Patents

Literature

59results about How to "Not easy to stack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

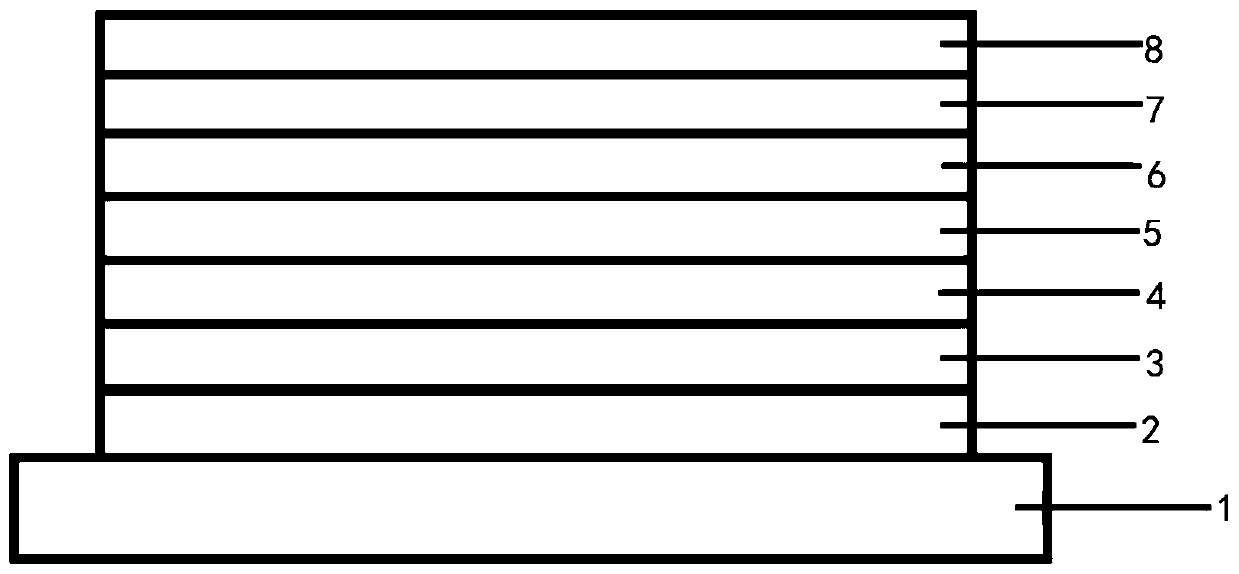

Arylamine compound, electronic component using arylamine compound, and electronic device

ActiveCN112110825AIncrease steric hindranceRigid and stableSilicon organic compoundsSolid-state devicesPhysicsPolymer chemistry

The invention belongs to the field of organic materials, and relates to an arylamine compound, an electronic element using the arylamine compound, and an electronic device, wherein the arylamine compound has a structure represented by the following formula 1. According to the invention, the arylamine compound is used as a hole transport material to be applied to an OLED device, so that good deviceperformance and low voltage can be obtained.

Owner:SHAANXI LIGHTE OPTOELECTRONICS MATERIAL CO LTD

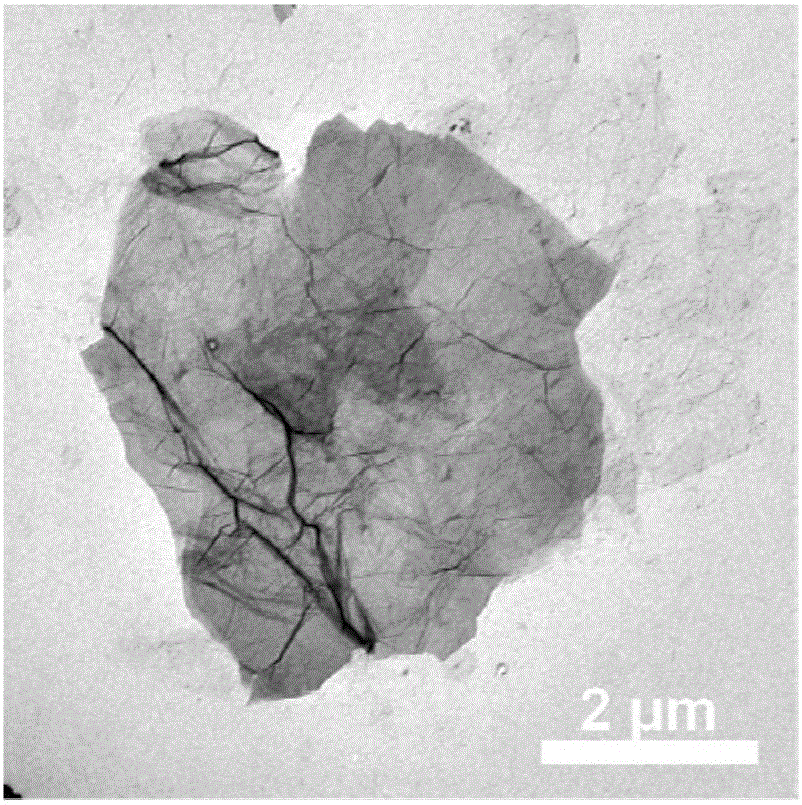

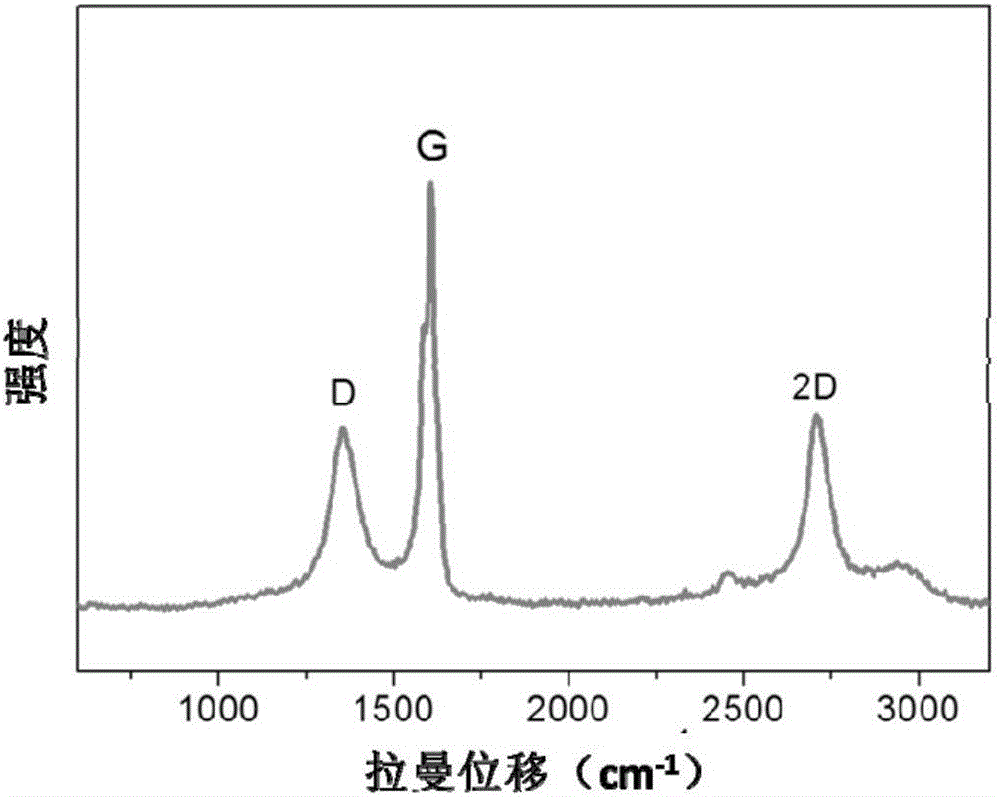

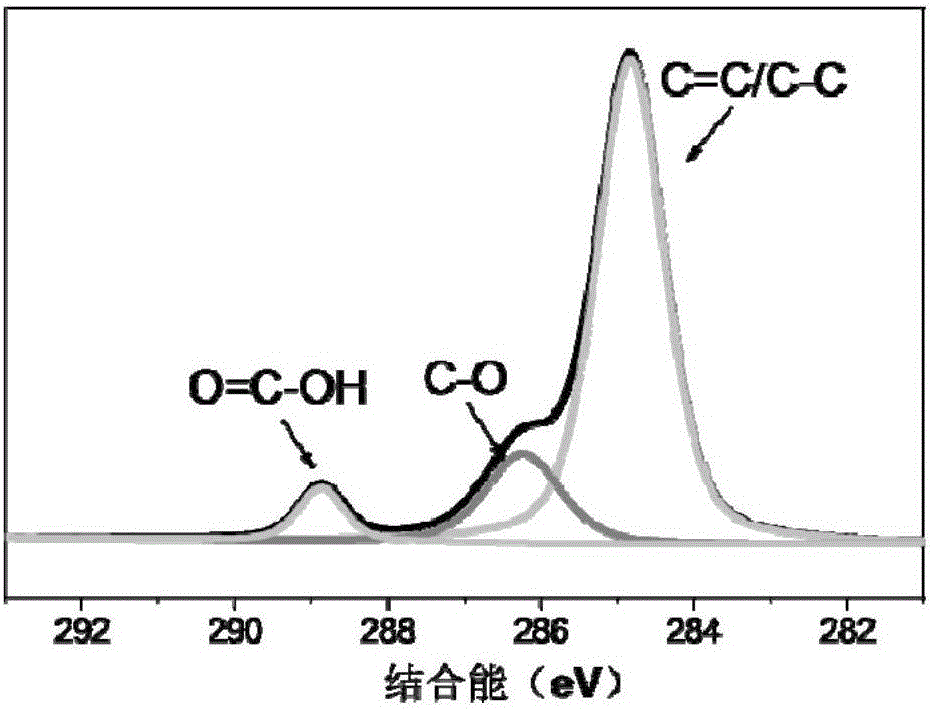

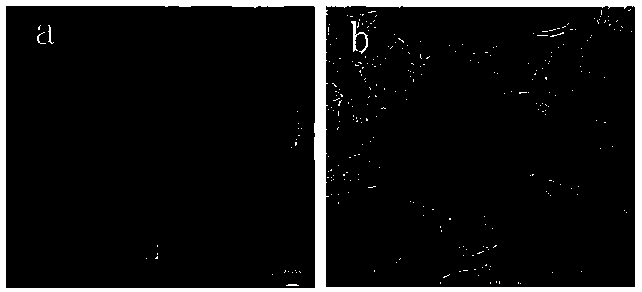

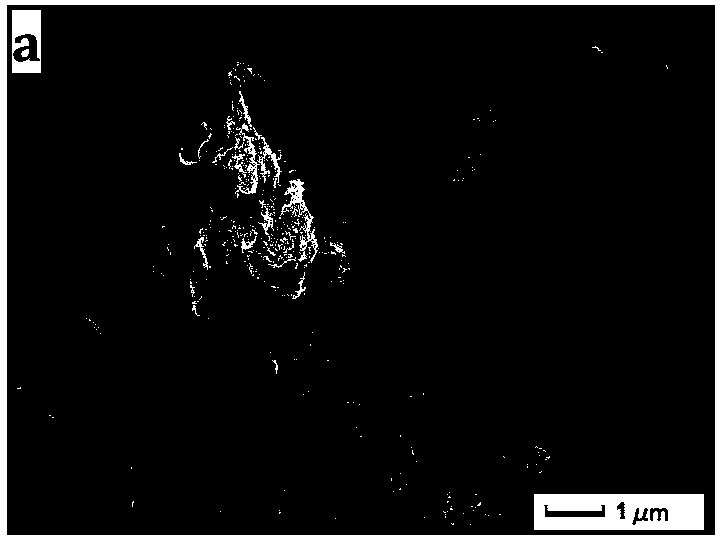

Edge functionalized graphene, preparation method thereof, and applications of edge functionalized graphene in preparing anticorrosive paint

ActiveCN106280578AGood dispersionPrevent stacking on top of each otherInorganic pigment treatmentAnti-corrosive paintsComposite filmCvd graphene

The invention belongs to the field of graphene functionalization and application, and relates to an edge functionalized graphene, a preparation method thereof, and applications of the edge functionalized graphene in preparing anticorrosive paint According to the preparation method, a chlorate-concentrated sulfuric acid-hydrogen peroxide system is adopted for functionalization of graphene so as to obtain the edge functionalized graphene, wherein carboxy groups are connected with the lamina edges of a whole structure via selective modification; the edge functionalized graphene is subjected to film formation alone, or is combined with an anticorrosive paint formula component for composite film formation so as to obtain the edge functionalized graphene anticorrosive paint. The preparation method is simple, is high in efficiency, is capable of solving problems that graphene is difficult to treat, and stacking is easily caused, providing graphene solution with processibility and treatability, avoiding destroying of the graphene lamellar structure, and maintaining the graphene lamellar structure and the characteristics; the obtained edge functionalized graphene anticorrosive paint possesses excellent corrosion resistance; and application range is wide.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

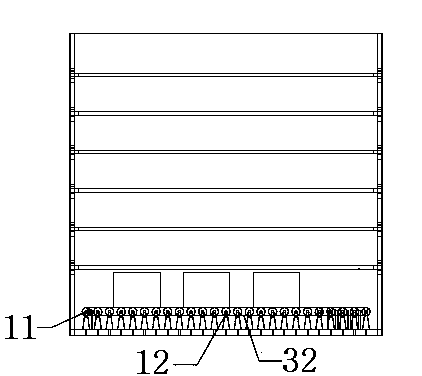

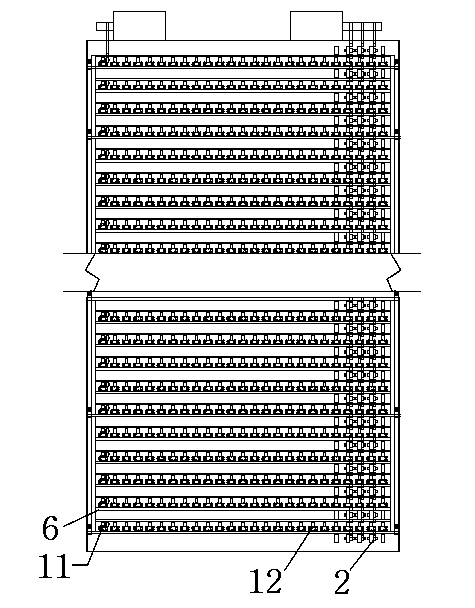

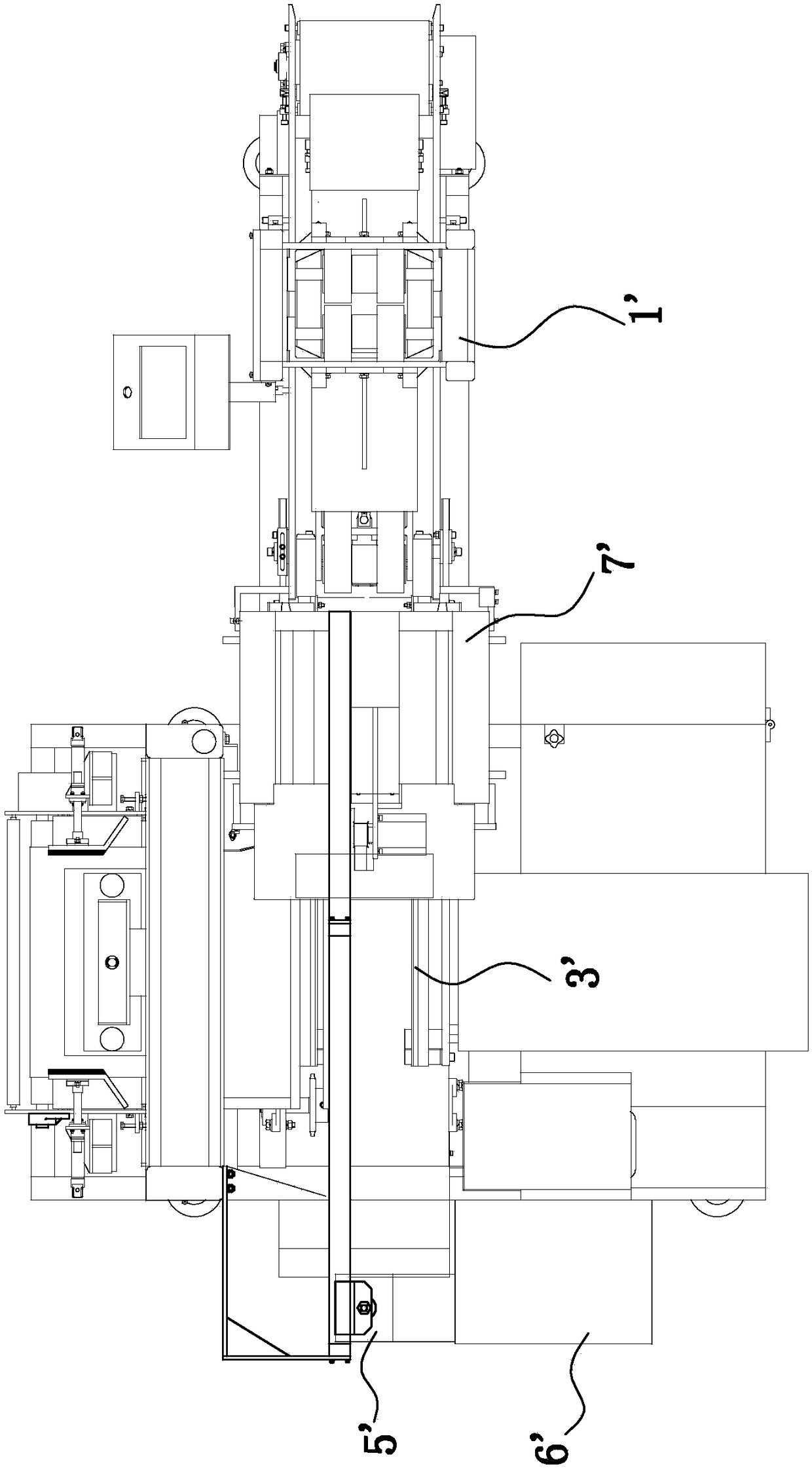

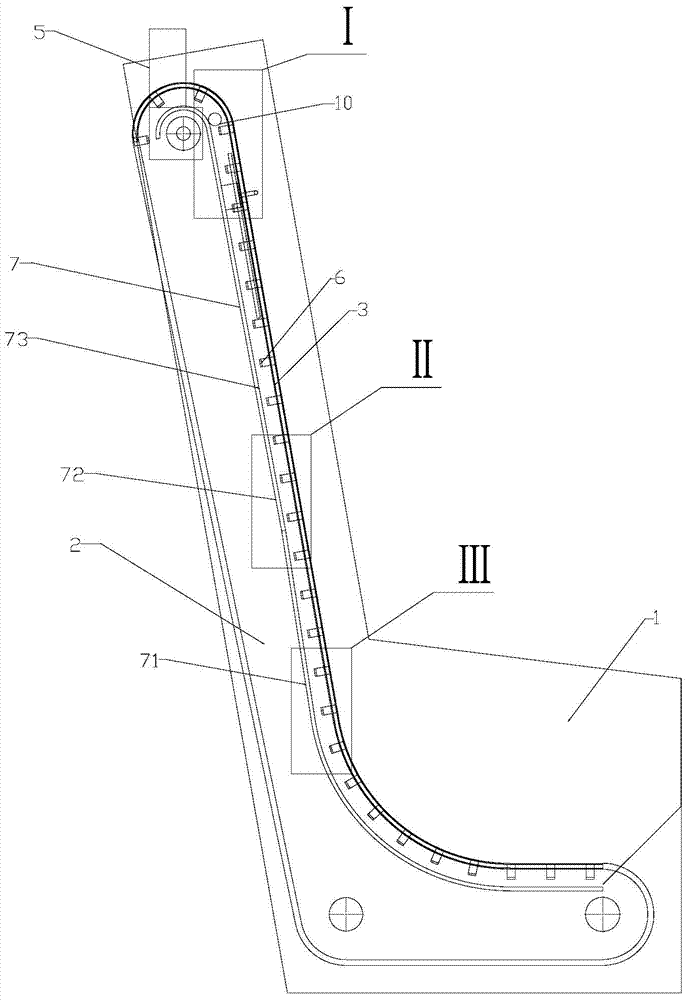

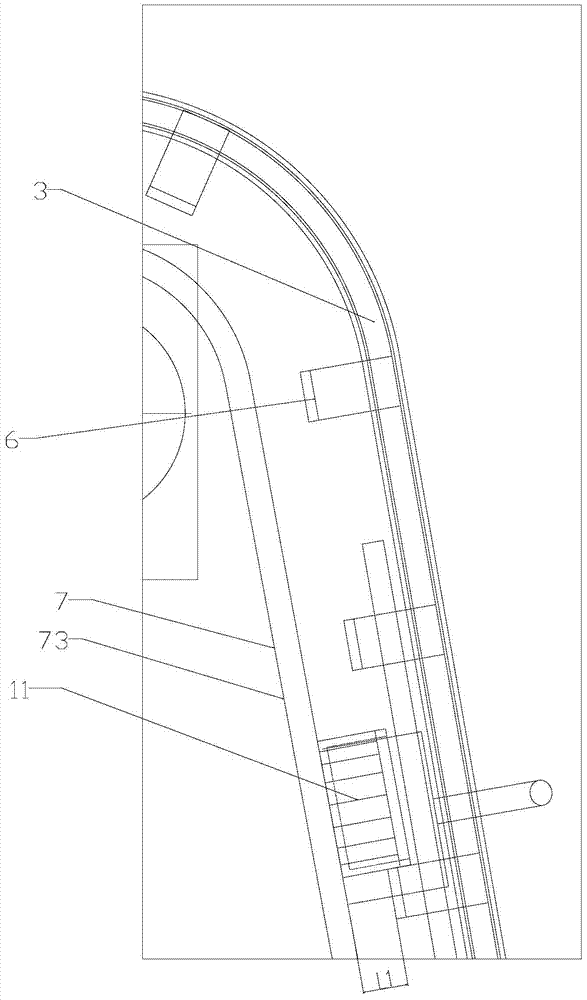

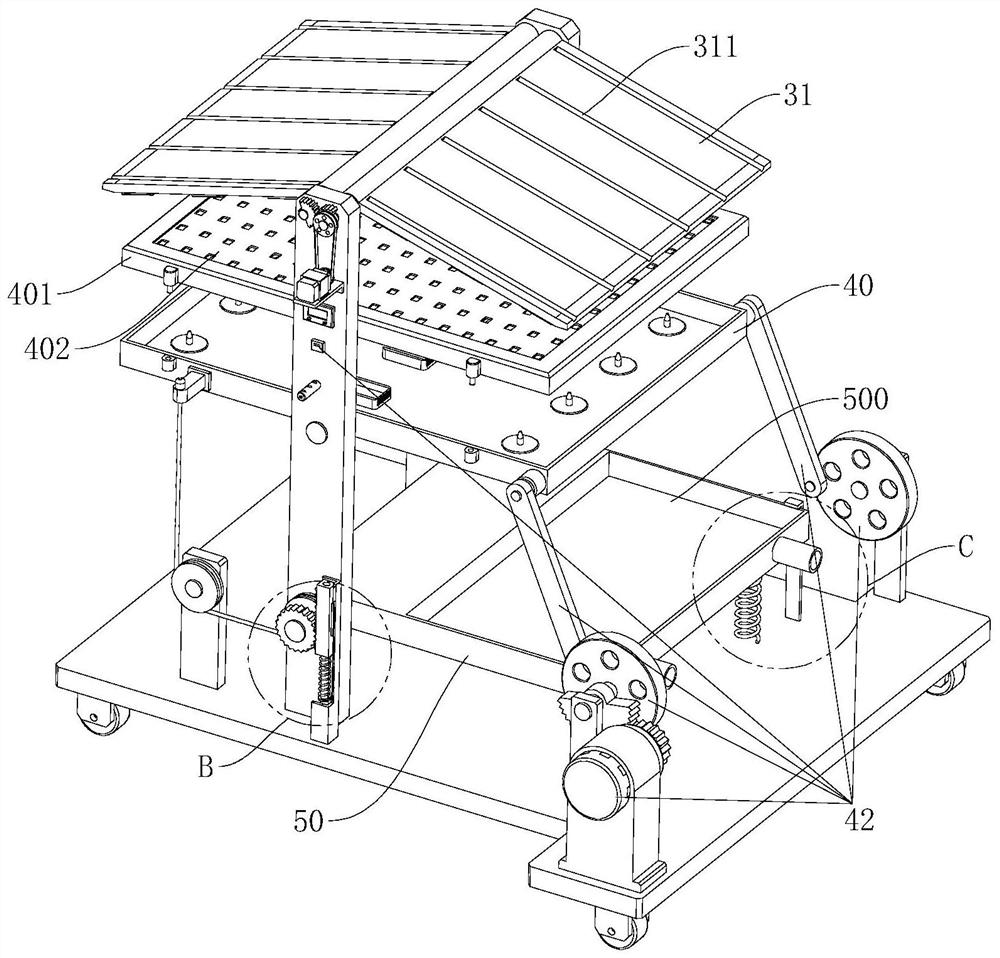

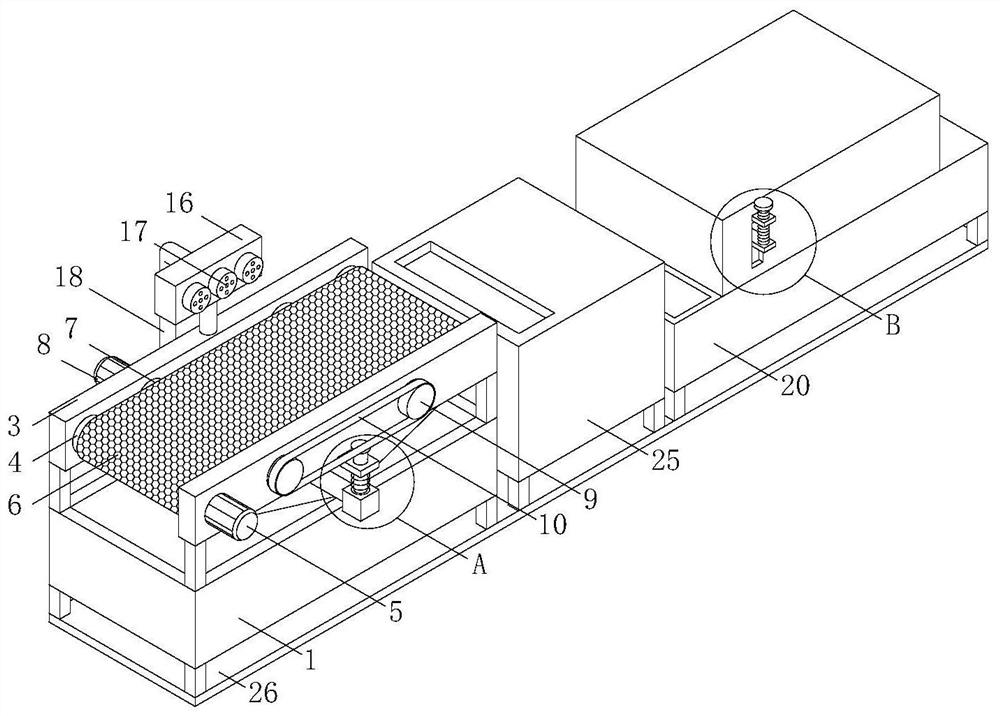

Automatically loaded carriage

InactiveCN103568918ARealize automatic loading and unloadingSave loading and unloading timeVehicle with raised loading platformVehicle with endless chains/beltsDrive wheelEngineering

