating by using a laminating machine. Plastic transparent and semitransparent business cards prepared according to the invention are high in transparency.

Owner:哈尔滨联邦智能卡技术开发有限责任公司

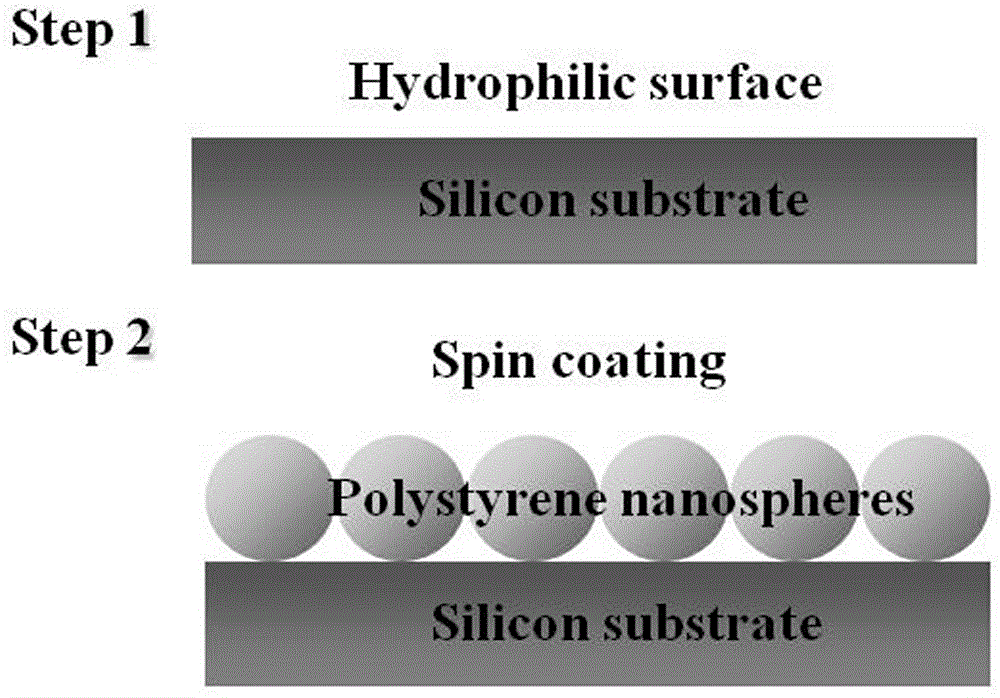

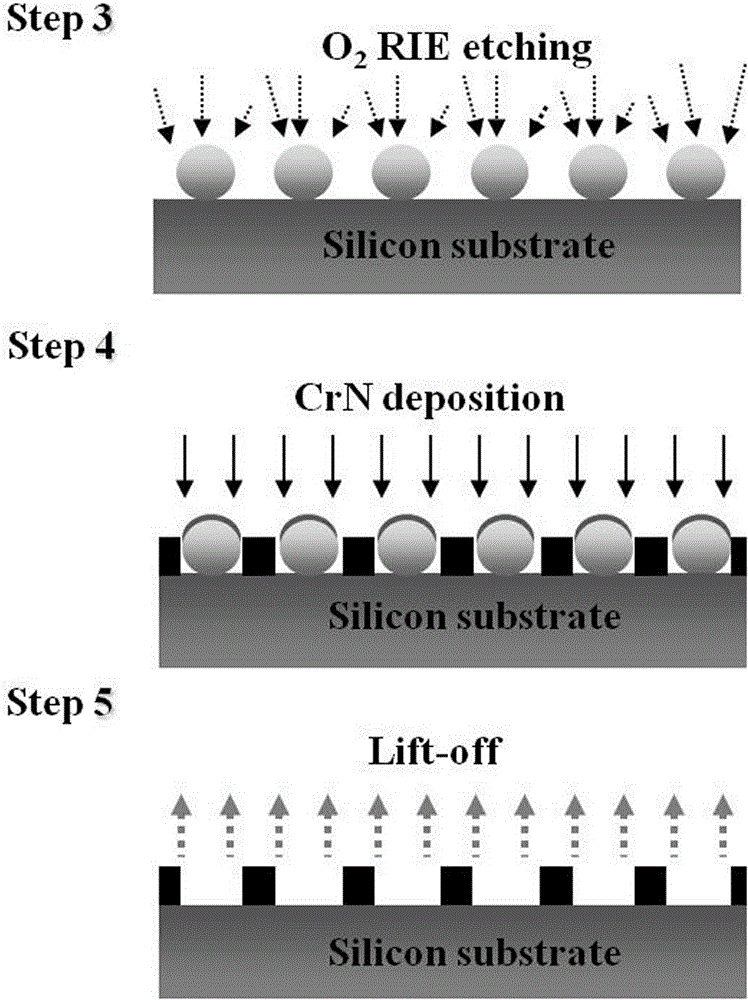

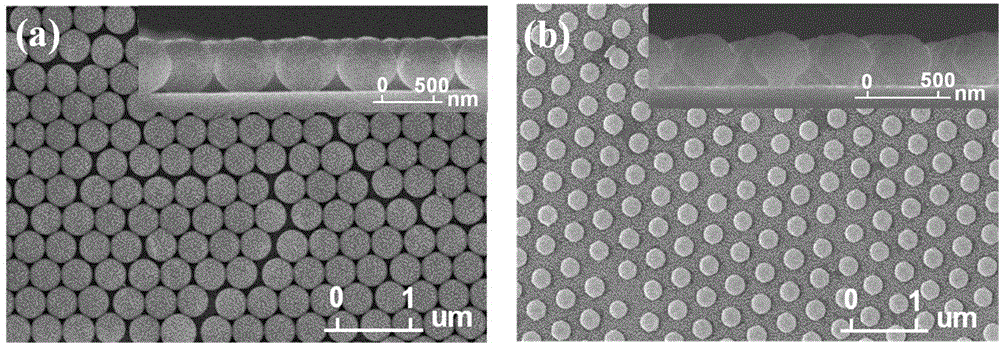

Method for manufacturing size-controllable two-dimensional nanostructure of CrN nanopore array

InactiveCN104141108AAccurate and controllable dimensional accuracyImprove the deposition effectMaterial nanotechnologyVacuum evaporation coatingOrganic solventOxygen

The invention discloses a method for manufacturing a size-controllable two-dimensional nanostructure of a CrN nanopore array. The method for manufacturing the size-controllable two-dimensional nanostructure of the CrN nanopore array comprises the following steps that (1) a substrate is placed in a mixed solution of ammonia water and hydrogen peroxide, and then hydrophilia treatment is conducted by means of ultrasonic waves; (2) a single-layer template on which macromolecular nanoballs are arranged periodically is manufactured on the substrate according to a rotary coating method; (3) the macromolecular nanoballs are etched with oxygen as the etching treatment gas, and then a new single-layer template is obtained after etching; (4) CrN sputtering deposition are conducted on the single-layer template obtained after etching in the step (3) through a closed field non-equilibrium magnetron sputtering ion plating system; (5) the template obtained after deposition in the step (4) is placed in organic solvent, and then the macromolecular nanoballs are dissolved away. According to the method for manufacturing the size-controllable two-dimensional nanostructure of the CrN nanopore array, an array template is manufactured by combining the nanoball rotary-coating technology and the nanoball photoetching method, and the array temperature with the size precision accurately controllable can be manufactured by adjusting the technological conditions.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