The invention provides an automatically loaded carriage, which is characterized by comprising a horizontal driving wheel, a horizontal driven wheel, a longitudinal idler wheel, a longitudinal driving belt, a horizontal driving belt, a driving chain, a conical gear, a lifting goods shelf, a rope, a fastening lock, a horizontal motor, a longitudinal motor, a rope motor, a chain guide wheel, a belt guide wheel and a guide groove, wherein the horizontal motor, the longitudinal motor and the rope motor are arranged at the end of the carriage, the horizontal motor drives the conical gear to rotate through the chain, the chain is guided by the chain guide wheel arranged at a box bottom, the conical gear is meshed with the horizontal driving wheel provided with conical gears, and the horizontal driving wheel is connected with a horizontal driven idler wheel through the horizontal driving belt. The device can be matched with a warehouse conveying goods crawler belt for realizing automatically loading goods into a warehouse and unloading the goods from the warehouse; the carriage is more applicable to fragile articles fear of heavy loading, and the carriage structure enables the goods to be placed in a layered manner and to be prevented from being pressed, so that the carriage is particularly suitable for the express industry.

Owner:王延斌

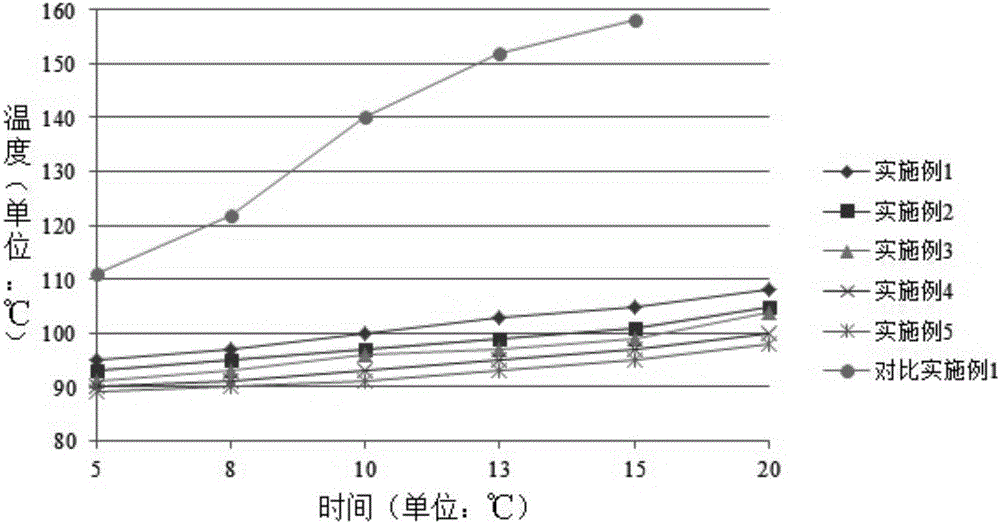

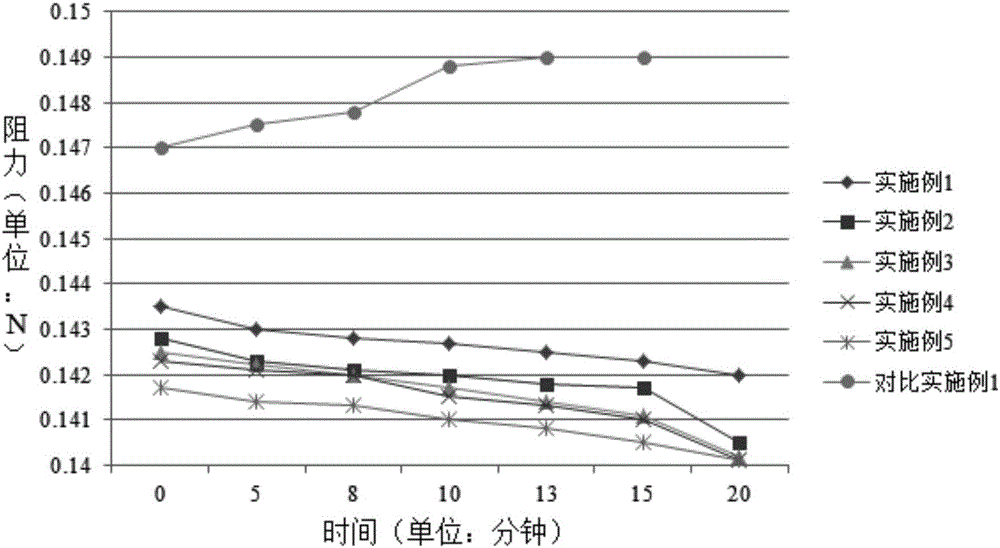

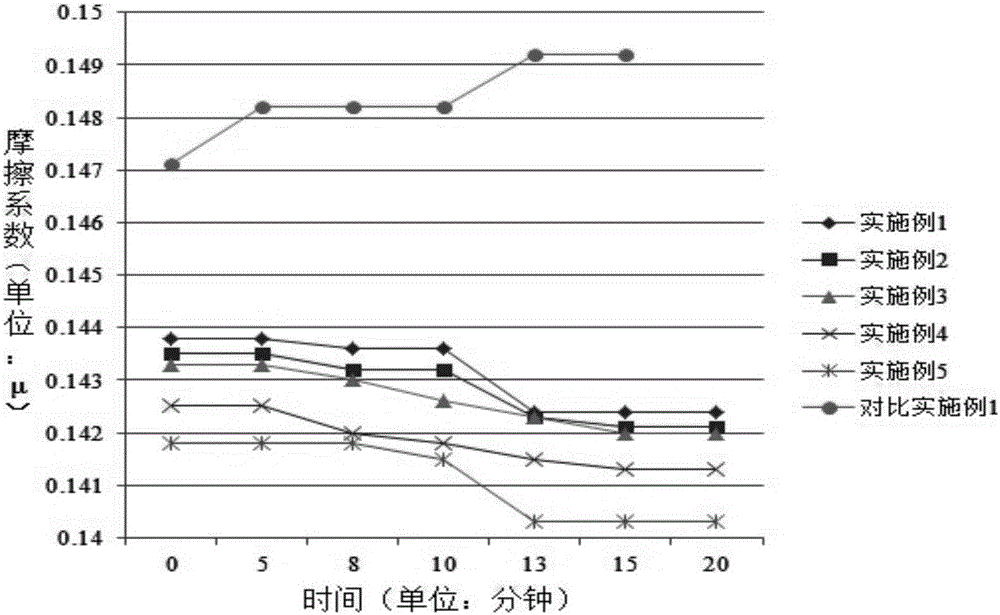

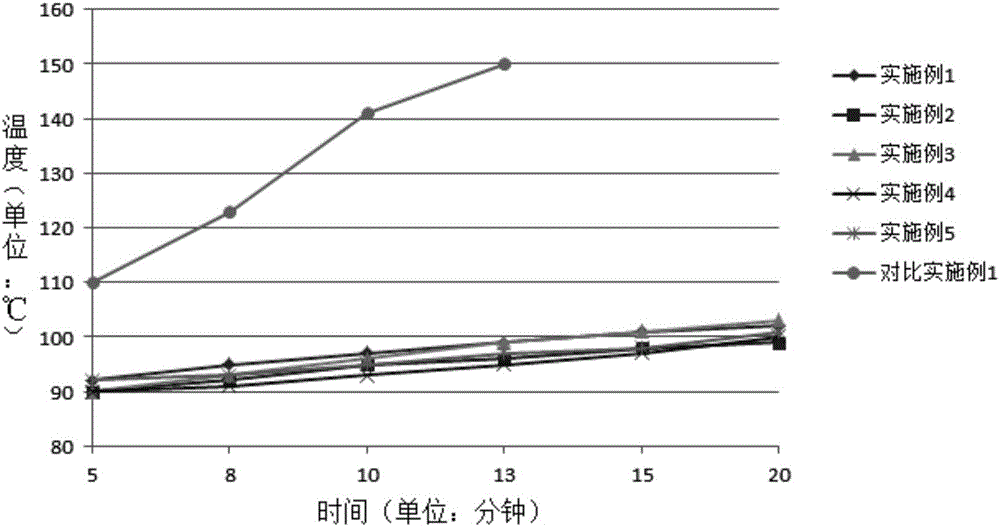

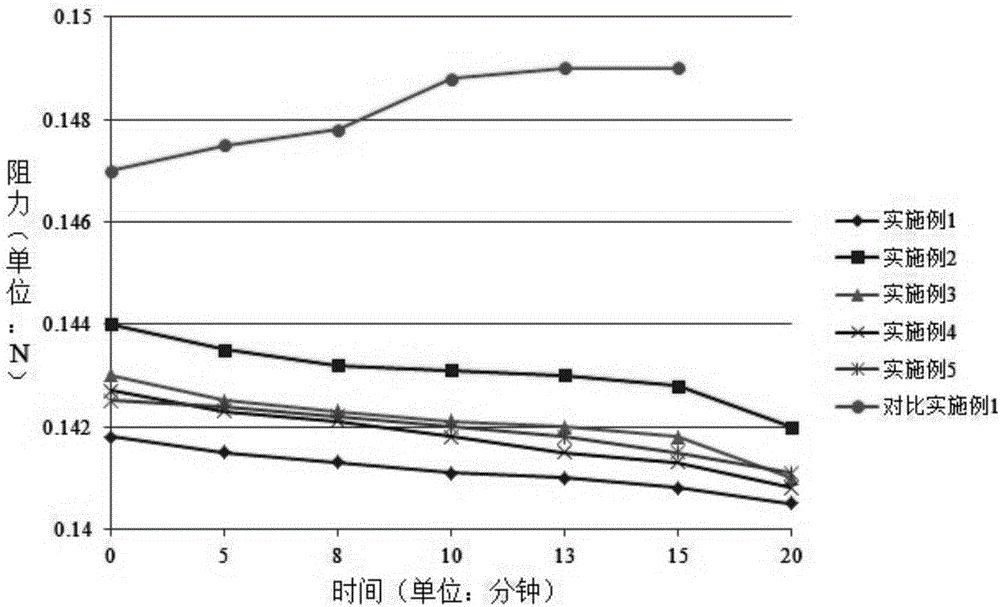

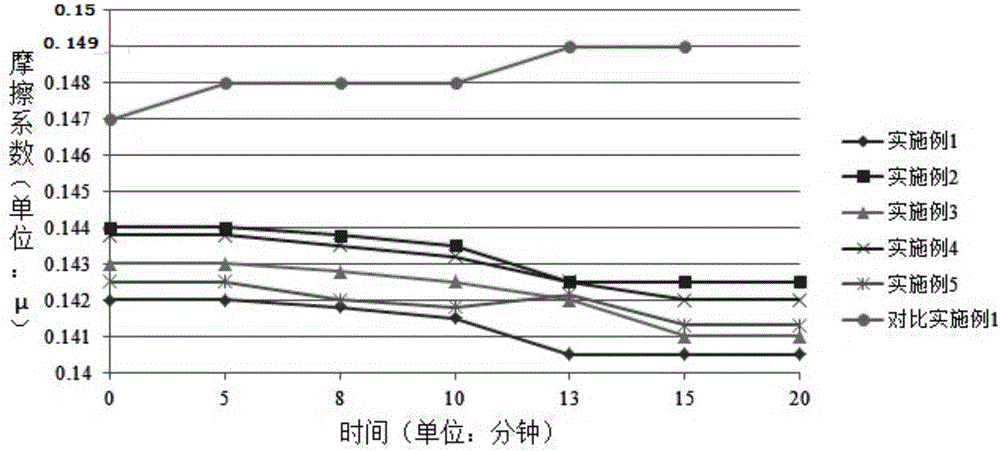

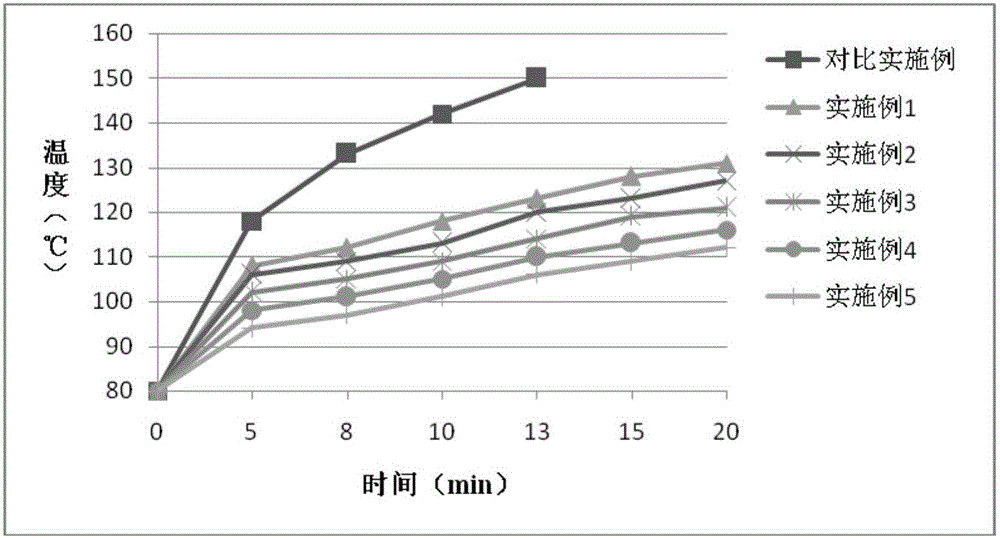

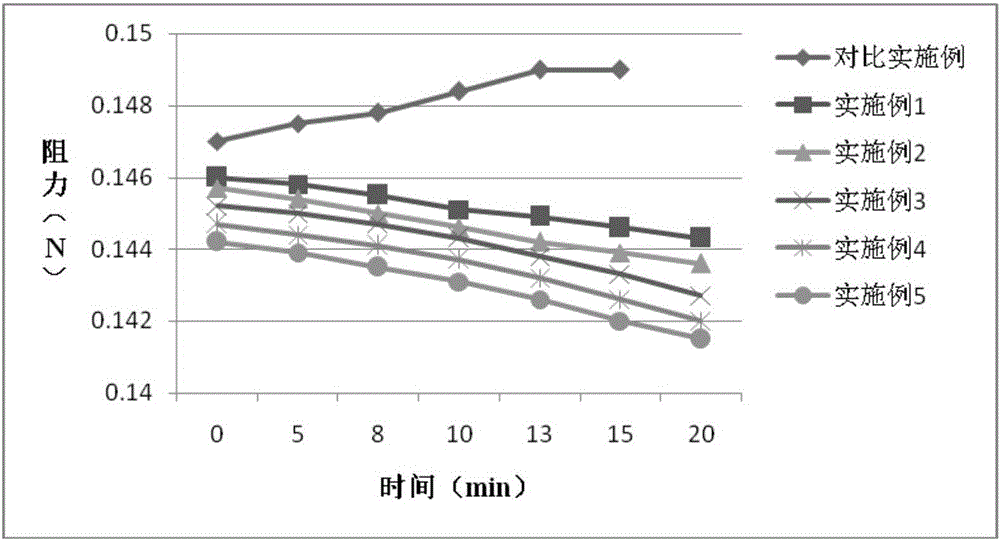

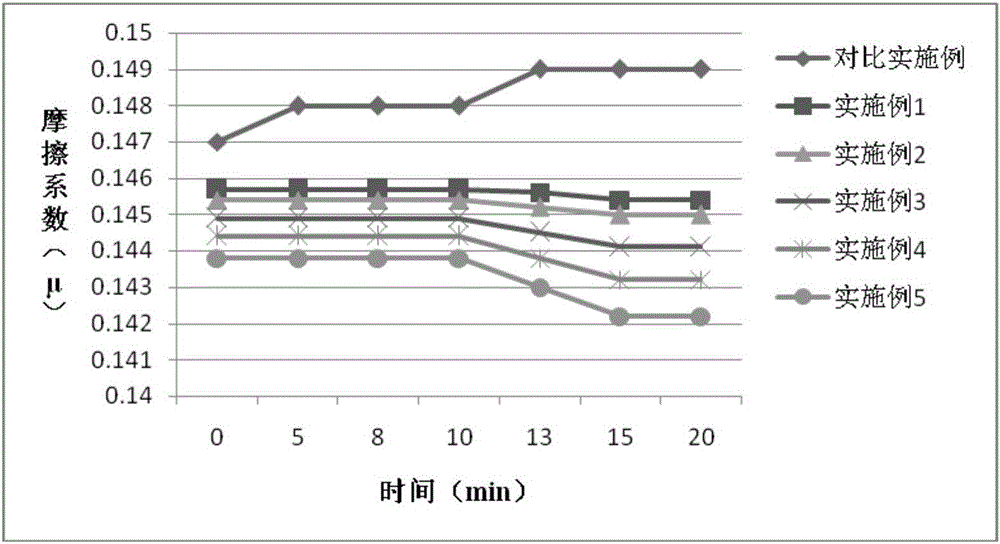

Modified graphene lubricating oil with high dispersibility and high affinity, and preparation method thereof

The invention discloses a modified graphene lubricating oil with high dispersibility and high affinity, and a preparation method thereof. The modified graphene lubricating oil comprises, by weight, 0.3-1.5 parts of modified graphene, 0.3-1.5 parts of a dispersing agent, 0.1-2 parts of an affiliation agent, and 100 parts of base oil. According to the present invention, the formula is reasonable, and the preparation method is simple; the prepared lubricating oil has advantages of good stability, good affinity and improved lubricating performance, and can form ink on a mechanical member in mechanical movement so as to reduce the movement resistance of the mechanical member, reduce the friction coefficient, provide the super strong lubricating property and wear resistance, prolong the service life of mechanical member, and achieve energy saving; and the modified graphene lubricating oil can be widely used in a variety of mechanical members, and has great market potential and broad market prospects.

Owner:CHONGQING DELING TECH

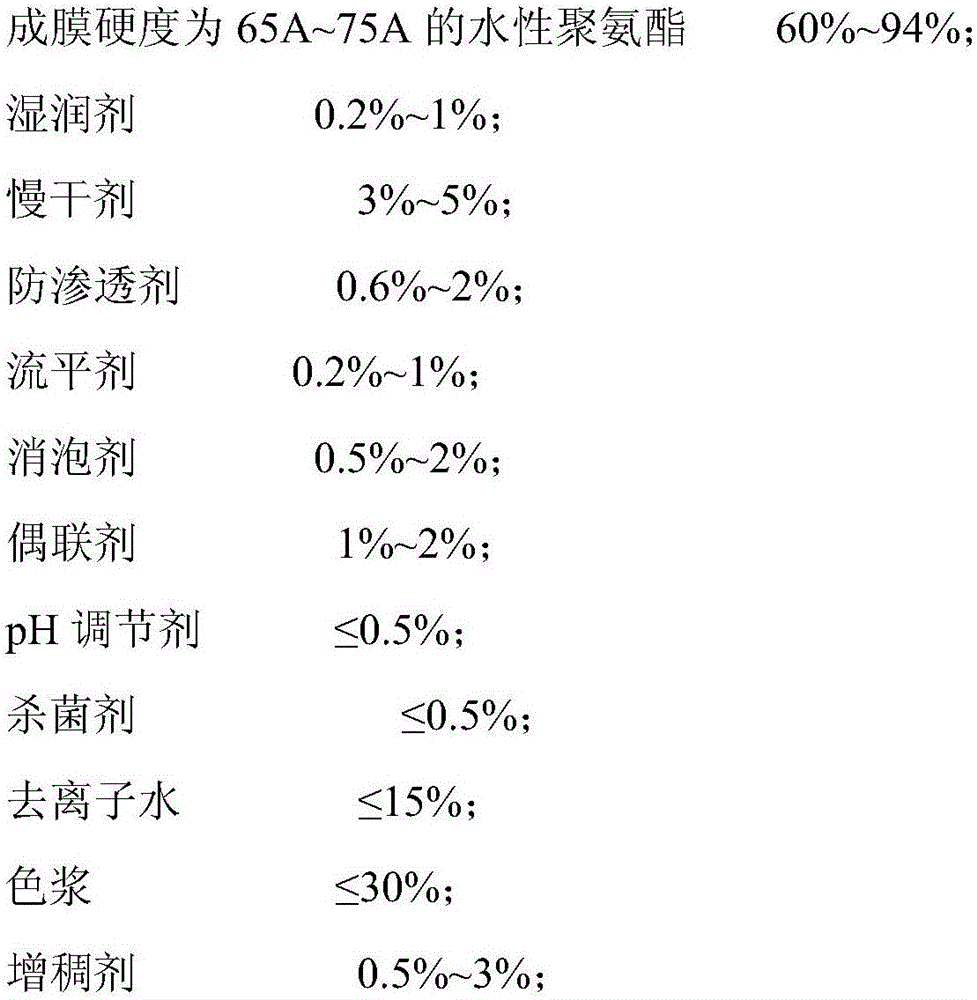

Printable waterborne polyurethane 3D golden oil or 3D ink

The invention discloses a printable waterborne polyurethane 3D golden oil or 3D ink. The 3D golden oil or 3D ink mainly includes the following components by mass percentage: waterborne polyurethane with film hardness of 65A-75A, a wetting agent, a slow drying agent, an anti-permeability agent, a leveling agent, a defoaming agent, a coupling agent, a pH regulator, a bactericide, deionized water, a color paste, and a thickening agent, etc. The golden oil or ink can be prepared into a coating on a textile surface directly through printing, the prepared coating has the advantages of strong stereo feel, good glossiness, easy stacking, no subsidence, soft handfeel, low temperature resistance, and good firmness, etc., and solves the problems of ink spreading, no blotting, cracking and other problems in existing printing ink.