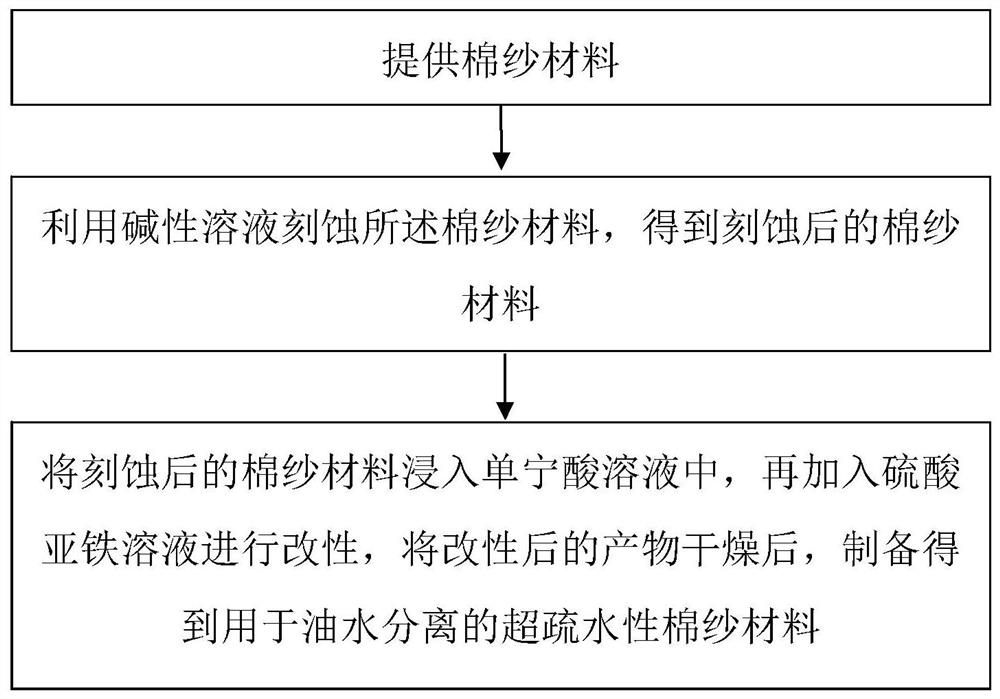

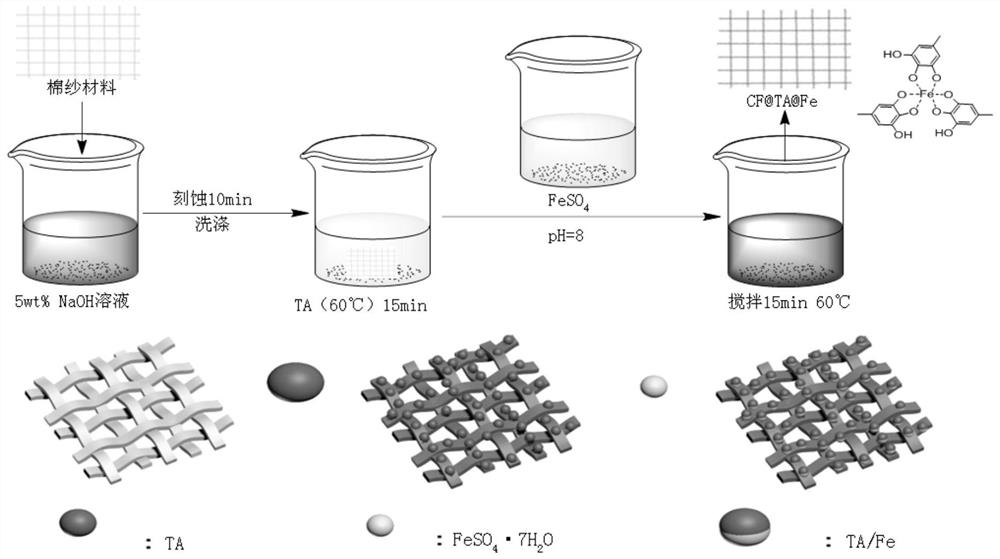

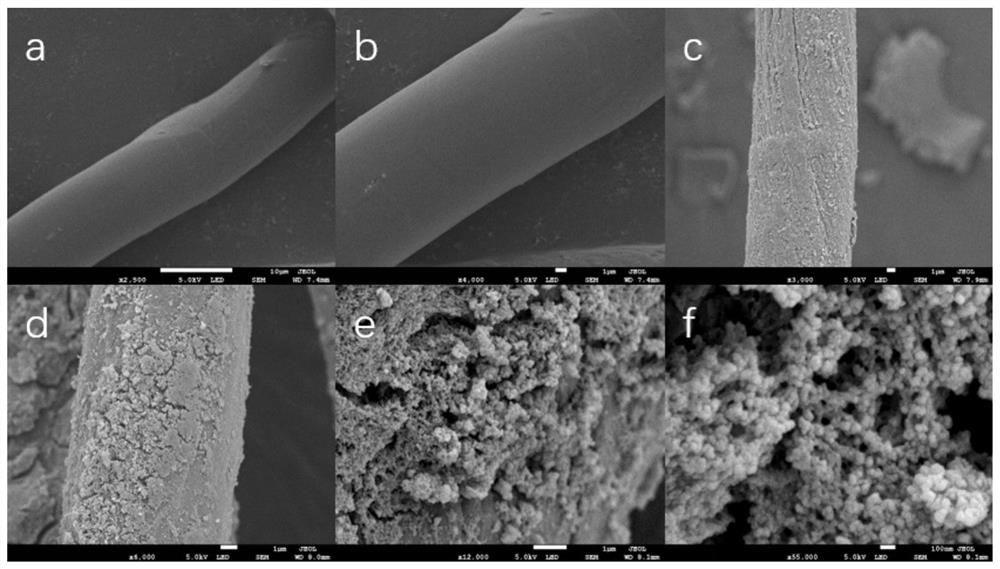

Super-hydrophobic cotton yarn material for oil-water separation as well as preparation method and application thereof

InactiveCN111871002AImprove adhesionImprove stain resistanceLiquid repellent fibresLiquid separationYarnPolymer science

The invention discloses a super-hydrophobic cotton yarn material for oil-water separation as well as a preparation method and application of the super-hydrophobic cotton yarn material. The preparationmethod of the super-hydrophobic cotton yarn material for oil-water separation comprises the following steps: providing a cotton yarn material; etching the cotton yarn material by using an alkaline solution to obtain an etched cotton yarn material; immersing the etched cotton yarn material into a tannic acid solution, then adding a ferrous sulfate solution for modification, circularly immersing the cotton yarn material into the mixed solution for multiple times, and drying the modified product to prepare the super-hydrophobic cotton yarn material for oil-water separation. The super-hydrophobiccotton yarn material for oil-water separation has good oil-water separation performance.

Owner:SHENZHEN UNIV

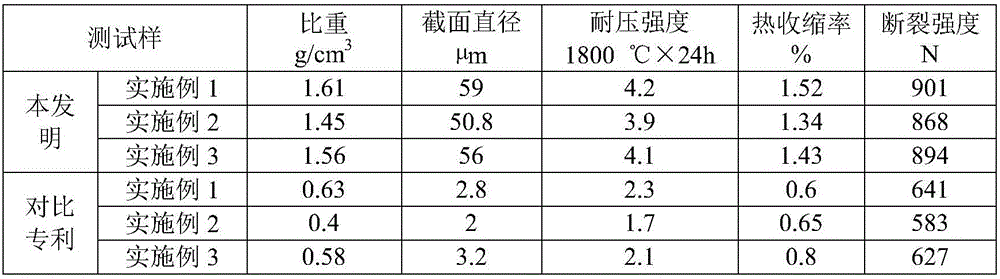

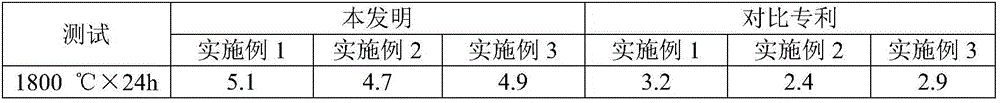

Wear-resistant aluminum silicate refractory fibers

InactiveCN107177904AStrong anti-frictionImprove impact performanceInorganic material artificial filamentsHeat resistant fibresFiberSlag

The invention belongs to the technical field of refractory materials and particularly discloses wear-resistant aluminum silicate refractory fibers. The wear-resistant aluminum silicate refractory fibers are prepared by, by weight, 100-120 parts of flint clay powder, 55-65 parts of aluminum oxide, 30-40 parts of silicon dioxide, 32-36 parts of silicon nitride, 20-25 parts of ABS resin, 18-22 parts of polyurethane, 10-15 parts of natural rubber, 1-2 parts of carbon black, 2-3 parts of zirconate coupling agent, 0.6-0.8 part of dicumyl peroxide, 16-20 parts of silicon dioxide aerogel, 0.2-0.6 part of dispersing agent, 15-25 parts of borax and 20-25 parts of refractory impregnation liquid. The wear-resistant aluminum silicate refractory fibers are high in friction resistance and impact resistance, resistant to the impact and abrasion of hot slag and hot waste residues, resistant to environment stress, high in aging resistance, capable of being used for a long time under high temperature and long in service life.