Owner:徐立新

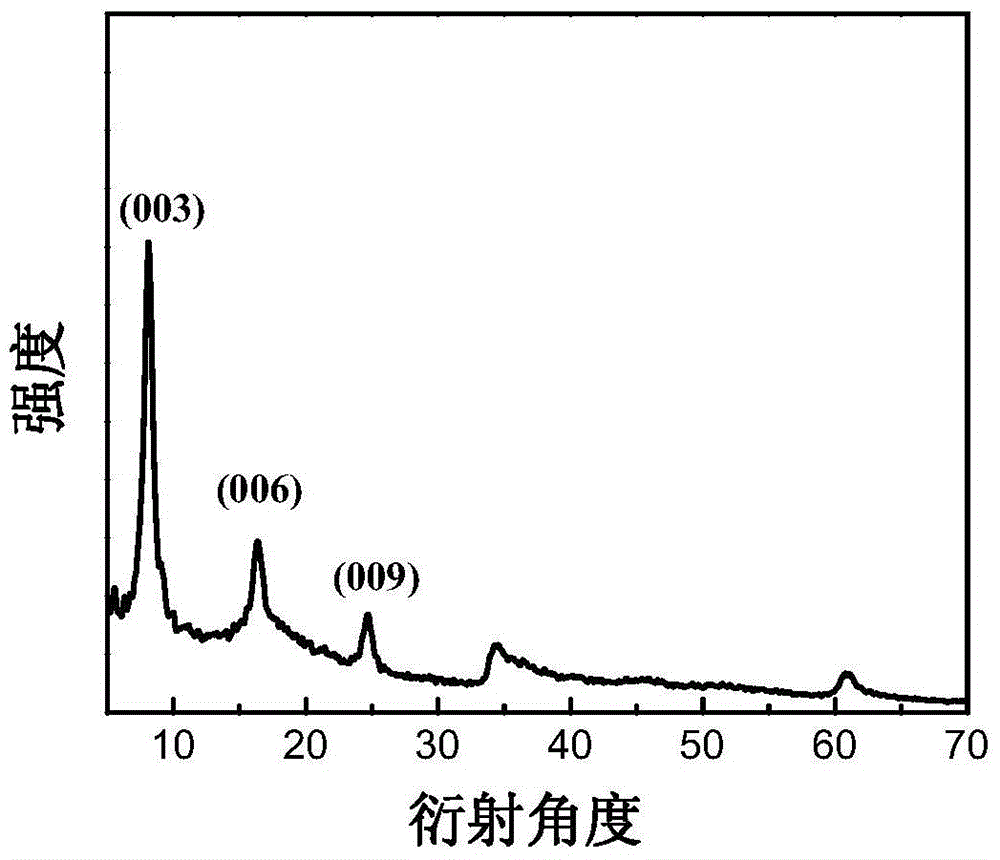

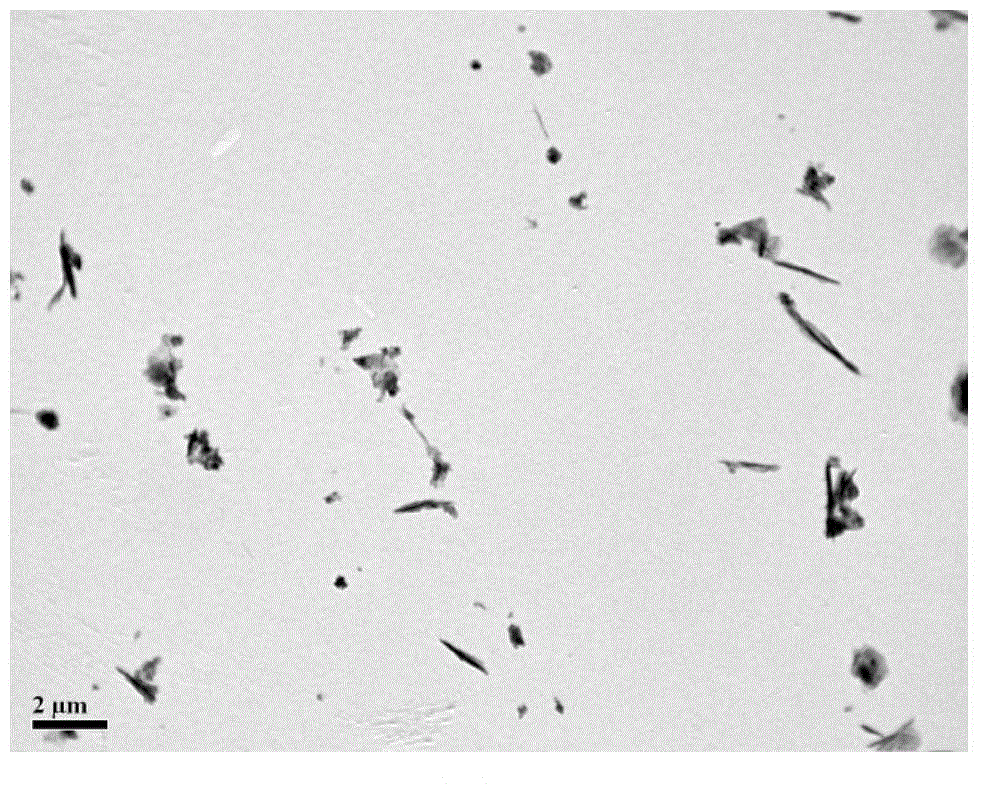

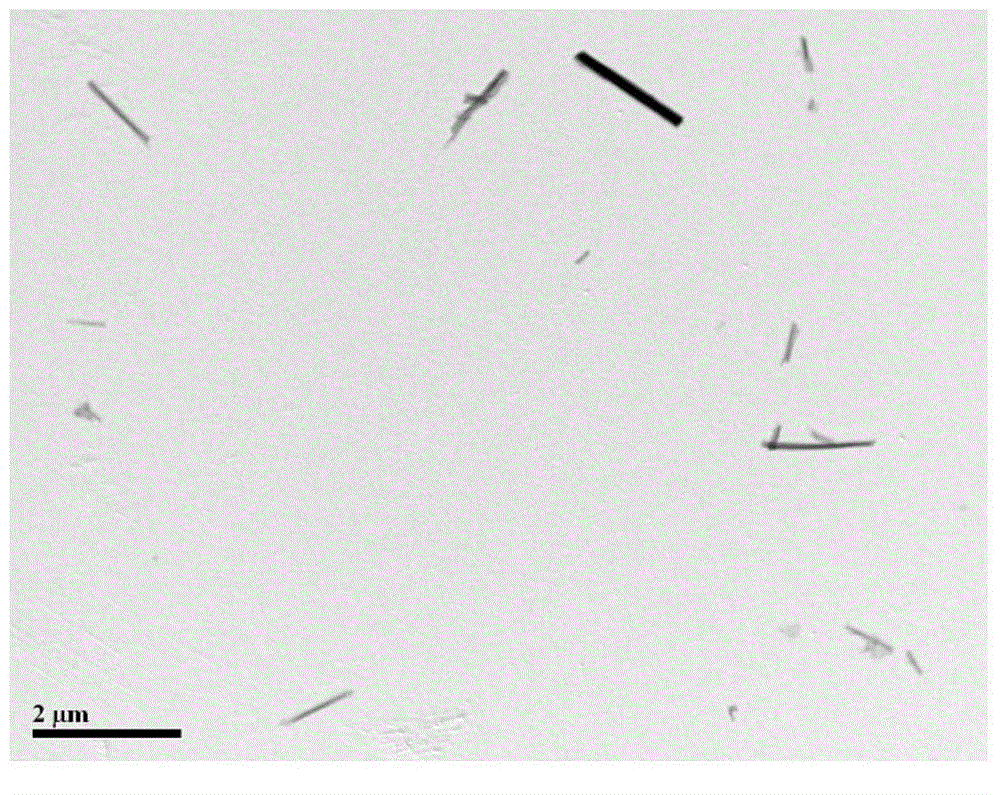

Preparation method for layered double hydroxide (LDH) nanoscrolls

The invention discloses a preparation method for layered double hydroxide (LDH) nanoscrolls. The preparation method specifically comprises the following steps: uniformly mixing a cationic surface active agent, a cosurfactant and an alkanes oil phase at room temperature to obtain a uniform and stable emulsus suspension system; then mixing a soluble bivalent metal salt and a soluble trivalent metal salt with deionized water, and adding the mixture to the emulsus suspension system to obtain a microemulsion system; and finally mixing an alkaline substance with deionized water, then adding the mixture to the microemulsion system, continuously stirring for 0.5-5 hours, and carrying out a hydrothermal reaction at 75-130 DEG C for 2-60 hours to obtain the LDH nanoscrolls. According to the preparation method disclosed by the invention, oligolamellar LDH is generated by means of the mutual action of LDH growth units and a drop film interface under a microemulsion condition, and is further folded to form the LDH nanoscrolls. The preparation method disclosed by the invention is mild in reaction conditions, simple and feasible and short in time consumption; the LDH nanoscrolls synthesized by the preparation method are regular in shape and favorable in dispersity.

Owner:ZHEJIANG UNIV

Lubricating oil with modified graphene and good dispersibility and method for preparing lubricating oil

The invention discloses lubricating oil with modified graphene and good dispersibility and a method for preparing the lubricating oil. The lubricating oil with the modified graphene comprises, by weight, 0.3-1.5 parts of modified graphene oxide, 0.3-1.5 parts of dispersing agents and 100 parts of base oil. The lubricating oil and the method have the advantages that formulas are reasonable, the method is simple, the prepared lubricating oil is good in stability and ultra-strong in lubricity and anti-attrition property, the lubricating properties can be enhanced, movement resistance can be reduced when the lubricating oil is used in mechanical movement, friction coefficients can be lowered, the service lives of mechanical components can be prolonged, and energy can be saved; the lubricating oil can be widely applied to various mechanical components, and accordingly the lubricating oil and the method have huge market potential and broad market prospects.

Owner:CHONGQING DELING TECH

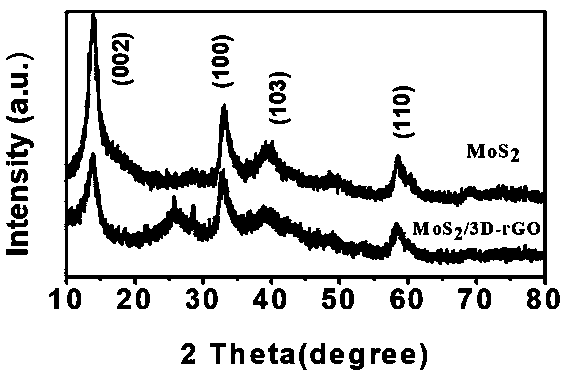

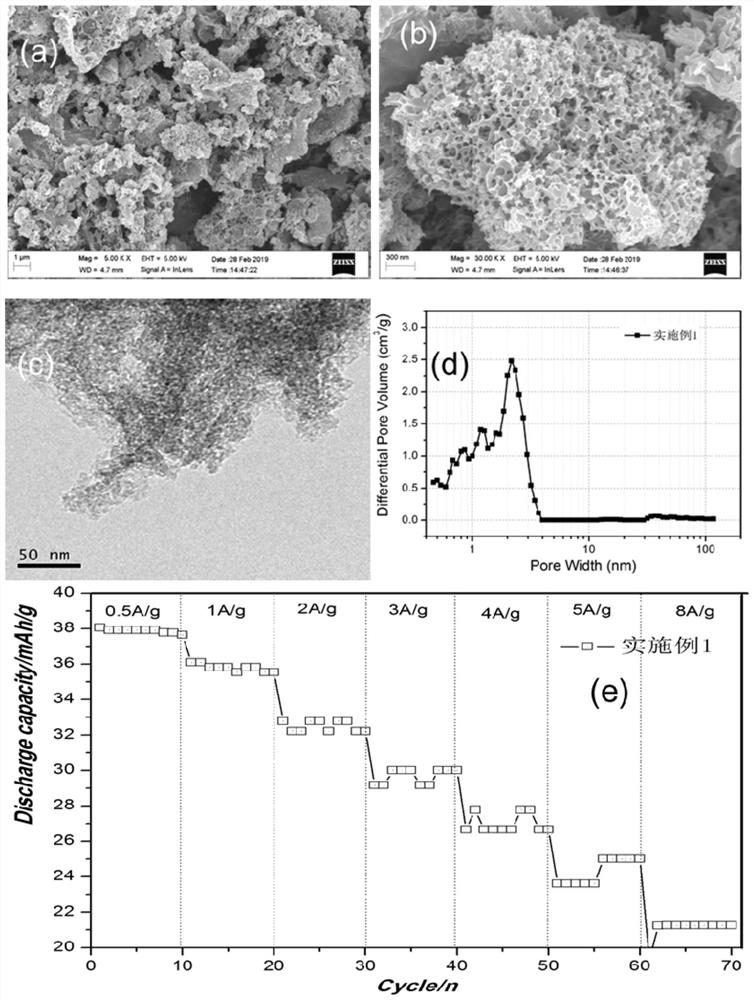

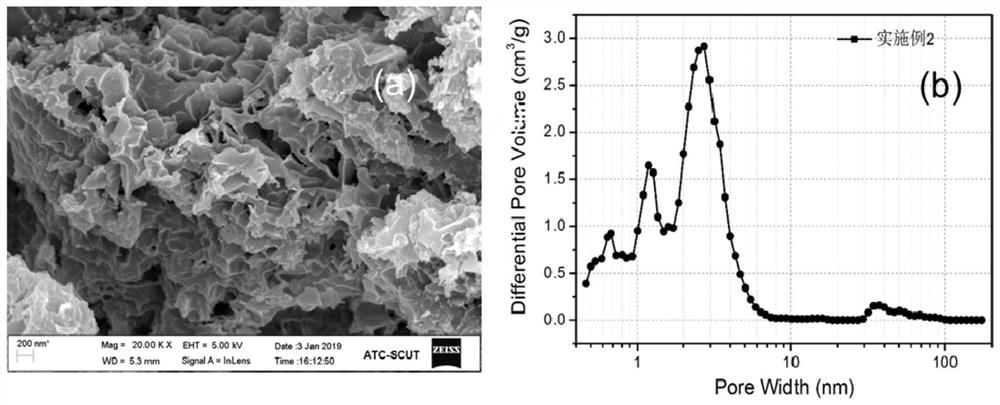

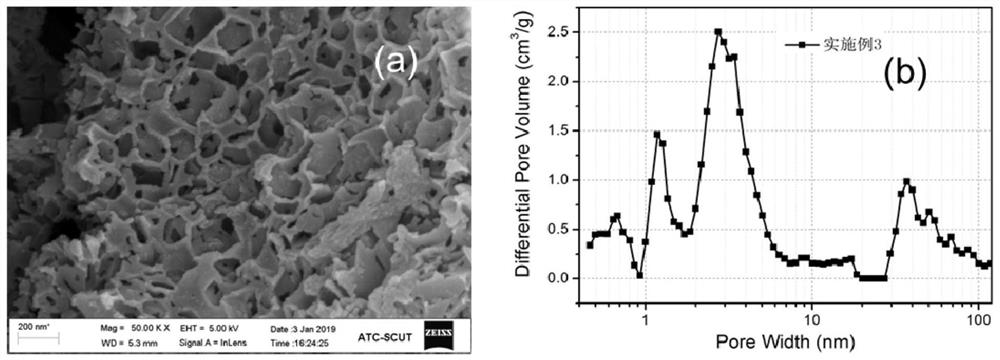

Preparation method of molybdenum sulfide/three-dimensional macroporous graphene and lithium ion battery negative electrode material

ActiveCN110556530AImprove conductivityImproved magnification performanceNegative electrodesSecondary cellsThioureaGlycerol

The invention relates to a preparation method of molybdenum sulfide / three-dimensional macroporous graphene for a lithium ion battery negative electrode material in the field of battery materials. According to the invention, molybdenum acetylacetonate powder is used as a molybdenum source, and the preparation method comprises the steps of adding the molybdenum acetylacetonate powder into a mixed solution composed of isopropanol, water and glycerol, preparing molybdenum glycerate spheres through solvothermal reaction, carrying out hydrothermal reaction on the molybdenum glycerate spheres and graphene oxide to obtain molybdenum glycerate sphere / three-dimensional macroporous graphene, taking thiourea as a sulfur source, taking ethanol and water as solvents, vulcanizing the molybdenum glyceratespheres by a solvothermal reaction to obtain molybdenum sulfide / three-dimensional macroporous graphene which is used for the lithium ion battery negative electrode material. The MoS2 / 3D-rGO compositematerial prepared by the method disclosed by the invention has the advantages that MoS2 is uniformly loaded on macroporous graphene, the specific surface area of graphene is increased, the infiltration of an electrolyte is facilitated, the migration rate of lithium ions is increased, structural collapse caused by volume expansion between molybdenum sulfide sheet layers can be effectively relievedby virtue of the porous structure of three-dimensional graphene, and the cycling stability of the battery is improved.

Owner:YANGZHOU UNIV

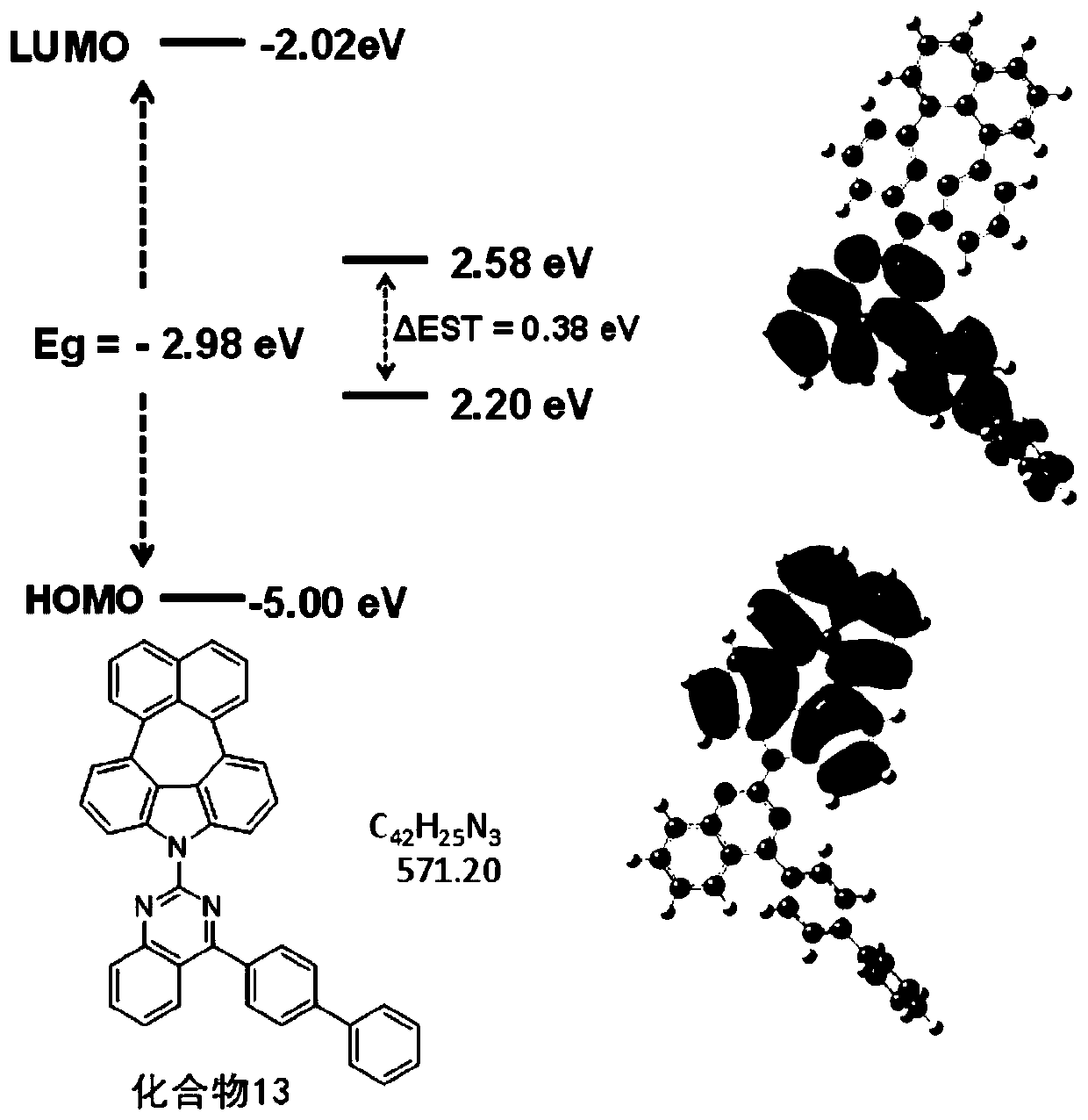

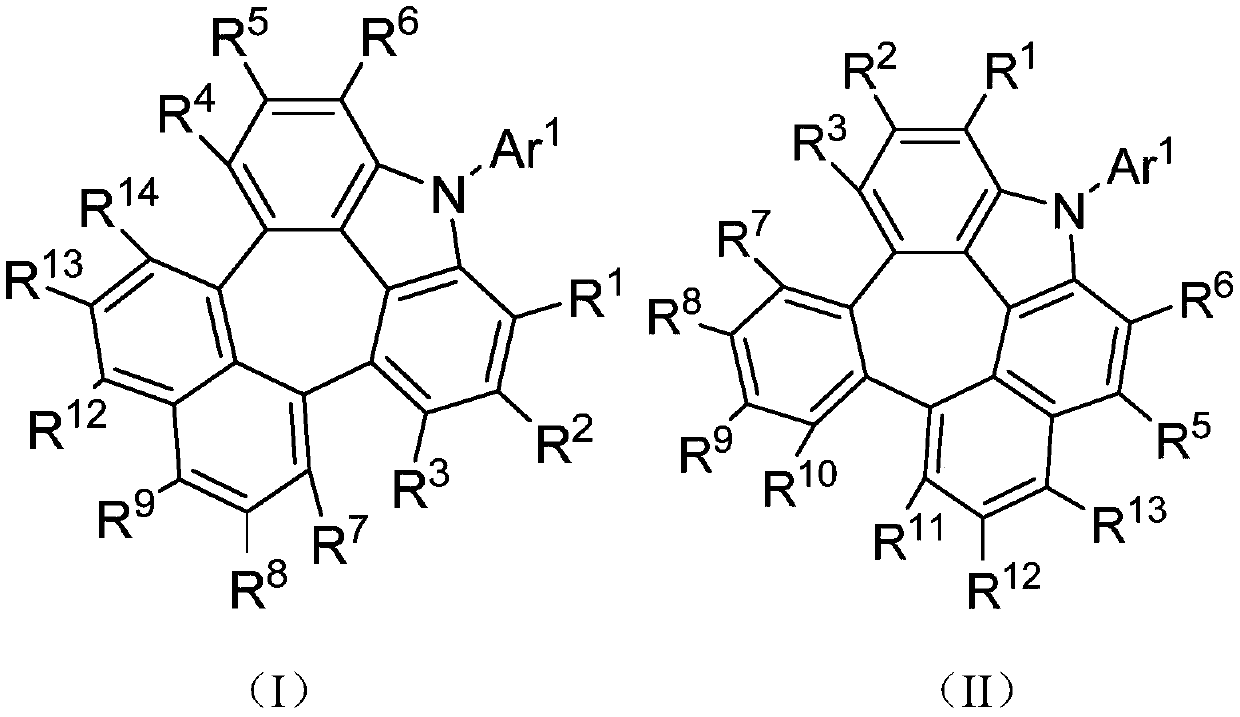

Fused ring compound, preparation method and applications thereof

ActiveCN111039850AEffective combinationModerate transmission capacityGroup 5/15 element organic compoundsSolid-state devicesElectron holeElectron donor

The invention discloses a fused ring compound, a preparation method and applications thereof. The fused ring compound has a structure represented by a formula (I) or a formula (II). According to the invention, the main body part of the compound serves as a large electron donor center and is well paired with an electron withdrawing group, so that electrons and holes are transmitted in a balanced manner, and effective combination of the electrons and the holes is promoted; the transmission capability of carriers is moderate, so that disappearing caused by over-high carrier concentration is avoided; hOMO and LUMO energy levels are matched with adjacent materials, and the driving voltage is small, so that the service life is remarkably prolonged; and the fused ring compound has good thermal stability and an appropriate sublimation temperature, and can avoid the thermal decomposition of a material in a film forming or using process, avoid the function loss of a material layer, and improve the luminous efficiency and the luminous performance of a device. The invention further provides a preparation method of the fused ring compound, an organic electroluminescent device and applications of the organic electroluminescent device in a lighting device or a display device.