Owner:浙江欣辉耐火材料股份有限公司

Preparation method of special disposable mechanically-applied fertilizer for corn

The invention relates to a preparation method of a special disposable mechanically-applied fertilizer for corn. According to the invention, urea, monoammonium phosphate, potassium chloride and zinc sulfate are compounded, a high-tower granulated compound fertilizer is used as the core fertilizer, and double film layers are coated, wherein the inner layer film is a urea film and used for improving the surface characteristic of the fertilizer granules, and the outer layer film is a thermoplastic resin coating and a thermosetting coating and is used for controlling the release of the nutrients. The special mechanically-applied fertilizer for corn has more smooth and harder surface, and is suitable for mechanical application. The fertilizer satisfies the requirements of corn for absorbing nitrogen, phosphorus, potassium, zinc and other nutrients; and the large-scale field test proves that the fertilizer has favorable yield increase effect.

Owner:菏泽金正大生态工程有限公司

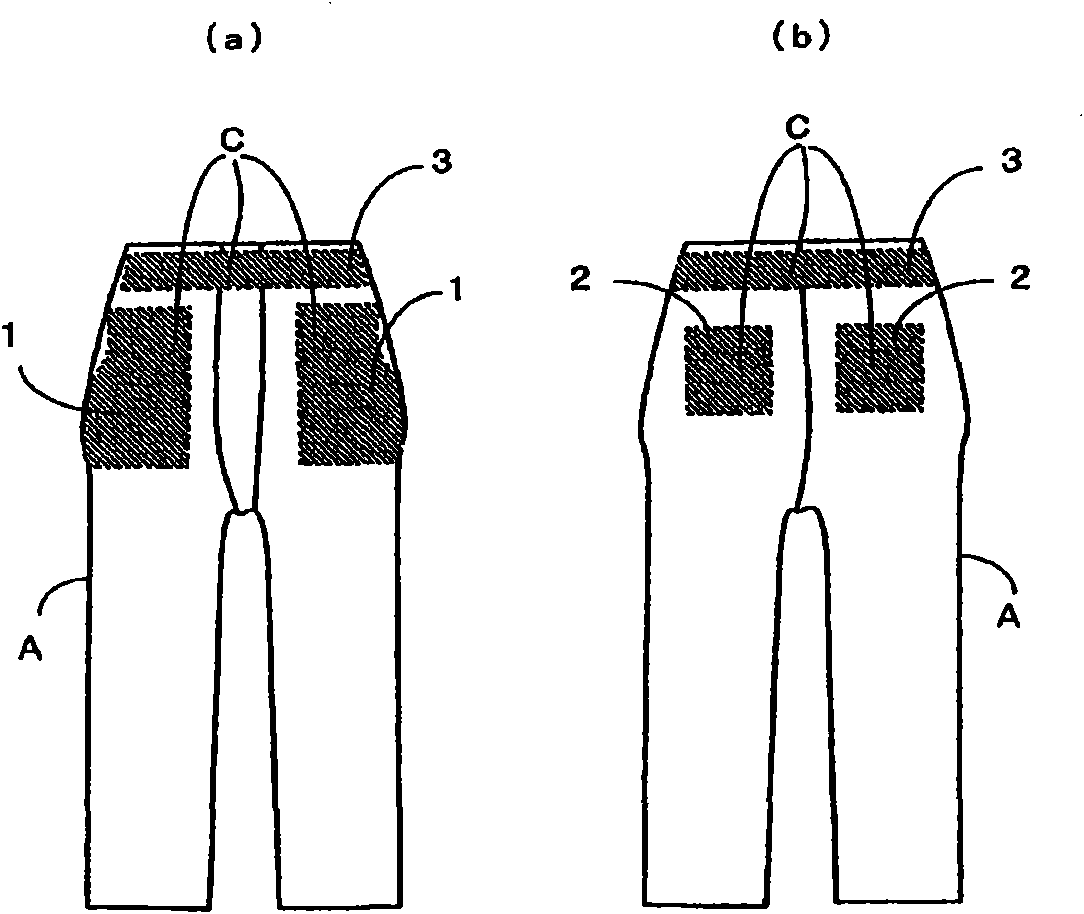

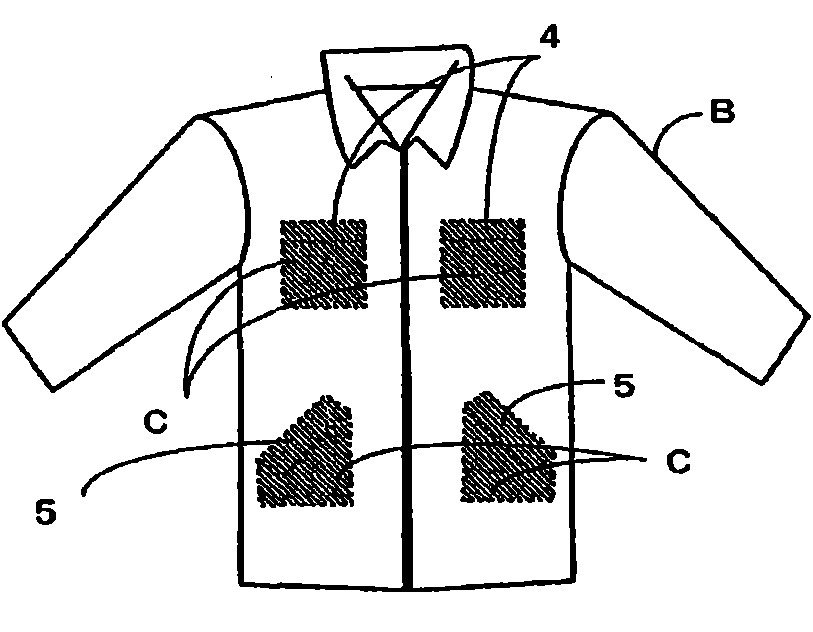

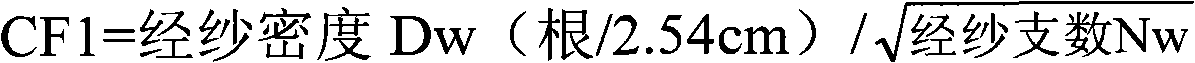

Lining for cloth, trousers and coat with the lining for cloth

The present invention provides a lining for cloth, trousers and coat with the lining for cloth, which satisfies the basic functions as the lining. Furthermore pilling, color fading, color lose, color change and appearance change hardly occurs for chlorine bleach or reduction bleach, or long-time rubbing load. The lining for cloth is made of composite fiber, wherein the composite fiber is obtained through compounding the following components: spun-dyed polyester fiber which comprises 0.2-5wt% of colorant relatively to gross amount, and spun-dyed cellulose fiber which comprises 0.2-5wt% of colorant relatively to gross amount. The mixing gross amount ratio (A / B) between the spun-dyed polyester fiber (A) and the spun-dyed cellulose fiber (B) is 80 / 20 to 30 / 70, and furthermore the coverage factor (CF) of the cloth surface is above 20 and below 45.

Owner:MORIRIN

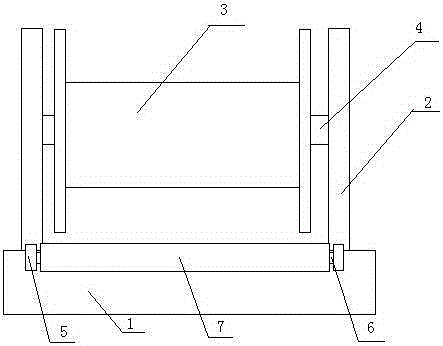

Anchor cable seat

InactiveCN105151231AMinimized retraction resistanceReduce frictionAnchor handling/lashingStructural engineeringEngineering