Owner:NINGBO LUMILAN NEW MATERIAL CO LTD

Multistage stacking packaging method for cigarettes

Owner:QUANZHOU KESHENG PACKAGING MACHINERY

High-dispersibility de-valence electron modified graphene lubricant and preparation method thereof

The invention relates to high-dispersibility de-valence electron modified graphene lubricant and a preparation method thereof. The lubricant is made from de-valence electron modified graphene, a dispersant, an anti-foaming agent, a preservative and basic oil, wherein the 0.3-1.5 parts of the de-valence electron modified graphene is used; the preparation method of the lubricant includes the steps of (1), adding the de-valence electron modified graphene, dispersant, anti-foaming agent and preservative gradually into the basic oil, and stirring well; (2), stirring a mixture of step (1) while ultrasonic vibration. The de-valence electron modified graphene in the lubricant is dispersed evenly, excellent antifriction effect can be provided, and the lubricant is imparted good mechanical protection and excellent stability and antioxidant property.

Owner:CHONGQING DELING TECH

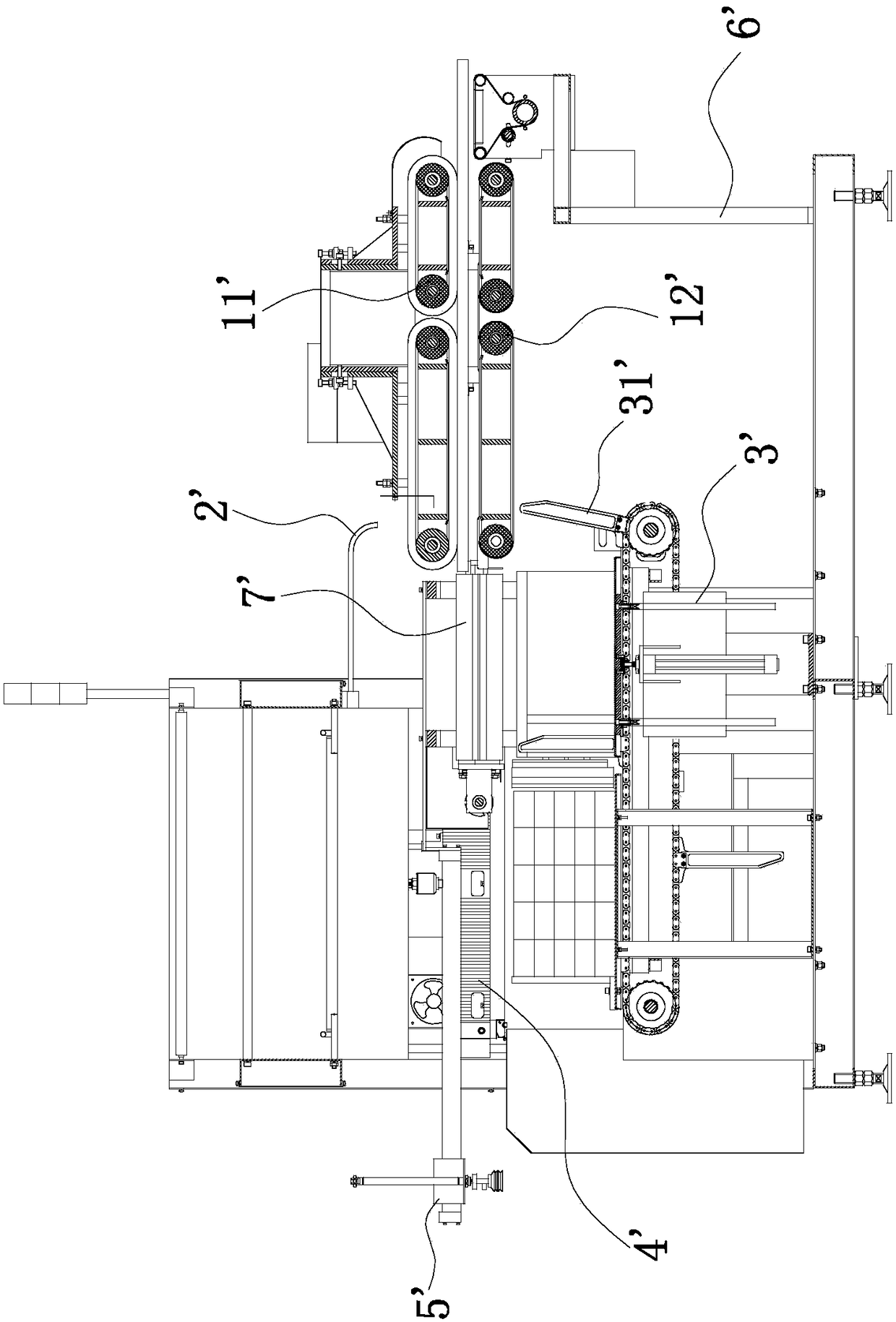

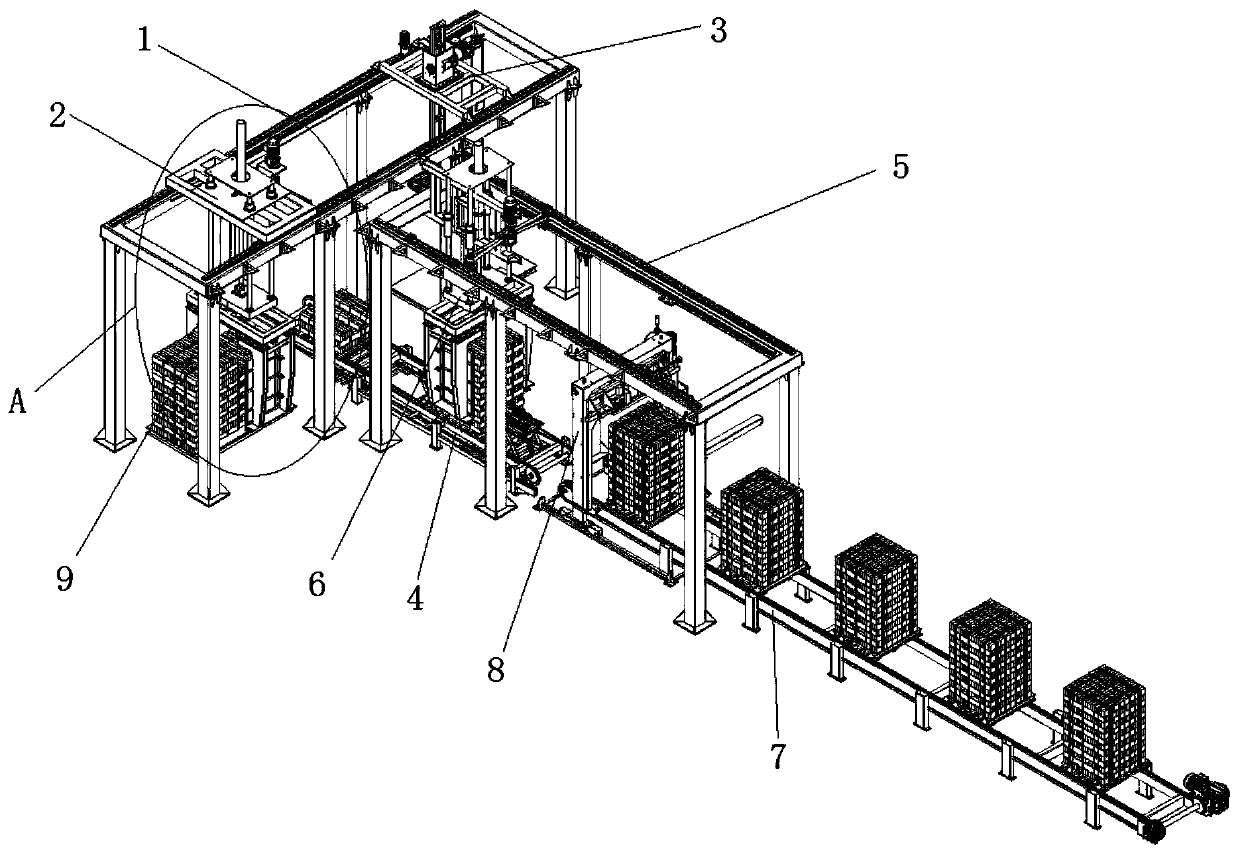

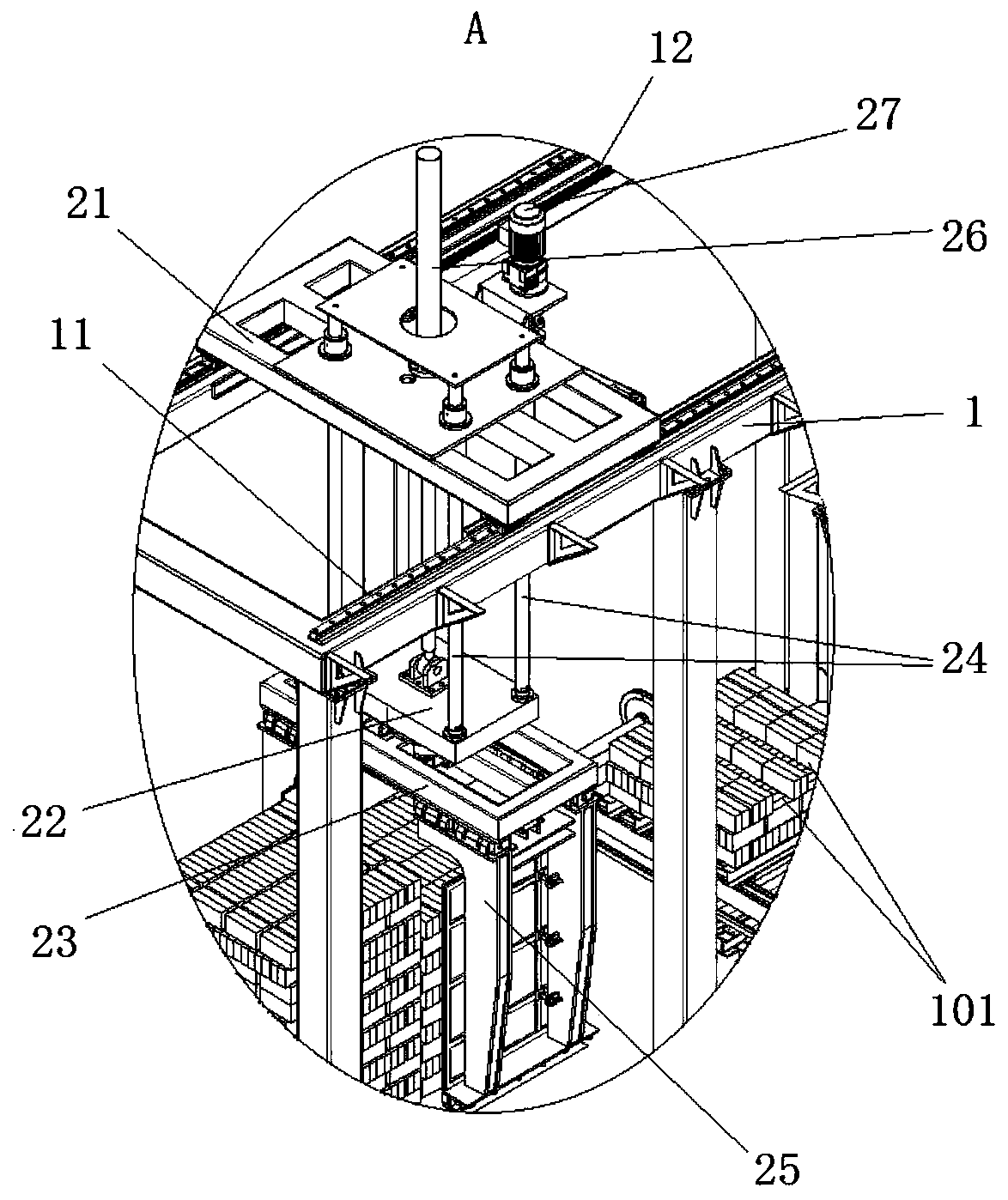

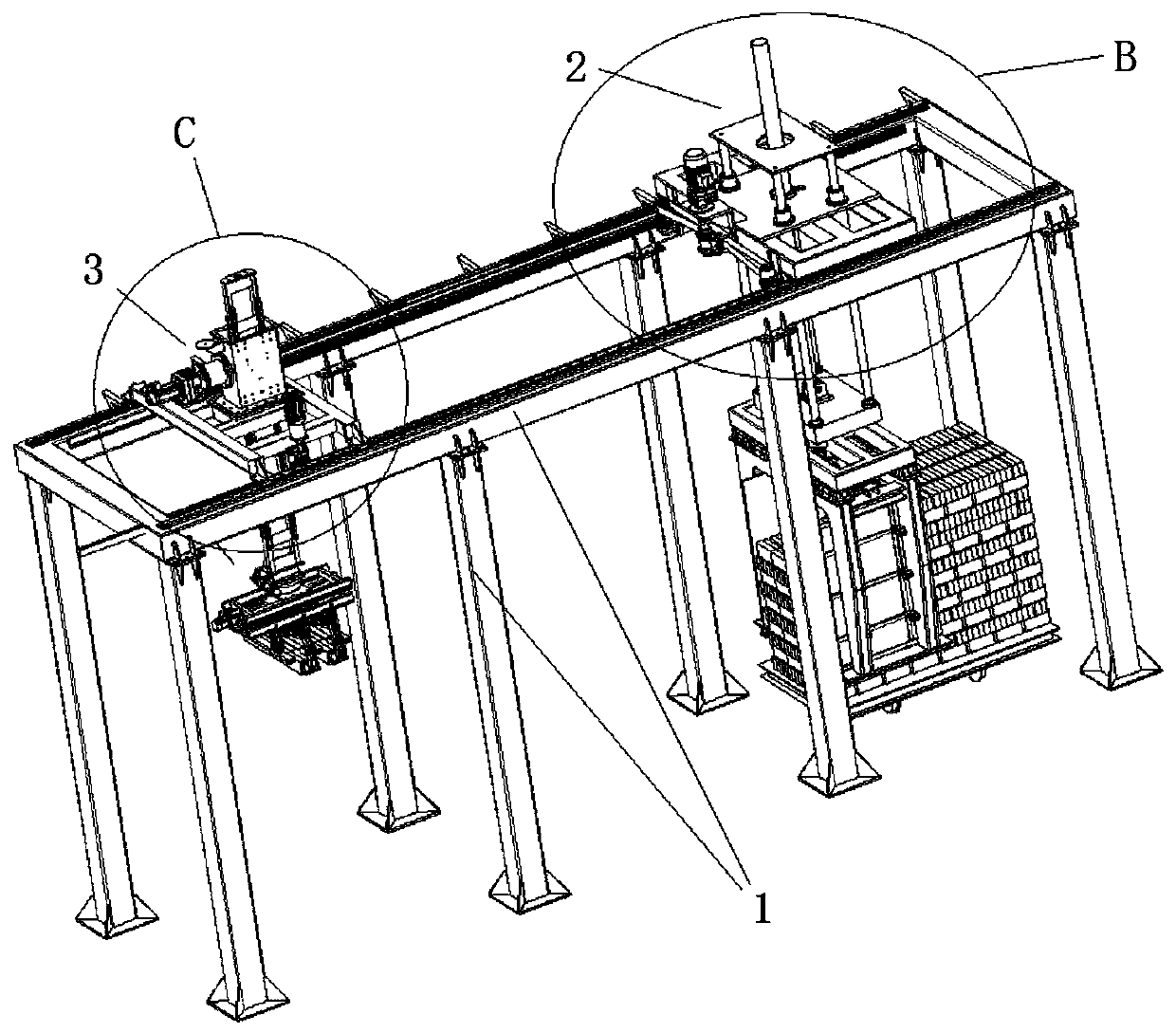

Full-automatic packing method and device capable of achieving brick stacking and reserving forklift holes

PendingCN110203443ANot easy to stackEasy to transportBuilding material packagingBundling machine detailsPacking methodMechanical engineering

The invention relates to a full-automatic packing method and device capable of achieving brick stacking and reserving forklift holes. A first grabbing clamp is used for grabbing at least two layers ofgreen bricks from a stacked brick stack, and the green bricks are placed on a first conveying device; a second grabbing clamp is used for taking two rows or two columns of green bricks along the intervals from the green bricks at the uppermost layer on the first conveying device; a plurality of layers of green bricks remaining are grabbed by the first grabbing clamp and placed above the green bricks of the first conveying device; a third grabbing clamp is used for closing gaps of the brick stack; the third grabbing clamp is used for grabbing the spliced brick stack onto a second conveying device, a bundling device is used for carrying out first bundling, and after the first bundling is finished, the first bundled brick stack is grabbed by the third grabbing clamp to rotate by 90 degrees,and bundling is carried out for the second time by the bundling device; and a forklift is used, two forklift arms of the forklift are inserted into the reserved forklift holes, and transportation is carried out. According to the device, the automatic packing and brick stacking can be automatically achieved, the forklift holes can be reserved, and meanwhile, the brick stack is stable in transportation and not prone to collapsing.

Owner:河南省机械院机械装备股份有限公司

Three-dimensional structure multilevel-hole graphene electrode material and preparation method thereof

InactiveCN104058397ADifficult interfacial molecular transportLarge voltage rangeOrganic solventChloride

The invention provides a three-dimensional structure multilevel-hole graphene electrode material and a preparation method thereof. The preparation method comprises the steps of 1) dispersing graphite oxide into an organic solvent to obtain a graphite oxide dispersion liquid, drying, and removing the organic solvent to obtain a graphite oxide powder after solvent treatment; 2) dispersing the graphite oxide powder after the solvent treatment, obtained in the step one, into water, adding a reducing agent, carrying out reaction for 0.5-3 hours at the temperature of 90-100 DEG C; and 3) adopting strong base, zinc chloride or carbon dioxide to carry out activation treatment on the graphene obtained in the step two, and preparing the three-dimensional structure multilevel-hole graphene electrode material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

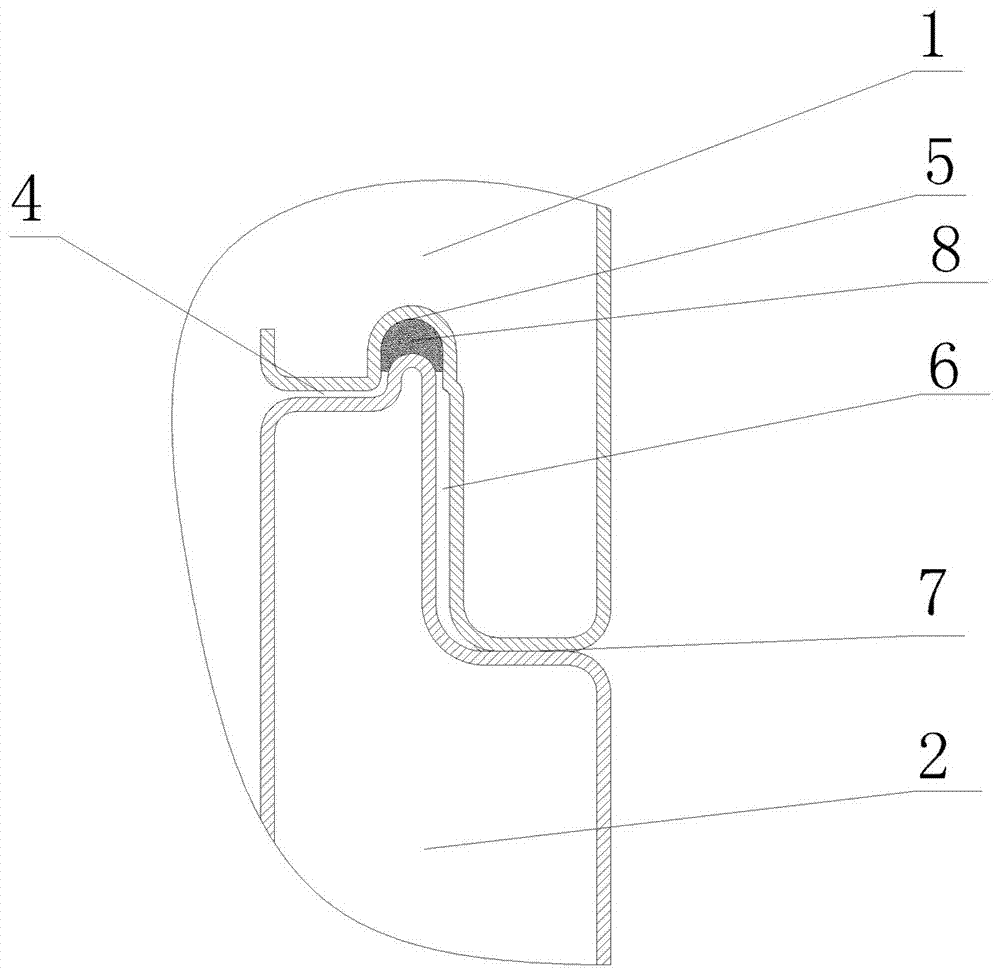

Air-drop type storage-transportation packaging box convenient to stack and preparation method of packaging box

ActiveCN107383579ANot easy to damageImprove toughnessCoatingsRigid containersLinear low-density polyethyleneLow-density polyethylene

The invention relates to an air-drop type storage-transportation packaging box convenient to stack and a preparation method of the packaging box, belonging to the package and transportation fields. The packaging box comprises a box body and a box cover which are mutually buckled, wherein the box body and the box cover are prepared from the following raw materials in parts by weight through rotational molding: 50-70 parts of linear low density polyethylene, 50-70 parts of low density polyethylene, 40-80 parts of high density polyethylene, 10-30 parts of medium density metallocene polyethylene and 1-6 parts of a coupling agent; and rig grids are arrayed at the bottom of the box body or the top of the box body or the box cover in a matrix manner, the rig grids at the top of the box body or the box cover are mutually seamed and clamped with the rig grids at the bottom of the box body on an upper layer so as to form embedding and splicing type anti-dislocation stacking structure. The packaging box is produced from the polyethylene materials with different densities through mixing and rotational molding, and modularized rid grid structures are arranged at the top and the bottom of the packaging box, so that the strength, impact resistance and packaging efficiency of the packaging box are improved, and the mutual stable stacking of different specifications of packaging boxes is realized.

Owner:河北金后盾塑胶有限公司

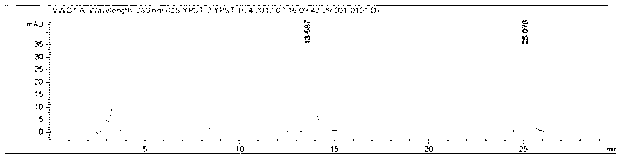

Content detecting and control method of epalrestat tablets

The invention discloses a content detecting and control method of epalrestat tablets, according to the method, high-performance liquid chromatography is used for detecting the epalrestat tablets. Analytical conditions such as an optimal internal standard compound, mobile phase composition, an elution program, elution flow velocity, a detecting wavelength and a chromatographic column are optimized through a large number of experiments. Many times of experimental verification indicates that the content detecting and control method of the epalrestat tablets is good in stability and repeatability, high in analysis efficiency, good in resolution and capable of detecting epalrestat sensitively and accurately in a qualitative and quantitative mode, so that the quality of the epalrestat tablets can be evaluated objectively, comprehensively and accurately, and the content detecting and control method of the epalrestat tablets is of great significance in controlling of the quality of the epalrestat tablets and ensuring of clinical effects.

Owner:YANGTZE RIVER PHARM GRP NANJING HAILING PHARM CO LTD

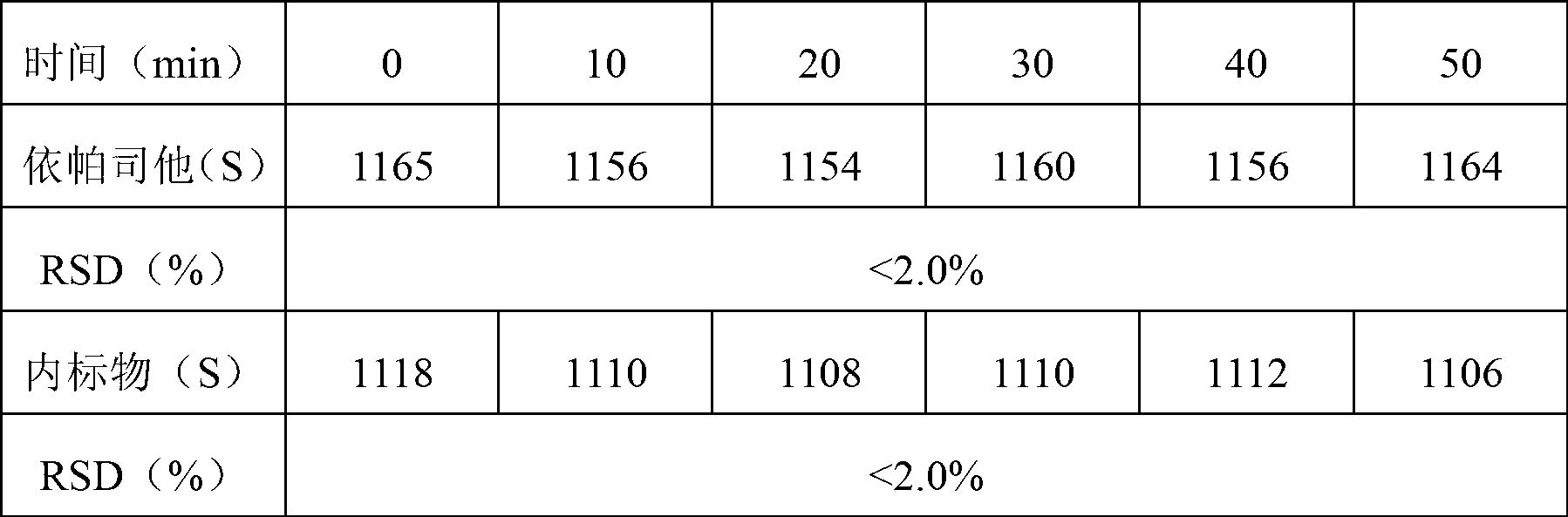

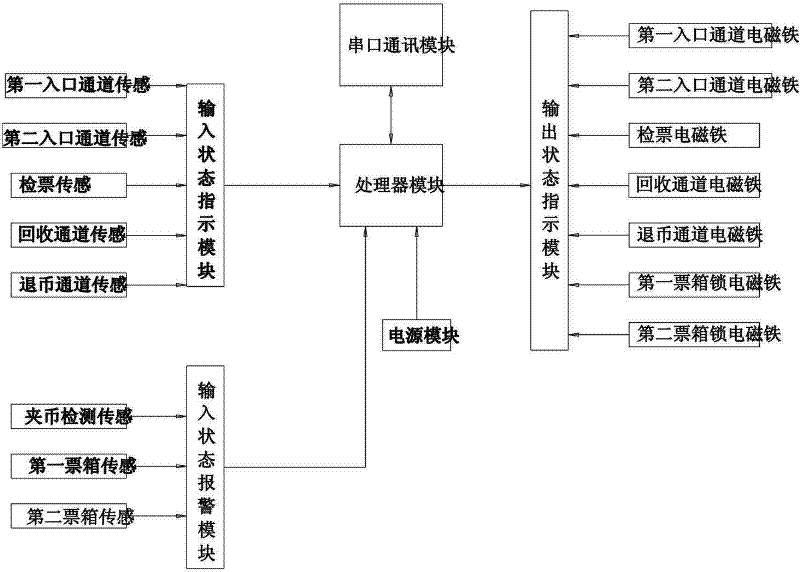

Automatic identification system for TOKEN

InactiveCN102646299AIncrease capacityExtended flow timeCoin/currency accepting devicesComputer moduleComputer science

The invention discloses an automatic identification system for TOKEN. The automatic identification system is characterized by comprising a processor module, a serial port communication module, a power supply module, input state indicating modules, an output state indication module, an input state warning module, an entrance sensing system, an exit sensing system and a warning sensing system, wherein the serial port communication module is connected with the processor module, the power supply module is connected with the processor module, the entrance sensing system is connected with the input state indicating modules, the input state indicating modules are connected, the output state indicating module is connected with the processor module, the exit sensing system is connected with the output state indicating module, the warning sensing system is connected with the input state warning module, and the input state warning module is connected with the processor module. The automatic identification system has the characteristics that the structure is simple, a host computer is not needed, the compatibility is high, the money clamping is avoided, and the practicability is high.

Owner:福建九天达信息科技股份有限公司

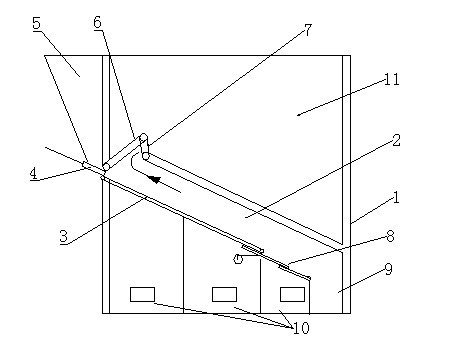

Solid fuel furnace and stepped combined fire grate for same

The invention discloses a solid fuel furnace and a stepped combined fire grate for the same. A hearth is arranged in a furnace body; an inclined fire grate is arranged in the hearth; a material pushing device is arranged on the furnace body at the front end of the fire grate; the fire grate is the stepped combined fire grate which comprises a fixed wet type fire grate part which is obliquely arranged and a reciprocating slag pushing fire grate part connected to the lower end of the fixed wet type fire grate part; and the reciprocating slag pushing fire grate part comprises a fixed fire grate and a slag pushing part which is arranged above the fixed fire grate and can be driven by a driving mechanism to do the reciprocating motion along the upper surface of the fixed fire grate. The fire grate of the solid fuel furnace is not easy to damage; the service period of the furnace is long; the temperature of the hearth is higher; and the thermal efficiency of the fuel can be increased and the emission of harmful gases is reduced.

Owner:孟氏锅炉(北京)有限公司

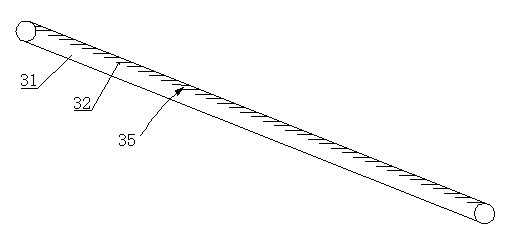

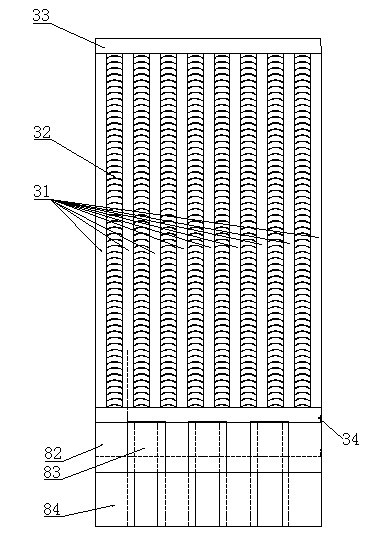

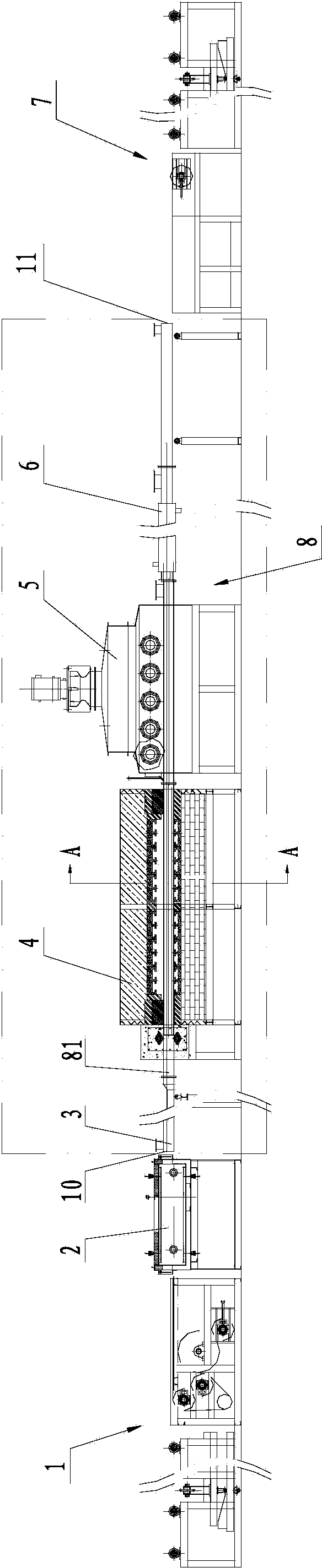

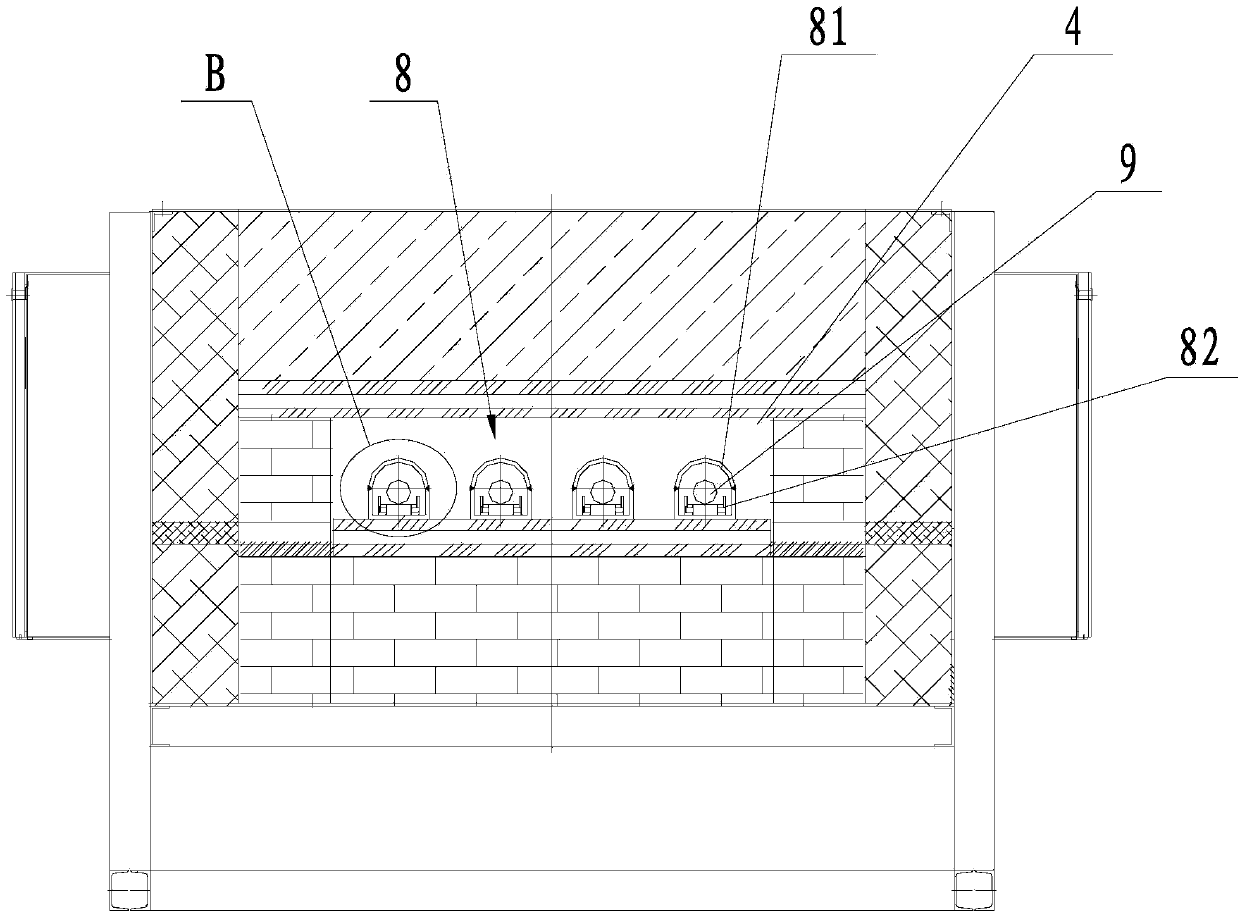

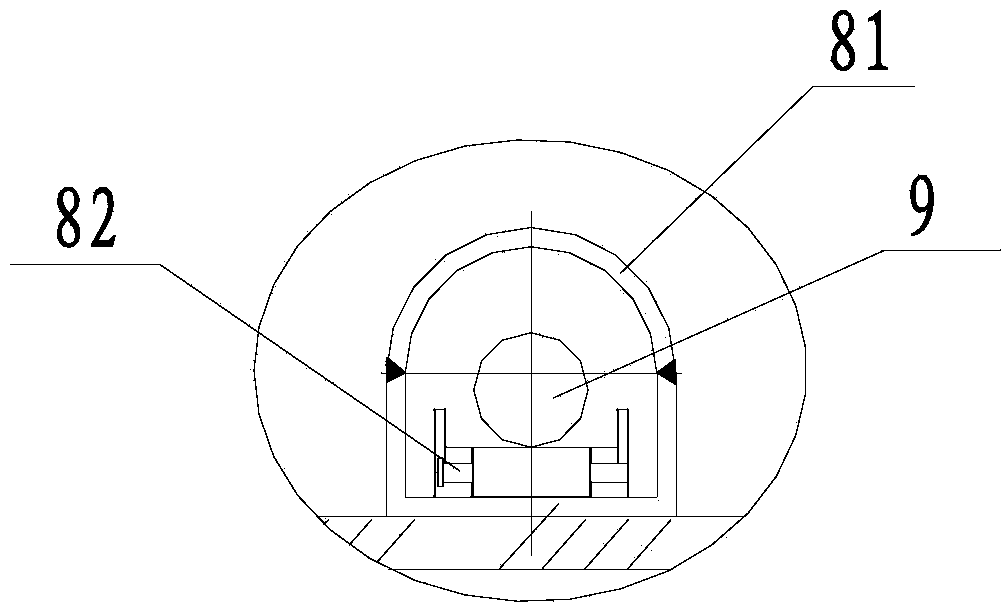

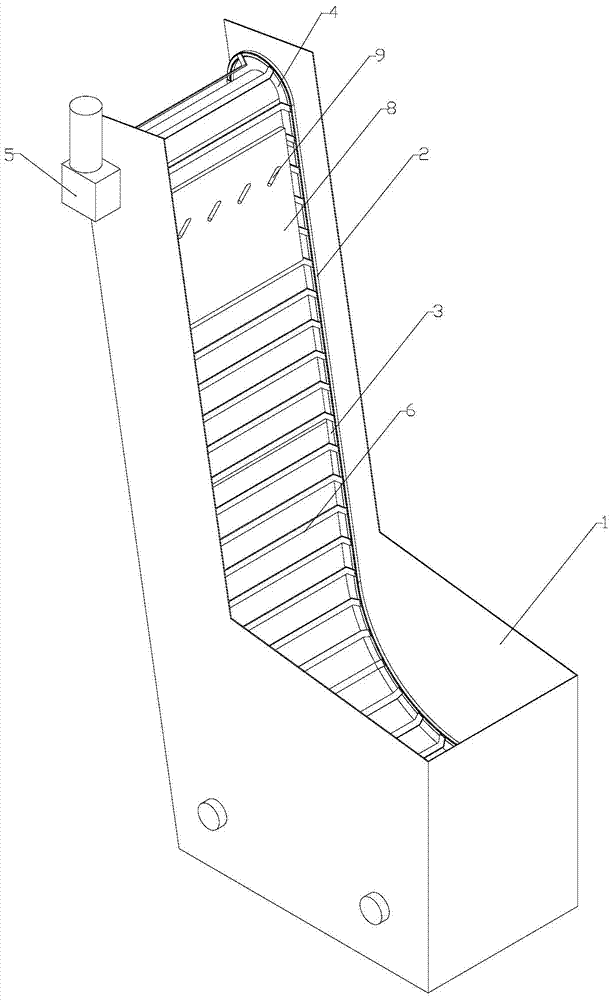

Tubular thermal treatment furnace capable of continuously conveying materials

ActiveCN103614537AEasier control of temperature and ambient atmosphereEnsure consistencyFurnace typesHeat treatment furnacesChemistryProcess engineering

The invention discloses a tubular thermal treatment furnace capable of continuously conveying materials. The tubular thermal treatment furnace comprises a furnace body with a material inlet and a material outlet and a material conveying mechanism for conveying workpieces, wherein the workpieces are conveyed by the tubular material conveying device into a preheating channel, a heating chamber, a water-cooling chamber and a water-cooling channel which are arranged in the furnace body in sequence, and subjected to corresponding treatments; the workpieces can be orderly conveyed in a conveying process and are difficult to stack, so that the number of the workpieces in the same conveying section is a fixed value; meanwhile, the workpieces entering the chamber or the channel of each treatment section are positioned in a relatively small region, so that the temperature and the environment atmosphere in each treatment section are easy to control, and the consistency between technical parameters of each treatment section and set parameters is guaranteed; therefore, the quality of the workpieces obtained through thermal treatment is guaranteed, and the quality of a product is improved.

Owner:SUZHOU ZHONGMENZI TECH

Bottle cap sorting device

The invention discloses a bottle cap sorting device, which comprises a cap storage hopper and a chain conveying device, wherein cap carrying plates are fixedly arranged on a circulation chain at intervals, a conveying bottom plate is arranged at the conveying function side of a support frame, and comprises a unified conveying section, a removing section and a positive direction conveying section, the plate surface of the removing section and the cap carrying plate corresponding to the position are simultaneously positioned at the inner side of the gravity centers of the vertical bottle caps with the outward cap tops, in addition, the plate surface of the removing section and the cap carrying plate corresponding to the position are respectively positioned at the two sides of the gravity centers of the vertical bottle caps with the inward cap tops, the unified conveying section, the cap carrying plate, the positive conveying section and the cap carrying plate are respectively positioned at the two sides of the gravity centers of the vertical bottle caps with the inward cap tops, and a press plate for removing bottle caps in the horizontal state is fixedly arranged in a position, positioned at the outer side of the circulation chain, of the upper end of the support frame, an air nozzle is arranged on the press plate, the top part of the support frame is provided with a guide-out opening, and the bottle caps can be conveniently blown out from the guide-out opening. The bottle cap sorting device has the advantages that the bottle cap sorting effect can be improved, the cap reversing rate is reduced, the bottle caps cannot be easily overlapped, and the bottle cap damage during the conveyance can be avoided.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