The invention relates to the technical field of hull machine manufacturing, in particular to an anchor cable seat. The anchor cable seat is composed of an anchor cable base, anchor cable supports and an anchor cable roller. The anchor cable supports are arranged on the left side and the right side of the anchor cable base respectively. The anchor cable roller is arranged between the anchor cable support on the left side and the anchor cable support on the right side. The anchor cable roller is connected with a hydraulic oil cylinder through a driving rotating shaft. The anchor cable seat is characterized in that a cable supporting roller composed of bearing brackets, a cross arm and a sleeve is arranged at the portion, between the anchor cable support on the left side and the anchor cable support on the right side, of the anchor cable base, the bearing brackets are arranged at the portion, between the anchor cable supports, of the anchor cable base, the two ends of the cross arm are connected with the bearing bracket on the left side and the bearing bracket on the right side respectively, and the sleeve is arranged on the cross arm in a sleeving mode to roll. The anchor cable seat has the advantages of being stable in structure, high in anti-friction capacity, high in cable guiding speed and the like.

Owner:WEIHAI ZHONGFU XIGANG SHIP

Lubricating composition for grinding roller bearing of vertical mill and tug wheel bearing of rotary kiln

InactiveCN109880676AWide viscosity rangeMeet viscosity grade requirementsLubricant compositionEngineeringWear resistance

The invention belongs to the technical field of lubricating compositions characterized by using mixtures of high molecular and non-high-molecular compounds as additives, and specifically relates to alubricating composition for a grinding roller bearing of a vertical mill and a tug wheel bearing of a rotary kiln. The lubricating composition is prepared from the following ingredients: synthetic oil, a bearing oil composite additive, an antirust agent, a metal deactivator and an anti-friction agent. The lubricating composition has excellent wear resistance, emulsification resistance and foam resistance.

Owner:重庆化工职业学院

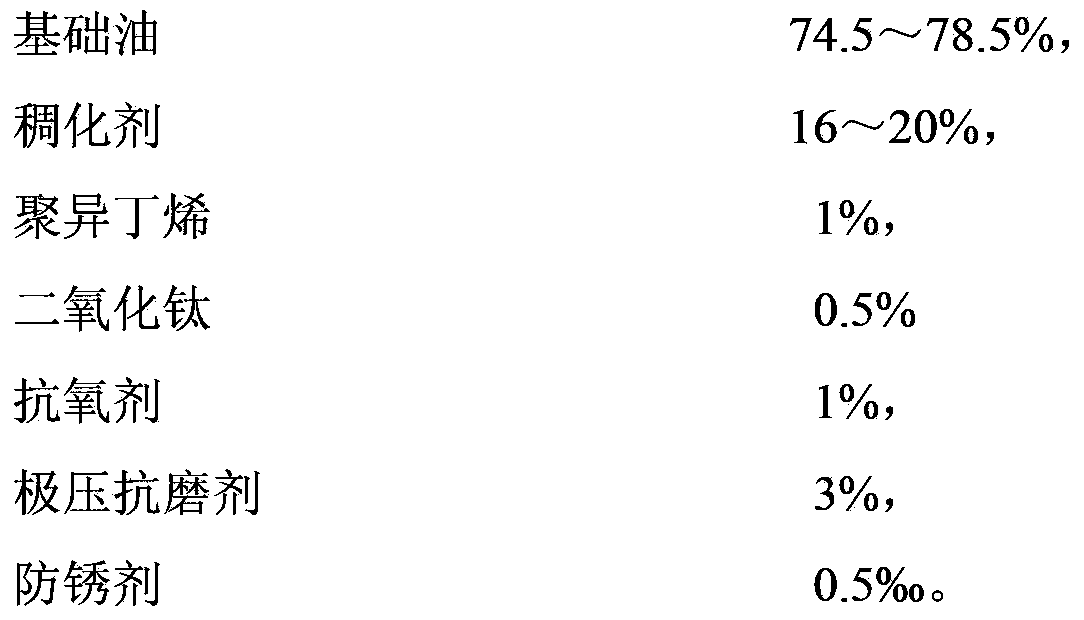

Special grease composition for dual mass flywheel and preparation method thereof

InactiveCN103497807AWide temperature rangeExtended service lifeLubricant compositionFriction reductionAntioxidant