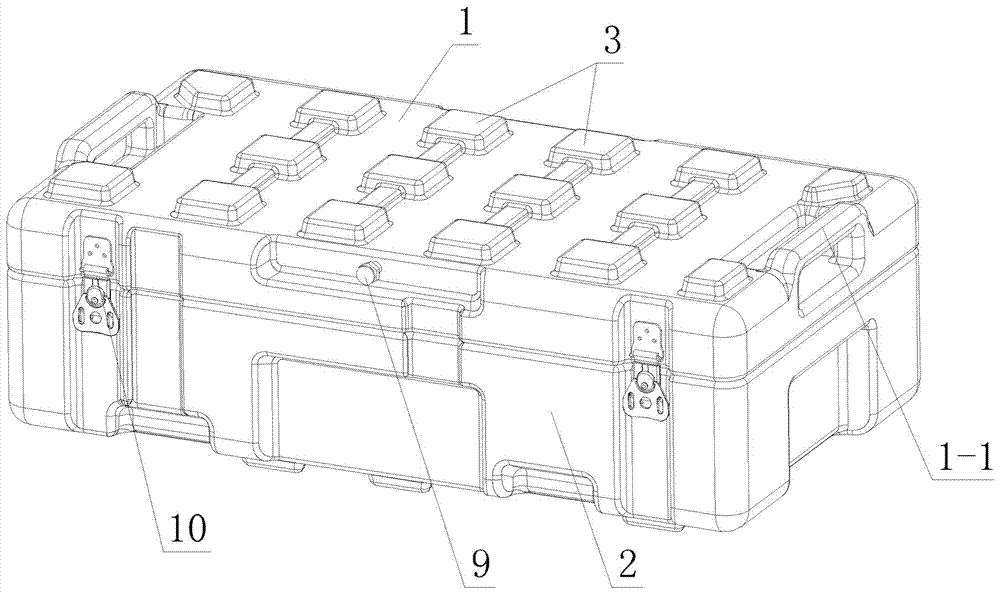

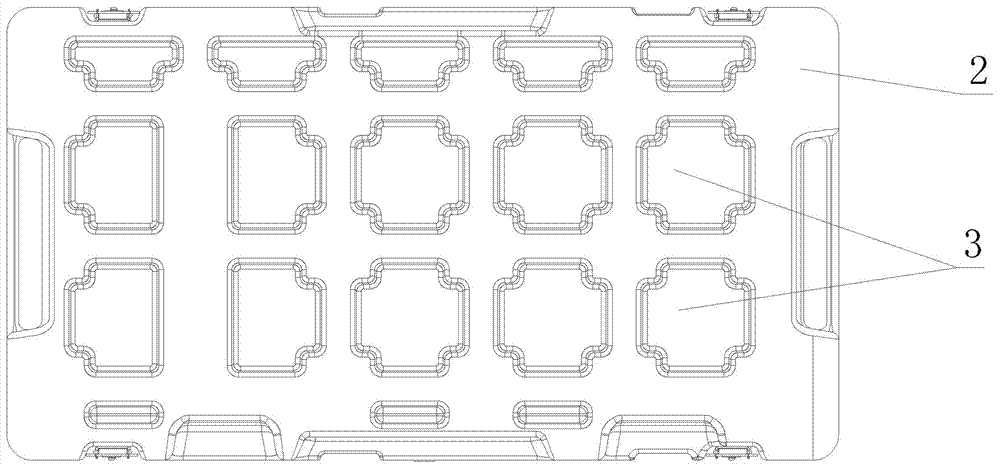

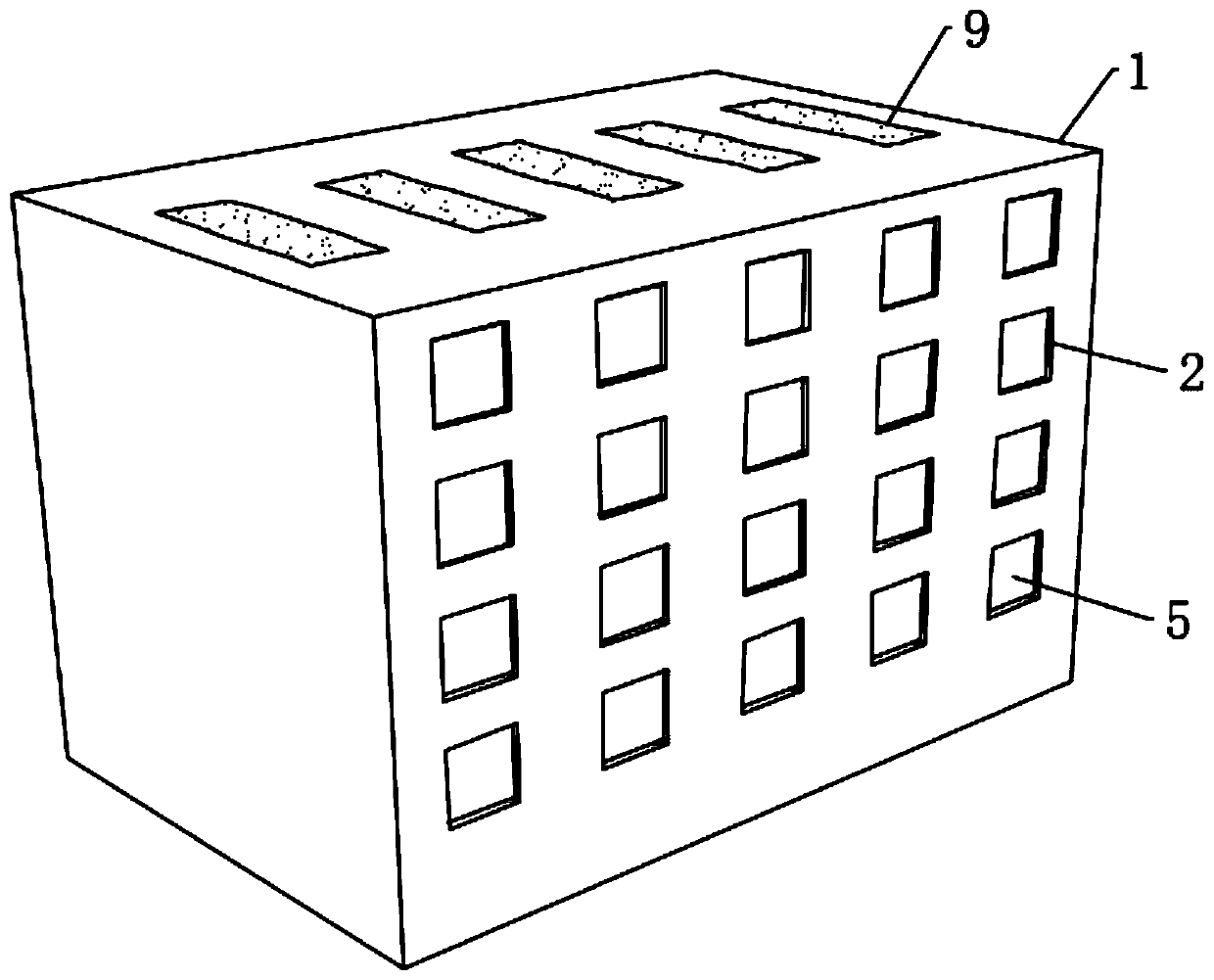

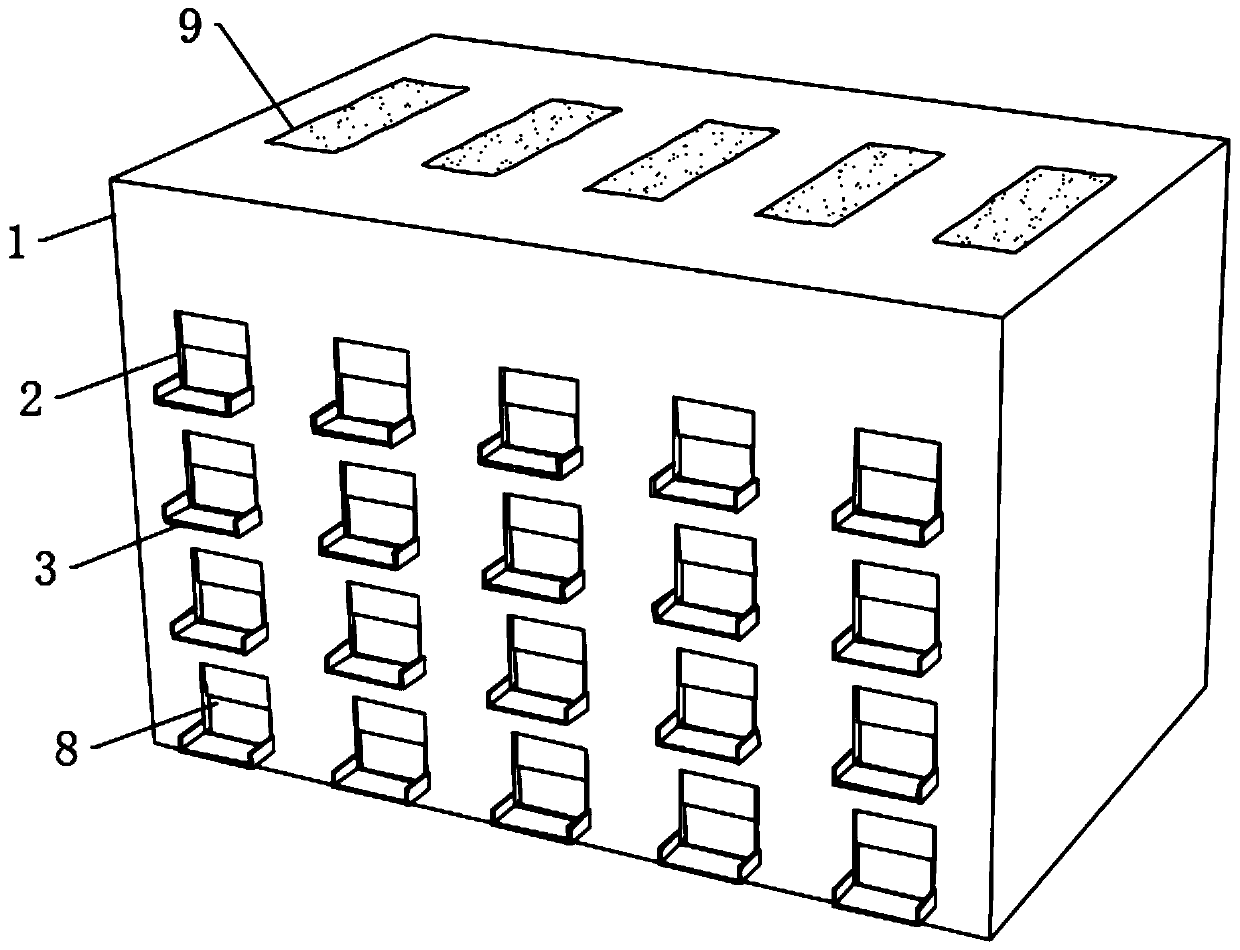

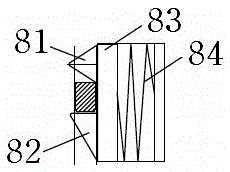

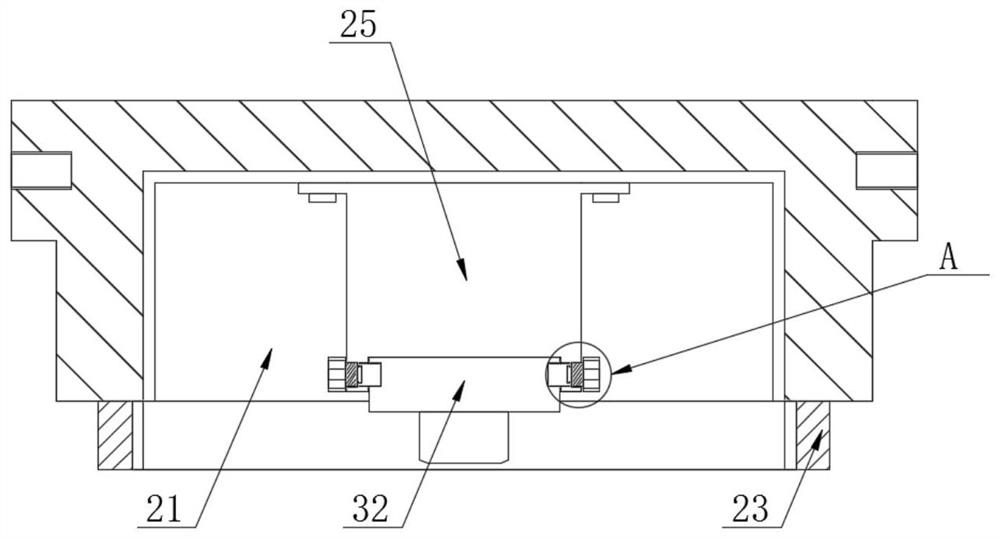

Portable storage device for taking and placing electronic components

InactiveCN110937227AEasy to put inNot easy to stackDischarging meansRigid containersEngineeringElectronic component

The invention discloses a portable storage device for taking and placing electronic components, and belongs to the technical field of electronic components. The storage device comprises a storage box,groups of storage holes of inclined structures are formed in the outer end of the storage box; the electronic components placed in the storage holes can slide down along inclined planes under the gravity effect of the electronic components, so that a worker can take the electronic components conveniently; due to the arrangement of a one-way rotating sealing door, the worker can put the electroniccomponents into the storage holes conveniently; operation is simple and convenient; the electronic components in the storage holes are arranged side by side, so that the electronic components tend not be overlapped; and the two adjacent electronic components are further separated and an electromagnetic signal therebetween is shielded due to a blocking effect of a polishing shielding sheet, and electronic components are not prone to being damaged due to mutual interference.

Owner:HANGZHOU LESHOU TECH CO LTD

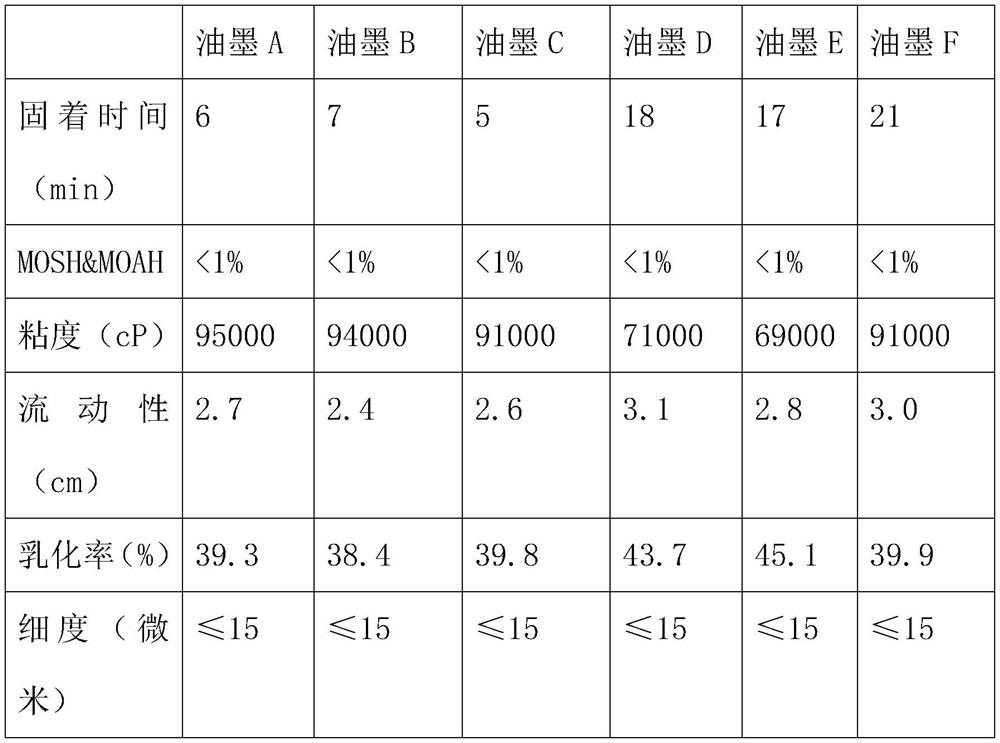

Vegetable oil-based low-halogen environment-friendly printing ink and preparation method thereof

The invention discloses plant oil-based low-halogen environment-friendly ink and a preparation method thereof. The plant oil-based low-halogen environment-friendly ink is prepared from the following raw materials: pigment particles, polyethylene wax, a binder, soybean methyl oleate, a cobalt drying agent and a dispersing agent. The printing ink disclosed by the invention is refined from pure vegetable oil, is green and environment-friendly, is suitable for various offset printing machines, is quick to fix, quick to dry, high in gloss, stable in on-machine printing and good in wear resistance, and is a product which is excellent in printing performance and wide in application and is very in line with the environment-friendly requirements of packaging and green printing in various industries; the preparation method comprises the steps of dispersing and matching, rolling and grinding and filtering and packaging. The modified short-oil alkyd resin is prepared by a double-bond copolymerization method, and the modified alkyd resin has excellent self-drying property; the self-made modified short oil alkyd resin is put into the preparation process of the connecting material through a two-step method, and the prepared connecting material endows the ink with excellent flowing and printing capabilities, so that an ink film is high in gloss and resistant to friction.

Owner:中山市富日印刷材料有限公司

An aromatic amine compound, an electronic component and an electronic device using the same

ActiveCN112110825BIncrease steric hindranceRigid and stableSilicon organic compoundsOrganic chemistry methodsLow voltageElectronic component

The present application belongs to the field of organic materials, and relates to an aromatic amine compound, electronic components and electronic devices using the same. The aromatic amine compound has the structure shown in the following formula 1. The arylamine compound of the present application is used as a hole transport material in an OLED device, and can obtain good device performance and lower voltage.

Owner:SHAANXI LIGHTE OPTOELECTRONICS MATERIAL CO LTD

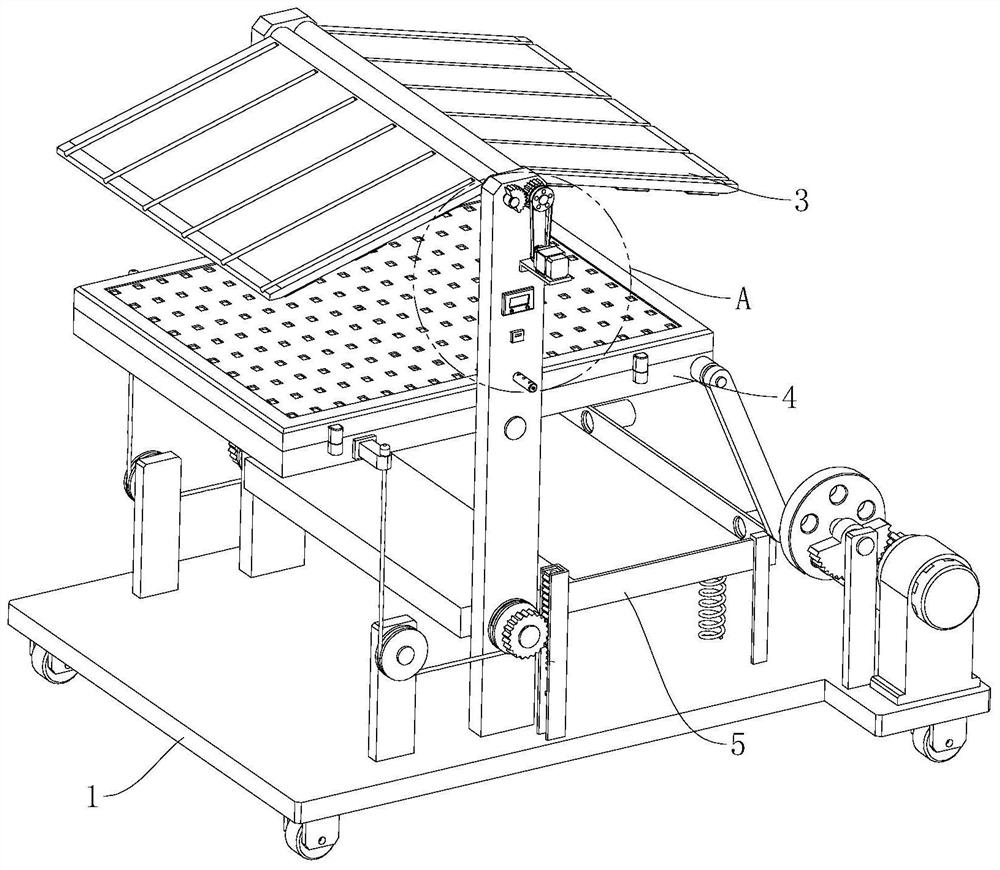

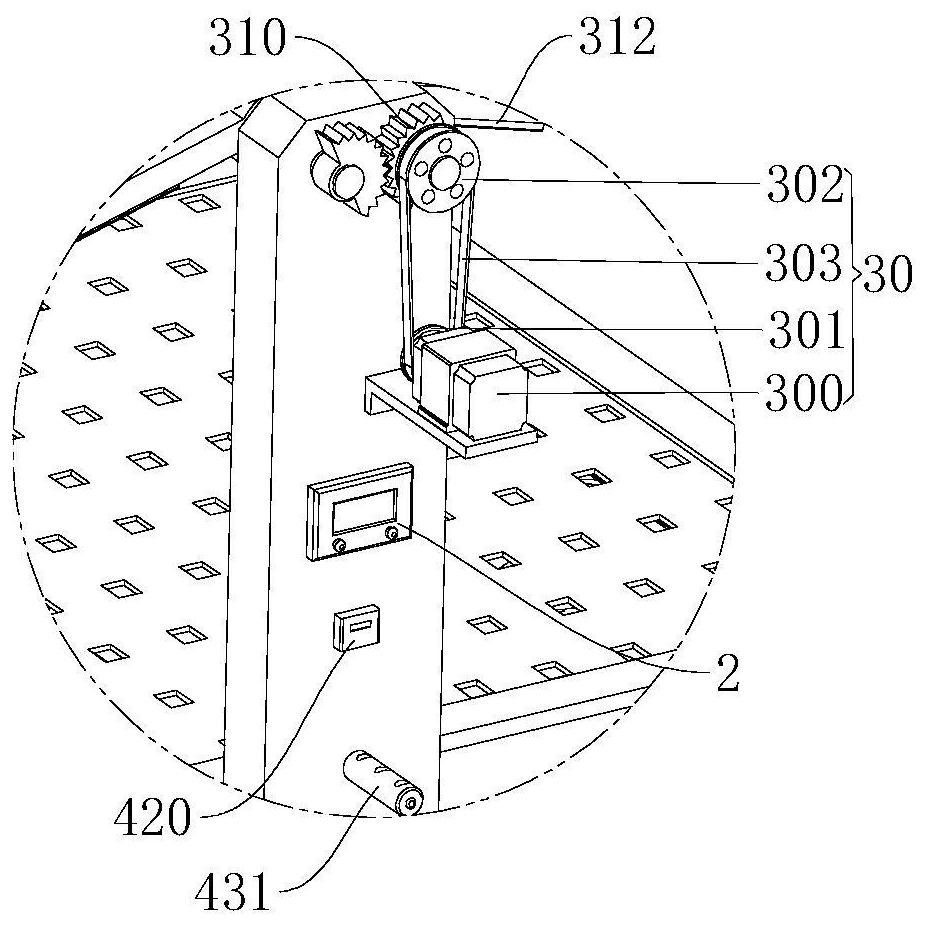

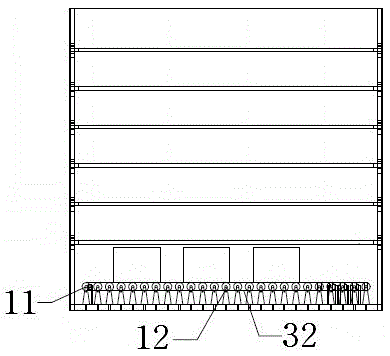

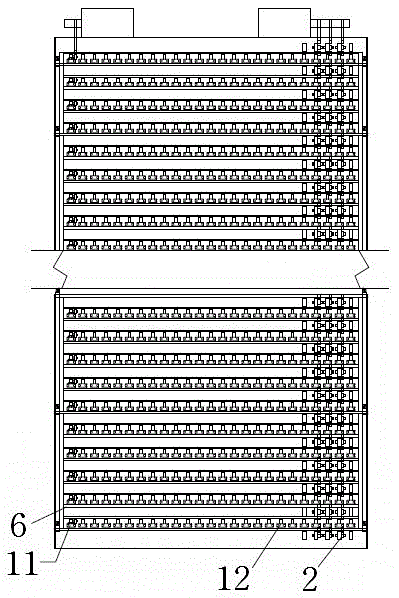

Aquatic product airing equipment

InactiveCN112400971AFully and evenly dryDry evenlyAnimal repellantsCleaning using liquidsAquatic productEnvironmental engineering

The invention relates to the technical field of aquatic product processing, in particular to aquatic product airing equipment. The equipment comprises a base and four universal wheels and further comprises a controller, a rainproof mechanism, an airing mechanism and a drainage mechanism, the airing mechanism comprises an airing disc, a placing assembly, an angle adjusting assembly and two verticalplates, the rainproof mechanism comprises a driving assembly and two baffles, the drainage mechanism comprises an adjusting plate, two traction assemblies and two limiting assemblies, the two limiting assemblies are symmetrically arranged at the end, away from the vertical plates, of the adjusting plate, the airing disc is located between the adjusting plate and the two baffles, and the angle adjusting assembly and the driving assembly are electrically connected with the controller. The aquatic product airing equipment has good drainage effect and better insect expelling effect, and no pollution is caused. Meanwhile, the airing angle can be automatically adjusted according to the illumination intensity, water such as grease generated during airing can be discharged in time, and taking isconvenient after airing.

Owner:李明磊

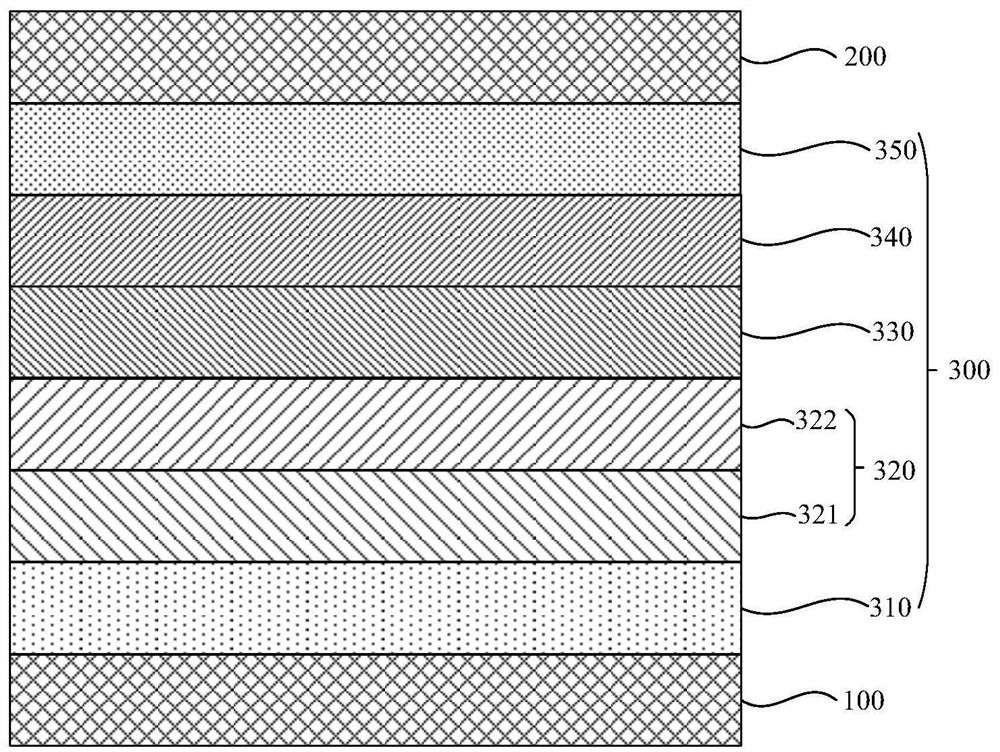

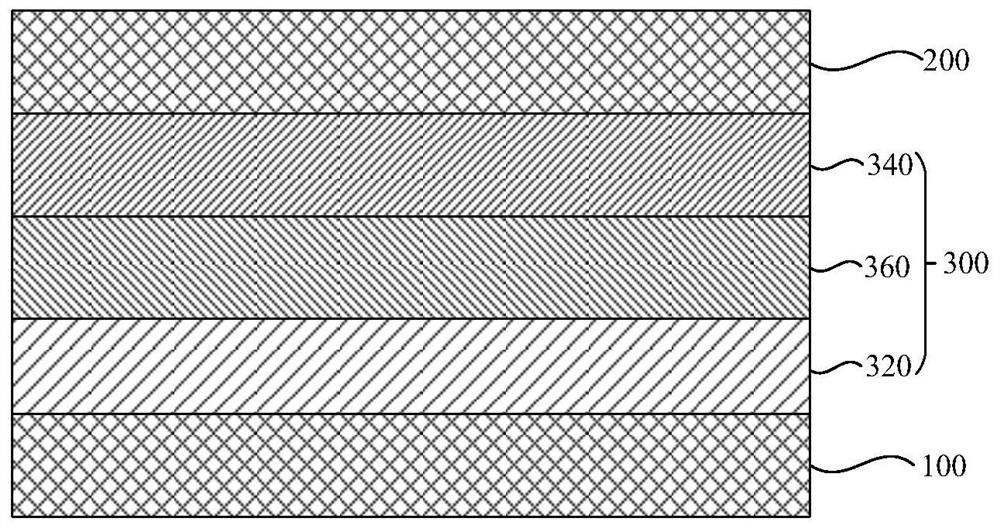

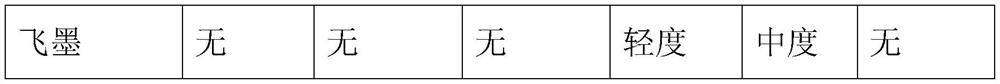

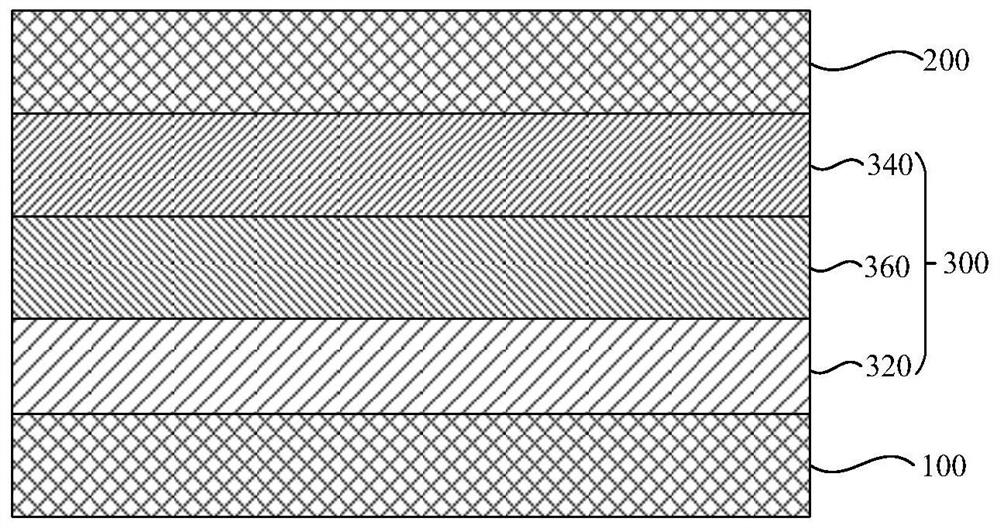

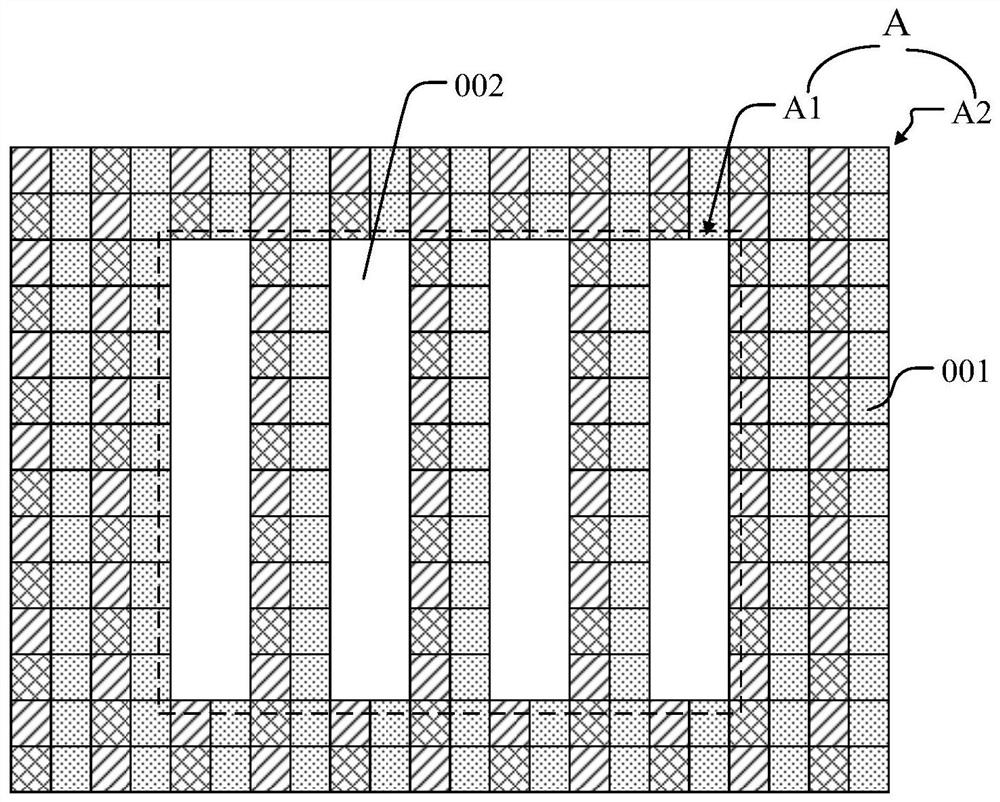

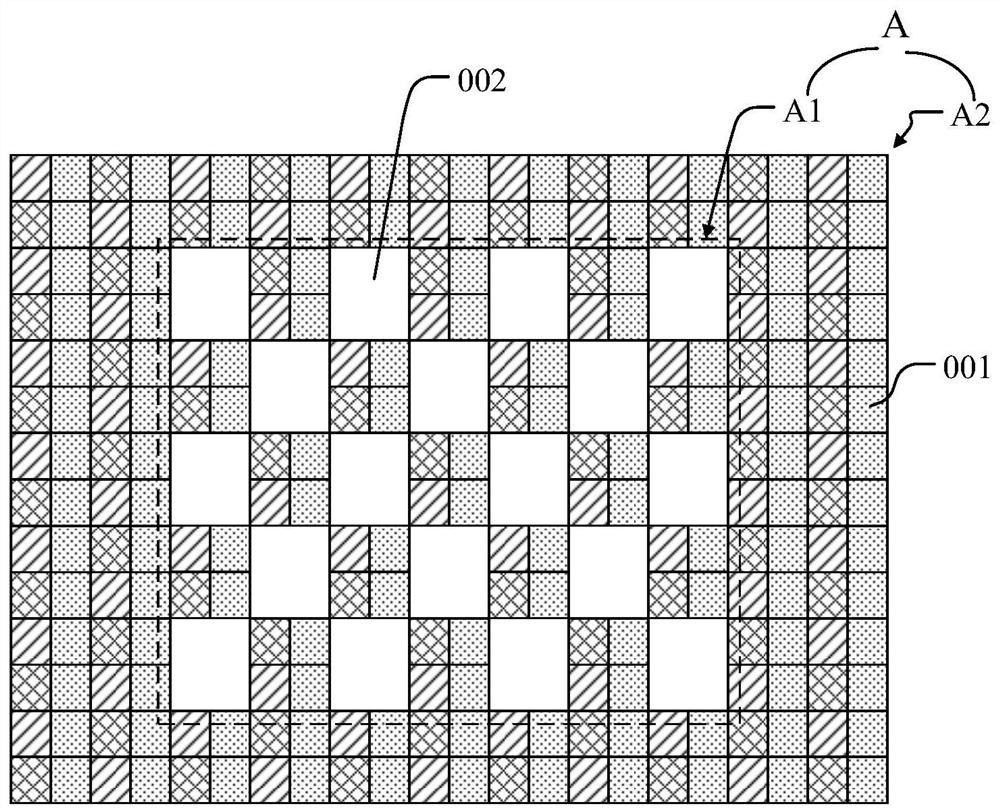

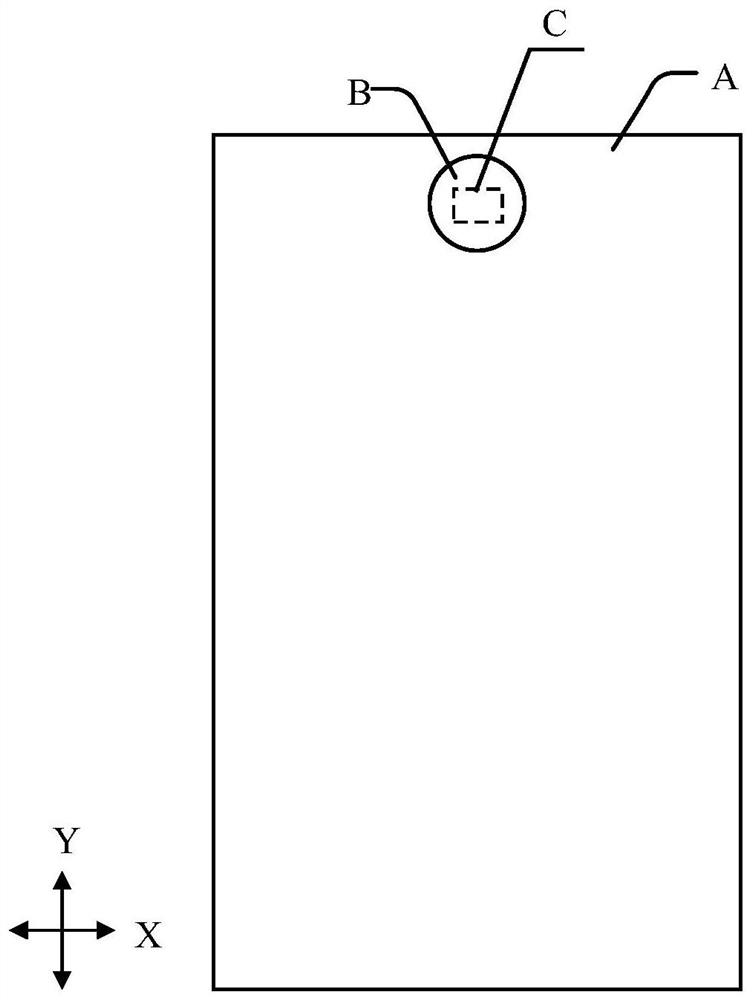

Display panel and terminal equipment

PendingCN112234083AEasy to take picturesEasy to shootSolid-state devicesSemiconductor devicesComputer graphics (images)Imaging quality

The invention relates to a display panel and terminal equipment, and relates to the technical field of display. The display panel comprises a display area, at least parts of the display area is a transparent area, the transparent area is provided with a plurality of pixel rows distributed in a column direction, each pixel row comprises a plurality of pixels and a plurality of transparent parts, the pixels and the transparent parts are alternately arranged in a row direction, and each pixel comprises a plurality of sub-pixels adjacently arranged in the row direction; each pixel row comprises aplurality of first pixel rows and a plurality of second pixel rows, a transparent part between every two adjacent pixels in the first pixel rows is a first transparent part, and a transparent part between every two adjacent pixels in the second pixel rows is a second transparent part; and the width of the first transparent part in the row direction is larger than that of the second transparent part in the row direction. According to the display panel and the terminal equipment, the imaging quality of under-screen camera shooting can be improved.

Owner:BOE TECH GRP CO LTD

An automatic loading and unloading carriage

InactiveCN103568918BRealize automatic loading and unloadingSave loading and unloading timeVehicle with raised loading platformVehicle with endless chains/beltsMotor driveDrive wheel

The invention provides an automatically loaded carriage, which is characterized by comprising a horizontal driving wheel, a horizontal driven wheel, a longitudinal idler wheel, a longitudinal driving belt, a horizontal driving belt, a driving chain, a conical gear, a lifting goods shelf, a rope, a fastening lock, a horizontal motor, a longitudinal motor, a rope motor, a chain guide wheel, a belt guide wheel and a guide groove, wherein the horizontal motor, the longitudinal motor and the rope motor are arranged at the end of the carriage, the horizontal motor drives the conical gear to rotate through the chain, the chain is guided by the chain guide wheel arranged at a box bottom, the conical gear is meshed with the horizontal driving wheel provided with conical gears, and the horizontal driving wheel is connected with a horizontal driven idler wheel through the horizontal driving belt. The device can be matched with a warehouse conveying goods crawler belt for realizing automatically loading goods into a warehouse and unloading the goods from the warehouse; the carriage is more applicable to fragile articles fear of heavy loading, and the carriage structure enables the goods to be placed in a layered manner and to be prevented from being pressed, so that the carriage is particularly suitable for the express industry.

Owner:王延斌

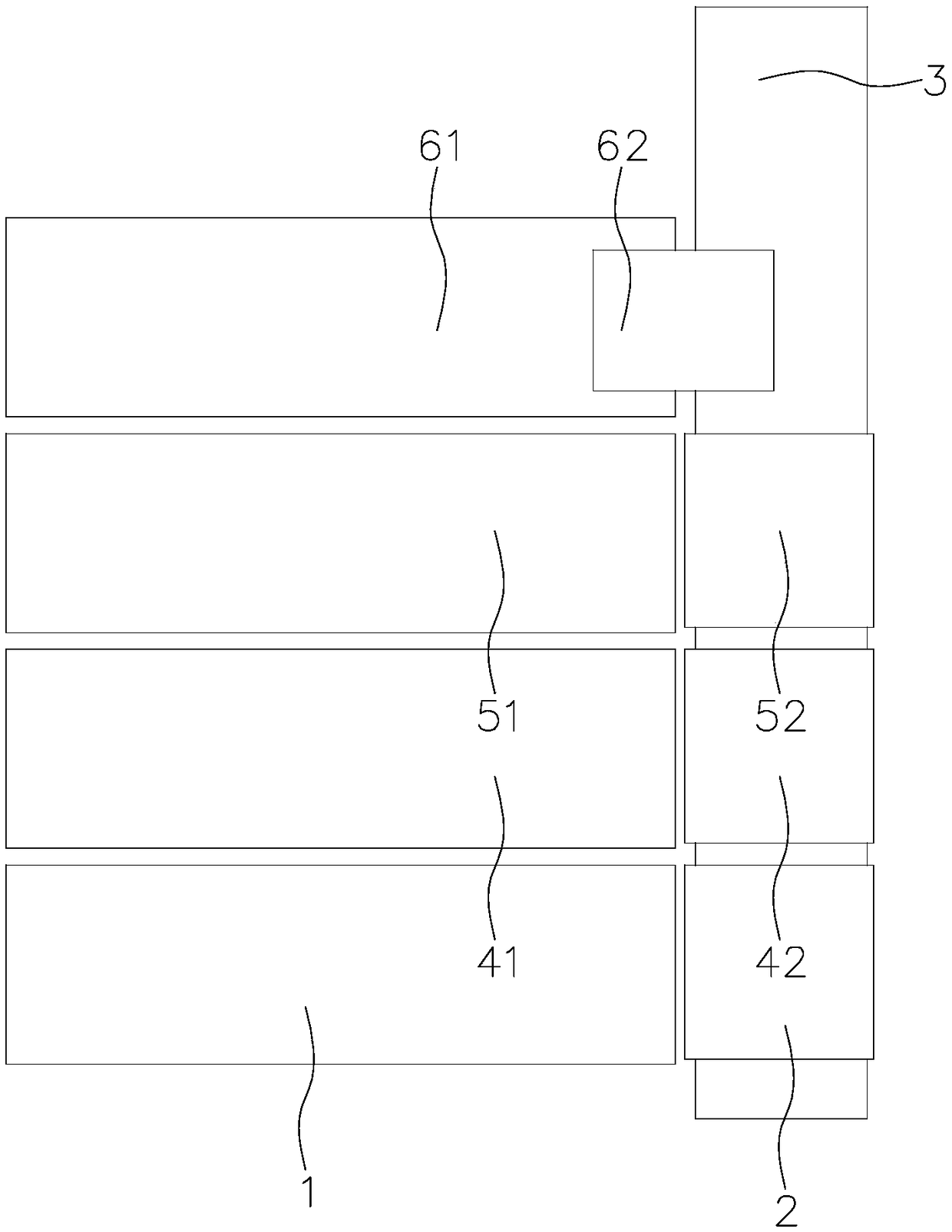

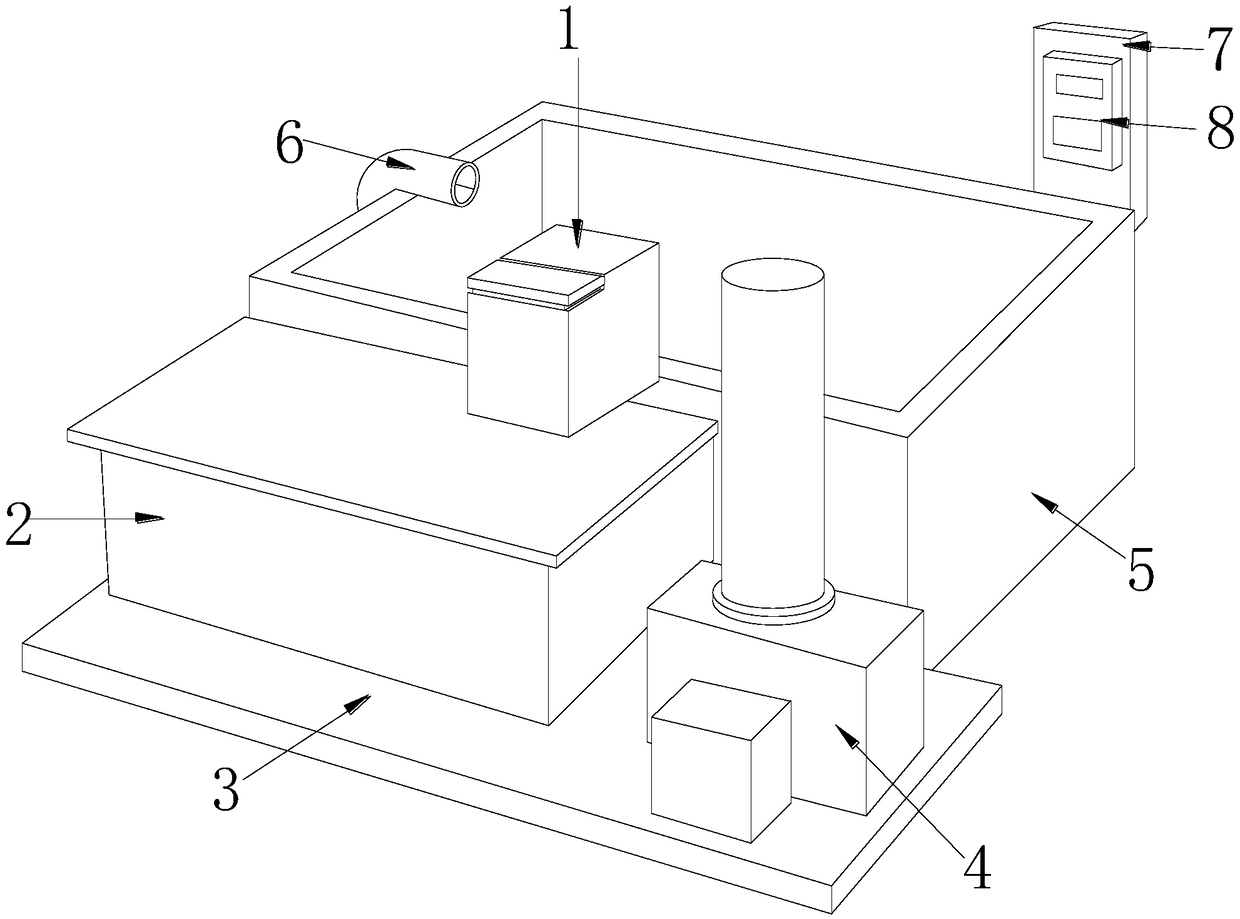

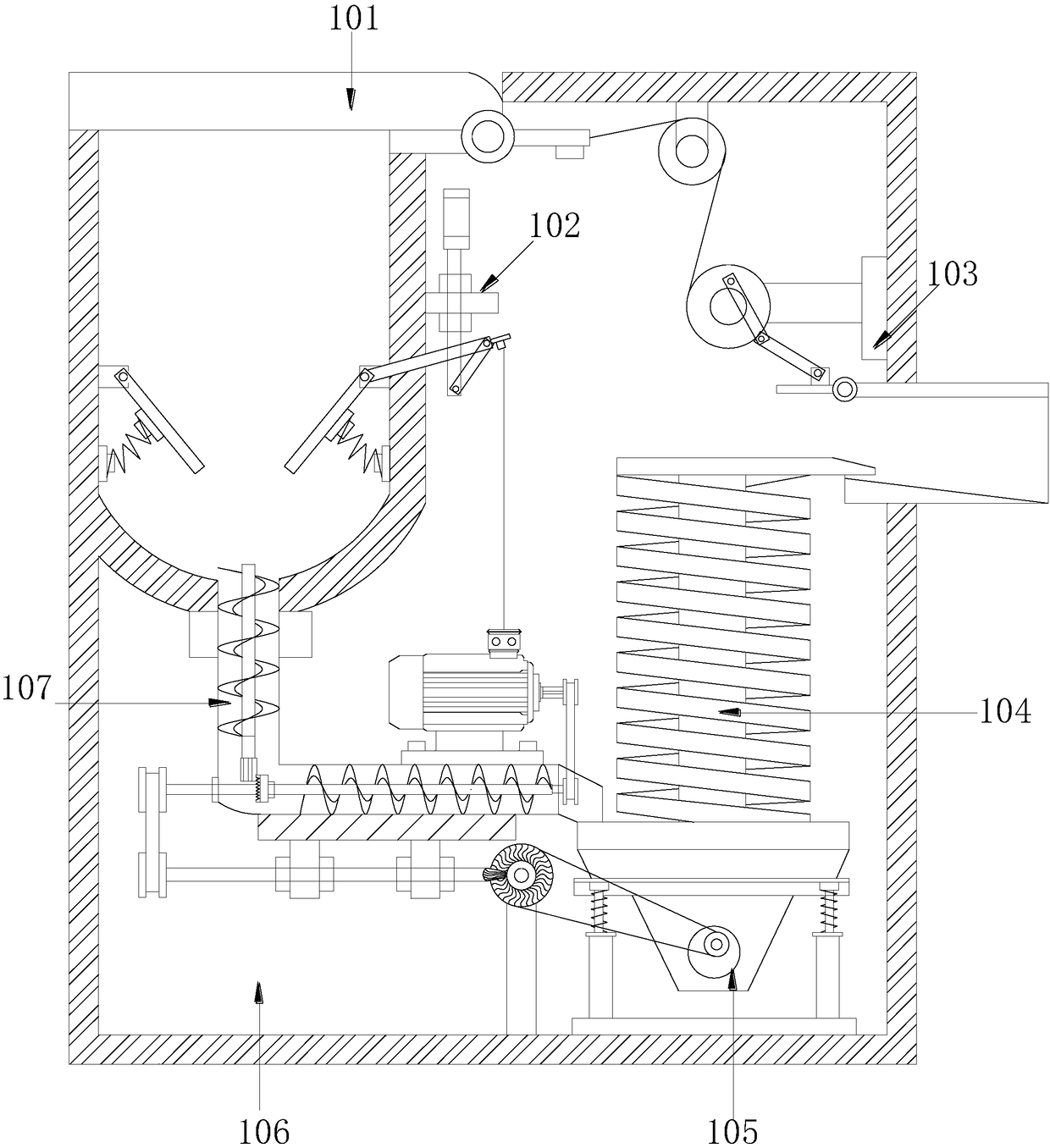

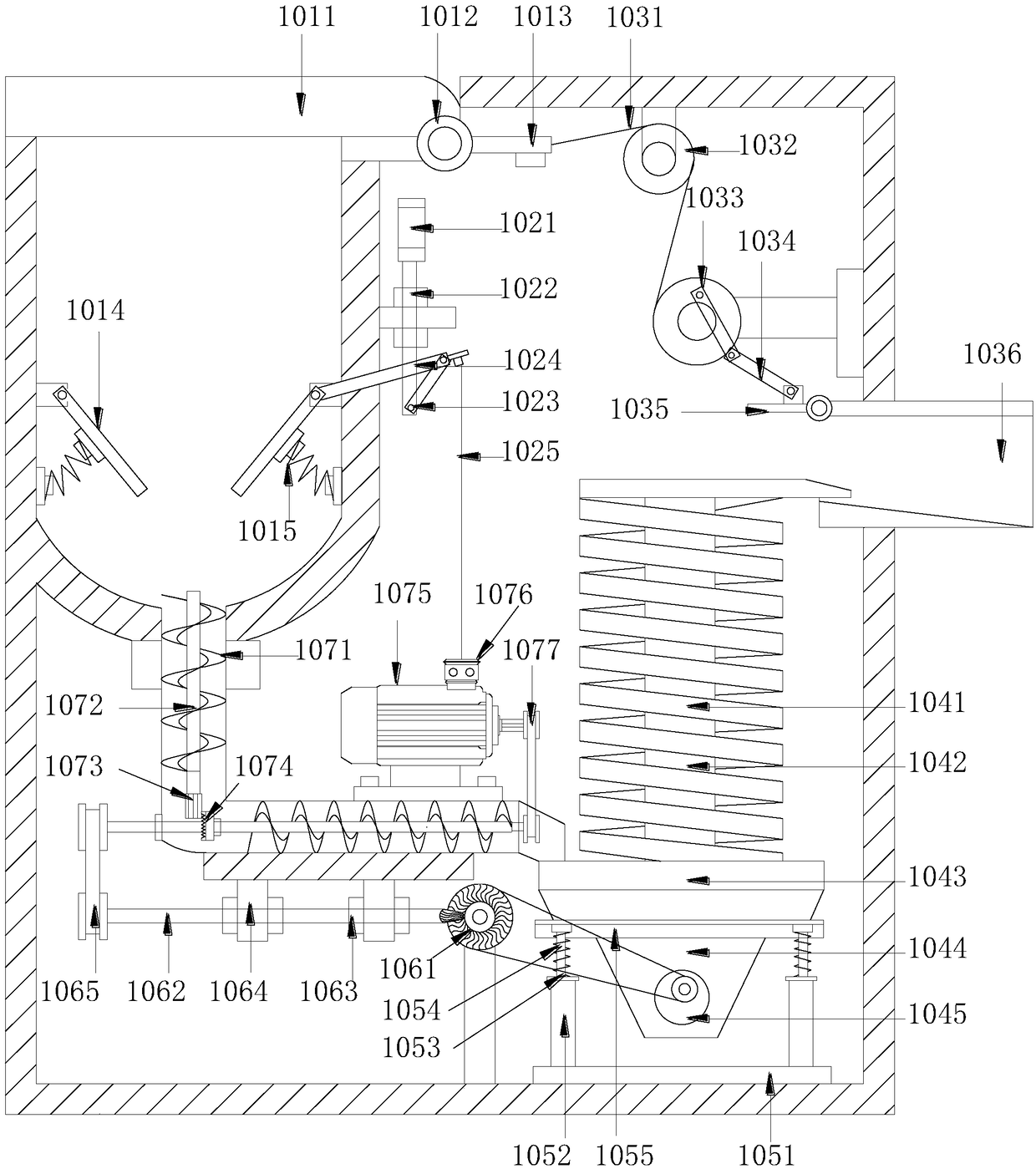

Continuous tunnel-type dried sweet potato making machine

PendingCN112515137ANot easy to stackNot easy to dryConveyorsFood treatmentAgricultural scienceGear wheel

The invention discloses a continuous tunnel-type dried sweet potato making machine. The continuous tunnel-type dried sweet potato making machine comprises a water tank, a slicing machine, a tunnel drying and airing machine and a base; the water tank, the slicing machine and the tunnel drying and airing machine are sequentially and fixedly installed at the top end of the base from left to right; apiston is connected to the middle part of the bottom end of the water tank in an inserted manner; the front face and the back face of the top end of the water tank are each fixedly connected with a connecting frame; a conveying mechanism is arranged between the two connecting frames; the conveying mechanism consists of two rollers, a first motor and a conveying mesh belt; and a cleaning mechanismis arranged in the conveying mesh belt. According to the continuous tunnel-type dried sweet potato making machine, through the cleaning mechanism, people can control an output shaft of a second motorto rotate to make two brush rollers rotate at the same time under drive of two gears and a gear belt; and the rotating direction of the two brush rollers are controlled to be opposite to that of the conveying mesh belt, so that bristles on the two brush rollers can penetrate through pores of the conveying mesh belt to brush the surfaces of sweet potatoes, and the cleaning effect is good.