A special grease composition for a dual mass flywheel is prepared from the following raw materials: by mass, 74.5-78.5% of base oil, 16-20% of a thickener, 1% of polyisobutylene, 0.5% of titanium dioxide, 1% of an antioxidant, 3% of an extreme pressure antiwear agent and 0.05 % of an anti-rust agent. The special grease for the dual mass flywheel has good high-temperature oxidation resistance, oil distribution resistance, friction resistance, low temperature startup performance, and anti rust performance and excellent adhesion performance, and can completely be applied to lubrication of flywheel parts of passenger cars. The special grease for the dual mass flywheel has a wider use temperature range and a longer service life, and has excellent lubrication, friction reduction and vibration reduction effects on use parts.

Owner:CHINA PETROLEUM & CHEM CORP

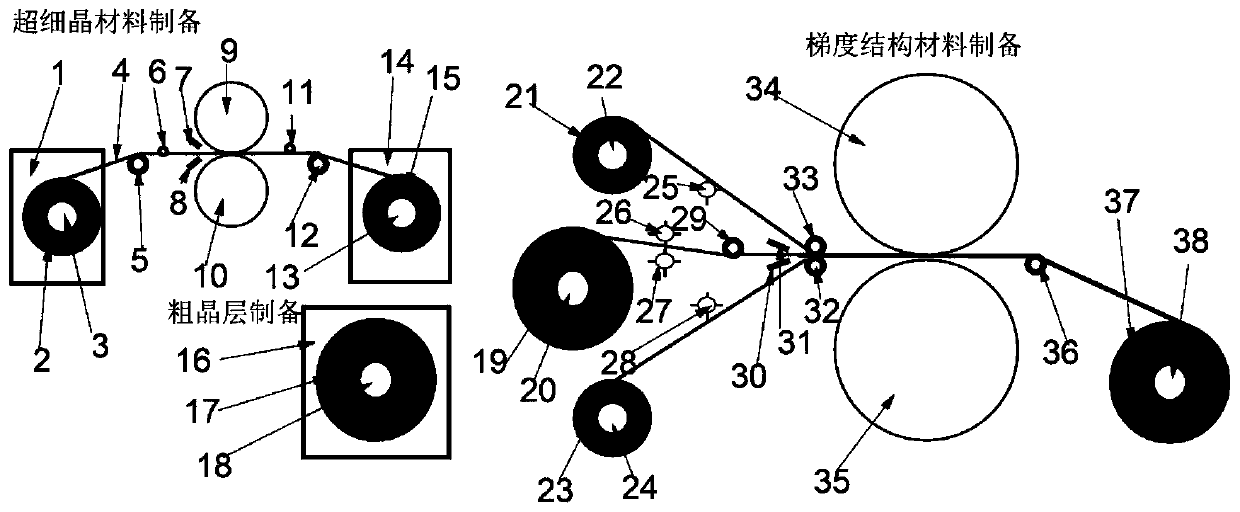

A kind of composite rolling preparation method of gradient structure strip

ActiveCN109201738BIncrease productivityHigh strengthTemperature control deviceMetal rolling arrangementsUltimate tensile strengthFine grain

A compound rolling preparation method of gradient structure strip comprises following steps: first, processing the coarse-grained strip and the ultrafine-grained strip into the same width; second, arranging according to that ultrafine grain strip material / the coarse grain strip material / the ultrafine grain strip material; third, carrying out surface treatment on that coarse-grained strip to realize surface melting; fourth, rolling that three-layer composite strip to realize the welding of the ultra-fine grain strip, the coarse grain strip and the ultra-fine grain strip to form the gradient structure strip. The invention can rapidly prepare the gradient structure strip material and improve the production efficiency of the gradient structure material. The surface layer of the gradient structure strip material is of ultra-fine grain structure, and the core region is of coarse grain. Compared with the traditional cold-rolled material, the gradient structure strip material has good strengthand better plasticity.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com