Owner:阳云飞

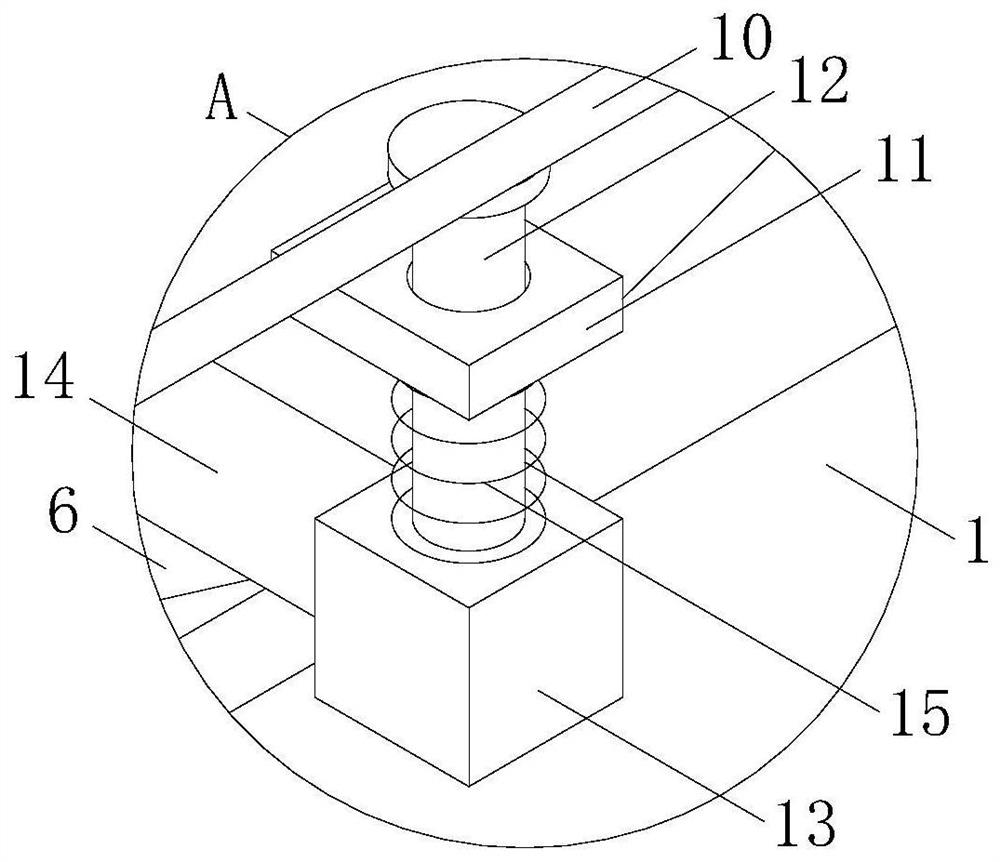

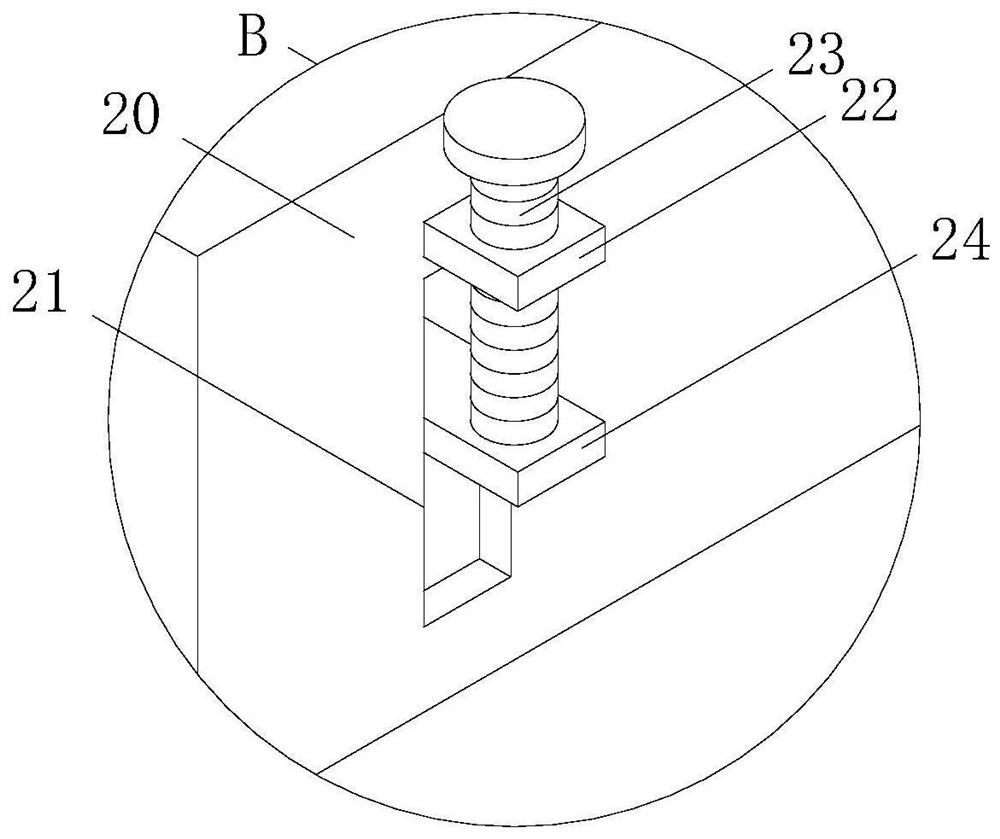

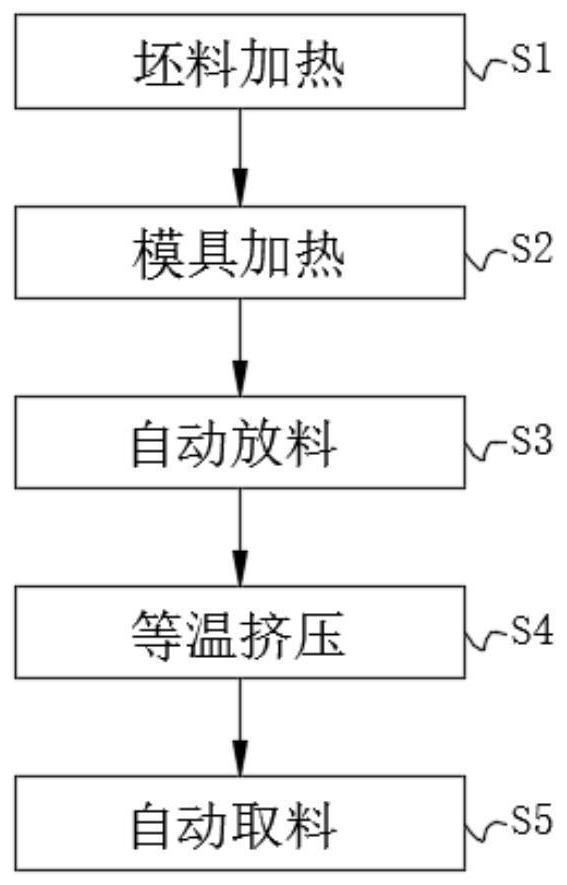

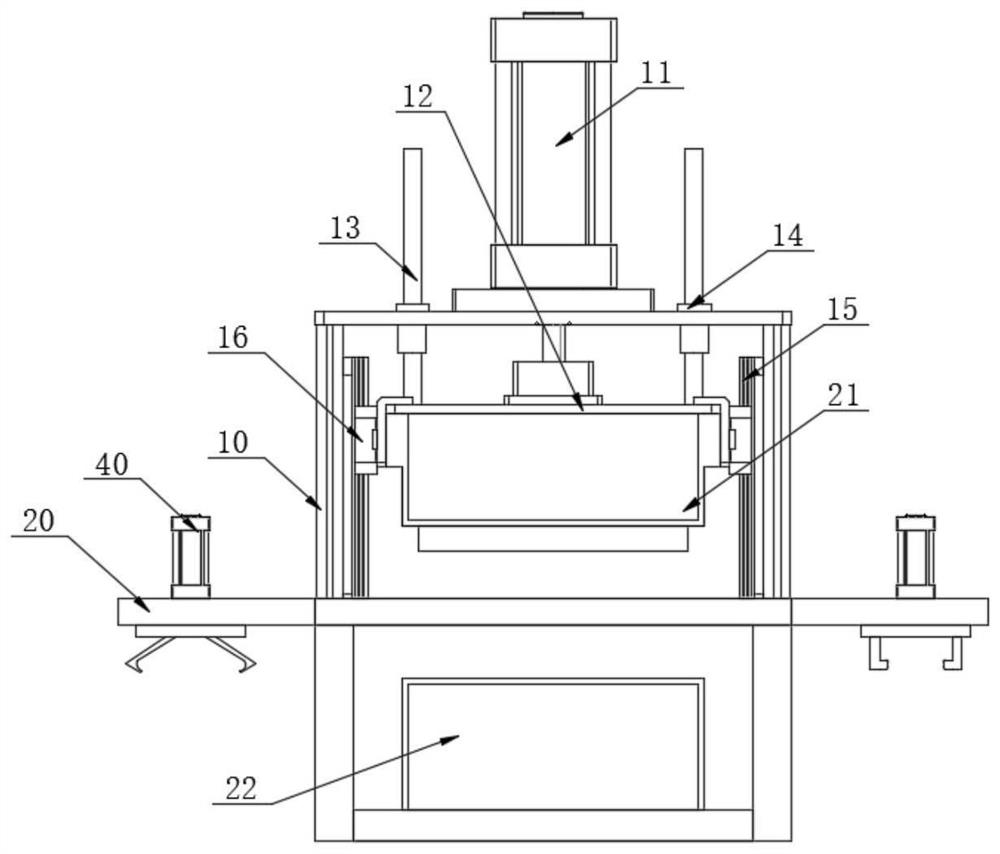

Isothermal extrusion process for titanium alloy profiled bar

InactiveCN113878013ASolve uneven deformationImprove enduranceShaping toolsMetal-working feeding devicesMetallic materialsBar pressing

The invention relates to an isothermal extrusion process for a titanium alloy profiled bar, which belongs to the technical field of metal material forming, and comprises the steps of titanium alloy blank heating, mold heating, automatic discharging, isothermal extrusion and automatic material taking. By preheating a titanium alloy blank and a forming die respectively, then the constant temperature of the titanium alloy blank in the extrusion forming process is kept through an isothermal mechanism, and the problem that in the prior art, when the titanium alloy blank is subjected to extrusion forming, due to the fact that the temperature difference between the surface and the core is large, deformation is uneven is solved; after preheating the titanium alloy blank, extrusion treatment is carried out, the tolerance of the titanium alloy blank is improved; the defects that the titanium alloy blank is prone to cracking and uneven in forming under the action of a pressing rod are effectively overcome; and in addition, the hollow pipe titanium alloy blank is adopted, the titanium alloy blank is not prone to stacking in the machining process, and the utilization rate of the titanium alloy blank is increased.

Owner:索罗曼(常州)合金新材料有限公司

Industrialized aquaculture pond

ActiveCN108770749AGrow fastReduce manual operationsClimate change adaptationPisciculture and aquariaElectricityFixed frame

The invention discloses an industrialized aquaculture pond comprising a feeder, a chassis, a base, an oxygen supply machine, a pool, a circulation pipe, a fixing frame and a controller; a bottom of the feeder is vertically mounted on a top of the chassis; a bottom of the chassis is welded to a left side of the top of the base; the inner part of the oxygen supply machine is electrically connected to a mainboard inside the controller through leads; the fixing frame is fixed at a rear end of an outer wall of the pool through bolts; the oxygen supply machine is vertically mounted at a right side of an outer wall of the chassis. The feeder inside the industrial aquaculture pond of the present invention cooperates with the controller, and the improved industrial aquaculture pond carries out thequantitative feeding of the aquatic products in the pool through the feeder, reducing manual operations, increasing delivery efficiency and increasing fish growth rate.

Owner:芜湖盛典休闲生态园有限公司

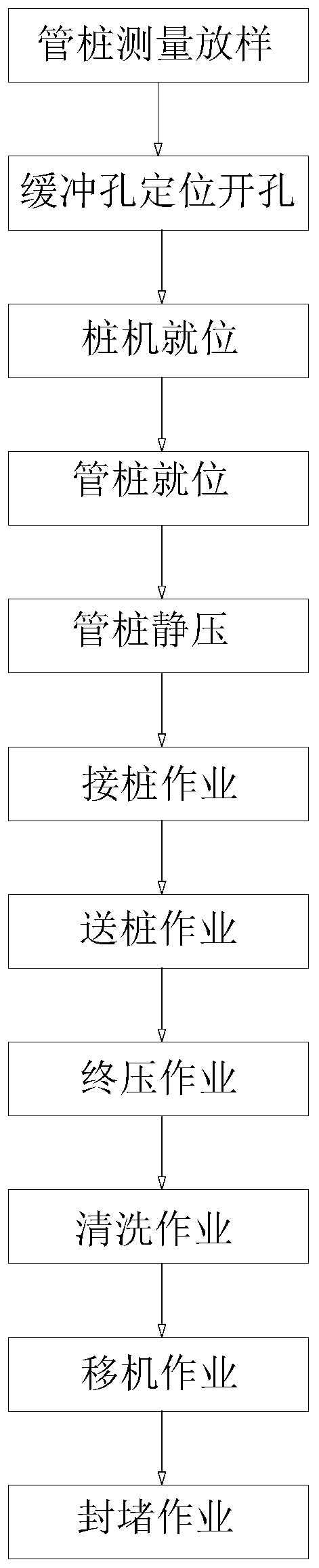

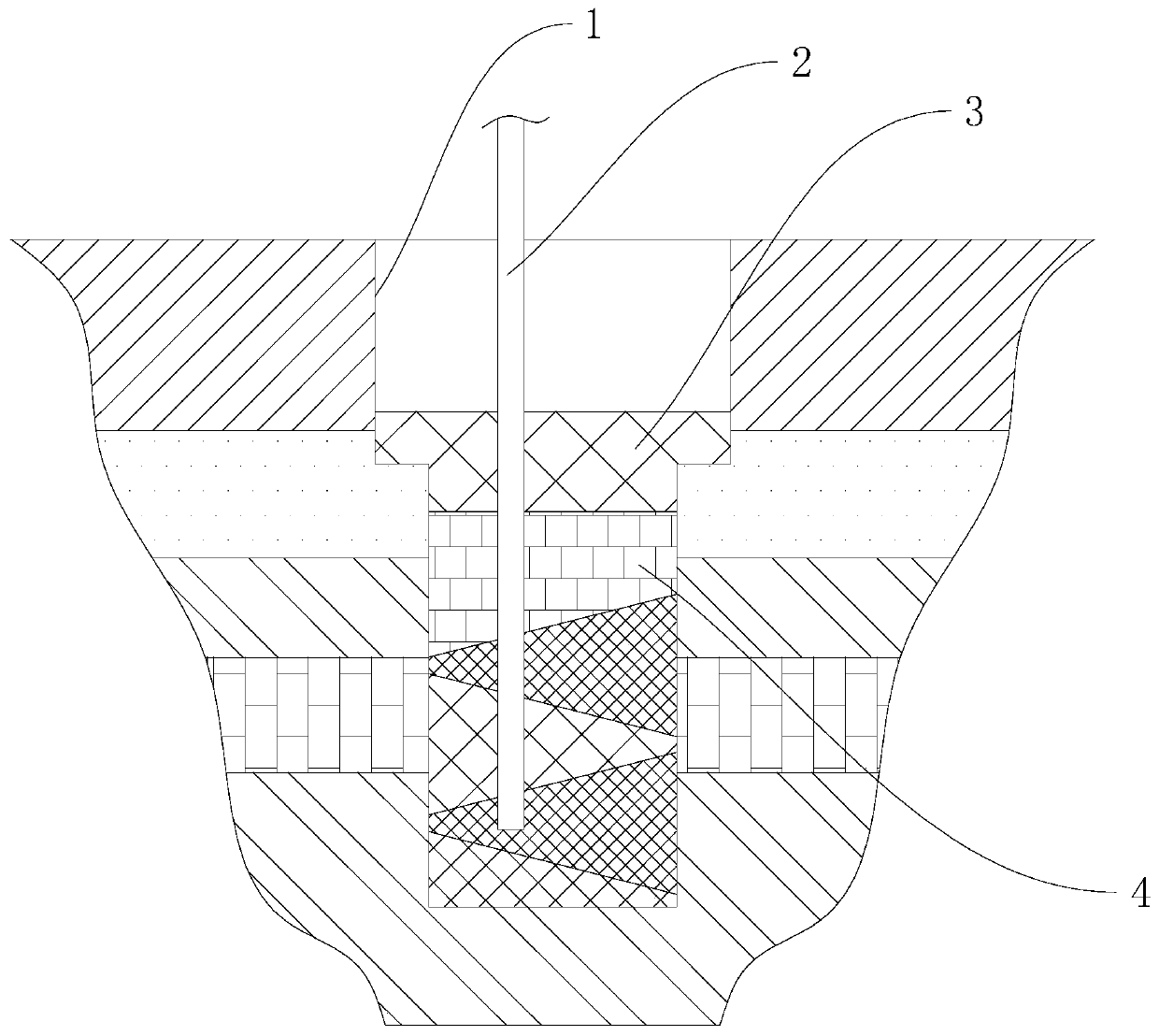

PHC pipe pile static pressure construction method

InactiveCN110219301ANot easy to stackSoil displacement is smallBulkheads/pilesStructural engineeringTrepanning

The invention relates to a PHC pipe pile static pressure construction method. The PHC pipe pile static pressure construction method comprises the following steps of S1, pipe pile measuring and layingoff are conducted, buffer hole locating and trepanning, pile machine in place, pipe pile in place, pipe pile static pressure, pile splicing operation, pile following operation, final pressure operation, cleaning operation, machine moving operation and blocking operation. The PHC pipe pile static pressure construction method has the effect that the side displacement of pile side soil bodies of adjacent pipe piles is not prone to overlaying.

Owner:广东厚普建设工程有限公司

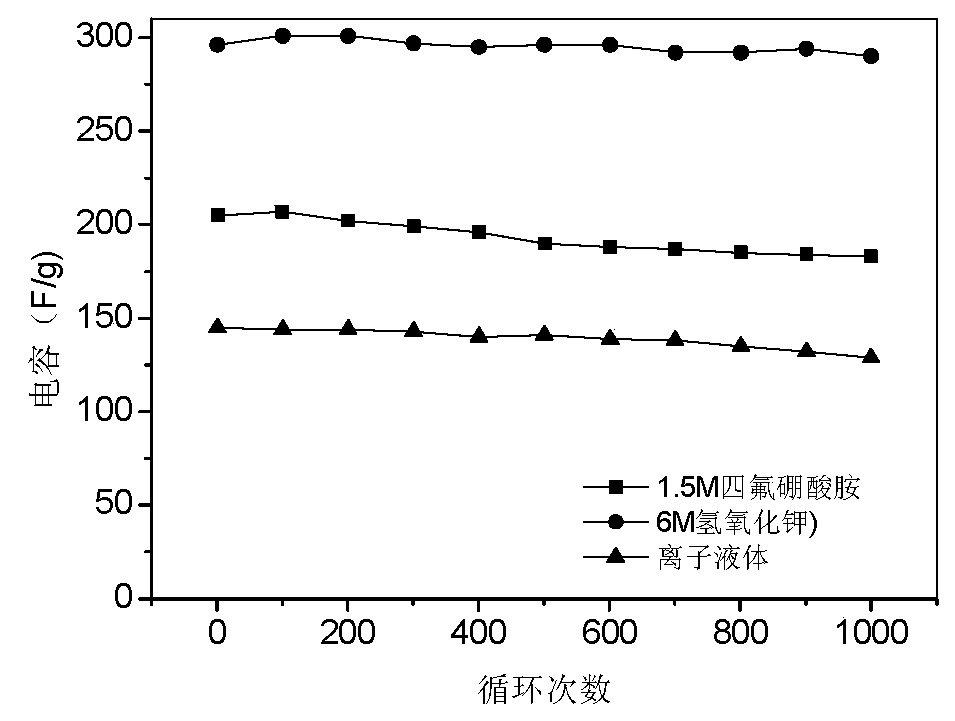

Porous carbon material and preparation method thereof and supercapacitor

ActiveCN113072066AEasy to removeSimple processCarbon compoundsHybrid capacitor electrodesActivated carbonEtching

The invention provides a preparation method of a porous carbon material. The method comprises the following steps: (1) putting a large-grid resin into a transition metal salt solution, stirring, and drying; (2) adding the product obtained in the step (1) and potassium bicarbonate into a calcium hydroxide solution, stirring and drying; and (3) carbonizing the product obtained in the step (2) in an inert atmosphere to obtain the porous carbon material. The preparation method of the porous carbon material has the advantages that the process is simple, later template etching is not needed, non-carbon residues are easy to remove, the cost is low, part of raw materials can be recycled, and large-scale production is easy to achieve; calcium hydroxide and potassium bicarbonate are adopted as pore-forming agents, and the pore structure in the carbon material can be regulated and controlled by regulating and controlling the ratio of the resin to the two alkalis; activated carbon has the advantages of few layers, large specific surface area, high conductivity, low density, difficulty in re-stacking and the like; and the liquid absorption amount is low, and the pole piece coating process performance is good.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com